Introduction: Navigating the Global Market for roll of leather material

Navigating the intricate landscape of the global market for rolls of leather material can be a daunting task for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, such as Germany and Brazil. As businesses strive to source high-quality leather that meets their specific needs, they often encounter challenges related to supplier reliability, material consistency, and cost efficiency. This guide offers a comprehensive resource for understanding the diverse types of leather rolls available, their myriad applications, and essential strategies for vetting suppliers.

Within these pages, readers will explore the various grades and finishes of leather, from vegetable-tanned to chrome-tanned options, as well as niche varieties like exotic leathers. The guide also delves into the practical applications of leather, whether for upholstery, fashion, or specialty goods, ensuring that buyers can make informed decisions tailored to their markets. Additionally, insights into cost structures and negotiation tactics empower businesses to maximize their purchasing power.

By equipping B2B buyers with the knowledge needed to navigate this complex market, this guide aims to foster confidence and strategic decision-making. Whether you are a seasoned importer or new to the leather industry, understanding these dynamics is crucial for establishing successful partnerships and achieving your business objectives in a competitive landscape.

Table Of Contents

- Top 5 Roll Of Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for roll of leather material

- Understanding roll of leather material Types and Variations

- Key Industrial Applications of roll of leather material

- 3 Common User Pain Points for ‘roll of leather material’ & Their Solutions

- Strategic Material Selection Guide for roll of leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for roll of leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘roll of leather material’

- Comprehensive Cost and Pricing Analysis for roll of leather material Sourcing

- Alternatives Analysis: Comparing roll of leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for roll of leather material

- Navigating Market Dynamics and Sourcing Trends in the roll of leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of roll of leather material

- Strategic Sourcing Conclusion and Outlook for roll of leather material

- Important Disclaimer & Terms of Use

Understanding roll of leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable-Tanned | Eco-friendly, retains natural characteristics, dyes well | Upholstery, leather goods, crafts | Pros: Durable, age beautifully; Cons: Longer tanning process, may be more expensive. |

| Chrome-Tanned | Soft, supple feel, quick drying, wide color range | Fashion, automotive interiors | Pros: Versatile, uniform finish; Cons: Less environmentally friendly. |

| Oil-Tanned | Water-resistant, rich texture, ideal for outdoor use | Work gear, outdoor equipment | Pros: Highly durable, excellent for rugged applications; Cons: Heavier, may require more maintenance. |

| Hair-On | Unique texture with hair left intact, natural look | Decorative items, upholstery | Pros: Distinctive aesthetic; Cons: Limited applications, requires careful handling. |

| Suede | Soft texture, matte finish, lightweight | Fashion accessories, garments | Pros: Luxurious feel, versatile; Cons: Less durable, can stain easily. |

What Are the Characteristics of Vegetable-Tanned Leather?

Vegetable-tanned leather is known for its eco-friendly properties, as it uses natural tannins from plant sources. This type of leather retains its natural characteristics, offering a unique aesthetic that ages beautifully over time. It is ideal for applications such as upholstery, leather goods, and crafts where durability and a classic look are desired. Buyers should consider the longer tanning process, which can affect lead times, and the potential for higher costs compared to other tanning methods.

How Does Chrome-Tanned Leather Stand Out?

Chrome-tanned leather is characterized by its soft, supple texture and quick drying capabilities, making it a popular choice in the fashion and automotive industries. This type of leather comes in a wide range of colors and finishes, allowing for versatility in design. However, while it offers a uniform appearance, its tanning process is less environmentally friendly, which may be a concern for buyers looking for sustainable options.

What Are the Benefits of Oil-Tanned Leather?

Oil-tanned leather is known for its water resistance and rich texture, making it particularly suitable for rugged applications such as work gear and outdoor equipment. This type of leather is highly durable and can withstand harsh conditions, which is a significant advantage for B2B buyers in industries requiring tough materials. However, it is typically heavier and may require more maintenance to keep it in optimal condition.

Why Choose Hair-On Leather?

Hair-on leather features the hair left intact, providing a unique texture and a natural look that appeals to designers and consumers alike. It is often used in decorative items and upholstery to create a distinctive aesthetic. Despite its appeal, hair-on leather has limited applications and requires careful handling to maintain its appearance. Buyers should weigh the uniqueness against the practicality of use in various projects.

What Makes Suede a Popular Choice?

Suede is recognized for its soft texture and matte finish, making it a favored option for fashion accessories and garments. It offers a luxurious feel and can be used in a variety of applications, from shoes to handbags. However, suede is less durable than other leather types and can be prone to staining, which buyers should consider when selecting materials for their products.

