Introduction: Navigating the Global Market for pleather plants

The global market for pleather plants presents a unique set of challenges and opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Sourcing high-quality pleather products that meet both aesthetic and functional requirements can be daunting, especially when considering factors such as sustainability, supplier reliability, and cost-effectiveness. This comprehensive guide aims to equip buyers with critical insights into the diverse types of pleather plants available, their applications across various industries, and effective strategies for supplier vetting.

Within these pages, you will find a detailed exploration of the pleather market, including the latest trends, innovative applications, and pricing structures that influence purchasing decisions. We will also address the importance of sustainability in the production of pleather, a significant consideration for modern businesses looking to align with environmentally conscious practices.

By leveraging the information in this guide, B2B buyers from countries like Saudi Arabia and Nigeria will be empowered to make informed decisions, ensuring they select the right products that not only enhance their brand’s image but also align with their operational needs. Navigate the complexities of the pleather market confidently, and discover how to foster successful supplier relationships that drive business growth.

Table Of Contents

- Top 7 Pleather Plants Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pleather plants

- Understanding pleather plants Types and Variations

- Key Industrial Applications of pleather plants

- 3 Common User Pain Points for ‘pleather plants’ & Their Solutions

- Strategic Material Selection Guide for pleather plants

- In-depth Look: Manufacturing Processes and Quality Assurance for pleather plants

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pleather plants’

- Comprehensive Cost and Pricing Analysis for pleather plants Sourcing

- Alternatives Analysis: Comparing pleather plants With Other Solutions

- Essential Technical Properties and Trade Terminology for pleather plants

- Navigating Market Dynamics and Sourcing Trends in the pleather plants Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pleather plants

- Strategic Sourcing Conclusion and Outlook for pleather plants

- Important Disclaimer & Terms of Use

Understanding pleather plants Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU (Polyurethane) Pleather | Soft, flexible, and often resembles genuine leather. | Fashion apparel, upholstery, accessories | Pros: Durable, water-resistant. Cons: May have limited breathability. |

| PVC (Polyvinyl Chloride) Pleather | Stiffer and more rigid, often used for its glossy finish. | Automotive interiors, furniture, bags | Pros: Cost-effective, easy to clean. Cons: Less environmentally friendly. |

| Biodegradable Pleather | Made from natural materials, designed to break down over time. | Eco-friendly fashion, sustainable products | Pros: Environmentally sustainable. Cons: Generally higher cost. |

| Recycled Pleather | Created from recycled plastics, promoting sustainability. | Fashion, bags, and footwear | Pros: Reduces waste, sustainable. Cons: Quality can vary based on source. |

| Microfiber Pleather | Ultra-soft, mimics the texture of genuine leather closely. | High-end fashion, luxury accessories | Pros: Luxurious feel, stain-resistant. Cons: Can be more expensive. |

What are the Key Characteristics of PU (Polyurethane) Pleather?

PU pleather is widely recognized for its softness and flexibility, closely mimicking the look and feel of genuine leather. It is often used in the fashion industry for clothing, accessories, and upholstery due to its durability and water resistance. B2B buyers should consider the longevity and comfort of PU pleather, especially for applications requiring frequent use. However, its breathability can be a concern in warmer climates, potentially affecting comfort.

How Does PVC (Polyvinyl Chloride) Pleather Differ from Other Types?

PVC pleather is characterized by its rigid structure and glossy finish, making it an ideal choice for automotive interiors and durable bags. This type is cost-effective and easy to clean, appealing to businesses looking to minimize maintenance costs. However, its environmental impact is a drawback, as PVC production is less sustainable compared to other materials. B2B buyers must weigh the benefits of lower costs against potential environmental concerns.

Why Choose Biodegradable Pleather for Sustainable Products?

