Introduction: Navigating the Global Market for fabric for motorcycle seat

As the demand for high-quality motorcycle seats continues to rise globally, sourcing the right fabric for motorcycle seat upholstery presents a significant challenge for B2B buyers. Whether you are looking for durable, weather-resistant materials or fabrics that enhance comfort and style, navigating the vast array of options can be daunting. This comprehensive guide addresses the essential factors that influence your purchasing decisions, including various fabric types, their applications, supplier vetting processes, and cost considerations.

For international buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of the global market is crucial. This guide not only highlights the leading materials available—such as marine-grade vinyl and stretchable upholstery fabrics—but also delves into the intricacies of customization options and performance characteristics. By providing actionable insights and expert recommendations, this resource empowers you to make informed decisions that align with your business needs.

Ultimately, this guide serves as a valuable tool for B2B buyers seeking to enhance their product offerings while ensuring quality and customer satisfaction. With a focus on practical solutions and market trends, you will be well-equipped to navigate the complexities of sourcing fabric for motorcycle seats, ensuring you select the best materials for your specific requirements.

Table Of Contents

- Top 7 Fabric For Motorcycle Seat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric for motorcycle seat

- Understanding fabric for motorcycle seat Types and Variations

- Key Industrial Applications of fabric for motorcycle seat

- 3 Common User Pain Points for ‘fabric for motorcycle seat’ & Their Solutions

- Strategic Material Selection Guide for fabric for motorcycle seat

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric for motorcycle seat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for motorcycle seat’

- Comprehensive Cost and Pricing Analysis for fabric for motorcycle seat Sourcing

- Alternatives Analysis: Comparing fabric for motorcycle seat With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric for motorcycle seat

- Navigating Market Dynamics and Sourcing Trends in the fabric for motorcycle seat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric for motorcycle seat

- Strategic Sourcing Conclusion and Outlook for fabric for motorcycle seat

- Important Disclaimer & Terms of Use

Understanding fabric for motorcycle seat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vinyl Upholstery | Durable, water-resistant, easy to clean | Motorcycle manufacturing, aftermarket repairs | Pros: Cost-effective, versatile. Cons: Less breathable than fabric. |

| Leather | Luxurious feel, high durability, natural breathability | Premium motorcycle seats, custom upholstery | Pros: Aesthetic appeal, comfort. Cons: Higher cost, requires maintenance. |

| Neoprene | Flexible, water-resistant, excellent grip | Off-road and sport motorcycles | Pros: Good cushioning, weather-resistant. Cons: Can be less durable than vinyl. |

| Stretch Vinyl | Highly elastic, conforms to seat shapes | Custom seat covers, DIY upholstery | Pros: Easy to work with, smooth finish. Cons: Limited color options. |

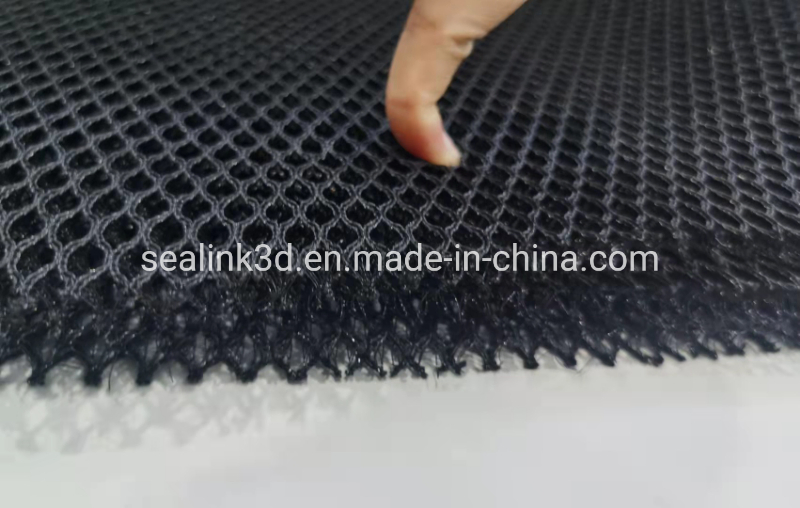

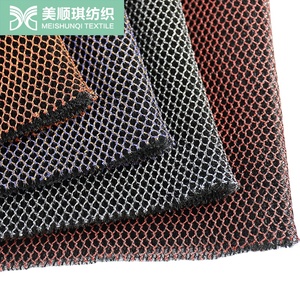

| Mesh Fabric | Breathable, lightweight, often used in hot climates | Touring motorcycles, long-distance riding | Pros: Excellent ventilation, comfort. Cons: May lack durability in rough conditions. |

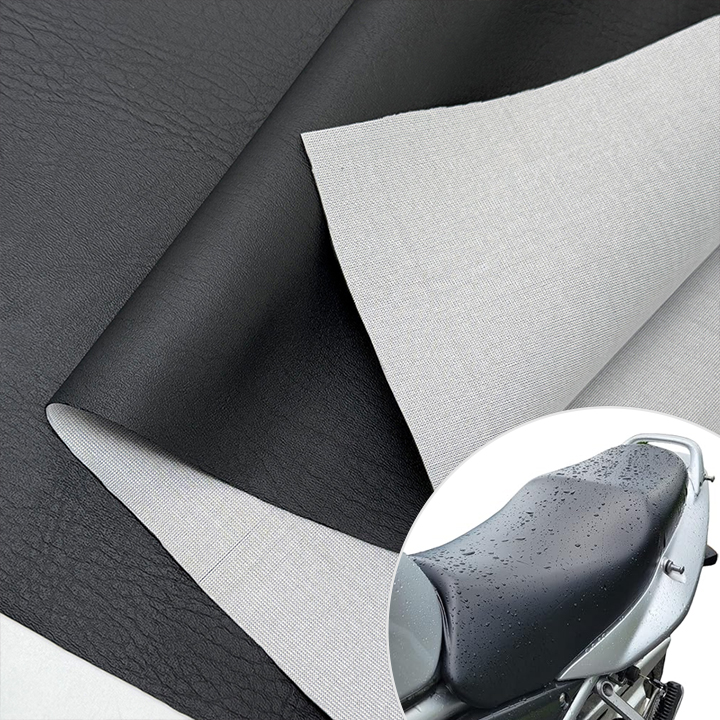

What Are the Characteristics of Vinyl Upholstery for Motorcycle Seats?

