Introduction: Navigating the Global Market for polyurethane leather paint

In an increasingly competitive global marketplace, sourcing high-quality polyurethane leather paint presents a formidable challenge for international B2B buyers. Companies across Africa, South America, the Middle East, and Europe, including regions like Nigeria and Vietnam, often struggle to find reliable suppliers who offer durable, versatile, and eco-friendly solutions. This guide serves as a comprehensive resource, addressing the complexities of selecting the right polyurethane leather paint. It delves into various types of products, application techniques, and essential considerations for supplier vetting, ensuring that businesses can make informed purchasing decisions.

From understanding the unique characteristics of polyurethane leather paint—such as its high resistance to wear and color fading—to exploring the myriad applications in automotive, furniture, and fashion industries, this guide equips decision-makers with the knowledge needed to navigate their procurement processes effectively. Additionally, it addresses cost factors and provides insights into establishing long-term supplier relationships, ultimately fostering a more efficient supply chain.

By harnessing the information contained within this guide, B2B buyers will be better positioned to select the right polyurethane leather paint that aligns with their specific operational needs, thereby enhancing product quality and customer satisfaction. Embrace the opportunity to streamline your sourcing process and elevate your business with superior polyurethane leather paint solutions.

Table Of Contents

- Top 5 Polyurethane Leather Paint Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for polyurethane leather paint

- Understanding polyurethane leather paint Types and Variations

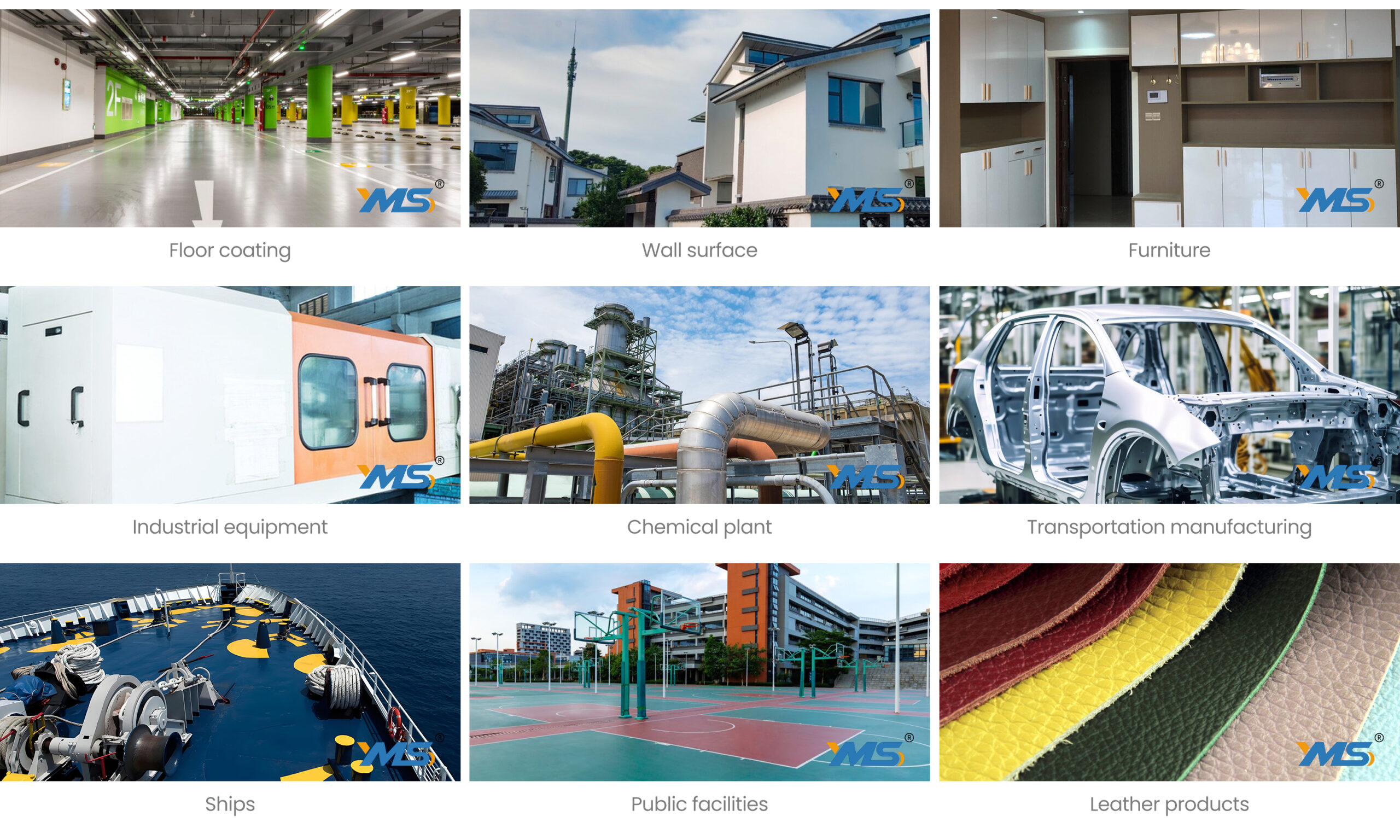

- Key Industrial Applications of polyurethane leather paint

- 3 Common User Pain Points for ‘polyurethane leather paint’ & Their Solutions

- Strategic Material Selection Guide for polyurethane leather paint

- In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather paint

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather paint’

- Comprehensive Cost and Pricing Analysis for polyurethane leather paint Sourcing

- Alternatives Analysis: Comparing polyurethane leather paint With Other Solutions

- Essential Technical Properties and Trade Terminology for polyurethane leather paint

- Navigating Market Dynamics and Sourcing Trends in the polyurethane leather paint Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather paint

- Strategic Sourcing Conclusion and Outlook for polyurethane leather paint

- Important Disclaimer & Terms of Use

Understanding polyurethane leather paint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Water-Based PU Paint | Non-toxic, easy cleanup, excellent flexibility | Automotive interiors, furniture, fashion accessories | Pros: Safe to use, minimal odor; Cons: Longer drying time compared to solvent-based options. |

| Solvent-Based PU Paint | High durability, excellent adhesion, quick drying | Heavy-duty applications, outdoor furniture | Pros: Superior wear resistance; Cons: Requires safety precautions during application. |

| PU Colorant | High pigment concentration, customizable colors | Leather restoration, color change for products | Pros: Excellent color coverage; Cons: Limited shelf life once opened. |

| Flexible PU Coating | Exceptional flexibility, abrasion resistance | Footwear, automotive parts | Pros: Maintains integrity under stress; Cons: May require multiple coats for desired effect. |

| Gloss and Matte Finishes | Adjustable gloss levels for aesthetic customization | Luxury goods, fashion items | Pros: Versatile finish options; Cons: Gloss levels may vary between batches. |

What Are the Key Characteristics of Water-Based PU Paints?

