Introduction: Navigating the Global Market for custom leather stamp maker

In an increasingly interconnected world, sourcing high-quality custom leather stamps can be a daunting task for B2B buyers, particularly those operating across diverse markets in Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reputable suppliers but also in navigating the myriad applications and specifications required for various leather crafting projects. This guide offers a comprehensive overview of custom leather stamp makers, detailing the different types of stamps available, their applications, and essential factors to consider when vetting suppliers.

From personalized branding solutions to intricate designs for leather goods, understanding the nuances of custom stamps can significantly impact your business’s branding and product quality. In this guide, we will explore the key aspects of sourcing leather stamps, including pricing structures, production timelines, and quality assurance processes. Additionally, we provide actionable insights into how to evaluate potential suppliers, ensuring that you partner with manufacturers who align with your quality standards and delivery expectations.

By leveraging the information contained in this guide, international B2B buyers can make informed purchasing decisions that not only enhance their product offerings but also foster successful supplier relationships. Whether you’re based in Nigeria, Germany, or anywhere in between, this resource is designed to empower your sourcing journey in the custom leather stamp market.

Table Of Contents

- Top 8 Custom Leather Stamp Maker Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamp maker

- Understanding custom leather stamp maker Types and Variations

- Key Industrial Applications of custom leather stamp maker

- 3 Common User Pain Points for ‘custom leather stamp maker’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamp maker

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp maker

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp maker’

- Comprehensive Cost and Pricing Analysis for custom leather stamp maker Sourcing

- Alternatives Analysis: Comparing custom leather stamp maker With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamp maker

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamp maker Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp maker

- Strategic Sourcing Conclusion and Outlook for custom leather stamp maker

- Important Disclaimer & Terms of Use

Understanding custom leather stamp maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Stamps | CNC milled from solid brass, customizable sizes & designs | Branding, logo stamping, personalized marks | Pros: Durable, precise, fast turnaround; Cons: Higher cost than other materials. |

| Leather Cutting Dies | Made from solid steel, outlines for shapes | Mass production of leather goods, crafts | Pros: High accuracy, reusable; Cons: Initial cost can be significant. |

| Mini Font Sets | Compact letter sets for detailed work | Custom lettering on smaller leather items | Pros: Versatile, easy to use; Cons: Limited character options. |

| Heat Branding Stamps | Designed for heat application, often larger designs | High-volume branding, unique textures | Pros: Creates deep impressions, durable; Cons: Requires additional equipment. |

| Letterset Accessories | Adjustable letter spacing, compatible with various presses | Custom text applications, signage | Pros: Flexibility in design, efficient; Cons: Complexity in setup. |

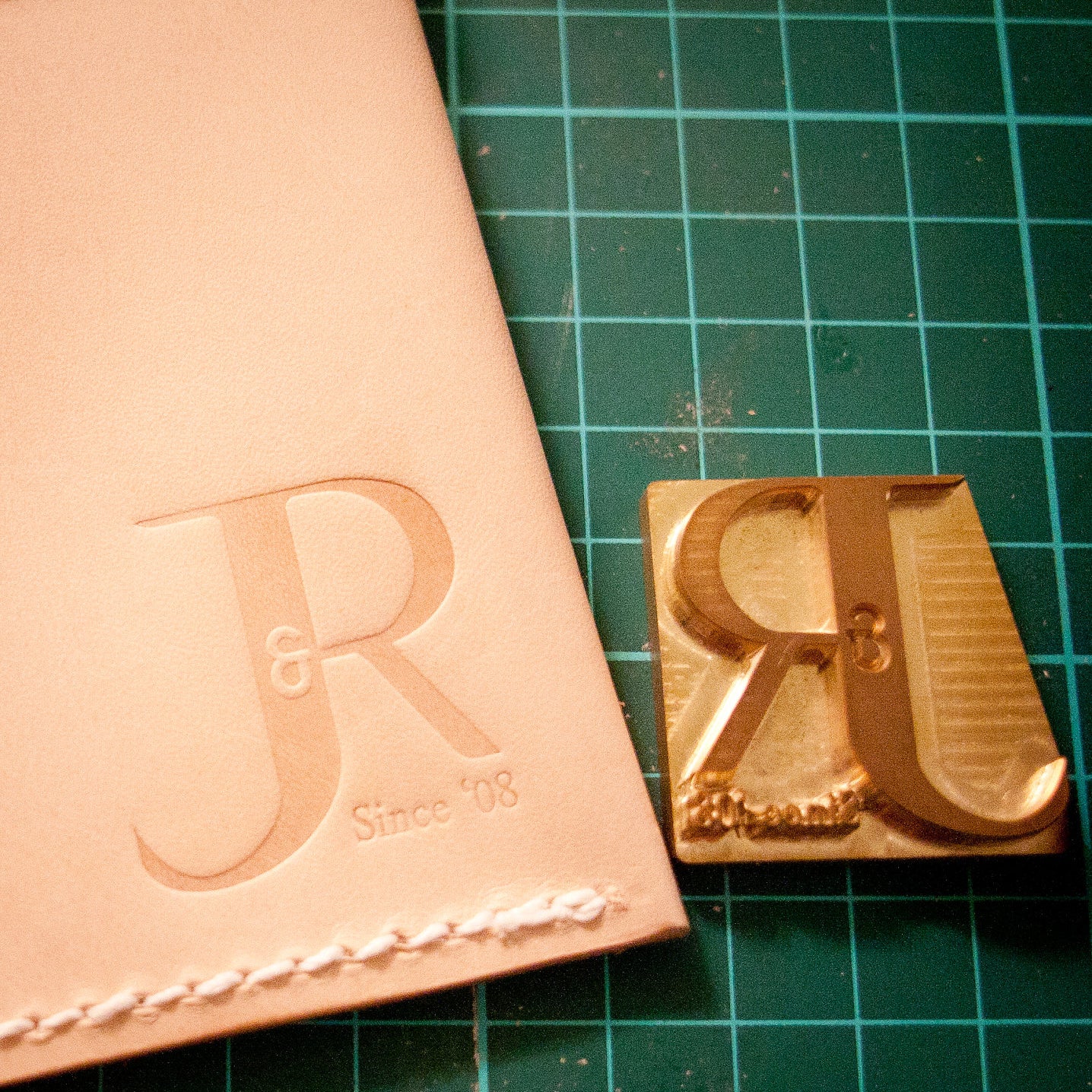

What Are the Key Characteristics of Custom Brass Stamps?

