Introduction: Navigating the Global Market for pu material

In an increasingly competitive marketplace, international B2B buyers face the challenge of sourcing high-quality PU material that meets their specific needs while balancing cost and sustainability. As companies from regions such as Africa, South America, the Middle East, and Europe (including Germany and Saudi Arabia) explore options for versatile materials, understanding the nuances of PU (polyurethane) material becomes paramount. This guide provides a comprehensive overview of PU material, detailing its various types, applications, and the critical factors to consider when selecting suppliers.

From furniture to automotive upholstery, PU material serves a multitude of industries, each with unique requirements and standards. This guide empowers B2B buyers to make informed purchasing decisions by exploring essential topics such as supplier vetting processes, cost considerations, and environmental impacts associated with different PU products. By delving into the advantages and limitations of PU material, buyers can navigate the complexities of sourcing effectively, ensuring they choose options that not only meet their operational demands but also align with their sustainability goals.

Whether you are looking to enhance product offerings or streamline procurement processes, this guide equips you with the insights needed to thrive in a global market. Make informed choices that benefit your business and contribute positively to the environment, ensuring a sustainable future for your operations.

Table Of Contents

- Top 4 Pu Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pu material

- Understanding pu material Types and Variations

- Key Industrial Applications of pu material

- 3 Common User Pain Points for ‘pu material’ & Their Solutions

- Strategic Material Selection Guide for pu material

- In-depth Look: Manufacturing Processes and Quality Assurance for pu material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu material’

- Comprehensive Cost and Pricing Analysis for pu material Sourcing

- Alternatives Analysis: Comparing pu material With Other Solutions

- Essential Technical Properties and Trade Terminology for pu material

- Navigating Market Dynamics and Sourcing Trends in the pu material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pu material

- Strategic Sourcing Conclusion and Outlook for pu material

- Important Disclaimer & Terms of Use

Understanding pu material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather | Synthetic leather made from thermoplastic polymers | Furniture, automotive interiors, fashion | Pros: Cost-effective, easy to clean, vegan options. Cons: Less durable, prone to cracking, can emit chemical odors. |

| Bicast Leather | Genuine leather with a polyurethane coating | Upholstery, handbags, accessories | Pros: Affordable, retains some leather texture. Cons: Limited lifespan, can peel over time. |

| Split Leather | Lower-grade leather split into layers, coated with PU | Footwear, budget-friendly products | Pros: Cost-efficient, offers leather-like feel. Cons: Less durability, may not be as visually appealing. |

| Bonded Leather | Made from leftover leather fibers bonded with PU | Low-cost furniture, fashion accessories | Pros: Eco-friendly recycling of materials. Cons: Shorter lifespan, lacks the quality of full-grain leather. |

| Vegan Leather | 100% synthetic, often made from PU or other plastics | Eco-conscious products, fashion items | Pros: Animal-friendly, available in various styles. Cons: Environmental concerns regarding plastic use, less durable. |

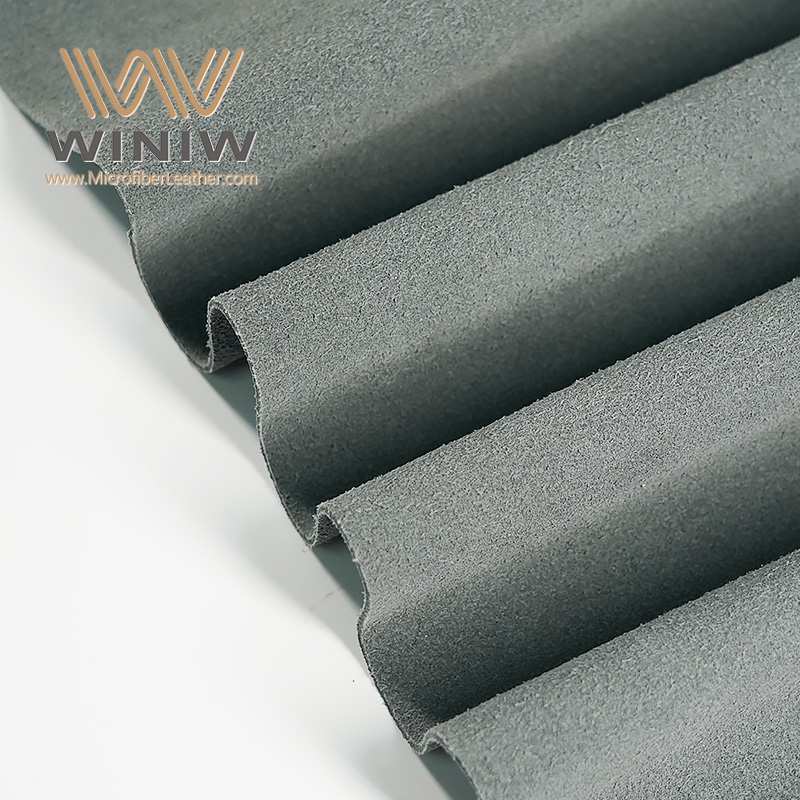

What Are the Key Characteristics of PU Leather?

PU Leather is a widely recognized synthetic alternative to genuine leather, characterized by its affordability and versatility. It is made from thermoplastic polymers that replicate the look and feel of leather, making it a popular choice in sectors such as furniture manufacturing, automotive interiors, and fashion. For B2B buyers, the cost-effectiveness of PU leather is a significant advantage, especially for bulk purchasing. However, potential buyers should be aware of its durability issues, as PU leather can crack and peel with frequent use.

How Does Bicast Leather Compare to Other Types?

Bicast Leather combines the appeal of genuine leather with a polyurethane coating, offering a unique blend of affordability and aesthetic. This type is particularly suitable for upholstery in commercial spaces, handbags, and fashion accessories. B2B buyers should consider its appearance, which retains some leather texture, but keep in mind that it may not withstand wear and tear as effectively as full-grain leather. Its lifespan is shorter, making it essential for businesses to weigh the balance between cost and durability.

