Introduction: Navigating the Global Market for how to make leather water resistant

Leather goods are a staple in many industries, revered for their durability and aesthetic appeal. However, a significant challenge faced by manufacturers and retailers alike is how to make leather water resistant. With varying climates across regions—be it the humid jungles of South America or the arid deserts of the Middle East—water damage can lead to costly product failures and dissatisfied customers. This guide provides an in-depth exploration of effective waterproofing techniques tailored for different leather types, ranging from full-grain to suede.

In this comprehensive resource, B2B buyers will discover the most effective waterproofing methods, including sprays, creams, and waxes, and learn how to select the right products for their specific needs. Additionally, the guide covers the importance of supplier vetting, ensuring that businesses can source high-quality materials and treatments that align with their operational standards. Cost considerations and market trends will also be addressed, enabling informed purchasing decisions in a competitive landscape.

By equipping international B2B buyers—particularly those from Africa, South America, Europe (including Germany), and the Middle East (such as Saudi Arabia)—with the knowledge and tools to protect their leather products, this guide aims to enhance product longevity and customer satisfaction. Empower your business with the insights needed to navigate the global market for leather waterproofing effectively.

Table Of Contents

- Top 8 How To Make Leather Water Resistant Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make leather water resistant

- Understanding how to make leather water resistant Types and Variations

- Key Industrial Applications of how to make leather water resistant

- 3 Common User Pain Points for ‘how to make leather water resistant’ & Their Solutions

- Strategic Material Selection Guide for how to make leather water resistant

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather water resistant

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather water resistant’

- Comprehensive Cost and Pricing Analysis for how to make leather water resistant Sourcing

- Alternatives Analysis: Comparing how to make leather water resistant With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make leather water resistant

- Navigating Market Dynamics and Sourcing Trends in the how to make leather water resistant Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather water resistant

- Strategic Sourcing Conclusion and Outlook for how to make leather water resistant

- Important Disclaimer & Terms of Use

Understanding how to make leather water resistant Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicone Sprays | Water-repellent coating, easy application | Footwear, outdoor gear, fashion accessories | Pros: Quick application, versatile; Cons: May require frequent reapplication. |

| Wax-Based Products | Creates a durable barrier, often requires heat | Leather bags, belts, jackets | Pros: Long-lasting protection; Cons: Can alter leather appearance. |

| Cream Conditioners | Moisturizes while providing water resistance | High-end leather goods, upholstery | Pros: Enhances texture and sheen; Cons: Takes longer to apply and dry. |

| Natural Oils | Penetrates leather fibers, enhancing water resistance | Artisan leather products, handmade goods | Pros: Eco-friendly, nourishes leather; Cons: Slower to dry, may darken leather. |

| Synthetic Coatings | Advanced chemical formulations for superior resistance | Industrial applications, outdoor furniture | Pros: High durability, excellent for extreme conditions; Cons: May be more expensive. |

What Are the Key Characteristics of Silicone Sprays for Waterproofing Leather?

Silicone sprays are widely used for waterproofing leather due to their ease of application and effectiveness. These sprays create a thin, water-repellent layer on the leather surface, making them ideal for footwear and outdoor gear. B2B buyers should consider their quick application process and versatility, which makes them suitable for various leather items. However, frequent reapplication may be necessary, especially in high-use environments, which can increase maintenance costs.

How Do Wax-Based Products Provide Long-Lasting Leather Protection?

Wax-based products are known for creating a robust barrier against water and stains. They often require heat application to penetrate the leather effectively, making them suitable for items like bags, belts, and jackets. B2B buyers appreciate the long-lasting nature of wax treatments, which can significantly extend the life of leather goods. However, these products may alter the leather’s appearance, which could be a drawback for businesses focused on aesthetics.

What Are the Benefits of Using Cream Conditioners for Leather?

Cream conditioners serve a dual purpose by moisturizing the leather while providing a degree of water resistance. This makes them particularly popular for high-end leather goods and upholstery, where maintaining appearance is crucial. B2B buyers should note that while these products enhance texture and sheen, the application process is more time-consuming compared to sprays. This may affect labor costs and turnaround times in a production setting.

Why Are Natural Oils a Sustainable Choice for Leather Waterproofing?

Natural oils penetrate the leather fibers and enhance water resistance, making them an eco-friendly option for artisans and manufacturers of handmade leather goods. Their nourishing properties help maintain the leather’s suppleness, which is a significant selling point for businesses focused on sustainability. However, the drying time is longer, and there is a risk of darkening the leather, which could be a concern for some buyers.

What Advantages Do Synthetic Coatings Offer for Extreme Conditions?

Synthetic coatings are formulated with advanced chemicals designed to provide superior water resistance, making them ideal for industrial applications and outdoor furniture. B2B buyers in sectors requiring high durability will find these coatings advantageous, as they can withstand extreme conditions and heavy use. However, the higher cost of synthetic options may be a consideration for budget-conscious businesses.

Key Industrial Applications of how to make leather water resistant

| Industry/Sector | Specific Application of how to make leather water resistant | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Waterproofing leather shoes and boots | Enhances durability and customer satisfaction | Sourcing high-quality waterproofing agents suitable for various leather types. |

| Automotive Industry | Leather upholstery for vehicles | Increases lifespan of interior materials, reducing replacement costs | Compatibility of treatments with automotive-grade leathers and safety regulations. |

| Fashion and Apparel | Leather jackets and bags | Protects against weather damage, maintaining aesthetic appeal | Understanding the specific leather types and finishes used in products. |

| Furniture Production | Leather sofas and chairs | Preserves quality and appearance, reducing maintenance costs | Selection of eco-friendly and non-toxic waterproofing solutions. |

| Sports Equipment | Waterproof leather gear for outdoor activities | Enhances performance and longevity in challenging conditions | Ensuring products meet industry standards for waterproofing effectiveness. |

How is Leather Waterproofing Used in Footwear Manufacturing?

