Introduction: Navigating the Global Market for hot stamping leather

In the competitive landscape of leather goods manufacturing, sourcing high-quality hot stamping leather can pose significant challenges for international B2B buyers. Whether you are in Brazil, Saudi Arabia, or any other region, understanding the nuances of hot stamping techniques is crucial to ensuring the branding and personalization of your products stand out in the market. This guide offers an in-depth exploration of hot stamping leather, addressing key considerations such as the types of leather suitable for hot stamping, applications across various industries, and best practices for supplier vetting.

Buyers will gain insights into the intricacies of equipment options, including electric branding irons and custom stamps, while also examining the cost factors that influence purchasing decisions. With a focus on actionable strategies, this comprehensive resource empowers businesses in Africa, South America, the Middle East, and Europe to make informed choices that align with their branding goals. By leveraging the information presented, B2B buyers can navigate the complexities of sourcing hot stamping leather, ensuring their products not only meet quality standards but also resonate with their target markets.

Ultimately, this guide serves as a crucial tool for any business looking to elevate its leather product offerings through effective branding techniques, fostering greater success in the global marketplace.

Table Of Contents

- Top 4 Hot Stamping Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hot stamping leather

- Understanding hot stamping leather Types and Variations

- Key Industrial Applications of hot stamping leather

- 3 Common User Pain Points for ‘hot stamping leather’ & Their Solutions

- Strategic Material Selection Guide for hot stamping leather

- In-depth Look: Manufacturing Processes and Quality Assurance for hot stamping leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot stamping leather’

- Comprehensive Cost and Pricing Analysis for hot stamping leather Sourcing

- Alternatives Analysis: Comparing hot stamping leather With Other Solutions

- Essential Technical Properties and Trade Terminology for hot stamping leather

- Navigating Market Dynamics and Sourcing Trends in the hot stamping leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hot stamping leather

- Strategic Sourcing Conclusion and Outlook for hot stamping leather

- Important Disclaimer & Terms of Use

Understanding hot stamping leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chrome Tanned Leather | Soft, supple texture; highly durable; versatile use | High-end fashion, accessories | Pros: Excellent for intricate designs; durable. Cons: Requires precise temperature control. |

| Vegetable Tanned Leather | Natural finish; environmentally friendly; stiff | Craftsmanship, artisanal goods | Pros: Ideal for traditional aesthetics; ages beautifully. Cons: Less resistant to moisture. |

| Suede | Soft, napped finish; available in various colors | Footwear, upholstery, fashion items | Pros: Unique texture; great for soft goods. Cons: More delicate; can be challenging to clean. |

| Faux Leather | Synthetic alternative; cost-effective; eco-friendly | Mass production, budget-friendly goods | Pros: Affordable; consistent quality. Cons: Less authentic feel; may not age well. |

| Exotic Leather | Unique textures (e.g., alligator, ostrich); luxury appeal | Luxury fashion, high-end accessories | Pros: Distinctive, high-value products. Cons: High cost; ethical considerations in sourcing. |

What Are the Key Characteristics of Chrome Tanned Leather for Hot Stamping?

Chrome tanned leather is known for its soft and supple texture, making it an ideal choice for hot stamping. This type of leather is highly durable and can withstand various environmental conditions, which is crucial for products like high-end fashion items and accessories. When purchasing chrome tanned leather for hot stamping, buyers should consider the need for precise temperature control during the stamping process to achieve optimal results without damaging the material.

Why Choose Vegetable Tanned Leather for Hot Stamping Applications?

Vegetable tanned leather offers a natural finish that is both environmentally friendly and aesthetically pleasing. This type of leather is often favored for its stiffness, making it suitable for artisanal goods and craftsmanship. Buyers looking to create traditional, high-quality products should consider vegetable tanned leather, as it develops a unique patina over time. However, it is essential to note that this leather is less resistant to moisture, which could impact its longevity in certain applications.

How Does Suede Stand Out in Hot Stamping Leather Types?

Suede is characterized by its soft, napped finish and is available in a variety of colors, making it a popular choice for footwear and upholstery. Its unique texture can enhance the visual appeal of stamped designs. However, buyers should be aware that suede is more delicate and can be challenging to clean. When selecting suede for hot stamping, consider the end product’s intended use and the potential need for additional care to maintain its appearance.

What Are the Advantages of Using Faux Leather for Hot Stamping?

Faux leather presents a cost-effective and eco-friendly alternative to traditional leather types. It is particularly suitable for mass production and budget-friendly goods, offering consistent quality across large batches. While faux leather is affordable and can mimic the appearance of genuine leather, buyers should consider its less authentic feel and potential longevity issues. This type of leather is best suited for products where cost is a primary concern, but quality cannot be compromised.

What Makes Exotic Leather a Unique Choice for Hot Stamping?

Exotic leather, such as alligator or ostrich, is prized for its unique textures and luxury appeal. This type of leather is often used in high-end fashion and accessories, providing a distinct and high-value product. However, the cost of exotic leather can be significantly higher than other types, and ethical considerations in sourcing may also influence purchasing decisions. Buyers should weigh the potential for high profit margins against the challenges of sourcing and pricing when considering exotic leather for hot stamping applications.

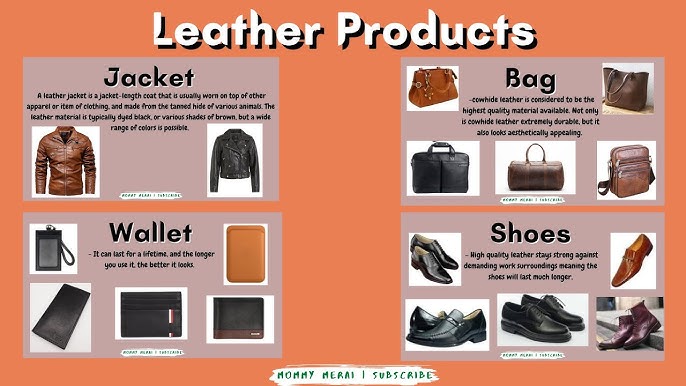

Key Industrial Applications of hot stamping leather

| Industry/Sector | Specific Application of hot stamping leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom branding on leather goods | Enhances brand visibility and product differentiation | Quality of materials, versatility in design, and pricing |

| Automotive | Interior leather branding | Adds luxury appeal and customization for vehicle interiors | Compatibility with various leather types and heat settings |

| Leather Goods Manufacturing | Personalized leather products | Increases customer loyalty through customization | Production capacity, lead times, and technology used |

| Hospitality & Retail | Branding for leather furnishings | Strengthens brand identity and customer experience | Durability of branding, aesthetics, and material sourcing |

| Promotional Products | Customized leather giveaways | Effective marketing tool that enhances brand recall | Minimum order quantities, design complexity, and cost |

How is hot stamping leather utilized in the fashion and apparel industry?