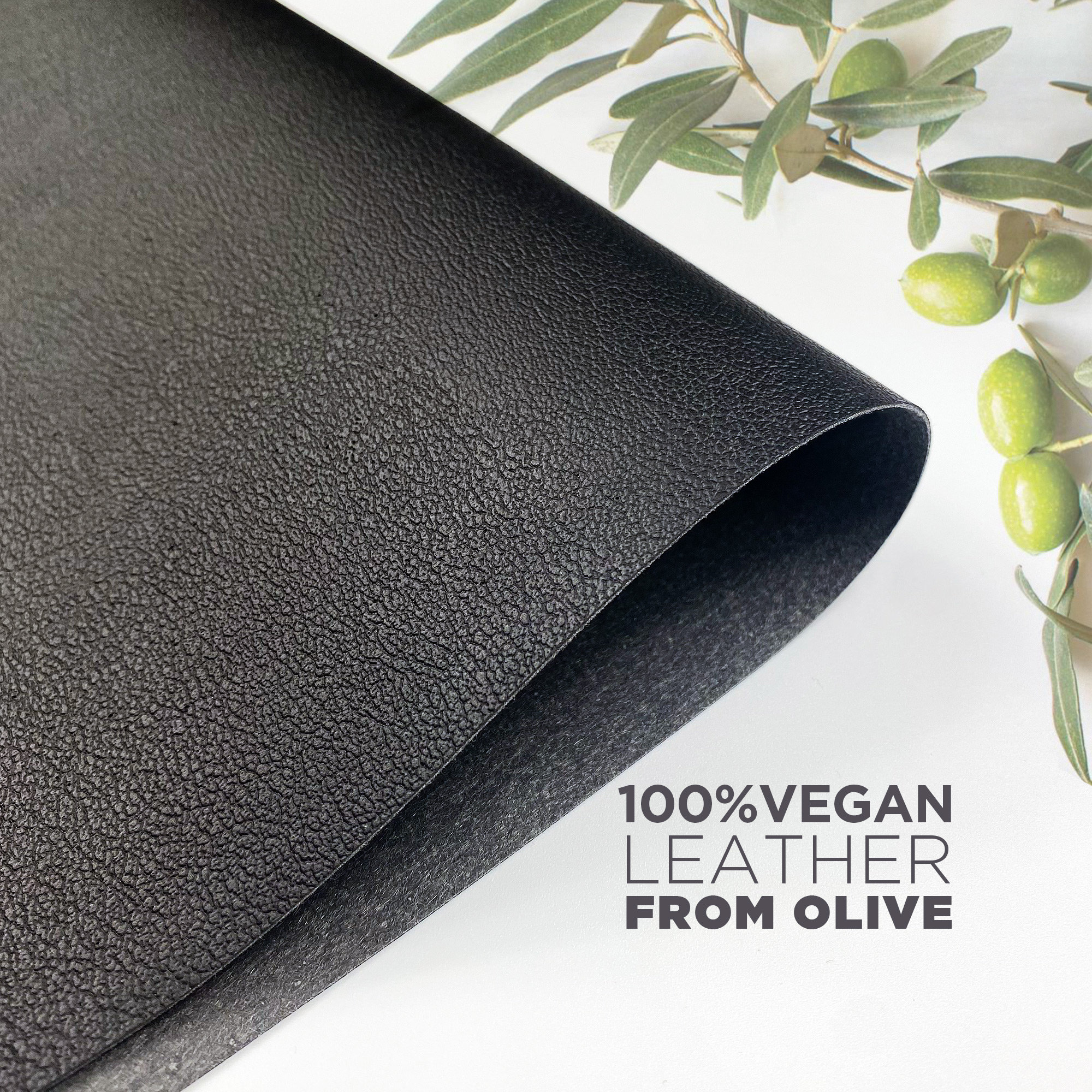

Biodegradable pleather is made from natural materials designed to decompose over time, making it a popular choice for eco-friendly fashion brands. This type appeals to businesses aiming to enhance their sustainability credentials. While the initial investment may be higher, the long-term benefits of aligning with environmentally conscious practices can attract a growing segment of eco-aware consumers. B2B buyers should consider their target market’s values when selecting this type.

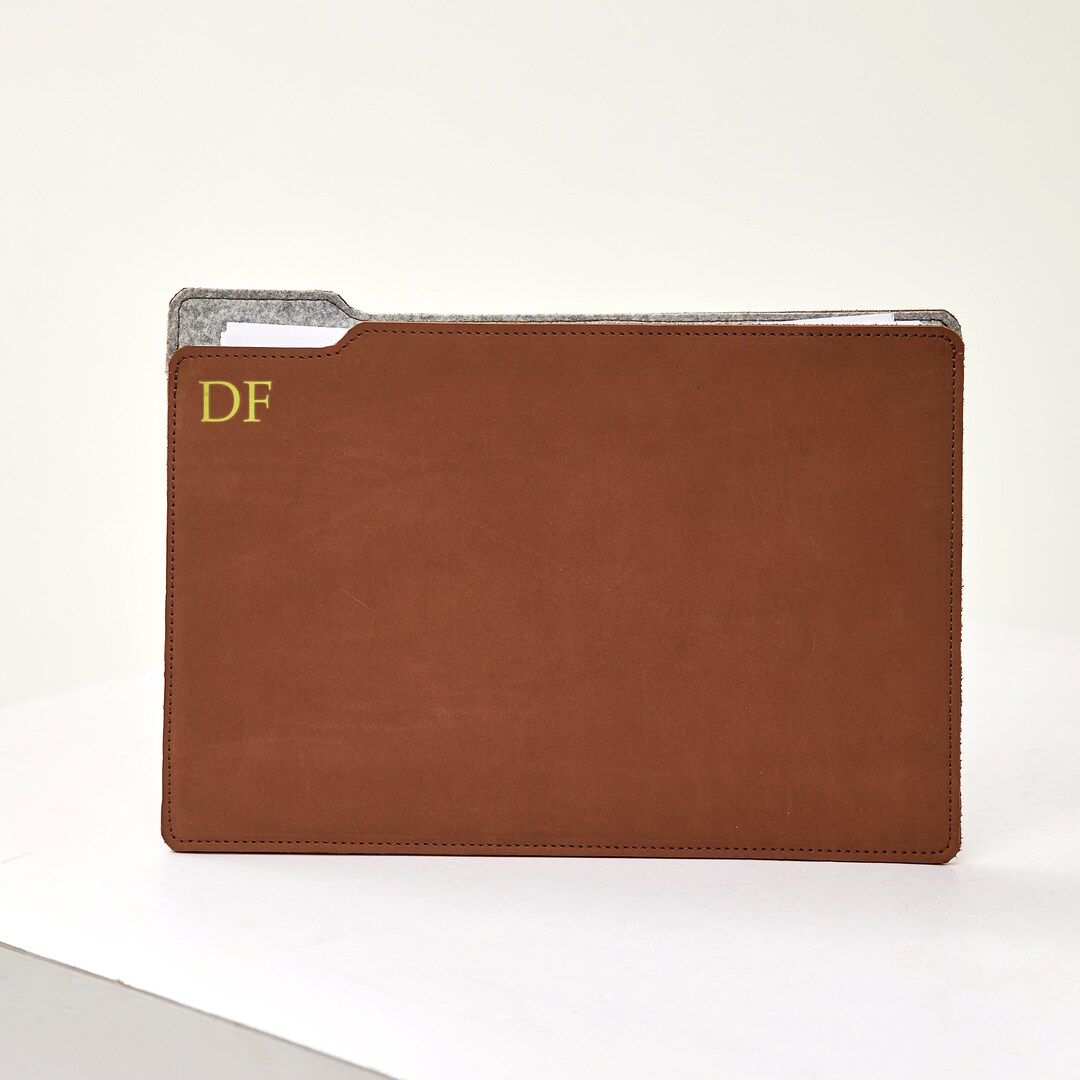

Illustrative image related to pleather plants

What Advantages Does Recycled Pleather Offer to Businesses?

Recycled pleather is crafted from reclaimed plastics, offering a sustainable alternative to traditional materials. This type is increasingly favored in the fashion industry for bags and footwear, as it helps reduce waste and promotes a circular economy. While it can vary in quality based on the source, B2B buyers looking to enhance their brand’s environmental responsibility will find recycled pleather an attractive option. Cost and quality consistency are critical factors to assess.

