Introduction: Navigating the Global Market for fabric for car roof

The global market for fabric for car roofs presents a unique set of challenges for B2B buyers, particularly when it comes to sourcing materials that meet both aesthetic and functional demands. As automotive interiors evolve, the need for high-quality, durable headliner fabrics becomes increasingly critical, especially in diverse markets across Africa, South America, the Middle East, and Europe. Buyers are tasked with not only finding fabrics that enhance the visual appeal of vehicles but also ensuring they withstand varying climates and conditions.

This comprehensive guide delves into the multifaceted world of automotive headliner fabrics, exploring various types, applications, and key considerations for procurement. From foam-backed materials designed for easy installation to specialized kits that cater to specific vehicle models, we cover a spectrum of options tailored to meet the needs of diverse automotive markets. Additionally, we provide insights into supplier vetting processes, helping you identify reliable partners who can deliver consistent quality and service.

By equipping B2B buyers with actionable insights on cost structures, quality assessments, and market trends, this guide empowers informed purchasing decisions. Whether you are a dealer in Saudi Arabia, an automotive manufacturer in Nigeria, or a supplier in Europe, understanding the dynamics of car roof fabric sourcing will enable you to enhance your offerings and meet customer expectations effectively.

Table Of Contents

- Top 3 Fabric For Car Roof Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric for car roof

- Understanding fabric for car roof Types and Variations

- Key Industrial Applications of fabric for car roof

- 3 Common User Pain Points for ‘fabric for car roof’ & Their Solutions

- Strategic Material Selection Guide for fabric for car roof

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric for car roof

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for car roof’

- Comprehensive Cost and Pricing Analysis for fabric for car roof Sourcing

- Alternatives Analysis: Comparing fabric for car roof With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric for car roof

- Navigating Market Dynamics and Sourcing Trends in the fabric for car roof Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric for car roof

- Strategic Sourcing Conclusion and Outlook for fabric for car roof

- Important Disclaimer & Terms of Use

Understanding fabric for car roof Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Foam-Backed Headliner | Soft, cushioned backing for enhanced comfort and insulation | Automotive upholstery, RVs, boats | Pros: Easy to install, versatile; Cons: May require specific adhesives for best results. |

| Velvet Upholstery Fabric | Luxurious texture and appearance, often used in premium vehicles | High-end automotive restoration | Pros: Aesthetic appeal, durable; Cons: Higher cost, may require special care. |

| Vinyl Headliner Material | Water-resistant, easy to clean, and durable | Fleet vehicles, commercial use | Pros: Cost-effective, low maintenance; Cons: Limited color options, less breathable. |

| Suede-Like Fabric | Soft texture, often used for a premium look | Custom car interiors | Pros: Attractive finish, good insulation; Cons: Requires careful maintenance to avoid staining. |

| Acoustic Foam | Specialized for sound dampening, often used in luxury vehicles | High-end audio vehicles | Pros: Reduces noise, enhances comfort; Cons: Heavier, may increase overall vehicle weight. |