Custom brass stamps are primarily distinguished by their construction from solid brass and the precision of their CNC milling process. This type of stamp can be tailored in size and design to meet specific branding needs, making them ideal for businesses looking to create a unique identity. B2B buyers should consider the durability and sharpness of the impressions, as well as the speed of delivery, which is often next business day. However, the cost may be higher compared to other materials, which is an important factor for budget-conscious businesses.

How Do Leather Cutting Dies Enhance Production Efficiency?

Leather cutting dies are crafted from solid steel and are designed to create precise outlines for various shapes. They are essential for businesses engaged in mass production of leather goods, such as bags, wallets, and upholstery. The ability to produce uniform shapes quickly can significantly enhance operational efficiency. While the initial investment can be substantial, these dies are reusable and can lead to cost savings over time. B2B buyers should evaluate the long-term benefits against the upfront costs to determine suitability.

In What Scenarios Are Mini Font Sets Most Effective?

Mini font sets are compact letter sets that allow for detailed custom lettering on smaller leather items. These stamps are particularly useful for businesses that require intricate designs or personalization, such as custom gifts or high-end accessories. Their versatility makes them a valuable addition to a leather workshop. However, the limited character options might restrict some creative designs. B2B buyers should assess their specific needs for lettering to determine if mini font sets align with their branding goals.

Why Choose Heat Branding Stamps for Unique Impressions?

Heat branding stamps are specifically designed for applications that require heat, allowing for deep impressions that create a unique texture on leather. This type of stamping is particularly popular among businesses that want to produce high-volume branded items or unique designs that stand out. While they provide a durable and professional finish, buyers must consider the additional equipment needed for heat application and the learning curve associated with its use.

How Do Letterset Accessories Improve Customization Options?

Letterset accessories offer adjustable letter spacing and compatibility with various presses, making them a flexible choice for businesses needing custom text applications, such as signage or product labels. Their ability to allow for quick changes in design can streamline the production process, enhancing efficiency. However, the complexity in setup might be a drawback for some users. B2B buyers should weigh the advantages of flexibility against potential setup challenges when considering letterset accessories for their operations.

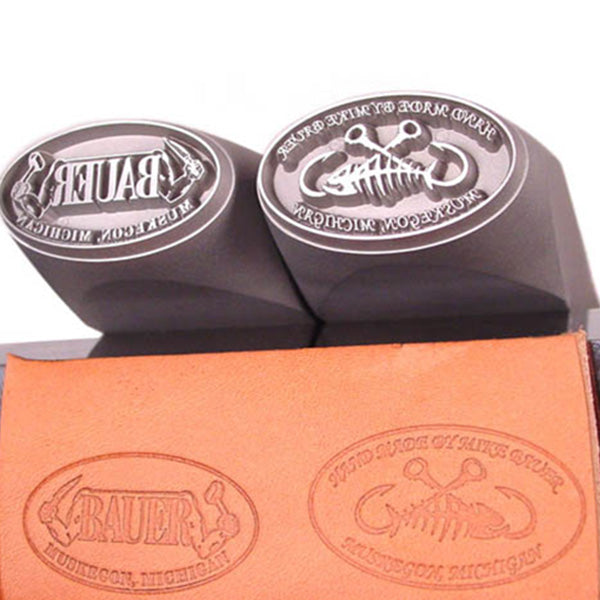

Illustrative image related to custom leather stamp maker

Key Industrial Applications of custom leather stamp maker

| Industry/Sector | Specific Application of custom leather stamp maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Creating branded leather tags for clothing and accessories | Enhances brand identity and customer loyalty | Quality of materials, customization options, turnaround time |

| Leather Goods Manufacturing | Customizing leather products with unique designs | Differentiates products in a competitive market | Precision in stamping, ability to handle bulk orders |

| Craft and Hobby Supplies | Providing stamps for DIY leathercraft projects | Enables hobbyists to create professional-quality items | Variety of designs, ease of use for non-professionals |

| E-commerce and Retail | Offering personalized leather goods for online sales | Attracts customers seeking unique, custom products | Shipping logistics, customer service responsiveness |

| Automotive Industry | Branding leather upholstery and accessories | Adds a premium touch to vehicles, enhancing perceived value | Durability of stamps, compatibility with different leather types |

How is Custom Leather Stamping Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather stamps are essential for creating branded leather tags that enhance product identity. These tags not only communicate the brand story but also add a touch of luxury to garments and accessories. For international buyers, particularly in regions like Africa and Europe, sourcing high-quality stamps that maintain consistency in design and durability is crucial. Fast turnaround times and the ability to accommodate various customization requests can significantly impact brand positioning in competitive markets.

What Role Does Custom Leather Stamping Play in Leather Goods Manufacturing?

Leather goods manufacturers utilize custom leather stamps to personalize their products, allowing them to stand out in a saturated market. Stamping can include logos, designs, or unique patterns that resonate with consumers. Buyers should consider the precision of the stamping process and the ability to fulfill bulk orders without compromising quality. Additionally, understanding the material compatibility of stamps with different leather types is essential for ensuring product integrity.

How Can Craft and Hobby Supplies Benefit from Custom Leather Stamps?

For craft and hobby suppliers, custom leather stamps provide an avenue for consumers to create personalized leather items, from wallets to belts. This application caters to DIY enthusiasts seeking professional-quality results. Sourcing stamps that are easy to use and offer a variety of designs can enhance customer satisfaction and repeat purchases. Furthermore, suppliers should ensure that they provide clear instructions and support to assist novice users in achieving optimal results.

Why is Custom Leather Stamping Important for E-commerce and Retail?

E-commerce platforms thrive on offering unique, personalized products, and custom leather stamps help retailers provide such options. By allowing customers to customize leather goods, retailers can attract a niche market looking for distinctive items. Key considerations for sourcing include effective logistics for international shipping and strong customer service to handle inquiries and customization requests promptly, especially in diverse markets like South America and the Middle East.