In the fashion and apparel industry, hot stamping leather is primarily used for custom branding on leather goods such as bags, wallets, and belts. This technique allows brands to imprint their logos or unique designs directly onto the leather, enhancing brand visibility and product differentiation. For international buyers, especially from regions like Africa and South America, understanding the nuances of leather quality and stamping techniques is crucial. Selecting the right materials can significantly affect the product’s marketability and consumer perception.

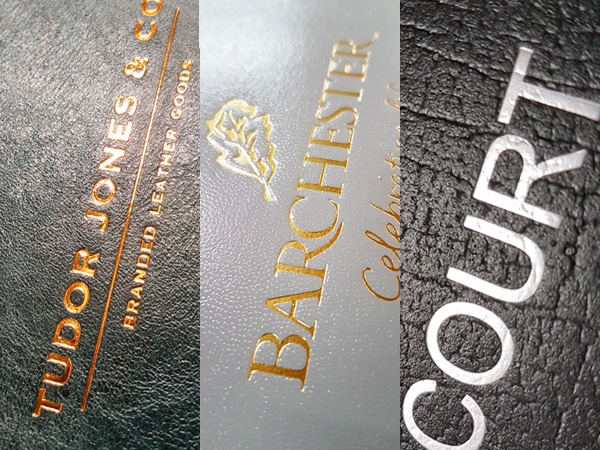

Illustrative image related to hot stamping leather

What role does hot stamping play in the automotive sector?

In the automotive industry, hot stamping leather is employed to brand interior leather components, such as seats and dashboards. This not only adds a luxurious touch to vehicles but also allows for customization that appeals to consumers seeking personalized features. Buyers in the Middle East and Europe should consider the compatibility of hot stamping techniques with various leather types and the necessary heat settings to ensure high-quality results that meet industry standards.

How does hot stamping leather benefit leather goods manufacturers?

Leather goods manufacturers leverage hot stamping to create personalized products for their customers, enhancing loyalty and satisfaction. This application addresses the demand for unique, tailored items in a competitive market. B2B buyers must prioritize suppliers who can accommodate varying production capacities, lead times, and utilize advanced technology to achieve high-quality results. Understanding these factors can help manufacturers optimize their supply chains and meet customer expectations.

Why is hot stamping important in hospitality and retail?

In the hospitality and retail sectors, hot stamping leather is utilized for branding leather furnishings, such as menus, coasters, and promotional items. This practice strengthens brand identity and enhances the overall customer experience. For international buyers, particularly in Europe and the Middle East, sourcing durable materials and aesthetically pleasing designs is essential to ensure that branded items withstand daily use while conveying a premium feel.

How can promotional products benefit from hot stamping leather?

Hot stamping leather is a valuable technique for creating customized leather promotional products, such as keychains and corporate gifts. This application serves as an effective marketing tool that enhances brand recall among customers. Buyers should consider minimum order quantities, design complexity, and overall cost when sourcing these products, ensuring they find suppliers who can deliver high-quality items that align with their marketing strategies.

3 Common User Pain Points for ‘hot stamping leather’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Quality in Hot Stamping

The Problem: B2B buyers often face challenges with achieving consistent quality when hot stamping leather. Variations in temperature settings, pressure applied, and even the type of leather used can lead to uneven imprints, which can tarnish the perceived quality of the products being offered. This inconsistency can result in wasted materials and increased labor costs, ultimately affecting the bottom line. Buyers may also struggle with determining the optimal settings for different leather types, leading to trial and error that can be both time-consuming and frustrating.

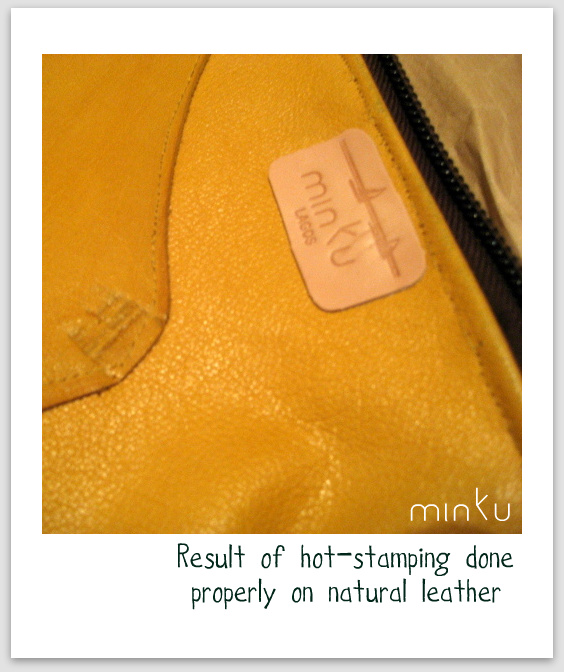

Illustrative image related to hot stamping leather

The Solution: To overcome this challenge, it is crucial for businesses to invest in high-quality, adjustable electric branding irons that offer variable temperature controls. This allows users to tailor the heat settings according to the specific type of leather, whether it’s chrome tanned or vegetable tanned. Additionally, keeping a detailed log of the settings used for different leather types can help standardize the process across multiple batches. Implementing a quality control checklist prior to production can also ensure that the leather is adequately prepared—cleaned, dried, and free from sealants—before stamping. Training staff on these procedures can further enhance consistency and reduce errors.

Scenario 2: Limited Design Flexibility with Current Stamping Equipment

The Problem: Many B2B buyers discover that their current stamping equipment limits the complexity of designs they can create. Traditional stamping methods may restrict them to smaller, simpler logos, whereas customer demands are evolving towards larger, more intricate designs. This limitation can stifle creativity and innovation, making it difficult for businesses to differentiate themselves in a competitive market.