Vinyl upholstery is a popular choice due to its durability and water resistance. It is easy to clean, making it ideal for motorcycle manufacturers and repair shops focused on practicality. When purchasing, consider the weight, thickness, and stretchability of the vinyl, as these factors impact its longevity and usability in different environments.

Illustrative image related to fabric for motorcycle seat

How Does Leather Compare as a Premium Choice for Motorcycle Seats?

Leather offers a luxurious feel and natural breathability, making it a favored option for high-end motorcycle seats. Its durability ensures that it withstands wear and tear, while its aesthetic appeal can enhance the overall look of a motorcycle. Buyers should weigh the higher cost and maintenance needs against the comfort and prestige that leather provides.

What Are the Advantages of Neoprene for Off-Road Motorcycles?

Neoprene is known for its flexibility and excellent grip, making it suitable for off-road and sport motorcycles. Its water-resistant properties help maintain comfort in various weather conditions. B2B buyers should consider the specific riding conditions and whether the cushioning provided by neoprene meets their performance requirements.

Why Choose Stretch Vinyl for Custom Seat Covers?

Stretch vinyl is highly elastic, allowing it to conform seamlessly to the contours of motorcycle seats. This makes it particularly useful for custom seat covers and DIY upholstery projects. When sourcing stretch vinyl, buyers should look for options that offer a smooth finish and sufficient color variety to match their design preferences.

How Does Mesh Fabric Enhance Comfort in Hot Climates?

Mesh fabric is lightweight and breathable, making it an excellent choice for motorcycle seats in hot climates. It enhances ventilation, ensuring that riders remain comfortable during long journeys. However, buyers should consider the potential trade-off in durability, especially in rugged riding conditions, when opting for mesh fabric.

Key Industrial Applications of fabric for motorcycle seat

| Industry/Sector | Specific Application of fabric for motorcycle seat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Upholstery for new motorcycle models | Enhances comfort and aesthetics, contributing to brand reputation | Durability, weather resistance, and compliance with industry standards |

| Custom Motorcycle Accessories | Custom seat covers and modifications | Differentiates product offerings, catering to niche markets | Availability of custom colors, patterns, and materials |

| Motorcycle Repair and Restoration | Replacement seat upholstery for vintage or damaged bikes | Increases resale value and customer satisfaction | Compatibility with various motorcycle models and ease of installation |

| Recreational Vehicle Production | Upholstery for ATVs and personal watercraft | Expands product lines and meets diverse consumer needs | Versatility in fabric types suitable for different environments |

| Export and Trade | Supply of motorcycle seat fabric to international markets | Access to emerging markets and increased sales potential | Understanding of local regulations and shipping logistics |

How is Fabric for Motorcycle Seats Used in Motorcycle Manufacturing?

In the motorcycle manufacturing sector, fabric for motorcycle seats is integral to the design and comfort of new models. Manufacturers prioritize high-quality materials that enhance the rider’s experience while ensuring durability and resistance to environmental factors. International buyers, particularly from regions like Africa and South America, must consider the fabric’s ability to withstand varying climates, as well as its compliance with local safety standards. Sustainable and eco-friendly materials are increasingly sought after, reflecting a growing consumer demand for environmentally responsible products.

What Role Does Fabric Play in Custom Motorcycle Accessories?

Custom motorcycle accessory businesses utilize specialized fabrics for creating bespoke seat covers and modifications tailored to individual customer preferences. This customization allows businesses to stand out in a competitive market by offering unique designs and enhanced comfort features. Buyers in this sector should focus on sourcing materials that allow for easy customization, including options for colors, textures, and patterns. Additionally, the fabric’s durability is crucial, as it must withstand regular use while maintaining its aesthetic appeal.

How is Fabric Used in Motorcycle Repair and Restoration?

In the motorcycle repair and restoration industry, fabric for motorcycle seats serves a critical role in refurbishing vintage or damaged bikes. High-quality upholstery can significantly enhance a motorcycle’s resale value and appeal to collectors. Buyers in this sector require fabrics that are compatible with various motorcycle models and easy to install. They must also consider the historical accuracy of materials used in restoration projects, ensuring that they meet the expectations of discerning customers.

Illustrative image related to fabric for motorcycle seat

What is the Application of Fabric in Recreational Vehicle Production?

Fabric for motorcycle seats is also applied in the production of recreational vehicles such as ATVs and personal watercraft. The versatility of these fabrics allows manufacturers to cater to a broader market, meeting the diverse needs of outdoor enthusiasts. When sourcing materials for this application, businesses should prioritize fabrics that offer resistance to water, UV rays, and abrasion, ensuring longevity in challenging environments. This adaptability can significantly enhance the appeal of recreational vehicles in competitive markets.

How Does Fabric Sourcing Impact Export and Trade Opportunities?

In the context of export and trade, sourcing motorcycle seat fabric for international markets presents unique opportunities and challenges. Businesses must navigate various regulations and standards that differ by region, particularly in emerging markets in Africa and the Middle East. Understanding local consumer preferences and compliance requirements is essential for successful market entry. Moreover, establishing reliable supply chains that can accommodate diverse fabric needs will enhance competitiveness and open new revenue streams in global markets.

3 Common User Pain Points for ‘fabric for motorcycle seat’ & Their Solutions

Scenario 1: Struggling with Durability and Weather Resistance in Motorcycle Seat Fabrics

The Problem: One of the most significant challenges faced by B2B buyers of motorcycle seat fabrics is ensuring durability and weather resistance. Buyers from regions with extreme weather conditions—such as the intense heat of the Middle East or the heavy rainfall common in parts of South America—often find that standard fabrics degrade quickly, leading to frequent replacements. This not only increases costs but also disrupts supply chains and customer satisfaction, as businesses struggle to provide reliable products.