In the footwear manufacturing sector, waterproofing leather shoes and boots is essential for enhancing their durability and ensuring customer satisfaction. Buyers in this industry require waterproofing agents that can penetrate various leather types, including full-grain and suede, while maintaining breathability. The effectiveness of waterproof treatments can significantly influence consumer buying decisions, especially in regions with wet climates. Manufacturers must consider sourcing high-quality waterproofing agents that are compatible with their production processes and can withstand rigorous testing.

Illustrative image related to how to make leather water resistant

What Role Does Leather Waterproofing Play in the Automotive Industry?

In the automotive industry, leather upholstery is a hallmark of luxury vehicles. Waterproofing these materials is critical to prolonging their lifespan and ensuring they remain visually appealing. Buyers must consider the compatibility of waterproofing treatments with automotive-grade leathers, which often require specialized solutions to meet safety regulations and performance standards. Effective waterproofing not only protects against spills and moisture but also enhances the resale value of vehicles, making it a strategic investment for automotive manufacturers.

Why is Leather Waterproofing Important in Fashion and Apparel?

In the fashion and apparel industry, waterproofing leather jackets and bags is vital for protecting products against weather-related damage. This not only maintains the aesthetic appeal of the items but also prolongs their usability, resulting in higher customer satisfaction and repeat purchases. Buyers need to understand the specific leather types and finishes used in their products to select the most appropriate waterproofing solutions. The right treatment can elevate a brand’s reputation for quality, particularly in competitive markets across Europe and the Middle East.

How Does Leather Waterproofing Benefit Furniture Production?

For furniture production, waterproofing leather sofas and chairs is essential to preserve their quality and appearance over time. This treatment helps reduce maintenance costs by preventing stains and damage from moisture. Buyers in this sector should prioritize sourcing eco-friendly and non-toxic waterproofing solutions, as consumer preferences are shifting towards sustainable products. The longevity of leather furniture not only enhances customer satisfaction but also contributes to a brand’s overall sustainability goals.

What Advantages Does Waterproofing Provide for Sports Equipment?

Waterproofing leather gear used in outdoor sports activities is crucial for enhancing performance and longevity in challenging conditions. Buyers in the sports equipment sector must ensure that the waterproofing products meet industry standards for effectiveness and durability. This is particularly important in regions with extreme weather conditions, where the performance of leather gear can be significantly impacted. By investing in high-quality waterproofing solutions, manufacturers can differentiate their products in a crowded marketplace, appealing to both amateur and professional athletes.

Illustrative image related to how to make leather water resistant

3 Common User Pain Points for ‘how to make leather water resistant’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Waterproofing Product for Different Leather Types

The Problem: B2B buyers often face challenges in selecting the appropriate waterproofing product suitable for various types of leather. With a plethora of options available—ranging from sprays to creams and waxes—it can be overwhelming to identify which product will best suit their specific leather items. This is particularly crucial in regions with diverse climates, where leather products are frequently exposed to moisture and humidity. A poor choice can lead to ineffective protection, discoloration, or even damage to the leather, resulting in costly replacements and dissatisfied customers.

The Solution: To mitigate this challenge, it is essential to first identify the type of leather being used. For example, full-grain leather requires a different treatment than suede or nubuck. Buyers should source high-quality waterproofing products from reputable suppliers who provide detailed specifications and recommendations based on leather types. A useful approach is to create a comparison chart that outlines various leather types alongside compatible waterproofing solutions. Additionally, conducting a small patch test on an inconspicuous area of the leather before full application can ensure compatibility and prevent unwanted damage. Regular training sessions for staff on the characteristics of different leather types and their respective treatments can also enhance product selection accuracy.

Scenario 2: Ineffective Application Leading to Poor Water Resistance

The Problem: Another common pain point for B2B buyers is the ineffective application of waterproofing products. Many users either do not follow the recommended application process or lack the knowledge on how to apply these products effectively, resulting in subpar water resistance. This is especially problematic in industries where leather products are expected to withstand harsh conditions, such as outdoor gear or workwear. Inadequate application can lead to product returns, increased warranty claims, and a tarnished brand reputation.

The Solution: To address this issue, companies should invest in comprehensive training for employees involved in the application process. Detailed instruction manuals or video tutorials demonstrating the correct application techniques—such as cleaning the leather first, applying evenly, and allowing proper drying time—can be invaluable. Implementing a checklist for each application can help ensure that no steps are overlooked. Additionally, purchasing waterproofing products that come with clear, easy-to-follow instructions can further streamline the process. For larger operations, consider organizing workshops with product manufacturers to gain firsthand knowledge and best practices.

Scenario 3: Maintaining Water Resistance Over Time

The Problem: B2B buyers often struggle with maintaining the water resistance of leather products over time. Factors such as frequent use, exposure to extreme weather, and inadequate storage can degrade the waterproofing treatment, leading to water damage and decreased product lifespan. This is particularly concerning for businesses that rely on leather goods for their brand image and customer satisfaction. Without a proper maintenance plan, the longevity and quality of leather products can significantly diminish, impacting both sales and customer loyalty.

The Solution: To ensure long-lasting water resistance, businesses should establish a regular maintenance schedule that includes periodic inspections and reapplication of waterproofing treatments. Creating a maintenance guide tailored to specific leather products can help inform customers about the importance of reapplication and proper care. Additionally, partnering with suppliers to offer maintenance kits that include the necessary products and instructions can encourage customers to take proactive steps in caring for their leather goods. Educating customers on the significance of storing leather items in a cool, dry place, away from direct sunlight, can also extend the life of the waterproofing treatment. Implementing these strategies will not only enhance product durability but also foster stronger customer relationships through proactive support and education.

Strategic Material Selection Guide for how to make leather water resistant

What Are the Key Materials for Making Leather Water Resistant?