The Solution: To address this pain point, businesses should consider upgrading to advanced hot stamping equipment that accommodates larger and more complex designs. Look for electric branding irons with customizable plates that can handle higher detail and size. Collaborating with experienced designers to create scalable digital mock-ups can also streamline the design process. Additionally, sourcing materials like brass or aluminum for the stamping plates can ensure durability and precision. Investing in training for operators on how to maximize the capabilities of new equipment will ensure that the designs are executed flawlessly, giving businesses a competitive edge.

Scenario 3: High Costs Associated with Material Waste and Production Delays

The Problem: High material waste and production delays are common issues faced by B2B buyers in the leather hot stamping industry. Inexperienced operators may misjudge stamping techniques, leading to damaged goods that must be discarded, driving up costs. Furthermore, inefficient processes can lead to longer production times, which can affect order fulfillment and customer satisfaction. For businesses operating on tight margins, these challenges can be detrimental.

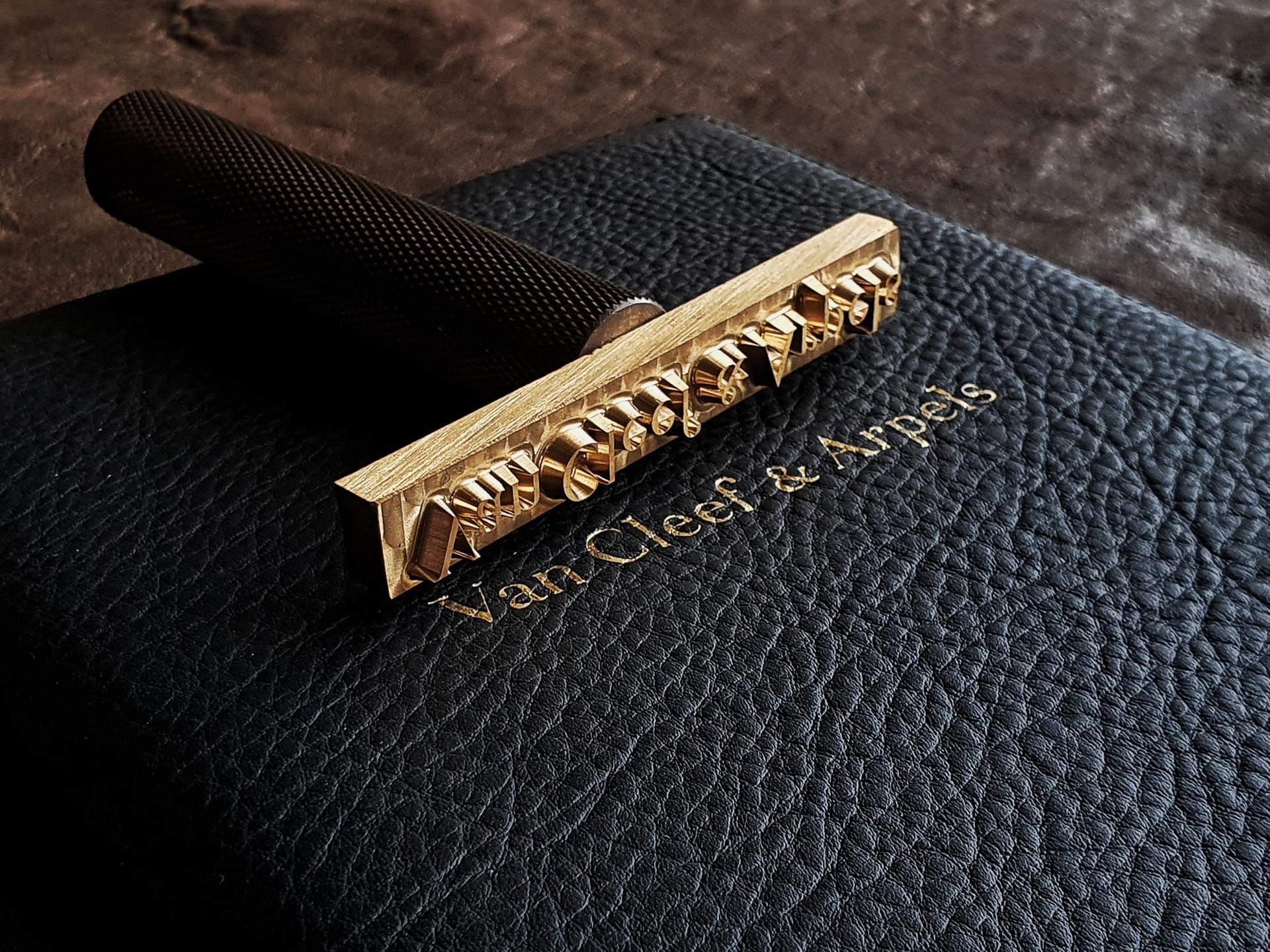

Illustrative image related to hot stamping leather

The Solution: Implementing a systematic approach to training employees on hot stamping techniques can significantly reduce material waste. Regular workshops can help staff become familiar with the nuances of different leather types and the optimal settings for each. Additionally, investing in pre-production testing—where small batches are stamped before full-scale production—can help identify potential issues before they escalate into larger problems. Streamlining the workflow by adopting lean manufacturing principles can also minimize delays and enhance efficiency. By creating a culture of continuous improvement and encouraging feedback from operators, businesses can refine their processes over time, ultimately reducing costs and improving productivity.

Strategic Material Selection Guide for hot stamping leather

What Are the Key Materials Used for Hot Stamping Leather?

When it comes to hot stamping leather, the choice of material is crucial for achieving optimal results. Different materials offer various properties that can significantly influence the performance and durability of the stamped product. Below, we analyze four common materials used for hot stamping leather, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Brass

Key Properties: Brass is known for its excellent thermal conductivity and durability, making it ideal for hot stamping applications. It can withstand high temperatures without deforming, typically rated for use in temperatures up to 300°C (572°F).

Pros & Cons: The primary advantage of brass is its longevity; it resists wear and can produce a crisp, clear impression on leather. However, brass can be more expensive than other materials, which may impact the overall cost of production. Additionally, it may require more complex manufacturing processes, such as CNC machining, to achieve precise designs.