Water-based polyurethane (PU) paints are designed for applications that prioritize safety and environmental considerations. They are non-toxic and easy to clean up, making them suitable for a variety of settings, including automotive interiors and furniture. B2B buyers should consider the longer drying time compared to solvent-based options, which may affect production schedules. However, the benefits of minimal odor and low environmental impact often outweigh these concerns, especially in regions with strict regulations.

How Do Solvent-Based PU Paints Stand Out?

Solvent-based polyurethane paints are recognized for their high durability and excellent adhesion properties. They are typically used in heavy-duty applications, such as outdoor furniture and automotive parts, where resistance to wear and weathering is crucial. While they offer quick drying times, buyers must be aware of the safety precautions required during application due to the presence of volatile organic compounds (VOCs). This type of paint is ideal for businesses that prioritize longevity and performance over ease of use.

What Makes PU Colorants Ideal for Leather Restoration?

PU colorants are specifically formulated for restoring or changing the color of leather products. They feature a high concentration of pigments that ensure excellent coverage and color retention. B2B buyers should note that while these colorants offer a wide range of customizable colors, they have a limited shelf life once opened. This is crucial for businesses that require consistent color matching in their production processes. The ability to match colors precisely can significantly enhance product offerings.

Why Choose Flexible PU Coatings for Dynamic Applications?

Flexible polyurethane coatings are engineered to maintain their integrity under stress, making them ideal for applications in footwear and automotive parts. These coatings provide exceptional flexibility and abrasion resistance, which is essential for products that undergo frequent movement or wear. B2B buyers should consider the potential need for multiple coats to achieve the desired finish, as this may impact labor costs and production timelines. However, the durability offered by these coatings can lead to lower long-term maintenance costs.

How Do Gloss and Matte Finishes Cater to Aesthetic Needs?

Gloss and matte finishes in polyurethane paints allow for aesthetic customization, catering to the luxury goods and fashion industries. B2B buyers can choose between different gloss levels to match their branding or product requirements. However, it is important to be aware that gloss levels may vary between batches, which can affect consistency in large production runs. This variability can influence purchasing decisions, especially for businesses focused on quality control and brand image.

Key Industrial Applications of polyurethane leather paint

| Industry/Sector | Specific Application of polyurethane leather paint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery and trim restoration | Enhances appearance and durability of vehicle interiors | Ensure high color fastness and flexibility for wear |

| Furniture Manufacturing | Color restoration and customization of leather goods | Provides a fresh look and extends product lifespan | Look for non-toxic formulations and high coverage rates |

| Fashion and Footwear | Design and repair of leather apparel and accessories | Enables trend adaptation and personal customization | Consider color matching services and quick drying times |

| Equestrian Equipment | Maintenance and color change for saddles and gear | Preserves quality and aesthetics of high-value items | Assess durability against outdoor conditions and wear |

| Home Décor | Restoration of leather furniture and decorative items | Increases product value and customer satisfaction | Verify compatibility with various leather types |

How is Polyurethane Leather Paint Used in the Automotive Industry?

In the automotive sector, polyurethane leather paint is essential for restoring and customizing vehicle interiors. It is used to revitalize upholstery, door panels, and other leather components, ensuring they remain visually appealing and durable. The paint’s excellent adhesion and flexibility address common issues such as wear and tear from daily use, making it a preferred choice for automotive refurbishments. B2B buyers must prioritize sourcing paints that offer high color fastness and resistance to scuffs, as these features are crucial for maintaining the quality of vehicle interiors in diverse climates, particularly in regions like Africa and the Middle East.

What Role Does Polyurethane Leather Paint Play in Furniture Manufacturing?

In furniture manufacturing, polyurethane leather paint is instrumental for color restoration and customization of leather goods. This application allows manufacturers to provide a fresh appearance and extend the lifespan of leather furniture, which is often subject to wear. The paint’s high coverage rates and soft finish make it ideal for achieving a natural look while ensuring durability. For international buyers, especially from South America and Europe, sourcing non-toxic formulations is vital, as it aligns with growing environmental regulations and consumer preferences for safe products.

How is Polyurethane Leather Paint Beneficial in the Fashion and Footwear Sector?

Within the fashion and footwear industry, polyurethane leather paint serves to design and repair leather apparel and accessories. This flexibility allows brands to adapt to changing trends and offer personalized products to customers. The paint’s quick drying time and excellent adhesion enable efficient production processes, essential for meeting market demands. B2B buyers should consider suppliers that provide reliable color matching services, as this feature is crucial for maintaining brand consistency across various product lines, especially in competitive markets such as Vietnam and Nigeria.

How Does Polyurethane Leather Paint Support Equestrian Equipment Maintenance?

In the equestrian industry, polyurethane leather paint is vital for maintaining and altering the appearance of saddles and riding gear. The paint helps preserve the quality and aesthetics of high-value items, ensuring they remain functional and attractive. It addresses common issues such as fading and scuffs, allowing for a cost-effective solution to repair rather than replace. Buyers in this sector should evaluate the paint’s durability against outdoor conditions and its ability to withstand frequent use, as these factors significantly impact the longevity of equestrian equipment.

What Advantages Does Polyurethane Leather Paint Offer for Home Décor?