What Makes Microfiber Pleather a Preferred Choice for Luxury Items?

Microfiber pleather is renowned for its luxurious feel and softness, closely resembling genuine leather. It is often used in high-end fashion and luxury accessories due to its stain resistance and durability. B2B buyers should consider the investment aspect, as microfiber pleather can be more expensive than traditional options. However, its appeal to consumers seeking quality and luxury can justify the cost in premium markets.

Key Industrial Applications of pleather plants

| Industry/Sector | Specific Application of pleather plants | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of faux leather garments | Cost-effective, cruelty-free alternatives to leather | Durability, texture, and color variety; compliance with local regulations on materials |

| Automotive | Upholstery and interior finishes | Enhances vehicle aesthetics while reducing costs | Resistance to wear and tear; fire safety certifications; environmental impact assessments |

| Furniture & Interior Design | Upholstery for sofas, chairs, and decor items | Eco-friendly options that offer style and comfort | Availability in various textures and patterns; compliance with safety standards; bulk order capabilities |

| Footwear | Manufacturing of shoes and boots | Lightweight, durable, and stylish alternatives to leather | Flexibility in design; moisture resistance; adherence to international quality standards |

| Sports Equipment | Padding and protective gear for sports items | Improved performance and comfort for athletes | Breathability and shock absorption properties; compliance with sports safety regulations; sourcing for specific sports applications |

How Are Pleather Plants Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, pleather plants play a crucial role in producing faux leather garments, such as pants, jackets, and accessories. These products provide a cost-effective and cruelty-free alternative to traditional leather, appealing to eco-conscious consumers. International buyers, particularly from regions like Africa and South America, should prioritize sourcing pleather that is durable and available in a variety of textures and colors to meet diverse fashion trends. Additionally, compliance with local regulations regarding materials and sustainability practices is essential to ensure market acceptance.

What Are the Benefits of Pleather in the Automotive Sector?

In the automotive industry, pleather is increasingly utilized for upholstery and interior finishes, enhancing the aesthetics of vehicles while being cost-effective. This material is favored for its durability and ease of maintenance, making it a practical choice for manufacturers. Buyers from the Middle East and Europe should focus on pleather that meets resistance to wear and tear, as well as fire safety certifications. Environmental impact assessments are also critical, as consumers are becoming more discerning about the sustainability of the materials used in their vehicles.

How Does Pleather Enhance Furniture and Interior Design?

Pleather plants supply materials used in the upholstery of sofas, chairs, and decorative items, offering stylish and eco-friendly options for interior design. This application allows furniture manufacturers to create attractive, comfortable products that appeal to modern consumers. Buyers in Europe and Africa should consider the availability of various textures and patterns to cater to different design aesthetics. Compliance with safety standards is also a vital consideration, ensuring that the products are safe for consumer use.

Why Is Pleather Important in Footwear Manufacturing?

In the footwear industry, pleather is used extensively in the manufacturing of shoes and boots, providing lightweight, durable alternatives to leather. This application allows brands to create stylish footwear without compromising on comfort or performance. International buyers should look for pleather that offers flexibility in design and moisture resistance, as these attributes enhance the overall quality of the footwear. Adherence to international quality standards is paramount to meet consumer expectations and regulatory requirements.

What Role Does Pleather Play in Sports Equipment Production?

Pleather is utilized in sports equipment, particularly for padding and protective gear, enhancing athletes’ performance and comfort. Its lightweight nature, combined with breathability and shock absorption properties, makes it an ideal choice for various sports applications. Buyers should ensure that the pleather sourced complies with sports safety regulations and can be tailored to specific sports needs. This focus on specialized applications can significantly improve the marketability of sports products in competitive environments.

3 Common User Pain Points for ‘pleather plants’ & Their Solutions

Scenario 1: Sourcing High-Quality Pleather Plants for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality pleather plants that meet the specific demands of their diverse markets. Buyers in regions like Africa and South America may find that local suppliers provide subpar materials that do not meet international standards, leading to issues in durability and aesthetics. Additionally, the lack of transparency in sourcing practices can lead to concerns over ethical production, which is increasingly important to consumers.

The Solution: To overcome these challenges, B2B buyers should prioritize building relationships with reputable manufacturers known for their high-quality pleather materials. Conducting thorough research to identify suppliers with established certifications for sustainability and quality control can significantly improve the sourcing process. Furthermore, buyers should consider visiting production facilities or participating in trade shows to assess the quality of materials firsthand. Utilizing platforms that focus on ethical sourcing can also help in identifying suppliers who align with the buyer’s values and market expectations.

Scenario 2: Addressing the Variability in Material Quality and Texture

The Problem: Another common pain point is the inconsistency in quality and texture of pleather plants, which can affect the end product’s appeal. Buyers may receive batches that vary significantly in feel, color, and durability, leading to dissatisfaction among their customers and potential returns. This issue is particularly prevalent when dealing with multiple suppliers or when sourcing from different regions.

Illustrative image related to pleather plants

The Solution: Implementing a standardized quality control process can help mitigate this issue. Buyers should establish clear specifications for the pleather’s texture, weight, and finish before placing orders. It’s beneficial to request sample swatches from suppliers before committing to larger orders. Additionally, maintaining an open line of communication with suppliers regarding quality expectations can help ensure consistency across different batches. Regular audits and feedback loops can also foster a better understanding of material performance, allowing suppliers to make necessary adjustments to meet buyer requirements.

Scenario 3: Navigating Compliance and Regulatory Challenges

The Problem: B2B buyers often face compliance issues related to environmental regulations and material safety standards when importing pleather plants. Different regions have varying regulations regarding the use of synthetic materials, and failing to adhere to these standards can result in significant fines and product recalls. This is particularly concerning for buyers in the Middle East and Europe, where regulations tend to be stricter.