Key Industrial Applications of roll of leather material

| Industry/Sector | Specific Application of roll of leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for vehicle interiors | Enhances aesthetic appeal and durability of vehicle interiors | Quality of leather, resistance to wear, color options |

| Furniture | Upholstery for sofas and chairs | Provides comfort, style, and longevity for furniture | Thickness, finish, and compatibility with design standards |

| Fashion and Apparel | Garments and accessories | Adds luxury and style to clothing and accessories | Sourcing from reputable tanneries, color consistency |

| Leather Goods Manufacturing | Bags, wallets, and belts | High-quality leather increases product value and longevity | Availability of sizes, tanning methods, and pricing |

| Sporting Goods | Equipment such as gloves and protective gear | Ensures durability and performance under extreme conditions | Weight, flexibility, and compliance with safety standards |

How is roll of leather material utilized in the automotive sector?

In the automotive industry, roll leather is primarily used for upholstery in vehicle interiors, enhancing both aesthetic appeal and durability. High-quality leather provides a luxurious feel and can withstand the rigors of daily use, making it an ideal choice for seats and interiors. For international buyers, sourcing leather that meets specific quality standards and is resistant to wear and tear is critical. Buyers should also consider the availability of various colors and finishes that align with automotive design trends.

What role does roll of leather material play in furniture manufacturing?

In the furniture sector, roll leather is widely used for upholstering sofas, chairs, and other seating solutions. Its soft texture and durability ensure that furniture not only looks appealing but also lasts for years, providing value to both manufacturers and consumers. When sourcing leather for furniture, businesses must pay attention to the thickness and finish, as these factors influence both comfort and aesthetic compatibility with existing designs. International buyers should ensure that the leather meets local regulations regarding materials and sustainability.

How is roll of leather material leveraged in fashion and apparel?

The fashion industry utilizes roll leather for creating garments and accessories, capitalizing on its luxurious appearance and tactile appeal. Leather garments, such as jackets and skirts, are often seen as high-end products, and the quality of the leather significantly impacts the perceived value. For B2B buyers, it is essential to source leather that is consistent in color and texture, as variations can affect brand image. Additionally, understanding the tanning methods used is vital, as these can influence the leather’s softness and durability.

In what ways is roll of leather material essential for leather goods manufacturing?

Manufacturers of leather goods, such as bags, wallets, and belts, rely on roll leather to produce high-quality products that command premium prices. The durability and timeless appeal of leather enhance the perceived value of these goods, making them attractive to consumers. Buyers should consider the availability of various sizes and tanning methods when sourcing leather to ensure they can meet production demands while maintaining quality. Competitive pricing is also a key consideration for manufacturers looking to optimize their profit margins.

How does roll of leather material benefit the sporting goods industry?

In the sporting goods sector, roll leather is essential for producing equipment such as gloves, protective gear, and footwear. Its durability and flexibility make it ideal for high-performance applications, ensuring that products can withstand extreme conditions. For international buyers, sourcing leather that complies with safety standards and offers the right balance of weight and flexibility is crucial. Additionally, understanding the specific requirements for different sports can help in selecting the most suitable leather types for various applications.

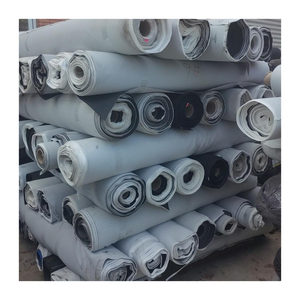

Illustrative image related to roll of leather material

3 Common User Pain Points for ‘roll of leather material’ & Their Solutions

Scenario 1: Sizing and Consistency Issues with Leather Rolls

The Problem:

B2B buyers often face challenges when ordering rolls of leather material, particularly regarding sizing and consistency. For instance, a furniture manufacturer might order a roll expecting to receive a standard width and length, only to find that the actual dimensions vary significantly. This inconsistency can lead to production delays and increased costs, as adjustments must be made to accommodate the mismatched materials. Buyers may also find that the texture, grain, and color do not match their expectations or previous orders, which complicates large-scale projects that require uniformity.

The Solution:

To mitigate sizing and consistency issues, buyers should prioritize sourcing from reputable suppliers who provide detailed specifications for their leather rolls. Requesting samples before placing a bulk order can help assess the quality, texture, and color consistency. Additionally, it’s beneficial to inquire about the supplier’s quality control processes and whether they adhere to industry standards. Establishing a strong relationship with suppliers can also facilitate better communication about specific requirements, allowing for custom orders that meet precise dimensions. Finally, maintaining a thorough inventory management system that tracks previous orders can help buyers ensure they are consistently receiving the same quality and characteristics from their suppliers.

Scenario 2: Understanding Tanning Processes for Optimal Use

The Problem:

Many B2B buyers are not fully aware of the different tanning processes that leather undergoes, which can lead to challenges in selecting the right type for their projects. For example, a manufacturer might purchase chrome-tanned leather for upholstery, only to discover that it is not suitable for high-temperature environments, leading to premature wear and tear. This lack of understanding can result in costly mistakes, including wasted materials and the need for rework or replacements.