How Does Custom Leather Stamping Enhance the Automotive Industry?

In the automotive sector, custom leather stamps are used to brand leather upholstery and accessories, adding a premium feel to vehicles. This application enhances perceived value and can differentiate luxury models from standard offerings. Buyers in this sector must focus on the durability of the stamps, ensuring they can withstand the rigors of automotive use. Compatibility with various leather types and finishes is also vital for achieving the desired aesthetic and quality.

3 Common User Pain Points for ‘custom leather stamp maker’ & Their Solutions

Scenario 1: Delayed Custom Stamp Orders

The Problem: Many B2B buyers face frustration with the turnaround time for custom leather stamps, especially when working on tight deadlines for product launches or client projects. Delays can occur due to miscommunication regarding specifications, production constraints, or shipping issues. This situation can lead to lost business opportunities or strained client relationships, as buyers may be unable to deliver finished products on time.

The Solution: To mitigate delays, it’s crucial to establish clear communication from the outset. Buyers should provide detailed specifications, including dimensions, design files, and any particular requirements, when placing an order with a custom leather stamp maker. Additionally, opting for suppliers that offer rapid prototyping services can significantly reduce lead times. Look for manufacturers that guarantee quick turnaround times—some offer next-day shipping for approved designs. By requesting a virtual proof before finalizing the order, buyers can ensure that the product meets their expectations and avoid rework that could further delay the process.

Scenario 2: Inconsistent Quality of Stamps

The Problem: Quality inconsistency in custom leather stamps can be a significant pain point for B2B buyers, especially those who rely on these tools for branding their products. Issues such as unclear impressions, durability problems, or misaligned designs can lead to wasted materials and increased costs. Buyers may find themselves questioning whether they can trust their supplier to deliver high-quality products consistently.

The Solution: To ensure consistent quality, buyers should conduct thorough research before partnering with a custom leather stamp maker. This includes reviewing customer testimonials and asking for samples of previous work. Engaging in a dialogue with potential suppliers about their manufacturing processes and quality control measures can also provide insight into their reliability. Additionally, establishing a clear feedback loop post-purchase allows buyers to communicate any issues directly, ensuring that the supplier can address concerns promptly and improve future orders. Consider specifying material choices that enhance durability, such as solid brass, which can withstand repeated use without degrading quality.

Scenario 3: Lack of Technical Support and Guidance

The Problem: Many B2B buyers, especially those new to leather crafting, encounter difficulties in using custom leather stamps effectively. Without adequate technical support, they may struggle with proper stamping techniques or how to achieve the desired effects, leading to dissatisfaction with the results. This lack of guidance can create a sense of frustration and discouragement, especially for small business owners trying to establish their brand identity.

The Solution: To overcome this challenge, buyers should seek out custom leather stamp makers that prioritize customer support and provide educational resources. Look for suppliers that offer comprehensive guides or tutorials on how to use their products effectively, including tips on stamping techniques and the ideal tools to pair with the stamps. Additionally, consider suppliers that offer direct access to customer service representatives who can answer questions and provide troubleshooting assistance. Engaging in online forums or communities related to leather crafting can also provide valuable insights and shared experiences from other users, helping new buyers to gain confidence in using their custom stamps effectively.

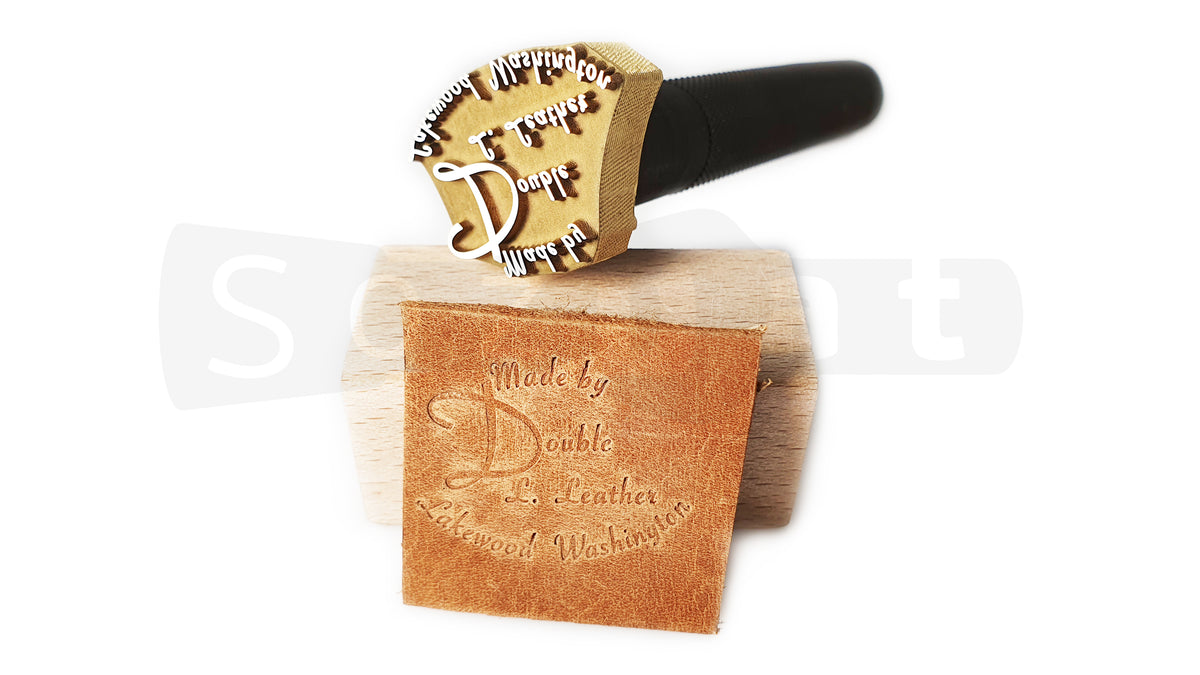

Illustrative image related to custom leather stamp maker

Strategic Material Selection Guide for custom leather stamp maker

What Are the Key Materials for Custom Leather Stamps?