When considering how to make leather water resistant, selecting the right materials is crucial for ensuring optimal performance and longevity. Below are several common materials used in waterproofing leather, along with their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Silicone-Based Treatments

Key Properties:

Silicone-based waterproofing agents provide a flexible barrier against water while maintaining the leather’s breathability. They are effective in a range of temperatures and are resistant to UV degradation, making them suitable for various climates.

Pros & Cons:

Silicone treatments are easy to apply and can be used on multiple leather types. However, they may require frequent reapplication, especially in high-use scenarios. Additionally, while they offer good water resistance, they may not provide sufficient protection against oil or dirt.

Impact on Application:

Silicone is compatible with most leather types but may alter the texture slightly. This could be a concern for high-end products where aesthetics are paramount.

Illustrative image related to how to make leather water resistant

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding chemical usage, as some regions may restrict silicone-based products. Understanding local preferences for product performance and durability is essential, especially in markets like Germany, where stringent standards apply.

2. Beeswax

Key Properties:

Beeswax is a natural waterproofing agent that creates a protective layer over leather. It is known for its excellent moisture resistance and ability to enhance the leather’s natural color and texture.

Pros & Cons:

While beeswax is biodegradable and environmentally friendly, it can be labor-intensive to apply and may require heat for optimal penetration. Its effectiveness can diminish over time, necessitating regular maintenance.

Impact on Application:

Beeswax is particularly effective for leather goods exposed to outdoor conditions, such as boots and jackets. However, it may not be suitable for items that require a more polished finish.

Considerations for International Buyers:

In regions like Africa and South America, where natural products are preferred, beeswax may be more appealing. Buyers should also consider the availability of sourcing and the potential for local production, which could reduce costs.

3. Polyurethane Coatings

Key Properties:

Polyurethane coatings provide a robust, durable layer that is resistant to water, chemicals, and abrasion. They can withstand high pressure and are available in various formulations to suit different leather types.

Pros & Cons:

These coatings offer long-lasting protection and are suitable for high-performance applications. However, they can be more expensive and may require specialized application techniques, increasing manufacturing complexity.

Illustrative image related to how to make leather water resistant

Impact on Application:

Polyurethane is ideal for leather products that face harsh environmental conditions, such as outdoor gear and industrial applications. However, it may limit the leather’s natural breathability, which could affect comfort in certain applications.

Considerations for International Buyers:

Buyers in Europe, particularly Germany, should ensure that polyurethane products meet local environmental regulations. Additionally, understanding the market demand for high-performance materials is crucial for successful product positioning.

4. Fluoropolymer Treatments

Key Properties:

Fluoropolymer treatments create a protective barrier that repels water, oil, and stains. They are highly effective at maintaining the leather’s original appearance while providing excellent water resistance.

Pros & Cons:

These treatments are known for their durability and effectiveness, but they can be costly and may require specialized application processes. Additionally, they may raise environmental concerns due to their chemical composition.

Illustrative image related to how to make leather water resistant

Impact on Application:

Fluoropolymer treatments are particularly suitable for luxury leather goods and high-performance outdoor gear. However, their application may not be compatible with all leather types, requiring careful consideration.

Considerations for International Buyers:

Buyers should be aware of environmental regulations surrounding fluorinated compounds, especially in Europe. Understanding the preferences for eco-friendly products in markets like the Middle East could influence material selection.

Summary Table

| Material | Typical Use Case for how to make leather water resistant | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone-Based | General leather goods, outdoor products | Flexible and breathable barrier | Requires frequent reapplication | Medium |

| Beeswax | Boots, jackets, outdoor gear | Natural, biodegradable | Labor-intensive application | Low |

| Polyurethane Coatings | High-performance outdoor gear, industrial applications | Durable and resistant to abrasion | Higher cost and complex application | High |

| Fluoropolymer Treatments | Luxury leather goods, high-performance items | Excellent water and stain resistance | Environmental concerns and compatibility issues | High |

This strategic material selection guide provides B2B buyers with actionable insights into the materials available for making leather water resistant, enabling informed decisions that align with their product requirements and regional preferences.

Illustrative image related to how to make leather water resistant

In-depth Look: Manufacturing Processes and Quality Assurance for how to make leather water resistant

What Are the Key Stages in the Manufacturing Process for Making Leather Water Resistant?

The manufacturing process for making leather water resistant involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a significant role in ensuring the final product meets quality and performance standards, especially for B2B buyers who require reliability and durability in their leather goods.

Material Preparation: How Is Leather Treated Before Waterproofing?

The first step in the manufacturing process is the preparation of the leather. Different types of leather, such as full-grain, top-grain, and suede, require specific treatments before waterproofing. The leather is typically sourced from tanneries that adhere to ethical and sustainable practices, which is increasingly important for buyers in regions like Europe and North America.

During preparation, the leather is cleaned and conditioned to remove any impurities that could affect the waterproofing process. This may involve using mild detergents or natural oils that help maintain the leather’s suppleness. Following this, it is essential to dry the leather thoroughly to ensure that any waterproofing agents can bond effectively with the material.

Forming: What Techniques Are Used to Shape Water-Resistant Leather Products?

Once the leather is prepared, it moves to the forming stage, where it is cut and shaped into the desired products, such as bags, shoes, or jackets. Cutting techniques can vary, with some manufacturers opting for automated cutting machines to ensure precision. This stage also includes the stitching and assembly of components, which is critical for achieving water resistance.

To enhance water resistance, manufacturers may incorporate techniques such as heat sealing or using waterproof linings during assembly. These methods create barriers against water ingress, especially in areas prone to exposure, such as seams and zippers.

Illustrative image related to how to make leather water resistant

Finishing: What Is Involved in the Final Treatment of Leather for Waterproofing?