The Solution:

To address this knowledge gap, buyers should invest time in understanding the various tanning processes and their implications for product performance. Engaging with suppliers who offer educational resources, such as webinars or detailed guides, can be invaluable. Buyers should also consult with industry experts or leather specialists who can provide insights into the best types of leather for specific applications. When placing orders, it’s crucial to communicate the intended use of the leather clearly, allowing suppliers to recommend the most appropriate tanning options. Furthermore, keeping abreast of the latest trends and innovations in leather tanning can help buyers make informed decisions that enhance the durability and functionality of their products.

Scenario 3: Environmental Concerns and Sustainable Sourcing

The Problem:

Increasingly, B2B buyers are encountering pressure to source materials sustainably, including leather. Buyers may struggle to find suppliers who can guarantee environmentally friendly practices, from animal husbandry to the tanning processes used. This concern is particularly pronounced for companies based in regions with strict regulations on sustainability. Failing to source responsibly can not only lead to reputational risks but may also result in financial penalties or loss of business opportunities.

The Solution:

To tackle environmental concerns, buyers should prioritize suppliers who are certified in sustainable practices, such as those recognized by the Leather Working Group or similar organizations. Conducting due diligence on suppliers to understand their sourcing and production methods is essential. Buyers can also look for leather that is byproduct of the food industry, thus ensuring no additional animals are harmed for the sake of leather production. Additionally, establishing partnerships with suppliers who are committed to transparency in their environmental impact can enhance buyer credibility and appeal to eco-conscious customers. Implementing a sustainability policy that includes leather sourcing criteria can also guide procurement decisions and align with broader corporate social responsibility goals.

Strategic Material Selection Guide for roll of leather material

What are the Key Properties of Different Leather Materials for Rolls?

When selecting leather materials for rolls, B2B buyers must consider various types of leather, each with unique properties that affect performance, durability, and suitability for specific applications. Below, we analyze four common leather types: Vegetable-tanned leather, Chrome-tanned leather, Oil-tanned leather, and Suede.

What are the Key Properties of Vegetable-tanned Leather?

Vegetable-tanned leather is known for its eco-friendly tanning process, using natural tannins from plant sources. This type of leather is durable and develops a unique patina over time, making it aesthetically appealing for products like bags and belts.

Illustrative image related to roll of leather material

- Key Properties: High tensile strength, excellent dye absorption, and good resistance to wear.

- Pros: Environmentally friendly, versatile for crafting, and offers a classic look.

- Cons: Prone to water damage and requires regular maintenance to keep its appearance.

- Impact on Application: Ideal for items that benefit from aesthetic aging, such as high-end fashion accessories.

- Considerations for International Buyers: Compliance with eco-friendly standards is crucial, especially in Europe where sustainability is highly valued.

How Does Chrome-tanned Leather Compare?

Chrome-tanned leather is produced using chromium salts, resulting in a softer and more flexible material. This type is widely used in the upholstery and automotive industries due to its durability and resistance to stains.

- Key Properties: High resistance to heat and moisture, with a smooth finish.

- Pros: Quick production time, excellent color retention, and flexibility.

- Cons: Less environmentally friendly due to the chemicals involved in tanning.

- Impact on Application: Suitable for high-traffic areas like furniture and car interiors, where durability is paramount.

- Considerations for International Buyers: Buyers must ensure that the leather meets local regulations regarding chemical content, especially in markets with stringent environmental laws.

What are the Advantages of Oil-tanned Leather?

Oil-tanned leather is treated with oils, making it water-resistant and highly durable. This type is commonly used for outdoor gear, work gloves, and saddlery.

- Key Properties: Excellent water resistance, flexibility, and a rugged appearance.

- Pros: Highly durable and resistant to harsh weather conditions.

- Cons: Can be heavier and more expensive than other types of leather.

- Impact on Application: Perfect for products that require longevity and exposure to the elements.

- Considerations for International Buyers: Buyers should verify the source of the oils used in tanning to ensure they meet international quality standards.

What Makes Suede a Popular Choice?

Suede, made from the underside of animal hides, offers a soft texture and luxurious feel. It is often used in fashion items and upholstery.

- Key Properties: Softness and a unique texture, but less durable than full-grain leather.

- Pros: Aesthetic appeal and comfort, making it popular for fashion items.

- Cons: More susceptible to stains and damage from water.

- Impact on Application: Best suited for products where appearance is prioritized over durability.

- Considerations for International Buyers: Buyers should consider the specific care instructions for suede, as maintenance can vary significantly by region.

Summary Table of Leather Materials

| Material | Typical Use Case for roll of leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-tanned Leather | Bags, belts, wallets | Eco-friendly and develops a unique patina | Prone to water damage and needs maintenance | Medium |

| Chrome-tanned Leather | Upholstery, automotive interiors | Soft, flexible, and stain-resistant | Less environmentally friendly | Medium |

| Oil-tanned Leather | Outdoor gear, work gloves, saddlery | Highly durable and water-resistant | Heavier and more expensive | High |

| Suede | Fashion items, upholstery | Luxurious feel and aesthetic appeal | Less durable and more susceptible to stains | Medium |

This guide provides essential insights into the strategic selection of leather materials for rolls, enabling international B2B buyers to make informed decisions based on performance, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for roll of leather material

What Are the Key Stages in the Manufacturing Process of Leather Rolls?