When selecting materials for custom leather stamps, several factors come into play, including durability, manufacturing complexity, and compatibility with various stamping applications. Below is an analysis of four common materials used in the production of custom leather stamps, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Brass Perform as a Material for Custom Leather Stamps?

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It can withstand high temperatures, making it suitable for heat branding applications.

Pros & Cons: Brass stamps offer high durability and can produce sharp, detailed impressions. However, they can be more expensive than other materials, and their manufacturing process may involve complex machining, which can lead to longer lead times.

Impact on Application: Brass is highly compatible with various leather types, providing a clean and professional finish. Its ability to retain heat makes it ideal for heat stamping applications.

International Considerations: Buyers from regions like Europe may prefer brass due to its compliance with environmental regulations, such as RoHS. Additionally, understanding the local standards for brass quality (e.g., ASTM B36) is crucial for ensuring product reliability.

Why Choose Steel for Custom Leather Stamps?

Key Properties: Steel, particularly carbon steel, is known for its strength and wear resistance. It can endure high pressure and is less prone to deformation under stress.

Pros & Cons: Steel stamps are incredibly durable and can withstand extensive use without losing their shape. However, they are heavier and may require more energy for manufacturing, which can increase costs.

Impact on Application: Steel is suitable for various stamping techniques, including both heat and cold stamping, making it versatile for different leather types.

Illustrative image related to custom leather stamp maker

International Considerations: Compliance with international standards such as DIN for steel quality is essential. Buyers from regions like South America may also consider the availability of steel and its sourcing implications.

What Are the Benefits of Aluminum in Custom Leather Stamps?

Key Properties: Aluminum is lightweight and has good corrosion resistance. It can be anodized for additional durability and aesthetic appeal.

Pros & Cons: Aluminum is less expensive than brass and steel, making it a cost-effective option for lower-volume production. However, it may not be as durable as brass or steel, particularly for high-pressure applications.

Impact on Application: Aluminum stamps are best suited for softer leathers and applications that do not require extreme pressure or heat. They can produce decent impressions but may wear out faster than their brass or steel counterparts.

International Considerations: For buyers in the Middle East, understanding the local regulations regarding aluminum sourcing and environmental impact is crucial. Compliance with JIS standards for aluminum quality can also be a factor.

How Does Plastic Compare as a Material for Custom Leather Stamps?

Key Properties: Plastic stamps are lightweight and can be manufactured with various properties, including flexibility and impact resistance. They are not as heat-resistant as metal options.

Pros & Cons: Plastic is the most cost-effective material, making it ideal for prototypes or low-budget projects. However, they are less durable and may not provide the same level of detail or longevity as metal stamps.

Impact on Application: Plastic stamps are suitable for temporary applications or softer materials but may not be ideal for high-pressure stamping tasks.

International Considerations: Buyers should be aware of the different types of plastics and their compliance with local environmental regulations, particularly in Europe, where standards for plastic use are stringent.

Illustrative image related to custom leather stamp maker

Summary Table of Material Selection for Custom Leather Stamps

| Material | Typical Use Case for custom leather stamp maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Heat branding and detailed impressions | Excellent durability and detail | Higher cost and complex machining | High |

| Steel | High-pressure stamping applications | Exceptional strength and wear resistance | Heavier and more energy-intensive | Medium |

| Aluminum | Softer leather stamping | Cost-effective and lightweight | Less durable than metal options | Low |

| Plastic | Prototyping or low-budget projects | Most economical material | Limited durability and detail | Low |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for custom leather stamps, enabling informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp maker

What Are the Key Stages in the Manufacturing Process of Custom Leather Stamps?

The manufacturing process of custom leather stamps involves several critical stages, each of which plays a vital role in ensuring the final product meets the high standards expected by B2B buyers. Here’s a breakdown of the main stages:

Material Preparation: What Materials Are Used in Custom Leather Stamps?

The first step in producing custom leather stamps is material preparation. Typically, high-quality brass is used for stamp production due to its durability and ability to hold intricate designs. Solid steel is often employed for cutting dies, which need to withstand significant pressure during the stamping process. Before manufacturing begins, raw materials are sourced, verified for quality, and prepared according to specifications. This includes cutting, shaping, and milling the materials to the desired dimensions for stamping or cutting.

Illustrative image related to custom leather stamp maker

How Are Custom Leather Stamps Formed?

Forming is a crucial stage where the actual shape and design of the stamp are created. CNC (Computer Numerical Control) milling is a popular technique utilized in this process. This method ensures precision and allows for the creation of complex designs that can include logos, text, and unique patterns. The CNC machine reads the digital design file and accurately carves the stamp from the brass or steel. This level of precision is essential for creating high-quality impressions, which are critical in leather goods branding.

What Does the Assembly Process Involve?

After forming, the components of the custom leather stamp are assembled. This may include attaching handles or mounting systems that allow the stamp to be used effectively with various presses. For cutting dies, assembly might involve ensuring the die fits seamlessly with the stamping machine. This stage also includes a thorough inspection of each component to ensure they meet the required specifications before moving on to the finishing process.

What Finishing Techniques Are Employed?

Finishing is the final stage in the manufacturing process, where the stamped products undergo surface treatment to enhance durability and appearance. Techniques such as polishing, coating, or anodizing are commonly used. These processes not only improve the aesthetic appeal of the stamps but also protect them from wear and tear, ensuring they perform reliably over time. The finishing stage is critical, especially for B2B buyers who expect high-quality products that can withstand frequent use.

What Quality Assurance Measures Are Essential for Custom Leather Stamps?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the custom leather stamps meet international and industry-specific standards. Here are the key components of a robust QA system:

Which International Standards Should B2B Buyers Be Aware Of?

To ensure high quality, manufacturers of custom leather stamps often comply with international standards such as ISO 9001, which focuses on maintaining quality management systems. This certification demonstrates that a company consistently meets customer requirements and enhances customer satisfaction. Other relevant standards might include CE marking for products sold within the European Economic Area and API specifications for certain industrial applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and rectify potential issues early. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards before production begins.

- In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the quality of the products being produced. This includes checking dimensions, material integrity, and the accuracy of designs.