Illustrative image related to fabric for motorcycle seat

The Solution: To address this issue, it’s essential to source high-quality, weather-resistant materials specifically designed for motorcycle seats. Fabrics like marine-grade vinyl or heavy-duty polyester offer superior durability and resistance to UV rays, moisture, and extreme temperatures. When selecting fabric, look for options that include features such as flame retardancy and anti-microbial properties, which enhance longevity and safety. Additionally, consider suppliers that offer warranties or guarantees on their products, as this can provide an added layer of assurance regarding the fabric’s performance in adverse conditions.

Scenario 2: Difficulty in Achieving Customization and Aesthetic Appeal

The Problem: B2B buyers often encounter difficulties in achieving the desired customization and aesthetic appeal when selecting motorcycle seat fabrics. Many businesses want to provide a unique look for their clients, whether it’s for a custom build or a series of branded motorcycles. However, sourcing fabrics that can be easily customized with colors, patterns, and embroidery can be a complex process, especially when dealing with multiple suppliers who may not offer the same level of service.

The Solution: To overcome this challenge, establish partnerships with suppliers who specialize in customizable motorcycle seat fabrics. Look for manufacturers that allow for bulk orders with a range of color options and the ability to add custom designs or logos. Utilizing digital printing techniques can also provide flexibility in achieving intricate designs without compromising fabric integrity. Additionally, consider collaborating with suppliers who have an in-house design team that can assist in creating bespoke solutions tailored to your specific needs. This not only streamlines the process but also enhances brand identity through consistent and appealing aesthetics.

Scenario 3: Challenges with Sourcing Sustainable and Eco-Friendly Fabrics

The Problem: With increasing pressure to adopt sustainable practices, many B2B buyers are finding it challenging to source eco-friendly motorcycle seat fabrics. Buyers are often torn between maintaining quality and performance while also adhering to environmental standards. This can be particularly frustrating for companies looking to enhance their brand image by promoting sustainability but struggling to find materials that meet both their performance requirements and eco-friendly criteria.

Illustrative image related to fabric for motorcycle seat

The Solution: To effectively source sustainable motorcycle seat fabrics, buyers should prioritize suppliers that specialize in eco-friendly materials, such as recycled polyester or organic cotton blends. Certifications like OEKO-TEX or Global Organic Textile Standard (GOTS) can help identify truly sustainable options. Furthermore, engage with manufacturers who can provide transparency in their supply chain, detailing the environmental impact of their products. Collaborating with fabric suppliers who emphasize sustainability in their production processes not only ensures compliance with eco-friendly standards but also appeals to environmentally-conscious consumers, thereby enhancing brand loyalty and market competitiveness.

Strategic Material Selection Guide for fabric for motorcycle seat

What Are the Key Properties of Common Materials for Motorcycle Seat Fabrics?

When selecting materials for motorcycle seat fabrics, several options are commonly considered, each with unique properties that impact performance, durability, and overall suitability for various applications. Here, we analyze four prevalent materials: vinyl, leather, neoprene, and polyester.

How Does Vinyl Perform as a Motorcycle Seat Fabric?

Vinyl is a popular choice for motorcycle seat upholstery due to its synthetic nature, which provides excellent durability and ease of maintenance. It typically offers a temperature resistance range of -60°F to 180°F, making it suitable for various climates. Vinyl is also resistant to moisture, UV rays, and abrasion, which enhances its longevity.

Illustrative image related to fabric for motorcycle seat

Pros: Vinyl is cost-effective, easy to clean, and available in various colors and textures. It is also flame retardant, which can be a crucial safety feature.

Cons: While durable, vinyl can become brittle over time, especially when exposed to extreme temperatures. It may not offer the same level of comfort as more breathable materials.

Impact on Application: Vinyl is compatible with most motorcycle seat designs and can be easily molded to fit complex shapes.

Illustrative image related to fabric for motorcycle seat

Considerations for International Buyers: Compliance with local regulations regarding chemical content and environmental impact is essential. Buyers in regions like Europe may prefer vinyl that meets REACH standards.

What Advantages Does Leather Offer for Motorcycle Seats?

Leather is revered for its aesthetic appeal and comfort. It provides excellent temperature regulation, making it suitable for both hot and cold climates. High-quality leather can withstand significant wear and tear, offering a longer lifespan compared to synthetic materials.

Pros: Leather is highly durable, offers a luxurious feel, and can improve with age, developing a unique patina. It also provides superior breathability compared to vinyl.

Cons: The initial cost of leather can be high, and it requires regular maintenance to prevent cracking and drying. Additionally, it is less resistant to water compared to synthetic options.

Impact on Application: Leather is often favored for high-end motorcycle seats and can be used in custom applications.

Considerations for International Buyers: Buyers should ensure that the leather complies with local animal welfare standards and environmental regulations, especially in Europe.

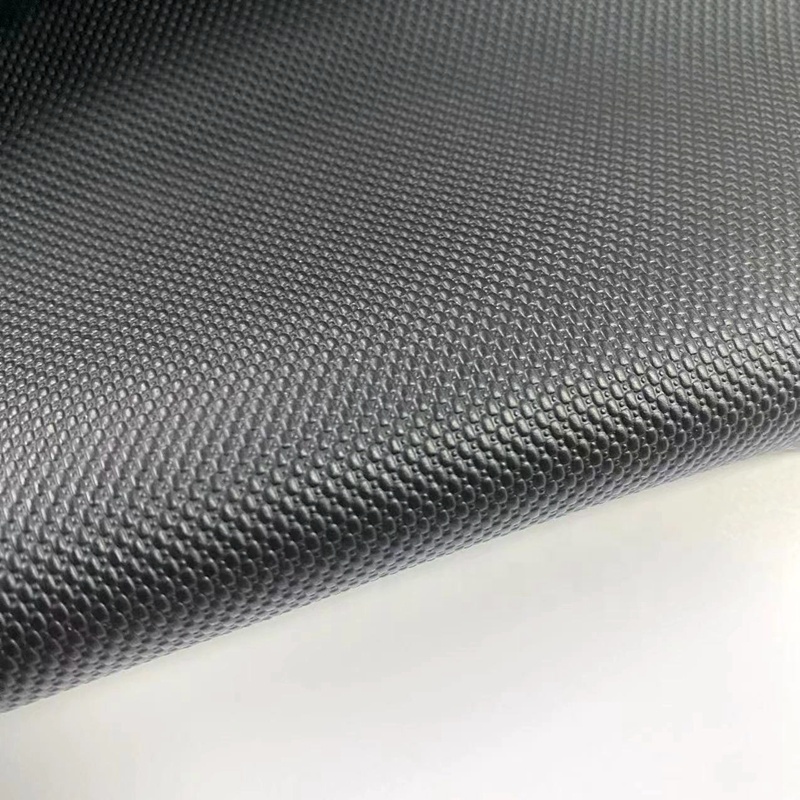

How Does Neoprene Compare as a Motorcycle Seat Fabric?