Polyurethane leather paint plays a crucial role in restoring leather furniture and decorative items in the home décor sector. By revitalizing worn pieces, it enhances product value and customer satisfaction, leading to increased sales opportunities. The paint’s ability to provide a soft feel and high durability ensures that restored items maintain their aesthetic appeal over time. For B2B buyers, verifying compatibility with various leather types is essential, as this ensures successful applications across a wide range of home furnishings, especially in diverse markets across Europe and Africa.

3 Common User Pain Points for ‘polyurethane leather paint’ & Their Solutions

Scenario 1: Difficulty Achieving Color Consistency Across Large Batches

The Problem: For B2B buyers managing large-scale upholstery or automotive projects, achieving uniform color consistency can be a significant challenge. Variations in batch production, environmental factors, and the application process can lead to discrepancies in the final appearance. Such inconsistencies can compromise product quality, customer satisfaction, and brand reputation, especially in industries where aesthetics are crucial.

The Solution: To ensure color consistency when using polyurethane leather paint, it is essential to establish a standardized process for sourcing and applying the paint. First, opt for a supplier that offers a reliable color matching service with a robust database of colors. When ordering, request a test batch that allows for color verification before full-scale application. Utilize proper storage conditions for the paint to minimize any potential degradation over time. During application, maintain consistent environmental conditions—such as temperature and humidity—and use the same application technique (e.g., spray gun settings) across all batches. Documenting these processes can help maintain quality control and ensure that future orders align with previous results.

Scenario 2: Paint Adhesion Issues on Various Leather Types

The Problem: Different leather types and finishes can present significant challenges when applying polyurethane leather paint. B2B buyers may find that the paint does not adhere properly, leading to peeling or flaking. This issue is particularly prevalent with greasy or oily leathers, which can hinder the paint’s ability to bond effectively. Such problems not only waste resources but also delay project timelines and increase costs.

The Solution: To overcome adhesion issues, it is crucial to prepare the leather surface meticulously before applying polyurethane leather paint. Begin with a thorough cleaning using a dedicated leather degreaser to remove any oils or contaminants. For added assurance, consider applying an adhesion promoter specifically designed for polyurethane paint. This product enhances the bond between the leather and paint, especially for challenging surfaces. Additionally, conduct a small test on an inconspicuous area to ensure compatibility before full application. By implementing these preparation steps, B2B buyers can significantly improve paint adhesion and durability, resulting in a more professional finish.

Scenario 3: Environmental and Safety Concerns During Application

The Problem: Many B2B buyers are increasingly aware of environmental and safety regulations regarding the use of chemical products, including polyurethane leather paint. Concerns about volatile organic compounds (VOCs) and other harmful emissions can complicate the decision-making process when sourcing paint. Buyers must balance quality performance with compliance to safety standards, which can be daunting.