The manufacturing process of leather rolls involves several critical stages that ensure the final product meets the necessary quality standards required by B2B buyers. Understanding these stages can help buyers make informed decisions when sourcing leather materials.

Material Preparation: How Is Raw Leather Processed?

The first step in the manufacturing process is the preparation of raw leather. This begins with sourcing high-quality hides, typically from cattle, which are selected based on specific criteria such as thickness, texture, and size. Once sourced, the hides undergo a process known as curing, where they are treated with salt or other preservatives to prevent decay.

After curing, the hides are soaked to remove salts and impurities. This is followed by the liming process, which involves treating the hides with lime to remove hair and fat, making the leather more pliable. The hides are then neutralized and washed to prepare them for tanning.

How Is Leather Formed and Assembled?

The next stage involves tanning, which transforms the raw hides into durable leather. Two primary tanning methods are used: chrome tanning and vegetable tanning. Chrome tanning is a faster process, typically taking a few hours, and results in softer leather with a wide range of colors. In contrast, vegetable tanning is a more traditional method, taking weeks to complete, and produces a firmer leather that develops a unique patina over time.

Once tanned, the leather is cut into rolls or sheets, depending on the buyer’s requirements. The cutting process must be precise to minimize waste and ensure uniformity in thickness. After cutting, the leather pieces are assembled, particularly if they are intended for upholstery or other large applications.

What Finishing Techniques Enhance Leather Quality?

Finishing is the final stage in the leather manufacturing process. This involves applying various treatments to enhance the leather’s appearance, durability, and resistance to wear. Common finishing techniques include dyeing, embossing, and applying protective coatings.

Dyeing allows for a wide array of colors, catering to the aesthetic preferences of end-users. Embossing can add texture and patterns, making the leather more visually appealing. Finally, protective coatings can enhance water resistance and durability, which is especially important for upholstery and automotive applications.

Illustrative image related to roll of leather material

How Is Quality Assurance Implemented in Leather Manufacturing?

Quality assurance (QA) is vital in ensuring that the leather rolls produced meet international standards and buyer specifications. Implementing a robust QA process not only enhances product quality but also builds trust with B2B buyers.

What International and Industry-Specific Standards Are Relevant?

Many manufacturers adhere to international standards such as ISO 9001, which outlines criteria for quality management systems. This certification ensures that the processes are consistently monitored and improved. Industry-specific standards, like CE marking for products sold within the European Economic Area, guarantee that the leather meets health, safety, and environmental protection requirements.

For leather products, compliance with standards such as the American Leather Chemists Association (ALCA) and the International Council of Tanners (ICT) can also be critical. These organizations provide guidelines for best practices in leather production, including environmental sustainability and chemical management.

Illustrative image related to roll of leather material

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process to ensure that defects are identified and addressed promptly.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting the raw hides for quality, size, and any defects before processing begins.

-

In-Process Quality Control (IPQC): During the tanning and finishing stages, samples are taken to ensure adherence to quality standards. This includes testing for color consistency, thickness, and softness.

-

Final Quality Control (FQC): Once the leather rolls are completed, a final inspection is conducted to verify that the product meets all specifications. This includes checking for any surface defects, measuring dimensions, and confirming dye uniformity.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensuring product reliability. Here are some effective methods:

What Audits and Reports Should Buyers Request?

Buyers should request detailed reports from suppliers regarding their quality assurance processes. This includes documentation of compliance with international standards, as well as records of any internal audits conducted. Regular audits provide insights into the supplier’s adherence to quality protocols and areas for improvement.

How Important Are Third-Party Inspections?

Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality control processes. These inspectors can verify compliance with industry standards and offer recommendations for improvements. Many buyers find it beneficial to have a third-party inspection before finalizing large orders, especially for critical projects.

What Are the Nuances of Quality Control for Different Regions?

International B2B buyers must navigate varying quality control requirements based on geographic location. For instance, European buyers may place a higher emphasis on environmental standards and sustainability, while buyers in Africa and South America may focus on cost-effectiveness and local sourcing.

Understanding these regional nuances can help buyers tailor their procurement strategies and establish more effective partnerships with suppliers. Additionally, buyers should be aware of potential language barriers and cultural differences that could impact communication regarding quality expectations.

Conclusion

The manufacturing processes and quality assurance practices for leather rolls are complex and multifaceted. B2B buyers should prioritize understanding these processes to ensure they source high-quality materials that meet their specific needs. By paying close attention to manufacturing techniques, quality control standards, and regional considerations, buyers can foster successful and sustainable relationships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roll of leather material’

The following guide serves as a comprehensive checklist for B2B buyers seeking to procure rolls of leather material. This step-by-step approach will help you ensure that your sourcing process is efficient, cost-effective, and aligned with your specific requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the type of leather you need (e.g., vegetable-tanned, chrome-tanned), the thickness, and the intended application (e.g., upholstery, garments). This clarity will guide your discussions with suppliers and help avoid misunderstandings later on.