Neoprene is a synthetic rubber that offers excellent water resistance and flexibility. It can withstand a wide temperature range, typically from -40°F to 200°F. Neoprene is also resistant to oils and chemicals, making it suitable for various applications.

Pros: The flexibility of neoprene allows for a snug fit on motorcycle seats, enhancing comfort. It is also resistant to mold and mildew.

Illustrative image related to fabric for motorcycle seat

Cons: Neoprene can be more expensive than vinyl and may not have the same aesthetic appeal as leather or high-quality vinyl.

Impact on Application: Neoprene is particularly beneficial for off-road or adventure motorcycles where exposure to water and dirt is common.

Considerations for International Buyers: Buyers should verify that neoprene materials comply with local environmental regulations, especially regarding chemical content.

Illustrative image related to fabric for motorcycle seat

What Role Does Polyester Play in Motorcycle Seat Fabrics?

Polyester is a versatile synthetic fabric known for its strength and resistance to stretching and shrinking. It typically offers good UV resistance and can be treated to enhance water repellency.

Pros: Polyester is lightweight, durable, and available at a lower cost compared to leather and neoprene. It is also easy to dye, allowing for a wide range of design options.

Cons: While durable, polyester may not offer the same level of comfort or breathability as leather or high-quality vinyl.

Impact on Application: Polyester is suitable for budget-friendly motorcycle seat covers and can be used in various designs.

Considerations for International Buyers: Buyers should check for compliance with international textile standards, such as Oeko-Tex, to ensure the absence of harmful substances.

Summary Table of Material Selection for Motorcycle Seat Fabrics

| Material | Typical Use Case for fabric for motorcycle seat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vinyl | Standard motorcycle seat covers | Cost-effective and easy to clean | Can become brittle over time | Low |

| Leather | High-end motorcycle seats | Luxurious feel and durability | Requires maintenance and high cost | High |

| Neoprene | Off-road motorcycle seats | Excellent water resistance | Higher cost and less aesthetic | Med |

| Polyester | Budget-friendly seat covers | Lightweight and versatile | Less comfort compared to leather | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric for motorcycle seat

What Are the Key Stages in the Manufacturing Process of Motorcycle Seat Fabric?

Manufacturing fabric for motorcycle seats involves several critical stages that ensure the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in the manufacturing process is material preparation. This involves selecting high-quality raw materials, such as vinyl, polyester, or polyurethane, which are preferred for their durability and resistance to environmental factors like UV light and moisture. Manufacturers often use high-tensile-strength fibers to ensure the fabric can withstand wear and tear from regular use.

Once the materials are chosen, they undergo a series of treatments, such as coating or dyeing, to enhance their properties. For example, flame retardants may be added to meet safety standards. This step is crucial as it directly affects the performance characteristics of the fabric, including its stretchability, breathability, and ease of cleaning.

What Techniques Are Used in the Forming and Assembly Stages?

After the materials are prepared, the next step is forming. This involves cutting the fabric into specific shapes and sizes according to design specifications. Advanced cutting techniques, such as laser cutting or die cutting, are often employed to ensure precision and minimize waste.

Following the cutting process, the assembly stage begins. This typically includes sewing the fabric pieces together using specialized stitching techniques that ensure durability and aesthetic appeal. Manufacturers may use double-stitched seams to reinforce high-stress areas, preventing fraying or tearing over time. Additionally, some producers may incorporate gel inserts or padding during this phase to enhance comfort for the rider.

How Does the Finishing Process Enhance the Quality of Motorcycle Seat Fabric?

The finishing stage is where the fabric is treated to enhance its final properties. This may include applying protective coatings to resist stains, water, and UV damage. Manufacturers also perform quality checks at this stage to ensure that the fabric meets specified standards for texture, color fastness, and overall finish.

Finishing may also involve the application of additional features such as embossed patterns or custom logos, adding value and personalization to the product. The final product is then packaged appropriately for shipping to maintain its quality during transport.

What Are the Key Quality Control Processes for Motorcycle Seat Fabric?

Quality control (QC) is an essential aspect of the manufacturing process, particularly for B2B buyers who rely on the consistency and reliability of their suppliers. Manufacturers often adhere to international standards like ISO 9001, which outlines requirements for a quality management system.

What International Standards Should B2B Buyers Be Aware Of?

In addition to ISO 9001, motorcycle seat fabrics may also need to comply with industry-specific standards such as CE marking for safety and API standards for durability. These certifications ensure that the fabric not only meets safety requirements but is also fit for the intended use.

What Are the QC Checkpoints Throughout the Manufacturing Process?

To maintain high-quality standards, manufacturers implement several QC checkpoints:

-

Incoming Quality Control (IQC): This initial check involves inspecting raw materials as they arrive at the facility. Suppliers must provide documentation confirming that materials meet required specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor adherence to quality standards. This includes checking stitching quality, color consistency, and dimensions.

-

Final Quality Control (FQC): After production, the finished fabric undergoes thorough testing to ensure it meets all specifications. This may involve physical testing for tensile strength, color fastness, and resistance to environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. This can include:

Illustrative image related to fabric for motorcycle seat

-

Conducting Audits: Regular audits of the manufacturing facility can provide insight into the QC processes in place. Buyers may also request to see the results of past audits or certifications.