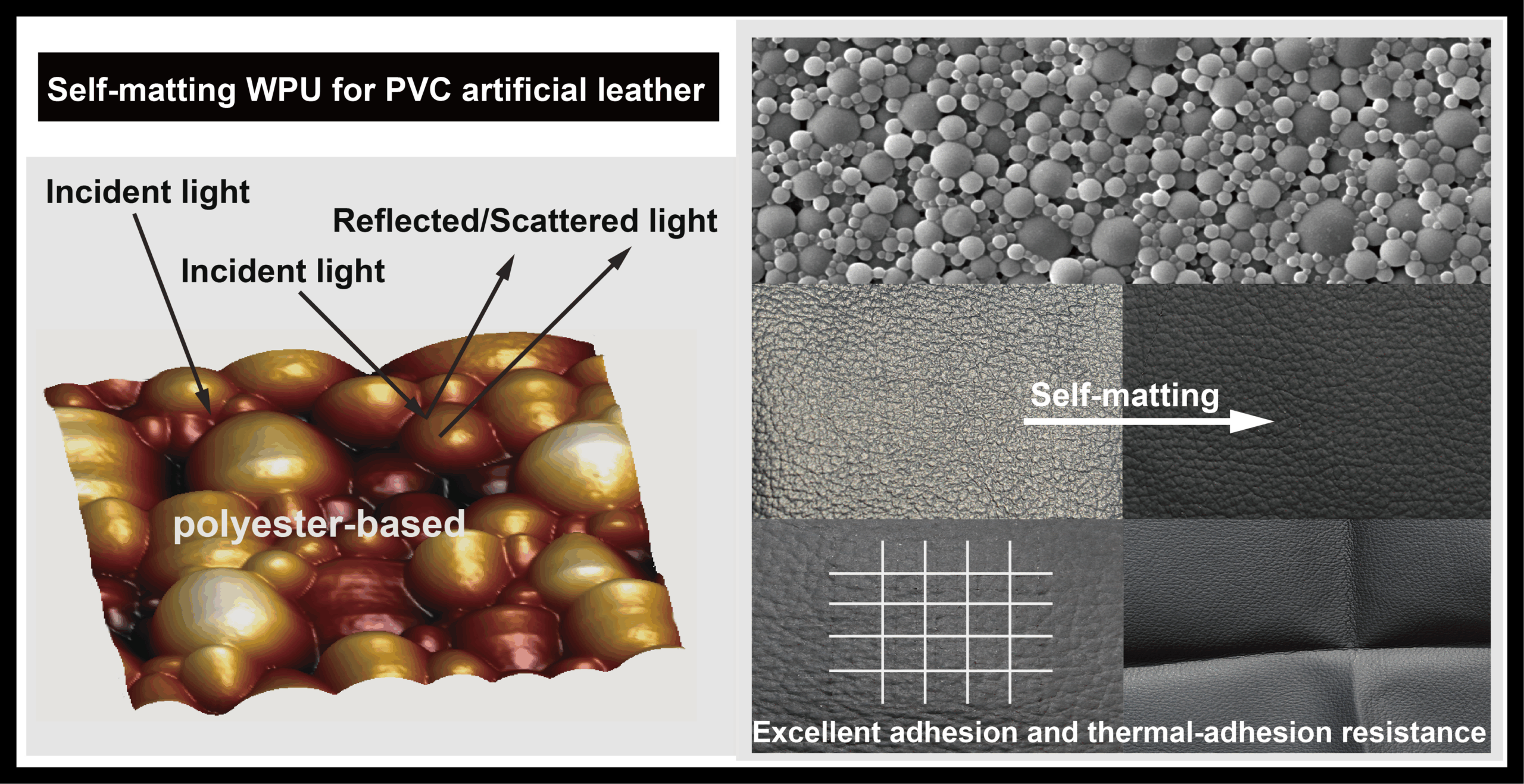

Illustrative image related to polyurethane leather paint

The Solution: When selecting polyurethane leather paint, prioritize products that are water-based and low in VOCs to align with environmental regulations while still providing high performance. Look for suppliers that provide detailed safety data sheets (SDS) and compliance certifications. Additionally, establish a safe application environment by ensuring adequate ventilation, using personal protective equipment (PPE), and adhering to local safety regulations. Training staff on proper handling and application procedures can further mitigate risks. By taking these proactive steps, B2B buyers can confidently use polyurethane leather paint while ensuring compliance with health and environmental standards.

Strategic Material Selection Guide for polyurethane leather paint

When selecting materials for polyurethane leather paint, it is essential to consider various properties and their implications for performance, durability, and compliance with international standards. Here, we analyze four common materials used in the formulation of polyurethane leather paints, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Polyurethane Resins in Leather Paint?

Polyurethane Resins are the primary component in polyurethane leather paints, offering flexibility and durability. They exhibit excellent abrasion resistance, chemical resistance, and adhesion properties, making them suitable for various leather applications. Polyurethane resins can withstand a wide range of temperatures, typically from -30°C to +80°C, and can be formulated to meet specific hardness requirements.

- Pros: High durability and flexibility, excellent adhesion, and resistance to UV light and chemicals.

- Cons: Higher manufacturing complexity and costs compared to other resins.

- Impact on Application: Ideal for high-wear applications like automotive interiors or furniture that require long-lasting finishes.

- Considerations for International Buyers: Compliance with ASTM and DIN standards is crucial, especially in automotive and furniture sectors. Buyers should ensure that the resins used are compliant with local regulations regarding VOC emissions.

How Do Acrylic Polymers Enhance Polyurethane Leather Paint?

Acrylic Polymers are often blended with polyurethane to enhance the performance of leather paints. They provide additional flexibility and UV stability, which can be particularly beneficial in outdoor applications or regions with high sunlight exposure.

- Pros: Improved weather resistance and color retention; lower cost compared to pure polyurethane.

- Cons: May not provide the same level of abrasion resistance as pure polyurethane.

- Impact on Application: Suitable for applications where UV stability is critical, such as outdoor furniture or automotive exteriors.

- Considerations for International Buyers: Buyers in regions with high UV exposure, like Africa and South America, should prioritize formulations with high acrylic content for better longevity.

What Role Does Pigment Play in Polyurethane Leather Paint?

Pigments are essential for achieving the desired color and opacity in polyurethane leather paints. The choice of pigments can significantly affect the paint’s lightfastness and overall aesthetic appeal.

- Pros: Wide range of colors available; ability to match existing leather colors precisely.

- Cons: Some pigments may have lower durability and fade over time, particularly in harsh environments.

- Impact on Application: Critical for aesthetic applications, ensuring that the end product meets customer expectations for color and finish.

- Considerations for International Buyers: Buyers should seek suppliers that offer a robust color matching service and ensure pigments comply with international safety standards, especially in the EU and the Middle East.

How Do Additives Improve the Performance of Polyurethane Leather Paint?

Additives, such as plasticizers and stabilizers, are often included in polyurethane leather paint formulations to enhance performance characteristics. Plasticizers improve flexibility, while stabilizers can enhance heat and light stability.

- Pros: Enhanced flexibility and durability; improved processing characteristics.

- Cons: Potential for increased costs and complexity in formulation.

- Impact on Application: Essential for applications requiring high flexibility, such as clothing or soft furnishings.

- Considerations for International Buyers: Buyers should verify that additives comply with local regulations, especially in regions with strict chemical safety laws, such as Europe.

Summary Table of Material Selection for Polyurethane Leather Paint

| Material | Typical Use Case for polyurethane leather paint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Resins | Automotive interiors, high-wear furniture | Excellent durability and flexibility | Higher manufacturing complexity | High |

| Acrylic Polymers | Outdoor furniture, automotive exteriors | Improved UV stability | Lower abrasion resistance | Medium |

| Pigments | Aesthetic applications, color matching | Wide color range | Some may fade over time | Medium |

| Additives | Clothing, soft furnishings | Enhanced flexibility | Increased cost and complexity | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers in diverse regions, helping them make informed decisions about polyurethane leather paint formulations that meet their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather paint

What Are the Main Stages in the Manufacturing Process of Polyurethane Leather Paint?

The manufacturing process of polyurethane leather paint involves several critical stages, each designed to ensure the final product meets the required performance and aesthetic standards. Here are the main stages:

-

Material Preparation: The process begins with sourcing high-quality raw materials, including polyurethane resins, solvents, pigments, and additives. Suppliers often perform rigorous checks on these materials to ensure compliance with industry standards and specifications. In regions like Africa and South America, local sourcing can reduce costs but necessitates careful supplier evaluation to maintain quality.

-

Forming: Once the materials are prepared, they are combined in specific ratios to create the polyurethane base. This stage typically involves mixing the resins with solvents and pigments in large industrial mixers. The mixing process must achieve a homogeneous blend to ensure consistent color and texture. Advanced techniques, such as high-shear mixing, may be employed to enhance dispersion of pigments and additives.

-

Assembly: After forming, the mixture is transferred to a storage tank where it can be maintained under controlled conditions. This stage may also involve the addition of specialized additives that enhance properties such as flexibility, durability, and UV resistance. The formulation must be carefully monitored to prevent variations that could affect the final product’s performance.

-

Finishing: The final stage involves quality control procedures, where samples of the paint are tested for viscosity, color accuracy, and drying time. The paint is then packaged in various sizes for distribution. Some manufacturers may offer custom color matching services, allowing businesses to order specific hues that match their branding or product requirements.