The finishing stage is where waterproofing agents are applied to the leather. Common methods include the use of sprays, creams, or waxes, each chosen based on the leather type and intended use. For example, wax-based products might be used for rugged outdoor gear, while sprays may be more suitable for fashion items.

After application, the leather undergoes a drying process, which can take several hours depending on the type of treatment used. Proper drying is essential to ensure that the waterproofing agents form a durable barrier. The final finish may also include polishing to enhance the leather’s appearance and provide an additional layer of protection against moisture.

What Quality Control Measures Should Be in Place for Leather Waterproofing?

Quality control (QC) is vital in the manufacturing process, especially for international B2B buyers who rely on consistent product quality. Adhering to recognized international standards, such as ISO 9001, ensures that manufacturing processes meet established benchmarks for quality management.

What International Standards Are Relevant for Leather Waterproofing?

ISO 9001 outlines criteria for quality management systems, focusing on meeting customer expectations and ensuring continuous improvement. For leather products, compliance with additional standards such as CE marking for consumer safety or API specifications for industrial applications may be necessary, depending on the end-use of the leather goods.

These standards help manufacturers implement rigorous QC protocols, ensuring that each batch of leather undergoes thorough testing and inspection. B2B buyers should inquire about a supplier’s adherence to these standards, as it reflects their commitment to quality and reliability.

Illustrative image related to how to make leather water resistant

What Are the Key QC Checkpoints in Leather Manufacturing?

Quality control in leather manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial stage assesses raw materials to ensure they meet quality specifications. Suppliers should provide documentation, such as certificates of authenticity and quality, for the leather received.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor compliance with established standards. This includes checking the effectiveness of waterproofing treatments and ensuring proper application techniques are followed.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is performed to verify that all items meet quality standards. This may involve testing for water resistance, checking for defects, and ensuring that products adhere to design specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are actionable steps buyers can take:

-

Request Documentation: Ask suppliers for detailed quality assurance documentation, including QC reports, compliance certificates, and records of past audits. This information can provide insights into their manufacturing practices and adherence to international standards.

-

Conduct Supplier Audits: Regular audits can help buyers assess a supplier’s manufacturing processes and QC measures. Audits can be conducted by the buyer’s team or through third-party inspection agencies specializing in leather products.

-

Utilize Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality control processes. These services can include pre-shipment inspections, where samples are tested for waterproofing effectiveness and overall quality.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the complexities of QC and certification can be particularly challenging for international B2B buyers, especially those from diverse markets like Africa, South America, the Middle East, and Europe. Here are some nuances to consider:

-

Regional Standards: Different regions may have varying requirements for leather goods. For instance, European markets may demand compliance with REACH regulations concerning chemical safety, while Middle Eastern buyers might prioritize durability and weather resistance.

-

Cultural Expectations: Understanding cultural expectations regarding product quality and sustainability is crucial. Buyers from regions with strong environmental regulations may prioritize suppliers who demonstrate eco-friendly practices in their waterproofing processes.

-

Logistical Challenges: International shipping can introduce complications related to product quality. Buyers should consider potential delays in quality control checks due to customs inspections or shipping logistics, which could affect product timelines.

In conclusion, understanding the manufacturing processes and quality assurance measures for making leather water resistant is essential for B2B buyers. By focusing on effective manufacturing techniques, adhering to international standards, and implementing rigorous quality control practices, suppliers can deliver high-quality leather products that meet the demands of global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make leather water resistant’

Introduction

This guide provides a comprehensive checklist for B2B buyers seeking to procure solutions for making leather water-resistant. Given leather’s vulnerability to moisture, it is essential to partner with suppliers who can deliver effective waterproofing products and services. Following this checklist will ensure you select the right materials and techniques, enhancing the durability and appeal of your leather goods.

Step 1: Identify Your Leather Type

Understanding the type of leather you are working with is crucial. Different leathers, such as full-grain, suede, or nubuck, require specific waterproofing methods and products. Assessing the leather type will help you determine the appropriate treatment, ensuring compatibility and effectiveness.

Illustrative image related to how to make leather water resistant

- Full-grain leather typically benefits from oils and waxes.

- Suede needs specialized sprays designed to avoid staining.

Step 2: Define Your Technical Specifications

Clearly outline the technical specifications for your waterproofing needs. This includes the desired level of water resistance, application method, and durability requirements. Establishing these parameters early will guide you in selecting the right products and suppliers.

- Consider factors like environmental exposure and expected usage.

- Determine if you need a temporary or permanent solution.

Step 3: Research Waterproofing Products

Conduct thorough research on available waterproofing products. Look for sprays, creams, and waxes that are tailored for your specific leather type and intended use. Understanding the product formulations will help you make informed decisions.

- Check for water-repellent technology and UV protection.

- Read product reviews and testimonials from other B2B buyers.

Step 4: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, product samples, and references from businesses in similar industries. This step is vital to ensure you are partnering with reputable suppliers who can meet your quality standards.

- Look for suppliers who offer certifications and quality guarantees.

- Ask for case studies showcasing successful waterproofing projects.

Step 5: Request Product Samples

Always request samples of the waterproofing products you are considering. Testing these samples on your specific leather types will provide insight into their effectiveness and compatibility. This hands-on approach will help you avoid costly mistakes in the procurement process.

- Perform patch tests on inconspicuous areas of the leather.

- Evaluate the product’s impact on color and texture.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier and products, it’s time to negotiate terms and conditions. Discuss pricing, minimum order quantities, and delivery schedules to ensure they align with your business needs. Clear agreements will help prevent misunderstandings later.

- Ensure clarity on return policies and warranty terms.

- Discuss the potential for bulk purchasing discounts.

Step 7: Plan for Regular Maintenance

Waterproofing is not a one-time task; it requires ongoing maintenance. Establish a routine for assessing the condition of your leather goods and reapplying waterproofing treatments as necessary. This proactive approach will extend the life of your leather products.

- Schedule regular inspections for wear and tear.