What Is Split Leather and Its Suitability for B2B Buyers?

Split Leather is derived from the lower layers of animal hides, often coated with PU to enhance its appearance. This material is commonly used in budget-friendly footwear and other products where cost is a primary concern. For B2B buyers, the main appeal lies in its affordability; however, it is crucial to understand that its durability and visual appeal are not on par with higher-quality leather options. Businesses should assess the trade-off between price and longevity when considering Split Leather for their product lines.

Why Choose Bonded Leather for Budget-Conscious Projects?

Bonded Leather is an innovative material created from leftover leather fibers bonded with PU, making it an eco-friendly option. It is often used in low-cost furniture and accessories, appealing to businesses looking to reduce waste while maintaining a leather-like aesthetic. While the environmental benefits are notable, B2B buyers should be cautious of its shorter lifespan and lower quality compared to genuine leather. Understanding the intended use and expected wear can help buyers make informed decisions.

What Are the Benefits and Drawbacks of Vegan Leather?

Vegan Leather, typically made from synthetic materials like PU, is designed to meet the needs of eco-conscious consumers and businesses. Its appeal lies in its animal-friendly nature and variety of styles available. However, B2B buyers must consider the environmental impact of plastic production and the material’s overall durability. As the market for sustainable products grows, understanding these factors will be essential for businesses aiming to align with consumer preferences while ensuring product longevity.

Key Industrial Applications of pu material

| Industry/Sector | Specific Application of PU Material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for office and home furniture | Cost-effective, easy to clean, and available in diverse colors | Ensure compliance with fire safety standards and durability tests |

| Automotive | Interior components such as seats and trims | Lightweight, durable, and resistant to wear and tear | Consider environmental regulations and material certifications |

| Footwear | Production of synthetic leather shoes | Versatile design options and lower production costs | Assess the longevity and comfort features for end-users |

| Fashion Accessories | Handbags, wallets, and belts | Eco-friendly alternatives to genuine leather with aesthetic appeal | Verify the sourcing of raw materials and ethical manufacturing practices |

| Medical Supplies | Covers for medical furniture and equipment | Easy to clean, waterproof, and resistant to chemicals | Ensure compliance with health and safety regulations |

How is PU Material Used in Furniture Manufacturing?

In the furniture manufacturing industry, PU material is extensively used for upholstery in office and home furniture. Its affordability allows manufacturers to create stylish, durable products without the high costs associated with genuine leather. PU upholstery is also easy to clean, making it ideal for environments that require hygiene, such as offices and homes with children or pets. International buyers should consider sourcing PU materials that meet local fire safety standards and durability tests to ensure compliance and customer satisfaction.

What Role Does PU Material Play in the Automotive Sector?

In the automotive sector, PU material is utilized for interior components, including seats, dashboards, and trims. Its lightweight nature contributes to overall vehicle efficiency, while its durability ensures that the interiors withstand wear and tear over time. Additionally, PU can be designed to mimic the appearance of genuine leather, providing a cost-effective alternative. B2B buyers should focus on suppliers that adhere to environmental regulations and offer materials with certifications for automotive use to guarantee safety and performance.

How is PU Material Transforming Footwear Production?

The footwear industry benefits significantly from PU material, which is widely used in the production of synthetic leather shoes. This material offers versatile design options and lower production costs compared to traditional leather. PU shoes are often lighter and can be produced in a variety of colors and styles, appealing to diverse consumer preferences. Buyers from international markets should evaluate the longevity and comfort features of PU footwear to ensure they meet the expectations of their customers.

Why is PU Material Popular for Fashion Accessories?

PU material is increasingly popular in the fashion accessories sector for products like handbags, wallets, and belts. It serves as an eco-friendly alternative to genuine leather, appealing to consumers who prioritize sustainability. The versatility in design and color makes it an attractive option for manufacturers looking to create trendy products. When sourcing PU materials, buyers should verify the ethical manufacturing practices and the sustainability of raw materials to align with consumer values and regulatory standards.

How is PU Material Applied in Medical Supplies?

In the medical supplies industry, PU material is used for covers on medical furniture and equipment due to its waterproof and chemical-resistant properties. This makes it easy to clean and maintain hygiene standards, which is crucial in medical settings. The durability of PU ensures that these covers last longer, reducing the need for frequent replacements. Buyers in this sector should ensure that the PU materials comply with health and safety regulations to protect both patients and staff.

3 Common User Pain Points for ‘pu material’ & Their Solutions

Scenario 1: Navigating Durability Concerns with PU Material

The Problem: A common challenge faced by B2B buyers when sourcing PU material is its perceived lack of durability. Many businesses, particularly those in the furniture and automotive sectors, find that PU leather products may crack or peel after minimal use, leading to increased replacement costs and dissatisfied customers. This concern is particularly acute for companies that pride themselves on delivering quality and longevity in their products. Buyers may feel pressured to choose more expensive alternatives, which could impact their margins.

The Solution: To combat durability issues, buyers should focus on sourcing high-quality PU materials from reputable manufacturers who provide transparency about their production processes. It’s advisable to request samples to assess the material’s thickness, texture, and overall quality before making bulk purchases. Additionally, specifying PU leather grades that include enhanced durability features, such as a protective coating or reinforcement layers, can significantly extend the material’s lifespan. Implementing a thorough quality control process during production and before shipment can also help ensure that only materials that meet durability standards are used in final products.

Scenario 2: Addressing Environmental Concerns in PU Material Production

The Problem: As sustainability becomes a critical factor for many B2B buyers, the environmental impact of PU materials raises significant concerns. The production of PU leather often involves chemicals that can be harmful to both the environment and human health. Buyers, particularly in Europe and other environmentally conscious markets, may struggle with the ethical implications of sourcing PU materials that do not align with their sustainability goals, potentially damaging their brand reputation.