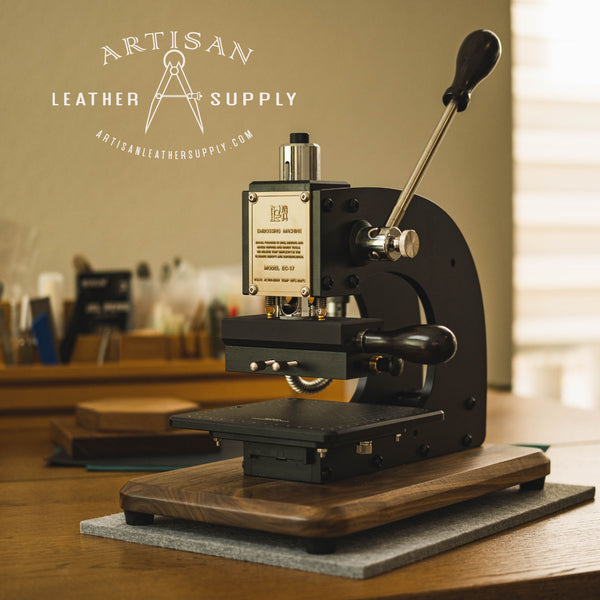

Illustrative image related to hot stamping leather

Impact on Application: Brass is suitable for a wide range of leather types, including vegetable-tanned and chrome-tanned leathers. Its compatibility with various media ensures that it can be used for intricate designs without losing detail.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN regarding material properties. In regions like Europe and the Middle East, where quality and durability are paramount, brass is often preferred despite its higher cost.

2. Aluminum

Key Properties: Aluminum is lightweight and has good thermal conductivity, making it a popular choice for hot stamping. It can handle temperatures up to 250°C (482°F) but may not be as durable as brass.

Pros & Cons: The main advantage of aluminum is its lower cost compared to brass, making it an attractive option for budget-conscious buyers. However, aluminum is more prone to wear and may not produce as crisp an impression over time. It is also less suitable for intricate designs due to its tendency to deform under high pressure.

Impact on Application: Aluminum can be used effectively with chrome-tanned leather but may struggle with thicker materials. Its lightweight nature makes it easier to handle during the stamping process.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the local availability of aluminum and its compliance with relevant standards. While it is a cost-effective option, the potential for reduced durability may not meet the expectations of high-end markets.

3. Steel

Key Properties: Steel is known for its exceptional strength and durability, making it ideal for heavy-duty applications. It can withstand high temperatures and pressures, typically rated for use above 300°C (572°F).

Pros & Cons: The primary advantage of steel is its robustness, allowing it to produce clear impressions even on thick leather. However, steel can be heavy and may require more effort to handle during the stamping process. Additionally, it can be more expensive due to the manufacturing complexity involved.

Impact on Application: Steel is particularly effective for large-scale production runs, where consistent quality is essential. It is suitable for a variety of leather types, including those that require higher pressure for stamping.

Considerations for International Buyers: Buyers should be aware of the compliance requirements in their region, particularly in Europe, where stringent quality standards apply. The higher initial investment in steel may be justified by its long-term performance and reliability.

4. Composite Materials

Key Properties: Composite materials combine various elements to enhance durability and reduce weight. They can be engineered to withstand high temperatures and pressures, making them versatile for hot stamping applications.

Illustrative image related to hot stamping leather

Pros & Cons: The advantage of composites is their ability to be tailored for specific applications, offering a balance between cost and performance. However, they may not provide the same level of durability as metals like brass or steel, leading to potential issues in high-volume stamping scenarios.

Impact on Application: Composites can be used effectively for various leather types, but their performance may vary based on the specific formulation. They are particularly useful for intricate designs where weight is a concern.

Considerations for International Buyers: Buyers from emerging markets should assess the availability and cost-effectiveness of composite materials. Compliance with international standards is essential to ensure product quality and market acceptance.

Illustrative image related to hot stamping leather

Summary Table

| Material | Typical Use Case for hot stamping leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-end leather goods | Excellent durability and detail | Higher cost and complexity | High |

| Aluminum | Budget-friendly leather products | Lower cost | Less durable and prone to wear | Medium |

| Steel | Heavy-duty stamping applications | Exceptional strength | Heavier and more expensive | High |

| Composite | Intricate designs in lightweight products | Tailored performance | May lack durability compared to metals | Medium |

This strategic material selection guide provides essential insights for international B2B buyers in the leather industry, helping them make informed decisions based on performance, cost, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hot stamping leather

What Are the Main Stages of the Manufacturing Process for Hot Stamping Leather?

The manufacturing process for hot stamping leather involves several critical stages that ensure the final product meets quality standards and customer expectations. Understanding these stages can help B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, make informed decisions when sourcing leather goods.

Material Preparation: How Is Leather Prepared for Hot Stamping?

The initial step in the hot stamping leather process is material preparation. This involves selecting the appropriate type of leather, which can include chrome-tanned, vegetable-tanned, or suede. Each type of leather has specific characteristics that affect how it reacts to heat and pressure during stamping.

Illustrative image related to hot stamping leather

-

Quality Assessment: Before any processing, raw leather should undergo a quality check to identify imperfections such as scars, wrinkles, or inconsistent thickness. This step is crucial, as defects can affect the final appearance and durability of the stamped products.

-

Cutting and Sizing: After quality assessment, the leather is cut into pre-defined sizes suitable for the final product (e.g., wallets, bags, or belts). Precision in cutting is vital to ensure uniformity across batches, especially for larger orders.

-

Dampening: Depending on the leather type, it may be lightly dampened to facilitate better impression retention during stamping. This step is particularly important for vegetable-tanned leather, as it helps to create a clearer and more defined imprint.

What Techniques Are Commonly Used in the Forming Stage of Hot Stamping?

The forming stage is where the actual hot stamping occurs. This stage is critical for ensuring that the branding is not only aesthetically pleasing but also durable.

-

Hot Stamping Process: Using a variable-temperature electric branding iron, the stamping design is applied to the leather. The right temperature setting is crucial—vegetable-tanned leather requires lower temperatures, while chrome-tanned leather may need higher settings to achieve optimal results.

-

Pressure Application: The branding iron is pressed onto the leather for a specific duration, allowing the heat to penetrate and create a permanent mark. This step requires precision timing and pressure to prevent burning or damaging the leather.

-

Cooling Period: After stamping, the leather must be allowed to cool before further handling. This cooling period helps to set the impression and ensures the durability of the stamp.