How Is Quality Assurance Implemented in Polyurethane Leather Paint Production?

Quality assurance (QA) is a critical component of the manufacturing process for polyurethane leather paint, ensuring that the product not only meets regulatory standards but also satisfies customer expectations. Here’s how QA is typically structured:

-

International Standards Compliance: Most manufacturers adhere to international quality standards such as ISO 9001, which outlines criteria for an effective quality management system. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) for certain formulations may be relevant.

-

Quality Control Checkpoints: The QA process generally includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Any discrepancies can halt production until resolved.

– In-Process Quality Control (IPQC): During manufacturing, random samples are taken to monitor parameters like viscosity, pH, and color consistency. This step ensures that any deviations are addressed promptly.

– Final Quality Control (FQC): After the paint is produced, a final inspection is conducted to evaluate the finished product against quality benchmarks. Testing methods may include adhesion tests, abrasion resistance, and color fastness assessments. -

Common Testing Methods: Various testing methods are employed to evaluate the performance of polyurethane leather paint. These include:

– Adhesion Tests: To ensure the paint adheres well to different substrates.

– Abrasion Resistance Tests: To determine how well the paint withstands wear and tear.

– Color Fastness Tests: To assess how well the color holds up against light exposure and washing.

– Viscosity Testing: To ensure the paint can be easily applied using different methods (brush, spray, etc.).

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to mitigate risks associated with inconsistent product quality. Here are practical steps to ensure robust supplier quality assurance:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes and quality control measures. This includes evaluating the cleanliness of the production environment, the qualifications of personnel, and the presence of quality management systems.

-

Requesting Quality Reports: B2B buyers should request and review quality assurance reports that detail the results of IQC, IPQC, and FQC processes. These reports provide insight into the supplier’s commitment to quality and can highlight any historical issues that may have arisen.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s manufacturing practices. These agencies can conduct unannounced inspections and provide detailed reports on compliance with international standards.

-

Certifications Verification: Buyers should verify that suppliers hold relevant certifications (e.g., ISO, CE) and that these certifications are current. This can usually be confirmed through the issuing body’s website or by contacting them directly.

-

Understanding QC Nuances for International Trade: Buyers should be aware of the specific quality standards and regulations applicable in their regions. For instance, European buyers may have stricter environmental regulations compared to those in other regions. Understanding these nuances can aid in selecting suppliers who not only meet quality standards but also comply with local regulations.

Conclusion

The manufacturing processes and quality assurance protocols for polyurethane leather paint are designed to ensure high performance and customer satisfaction. By understanding these processes and implementing effective verification strategies, B2B buyers can make informed decisions, minimize risks, and build long-term relationships with reliable suppliers. This approach is particularly important in diverse markets where quality expectations and regulatory requirements may vary significantly.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather paint’

This guide serves as a comprehensive checklist for B2B buyers looking to procure polyurethane leather paint. It outlines essential steps to ensure that your sourcing process is efficient, cost-effective, and aligned with industry standards. By following these steps, you can make informed decisions and establish strong partnerships with suppliers.

Step 1: Define Your Technical Specifications

Before initiating your search for polyurethane leather paint, clearly outline the technical specifications required for your project. This includes understanding the specific application needs, such as flexibility, colorfastness, and durability. Defining these parameters helps narrow down potential suppliers and ensures the paint meets your quality standards.

- Consider the environment: Will the paint be used in high-traffic areas or exposed to harsh conditions?

- Determine color requirements: Identify if you need standard colors or custom color matching services.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of polyurethane leather paint. Look for companies with a strong track record in the industry and positive reviews from previous clients.

- Check their portfolio: Assess case studies or examples of their work to gauge their expertise.

- Evaluate their customer base: Identify if they cater to clients in your specific industry or region.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications and compliance with international standards. This is crucial to ensure that the products you procure are safe and environmentally friendly.

- Look for ISO certifications: Suppliers with ISO certifications demonstrate a commitment to quality management.

- Check for environmental compliance: Ensure they adhere to regulations regarding VOC emissions and other environmental standards.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the polyurethane leather paint. Testing samples allows you to assess the product’s performance, color accuracy, and application ease.

- Conduct application tests: Apply the sample on a test surface to evaluate adhesion and finish.

- Assess durability: Perform rub tests or exposure to environmental conditions to ensure longevity.

Step 5: Inquire About Customization Options

If your project requires specific colors or finishes, inquire about customization options. Many suppliers offer color matching services or the ability to create bespoke formulations.

Illustrative image related to polyurethane leather paint

- Discuss color matching processes: Understand how they ensure consistency across batches.

- Evaluate gloss level options: Determine if they can provide the desired sheen, whether matte or gloss.

Step 6: Review Pricing and Payment Terms

Once you have identified potential suppliers, review their pricing structures and payment terms. This step is vital for budget management and ensuring transparency in transactions.

- Ask for detailed quotes: Ensure all costs, including shipping and customs, are clearly outlined.

- Negotiate payment terms: Discuss options that work for your cash flow, such as deposits or installment payments.

Step 7: Establish Communication Channels

Effective communication is key to a successful supplier relationship. Establish clear channels for updates, inquiries, and feedback throughout the procurement process.

- Set expectations for response times: Clarify how quickly you expect replies to your queries.

- Utilize multiple communication methods: Ensure you have access to email, phone, or even video calls for discussions.

By following these steps, B2B buyers can streamline their procurement process for polyurethane leather paint, ensuring they find reliable suppliers that meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for polyurethane leather paint Sourcing

What are the Key Cost Components in Sourcing Polyurethane Leather Paint?

When sourcing polyurethane leather paint, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of raw materials used, such as resins, pigments, and additives, significantly affects pricing. High-quality, eco-friendly materials may incur higher costs but provide better durability and performance.

-

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but this can impact quality. Skilled labor is often necessary for quality assurance during production.

-

Manufacturing Overhead: This encompasses expenses related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, thereby influencing the final price of the product.

-

Tooling: Initial tooling costs for custom formulations or packaging can be significant. These costs are usually amortized over larger orders, making them less impactful on pricing for bulk purchases.