The Solution: To address these environmental concerns, buyers should prioritize sourcing PU materials that are labeled as eco-friendly or compliant with environmental regulations. Engaging with suppliers who adopt sustainable manufacturing practices—such as using water-based adhesives or minimizing volatile organic compounds (VOCs)—can help mitigate these issues. Furthermore, buyers can request documentation and certifications proving the sustainability of the materials they intend to purchase. This not only ensures compliance with regulations but also enhances the buyer’s brand image as a responsible and environmentally conscious choice in the market.

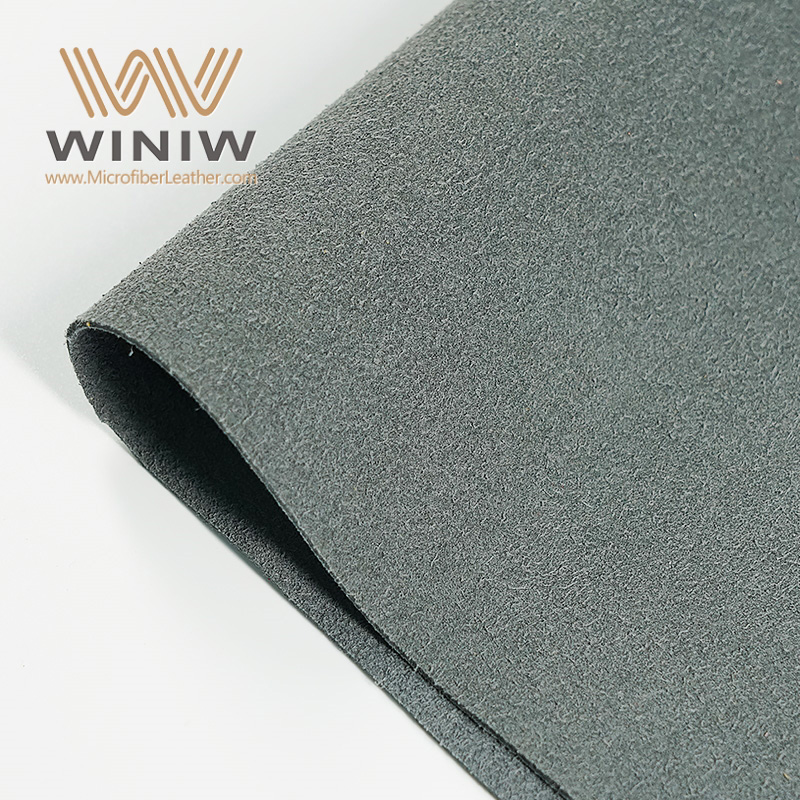

Illustrative image related to pu material

Scenario 3: Overcoming Misleading Product Labels for PU Material

The Problem: B2B buyers often encounter confusion due to the various labels and terminology associated with PU materials, such as “vegan leather,” “faux leather,” and “bicast leather.” This can lead to miscommunication and unintended purchases of products that do not meet the intended specifications. For buyers in sectors like fashion and furniture, ensuring the correct material type is critical for maintaining product integrity and consumer trust.

The Solution: To overcome labeling confusion, buyers should establish clear communication channels with their suppliers, requesting detailed product descriptions and material specifications for each item. Implementing a standardized terminology checklist can also help ensure that all parties have a mutual understanding of what constitutes PU material and its variants. Additionally, training procurement teams to recognize the differences between various synthetic leathers can significantly reduce the risk of purchasing the wrong product. By fostering a transparent relationship with suppliers and ensuring proper documentation, buyers can confidently select the right PU materials that align with their product requirements.

Strategic Material Selection Guide for pu material

What Are the Key Materials Used in PU Material Production?

When selecting materials for PU (polyurethane) products, it’s essential to understand the various types of substrates and coatings that can influence performance, durability, and application suitability. Below is an analysis of common materials used in PU production, focusing on their properties, pros and cons, and specific considerations for international B2B buyers.

What Are the Key Properties of PU Coatings?

PU coatings are typically made from thermoplastic polymers, which provide flexibility and a degree of water resistance. Key properties include:

- Temperature Resistance: PU can withstand a range of temperatures, making it suitable for various environments.

- Corrosion Resistance: The polymer structure offers good resistance to chemicals, though this can vary based on the specific formulation.

- Durability: While PU is generally less durable than genuine leather, high-quality formulations can offer adequate resistance to wear and tear.

What Are the Pros and Cons of Using PU Leather?

Pros:

– Cost-Effectiveness: PU leather is significantly cheaper than genuine leather, making it an attractive option for budget-conscious buyers.

– Variety: Available in numerous colors and textures, PU leather can be tailored to meet diverse aesthetic preferences.

– Ease of Maintenance: Unlike genuine leather, PU does not require conditioning and is easier to clean.

Cons:

– Durability Issues: PU leather can crack and peel over time, particularly in high-use applications, leading to a shorter lifespan.

– Environmental Concerns: The production process can involve toxic chemicals, raising sustainability issues.

– Lack of Breathability: Unlike natural leather, PU does not allow for airflow, which can be a disadvantage in certain applications.

How Does PU Material Impact Specific Applications?

The choice of PU material can significantly impact the performance of the final product. For instance, in furniture manufacturing, PU leather is often used for upholstery due to its aesthetic appeal and ease of cleaning. However, its susceptibility to wear means that it may not be suitable for high-traffic areas without regular maintenance.