- Leather Type: Consider the properties of each leather type, such as durability, finish, and aesthetic qualities.

- Thickness and Size: Specify the weight and dimensions you require, as these factors can significantly affect pricing and availability.

Step 2: Identify Potential Suppliers

Research and compile a list of potential suppliers that specialize in the type of leather you need. Look for manufacturers and wholesalers with a strong reputation in the industry, particularly those that cater to your target market regions such as Africa, South America, the Middle East, and Europe.

- Supplier Reputation: Check for reviews, testimonials, and case studies from previous clients to gauge reliability.

- Industry Experience: Prioritize suppliers with experience in your specific sector, as they will better understand your needs.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your chosen suppliers meet industry standards and certifications. Certifications ensure that the leather meets quality, environmental, and ethical standards, which is particularly important for B2B buyers focused on sustainable sourcing.

Illustrative image related to roll of leather material

- Quality Certifications: Look for ISO certifications or other relevant quality assurance measures.

- Sustainability Certifications: If applicable, check for certifications related to eco-friendly tanning processes or animal welfare.

Step 4: Request Sample Materials

Always request samples of the leather material before making bulk purchases. This step allows you to assess the quality, texture, and finish of the leather firsthand, ensuring it meets your specifications and expectations.

- Sample Size: Ask for samples that are representative of the material you intend to purchase.

- Testing: Evaluate the samples for durability and compatibility with your intended use.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier based on quality and reliability, enter negotiations to establish pricing and terms of sale. Be prepared to discuss volume discounts, payment terms, and shipping arrangements to ensure you receive the best value for your investment.

- Volume Discounts: Inquire about price reductions for larger orders, which can significantly impact your overall costs.

- Payment Terms: Clarify payment methods and timelines to prevent cash flow issues.

Step 6: Review and Finalize the Contract

Carefully review all terms outlined in the contract before signing. Ensure that it includes all specifications, pricing agreements, and delivery timelines. This step protects both parties and helps mitigate risks associated with the transaction.

- Legal Review: Consider having a legal professional review the contract, especially for larger orders.

- Amendments: Ensure there is a clause for handling disputes or changes in order requirements.

Step 7: Establish a Long-Term Relationship

After completing your first purchase, focus on building a long-term relationship with your supplier. Regular communication and feedback can lead to better pricing, improved service, and preferential access to new products in the future.

- Feedback Loop: Share insights on product performance and areas for improvement.

- Future Orders: Discuss upcoming needs early, allowing the supplier to prepare and possibly offer better terms.

By following these steps, you can effectively source rolls of leather material that meet your business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for roll of leather material Sourcing

What Are the Key Cost Components in Leather Material Sourcing?

When evaluating the cost structure for sourcing rolls of leather material, several components play a crucial role. The primary cost components include:

Illustrative image related to roll of leather material

-

Materials: The type of leather (e.g., cowhide, pigskin, exotic leathers) significantly influences the base cost. For instance, premium hides like full-grain leather will command a higher price compared to lower-quality options.

-

Labor: Skilled labor is essential for the tanning and processing of leather. Regions with higher labor costs may see increased pricing, impacting the overall sourcing cost.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and equipment used in the production process. Efficient manufacturing practices can help mitigate these costs.

-

Tooling: The cost associated with specialized machinery and tools required for cutting and finishing leather. Custom tooling can add to upfront costs but may lead to savings in production efficiency.

-

Quality Control (QC): Ensuring that leather meets specific quality standards involves additional costs. Rigorous QC processes help maintain product integrity but may increase overall expenses.

-

Logistics: Shipping costs can vary significantly based on origin, destination, and the chosen transportation method. Import duties and tariffs can also affect the total cost.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the margin expectations of suppliers can aid in negotiations.

How Do Price Influencers Affect Leather Material Costs?

Several factors influence the pricing of leather materials, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often benefit from price breaks. Buyers should assess their needs against MOQ requirements to optimize costs.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the need for specialized processing. However, tailored products may justify the higher price through added value.

-

Materials and Quality Certifications: Leather sourced from reputable suppliers with quality certifications (e.g., ISO, environmental certifications) may carry a premium price but offers assurance of quality and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate responsibility for shipping costs, risks, and logistics, impacting the total landed cost of the leather material.

What Tips Can B2B Buyers Use to Optimize Leather Material Costs?

International B2B buyers can employ several strategies to enhance cost efficiency when sourcing leather materials:

-

Negotiate Pricing: Engage suppliers in discussions about pricing, especially for larger orders. Building a relationship with suppliers can lead to better deals and terms.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes logistics, potential waste, and future maintenance costs. A lower initial cost may not always translate to overall savings.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of regional pricing dynamics, currency fluctuations, and local demand trends that may affect costs.

-

Evaluate Multiple Suppliers: Conduct market research to compare prices and offerings from different suppliers. This not only provides leverage in negotiations but also helps identify the best value options.