How Is the Assembly of Hot Stamped Leather Products Conducted?

Once the stamping is complete, the next stage is assembly. This involves stitching, gluing, or otherwise joining pieces together to form the final product.

-

Stitching and Assembly: Depending on the product design, leather pieces may be stitched together using industrial sewing machines. Quality stitching is essential for both aesthetics and durability, particularly in high-use items like bags and wallets.

-

Final Touches: Assembly might also include adding hardware (like zippers or buckles), linings, or other components. Quality checks at this stage ensure that all parts fit correctly and function as intended.

What Finishing Techniques Are Used to Enhance Hot Stamped Leather Products?

The finishing stage is crucial for enhancing the appearance and longevity of hot stamped leather products.

-

Edge Finishing: Edges may be treated with dyes or sealants to prevent fraying and enhance appearance. This step is especially important for products that will see frequent use.

-

Surface Treatment: Additional treatments, such as conditioners or protective sprays, can be applied to improve water resistance and maintain the leather’s suppleness.

-

Inspection: A thorough inspection is conducted to ensure that the final products meet quality standards before they are packaged and shipped.

What International Quality Standards Should B2B Buyers Be Aware Of?

Quality assurance in hot stamping leather products is paramount, particularly for B2B buyers who may be sourcing from various international suppliers. Several standards and practices can help ensure product quality.

-

ISO 9001 Certification: This internationally recognized standard focuses on quality management systems. Suppliers with ISO 9001 certification demonstrate their commitment to maintaining quality throughout their processes.

-

CE Marking: For products sold in Europe, the CE marking indicates compliance with EU safety, health, and environmental protection standards. This is particularly relevant for products that may come into contact with consumers.

-

API Standards: Specific industries may have additional standards (e.g., API for oilfield equipment), which can impact the choice of leather products used in these applications.

What Are the Key Quality Control Checkpoints in Hot Stamping Leather Manufacturing?

Quality control (QC) is vital in ensuring that hot stamping leather products meet the required standards. Key checkpoints include:

-

Incoming Quality Control (IQC): Before production begins, raw materials should be inspected for quality and compliance with specifications. This includes checking leather thickness, texture, and color consistency.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks should be conducted to monitor each stage, from stamping to assembly. This helps to catch any issues early and ensures uniformity across batches.

-

Final Quality Control (FQC): Once production is complete, a final inspection should take place to verify that the finished products meet quality standards. This includes checking for correct branding, stitching quality, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must be proactive in verifying the quality control practices of their suppliers to ensure they receive high-quality products.

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This helps buyers to assess compliance with international standards.

-

Requesting Quality Reports: Suppliers should provide documentation outlining their quality control processes and results. Reviewing these reports can help buyers gauge the reliability of their suppliers.

-

Third-Party Inspections: Engaging third-party inspection services can provide an impartial assessment of a supplier’s quality control practices. These services can conduct checks at various stages of production and provide detailed reports.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions, should be aware of specific nuances in quality control when sourcing hot stamping leather products.

-

Regulatory Compliance: Different countries may have varying regulations regarding leather products, including chemical treatments and environmental impact. Buyers should ensure that their suppliers are compliant with local regulations.

-

Cultural Preferences: Quality standards may vary based on cultural preferences. Understanding the target market’s expectations can help buyers select the right products and ensure that they meet those standards.

-

Supply Chain Transparency: Building a transparent supply chain can help buyers maintain quality control. Knowing where materials come from and how products are made can lead to better quality assurance.

By understanding the manufacturing processes and quality assurance practices associated with hot stamping leather, B2B buyers can make informed decisions that enhance their product offerings and build strong supplier relationships.

Illustrative image related to hot stamping leather

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot stamping leather’

To effectively procure hot stamping leather for your business, it is essential to follow a structured approach that ensures quality, compatibility, and cost-effectiveness. This checklist provides a clear roadmap to guide B2B buyers through the sourcing process, helping you make informed decisions and secure the best materials for your production needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is the foundation of successful sourcing. Determine the type of leather you need (e.g., chrome tanned, vegetable tanned, suede) and the desired thickness, as these factors influence the hot stamping process. Additionally, outline any specific characteristics such as color, finish, and texture that align with your product design.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in hot stamping leather. Look for companies with a proven track record and expertise in the leather industry. Utilize online directories, trade shows, and industry publications to compile a list of potential candidates. Pay attention to their geographical location, especially if you prefer suppliers closer to your operational base.

Illustrative image related to hot stamping leather

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to assess the suppliers’ capabilities. Request information about their production processes, equipment, and quality control measures. Ensure they can handle your specific requirements, such as large orders or complex designs. Additionally, inquire about their experience with different types of leather to verify their versatility and expertise.

Step 4: Verify Supplier Certifications

Supplier certifications are vital for ensuring quality and compliance with industry standards. Check for certifications related to leather production, such as ISO standards or environmental certifications. This helps assure you that the supplier adheres to best practices in production and sustainability, which is increasingly important for consumers and regulatory bodies alike.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the leather to evaluate quality and suitability. Conduct tests for durability, heat resistance, and how well the leather accepts hot stamping. This step is critical to avoid issues later in the production process and ensures the final product meets your standards.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms with potential suppliers. Understand the cost implications of different leather types, as well as any additional fees related to customization or shipping. Clear agreements on payment terms can prevent misunderstandings and foster a positive supplier relationship.

Step 7: Establish a Clear Communication Channel

Effective communication is key to a successful sourcing experience. Establish a clear line of communication with your chosen supplier to facilitate ongoing discussions about orders, production timelines, and any potential issues. Regular updates can help you stay informed about the status of your orders and maintain a productive partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing hot stamping leather with confidence, ensuring that they select the right materials to enhance their product offerings.

Comprehensive Cost and Pricing Analysis for hot stamping leather Sourcing

What Are the Key Cost Components for Hot Stamping Leather?

Understanding the cost structure of hot stamping leather is crucial for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

-

Materials: The choice of leather significantly affects the cost. Chrome-tanned leather tends to be less expensive than vegetable-tanned leather, which may command a premium due to its natural processing. Additionally, the quality of the stamping foil or branding tool impacts the overall material cost.

-

Labor: Skilled labor is essential for both the hot stamping process and quality assurance. Labor costs can vary significantly based on the region and the complexity of the design. In markets with higher labor costs, such as parts of Europe, buyers should be prepared for higher initial expenses.