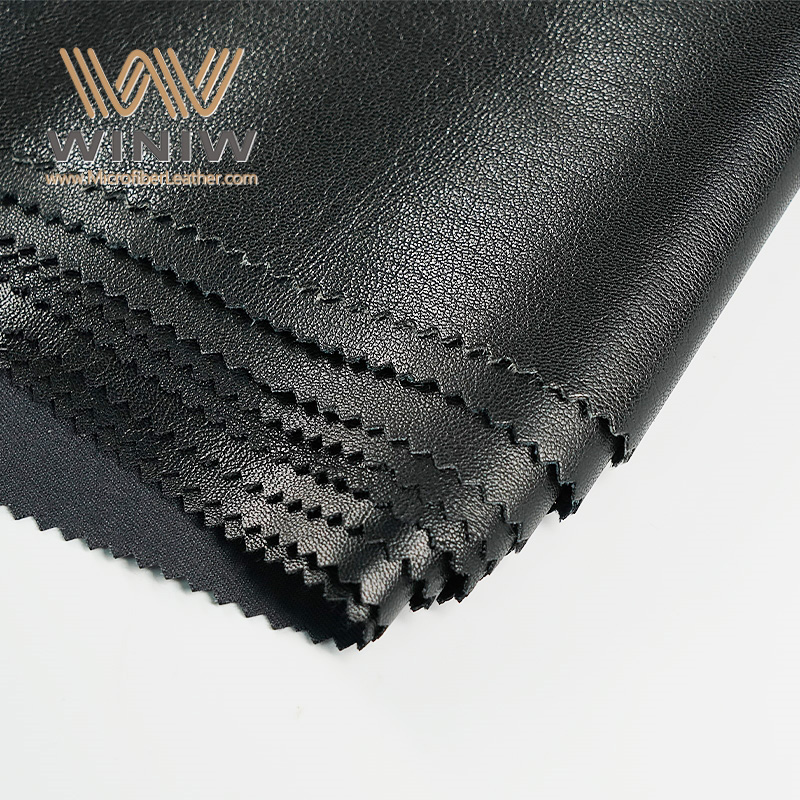

Illustrative image related to pu material

In automotive applications, PU is used for seat covers and interiors, where its resistance to moisture is beneficial. However, the potential for cracking under extreme temperatures must be considered, especially in regions with harsh climates, such as parts of Africa and the Middle East.

What Should International Buyers Consider When Sourcing PU Materials?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, several factors should be taken into account:

- Compliance with Standards: Ensure that the PU materials meet relevant international standards, such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), or JIS (Japanese Industrial Standards).

- Local Preferences: Buyers should be aware of local market preferences, which may favor either synthetic or natural materials based on cultural attitudes toward sustainability and animal welfare.

- Logistics and Supply Chain: Consider the availability of materials and the reliability of suppliers, especially when sourcing from regions with varying infrastructure capabilities.

Summary Table of PU Materials

| Material | Typical Use Case for PU Material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PU Leather | Upholstery for furniture | Cost-effective and versatile | Less durable than genuine leather | Low |

| Bicast Leather | Fashion accessories | Combines real leather with PU | Can still show wear over time | Medium |

| Bonded Leather | Bookbinding and stationery | Eco-friendly use of leather scraps | Limited lifespan | Medium |

| Coated Fabric | Automotive interiors | Good moisture resistance | Can crack in extreme temperatures | Low |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions when selecting PU materials for their specific applications. Understanding the properties, advantages, and limitations of these materials will ensure that buyers can align their choices with market demands and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for pu material

What Are the Main Stages of PU Material Manufacturing?

The manufacturing process of PU (polyurethane) material involves several critical stages, each vital for producing a high-quality end product. Understanding these stages helps B2B buyers ensure they are partnering with reputable suppliers who adhere to industry best practices.

Material Preparation: What Goes Into PU Production?

The first step in PU material manufacturing is material preparation. This involves sourcing the base materials—polyols and isocyanates—along with additives that enhance performance characteristics such as flexibility, durability, and color stability. Suppliers often conduct extensive research to select high-grade raw materials that meet the specific requirements for various applications, from upholstery to automotive parts.

During this stage, suppliers should maintain strict quality control measures, ensuring that all materials meet industry standards. B2B buyers should inquire about the suppliers’ sourcing practices, as this can affect the material’s overall quality.

How Is PU Material Formed?

The second stage is the actual formation of the PU material. There are two primary methods used: casting and foaming.

-

Casting: In this method, a mixture of polyol and isocyanate is poured into molds. This technique is often used for producing solid PU parts and offers high precision in shaping.

-

Foaming: This method involves mixing the components with a blowing agent, creating a foamed structure. Foamed PU is commonly used in cushions and mattresses due to its lightweight and insulating properties.

The choice of method depends on the intended application. Buyers should assess whether their suppliers utilize modern, efficient machinery for these processes to ensure consistent quality.

What Happens During Assembly and Finishing?

Once formed, the PU material undergoes assembly and finishing. This includes cutting, stitching, and bonding PU to other materials, such as fabric or leather, depending on the final product requirements.

Finishing processes may involve applying coatings that enhance the material’s appearance and functionality, such as water resistance or UV protection. B2B buyers should be aware that the finishing stage significantly impacts the product’s durability and aesthetic appeal. Therefore, it’s beneficial to ask suppliers about their finishing techniques and any additional treatments applied.

Illustrative image related to pu material

What International Standards Should B2B Buyers Be Aware Of for PU Material Quality Assurance?

Quality assurance is crucial in the production of PU materials, especially for international B2B transactions. Various international standards help ensure that manufacturers meet quality expectations.

How Does ISO 9001 Impact PU Material Quality?

ISO 9001 is a globally recognized quality management standard that emphasizes customer satisfaction and continuous improvement. Manufacturers that comply with ISO 9001 demonstrate their commitment to quality processes, which can give B2B buyers confidence in the reliability of their products.

Buyers should request documentation of ISO 9001 certification from suppliers, as this indicates adherence to systematic quality assurance practices throughout the manufacturing process.

What Are the Relevant Industry-Specific Standards?

In addition to ISO 9001, there are industry-specific standards such as CE marking in Europe, which signifies compliance with health, safety, and environmental protection standards. In regions like the Middle East and Africa, understanding local regulatory requirements for PU materials is essential. This is particularly important for products used in construction, automotive, and consumer goods.

B2B buyers should verify that suppliers hold relevant certifications and comply with these standards to mitigate risks associated with substandard materials.

Illustrative image related to pu material

What Are the Key QC Checkpoints in PU Material Production?

Quality control (QC) is integral to ensuring that PU materials meet specified standards. Several checkpoints in the manufacturing process help maintain consistent quality.