-

Stay Informed on Market Trends: Keeping abreast of trends in the leather industry, such as shifts in raw material availability and environmental regulations, can inform better purchasing decisions.

Disclaimer for Indicative Prices

Pricing for leather materials can vary widely based on numerous factors, including market demand, geographic location, and specific supplier conditions. It is advisable for buyers to conduct thorough research and obtain quotes tailored to their specific needs to ensure accurate budgeting and planning.

Illustrative image related to roll of leather material

Alternatives Analysis: Comparing roll of leather material With Other Solutions

Introduction: Exploring Alternatives to Roll of Leather Material

In the competitive landscape of leather and upholstery materials, B2B buyers must evaluate various options to meet specific project requirements. While roll of leather material is a popular choice due to its versatility and durability, there are alternative solutions that may offer unique advantages. This analysis compares roll of leather material with pre-cut leather sheets and synthetic leather, providing insights into performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Roll Of Leather Material | Pre-Cut Leather Sheets | Synthetic Leather |

|---|---|---|---|

| Performance | High durability, flexible for various applications | Good for specific projects, limited in size | Durable, weather-resistant, but may not be as breathable |

| Cost | Generally higher price per unit due to quality | Lower cost, especially for small projects | Typically lower cost, but quality varies |

| Ease of Implementation | Requires cutting and preparation | Ready to use, minimal preparation needed | Easy to cut and sew, requires no special tools |

| Maintenance | Requires conditioning and care to maintain quality | Minimal maintenance, easy to handle | Easy to clean, often resistant to stains |

| Best Use Case | Upholstery, high-end products, custom projects | Crafting, small items, hobbyist use | Cost-effective furniture, automotive interiors |

Detailed Breakdown of Alternatives

Pre-Cut Leather Sheets

Pre-cut leather sheets offer a practical alternative for buyers who need specific sizes without the commitment of purchasing a full roll. These sheets come in various colors and types, making them suitable for smaller projects such as wallets, bags, or decorative items. The primary advantage is cost-effectiveness, especially for businesses that do not require large quantities. However, they may not provide the same level of customization or flexibility in larger applications as roll leather.

Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), serves as a lower-cost substitute for traditional leather. It is particularly advantageous in industries where water resistance and ease of cleaning are paramount, such as in automotive and furniture upholstery. While synthetic leather can replicate the appearance of genuine leather, it may lack the durability and luxurious feel that comes with natural materials. Buyers should consider the longevity and aesthetic requirements of their projects when choosing synthetic alternatives.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate material for a project depends on various factors, including budget, application, and desired performance. Roll of leather material remains an excellent choice for high-end products requiring durability and aesthetic appeal. However, for smaller projects or cost-sensitive applications, pre-cut leather sheets or synthetic leather may provide viable alternatives. By carefully assessing the unique needs of each project, B2B buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for roll of leather material

What Are the Key Technical Properties of Roll Leather Material?

When sourcing roll leather material, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality of the leather, which can range from A-grade (premium) to lower grades (B, C, or D). A-grade leather is typically more durable, has fewer imperfections, and offers better aesthetics. For B2B buyers, selecting the right material grade is crucial as it directly impacts the end product’s quality and longevity, influencing customer satisfaction and brand reputation.

2. Thickness

Thickness is measured in ounces or millimeters and can significantly affect the leather’s use. Common thickness ranges from 1 to 8 oz (approximately 0.4 to 3.2 mm). Thicker leather is often more durable and suitable for heavy-duty applications, while thinner leather is preferred for garments and intricate designs. For manufacturers, understanding the required thickness ensures that the leather meets specific application needs without compromising quality.

3. Tannage Type

Tannage is the process that transforms raw animal hides into leather. Common types include chrome tanning and vegetable tanning. Chrome-tanned leather is more supple and resistant to water, making it ideal for upholstery and garments. In contrast, vegetable-tanned leather offers a natural finish and is often preferred for tooling and crafting. Knowing the tanning type helps buyers select leather that aligns with their product requirements and sustainability goals.

4. Finish

The finish refers to the surface treatment applied to leather, affecting its appearance and durability. Common finishes include aniline, semi-aniline, and pigmented. Aniline finishes showcase the leather’s natural texture and are softer, while pigmented finishes provide greater protection against wear. For B2B buyers, selecting the right finish is essential as it impacts the leather’s aesthetic appeal and its suitability for various applications.

Illustrative image related to roll of leather material

5. Size and Area

Leather is typically sold by the hide or roll, with standard sizes ranging from 40 to 70 square feet. Understanding the area helps buyers estimate how much material they need for their projects, reducing waste and ensuring cost-effectiveness. For manufacturers, accurate size specifications are vital for inventory management and production planning.