-

Requesting Quality Reports: Suppliers should be able to provide documentation detailing their QC processes and test results. This transparency helps establish trust and ensures that the products meet the buyer’s standards.

-

Engaging Third-Party Inspectors: For international transactions, it may be beneficial to hire third-party inspection services. These organizations can conduct independent assessments of the manufacturing process and product quality before shipment.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of additional nuances in quality control. Factors such as shipping regulations, customs requirements, and regional standards can affect product acceptance.

-

Understanding Local Regulations: Different countries may have varying standards for materials used in motorcycle seat fabrics. Buyers should familiarize themselves with these regulations to ensure compliance upon import.

-

Navigating Language Barriers: Effective communication is crucial. Buyers should ensure that specifications and quality requirements are clearly articulated and understood by all parties involved, potentially requiring translated documentation.

-

Establishing Clear Terms: Clear contractual terms regarding quality expectations, delivery timelines, and penalties for non-compliance can help mitigate risks associated with international sourcing.

By understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing motorcycle seat fabric. Prioritizing suppliers who demonstrate rigorous quality control and adherence to international standards will ensure that the products meet their performance and safety expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for motorcycle seat’

In the competitive landscape of motorcycle seat fabric procurement, a structured approach is essential for B2B buyers. This guide provides a step-by-step checklist to ensure you select the right fabric, suppliers, and materials to meet your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for selecting the right motorcycle seat fabric. Consider factors such as durability, stretchability, weather resistance, and ease of maintenance. Additionally, identify the specific colors, patterns, and textures that align with your brand or customer preferences.

- Durability: Look for fabrics that can withstand wear and tear.

- Weather Resistance: Ensure the fabric can handle various environmental conditions, especially if used in outdoor settings.

Step 2: Research Available Materials

Various materials are available for motorcycle seat upholstery, each with unique properties. Common choices include vinyl, leather, and synthetic fabrics. Evaluate the pros and cons of each material based on your technical specifications.

Illustrative image related to fabric for motorcycle seat

- Vinyl: Typically more affordable and easier to clean, making it a popular choice.

- Leather: Offers a premium feel but may require more maintenance and care.

Step 3: Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for manufacturers and distributors that specialize in motorcycle seat fabrics and have a solid reputation in the industry.

- Local vs. International: Consider sourcing from both local and international suppliers to compare pricing and quality.

- Supplier Experience: Prioritize suppliers with experience in the motorcycle industry, as they are more likely to understand your specific needs.

Step 4: Evaluate Supplier Certifications and Standards

Before making any commitments, verify that suppliers adhere to relevant industry standards and certifications. This step ensures that the materials meet safety and quality benchmarks.

- ISO Certification: Check if the supplier is ISO certified, indicating adherence to international quality management standards.

- Environmental Compliance: Ensure the fabrics are produced in an environmentally responsible manner, which is increasingly important for many businesses.

Step 5: Request Samples and Test Fabrics

Before finalizing your order, always request samples of the fabrics you are considering. Testing these samples for durability, comfort, and aesthetic appeal is vital to ensuring they meet your requirements.

- Durability Tests: Conduct abrasion tests to evaluate how well the fabric holds up under stress.

- Comfort Assessment: Consider how the fabric feels and looks on an actual motorcycle seat.

Step 6: Negotiate Terms and Pricing

Once you have selected a preferred supplier, engage in negotiations regarding pricing, minimum order quantities, and lead times. A clear understanding of these elements will help avoid any surprises later.

Illustrative image related to fabric for motorcycle seat

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Payment Terms: Clarify payment terms to ensure they align with your financial capabilities.

Step 7: Finalize Your Order and Confirm Delivery

After negotiating terms, finalize your order with a written contract that outlines all details, including pricing, quantities, and delivery timelines. Confirm the delivery schedule to ensure timely arrival.

- Tracking Information: Request tracking information for shipments to monitor progress and address any potential delays proactively.

By following this checklist, B2B buyers can make informed decisions when sourcing fabric for motorcycle seats, ensuring that they select high-quality materials that meet their specific business needs.

Comprehensive Cost and Pricing Analysis for fabric for motorcycle seat Sourcing

What are the Key Cost Components in Motorcycle Seat Fabric Sourcing?

When sourcing fabric for motorcycle seats, understanding the cost structure is essential. The primary cost components include:

Illustrative image related to fabric for motorcycle seat

-

Materials: The choice of fabric significantly impacts pricing. Common materials like vinyl can range from $23.99 to $39.95 per linear yard, depending on quality and specifications. High-performance fabrics may incur higher costs but offer durability and comfort.

-

Labor: Labor costs vary based on the complexity of the fabric’s construction and the region of production. Skilled labor is required for sewing and finishing, which can add to the overall cost.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Overhead can vary significantly depending on the efficiency of the manufacturing processes.

-

Tooling: Custom tooling for specific designs or patterns increases initial costs but can lead to efficiencies in larger production runs.

-

Quality Control (QC): Ensuring that fabrics meet specified standards incurs additional costs. QC processes are crucial to avoid defects that could lead to costly returns or replacements.

-

Logistics: Shipping costs can be substantial, especially for international buyers. Factors such as distance, shipping method, and customs duties influence these expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This can vary based on market conditions and competitive pricing strategies.

What Influences Pricing in Motorcycle Seat Fabric Sourcing?

Several factors can influence the pricing of motorcycle seat fabrics:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract lower per-unit costs due to economies of scale. Negotiating MOQs can lead to significant savings.

-

Specifications and Customization: Custom designs or specific fabric properties (e.g., UV resistance, water-proofing) can increase costs. Buyers should balance customization needs with budget constraints.

-

Material Quality and Certifications: Fabrics that come with industry certifications or are made from high-quality materials generally command a higher price. Buyers should assess whether these certifications are necessary for their market.

-

Supplier Factors: Supplier reputation, reliability, and lead times can affect pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: The agreed-upon shipping terms (e.g., FOB, CIF) can impact total costs. Understanding these terms helps in calculating the landed cost of the fabric.