- Keep track of when treatments need to be reapplied based on usage.

By following this checklist, B2B buyers can effectively source the right solutions for making leather water-resistant, ensuring the longevity and aesthetic appeal of their products.

Comprehensive Cost and Pricing Analysis for how to make leather water resistant Sourcing

Understanding the cost structure and pricing for waterproofing leather is essential for B2B buyers, especially those operating in diverse international markets. This analysis will break down the key cost components and price influencers while providing actionable insights tailored for buyers in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Waterproofing Leather?

Materials: The primary costs in making leather water-resistant stem from the materials used. Waterproofing agents vary in price based on their composition and effectiveness. Common options include silicone sprays, wax-based products, and specialized creams. The choice of material not only influences the upfront cost but also the long-term durability and effectiveness of the waterproofing treatment.

Labor: Labor costs encompass the workforce required to apply waterproofing treatments. This can include cleaning, applying the waterproofing agent, and performing quality checks. Depending on the region, labor costs may vary significantly, impacting overall pricing structures.

Illustrative image related to how to make leather water resistant

Manufacturing Overhead: This includes expenses related to the facilities, equipment, and technology used in the waterproofing process. Companies with advanced machinery may incur higher overhead costs, but they often achieve better efficiency and quality, which can justify a higher price point.

Tooling: Depending on the waterproofing method chosen, specific tools or equipment may be required. For instance, spray application may need specialized machinery that can increase the initial investment but provide consistent results.

Quality Control (QC): Ensuring that leather goods are effectively waterproofed requires stringent quality control measures. This may involve testing batches of treated leather for water resistance and durability, adding to overall costs.

Logistics: Shipping and handling costs can significantly affect pricing, especially for international buyers. Understanding shipping terms and potential tariffs is crucial for calculating the total cost.

Margin: Suppliers typically include a profit margin that reflects their operational costs and market positioning. In competitive markets, margins may be tighter, while in niche segments, they can be more substantial.

Illustrative image related to how to make leather water resistant

How Do Price Influencers Impact Waterproofing Leather?

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to cost savings due to economies of scale. Suppliers may offer discounts for higher quantities, making it financially advantageous for businesses to purchase larger volumes.

Specifications and Customization: Customized waterproofing solutions may incur additional costs. Buyers seeking specific formulations or tailored applications should be prepared for potential price increases.

Material Quality and Certifications: Higher-quality waterproofing agents that comply with environmental standards or possess certifications will typically command a higher price. Buyers should weigh the importance of these certifications against their budget and requirements.

Supplier Factors: Supplier reputation, experience, and reliability can influence pricing. Established suppliers may charge a premium due to their proven track record, while new entrants may offer lower prices to penetrate the market.

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing and total landed costs, which are crucial for buyers managing budgets across different currencies and regions.

What Are Effective Buyer Tips for Negotiation and Cost-Efficiency?

Negotiation: Buyers should approach negotiations with a clear understanding of their needs and the market landscape. Knowing competitor pricing and being aware of alternative suppliers can strengthen negotiation positions.

Total Cost of Ownership: When evaluating suppliers, consider not just the initial purchase price but the total cost of ownership. This includes maintenance, durability, and the frequency of reapplication required for waterproofing treatments.

Pricing Nuances for International Buyers: Currency fluctuations, import duties, and local market conditions can affect pricing for international buyers. It’s essential to factor in these elements when budgeting for waterproofing leather.

Illustrative image related to how to make leather water resistant

Disclaimer on Indicative Prices

The prices associated with waterproofing leather can vary widely based on the factors mentioned above. Buyers are encouraged to obtain quotes from multiple suppliers and consider the total cost of ownership when making purchasing decisions.

Alternatives Analysis: Comparing how to make leather water resistant With Other Solutions

Exploring Alternatives for Making Leather Water Resistant

In the quest to protect leather goods from moisture and environmental damage, various methods exist beyond traditional waterproofing techniques. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their specific needs, ensuring the longevity and aesthetics of leather products. Below, we present a comparison of conventional leather waterproofing against two viable alternatives: synthetic leather treatments and silicone-based coatings.

| Comparison Aspect | How To Make Leather Water Resistant | Synthetic Leather Treatments | Silicone-Based Coatings |

|---|---|---|---|

| Performance | Provides moderate water resistance; requires reapplication. | Excellent water resistance; often more durable. | High water resistance; creates a flexible barrier. |

| Cost | Moderate cost for products (sprays, creams). | Typically higher initial cost but may last longer. | Generally lower to moderate cost depending on brand. |

| Ease of Implementation | Requires cleaning, testing, and applying multiple layers. | Simple application, often pre-treated. | Easy to apply but requires specific conditions for best results. |

| Maintenance | Needs regular reapplication, especially for high-use items. | Minimal maintenance, depending on the quality. | Low maintenance; can last a long time before needing reapplication. |

| Best Use Case | Ideal for high-end leather goods requiring care. | Suitable for everyday items and cost-effective solutions. | Best for outdoor gear and items exposed to harsh conditions. |

What Are the Pros and Cons of Synthetic Leather Treatments?

Synthetic leather treatments are gaining traction as a water-resistant alternative, offering excellent performance against moisture. These products typically incorporate advanced polymers that create a durable barrier. The primary advantages include their long-lasting nature and ease of application, as many synthetic leathers come pre-treated. However, the higher initial cost may deter some buyers, and the aesthetic appeal may not match that of genuine leather, which is a critical factor for luxury brands.

How Do Silicone-Based Coatings Compare?

Silicone-based coatings present another effective solution for waterproofing leather. They create a flexible, water-repellent barrier that allows leather to maintain its natural feel while providing superior moisture protection. The application process is straightforward, often requiring only a spray or wipe-on method. While these coatings can be cost-effective and require minimal maintenance, they may not bond as effectively with all leather types and can sometimes alter the texture or appearance of the leather if not applied correctly.