What Are Common Trade Terms Used in the Leather Industry?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are some common trade terms relevant to leather sourcing:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then sold under another company’s brand. In the leather industry, buyers often work with OEMs to create custom leather goods. Knowing this term is essential for manufacturers looking to develop unique products while leveraging existing expertise.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is critical for B2B buyers as it impacts the overall cost of procurement and inventory management. Understanding MOQ helps businesses plan their orders and budget effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific quantities and types of leather. This process helps buyers compare prices and services, ensuring they receive the best value for their purchases. For international buyers, crafting a clear RFQ is essential for effective communication with suppliers.

Illustrative image related to roll of leather material

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to avoid misunderstandings regarding delivery and payment obligations.

5. Hide vs. Skin

In leather terminology, “hide” typically refers to larger animal skins (e.g., cowhide), while “skin” refers to smaller animals (e.g., lambskin). This distinction is important for buyers to ensure they procure the right type of leather for their specific applications.

Incorporating a thorough understanding of these technical properties and trade terms will empower B2B buyers to make informed decisions, optimize sourcing strategies, and enhance product quality in their leather applications.

Illustrative image related to roll of leather material

Navigating Market Dynamics and Sourcing Trends in the roll of leather material Sector

What are the Current Market Dynamics and Key Trends in the Roll of Leather Material Sector?

The global roll of leather material market is experiencing significant growth, driven by various factors including increased demand for luxury goods, rising disposable incomes, and the expansion of the automotive and furniture industries. In regions like Africa, South America, the Middle East, and Europe, buyers are becoming more discerning, seeking high-quality materials that not only meet their design needs but also align with their corporate values. The trend towards customization is also prevalent, with buyers increasingly looking for specific colors, textures, and finishes to differentiate their products in a competitive market.

Emerging technologies are reshaping sourcing practices. Innovations such as artificial intelligence and blockchain are enhancing transparency and efficiency in supply chains. Buyers can now track the origin and quality of leather materials more easily, ensuring they are sourcing from reputable suppliers. Additionally, e-commerce platforms are enabling international buyers to access a wider range of leather products, facilitating direct communication with manufacturers and reducing the time and cost associated with traditional procurement methods.

As the market evolves, it is essential for buyers to stay informed about shifts in consumer preferences, particularly regarding sustainability and ethical sourcing. This knowledge will empower them to make informed decisions that resonate with their target markets while ensuring compliance with international regulations.

How is Sustainability Influencing B2B Sourcing of Leather Materials?

Sustainability has become a pivotal consideration in the leather material sector, influencing sourcing strategies among B2B buyers. The environmental impact of leather production, including water usage, chemical waste, and deforestation, has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who adopt eco-friendly methods, such as vegetable tanning, which significantly reduces harmful chemical emissions.

The importance of ethical supply chains cannot be overstated. International buyers are now more vigilant about ensuring their suppliers adhere to labor standards and fair trade practices. This trend is particularly relevant in regions where labor exploitation has been a concern. Certifications like the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction, offering buyers a way to verify the sustainability of their sources.

Illustrative image related to roll of leather material

Moreover, the demand for ‘green’ materials is rising, with buyers seeking alternatives such as recycled leather or leather made from by-products of the food industry. These innovations not only minimize waste but also appeal to environmentally conscious consumers, providing a competitive edge in the marketplace.

What is the Historical Context of the Leather Material Industry?

The leather material industry has a rich history that dates back thousands of years. Initially, leather was primarily used for clothing and shelter, with methods of tanning evolving over time to enhance durability and aesthetic appeal. By the Middle Ages, leather became a staple in various sectors, including fashion, armor, and bookbinding.

In the 19th and 20th centuries, industrialization revolutionized leather production, leading to mass manufacturing techniques that made leather goods more accessible. However, this era also brought significant environmental challenges due to the widespread use of toxic chemicals in tanning processes.

Today, the industry is at a crossroads, balancing traditional craftsmanship with modern sustainability demands. As B2B buyers navigate this evolving landscape, understanding the historical context can provide valuable insights into current trends and future opportunities in the roll of leather material sector.

Frequently Asked Questions (FAQs) for B2B Buyers of roll of leather material

-

How do I choose the right type of leather roll for my project?

Choosing the right type of leather roll depends on the intended use, desired aesthetics, and required durability. Consider factors such as the leather’s thickness, tanning process (e.g., vegetable or chrome tanning), and finish. For upholstery, a thicker, more durable leather is often ideal, while garment-making may require softer, thinner options. Always request samples to assess the texture and quality before making a bulk purchase. -

What are the advantages of sourcing leather rolls from international suppliers?

Sourcing leather rolls internationally can provide access to a broader range of materials, colors, and textures not available locally. It can also lead to cost savings, especially when purchasing in bulk. However, it’s essential to consider factors like import duties, shipping costs, and compliance with local regulations. Engaging with reputable suppliers who understand international trade can mitigate risks and enhance the quality of your procurement. -

What minimum order quantities (MOQs) should I expect when buying leather rolls?

Minimum order quantities for leather rolls can vary significantly based on the supplier and the specific type of leather. Typically, MOQs range from 50 to 100 square feet, but some suppliers may offer smaller quantities for specific products. It’s advisable to discuss your needs with potential suppliers to determine if they can accommodate smaller orders or if they offer pre-cut options that may meet your requirements. -

How do I ensure the quality of leather rolls before purchasing?