- Final Quality Control (FQC): After the manufacturing process is complete, a final inspection is conducted to ensure that all products meet the agreed-upon specifications before shipping. This can include testing for functionality, durability, and aesthetic quality.

What Common Testing Methods Are Used?

Manufacturers utilize various testing methods to ensure product reliability. Common methods include:

- Dimensional Testing: Using precision tools to measure the dimensions of the stamps and dies.

- Durability Testing: Subjecting the products to stress tests to ensure they can withstand the conditions they will face during use.

- Performance Testing: Evaluating how well the stamps perform on different leather types and under various application techniques.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance processes of suppliers is crucial. Here are actionable steps to ensure supplier reliability:

Illustrative image related to custom leather stamp maker

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request copies of quality assurance audits and reports from potential suppliers. These documents provide insight into the supplier’s compliance with international standards and their internal QC processes. Look for detailed records of previous inspections, corrective actions taken, and overall performance metrics.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services is another effective way to verify supplier quality. These independent organizations can conduct audits and inspections, providing unbiased assessments of the supplier’s manufacturing processes and product quality. This can be particularly reassuring for buyers unfamiliar with local manufacturing standards or practices.

What Are the QC/CERT Nuances for International Buyers?

Understanding the nuances of quality certification is essential for international buyers. Different regions may have varying standards, and ensuring compliance with local regulations is critical for smooth importation. For example, buyers in Europe need to be aware of CE marking requirements, while those in the Middle East may need to consider local industry standards.

Conclusion: Ensuring Quality in Custom Leather Stamp Procurement

In summary, the manufacturing processes and quality assurance measures for custom leather stamps are complex yet vital for ensuring product excellence. B2B buyers must engage with suppliers who adhere to stringent quality standards and can provide transparency throughout the manufacturing process. By understanding the stages of production and quality checkpoints, buyers can make informed decisions, ultimately leading to successful partnerships in the leather goods industry.

Illustrative image related to custom leather stamp maker

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp maker’

The following guide is designed for B2B buyers looking to source custom leather stamps effectively. By following these structured steps, you can ensure that you select a supplier who meets your specific needs and delivers high-quality products.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your requirements. This includes the type of stamp you need—be it a logo stamp, a maker’s mark, or a specific design. Having detailed specifications helps suppliers provide accurate quotes and ensures that the final product aligns with your expectations.

- Material Type: Specify whether you require brass, steel, or another material.

- Size and Thickness: Indicate the dimensions you need for your stamps.

Step 2: Research Potential Suppliers

Conduct thorough research on suppliers that specialize in custom leather stamps. Look for companies with a proven track record, positive customer reviews, and a comprehensive range of products.

- Online Presence: Review their website for product catalogs and client testimonials.

- Industry Experience: Consider suppliers with experience in your specific industry or region.

Step 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of your shortlisted suppliers. This includes checking their production methods and whether they can accommodate custom requests.

- Technology Used: Determine if they use advanced manufacturing techniques like CNC milling for precision.

- Customization Options: Ensure they can create bespoke designs that meet your unique needs.

Step 4: Verify Quality Assurance Processes

Quality is paramount when sourcing custom leather stamps. Inquire about the supplier’s quality assurance procedures to ensure their products meet industry standards.

Illustrative image related to custom leather stamp maker

- Certifications: Look for suppliers with relevant certifications that indicate compliance with quality standards.

- Sample Requests: Request samples or proofs of previous work to evaluate craftsmanship before placing a bulk order.

Step 5: Assess Customer Service and Support

Effective communication and support can significantly impact your sourcing experience. Evaluate how responsive and helpful the supplier is during your initial interactions.

- Response Time: Note how quickly they respond to inquiries and whether they provide clear answers.

- Support Services: Check if they offer assistance with design modifications or troubleshooting during the production process.

Step 6: Request Quotes and Compare Prices

Once you have a clear understanding of your requirements and have evaluated potential suppliers, request quotes from multiple vendors. Comparing prices helps ensure you receive competitive offers.

- Cost Breakdown: Ask for detailed pricing that includes setup fees, production costs, and shipping.

- Minimum Order Quantities: Be aware of any minimum order requirements that could affect your budget.

Step 7: Finalize Your Order and Establish Terms

Once you select a supplier, finalize your order by confirming specifications and establishing clear terms. This includes delivery timelines, payment terms, and any warranties or guarantees.

- Written Agreement: Ensure all details are documented in a formal contract to avoid misunderstandings.

- Follow-Up Communication: Maintain open lines of communication throughout the production process to address any issues promptly.

By adhering to this checklist, B2B buyers can navigate the sourcing process for custom leather stamps with greater confidence and efficiency, ultimately securing high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for custom leather stamp maker Sourcing

What Are the Key Cost Components in Sourcing Custom Leather Stamps?

When analyzing the cost structure of custom leather stamp manufacturing, several key components must be considered:

-

Materials: The primary materials used in custom leather stamps include solid brass for the stamps themselves and solid steel for cutting dies. Prices can vary based on market fluctuations, quality, and source location. Buyers should look for suppliers who use high-grade materials to ensure durability and performance.

-

Labor: Skilled labor is essential in the production of custom leather stamps. This includes the design, machining, and finishing processes. Labor costs can vary significantly depending on the region, with countries in Europe generally having higher wage standards than those in Africa or South America.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and maintenance of machinery. Overhead costs can affect pricing structures, especially for smaller manufacturers who may not benefit from economies of scale.

-

Tooling: The initial setup for custom stamps can require specialized tooling, which can be a significant upfront cost. This includes CNC machines and dies that are tailored to specific designs. Buyers should inquire about these costs, as they may be included in the overall pricing or charged separately.

-

Quality Control (QC): Ensuring that each stamp meets quality standards is crucial. QC processes can add to the overall cost but are essential for maintaining high product standards. Buyers should consider the reputation of the manufacturer regarding their QC practices.

-

Logistics: Shipping and handling costs can vary widely depending on the destination. International shipments may incur additional duties and tariffs, affecting the total cost. Understanding Incoterms is vital for international buyers to clarify who is responsible for shipping costs and liabilities.