-

Manufacturing Overhead: This encompasses utilities, maintenance of machinery, and facility costs. Efficient production processes can help mitigate these overhead costs, making it essential for suppliers to optimize their operations.

-

Tooling: Custom stamps and branding irons require upfront investment. The cost can vary depending on the size and intricacy of the design. Investing in high-quality tooling can yield better results and longevity, impacting the total cost over time.

-

Quality Control (QC): Ensuring that each piece meets quality standards is vital, particularly for high-end products. QC processes can add to the overall cost but are necessary to avoid defects that could lead to returns or customer dissatisfaction.

-

Logistics: Shipping costs are influenced by distance, volume, and packaging requirements. International buyers must consider customs duties and tariffs, which can significantly affect total expenses.

-

Margin: Suppliers will typically add a profit margin on top of their costs. This margin can fluctuate based on market demand and competition, making it essential for buyers to shop around.

What Factors Influence Pricing in Hot Stamping Leather?

Several factors can affect the pricing of hot stamping leather:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ). Larger orders may qualify for discounts, allowing buyers to optimize their costs.

-

Specifications and Customization: Custom designs and specifications can increase costs due to the additional labor and tooling required. Buyers should weigh the benefits of customization against the potential increase in price.

-

Material Quality and Certifications: Premium materials or those that meet specific environmental or quality certifications can raise costs. Buyers should assess whether these certifications add value to their end product.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge more but often deliver better quality and consistency.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is essential. Different terms can shift costs and responsibilities, affecting the total price.

How Can Buyers Negotiate and Ensure Cost-Efficiency?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings:

Illustrative image related to hot stamping leather

-

Research and Benchmarking: Familiarize yourself with market rates and competitive offerings to have a solid basis for negotiation.

-

Volume Commitments: Offer to increase order quantities in exchange for lower pricing. This approach can benefit both parties.

-

Long-Term Partnerships: Building a long-term relationship with suppliers can lead to better pricing over time as trust and reliability develop.

-

Total Cost of Ownership (TCO): Consider not just the upfront costs but also maintenance, potential defects, and logistics. A supplier offering higher quality may result in lower overall costs.

-

Pricing Nuances: Be aware of fluctuations in currency exchange rates and how they impact pricing. This is particularly relevant for buyers in emerging markets.

Disclaimer

Prices for hot stamping leather can vary widely based on the discussed factors and are subject to change. It is advisable for buyers to obtain multiple quotes and conduct thorough due diligence to ensure the best possible pricing and quality.

Alternatives Analysis: Comparing hot stamping leather With Other Solutions

Introduction to Alternatives in Leather Stamping

When it comes to branding leather products, businesses often seek the most effective methods to ensure durability, aesthetic appeal, and cost-efficiency. While hot stamping leather is a popular choice, there are several alternative solutions available that may cater to different needs and preferences. This section explores how hot stamping compares with other viable techniques, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Hot Stamping Leather | Leather Stamping (Cold Stamping) | Laser Engraving |

|---|---|---|---|

| Performance | Provides a clean, modern finish; durable | Offers a traditional look; less durable on softer leathers | Highly precise; can create intricate designs |

| Cost | Moderate initial investment; consistent for large runs | Lower upfront cost; labor-intensive for larger projects | Higher initial cost for machinery; cost-effective for small runs |

| Ease of Implementation | Requires specific equipment and temperature control | Simple tools; easy for small-scale operations | Requires technical skill; setup time can be lengthy |

| Maintenance | Low maintenance if equipment is quality; regular checks needed | Minimal maintenance; tools need occasional replacement | Higher maintenance due to complex machinery |

| Best Use Case | Ideal for large-scale branding; consistent results | Best for artisanal products; custom, one-off designs | Perfect for detailed logos and designs; small batches |

Detailed Breakdown of Alternatives

Leather Stamping (Cold Stamping)

Leather stamping, or cold stamping, involves using a manual stamp and mallet to imprint designs onto the leather. This method is straightforward, making it suitable for smaller operations or artisans who value traditional craftsmanship. The main advantage of cold stamping is its lower cost and ease of use. However, the durability of the imprint can be compromised, especially on softer leathers, and achieving uniformity across larger batches can be challenging. This method is best suited for bespoke items where unique designs are desired.

Laser Engraving

Laser engraving utilizes advanced technology to etch designs onto leather with high precision. This method allows for intricate patterns and detailed logos that can be difficult to achieve with other techniques. The main benefits of laser engraving include its accuracy and ability to handle complex designs. However, it requires significant upfront investment in machinery and technical expertise to operate effectively. While it may not be the best option for high-volume production due to slower speeds compared to hot stamping, it excels in creating unique, detailed items for niche markets.

Illustrative image related to hot stamping leather

Conclusion: Choosing the Right Leather Branding Solution

For B2B buyers, selecting the appropriate branding solution depends on specific business needs, product types, and budget considerations. Hot stamping leather offers a balance of durability and aesthetic appeal, making it ideal for larger production runs where consistency is critical. However, for those focusing on artisanal craftsmanship, leather stamping provides a more traditional approach at a lower cost. Alternatively, laser engraving presents a modern solution for intricate designs, suitable for smaller batches. Evaluating these alternatives against your brand’s goals and operational capabilities will help you make an informed choice that aligns with your overall strategy.

Essential Technical Properties and Trade Terminology for hot stamping leather

What Are the Key Technical Properties of Hot Stamping Leather?

When considering hot stamping leather, understanding the technical properties is crucial for ensuring high-quality results. Here are some essential specifications that B2B buyers should be aware of:

1. Material Grade

The type of leather used significantly impacts the hot stamping process. Leather can be classified into grades such as chrome-tanned or vegetable-tanned, each having unique characteristics. Chrome-tanned leather is more flexible and durable, making it suitable for intricate designs, while vegetable-tanned leather offers a more traditional appearance. Selecting the appropriate material grade ensures the longevity and aesthetic appeal of the final product.

2. Leather Thickness

Leather thickness typically ranges from 1.5 mm to several millimeters. For effective hot stamping, it is essential to work with leather that is at least 1.5 mm thick. Thicker leather allows for deeper impressions and reduces the risk of puncturing during the stamping process. Buyers must confirm thickness specifications to achieve optimal results, especially when dealing with large production volumes.