To ensure quality, request samples of the leather rolls you are considering. Examine the leather for consistency in color, texture, and thickness. Additionally, inquire about the tanning process and the supplier’s quality assurance practices. Certifications or third-party testing reports can provide further assurance of the leather’s quality and compliance with international standards. -

What payment terms are typically offered by international leather suppliers?

Payment terms can vary widely among international suppliers. Common arrangements include upfront payments, partial payments with the balance upon delivery, or payment via letter of credit. It’s crucial to negotiate terms that align with your cash flow needs while also ensuring the supplier’s confidence in the transaction. Always confirm accepted payment methods and consider using escrow services for added security. -

How can I verify the reliability of a leather supplier?

To verify a supplier’s reliability, conduct thorough research, including checking online reviews and testimonials. Request references from previous clients and assess their responsiveness to inquiries. Additionally, consider visiting the supplier’s facility if feasible, or request a video tour. Certifications from industry bodies can also indicate a commitment to quality and ethical practices. -

What should I know about logistics and shipping when sourcing leather rolls?

Logistics and shipping play a crucial role in sourcing leather rolls. Be aware of shipping costs, estimated delivery times, and the potential for delays due to customs. Choose a supplier experienced in international shipping to navigate these challenges effectively. Additionally, consider shipping insurance to protect your investment during transit and ensure compliance with import regulations in your country. -

Can I customize my leather order, and what are the implications?

Many suppliers offer customization options, such as specific colors, finishes, or sizes for leather rolls. Custom orders may require longer lead times and higher MOQs. Discuss your specific needs with potential suppliers to understand their capabilities and any additional costs involved. Customization can differentiate your products in the market, but ensure that the supplier can meet your specifications consistently.

Top 5 Roll Of Leather Material Manufacturers & Suppliers List

1. Leather Hide Store – Black Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Black Upholstery Leather available at Leather Hide Store. Sold by the hide, not on rolls or sheets. Average size of cowhides is 50 square feet. Widely used for furniture, automotive, and general leathercraft. Closeouts available with exceptional quality at greater savings. Specific products include: K1329 Rich Black Pebble (32 available), K1325 Midnight Marble Suede (14 available), K1395 Jet Black…

2. Decorative Fabrics Direct – Genuine Leather Hides

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Genuine Leather Hides for Upholstery, produced using premium cowhide and tanning methods, ensuring quality, strength, and durability. Ideal for furniture, garments, chaps, handbags, and other leather goods. Available in various colors and textures, with prices ranging from $7.69 to $14.97 per square foot. Special order only with a minimum order of 1 hide. In stock and ready to ship.

3. Tandy Leather – Leather Essentials

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: Shop Leather Essentials at Tandy — Tandy Leather, Inc. SAVE 15% OFF EVERYTHING* THIS WEEKEND ONLY!

4. Fabric Wholesale Direct – Leather by the Yard

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Leather by the Yard, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Hobby Lobby – Leather Rolls & Remnants

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: Leather Pieces & Remnants | Leather Rolls | Hobby Lobby

– Assorted Leather Remnants – 3 Pound: $5.99 (21 reviews)

– Suede Leather Roll: $18.99 (5 reviews)

– Brown Full Grain Leather Roll: $30.99 (9 reviews)

– Brown Suede Cowsplit: $25.99 (1 review)

– Dark Brown Triumph Leather: $9.49 (0 reviews)

– Tooling Leather: $9.99 (17 reviews)

– Cowhide Leather: $11.99 (3 reviews)

– Assorted Leather Trim Pi…

Strategic Sourcing Conclusion and Outlook for roll of leather material

What Are the Key Insights for B2B Buyers in Leather Material Sourcing?

In conclusion, the strategic sourcing of roll leather material presents a wealth of opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the diverse types of leather—ranging from vegetable-tanned to chrome-tanned—enables buyers to select materials that align with their specific project requirements. The availability of pre-cut sheets and upholstery hides offers flexibility, catering to both large-scale and bespoke projects.

Illustrative image related to roll of leather material

Additionally, leveraging closeout deals can lead to significant cost savings without compromising on quality. Buyers should prioritize sourcing from reputable suppliers who emphasize the durability and sustainability of their leather products. This ensures long-term satisfaction and enhances brand reputation in competitive markets.

How Can International Buyers Prepare for Future Trends in Leather Sourcing?

As we move forward, the leather industry is poised for innovation, with an increasing emphasis on eco-friendly practices and unique finishes. B2B buyers are encouraged to stay ahead of these trends by forging strategic partnerships with suppliers that prioritize sustainable sourcing and innovative tanning techniques.

Investing in quality leather now not only meets current demands but positions your business for future growth. Engage with suppliers, explore diverse product offerings, and make informed purchasing decisions to capitalize on the evolving landscape of leather materials. The future is bright for those ready to embrace change and quality in their sourcing strategies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.