-

Quality Control (QC): Ensuring that the polyurethane leather paint meets specific standards necessitates quality control measures. Rigorous testing and compliance with industry standards can add to the overall cost.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors such as distance, shipping method, and Incoterms can significantly affect total logistics costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit margin. Understanding this can aid in negotiations and help buyers gauge the fairness of the pricing.

How Do Price Influencers Impact the Cost of Polyurethane Leather Paint?

Several factors can influence the pricing of polyurethane leather paint, making it essential for buyers to understand these dynamics:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually result in lower per-unit costs due to economies of scale. Negotiating for a favorable MOQ can lead to significant savings.

-

Specifications and Customization: Custom formulations or unique color requirements may increase costs. Buyers should evaluate whether the benefits of customization outweigh the additional expenses.

-

Material Quality and Certifications: Products that are certified for environmental compliance or possess high-quality ratings often command higher prices. Buyers should weigh the long-term benefits of investing in quality against initial cost savings.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality and timely delivery may charge a premium, but they often provide peace of mind.

-

Incoterms: Understanding the agreed-upon Incoterms is vital as they define the responsibilities of buyers and sellers regarding shipping costs and risks. This knowledge can prevent unexpected costs from arising during the procurement process.

What Tips Can Help B2B Buyers Optimize Costs for Polyurethane Leather Paint?

To achieve cost-efficiency while sourcing polyurethane leather paint, consider these actionable tips:

-

Negotiation: Leverage your position as a buyer by negotiating terms, especially on pricing and delivery schedules. Building a strong relationship with suppliers can lead to better deals.

-

Total Cost of Ownership (TCO): Evaluate the total cost beyond the initial purchase price. Consider factors such as durability, maintenance, and potential replacement costs, which can significantly affect long-term expenditure.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can impact the overall cost of sourcing. Conducting thorough market research in target regions such as Africa, South America, the Middle East, and Europe will provide insights into pricing trends and expectations.

-

Supplier Audits: Periodically reviewing supplier performance can help ensure that you are receiving the best value for your investment. This can also reveal opportunities for bulk purchasing or long-term contracts that benefit both parties.

-

Sustainability Considerations: Investing in eco-friendly polyurethane leather paint may have higher upfront costs but can enhance brand reputation and customer loyalty, leading to increased sales in the long run.

Disclaimer on Indicative Prices

Prices for polyurethane leather paint can fluctuate based on market conditions, raw material availability, and supplier pricing strategies. It is advisable for buyers to seek multiple quotes and conduct thorough due diligence before finalizing any procurement decisions.

Alternatives Analysis: Comparing polyurethane leather paint With Other Solutions

Exploring Alternatives to Polyurethane Leather Paint

In the realm of leather restoration and customization, polyurethane leather paint is a widely recognized solution due to its durability and versatility. However, various alternative methods and products can also achieve similar results. This analysis will explore three viable alternatives: acrylic leather paint, leather dye, and leather conditioner, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Polyurethane Leather Paint | Acrylic Leather Paint | Leather Dye | Leather Conditioner |

|---|---|---|---|---|

| Performance | High durability, excellent color retention, scuff-resistant | Good flexibility, decent color coverage | Deep penetration, vibrant colors | Enhances softness and suppleness, not for color change |

| Cost | Moderate ($21.95 per liter) | Generally lower ($10-$15 per 500ml) | Varies ($15-$30 per 250ml) | Low to moderate ($10-$20 per 500ml) |

| Ease of Implementation | Requires preparation and sealing | Easy to apply, minimal prep | Requires pre-treatment and careful application | Simple application, no special tools needed |

| Maintenance | Low, durable finish; occasional touch-ups needed | Moderate; may require reapplication | High; may fade over time, requires frequent reapplication | Low; regular use maintains leather quality |

| Best Use Case | Ideal for furniture, automotive interiors, and high-wear items | Best for crafting, light-use items | Excellent for color restoration of absorbent leathers | Suitable for maintaining leather’s natural look and feel |

What are the Pros and Cons of Acrylic Leather Paint?

Acrylic leather paint offers a flexible and user-friendly alternative to polyurethane leather paint. Its ease of application makes it suitable for smaller projects or crafting, where precision is necessary. The initial cost is generally lower, making it an attractive option for budget-conscious buyers. However, it may not provide the same level of durability and scuff resistance as polyurethane paint. Over time, acrylic paint might require more frequent touch-ups, especially in high-traffic areas.

Illustrative image related to polyurethane leather paint

How Does Leather Dye Compare to Polyurethane Leather Paint?

Leather dye is another alternative that excels in providing vibrant colors and deep penetration into the leather fibers. This method is particularly effective for restoring the original color of absorbent leathers. However, dyeing requires meticulous preparation to ensure proper adhesion and may lead to uneven results if not applied correctly. While it can produce stunning results, the maintenance is higher than that of polyurethane paint, as colors can fade and may necessitate reapplication.

When is Leather Conditioner the Best Choice?

Leather conditioner plays a different role than paint or dye. Its primary function is to nourish and protect leather, enhancing its softness and suppleness without altering its color. This makes it a great option for maintaining high-quality leather goods, such as handbags and shoes, where appearance and feel are paramount. The ease of application and low maintenance requirements are significant advantages, but it does not provide any color change or restoration capabilities, limiting its use in projects where a visual transformation is desired.

How Can B2B Buyers Choose the Right Leather Treatment Solution?

When selecting the right solution for leather treatment, B2B buyers should consider their specific needs, including the type of leather involved, the desired outcome, and the longevity of the solution. Polyurethane leather paint is ideal for high-wear applications requiring durability and color stability. In contrast, acrylic paint may suit smaller projects or crafting needs. Leather dye is perfect for deep color restoration, while leather conditioner is best for maintenance and care. By weighing these factors, buyers can make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for polyurethane leather paint

What Are the Key Technical Properties of Polyurethane Leather Paint?