Conclusion: Which Leather Waterproofing Solution is Right for You?

Choosing the right method for making leather water-resistant hinges on the specific needs of your business. For high-end leather products where aesthetics and craftsmanship are paramount, traditional waterproofing methods may be preferable. In contrast, synthetic treatments and silicone coatings may suit businesses focused on durability and ease of maintenance, particularly for everyday items or outdoor applications. Assessing the performance, cost, and maintenance requirements of each option will empower B2B buyers to select a solution that aligns with their brand’s values and customer expectations.

Essential Technical Properties and Trade Terminology for how to make leather water resistant

What are the Key Technical Properties of Leather Waterproofing?

Understanding the essential technical properties related to waterproofing leather is crucial for B2B buyers who seek to invest in high-quality leather products. Here are some critical specifications that should be considered:

-

Water Resistance Rating

This rating indicates the level of water resistance a leather product offers. Measured in terms of hydrostatic pressure (measured in millimeters), a higher rating signifies better resistance to water penetration. For manufacturers, understanding this rating helps in selecting suitable materials for specific applications, ensuring that the final product meets customer expectations, especially in regions with high humidity or rainfall. -

Leather Type

Different types of leather (e.g., full-grain, top-grain, suede, nubuck) have unique characteristics that affect their waterproofing needs. For instance, full-grain leather is more resistant to water than suede. B2B buyers must recognize these distinctions to ensure they are sourcing the right type of leather for their products, as this impacts both performance and customer satisfaction. -

Finish and Treatment Process

The finishing process can significantly affect the leather’s water resistance. Common treatments include oils, waxes, and synthetic coatings, each offering varying degrees of protection. Knowledge of these processes allows buyers to assess the quality of leather products and make informed purchasing decisions based on durability and maintenance requirements. -

Durability and Abrasion Resistance

Leather products must withstand wear and tear, especially in high-usage environments. The durability of the waterproofing treatment, often evaluated through abrasion tests, is crucial for ensuring the longevity of leather goods. B2B buyers should prioritize suppliers who can provide data on the abrasion resistance of their products, ensuring they meet industry standards. -

Environmental Resistance

Leather is susceptible to damage from UV rays, mold, and mildew. Waterproofing treatments should also offer protection against these environmental factors. Buyers should inquire about the environmental resistance of leather products to ensure they can maintain their appearance and functionality over time. -

Chemical Resistance

The ability of leather to resist degradation from exposure to chemicals (e.g., oils, detergents, and solvents) is essential for certain applications. Understanding the chemical resistance properties of leather helps businesses select products that will not only withstand everyday use but also maintain their integrity in harsher environments.

Which Trade Terms are Essential for Leather Waterproofing?

In the realm of leather manufacturing and waterproofing, familiarity with trade terminology is vital for effective communication and transactions. Here are some common terms that B2B buyers should understand:

Illustrative image related to how to make leather water resistant

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For leather goods, understanding OEM relationships can help buyers identify reliable suppliers and ensure quality control in the manufacturing process. -

MOQ (Minimum Order Quantity)

This term refers to the smallest quantity of a product that a supplier is willing to sell. B2B buyers should be aware of the MOQ when negotiating with suppliers, as it impacts inventory management and cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing on specific products or services. Using an RFQ allows buyers to compare offers and negotiate better terms, making it a critical tool for procurement. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps businesses manage shipping costs and responsibilities effectively. -

TPO (Thermoplastic Olefin)

In the context of leather treatment, TPO refers to a type of synthetic material used in waterproofing. Knowledge of TPO can guide buyers in selecting advanced waterproofing technologies that enhance the performance of leather products. -

Tanning Process

This refers to the method used to treat animal hides to produce leather. Different tanning methods (e.g., chrome, vegetable) affect the leather’s properties, including its water resistance. Buyers should be informed about the tanning process to understand how it influences the final product quality.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions in sourcing and purchasing leather products that meet their needs for durability and water resistance.

Navigating Market Dynamics and Sourcing Trends in the how to make leather water resistant Sector

What Are the Key Market Drivers in the Leather Waterproofing Sector?

The leather waterproofing market is driven by several global factors, including the increasing demand for durable leather products across diverse sectors such as fashion, automotive, and outdoor gear. As consumers become more environmentally conscious, there is a rising preference for products that withstand the elements while maintaining their aesthetic appeal. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where climatic conditions vary significantly, necessitating effective waterproofing solutions.

Emerging technologies in B2B sourcing, such as advanced waterproofing formulations and eco-friendly treatments, are reshaping the industry. For instance, nanotechnology is being leveraged to create water-resistant coatings that not only protect leather but also enhance its breathability. Additionally, the rise of e-commerce platforms enables international buyers to access a broader range of waterproofing products and techniques, fostering competitive pricing and innovation.

Illustrative image related to how to make leather water resistant

Moreover, market dynamics indicate a shift towards customization and personalization. B2B buyers are increasingly looking for tailored waterproofing solutions that meet specific product requirements, whether for high-end fashion brands or rugged outdoor gear. This trend emphasizes the importance of suppliers who can offer both versatility and quality in their waterproofing methods.

How Is Sustainability Shaping the Leather Waterproofing Industry?

Sustainability and ethical sourcing have become paramount in the leather waterproofing sector. The environmental impact of traditional leather processing methods has prompted manufacturers to seek alternatives that reduce carbon footprints and promote ethical practices. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using biodegradable waterproofing agents or sourcing leather from certified sustainable farms.

Certifications like the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction, providing buyers with assurance regarding the environmental and ethical standards of their suppliers. These certifications not only enhance brand reputation but also align with the growing consumer demand for eco-friendly products.