The Solution: To navigate these compliance challenges effectively, buyers should invest time in understanding the regulatory landscape of their target markets. This includes familiarizing themselves with local laws regarding material safety and environmental impact. Collaborating with legal experts or compliance consultants can provide valuable insights and help in the development of strategies that ensure adherence to these regulations. Furthermore, buyers should seek suppliers who are already compliant with international standards, as this can simplify the import process and reduce the risk of legal complications. Regular training and updates on compliance requirements for all stakeholders involved in the supply chain can further enhance awareness and adherence to regulations.

Strategic Material Selection Guide for pleather plants

What Are the Key Materials Used in Pleather Plants?

In the production of pleather (synthetic leather) plants, selecting the right materials is crucial for ensuring product quality and performance. Below, we analyze four common materials used in pleather manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to pleather plants

1. Polyurethane (PU)

Key Properties:

Polyurethane is known for its versatility and can mimic the look and feel of genuine leather. It has excellent abrasion resistance and can withstand a range of temperatures, typically between -30°C to 80°C. PU is also resistant to UV light, which helps maintain color stability.

Pros & Cons:

The primary advantage of PU is its soft texture and flexibility, making it suitable for various applications, including fashion and upholstery. However, it is generally less durable than PVC and can be more susceptible to wear and tear over time. The manufacturing process for PU can be complex, often requiring specialized equipment.

Impact on Application:

PU is compatible with a variety of media, including water and oils, making it ideal for fashion items and soft furnishings. However, it may not perform well in heavy-duty applications where high durability is essential.

Illustrative image related to pleather plants

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should be aware of local regulations regarding chemical safety and environmental impact. Compliance with standards such as ASTM or DIN is crucial for market acceptance.

2. Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used synthetic material known for its high resistance to chemicals and moisture. It can withstand temperatures from -10°C to 60°C, making it suitable for various climates.

Pros & Cons:

The main advantage of PVC is its durability and cost-effectiveness, making it a popular choice for budget-conscious projects. However, it can be less breathable than PU, which may limit its use in clothing. The manufacturing process is relatively straightforward, but the environmental impact of PVC production is a concern.

Impact on Application:

PVC is ideal for applications requiring high resistance to liquids and chemicals, such as automotive interiors and outdoor furniture. Its limited breathability may affect comfort in clothing applications.

Considerations for International Buyers:

Buyers should ensure that PVC products meet local environmental regulations, especially in Europe, where stricter compliance standards are in place. Awareness of the potential for phthalates in PVC is also important for health considerations.

Illustrative image related to pleather plants

3. Thermoplastic Polyurethane (TPU)

Key Properties:

TPU combines the best features of rubber and plastic, offering excellent elasticity, transparency, and resistance to abrasion. It can operate effectively within a temperature range of -40°C to 100°C.

Pros & Cons:

The flexibility and durability of TPU make it suitable for high-performance applications, such as sportswear and protective gear. However, it can be more expensive than both PU and PVC, which may deter some buyers. The manufacturing process can also be complex, requiring advanced technology.

Impact on Application:

TPU is compatible with a wide range of media, including oils and greases, making it ideal for industrial applications. Its high elasticity allows for dynamic movement, which is beneficial in activewear.

Considerations for International Buyers:

For buyers in South America and Africa, understanding local market demands for high-performance materials is essential. Compliance with international quality standards can enhance marketability.

4. Recycled Materials (e.g., rPET)

Key Properties:

Recycled materials, such as recycled polyethylene terephthalate (rPET), are gaining traction in the pleather industry due to their environmental benefits. They offer good durability and chemical resistance, with temperature ratings similar to those of virgin materials.

Illustrative image related to pleather plants

Pros & Cons:

Using recycled materials can significantly reduce environmental impact and appeal to eco-conscious consumers. However, the availability and consistency of quality can be a challenge, as recycled materials may vary in performance. The manufacturing process may also be more complex due to the need for sorting and processing.

Impact on Application:

Recycled materials are suitable for a range of applications, from fashion to upholstery, but may not always meet the performance standards required for high-stress environments.

Considerations for International Buyers:

Buyers in Europe are increasingly prioritizing sustainable materials, making recycled options more attractive. Compliance with sustainability certifications can enhance product appeal in these markets.

Summary Table

| Material | Typical Use Case for pleather plants | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Fashion items, upholstery | Soft texture and flexibility | Less durable than PVC | Medium |

| Polyvinyl Chloride (PVC) | Automotive interiors, outdoor furniture | High durability and cost-effectiveness | Less breathable, environmental concerns | Low |

| Thermoplastic Polyurethane (TPU) | Sportswear, protective gear | Excellent elasticity and abrasion resistance | Higher cost, complex manufacturing | High |

| Recycled Materials (rPET) | Fashion, upholstery | Environmentally friendly, reduces waste | Variable quality and performance | Medium |

This strategic material selection guide aims to provide B2B buyers with essential insights into the various materials used in pleather plants, enabling informed decision-making based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pleather plants

What Are the Key Stages in the Manufacturing Process of Pleather?

The manufacturing process for pleather (synthetic leather) is intricate, encompassing several stages that ensure the final product meets both aesthetic and functional requirements. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial stage involves selecting the appropriate base materials, typically polyurethane (PU) or polyvinyl chloride (PVC). These materials are chosen based on desired characteristics such as flexibility, durability, and appearance. They undergo various treatments to enhance adhesion and compatibility with coatings.

-

Forming: In this stage, the prepared materials are transformed into sheets or rolls. This is usually achieved through processes like calendaring or extrusion, where the material is heated and pressed into thin layers. This step is crucial as it determines the thickness and texture of the pleather, which can vary from smooth to textured finishes.

-

Assembly: Once the sheets are formed, they are cut and sewn into various products, such as garments, upholstery, or accessories. Advanced techniques, such as laser cutting or ultrasonic welding, may be employed for precision and efficiency. This stage also involves quality checks to ensure that there are no defects in stitching or material alignment.

-

Finishing: The final stage involves applying coatings or treatments that enhance the appearance and performance of the pleather. This can include embossing for texture, dyeing for color, and applying protective layers to improve water resistance or UV stability. The finishing process is critical for achieving the desired aesthetic appeal and durability of the final product.

How Is Quality Assurance Implemented in Pleather Manufacturing?