What Is Involved in Incoming Quality Control (IQC)?

Incoming Quality Control (IQC) focuses on assessing the quality of raw materials before they enter the production process. This includes visual inspections, material testing for consistency, and verification against specifications. B2B buyers should inquire about the IQC processes of their suppliers to ensure they are proactive in quality management.

How Is In-Process Quality Control (IPQC) Conducted?

In-Process Quality Control (IPQC) involves monitoring the manufacturing process to detect any deviations from the established quality standards. This includes regular inspections during material formation, assembly, and finishing. Implementing IPQC helps identify issues early, reducing the risk of defective products reaching the market.

What Should B2B Buyers Know About Final Quality Control (FQC)?

Final Quality Control (FQC) is the last checkpoint before products are shipped. This stage typically involves comprehensive testing, including physical properties assessment, durability tests, and aesthetic evaluations. B2B buyers should ask suppliers about their FQC procedures and the types of tests conducted to ensure the final product meets their expectations.

How Can B2B Buyers Verify Supplier Quality Assurance?

Verifying a supplier’s quality assurance processes is crucial for B2B buyers looking to mitigate risks.

What Role Do Audits Play in Supplier Verification?

Conducting audits is an effective way for buyers to evaluate a supplier’s quality management systems. Regular audits can uncover potential issues, provide insights into the manufacturing process, and ensure compliance with international standards. Buyers should consider third-party audits for an unbiased assessment of supplier practices.

How Important Are Quality Assurance Reports?

Quality assurance reports provide detailed insights into a supplier’s QC measures and product performance. B2B buyers should request these reports to gauge the reliability of the supplier’s products. Additionally, they should look for documentation of past QC issues and how they were addressed.

What Are the Benefits of Third-Party Inspections?

Engaging third-party inspectors can offer an additional layer of assurance for B2B buyers. These inspectors can provide unbiased evaluations of the manufacturing processes, materials, and final products. Buyers should consider utilizing these services, especially when sourcing from international suppliers.

Conclusion: Navigating Quality in PU Material Procurement

Understanding the manufacturing processes and quality assurance standards for PU materials is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing stages, as well as adhering to international standards and implementing robust QC measures, buyers can ensure they partner with reliable suppliers. This knowledge not only enhances product quality but also fosters long-term relationships in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu material’

In the competitive landscape of sourcing PU material, having a structured approach can significantly enhance your procurement process. This guide offers a step-by-step checklist to help international B2B buyers effectively source PU material, ensuring quality, compliance, and sustainability.

Step 1: Define Your Technical Specifications

Clearly outline the characteristics required for your PU material. This includes thickness, texture, color, and any specific performance attributes such as water resistance or breathability. Defining these specifications upfront ensures that you communicate your needs effectively to potential suppliers, reducing the risk of receiving unsuitable products.

- Consider the end use: Different applications may require varying levels of durability and aesthetic qualities.

- Sustainability requirements: If eco-friendliness is a priority, specify biodegradable options or low-VOC materials.

Step 2: Research and Identify Suppliers

Conduct thorough research to identify reputable suppliers of PU material. Look for manufacturers with a proven track record in the industry. This is crucial as the quality of PU can vary significantly among suppliers.

- Utilize online directories and trade shows: Platforms like Alibaba or trade expos in your region can provide insights into various suppliers.

- Check for local and international certifications: These can include ISO certifications that reflect adherence to quality and environmental standards.

Step 3: Evaluate Potential Suppliers

Assess the capabilities and credibility of potential suppliers. Request company profiles, product samples, and case studies to understand their experience in your specific market.

- Seek references: Ask for contact details of existing clients, particularly those in similar industries or regions, to gain insights into their reliability.

- Inspect manufacturing processes: If possible, arrange visits to the supplier’s production facilities to evaluate their quality control measures.

Step 4: Verify Product Compliance and Certifications

Ensure that the PU material meets all necessary regulatory and industry standards. This is especially important if your products will be used in markets with stringent regulations.

- Inquire about material safety data sheets (MSDS): These documents should outline the chemical composition and any associated risks.

- Confirm compliance with international standards: Depending on your target market, this may include REACH in Europe or other regional regulations.

Step 5: Assess Pricing and Terms

Analyze pricing structures and payment terms to ensure they align with your budget and cash flow needs. Look beyond the initial price; consider the total cost of ownership, which includes shipping, customs duties, and potential waste.

- Negotiate terms: Don’t hesitate to discuss bulk purchase discounts or favorable payment terms based on your order volume.

- Evaluate warranty and return policies: Understanding these can protect you against defects or unsatisfactory performance.

Step 6: Place Sample Orders

Before finalizing your order, request samples of the PU material. This step is vital for assessing the quality and suitability of the product for your specific needs.

- Conduct thorough testing: Evaluate the samples for durability, feel, and performance in real-world conditions.

- Gather feedback from stakeholders: Involve relevant team members in the assessment process to ensure the material meets all expectations.

Step 7: Finalize Contractual Agreements

Once satisfied with the supplier and product, finalize the contractual agreements. Ensure that the contract includes clear terms regarding delivery schedules, quality assurance processes, and penalties for non-compliance.

- Include clauses for regular reviews: This can help maintain quality and address any issues that may arise during the partnership.

- Clarify dispute resolution mechanisms: Having a clear process can mitigate risks and foster a more collaborative relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing PU material, ensuring they make informed decisions that align with their business goals.

Illustrative image related to pu material

Comprehensive Cost and Pricing Analysis for pu material Sourcing

What Are the Key Components of PU Material Sourcing Costs?

When sourcing PU (polyurethane) material, understanding the cost structure is crucial for B2B buyers. The main cost components include:

-

Materials: The base material for PU leather involves thermoplastic polymers. Prices can fluctuate based on global oil prices since PU production relies on petroleum. Additionally, variations in quality and the inclusion of additives can impact costs.

-

Labor: Labor costs will vary by region, influenced by local wage standards and labor laws. Countries with lower labor costs may present a more economical option, but this can sometimes compromise quality.