-

Margin: Finally, the manufacturer’s margin is a critical component of the pricing structure. This margin can vary based on competition, brand reputation, and the level of customization offered.

What Factors Influence Pricing in Custom Leather Stamp Sourcing?

Several factors can influence pricing when sourcing custom leather stamps:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from volume discounts. Buyers should negotiate MOQ terms to optimize costs, especially if they can commit to higher quantities.

-

Specifications and Customization: The complexity of the design, including the intricacies of logos or fonts, can significantly affect pricing. More complex designs may require additional tooling and longer production times.

-

Material Quality and Certifications: Premium materials and certifications (e.g., ISO standards) can increase costs but may also enhance product longevity and brand reputation. Buyers should weigh the benefits of these factors against their budget.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can affect pricing. For instance, suppliers in regions with lower labor costs may offer competitive pricing but could have longer lead times or less stringent quality controls.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) can help buyers manage costs effectively and avoid unexpected fees.

What Buyer Tips Can Enhance Cost-Efficiency in Custom Leather Stamp Sourcing?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can enhance cost-efficiency by considering the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, payment terms, and delivery schedules with suppliers. Establishing a good relationship can lead to better deals and flexibility in future orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but the long-term costs associated with maintenance, replacement, and shipping. A higher initial investment in quality stamps may yield savings over time due to durability.

-

Understand Pricing Nuances: Be aware of how local economic conditions, currency fluctuations, and geopolitical factors can impact pricing. Staying informed about market trends can help buyers make timely purchasing decisions.

-

Leverage Local Suppliers When Possible: Sourcing from local suppliers can reduce shipping costs and lead times. Additionally, local manufacturers may be more attuned to regional market needs and preferences.

Disclaimer

The pricing and cost components discussed are indicative and can vary based on numerous factors, including supplier negotiations, market conditions, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing custom leather stamp maker With Other Solutions

In the quest for efficient branding and customization in leatherwork, businesses have several options at their disposal. While a custom leather stamp maker is a prominent solution, it is essential to consider alternative methods that can meet similar needs. This comparison will highlight key aspects of different solutions, enabling B2B buyers to make informed decisions based on their specific requirements.

| Comparison Aspect | Custom Leather Stamp Maker | Laser Engraving Machines | Pre-Made Stamps |

|---|---|---|---|

| Performance | High-quality, detailed impressions | Extremely precise, versatile for various materials | Good quality, but limited designs |

| Cost | Moderate (depends on customization) | High initial investment; operational costs | Low cost per stamp, but limited options |

| Ease of Implementation | Simple online ordering, quick turnaround | Requires training and setup | Very easy; immediate use without setup |

| Maintenance | Minimal; occasional cleaning | Regular maintenance required | No maintenance needed |

| Best Use Case | Unique, custom designs for branding | Complex designs and multiple materials | Quick, low-cost branding for common designs |

What Are the Benefits and Drawbacks of Using Laser Engraving Machines?

Laser engraving machines offer a high degree of precision and flexibility. They can engrave detailed designs not only on leather but also on other materials like wood and metal, making them a versatile choice for businesses that diversify their product lines. However, the initial investment is significant, and there are ongoing operational costs associated with maintenance and materials. Additionally, users may require training to operate these machines effectively, which could pose a barrier for smaller businesses or those just starting in leatherwork.

How Do Pre-Made Stamps Compare in Practicality?

Pre-made stamps represent a cost-effective solution for businesses looking for quick branding options. They are readily available and easy to use, requiring no setup time. However, the designs are often limited to generic shapes and letters, which may not meet the branding needs of companies seeking unique identifiers. While they offer an economical alternative, they lack the customization that a custom leather stamp maker provides, potentially limiting a brand’s ability to stand out in a competitive market.

Illustrative image related to custom leather stamp maker

How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding between a custom leather stamp maker and alternative solutions like laser engraving machines or pre-made stamps, B2B buyers should consider several factors. Assess the specific branding needs of your business, including the level of customization required, budget constraints, and the desired turnaround time for products. For businesses focused on unique branding and high-quality impressions, a custom leather stamp maker may be the best fit. Conversely, if precision across multiple materials is essential, investing in a laser engraving machine could yield long-term benefits. For those needing quick and economical solutions, pre-made stamps offer a straightforward approach, albeit with less flexibility. Ultimately, aligning the chosen solution with your operational goals will ensure the best outcome for your branding efforts.

Essential Technical Properties and Trade Terminology for custom leather stamp maker

What Are the Key Technical Properties for Custom Leather Stamps?

When selecting a custom leather stamp, understanding the essential technical properties is critical for ensuring quality and performance. Here are some of the most important specifications to consider:

1. Material Grade

Custom leather stamps are typically made from materials like brass, steel, or aluminum. Brass is favored for its durability and ability to produce crisp, clear impressions. Steel offers high strength and is ideal for cutting dies. The material grade impacts the longevity and effectiveness of the stamp, making it essential for B2B buyers to choose a reputable manufacturer that uses high-quality materials.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. For custom leather stamps, a tight tolerance is crucial to ensure that the stamp fits precisely with the intended application. This is particularly important when aligning stamps with cutting dies. A better tolerance can lead to more consistent and professional-quality results, which is vital for businesses aiming for precision in branding.

3. Thickness

The thickness of the stamp affects its durability and the depth of the impression it can create. Custom stamps can vary in thickness, usually up to 1 inch. Thicker stamps can withstand more pressure without bending or warping, making them suitable for more demanding applications. Understanding the required thickness for specific projects helps businesses avoid frequent replacements and ensures reliable performance over time.

Illustrative image related to custom leather stamp maker

4. Customization Options

Customization options include the ability to create unique designs, logos, or fonts. A manufacturer that offers extensive customization can cater to a wider range of client needs, allowing businesses to create personalized products. This capability enhances brand identity and can be a significant selling point for B2B buyers looking to differentiate their offerings in the market.

5. Compatibility with Equipment

Custom leather stamps must be compatible with the equipment used in the stamping process, such as hydraulic or mechanical presses. Knowing whether the stamp will work with existing machinery can save time and costs associated with additional equipment purchases or modifications. Buyers should verify compatibility to ensure seamless integration into their production processes.