Quality assurance (QA) in pleather manufacturing is essential for ensuring that products meet international standards and customer expectations. Various quality control (QC) processes are integrated throughout the manufacturing stages.

-

International Standards: Adhering to international quality standards, such as ISO 9001, is vital for manufacturers aiming to establish credibility in global markets. This certification signifies that a company has implemented a quality management system that consistently meets customer and regulatory requirements.

-

Industry-Specific Standards: In addition to ISO certifications, manufacturers may also comply with industry-specific standards like CE marking for safety in the European market or API standards for the oil and gas industry. These certifications can enhance marketability and compliance with local regulations.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial stage assesses raw materials upon arrival to ensure they meet specified criteria before production begins. This step helps prevent defects from occurring later in the manufacturing process.

– In-Process Quality Control (IPQC): During manufacturing, IPQC involves ongoing inspections at various stages, such as during forming and assembly. This proactive approach allows for immediate rectification of any issues that may arise.

– Final Quality Control (FQC): After the products are finished, FQC ensures that they meet the established quality standards before shipping. This may involve visual inspections, physical tests, and performance evaluations.

What Common Testing Methods Are Used in Pleather Quality Control?

Testing methods are critical for validating the quality and durability of pleather products. Key testing methods include:

- Physical Testing: This includes tensile strength tests, abrasion resistance tests, and tear strength tests. These assessments determine how well the pleather can withstand wear and tear over time.

- Chemical Testing: Manufacturers often conduct tests for chemical resistance, particularly for products intended for specific industries, such as automotive or upholstery. This ensures the pleather can withstand exposure to oils, solvents, and other chemicals.

- Environmental Testing: This may include UV resistance tests to ensure that the pleather maintains its color and structural integrity when exposed to sunlight, as well as tests for water and weather resistance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying the quality control practices of suppliers is essential to ensure that the products meet their specifications and standards. Here are several actionable steps buyers can take:

-

Supplier Audits: Conducting on-site audits can provide insight into a supplier’s manufacturing processes, quality control measures, and adherence to international standards. An audit allows buyers to assess the supplier’s commitment to quality firsthand.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the outcomes of the supplier’s quality control processes. These reports should include data on testing results, compliance with standards, and any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an additional layer of assurance. These agencies can perform independent quality assessments and provide unbiased reports on the supplier’s products.

What Are the Unique QC and Certification Considerations for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate various certification and quality control nuances when sourcing pleather products.

Illustrative image related to pleather plants

- Regional Standards Compliance: Different regions may have specific regulations regarding material safety and environmental impact. Understanding these local requirements is crucial for compliance and market entry.

- Cultural Expectations: Buyers should consider regional preferences in product design and functionality, which may affect quality expectations. For instance, the demand for eco-friendly materials is rising, particularly in Europe and parts of South America.

- Logistical Challenges: International shipping and customs regulations can impact product quality. Buyers should ensure that suppliers have robust logistics processes to mitigate risks associated with transportation and storage.

By understanding the manufacturing processes and quality assurance practices specific to pleather plants, B2B buyers can make informed decisions, ensuring that they source high-quality products that meet their needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pleather plants’

Introduction

This guide serves as a practical checklist for B2B buyers looking to source pleather plants effectively. Pleather, or faux leather, is increasingly popular due to its sustainability and ethical considerations. By following this step-by-step checklist, buyers can ensure they select the right suppliers and products that meet their quality and compliance standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for pleather plants. This includes the type of pleather (e.g., polyurethane or PVC), thickness, texture, and any specific certifications (such as eco-friendliness). Defining these specifications early helps streamline communication with suppliers and ensures that you receive products that meet your exact needs.

- Consider product use: Determine whether the pleather will be used for fashion, upholstery, or automotive applications, as each may require different specifications.

- Identify compliance needs: Ensure that your specifications align with local and international regulations regarding materials used in manufacturing.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in pleather plants. Utilize online marketplaces, industry directories, and trade fairs to gather a list of qualified candidates. A robust supplier base increases your chances of finding the best quality and pricing.

Illustrative image related to pleather plants

- Check supplier reputation: Look for reviews, ratings, and testimonials from previous clients to gauge the reliability and quality of their products.

- Investigate industry presence: Suppliers with a strong presence in your target markets (e.g., Africa, South America) may better understand local preferences and regulations.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001 for quality management or OEKO-TEX for textile safety can provide assurance of product quality and safety.

- Request documentation: Ask suppliers for copies of their certifications and any third-party audit reports.

- Understand compliance requirements: Familiarize yourself with the necessary certifications required in your target markets to avoid legal issues.

Step 4: Request Samples for Quality Assessment

Always request product samples before making large orders. This step allows you to assess the quality, durability, and appearance of the pleather firsthand. Evaluating samples can help avoid costly mistakes later in the procurement process.

- Test for performance: Assess the samples for characteristics such as flexibility, abrasion resistance, and ease of maintenance.

- Consider aesthetic factors: Ensure that the color, texture, and overall appearance meet your design requirements.

Step 5: Negotiate Pricing and Terms

Once you have evaluated potential suppliers and their samples, proceed to negotiate pricing and terms. Consider factors such as minimum order quantities, lead times, and payment conditions. Effective negotiation can lead to favorable terms that enhance your profit margins.

Illustrative image related to pleather plants

- Explore bulk pricing: Inquire about discounts for larger orders to maximize cost-efficiency.

- Clarify delivery timelines: Ensure that agreed-upon delivery schedules align with your production timelines to avoid disruptions.

Step 6: Establish a Long-Term Relationship

Building a long-term relationship with your chosen supplier can lead to better pricing, priority service, and collaborative innovation. Keep lines of communication open and provide feedback on product performance and service.

- Schedule regular check-ins: Maintain regular communication to discuss any issues or improvements.

- Consider collaborative projects: Explore opportunities for co-development of new products or custom designs tailored to your market needs.

By following these steps, B2B buyers can navigate the sourcing process for pleather plants effectively, ensuring they obtain high-quality materials that meet their business needs while fostering sustainable practices.