Furthermore, the use of plant-based and synthetic materials as alternatives to traditional leather is on the rise. Innovations in bio-based waterproofing treatments are helping to reduce reliance on harmful chemicals, making the sourcing process more sustainable. B2B buyers who prioritize these materials can enhance their product offerings while addressing consumer concerns about environmental stewardship.

Illustrative image related to how to make leather water resistant

What Is the Historical Context of Leather Waterproofing Techniques?

The evolution of leather waterproofing can be traced back to ancient civilizations, where natural oils and waxes were used to protect leather goods from moisture and wear. Over the centuries, advancements in chemistry have led to the development of more effective waterproofing agents, transitioning from animal fats to synthetic compounds.

In the 20th century, the rise of outdoor activities and sportswear further propelled innovation in waterproofing technologies, with brands experimenting with various coatings and treatments to enhance performance. Today, the focus has shifted towards not only improving water resistance but also ensuring that these solutions are environmentally friendly and sustainable.

Understanding this historical context is essential for B2B buyers, as it highlights the continuous evolution of materials and methods in the leather waterproofing market. Buyers who are aware of these trends can better navigate the marketplace and make informed sourcing decisions that align with both performance and sustainability goals.

Illustrative image related to how to make leather water resistant

Frequently Asked Questions (FAQs) for B2B Buyers of how to make leather water resistant

-

How do I solve water damage issues in leather products?

To address water damage in leather products, start by cleaning the affected area with a damp cloth to remove any dirt or residue. Once clean, allow the leather to dry completely at room temperature, avoiding direct heat sources. After drying, apply a suitable leather waterproofing product, such as sprays or creams, specifically designed for the leather type. Regular maintenance, including reapplication of waterproofing agents, will help prevent future water damage. -

What is the best waterproofing method for full-grain leather?

For full-grain leather, the best waterproofing method involves using a high-quality wax or cream designed for leather care. These products penetrate the leather fibers, providing a protective barrier against moisture while maintaining breathability. Always clean the leather first, apply the product evenly, and allow adequate drying time. Regular reapplication is essential to ensure continued protection, especially in high-use items like bags or shoes. -

How can I ensure the leather waterproofing product is suitable for my needs?

To ensure the waterproofing product meets your needs, first identify the type of leather you are working with, as different leathers require different treatments. Read product labels carefully to check compatibility with your leather type and intended use. Additionally, conduct a patch test on a small area to observe any adverse reactions. Consulting with suppliers or manufacturers can also provide insights into the best options for your specific leather goods. -

What factors should I consider when sourcing leather waterproofing products internationally?

When sourcing leather waterproofing products internationally, consider the supplier’s reputation and product quality. Check for certifications and compliance with international standards. Evaluate shipping logistics and costs, including any potential tariffs or customs regulations. It’s also essential to assess the minimum order quantities (MOQs) and lead times to ensure they align with your inventory and production schedules. -

How can I vet suppliers for leather waterproofing products?

Vetting suppliers for leather waterproofing products involves researching their background, product offerings, and customer reviews. Request samples to evaluate product quality firsthand. Verify their production capabilities and certifications, such as ISO or other relevant industry standards. Establish communication to gauge their responsiveness and willingness to address your specific needs. Finally, consider visiting their facilities if possible to assess their operations and quality control processes. -

What customization options are available for leather waterproofing products?

Many suppliers offer customization options for leather waterproofing products, such as specific formulations tailored to unique leather types or environmental conditions. You can inquire about private labeling, allowing your brand to be associated with the product. Additionally, some manufacturers may provide customized packaging solutions to enhance your branding efforts. Discuss your requirements with potential suppliers to explore available options. -

What payment terms are commonly offered by suppliers in the leather industry?

Payment terms in the leather industry can vary widely among suppliers. Common practices include upfront payments, partial payments with the balance due upon delivery, or net payment terms (e.g., net 30 or net 60 days). It’s crucial to negotiate terms that align with your cash flow and financial capabilities. Always ensure that payment methods are secure and that you have a clear agreement documented to avoid potential disputes. -

How do I manage logistics for importing leather waterproofing products?

Managing logistics for importing leather waterproofing products requires careful planning. Start by selecting reliable freight forwarders who specialize in international shipping. Understand the documentation required, such as bills of lading, customs declarations, and product compliance certificates. Monitor shipping timelines and establish clear communication with suppliers regarding expected delivery dates. Additionally, consider warehousing options upon arrival to streamline distribution to your customers.

Top 8 How To Make Leather Water Resistant Manufacturers & Suppliers List

1. Tandy Leather – Conditioning Creams & Waxes

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Conditioning Creams & Waxes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reddit – Coach Backpack

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Coach backpack, natural brown leather, likely has a slight pigment layer for water resistance.

3. Buffalo Jackson – Leather Waterproofing Solutions

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: This company, Buffalo Jackson – Leather Waterproofing Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Instructables – Homemade Leather Preserver

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Home-made Leather Preserver and Waterproofing ingredients: 200 ml of Extra Virgin Olive Oil, 50g Beeswax, 20 drops of Lavender essential oil, 10 drops of Tea Tree essential oil. Method: Melt Beeswax into Olive Oil, add essential oils, stir until cool and stiffened. Uses: Suitable for leather items like hats, belts, boots, shoes, and bags.

5. Carl Friedrik – Leather Cream

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: Carl Friedrik Leather Cream is a product designed to waterproof leather, enhancing its natural water resistance and prolonging its lifespan. The cream helps maintain the appearance and texture of leather goods, making them look healthier and more consistent. It is particularly beneficial for full-grain leather products, which are known for their durability and water resistance. The cream can be ap…

6. Billy Tannery – Leather Care Kit

Domain: billytannery.co.uk

Registered: 2016 (9 years)

Introduction: Billy Tannery Leather Care Kit includes: 1. Collonil Wax Leather premium waterproofing cream (containing beeswax and conditioning oils) 2. A quality cotton cloth for removing excess wax and polishing 3. A polishing cloth for polishing fittings. The kit is designed to make leather waterproof and extend the lifetime of leather goods.