-

Manufacturing Overhead: This encompasses expenses related to the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, impacting the final price.

-

Tooling: Custom molds or tooling for specific PU products may incur additional costs. Buyers looking for unique designs should factor this into their budget.

-

Quality Control (QC): Implementing stringent QC processes can add to costs but is essential for ensuring product reliability. Certifications for safety and environmental standards may also incur fees.

-

Logistics: Shipping costs can vary significantly based on destination, shipment size, and chosen Incoterms. Understanding logistics is vital, especially for international transactions.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. The margin can vary widely depending on competition, product demand, and the supplier’s market position.

How Do Price Influencers Affect PU Material Costs?

Several factors can influence the pricing of PU materials:

-

Volume/MOQ: Bulk orders often lead to reduced unit prices. Buyers should assess their needs carefully and consider negotiating minimum order quantities (MOQs) for better pricing.

-

Specifications and Customization: Custom specifications, such as color, texture, or treatment, can increase costs. Standardized products may offer better pricing due to economies of scale.

-

Material Quality and Certifications: Higher-quality PU materials or those with specific certifications (like eco-friendly labels) typically command higher prices. Buyers should evaluate whether the additional cost aligns with their product requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The choice of Incoterms affects pricing as it determines who bears the cost and risk during transit. Buyers should carefully negotiate Incoterms to optimize their total cost.

What Negotiation Tips Can Help Optimize PU Material Sourcing Costs?

Effective negotiation can lead to significant cost savings. Here are actionable tips for B2B buyers:

-

Understand Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, durability, and potential replacements.

-

Leverage Volume Discounts: If planning to source larger quantities, use this as a bargaining chip to negotiate better pricing.

-

Research Market Trends: Stay informed about market dynamics, including fluctuations in raw material prices, to time your purchases effectively.

-

Evaluate Alternative Suppliers: Don’t settle for the first offer. Comparing multiple suppliers can provide leverage in negotiations and help uncover better pricing options.

-

Build Long-Term Relationships: Developing a strong relationship with suppliers can lead to preferential pricing and improved service over time.

What Are the Pricing Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges:

-

Currency Fluctuations: Exchange rate variations can impact the final cost. Buyers should consider hedging strategies to mitigate risks.

-

Import Duties and Taxes: Understanding the import regulations and associated costs in the destination country is crucial for accurate pricing assessments.

-

Cultural Differences: Negotiation styles can differ by region. Familiarizing yourself with local customs can enhance negotiation outcomes.

-

Logistical Challenges: International shipping may involve longer lead times and increased costs. Planning for these factors is essential to avoid delays.

Conclusion

While sourcing PU materials can offer cost-effective solutions for various applications, a thorough understanding of the cost structure, pricing influences, and negotiation strategies is essential for international B2B buyers. By leveraging this knowledge, businesses can make informed decisions that optimize their sourcing processes.

Alternatives Analysis: Comparing pu material With Other Solutions

Exploring Alternatives to PU Material: A Comprehensive Comparison

When considering the best materials for specific applications, businesses often evaluate alternatives to PU (polyurethane) material. Understanding the strengths and weaknesses of various options can guide B2B buyers in making informed purchasing decisions. In this section, we will compare PU material with two viable alternatives: genuine leather and vegetable-tanned leather, focusing on key aspects that matter to international buyers.

| Comparison Aspect | PU Material | Genuine Leather | Vegetable-Tanned Leather |

|---|---|---|---|

| Performance | Moderate durability; prone to cracking and peeling over time. | High durability; ages well and develops a unique patina. | Excellent durability; eco-friendly and can last decades. |

| Cost | Generally lower cost; affordable for mass production. | Higher cost; considered a premium product. | Mid-range cost; offers good long-term value. |

| Ease of Implementation | Easy to produce and mold into various shapes and styles. | Requires skilled craftsmanship, leading to longer production times. | Handcrafted; may involve longer lead times but offers customization. |

| Maintenance | Low maintenance; easy to clean but may require replacement. | Requires occasional conditioning and care to maintain appearance. | Simple care routine; can be cleaned and conditioned for longevity. |

| Best Use Case | Ideal for budget-conscious applications such as fashion and furniture. | Best for luxury items where quality and durability are paramount. | Suitable for eco-conscious brands wanting sustainable options. |

An In-Depth Look at Each Alternative

What are the Key Advantages and Disadvantages of Genuine Leather?

Genuine leather is a highly sought-after material due to its durability and aesthetic appeal. It typically lasts much longer than PU material, often outlasting its synthetic counterpart by decades. The aging process of genuine leather enhances its character, allowing it to develop a rich patina over time. However, genuine leather comes at a premium price, which may deter cost-sensitive buyers. Additionally, it requires regular maintenance, including conditioning to prevent drying and cracking.

How Does Vegetable-Tanned Leather Compare to PU Material?

Vegetable-tanned leather is an excellent alternative for businesses focused on sustainability and ethical sourcing. This material is produced using natural tannins derived from plant sources, making it biodegradable and environmentally friendly. Like genuine leather, vegetable-tanned leather is durable and ages beautifully, offering a unique appearance over time. However, it also tends to be more expensive than PU material and may require a longer lead time due to the handcrafted nature of its production.

Making the Right Choice for Your Business Needs

When selecting the appropriate material for your business applications, consider factors such as budget, durability, maintenance requirements, and sustainability. PU material offers a cost-effective solution for those prioritizing affordability and ease of production, while genuine leather and vegetable-tanned leather provide superior durability and aesthetic qualities, albeit at a higher cost. Ultimately, understanding the specific needs of your target market and aligning them with the material’s characteristics will empower you to make the best decision for your business.

Essential Technical Properties and Trade Terminology for pu material

What Are the Key Technical Properties of PU Material?