Comprehensive Cost and Pricing Analysis for pleather plants Sourcing

What Are the Key Cost Components in Pleather Plant Sourcing?

When sourcing pleather plants, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The choice of synthetic materials, such as polyurethane (PU) or polyvinyl chloride (PVC), significantly affects the overall cost. Higher-quality materials will typically incur a higher price but can lead to better product durability and customer satisfaction.

-

Labor: Labor costs can vary based on geographic location and local wage standards. Countries with lower labor costs might offer competitive pricing but could compromise on quality if not monitored effectively.

-

Manufacturing Overhead: This includes utilities, factory maintenance, and equipment depreciation. Efficient production processes can help reduce overhead costs, making the final product more competitive in the market.

-

Tooling: Initial tooling costs for molds and machinery can be substantial, particularly for custom designs. These costs should be factored into the pricing, especially for smaller production runs.

-

Quality Control (QC): Investing in robust QC processes can prevent defects and ensure compliance with international standards, impacting long-term costs positively by reducing returns and enhancing brand reputation.

-

Logistics: Transportation and warehousing costs are significant components of the total cost. Efficient logistics strategies can reduce these expenses, especially when sourcing from international suppliers.

-

Margin: Suppliers will add a margin to cover risks and profit. Understanding typical margins in the pleather industry can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Pleather Plant Costs?

Several factors can influence the pricing of pleather plants, making it essential for buyers to understand these dynamics:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Higher volumes typically result in lower per-unit costs, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom designs and specific material requirements can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials: As previously mentioned, the type of synthetic material impacts pricing. Buyers should consider both the immediate cost and the long-term value of higher-quality materials.

-

Quality and Certifications: Products that meet certain quality standards or certifications often come at a premium. However, these certifications can enhance marketability and customer trust.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can significantly affect pricing. Established suppliers may command higher prices due to perceived quality and service.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers during the shipping process. Understanding these terms can help manage costs associated with freight, insurance, and customs.

What Buyer Tips Can Enhance Cost-Efficiency in Pleather Plant Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to optimize sourcing costs:

-

Negotiation: Engage in robust negotiations with suppliers to secure better pricing, especially for larger orders. Establishing long-term relationships can also lead to favorable terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors like durability, maintenance, and potential waste when assessing overall value.

-

Pricing Nuances for International Markets: Be aware of regional market differences that can influence pricing. Currency fluctuations, import tariffs, and local demand can all impact final costs.

-

Research and Comparison: Conduct thorough market research to compare prices and quality from multiple suppliers. Utilize online platforms and industry networks to gather insights and make informed decisions.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific order requirements. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your sourcing needs.

Alternatives Analysis: Comparing pleather plants With Other Solutions

Understanding the Alternatives to Pleather Plants

In the quest for sustainable and ethical materials in fashion and upholstery, pleather plants have emerged as a noteworthy solution. However, businesses often face the challenge of selecting the best materials for their needs. This section explores alternative solutions to pleather plants, including synthetic leather, natural leather, and recycled materials. Each alternative offers unique benefits and drawbacks, making it crucial for B2B buyers to understand their options.

| Comparison Aspect | Pleather Plants | Synthetic Leather | Natural Leather |

|---|---|---|---|

| Performance | Durable, water-resistant | Highly durable, versatile | Excellent durability, breathability |

| Cost | Moderate initial investment | Generally lower cost | Higher cost due to sourcing and processing |

| Ease of Implementation | Requires specialized production | Easier to produce, widely available | Complex sourcing, tanning processes |

| Maintenance | Low maintenance, easy to clean | Moderate maintenance, may require special cleaners | High maintenance, needs conditioning |

| Best Use Case | Fashion apparel, accessories | Fashion, automotive, furniture | High-end fashion, luxury goods |

Exploring Synthetic Leather as an Alternative

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a range of benefits. One of its key advantages is cost-effectiveness, as it is typically less expensive than both pleather and natural leather. Its production is generally straightforward, allowing manufacturers to produce it at scale. However, while synthetic leather is durable and versatile, it may not possess the same breathability or luxury feel as natural leather. Additionally, concerns regarding environmental impact and the use of non-biodegradable materials may deter eco-conscious buyers.

Evaluating Natural Leather for Sustainability and Aesthetics

Natural leather remains a classic choice known for its exceptional durability and luxurious feel. It provides breathability and develops a unique patina over time, adding character to products. However, the cost of natural leather can be significantly higher due to sourcing and tanning processes. Moreover, its maintenance requirements are more demanding, necessitating regular conditioning to preserve its quality. Businesses focusing on high-end fashion or luxury goods may find that the aesthetic value of natural leather justifies the investment.

Assessing Recycled Materials for Eco-Friendly Solutions

Recycled materials, such as those derived from post-consumer plastics or waste fabrics, present a sustainable alternative to pleather plants. These materials can significantly reduce environmental impact by diverting waste from landfills. They are often available at a competitive price point, making them attractive for budget-conscious buyers. However, the performance and aesthetic quality of recycled materials can vary, which may affect their suitability for certain applications. Businesses prioritizing sustainability may find recycled materials align well with their corporate social responsibility goals.

Making the Right Choice for Your Business Needs

When selecting between pleather plants and alternative materials, B2B buyers must consider factors such as performance, cost, ease of implementation, and maintenance. Each option presents unique strengths and weaknesses, making it essential to align the material choice with the specific requirements of your product line and target market. By carefully evaluating these alternatives, businesses can make informed decisions that not only meet their operational needs but also resonate with their sustainability goals and customer expectations.

Illustrative image related to pleather plants

Essential Technical Properties and Trade Terminology for pleather plants

What Are the Critical Technical Properties of Pleather Used in Manufacturing?