How Can International B2B Buyers Optimize Costs in Fabric Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing costs involves strategic planning:

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing, volume discounts, and payment terms. Establishing a good relationship can lead to better deals.

-

Focus on Total Cost of Ownership (TCO): Rather than just the purchase price, consider the TCO, which includes logistics, maintenance, and potential waste. This perspective can guide better purchasing decisions.

-

Understand Pricing Nuances for Different Markets: Different regions may have varying pricing structures due to local competition, tariffs, and shipping costs. Conducting market research can provide insights into fair pricing.

-

Leverage Technology: Utilize digital platforms for sourcing and comparing suppliers. This can streamline the procurement process and enhance transparency in pricing.

Conclusion and Disclaimer

While indicative prices for motorcycle seat fabrics can provide a starting point for negotiations, actual costs will vary based on the discussed factors. Buyers should conduct thorough market research and supplier evaluations to ensure that they make informed purchasing decisions that align with their business needs.

Alternatives Analysis: Comparing fabric for motorcycle seat With Other Solutions

Introduction to Alternatives for Motorcycle Seat Fabric

When considering upholstery options for motorcycle seats, the fabric chosen can significantly impact performance, comfort, and durability. While traditional fabric for motorcycle seats, such as vinyl and leather, is commonly used, alternative solutions are available that may better suit specific needs or preferences. This analysis will compare traditional motorcycle seat fabric with two viable alternatives: gel inserts and neoprene covers.

Illustrative image related to fabric for motorcycle seat

Comparison Table

| Comparison Aspect | Fabric For Motorcycle Seat | Gel Inserts | Neoprene Covers |

|---|---|---|---|

| Performance | Good durability and aesthetics, resistant to wear | Excellent shock absorption, enhancing comfort on long rides | Water-resistant, flexible, and durable |

| Cost | Moderate ($20-$40 per yard) | Higher upfront ($75-$200) | Affordable ($30-$60) |

| Ease of Implementation | Requires sewing skills for installation | Professional installation recommended | DIY-friendly, easy to install |

| Maintenance | Easy to clean, but can crack over time | Requires occasional replacement | Simple maintenance, machine washable |

| Best Use Case | Custom upholstery for standard seats | Ideal for enhancing comfort during long rides | Suitable for casual riding in wet conditions |

Detailed Breakdown of Alternatives

1. Gel Inserts

Gel inserts are designed to provide enhanced comfort and shock absorption for motorcycle riders. They are particularly beneficial for long-distance riding, as they help alleviate pressure points and reduce fatigue. However, gel inserts come at a higher cost, often requiring an investment of $75 to $200 for a quality product. Furthermore, they may necessitate professional installation, which can increase overall expenses. While gel inserts do offer excellent performance in terms of comfort, they may not be the best choice for every rider, especially those looking for a budget-friendly solution.

2. Neoprene Covers

Neoprene covers present an innovative alternative to traditional motorcycle seat fabric. Known for their flexibility and water resistance, neoprene covers are an excellent choice for riders who frequently encounter wet conditions. Priced between $30 and $60, they offer a cost-effective solution without sacrificing quality. Installation is generally straightforward, making them accessible for DIY enthusiasts. However, while neoprene provides good durability, it may not match the aesthetic appeal of traditional upholstery fabrics. This makes it less suitable for high-end or custom motorcycles where appearance is a priority.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right upholstery for motorcycle seats involves evaluating various factors, including performance, cost, and ease of implementation. For B2B buyers, understanding the specific needs of their target market is crucial. If comfort during long rides is a primary concern, gel inserts may be the ideal choice despite their higher cost. Conversely, for those prioritizing budget and ease of installation, neoprene covers can offer a practical solution. Ultimately, the decision should align with the specific demands of the motorcycle riding experience, ensuring that the chosen solution meets both functional and aesthetic requirements.

Essential Technical Properties and Trade Terminology for fabric for motorcycle seat

When sourcing fabric for motorcycle seats, understanding the essential technical properties and trade terminology can significantly impact purchasing decisions. This knowledge helps ensure that buyers select materials that meet performance, durability, and regulatory requirements.

What are the Key Technical Properties of Motorcycle Seat Fabrics?

-

Material Grade

Fabric for motorcycle seats is typically made from materials like vinyl, leather, or synthetic blends. The material grade indicates the quality and durability of the fabric. Higher-grade materials are more resistant to wear, UV damage, and moisture, which is critical for longevity in diverse climates. Buyers should prioritize materials that meet industry standards for automotive upholstery. -

Tensile Strength

This property measures the fabric’s resistance to being pulled apart. It is expressed in pounds per square inch (PSI). High tensile strength is essential for motorcycle seat fabric, as it ensures the material can withstand the stresses of regular use without tearing. For B2B buyers, this is crucial for maintaining customer satisfaction and reducing warranty claims. -

Cold Crack Resistance

The ability of fabric to remain flexible and functional at low temperatures is vital, particularly for regions with harsh winters. Cold crack resistance is measured at specific temperatures, often around -60°F. Fabrics with high cold crack resistance will not become brittle and prone to cracking, ensuring safety and comfort for riders. -

UV Resistance

Motorcycle seats are exposed to sunlight, which can cause fading and degradation over time. UV resistance indicates how well the fabric can withstand ultraviolet light without losing its integrity or color. Fabrics with high UV resistance reduce replacement costs and enhance the aesthetic appeal of motorcycles. -

Flame Retardancy

This property is especially important for safety in the event of an accident. Flame retardant fabrics are treated to resist ignition and slow the spread of fire. B2B buyers should ensure that the fabrics they select comply with relevant safety standards, as this can be a selling point for motorcycle manufacturers. -

Water Resistance

Water-resistant fabrics repel moisture, preventing mold and mildew growth. This is particularly important for motorcycle seats, which can be exposed to rain and spills. Fabrics that offer water resistance enhance the longevity of the seat and improve rider comfort.