What Are Common Trade Terms in the Custom Leather Stamp Industry?

Understanding industry jargon is essential for effective communication and negotiations in the custom leather stamp market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom leather stamps, businesses may work with OEMs to create specialized stamps that are then branded and sold under their name. Knowing about OEM relationships can help buyers understand the supply chain and quality assurance processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For custom leather stamps, this can vary significantly between manufacturers. Understanding MOQ is crucial for businesses to gauge production feasibility and manage inventory effectively, especially for new product lines or limited-edition items.

3. RFQ (Request for Quotation)

An RFQ is a standard business process wherein a buyer requests a quote from suppliers for specific products or services. In the custom leather stamp industry, submitting an RFQ allows businesses to compare pricing, lead times, and capabilities from multiple manufacturers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. For B2B buyers in regions like Africa or South America, understanding Incoterms can help manage logistics and cost expectations when importing custom leather stamps.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. In the custom leather stamp industry, lead time can significantly affect production schedules. Knowing the lead times of various suppliers helps businesses plan accordingly and ensures timely delivery for projects or product launches.

Illustrative image related to custom leather stamp maker

By familiarizing themselves with these technical properties and trade terminology, B2B buyers can make more informed decisions, streamline their procurement processes, and enhance their operational efficiency in the competitive custom leather stamp market.

Navigating Market Dynamics and Sourcing Trends in the custom leather stamp maker Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Stamp Maker Sector?

The custom leather stamp maker sector is experiencing significant growth driven by several global trends. The rise of personalized products, particularly in luxury and artisanal markets, is a key factor. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (e.g., Nigeria, Germany) are increasingly seeking unique branding solutions that resonate with local cultures and consumer preferences. This trend is amplified by the burgeoning e-commerce landscape, which facilitates easy access to custom products and services.

Emerging B2B technologies are reshaping sourcing strategies in this sector. Innovations such as CNC milling and 3D printing are enhancing precision and reducing lead times for custom orders. Furthermore, digital platforms are streamlining the design and approval processes, allowing for quicker turnaround times and improved customer experiences. Buyers are also leveraging data analytics to better understand market demands, enabling them to make informed purchasing decisions that align with consumer trends.

Illustrative image related to custom leather stamp maker

Market dynamics are also influenced by competitive pricing strategies and the quality of materials used in production. Buyers are increasingly prioritizing suppliers who offer a combination of affordability and high-quality craftsmanship. This is particularly relevant in regions where local artisans are looking to scale their operations while maintaining product integrity. As the sector evolves, adaptability and responsiveness to market changes will be crucial for suppliers aiming to capture the attention of international buyers.

How Important Is Sustainability and Ethical Sourcing in the Custom Leather Stamp Maker Sector?

Sustainability and ethical sourcing are becoming paramount in the custom leather stamp maker sector, driven by increasing consumer awareness and demand for environmentally friendly products. Buyers are now scrutinizing the environmental impact of their purchases, pushing suppliers to adopt sustainable practices. This includes sourcing leather from tanneries that utilize eco-friendly processes, such as vegetable tanning, which minimizes chemical use and pollution.

Ethical supply chains are crucial, as buyers are more inclined to support companies that demonstrate social responsibility. This includes fair labor practices and transparency in sourcing materials. Suppliers that can showcase certifications for ethical practices, such as Fair Trade or organic certifications, gain a competitive edge in the market. By ensuring that their products meet these standards, businesses can not only attract conscientious buyers but also enhance their brand reputation.

In addition, the use of ‘green’ materials in production—such as recycled metals for stamps and biodegradable packaging—can significantly reduce the overall carbon footprint. As sustainability becomes a core component of business strategy, suppliers must invest in responsible sourcing and production methods to align with the values of their international clientele.

What Is the Evolution of the Custom Leather Stamp Maker Sector?

The custom leather stamp maker sector has evolved significantly over the past few decades, transitioning from traditional handcrafting methods to modern, technology-driven production. Initially, leather stamping was a labor-intensive process reliant on skilled artisans who manually crafted each stamp. However, advancements in technology, such as CNC milling and laser engraving, have streamlined production, allowing for greater precision and scalability.

This evolution has also been driven by the shift in consumer preferences towards personalized and unique products. As businesses and individual consumers increasingly seek custom branding solutions, the demand for high-quality, efficient manufacturing processes has risen. Today, suppliers are not only expected to deliver fast turnaround times but also to provide innovative design options that meet the diverse needs of their clients.

As the market continues to grow, the integration of sustainability into manufacturing practices will likely shape the future of the custom leather stamp maker sector, making it essential for suppliers to adapt to these changes to remain competitive.

Illustrative image related to custom leather stamp maker

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp maker

-

How do I ensure the quality of custom leather stamps before placing a large order?

To guarantee the quality of custom leather stamps, request samples or prototypes from the manufacturer before committing to a bulk order. This allows you to assess the craftsmanship, material quality, and precision of the stamps. Additionally, verify the manufacturer’s reputation through online reviews and testimonials from other businesses. Establishing clear communication regarding your specifications and expectations during the design process will also help in achieving the desired quality. -

What is the best way to communicate my custom design needs to a leather stamp maker?

The most effective way to communicate your custom design needs is to provide a detailed brief that includes sketches, dimensions, and any specific requirements such as font styles or logos. Utilizing digital tools to create mockups or CAD drawings can enhance clarity. Always encourage open dialogue by asking for feedback and suggestions from the manufacturer, as they may have valuable insights based on their expertise and experience with similar projects. -

What factors should I consider when choosing a supplier for custom leather stamps?

When selecting a supplier for custom leather stamps, consider their experience, manufacturing capabilities, and customer service. Evaluate their portfolio for previous work that aligns with your needs and check references or testimonials from other clients. Additionally, assess their production lead times, quality control processes, and willingness to accommodate custom requests. It’s also beneficial to inquire about their logistics capabilities, especially if you are sourcing internationally. -

What are typical minimum order quantities (MOQs) for custom leather stamps?