Understanding the technical properties of pleather (synthetic leather) is essential for B2B buyers, especially in industries like fashion, automotive, and furniture. Here are some key specifications that influence purchasing decisions:

-

Material Grade

Material grade refers to the quality of the synthetic material used in pleather production. Common grades include PVC (polyvinyl chloride) and PU (polyurethane). PU is often preferred for its superior durability, softness, and breathability, making it suitable for high-end applications. Buyers should ensure they are sourcing the correct grade based on the intended use, as this affects both the product lifespan and consumer satisfaction. -

Thickness

The thickness of pleather is measured in millimeters (mm) and is crucial for determining its application. Thicker materials are generally more durable and suitable for products like furniture upholstery, while thinner options may be ideal for clothing. Buyers must specify thickness to ensure compatibility with manufacturing processes and desired end-product performance. -

Tensile Strength

Tensile strength measures the material’s resistance to being pulled apart, expressed in megapascals (MPa). This property is vital for applications that require durability, such as bags and automotive interiors. A higher tensile strength indicates better performance under stress, which is critical for B2B buyers looking for long-lasting products. -

Color Fastness

Color fastness is the ability of pleather to retain its color when exposed to light, washing, or abrasion. This property is particularly important in fashion and upholstery applications where visual appeal is paramount. Buyers should verify color fastness ratings to ensure that the products maintain their aesthetic quality over time. -

Flame Resistance

Flame resistance indicates how well the pleather material can withstand fire. This property is essential for applications in automotive and home furnishings, where safety regulations are stringent. B2B buyers should prioritize materials that meet relevant safety standards to ensure compliance and reduce liability.

Which Trade Terminology Is Crucial for Pleather Plant Suppliers?

In addition to understanding technical properties, familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then branded by another company. For pleather manufacturers, being an OEM means they can supply custom products that meet specific design requirements for various brands. This relationship is crucial for B2B partnerships, as it allows for tailored solutions. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers to ensure they can meet production needs without overcommitting resources. Negotiating a favorable MOQ can significantly impact cash flow and inventory management. -

RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing and terms for specific products. This process allows buyers to compare options and make informed purchasing decisions. Crafting a detailed RFQ can lead to better pricing and service terms from suppliers. -

Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers manage shipping, risk, and costs effectively. Familiarity with Incoterms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can prevent misunderstandings in trade agreements. -

Lead Time

Lead time is the time taken from placing an order to receiving the goods. This metric is crucial for inventory planning and ensuring that production schedules are met. Buyers should negotiate and confirm lead times to avoid disruptions in their supply chain. -

Certification Standards

Certification standards refer to the quality and safety benchmarks that pleather products must meet, such as ISO or ASTM certifications. Knowing which certifications are relevant to specific markets can help buyers ensure compliance and gain consumer trust.

In summary, understanding both the technical properties of pleather and the relevant trade terminology is essential for B2B buyers. This knowledge not only facilitates better purchasing decisions but also strengthens supplier relationships across international markets.

Navigating Market Dynamics and Sourcing Trends in the pleather plants Sector

What Are the Key Drivers and Trends Shaping the Pleather Plants Market?

The global pleather plants sector is currently experiencing significant growth, driven by increasing consumer demand for sustainable and cruelty-free materials. As awareness of environmental issues rises, both consumers and businesses are actively seeking alternatives to traditional leather, which has led to the emergence of innovative synthetic materials. Key trends include the integration of advanced technologies such as 3D printing and digital design, enabling manufacturers to produce high-quality pleather with reduced waste. Additionally, the rise of e-commerce platforms has expanded market access for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Nigeria.

Illustrative image related to pleather plants

B2B buyers are increasingly looking for suppliers that offer not only competitive pricing but also transparency in their sourcing practices. This demand for visibility is reshaping how businesses operate, pushing them toward more accountable supply chains. Furthermore, collaborations between fashion brands and tech companies are on the rise, leading to the development of smart textiles that offer functionality alongside aesthetics. The ongoing shift toward personalization in fashion is also influencing pleather plant production, allowing buyers to request customized designs that meet specific market needs.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions in the Pleather Plants Sector?

The environmental impact of traditional leather production is significant, prompting a shift towards more sustainable and ethical sourcing practices in the pleather plants sector. For B2B buyers, this means prioritizing suppliers who adhere to sustainable practices, such as utilizing eco-friendly materials and processes. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® can serve as benchmarks for assessing the sustainability credentials of potential partners.

Moreover, ethical sourcing encompasses fair labor practices and the promotion of social responsibility within the supply chain. As consumers become more conscious of the origins of their products, B2B buyers can leverage ethical sourcing as a competitive advantage. By collaborating with suppliers who prioritize sustainability, businesses can not only mitigate their environmental footprint but also enhance their brand reputation. This commitment to ethical sourcing can resonate well with eco-conscious customers, driving loyalty and potentially leading to higher sales.

What Is the Evolution of the Pleather Plants Sector and Its Significance for B2B Buyers?

The pleather plants sector has evolved significantly over the past few decades, transitioning from niche markets to mainstream acceptance. Initially, pleather materials were viewed as inferior alternatives to genuine leather. However, advancements in technology and manufacturing processes have improved the quality and durability of synthetic materials, making them a viable option for various applications, including fashion, automotive, and home décor.

The growth of the pleather market is closely linked to changing consumer preferences, with a clear shift towards sustainable and cruelty-free products. As a result, B2B buyers can capitalize on this trend by sourcing pleather materials that align with the values of their target markets. Understanding the historical context of pleather’s evolution can also provide valuable insights into future trends and innovations, enabling businesses to make informed sourcing decisions that meet both current demands and future market shifts.

Frequently Asked Questions (FAQs) for B2B Buyers of pleather plants

1. How do I ensure the quality of pleather plants from suppliers?

To ensure quality, start by conducting thorough research on potential suppliers. Request samples of their pleather plants to assess material quality, craftsmanship, and durability. Consider visiting the supplier’s facility if possible or utilizing third-party inspection services to evaluate their production processes. Always check for certifications that indicate compliance with international quality standards, such as ISO or ASTM, and request customer testimonials or case studies to validate their reliability and product performance.