Understanding the technical specifications of polyurethane leather paint is crucial for B2B buyers, as these properties directly impact product performance, application, and longevity. Here are some essential properties to consider:

1. Flexibility and Durability

Polyurethane leather paint is known for its exceptional flexibility, capable of withstanding up to 100,000 flexes. This property is critical for applications in automotive and furniture industries, where materials undergo frequent movement and wear. A highly flexible paint prevents cracking and peeling, ensuring a longer lifespan for finished products.

2. Color Coverage and Adhesion

High color coverage is another vital property of polyurethane leather paint. The paint’s formulation allows for a minimal number of applications while achieving full opacity. This is particularly important for manufacturers looking to reduce production time and costs. Additionally, strong color adhesion prevents fading and flaking, maintaining the aesthetic quality of leather products over time.

3. Scuff and Scratch Resistance

The ability of polyurethane leather paint to resist scuffs and scratches is essential, especially in high-traffic environments. A surface that can withstand everyday wear without showing signs of damage is crucial for maintaining customer satisfaction and product integrity. This property is particularly beneficial for automotive interiors and upholstery, where durability is paramount.

4. Easy Application and Cleanup

Polyurethane leather paint can be easily applied using various methods, such as spray guns, sponges, or brushes. This versatility allows manufacturers to choose the best application method for their processes. Furthermore, water-based formulations enable easy cleanup, which reduces downtime and enhances operational efficiency.

5. Environmental Safety

As a water-based product, polyurethane leather paint is non-harmful and non-hazardous, making it a safer option for both users and the environment. This property is increasingly important for companies seeking to comply with global regulations and demonstrate corporate responsibility.

Which Trade Terminology Should B2B Buyers Know?

Navigating the world of polyurethane leather paint also involves understanding specific industry jargon. Here are some common terms that B2B buyers should be familiar with:

Illustrative image related to polyurethane leather paint

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of polyurethane leather paint, an OEM might be a manufacturer of automotive interiors that uses this type of paint for their products. Understanding OEM relationships can help buyers identify potential partners and streamline supply chains.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost efficiency. Suppliers often set MOQs to cover production costs, so understanding these requirements can help buyers negotiate better terms.

3. RFQ (Request for Quotation)

An RFQ is a document issued when a buyer wants to procure goods or services and requests price quotations from suppliers. For buyers of polyurethane leather paint, submitting an RFQ can facilitate competitive pricing and help secure favorable terms.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs, making them essential for B2B buyers dealing with suppliers from different countries. Familiarity with Incoterms can prevent misunderstandings and ensure smooth transactions.

5. Lead Time

Lead time refers to the time it takes for a supplier to fulfill an order. For businesses in the leather goods industry, understanding lead times is vital for planning production schedules and meeting customer demands. Efficient lead times can enhance customer satisfaction and optimize supply chain operations.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, negotiate better deals, and enhance their overall procurement strategies for polyurethane leather paint.

Navigating Market Dynamics and Sourcing Trends in the polyurethane leather paint Sector

What Are the Key Market Dynamics and Trends Influencing Polyurethane Leather Paint?

The polyurethane leather paint market is experiencing significant growth driven by several global factors. One of the primary drivers is the increasing demand for high-quality, durable, and aesthetically pleasing leather products across various industries, including automotive, furniture, and fashion. The rise in disposable income in emerging markets, particularly in Africa and South America, is leading to higher consumer spending on premium leather goods, thereby boosting the demand for advanced polyurethane coatings that offer superior performance and longevity.

Current sourcing trends indicate a shift towards digital platforms for procurement. B2B buyers are increasingly leveraging e-commerce solutions and digital marketplaces to source polyurethane leather paint, facilitating a more streamlined purchasing process. Additionally, the integration of advanced technologies such as artificial intelligence and machine learning in supply chain management is enabling companies to optimize inventory and improve demand forecasting. This trend is particularly pertinent for international buyers from regions like the Middle East and Europe, where efficient supply chain logistics are crucial for maintaining competitive advantages.

Emerging sustainability trends are also reshaping the market dynamics. Buyers are seeking products that not only meet performance specifications but also adhere to eco-friendly practices. As a result, manufacturers are investing in the development of water-based polyurethane paints that minimize environmental impact while ensuring high durability and flexibility.

Illustrative image related to polyurethane leather paint

How Important Is Sustainability and Ethical Sourcing in the Polyurethane Leather Paint Industry?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the polyurethane leather paint sector. The environmental impact of chemical manufacturing processes is prompting stakeholders to prioritize eco-friendly alternatives. Water-based polyurethane paints, for instance, are gaining traction due to their reduced volatile organic compounds (VOCs), which contribute to air pollution and pose health risks.

Ethical supply chains are essential in ensuring that raw materials are sourced responsibly, aligning with global sustainability goals. B2B buyers are increasingly looking for suppliers who can provide transparency regarding their sourcing practices and compliance with environmental regulations. Certifications such as Green Seal and OEKO-TEX® Standard 100 are becoming vital indicators of a supplier’s commitment to sustainability, offering assurance to buyers that the products they procure are environmentally friendly.

Moreover, as consumers grow more environmentally conscious, they are likely to favor brands that demonstrate a commitment to sustainable practices. This shift is prompting manufacturers to innovate and adopt greener materials and processes, which not only meet regulatory requirements but also enhance brand reputation and marketability.

What Is the Historical Context of Polyurethane Leather Paint Development?

The evolution of polyurethane leather paint can be traced back to the mid-20th century when advancements in polymer chemistry led to the development of synthetic alternatives to traditional leather finishing. Initially, these products were primarily used in the automotive industry, where durability and resistance to wear and tear were paramount. Over the decades, as consumer preferences shifted towards more sustainable and versatile materials, polyurethane leather paint found applications in various sectors, including furniture and fashion.

By the 1990s, the introduction of water-based formulations marked a significant milestone in the industry, providing an environmentally friendly alternative to solvent-based paints. This shift not only catered to growing environmental concerns but also opened new markets for polyurethane leather paint, allowing for greater customization and color matching options. Today, the sector continues to evolve with a focus on sustainability, technological innovation, and meeting the diverse needs of B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather paint

-

How do I ensure the polyurethane leather paint adheres properly to my leather surfaces?