3. Temperature Control

Temperature is a critical factor in hot stamping leather. Different types of leather require varying heat levels for effective branding. For example, chrome-tanned leather may need higher temperatures compared to vegetable-tanned leather. A variable-temperature branding iron is essential for maintaining consistent results across different leather types, which can significantly impact production efficiency and product quality.

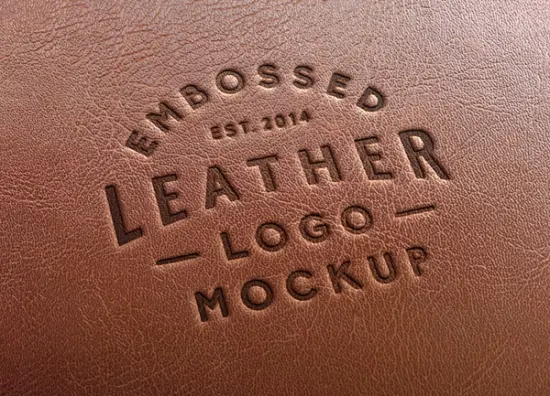

4. Impression Quality

The quality of the impression left by hot stamping depends on several factors, including the branding iron’s design, the heat applied, and the leather type. A well-executed impression should be clear, crisp, and consistent across multiple items. High-quality impressions not only enhance product aesthetics but also reinforce brand identity, making it a key consideration for B2B buyers.

5. Production Consistency

In a B2B environment, the ability to produce consistent results is paramount, especially when fulfilling large orders. Hot stamping technology should facilitate uniformity across products, ensuring that each branded item meets the same quality standards. This consistency helps build trust with customers and enhances brand reputation.

Illustrative image related to hot stamping leather

What Are Common Trade Terms in Hot Stamping Leather?

Understanding industry jargon is essential for effective communication and negotiation in the leather stamping market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, it often pertains to suppliers that provide custom branding tools or equipment used for hot stamping. Knowing OEM partners can help buyers secure quality tools tailored to their specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for businesses looking to manage costs while ensuring they meet production needs. Understanding the MOQ allows buyers to plan their orders effectively and avoid excess inventory.

Illustrative image related to hot stamping leather

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. In the context of hot stamping leather, an RFQ can help businesses compare prices and terms from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is crucial for B2B buyers engaged in cross-border transactions to avoid misunderstandings.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This is especially important in the leather stamping industry, where production schedules may vary significantly based on the complexity of designs and order volumes. Understanding lead times helps businesses plan their inventory and marketing strategies effectively.

By grasping these technical properties and trade terms, B2B buyers can navigate the hot stamping leather landscape with greater confidence and make informed purchasing decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the hot stamping leather Sector

What Are the Current Market Dynamics and Key Trends in Hot Stamping Leather?

The hot stamping leather market is experiencing robust growth driven by several global factors. Increased demand for personalized leather goods, such as bags, wallets, and accessories, is propelling manufacturers to adopt hot stamping techniques for branding and customization. This method offers a modern aesthetic that appeals to consumers seeking unique products. Additionally, advancements in technology, such as variable-temperature electric branding irons, are enhancing the precision and efficiency of the hot stamping process, thereby attracting international B2B buyers.

Emerging trends in sourcing include a shift towards automation and digital integration in production. Manufacturers are increasingly utilizing digital tools for design and quality control, which allows for greater customization and faster turnaround times. The rise of e-commerce platforms has also expanded the market reach for hot stamping leather suppliers, particularly in regions like Africa, South America, and the Middle East, where traditional retail channels may be less developed. Buyers from these regions are seeking suppliers who can offer not only quality products but also flexible and scalable production capabilities.

Another key trend is the growing preference for eco-friendly materials and processes. As consumers become more environmentally conscious, B2B buyers are prioritizing suppliers who demonstrate sustainable practices and can provide certifications for their products.

How Is Sustainability and Ethical Sourcing Reshaping the Hot Stamping Leather Industry?

Sustainability is becoming a focal point in the hot stamping leather sector, influencing purchasing decisions among B2B buyers. The environmental impact of leather production, particularly in terms of water usage and chemical treatments, has prompted a shift towards more sustainable sourcing practices. Suppliers are increasingly adopting eco-friendly tanning methods, such as vegetable tanning, which significantly reduce harmful emissions and waste.

Illustrative image related to hot stamping leather

Ethical sourcing is also gaining traction, with buyers demanding transparency in supply chains. This includes ensuring fair labor practices and humane treatment of animals. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for suppliers aiming to attract conscientious buyers. These certifications not only validate the sustainability of materials used but also enhance the marketability of products in regions like Europe and North America, where consumers are more likely to support brands committed to ethical practices.

In addition, the trend towards circular economy principles is encouraging manufacturers to explore upcycling and recycling options, further reducing the environmental footprint of hot stamping leather products. B2B buyers who prioritize sustainability can differentiate themselves in the market, appealing to a growing segment of environmentally aware consumers.

How Has the Hot Stamping Leather Industry Evolved Over Time?

The evolution of hot stamping leather can be traced back to traditional leatherworking techniques, where artisans would use rudimentary tools to imprint designs on leather surfaces. Over the decades, advancements in technology have transformed this craft into a more sophisticated process. The introduction of electric branding irons has allowed for greater precision and consistency, enabling manufacturers to produce intricate designs with ease.

The market has also seen a shift in consumer preferences, moving from standard leather goods to customized and personalized products. This demand has prompted manufacturers to innovate, leading to the development of automated stamping machines that can handle higher volumes while maintaining quality. As a result, the hot stamping leather industry has not only embraced technological advancements but has also adapted to the changing landscape of consumer expectations, positioning itself for continued growth in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of hot stamping leather

-

How do I choose the right supplier for hot stamping leather?

When selecting a supplier for hot stamping leather, consider their experience, product quality, and reputation in the industry. Look for suppliers who specialize in leather products and have a proven track record of meeting international standards. Request samples to evaluate the quality of their leather and stamping techniques. Additionally, check customer reviews and testimonials to gauge reliability. It’s also essential to ensure they can meet your specific customization needs and production timelines. -

What are the key factors to consider when customizing hot stamped leather products?