2. What is the best way to customize pleather plants for my business needs?

Customization options for pleather plants can vary significantly by supplier. To achieve your desired specifications, clearly outline your requirements, including material type, color, texture, and design. Engage in detailed discussions with suppliers about their customization capabilities, including minimum order quantities (MOQs) for custom designs. Request prototypes to evaluate the final product before placing a bulk order to ensure it meets your expectations and aligns with your brand identity.

3. What are the typical minimum order quantities (MOQs) for pleather plants?

Minimum order quantities for pleather plants depend on the supplier and the complexity of the product. Generally, MOQs can range from 100 to 1,000 units. It’s essential to discuss this with potential suppliers upfront, as higher MOQs may be required for custom designs or specific materials. Some suppliers may offer flexibility in MOQs for first-time buyers or trial orders, allowing you to test the market without a significant upfront commitment.

4. How can I effectively vet suppliers of pleather plants?

Vetting suppliers involves several key steps. Begin by checking their business credentials, including registration and licensing. Look for reviews and ratings from other clients, and inquire about their experience in the industry. Request references and follow up with them to gauge satisfaction levels. Additionally, assess their production capabilities, quality control processes, and compliance with international trade regulations. This thorough approach will help ensure you partner with reliable and reputable suppliers.

5. What payment terms should I negotiate with pleather plant suppliers?

Payment terms can vary widely among suppliers, so it’s crucial to negotiate terms that protect your interests. Common options include a deposit (usually 30% to 50%) before production, with the remaining balance due upon completion or prior to shipping. Consider negotiating for payment through secure methods, such as letters of credit or escrow services, to mitigate risks. Always clarify the terms related to refunds or returns in case the product does not meet agreed specifications.

6. What logistics considerations should I keep in mind when sourcing pleather plants?

Logistics play a critical role in international sourcing. Consider shipping methods, costs, and timelines when planning your order. Assess whether the supplier offers shipping support or if you need to engage a freight forwarder. Be aware of customs regulations and duties in your country to avoid unexpected costs. Additionally, ensure that your supplier can provide proper documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance.

7. How do I handle quality assurance (QA) for pleather plants?

Implementing a solid quality assurance process is vital when sourcing pleather plants. Define your quality standards and communicate them clearly to your supplier. Conduct regular inspections during production and before shipping, either through in-house teams or third-party inspectors. Establish a protocol for addressing quality issues, including returns or replacements, to ensure your business maintains high standards and customer satisfaction.

8. What are the trends in the pleather plant market that I should be aware of?

Staying informed about market trends is essential for strategic sourcing. Currently, there is a growing demand for sustainable and eco-friendly materials in the pleather sector, driven by consumer awareness. Additionally, advancements in manufacturing technology are leading to improved quality and variety in pleather products. Keep an eye on emerging styles, colors, and designs that resonate with current fashion trends, as these can significantly impact your product offerings and market competitiveness.

Top 7 Pleather Plants Manufacturers & Suppliers List

1. H&M – Women’s Faux Leather Pants

Domain: www2.hm.com

Registered: 1997 (28 years)

Introduction: Women’s Faux Leather Pants available in various colors, fits, styles, and shapes. Options include super high-shine black leather leggings, wet look pants in bold prints, brown flared leather pants, and leather joggers. Styles include high-waisted and low-rise options, as well as breathable linen pants.

2. Freddy – Faux Leather Pants

3. Macy’s – Women’s Faux Leather Pants

Domain: macys.com

Registered: 1994 (31 years)

Introduction: This company, Macy’s – Women’s Faux Leather Pants, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. NYDJ – Faux Leather Pants and Skirts

Domain: nydj.com

Registered: 1998 (27 years)

Introduction: NYDJ’s faux leather pants and skirts feature a chic texture that adds a bold edge to outfits. Made from compression vegan leather, they are suitable for dressy occasions and holidays, pairing well with various tops. Each style incorporates exclusive Lift Tuck® Technology for a flattering fit. Available colors include black faux leather pants and green vegan leather skirts.

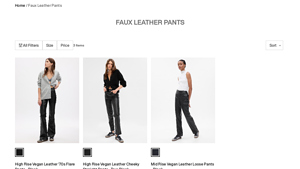

5. Gap – Faux Leather Pants Collection

Domain: gap.com

Registered: 1993 (32 years)

Introduction: Faux Leather Pants collection at Gap includes various styles such as High Rise Vegan Leather ’70s Flare Pants, High Rise Vegan Leather Cheeky Straight Pants, and Mid Rise Vegan Leather Loose Pants. Prices range from $19.97 to $89.95, with many items on final sale. The pants are designed for comfort and style, made from high-quality materials that mimic genuine leather while being animal-friendly. …

6. This Blonde’s Shopping Bag – Faux Leather Pants

Domain: thisblondesshoppingbag.com

Introduction: Faux leather pants for spring in beachwood beige color, a mix of taupe, gold, and khaki. Slim, straight fit that is flattering and runs true to size (TTS). Available in different inseam lengths. Softens with wear and can be styled for work or play. Versatile and can be paired with neutral or colorful tops. Currently on sale.

7. Target – Women’s Pleather Pants

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Women’s Pleather Pants, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for pleather plants

In the rapidly evolving landscape of pleather production, strategic sourcing emerges as a pivotal element for international B2B buyers aiming to capitalize on market opportunities. By understanding supply chain dynamics and establishing robust supplier relationships, businesses can secure high-quality materials while optimizing costs. The shift towards sustainability and ethical practices in sourcing pleather not only aligns with consumer preferences but also enhances brand reputation across diverse markets, including Africa, South America, the Middle East, and Europe.

As the demand for versatile, fashionable, and eco-friendly alternatives to traditional leather continues to grow, staying ahead of trends and consumer preferences becomes crucial. Buyers should prioritize suppliers who demonstrate innovation and adaptability in their offerings, ensuring a competitive edge in their respective markets.

Looking ahead, it is essential for businesses to invest in strategic sourcing initiatives that foster collaboration, transparency, and sustainability. By doing so, international buyers can not only enhance their product offerings but also contribute to a more responsible industry. Engage with potential suppliers today to explore how strategic sourcing can elevate your business in the pleather market.

Illustrative image related to pleather plants

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to pleather plants