Understanding the essential technical properties of polyurethane (PU) material is crucial for B2B buyers, especially when considering applications in furniture, automotive, and fashion industries. Here are some key specifications that buyers should be aware of:

1. Material Grade

Material grade refers to the specific classification of PU based on its chemical composition and intended use. Different grades of PU can exhibit varying levels of durability, flexibility, and resistance to wear and tear. For instance, high-grade PU is often used in applications requiring enhanced durability, such as automotive upholstery, while lower grades may be suitable for less demanding uses. Selecting the appropriate grade can significantly impact product performance and longevity.

2. Tensile Strength

Tensile strength measures the material’s resistance to being pulled apart. This property is critical for applications where the PU will be subjected to stress, such as furniture covers or automotive interiors. A higher tensile strength indicates a stronger, more durable material, which is essential for ensuring the longevity and reliability of the end product. Buyers should look for tensile strength ratings to ensure that the PU material meets their specific performance requirements.

3. Elongation at Break

Elongation at break indicates how much a material can stretch before it breaks. This property is particularly important in applications where flexibility is required, such as in clothing or soft furnishings. A higher elongation percentage means the material can accommodate movement without tearing, which is vital for comfort and usability. Buyers should consider elongation ratings when assessing the suitability of PU for their products.

4. Water Resistance

Water resistance is a key property for PU materials, especially in applications exposed to moisture, such as outdoor furniture or automotive interiors. PU’s ability to repel water makes it easier to clean and maintain, enhancing its appeal for various uses. Buyers should verify water resistance ratings to ensure that the material will withstand environmental conditions without degrading.

Illustrative image related to pu material

5. Chemical Resistance

Chemical resistance refers to PU’s ability to withstand exposure to various chemicals, including oils, solvents, and cleaning agents. This property is crucial for industries such as automotive and healthcare, where materials may come into contact with harsh substances. Buyers should assess the chemical resistance of PU materials to ensure they will not degrade or lose functionality over time.

What Are Common Trade Terms Related to PU Material?

Familiarizing oneself with industry jargon is essential for effective communication in B2B transactions. Here are several common terms relevant to PU materials:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of PU materials, OEMs often require specific grades and formulations tailored to their product lines. Understanding OEM specifications is crucial for suppliers to meet the exact requirements of their clients.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For PU materials, MOQs can vary significantly based on production capabilities and material types. Buyers should inquire about MOQs when negotiating with suppliers to ensure that their order aligns with their production needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. When procuring PU materials, an RFQ can help buyers compare options from different suppliers, ensuring they receive competitive pricing and suitable terms for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers sourcing PU materials globally, as they dictate who is responsible for shipping, insurance, and tariffs.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. In the context of PU materials, understanding lead times is essential for planning production schedules and inventory management. Buyers should communicate clearly with suppliers to ensure that lead times align with their operational timelines.

By comprehending these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing PU materials, ensuring that they select the best products for their specific applications.

Illustrative image related to pu material

Navigating Market Dynamics and Sourcing Trends in the pu material Sector

What Are the Key Market Dynamics and Trends Influencing PU Material Sourcing?

The PU material sector is experiencing notable shifts driven by globalization, technological advancements, and changing consumer preferences. International buyers, especially from Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Germany), should be aware of several key trends. First, the demand for PU leather as a cost-effective alternative to genuine leather continues to grow, particularly in the furniture, automotive, and fashion industries. This trend is supported by the increasing awareness of animal welfare and a shift towards vegan and cruelty-free products.

Emerging technologies are also reshaping sourcing practices. Digital platforms and B2B marketplaces are facilitating more efficient procurement processes, allowing buyers to access a wider array of suppliers and products. Additionally, the rise of artificial intelligence and data analytics in supply chain management is enhancing inventory control and demand forecasting, which can lead to cost reductions and improved service levels.

Furthermore, buyers should be mindful of regional market dynamics. For instance, European markets are becoming increasingly stringent regarding product safety and environmental regulations, pushing suppliers to adopt higher quality standards. In contrast, African and South American markets may present opportunities for growth due to rising middle-class populations and increased purchasing power, making them attractive for PU material suppliers looking to expand their reach.

How Can Sustainability and Ethical Sourcing Shape Your PU Material Procurement Strategy?

Sustainability and ethical sourcing are becoming critical considerations in the PU material sector. The environmental impact of PU materials is significant, as traditional production methods often involve toxic chemicals and contribute to pollution. Buyers are increasingly scrutinizing their supply chains for environmental compliance and seeking suppliers that prioritize sustainability.

One effective approach is to look for certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which indicate that the materials used are environmentally friendly and free from harmful substances. Moreover, sourcing from manufacturers that utilize eco-friendly processes, such as water-based adhesives and non-toxic dyes, can reduce the overall carbon footprint of PU products.

Ethical sourcing goes hand-in-hand with sustainability. Buyers should engage with suppliers who demonstrate transparency in their operations, ensuring fair labor practices and responsible resource management. This not only mitigates risks associated with unethical practices but also enhances brand reputation and customer loyalty.

What Is the Historical Context Behind PU Material Development?

The evolution of PU materials dates back to the early 20th century when polyurethane was first synthesized. Initially used in insulation and coatings, its versatility quickly led to applications in various industries, including textiles. By the 1960s, PU leather emerged as a popular alternative to genuine leather due to its lower cost and ease of maintenance.

Over the decades, advancements in production techniques have improved the quality and aesthetic appeal of PU materials, allowing them to closely mimic the look and feel of real leather. As consumer preferences shifted towards more sustainable and ethical options in the 21st century, PU materials have gained traction as a viable choice for environmentally conscious buyers, further solidifying their place in the global market.

Illustrative image related to pu material

In summary, navigating the PU material sector requires a keen understanding of market dynamics, sustainability considerations, and historical context. B2B buyers can leverage these insights to make informed sourcing decisions that align with both their business objectives and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of pu material

-

How do I evaluate the quality of PU material from suppliers?