Customization of hot stamped leather products involves several key factors. First, determine the type of leather suitable for your needs, as different leathers respond differently to hot stamping. Second, consider the design complexity and size of your logo, as this affects the choice of stamping equipment. Temperature control is crucial for achieving clean impressions. Lastly, discuss minimum order quantities (MOQs) with your supplier, as customization often requires a commitment to larger orders. -

What is the minimum order quantity (MOQ) for hot stamping leather?

Minimum order quantities for hot stamping leather can vary widely depending on the supplier and the complexity of the customization. Typically, MOQs can range from 100 to 500 units for standard designs. However, if you require more intricate designs or higher quality materials, the MOQ may increase. Always clarify these details with potential suppliers to ensure they align with your production needs and budget. -

What payment terms should I expect when sourcing hot stamping leather internationally?

When sourcing hot stamping leather internationally, payment terms can vary significantly based on the supplier and your business relationship. Common terms include a 30% deposit upon order confirmation with the remaining balance due before shipment. Some suppliers may offer letters of credit or payment upon delivery for established customers. It’s crucial to negotiate and agree on payment terms that protect both parties and ensure a smooth transaction. -

How can I ensure quality assurance when sourcing hot stamping leather?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request samples and conduct quality checks at different production stages. Consider using third-party inspection services to evaluate the products before shipment. Additionally, maintain open communication with your supplier to address any concerns promptly. A reputable supplier should be willing to provide documentation of their quality control processes. -

What logistics considerations should I keep in mind when importing hot stamping leather?

Logistics play a crucial role in importing hot stamping leather. First, understand the shipping methods available, such as air freight for speed or sea freight for cost-effectiveness. Ensure your supplier can provide the necessary documentation for customs clearance, including invoices and certificates of origin. Additionally, consider insurance for your shipment to mitigate risks. Lastly, be aware of import tariffs and regulations in your country to avoid unexpected costs. -

What types of leather are best suited for hot stamping?

Hot stamping is effective on various types of leather, including chrome-tanned, vegetable-tanned, and suede. Chrome-tanned leather is popular for its durability and ability to hold intricate designs, while vegetable-tanned leather offers a more traditional look. Suede can also be hot stamped, but it requires careful temperature control to avoid damage. Your choice will depend on the intended use of the product and the aesthetic you wish to achieve. -

How do I handle design issues during the hot stamping process?

Design issues during the hot stamping process can arise from improper temperature settings, inconsistent pressure, or unsuitable leather types. To minimize these problems, conduct thorough testing with various leather samples and stamping temperatures. Collaborate closely with your supplier to refine the design and ensure it is compatible with the chosen leather. Regular communication and adjustments during the production run can help achieve the desired results without significant delays.

Top 4 Hot Stamping Leather Manufacturers & Suppliers List

1. Reddit – Stamp Crafting Essentials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Stamps: Two stamps tapped at 8 mm; Gold foil for hot stamping; Electric handle (350 watts); Butcher paper for protection; Wooden table with rubber cutting mat underneath; Vegan leather (20 bucks for 3 pounds of scrap); Heavy Weight Veg-Tan Leather (Sepici Leather 2 LBS Leather Scrap Bags); Big stamp size: 4 in x 5 in; Small stamp size: 2 in x 2.5 in.

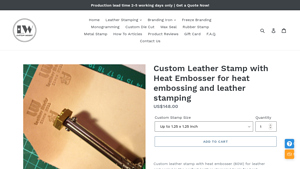

2. LW Leathers – Custom Leather Stamp with Heat Embosser

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Custom Leather Stamp with Heat Embosser”, “regular_price”: “US$148.00”, “custom_stamp_size_options”: [“Up to 1.25 x 1.25 inch”, “Up to 1.5 x 1.5 inch”], “power”: “60W (110V / 220V)”, “temperature_range”: “200-450 °C”, “material”: “Solid Brass”, “design_size_limit”: “up to 10 cm square”, “stamp_thickness”: “8mm”, “engraving_height”: “3mm”, “warranty”: “12 months”, “shipping_time”:…

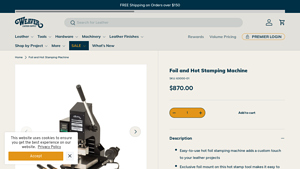

3. Weaver Leather Supply – Hot Foil Leather Stamping Machine

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: {“name”: “Hot Foil Leather Stamping Machine”, “SKU”: “63000-01”, “price”: “$870.00”, “features”: [{“description”: “Easy-to-use hot foil stamping machine adds a custom touch to your leather projects.”}, {“description”: “Exclusive foil mount on this hot stamp tool makes it easy to convey the stamping foil and flips out of the way when not in use.”}, {“description”: “Digital heat control adjusts up t…

4. Infinity Stamps Inc. – Leather Stamping Solutions

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Hot Stamps for Leather – Infinity Stamps Inc. offers a variety of stamping products specifically designed for leather. The product range includes Metal Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, and Steel Type Stamps & Holders. The company emphasizes its commitment to quality, being family-owned for over 25 years and manufacturing in the USA. Customers can contact stamping spec…

Strategic Sourcing Conclusion and Outlook for hot stamping leather

What Are the Key Takeaways for B2B Buyers in Hot Stamping Leather?

As the demand for customized leather goods grows, understanding the nuances of hot stamping leather becomes essential for B2B buyers. This technique not only enhances product aesthetics but also offers branding opportunities that can distinguish your offerings in competitive markets. When sourcing hot stamping solutions, consider the type of leather, the equipment used, and the production volume to ensure consistency and quality. Strategic sourcing of tools, such as variable-temperature electric branding irons, can significantly streamline your production process, allowing for efficient branding across various leather types.

Illustrative image related to hot stamping leather

How Can Strategic Sourcing Impact Your Business?

Emphasizing a strategic sourcing approach will enable you to secure high-quality materials and tools, ultimately leading to superior product offerings. Collaborating with reputable suppliers who understand regional preferences and market trends can further enhance your competitive edge, particularly in emerging markets across Africa, South America, the Middle East, and Europe.

What’s Next for Your Hot Stamping Leather Needs?

As you navigate the evolving landscape of hot stamping leather, prioritize innovation and adaptability in your sourcing strategies. By investing in reliable partners and cutting-edge technologies, you position your business for sustained growth. Embrace this opportunity to elevate your brand and meet the increasing demands of discerning customers. Start sourcing strategically today to unlock the full potential of your leather products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to hot stamping leather