What are Common Trade Terms Related to Motorcycle Seat Fabrics?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are sold to another company for use in its products. In the context of motorcycle seats, OEM fabrics are those that meet the specifications required by manufacturers, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for B2B buyers to assess whether they can meet purchasing requirements without incurring excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. It is a critical step in the procurement process, allowing buyers to compare prices and terms from multiple vendors. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) that outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk, and responsibilities associated with their purchases. -

Lead Time

This refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for inventory management and planning, especially in industries with tight production schedules. -

Technical Data Sheet (TDS)

A TDS provides essential information about the properties and specifications of a fabric, including its performance characteristics, recommended uses, and care instructions. B2B buyers should request TDS from suppliers to make informed decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting fabrics for motorcycle seats, ensuring they meet both quality and safety standards.

Navigating Market Dynamics and Sourcing Trends in the fabric for motorcycle seat Sector

What Are the Current Market Dynamics and Key Trends in the Fabric for Motorcycle Seat Sector?

The fabric for motorcycle seat sector is influenced by various global drivers, including rising consumer demand for customization and enhanced comfort in riding experiences. As motorcycle enthusiasts increasingly seek personalized solutions, B2B suppliers are responding with innovative upholstery options. Emerging technologies such as digital printing and advanced textile manufacturing are enabling the production of high-quality, customizable fabrics that cater to specific aesthetic and functional needs. This trend is particularly pronounced in regions like Europe and South America, where motorcycle culture is deeply rooted and continues to grow.

International B2B buyers are also navigating fluctuating raw material prices and supply chain disruptions, exacerbated by geopolitical factors and the ongoing impacts of the COVID-19 pandemic. These challenges underscore the importance of strategic sourcing relationships and the adoption of just-in-time inventory practices to mitigate risks. Additionally, sustainability is becoming a focal point for buyers in Africa, the Middle East, and Europe, driving a shift toward eco-friendly materials and processes that align with consumer values.

As the market evolves, companies that invest in digital transformation and data analytics can gain insights into customer preferences and market trends, allowing them to stay competitive. Buyers should prioritize partnerships with suppliers who offer not only quality fabrics but also transparency in their sourcing and manufacturing processes.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Fabric for Motorcycle Seat Sector?

The environmental impact of the fabric industry is a growing concern, making sustainability a key focus for B2B buyers in the motorcycle seat fabric sector. The production of synthetic fabrics often involves harmful chemicals and processes that contribute to pollution and waste. Therefore, the importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using recycled materials or low-impact dyes, to minimize their carbon footprint.

Green certifications, such as OEKO-TEX® and Global Organic Textile Standard (GOTS), are becoming essential for fabric suppliers aiming to attract conscientious buyers. These certifications signal a commitment to environmentally friendly practices and provide assurance that products meet specific safety and sustainability standards. By sourcing certified materials, B2B buyers can enhance their brand reputation and appeal to eco-conscious consumers, ultimately driving sales.

In addition to environmental considerations, ethical sourcing also encompasses fair labor practices and community engagement. Buyers should evaluate suppliers not just on the quality of their fabrics but also on their commitment to social responsibility. Building relationships with suppliers who share these values can lead to long-term partnerships and a competitive advantage in the market.

What Is the Evolution of the Fabric for Motorcycle Seat Sector?

The fabric for motorcycle seat sector has evolved significantly over the past few decades. Initially dominated by basic materials such as leather and simple vinyl, the industry has witnessed a shift towards more advanced synthetic fabrics that offer improved durability, comfort, and aesthetic appeal. Innovations in textile technology have led to the development of breathable, weather-resistant materials that enhance the riding experience.

In recent years, the introduction of customizable options has transformed the market, allowing consumers to select fabrics that suit their individual preferences and riding styles. This evolution reflects broader trends in consumer behavior, where personalization and quality are increasingly prioritized. As the motorcycle industry continues to grow, the fabric sector is likely to see further innovations that cater to the needs of modern riders while addressing sustainability and ethical sourcing challenges.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric for motorcycle seat

-

How do I choose the right fabric for motorcycle seats?

Selecting the right fabric for motorcycle seats involves considering durability, comfort, and aesthetics. Look for materials that are UV-resistant, waterproof, and abrasion-resistant to withstand outdoor conditions. Vinyl and synthetic leathers are popular choices due to their easy maintenance and resistance to wear. Additionally, consider the texture and grip of the fabric, as these factors impact rider comfort and safety. If possible, request samples to evaluate the fabric’s feel and performance before making a bulk order. -

What is the best material for motorcycle seat upholstery?

The best material for motorcycle seat upholstery typically includes high-quality vinyl or synthetic leather. These materials offer excellent durability, are easy to clean, and provide good weather resistance. Look for fabrics with high tensile strength and flexibility to accommodate the seat’s shape and provide comfort during long rides. Some manufacturers also offer specialized fabrics with additional features like gel inserts for enhanced comfort, which can be a valuable selling point for your customers. -

What are the common minimum order quantities (MOQs) for motorcycle seat fabric?

Minimum order quantities (MOQs) for motorcycle seat fabric can vary significantly by supplier and material type. Generally, MOQs can range from as low as 50 yards to several hundred yards, depending on the manufacturer and the fabric’s specifications. It’s advisable to inquire directly with suppliers about their MOQs, as some may offer flexible options for first-time buyers or smaller businesses. Establishing a strong relationship with your supplier can also lead to better negotiation opportunities regarding MOQs. -

How can I ensure the quality of motorcycle seat fabric?

To ensure the quality of motorcycle seat fabric, request product certifications and test reports from suppliers. Look for fabrics that meet industry standards for durability, UV resistance, and water repellency. Additionally, consider ordering samples for hands-on evaluation before committing to a larger purchase. Engage in discussions with suppliers about their quality control processes and any guarantees they offer on their products to minimize the risk of receiving subpar materials. -

What are the best practices for vetting motorcycle seat fabric suppliers?

Vetting suppliers involves researching their reputation, production capabilities, and customer feedback. Look for suppliers with a proven track record in the motorcycle industry and positive reviews from other B2B buyers. Request references and check if they have experience in international trade, especially if you are importing from different regions like Africa or South America. Additionally, consider visiting their manufacturing facilities, if feasible, to assess their operations and quality control processes firsthand. -

What payment terms are typically offered in B2B fabric transactions?