To assess the quality of PU material, consider requesting samples before making large orders. Evaluate the material’s texture, flexibility, and durability by performing basic tests, such as bending and stretching. Additionally, inquire about the production processes and materials used, ensuring that they comply with international standards. Certifications like ISO or OEKO-TEX can also indicate quality and safety. Finally, check for customer reviews and testimonials to gauge the supplier’s reliability and product performance in real-world applications. -

What are the best applications for PU material in my industry?

PU material is versatile and can be effectively used in various applications, including upholstery for furniture, automotive interiors, fashion accessories, and protective gear. In the furniture industry, PU is popular due to its durability and ease of maintenance. In fashion, it provides a vegan alternative to leather, appealing to environmentally conscious consumers. Assess your specific industry needs and consider how PU’s characteristics—like water resistance and color variety—can enhance your product offerings. -

What are the typical minimum order quantities (MOQ) for PU material?

Minimum order quantities for PU material can vary significantly between suppliers. Typically, MOQs range from 100 to 1,000 meters, depending on the type of PU and the supplier’s production capabilities. It’s advisable to negotiate MOQs based on your business needs, especially if you are a smaller buyer or testing a new product line. Some suppliers may offer flexibility on MOQs for first-time buyers or larger, long-term contracts, so be sure to communicate your requirements clearly. -

What payment terms should I expect when sourcing PU material internationally?

Payment terms for international purchases of PU material usually involve a deposit (commonly 30% to 50%) upfront, with the balance due before shipment or upon delivery. However, terms can vary based on supplier policies, order size, and buyer-supplier relationships. It’s crucial to discuss payment methods—such as wire transfers, letters of credit, or escrow services—to ensure security and reduce risk. Always confirm the currency and any potential additional fees that may apply, especially in cross-border transactions. -

How can I ensure compliance with international regulations when importing PU material?

To ensure compliance with international regulations, familiarize yourself with the specific import laws and standards of your country and the country of origin. Request documentation from your supplier, including material safety data sheets (MSDS) and certifications that demonstrate compliance with environmental and safety regulations, such as REACH or RoHS. Collaborating with a customs broker can also streamline the import process, ensuring that all necessary documentation is in order and reducing the risk of delays or penalties. -

What quality assurance measures should I implement when sourcing PU material?

Implementing quality assurance (QA) measures is crucial to maintaining product standards. Start by establishing clear specifications and performance criteria for the PU material. Conduct regular inspections of incoming shipments and consider third-party quality audits to verify compliance with your standards. Additionally, maintain open communication with your supplier to address any discrepancies promptly. Documenting all quality checks and supplier communications will help build a reliable supply chain and foster a strong partnership. -

What are the logistics considerations for shipping PU material internationally?

When shipping PU material internationally, consider factors such as shipping methods, costs, and delivery times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Work with logistics providers experienced in handling PU materials to ensure proper packaging and handling to prevent damage. Also, factor in customs clearance and potential tariffs, and plan your inventory accordingly to avoid stockouts or delays in production. -

How can I customize PU material for my specific product needs?

Customizing PU material often involves selecting specific colors, textures, and finishes that align with your product requirements. Discuss your design specifications with potential suppliers to see what options they offer. Many manufacturers can accommodate custom orders, though this may affect MOQs and lead times. Additionally, inquire about the possibility of adding features such as water resistance or flame retardancy, and ensure that any customizations adhere to relevant safety and quality standards.

Top 4 Pu Material Manufacturers & Suppliers List

1. Manuel Dreesmann – PU Leather Accessories

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: PU leather is a synthetic material made from polyurethane, designed to mimic the look and feel of genuine leather. It is often used in various products such as wallets, bags, and accessories. However, the article suggests avoiding PU leather due to its lower durability compared to real leather, potential environmental concerns in its production, and the possibility of it not being as breathable or…

2. Mitchell Faux Leathers – Premium PU Materials

Domain: mitchellfauxleathers.com

Registered: 2011 (14 years)

Introduction: Polyurethane (PU) is a composite material made of polymer resins and a textile backing (polyester, cotton, nylon, or ground leather). It is water resistant, lightweight, flexible, and provides a realistic imitation of leather. PU does not require plasticizers, preventing cracking or peeling. It is considered greener than vinyl and costs less than real leather but can be more expensive to produce t…

3. HowStuffWorks – PU Leather Essentials

Domain: home.howstuffworks.com

Registered: 1998 (27 years)

Introduction: PU (Polyurethane) leather is an artificial leather made from polyurethane, a type of plastic. It is 100% vegan, with no animal skin involved. There are two types of PU leather: full-synthetic (completely vegan) and semi-synthetic (which has a natural leather base). PU leather is water-resistant, easy to clean, and available in a wide variety of colors, making it suitable for upholstery in kitchens…

4. Carl Friedrik – PU Leather Products

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: PU leather, also known as artificial or imitation leather, is made from polyurethane, a type of plastic. It is created by applying a PU resin coating to natural fabrics like nylon, cotton, or vinyl. 100% PU leather is vegan-friendly as it contains no animal by-products, while PU leather made with split leather is not vegan. Benefits of PU leather include being softer and lighter than animal leathe…

Strategic Sourcing Conclusion and Outlook for pu material

As the demand for PU material continues to rise across various industries, understanding its unique characteristics and implications for sourcing is essential for international B2B buyers. PU leather offers a cost-effective alternative to genuine leather, appealing for its versatility and aesthetic appeal. However, it is crucial to weigh its benefits against potential drawbacks, including durability concerns and environmental impacts.

Strategic sourcing involves not only evaluating the material’s initial cost but also its long-term value and sustainability. Buyers should prioritize suppliers who are transparent about their production processes and committed to reducing environmental footprints. By fostering relationships with responsible manufacturers, businesses can ensure they are making informed decisions that align with both financial goals and ethical standards.

Looking ahead, as consumers become increasingly eco-conscious, the market for high-quality, sustainable PU materials is likely to expand. International buyers from Africa, South America, the Middle East, and Europe should seize the opportunity to lead in this evolving landscape by sourcing responsibly. Embrace this shift and explore the potential of PU material as a strategic asset in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.