7. Obenauf’s – Leather Treatment

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1. Obenauf’s – A product mentioned for treating leather to enhance water resistance. 2. Mink Oil – Another product referenced for waterproofing leather. 3. Mirror Coat – A finish available in woodworking stores that can make leather waterproof but alters its feel and performance. 4. Clear Coat – Similar to Mirror Coat, it provides a hard, shell-like finish. 5. Latigo Leather – Suggested as a start…

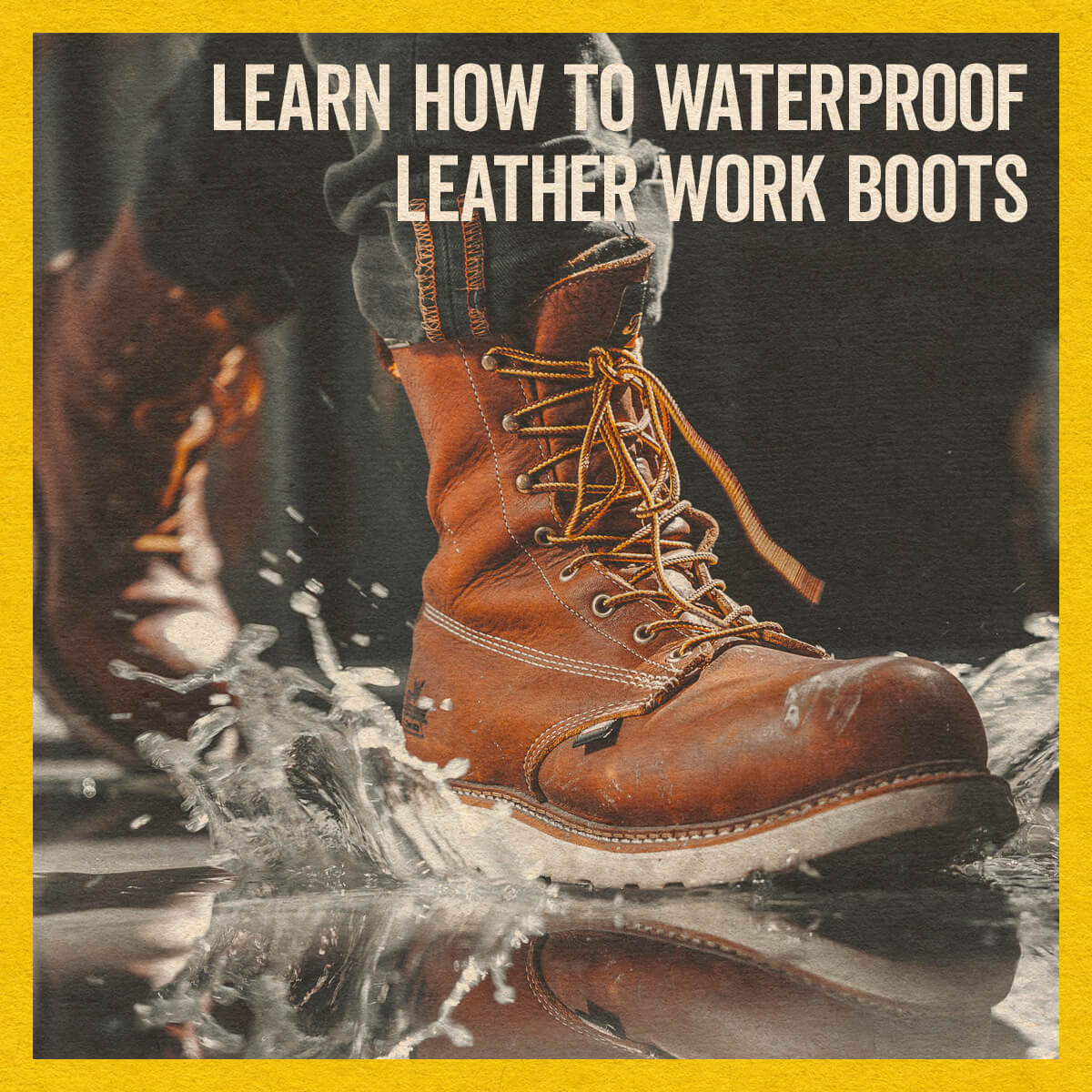

8. Thorogood – Waterproof Leather Work Boots

Domain: thorogoodusa.com

Registered: 2013 (12 years)

Introduction: Thorogood offers a variety of waterproof leather work boots designed to protect against moisture and extend the life of the footwear. Key features include:

– Types of Work Boots: Moc Toe, Safety Toe, Composite Toe, Steel Toe, Waterproof, Insulated, Tactical, and Uniform Shoes.

– Popular Series: Genesis Series, American Heritage Series, Hammerhead Series, 1957 Series, Western Work Series, Logger …

Strategic Sourcing Conclusion and Outlook for how to make leather water resistant

In summary, effectively waterproofing leather is not merely a maintenance task; it’s a strategic investment in the longevity and value of leather products. By understanding the unique properties of different leather types and selecting appropriate waterproofing methods—be it sprays, creams, or waxes—B2B buyers can ensure their products withstand environmental challenges. Regular upkeep and the right storage conditions further enhance the resilience of leather goods, safeguarding them against moisture, stains, and UV damage.

For businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, sourcing high-quality waterproofing solutions is crucial. As the global demand for durable leather products continues to rise, establishing partnerships with reliable suppliers who prioritize quality and sustainability will position your business for long-term success.

Looking ahead, consider investing in advanced waterproofing technologies and eco-friendly solutions that align with consumer preferences for sustainability. By doing so, you not only enhance product offerings but also build a reputation as a leader in the leather industry. Now is the time to act—secure your supply chain and elevate your leather products to meet the demands of the modern market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to how to make leather water resistant

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.