Minimum order quantities for custom leather stamps can vary significantly by supplier and the complexity of the design. Some manufacturers may have MOQs as low as 5-10 pieces for simple designs, while others may require larger orders for intricate or customized stamps. Always clarify MOQs during initial discussions and inquire if they offer flexibility for smaller orders or trial runs to help you gauge their products without committing to a large purchase. -

What payment terms should I expect when ordering custom leather stamps internationally?

Payment terms for international orders of custom leather stamps typically range from upfront payments to net terms based on trust and prior agreements. Common practices include a 50% deposit upon order confirmation and the balance due before shipment. Ensure you discuss acceptable payment methods, such as wire transfers or credit cards, and clarify any additional fees related to currency exchange or international transactions. Always document the payment terms in the purchase agreement to avoid misunderstandings. -

How can I handle shipping and logistics for my custom leather stamps?

To manage shipping and logistics for your custom leather stamps, collaborate closely with your supplier to determine the best shipping methods based on cost and delivery speed. Request information on shipping options, tracking capabilities, and insurance for high-value items. Additionally, familiarize yourself with customs regulations in your country to prevent delays at borders. It’s advisable to partner with a reliable freight forwarder who can streamline the logistics process and ensure timely delivery. -

What should I know about customs duties and taxes when importing leather stamps?

When importing custom leather stamps, be aware that customs duties and taxes may apply, depending on the country of origin and destination. Research the specific tariff codes for leather goods in your region to estimate potential costs. It is also beneficial to consult with a customs broker who can provide guidance on compliance and help you navigate the import process efficiently. Accurate documentation and proper classification of your goods will minimize delays and additional charges. -

How can I ensure effective quality assurance for my custom leather stamps?

To implement effective quality assurance for your custom leather stamps, establish clear quality standards and specifications with your supplier from the outset. Request regular updates during the production process, including photos or videos of the stamps being made. Once the stamps arrive, conduct a thorough inspection to verify that they meet your requirements. Consider setting up periodic audits or quality checks if you plan to place ongoing orders, ensuring consistent quality over time.

Top 8 Custom Leather Stamp Maker Manufacturers & Suppliers List

1. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more. Custom stamps are CNC milled from solid brass, available up to 1″ thickness and custom size. Compatible with branding irons and standard presses. Custom leather cutting dies made from solid steel, usable with mechanical, hydraulic…

2. Infinity Stamps – Leather Stamping Solutions

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Leather Stamps – Infinity Stamps Inc. offers a variety of leather stamping products including: Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, Hot Stamps, and Steel Type Stamps & Holders. The company is family-owned and has been in business for over 25 years, emphasizing quality and American manufacturing.

3. Buckeye Engraving – Custom Leather Stamps

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Buckeye Engraving offers custom leather stamps, dies, and branding irons made in the USA. The stamps can be made from aluminum, steel, or brass, with brass being the most popular choice due to its durability and resistance to rust. Customization options include creating original stamps from artwork, signatures, or sketches, and the ability to design artwork for the stamps. The products are hand-fi…

4. Leather Stamps – Custom Options at Competitive Prices

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather stamps, good price point, quality stamp, options include: Leatherstampstools on Etsy (custom stamps, easy to work with), Springfield Leather (makes stamps from your PDF design, mounted to a base), leatherstampmaker (free quotes and proof, quick turnaround), TyraCraftTools on Etsy (custom design, $55 for a 2.5 cm x 5 cm stamp, clean finish).

5. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Custom Leather Stamp”, “regular_price”: “US$68.00”, “size_options”: [“Up to 1.25 x 1.25 inch / 3 x 3 cm”, “Up to 1.5 x 1.5 inch / 4 x 4 cm”, “Up to 2 x 2 inch / 5 x 5 cm”, “Up to 3 x 3 inch / 7.5 x 7.5 cm”, “Up to 4 x 4 inch / 10 x 10 cm”], “lead_time”: “2-5 working days”, “material”: “Solid Brass”, “stamp_thickness”: “8mm”, “engraving_depth”: “3mm”, “applications”: [“Leather emb…

6. Steel Stamps Inc. – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Introduction: Custom Leather Stamps available at Steel Stamps Inc. include various categories such as Custom Jewelry Stamps, Custom Steel Stamps for Knife Makers, Blacksmiths, Farriers, and Custom Locksmith Stamps & Industrial Markings. The collection features Leather Design Stamps, including Sheridan Flowers/Leaves, Leather State Stamps, and various Pro Series Designs. Additionally, there are items on sale and…

7. Custom Stamps – Personalized Branding Solutions

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Custom Stamps – Personalized Branding Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. DMLeather – Custom Leather Stamp Maker

Domain: dmleatherstudio.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Custom Leather Stamp Maker”, “brand”: “DMLeather”, “product_code”: “BLSS-1010WSR”, “price”: “$5.00”, “availability”: “Many in stock”, “sizes_available”: [“10mm x 10mm”, “10mm x 15mm”, “10mm x 20mm”, “10mm x 25mm”, “15mm x 15mm”, “15mm x 20mm”, “15mm x 25mm”, “20mm x 20mm”, “20mm x 25mm”, “25mm x 25mm”], “steel_rod_options”: [“with steel rod”, “no steel rod”], “material”: “brass (…

Strategic Sourcing Conclusion and Outlook for custom leather stamp maker

In today’s competitive landscape, strategic sourcing for custom leather stamps and dies is essential for businesses aiming to enhance their branding and product offerings. By partnering with a reputable manufacturer, buyers can access high-quality, customizable products tailored to their specific needs. This not only ensures consistency in branding but also improves operational efficiency, as quick turnaround times and robust customer support are often hallmarks of reliable suppliers.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the advantages of sourcing custom leather stamps are substantial. These products not only elevate the aesthetic appeal of leather goods but also serve as a unique selling proposition in diverse markets. Leveraging advanced manufacturing technologies, like CNC milling, can significantly enhance the precision and quality of stamps, setting businesses apart from competitors.

As the market for personalized leather goods continues to expand, now is the time to invest in high-quality custom stamps. Engage with suppliers who prioritize customer satisfaction and offer quick, reliable service. Embrace the opportunity to elevate your brand, streamline your production processes, and meet the evolving demands of your customers. Start your strategic sourcing journey today to unlock the full potential of your leather crafting business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather stamp maker

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.