Payment terms in B2B fabric transactions can vary, but common options include net 30, net 60, or upfront payment. Some suppliers may offer discounts for early payments or flexible terms for established customers. It’s important to clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. Ensure that the terms are documented in your purchase agreement to avoid misunderstandings later in the transaction process. -

How do logistics and shipping impact my fabric order?

Logistics and shipping play a crucial role in the timely delivery of your fabric order. Factors such as shipping method, customs clearance, and supplier location can significantly affect lead times and costs. Choose a supplier with experience in international shipping to ensure compliance with local regulations. Additionally, consider using freight forwarders to streamline the process and mitigate potential delays. Always factor in shipping times when planning your inventory and production schedules. -

Can I customize motorcycle seat fabric for my brand?

Yes, many suppliers offer customization options for motorcycle seat fabric, including color, texture, and branding elements such as logos or patterns. Customization can enhance your product’s appeal and differentiate it in the marketplace. When discussing options with suppliers, inquire about their capabilities for digital printing or embroidery. Be prepared to provide design specifications and minimum order quantities for customized products, as these may differ from standard offerings.

Top 7 Fabric For Motorcycle Seat Manufacturers & Suppliers List

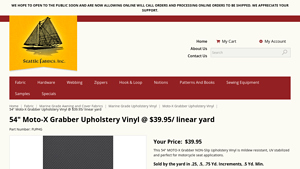

1. Seattle Fabrics – 54 Moto-X Grabber Upholstery Vinyl

Domain: seattlefabrics.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “54” Moto-X Grabber Upholstery Vinyl”, “Price”: “$39.95/linear yard”, “Part Number”: “FUPHG”, “Width”: “54 inches”, “Material Type”: “NON-Slip Upholstery Vinyl”, “Features”: [“Mildew resistant”, “UV stabilized”], “Applications”: “Perfect for motorcycle seat applications”, “Availability”: “Sold by the yard in .25, .5, .75 yard increments, .5 yard minimum”, “Color”: “Black”, “Weight…

2. Luimoto – Premium Motorcycle Seat Covers

Domain: luimoto.com

Registered: 2004 (21 years)

Introduction: Motorcycle Seat Covers, Tank Grips & More – Luimoto offers premium aftermarket Rider Seat Covers made from marine-grade materials for comfort and style, tailored for various motorcycles. Passenger Seat Covers enhance grip and styling, outperforming OEM covers. Custom Seat Covers allow personalization with special stitching and embroidery, built on-site in Vancouver. Premium Gold Gel inserts reduce…

3. Reddit – Motorcycle Seat Recovery Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: For re-covering a motorcycle seat on an ADV bike, marine-grade vinyl is recommended for its durability and water resistance. Polyester is also a viable option for a lightweight alternative. Adding foam padding can enhance comfort.

4. All Sport – Motorcycle Vinyl

Domain: diyupholsterysupply.com

Registered: 2004 (21 years)

Introduction: Product: Motorcycle Vinyl

Brand: All Sport

Description: Stretchable, pliable upholstery vinyl suitable for gaming rails, marine applications, ATVs, snow machines, and motorcycles. Features a -60°F cold crack, 360° stretch, and is flame retardant.

Color Options and Prices:

– All Sport Black: $23.99

– All Sport High-Tac Black: $23.99

– All Sport Chalk: $23.99

– All Sport Nu Bright Yellow: $23.99

– A…

5. Advrider – Sunbrella Outdoor Fabric

Domain: advrider.com

Registered: 2001 (24 years)

Introduction: 1. Sunbrella outdoor fabric: Fade and stain resistant, waterproof, wear resistant, available in various colors, textures, and weights. Recommended for bike seats for traction and aesthetics. 2. High-grade leather-look grain black vinyl: Durable but may not be breathable. 3. 4-way stretch vinyl: Easier to work with, reduces creases and folds, durable. 4. Hospital/industrial grade vinyl: Recommended…

6. Sailrite – Morbern™ Allsport 360º Stretch Vinyl Fabric

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Materials List: Morbern™ Allsport 360º Stretch Electric Blue 54″ Vinyl Fabric (#104175), Morbern™ Allsport 360º Stretch Black 54″ Vinyl Fabric (#104182), PremoBond® Tex 90 (V-92) White UV Bonded Polyester Thread 4 oz. (1,350 yds.) (#123337), Cushion Wrap Silk Film 54″ (#103933), 5-Ply Waxed Polyester Twine Bobbin (81 ft.) (#29206), 21 Gauge 3/8″ (10mm) Staples 10,000/Box (Stainless Steel) (#8010SS…

7. eBay – Motorcycle Upholstery Fabrics

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: By the Yard Motorcycle Upholstery Craft Fabrics for sale on eBay. Related searches include Motorcycle Fabric by the Yard, Motorcycle Fabric, Fabric with Motorcycle Print, Harley Davidson Fabric by the Yard, Leather Fabric by the Yard, Upholstery Fabric by the Yard, Designer Upholstery Fabric by the Yard, Faux Leather Fabric by the Yard, Genuine Leather Fabric by the Yard, and Outdura Fabric by the…

Strategic Sourcing Conclusion and Outlook for fabric for motorcycle seat

In conclusion, the strategic sourcing of fabric for motorcycle seats is crucial for enhancing product quality and meeting consumer demands. As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding the diverse options—from durable vinyls to customizable upholstery—can significantly impact your procurement strategies. Engaging with suppliers who offer high-quality materials, such as stretch vinyl that withstands the rigors of motorcycle use, ensures that you can deliver superior products to your customers.

Furthermore, leveraging local manufacturing capabilities can optimize supply chain efficiency and reduce lead times. By fostering strong relationships with fabric suppliers, you can negotiate better terms, access exclusive materials, and stay ahead of market trends.

As the motorcycle industry continues to evolve, now is the time to invest in innovative fabric solutions that not only enhance comfort and safety but also reflect your brand’s commitment to quality. Take proactive steps today to explore sourcing opportunities that align with your business goals, and position your company for sustained success in this competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to fabric for motorcycle seat