To ensure optimal adhesion of polyurethane leather paint, begin by thoroughly cleaning the leather surface to remove any dirt, grease, or residues. Use a leather cleaner or degreaser to prepare the surface. It’s also recommended to use a primer or adhesion promoter specifically designed for leather before applying the paint. Testing a small, inconspicuous area first will help you confirm that the paint adheres well and achieves the desired finish. -

What is the best polyurethane leather paint for outdoor applications?

When selecting polyurethane leather paint for outdoor use, look for products specifically formulated for high durability and UV resistance. Paints that are water-based and contain additives to enhance flexibility and scuff resistance are ideal. Additionally, ensure that the paint is weatherproof to withstand varying climates and conditions. Always check the manufacturer’s specifications and consider conducting a small test before large-scale application. -

What are the minimum order quantities (MOQ) for polyurethane leather paint?

Minimum order quantities (MOQ) can vary significantly among suppliers, often depending on the type of paint and specific formulations. Generally, MOQs for polyurethane leather paint can range from 50 liters to 500 liters. It’s advisable to inquire directly with suppliers to understand their specific requirements and to negotiate MOQs, especially if you are looking for customized colors or formulations. -

How can I vet suppliers of polyurethane leather paint for quality assurance?

To vet suppliers, start by researching their reputation in the industry. Look for certifications, customer testimonials, and case studies demonstrating successful projects. Request samples to evaluate the paint’s quality and performance. Additionally, consider suppliers who have clear quality assurance processes in place, such as ISO certifications, and those who provide detailed product information, including safety data sheets and technical data sheets. -

What customization options are available for polyurethane leather paint?

Most suppliers offer customization options for polyurethane leather paint, including color matching services and formulation adjustments to meet specific performance needs. You can often request a custom color based on a sample or choose from a color database. Discuss your requirements with potential suppliers to ensure they can accommodate your needs and provide a consistent quality across batches. -

What are the typical payment terms when sourcing polyurethane leather paint internationally?

Payment terms can vary by supplier and region, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may also offer letters of credit or payment upon delivery for established customers. It’s essential to clarify payment terms upfront and consider using secure payment methods to protect your investment, especially when dealing with international transactions. -

How should I handle logistics and shipping for polyurethane leather paint?

When handling logistics for polyurethane leather paint, consider the supplier’s shipping capabilities and the best shipping methods based on your location. Evaluate costs, transit times, and customs regulations that may apply to hazardous materials. Collaborate with logistics partners experienced in handling chemical shipments to ensure compliance and safety during transportation. It’s also wise to track shipments closely to anticipate arrival times and manage inventory effectively. -

What should I do if I encounter quality issues with the polyurethane leather paint?

If you experience quality issues with the polyurethane leather paint, first document the problem with photos and detailed notes. Contact the supplier immediately to report the issue, referencing your order details and any applicable warranties. Most reputable suppliers will have a returns policy or a process for addressing quality complaints. Ensure you understand their terms regarding returns or replacements and maintain open communication to resolve the issue promptly.

Top 5 Polyurethane Leather Paint Manufacturers & Suppliers List

1. Reddit – Car Interior Transformation Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Faux leather car interior: Blue color, wanting to change to black. 2. Suggested products: Leather dye, primer for plastic, paints for vinyl. 3. Recommended process: Use a deglazer, leather paint, and a top coat sealer. 4. Tools needed: Paint gun, airbrush, spray can (for larger areas). 5. Specific paint brand mentioned: SEM paints (available in rattle cans). 6. DIY methods discussed: Acrylic + …

2. WikiHow – Acrylic and Leather Paints

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: 1. Acrylic Paint: Available in a range of colors, including metallic and glittery shades; adheres well to faux leather; flexible and less likely to crack over time. 2. Leather Paint: Acrylic-based, specifically formulated for real and artificial leather; costs between $2 and $8 for a small bottle; less likely to chip or fade. 3. Chalk-Based Paint: Adheres to various surfaces and fabrics; provides …

3. Facebook – Leather Painting Guide

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Painting leather or faux leather furniture, step by step guide, #paintleather #dixiebellepaint #paintedleather #furnitureflip

4. Angelus – Leather Paint

Domain: therpf.com

Registered: 2006 (19 years)

Introduction: 1. Angelus Leather Paint: Works on leather, plastic, vinyl, polyurethane, canvas; waterproof; recommended for durability. 2. Krylon Spray Paint: Used successfully for faux leather gloves; requires clear coat sealer. 3. Meltonian Nu-Life Color Spray: Intended for shoes and boots; requires two light coats; minimal scuffing after use. 4. Dollar Craft Paint: Durable option; holds up well over time. 5….

5. Rub ‘n Restore® – Leather Paint

Domain: rubnrestore.com

Registered: 2010 (15 years)

Introduction: Rub ‘n Restore® leather paint is designed for changing the color of leather and vinyl, offering full coverage and the ability to lighten colors. It is a water-based acrylic finish that does not require stripping or sanding before touch-ups. The product is effective for absorbent leathers but may require periodic touch-ups and more maintenance compared to restoring the original color. It is not rec…

Strategic Sourcing Conclusion and Outlook for polyurethane leather paint

In conclusion, strategic sourcing of polyurethane leather paint is essential for B2B buyers aiming to enhance product offerings while ensuring sustainability and quality. The versatility of polyurethane paints, with their high durability and color retention properties, allows manufacturers and retailers to meet diverse consumer demands across various markets. By investing in reliable suppliers who offer customization and color matching services, businesses can ensure that they provide high-quality products tailored to their customers’ specific needs.

Furthermore, with increasing awareness of eco-friendly materials, sourcing water-based polyurethane paints not only aligns with sustainability goals but also appeals to environmentally conscious consumers. This opens up new opportunities for market differentiation and competitive advantage.

As we look ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize strategic partnerships with manufacturers who understand local market dynamics and can deliver consistent quality. Embrace the potential of polyurethane leather paint to elevate your product line and drive growth in your business. Explore options, engage with suppliers, and make informed sourcing decisions that will position your company for success in the evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.