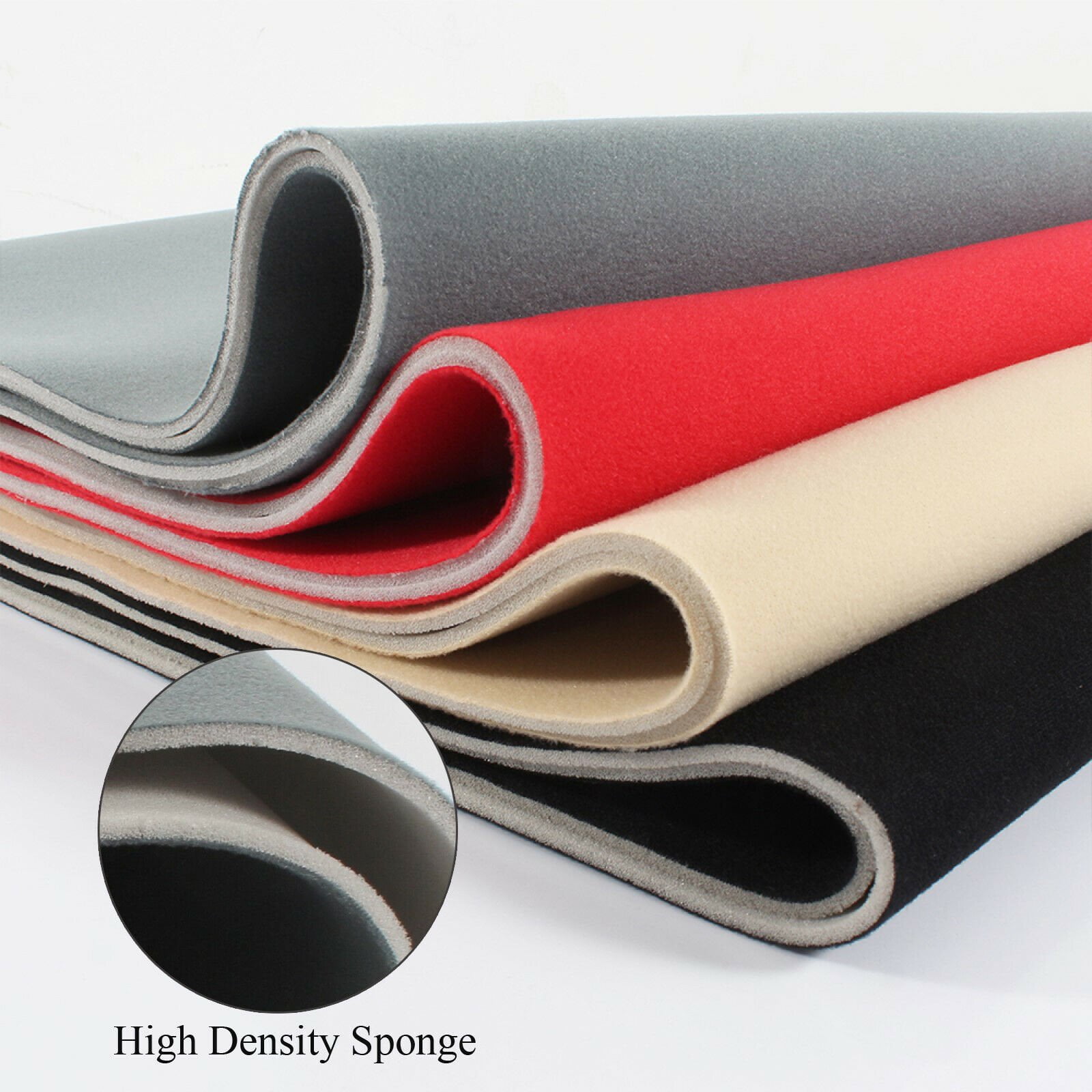

What Are the Key Characteristics of Foam-Backed Headliner Fabrics?

Foam-backed headliner fabrics are designed with a soft backing that provides both comfort and insulation. This type of fabric is ideal for automotive upholstery, RVs, and boats, making it a versatile choice for various vehicle types. When purchasing, buyers should consider the ease of installation and the need for specific adhesives to ensure durability and longevity.

Why Choose Velvet Upholstery Fabric for Premium Applications?

Velvet upholstery fabric is known for its luxurious texture and aesthetic appeal, often found in high-end vehicles. This fabric offers durability and a high-quality finish, making it an excellent choice for automotive restoration projects. B2B buyers should weigh the higher costs against the potential for increased vehicle value and customer satisfaction.

What Are the Benefits of Using Vinyl Headliner Material?

Vinyl headliner material is favored for its water-resistant properties and ease of cleaning, making it suitable for fleet vehicles and commercial use. Its cost-effectiveness and low maintenance requirements are significant advantages for B2B buyers looking to optimize budget and functionality. However, limited color options may restrict design choices.

How Does Suede-Like Fabric Enhance Custom Car Interiors?

Suede-like fabric provides a soft texture and premium appearance, making it a popular choice for custom car interiors. This fabric not only enhances the aesthetic but also offers good insulation properties. Buyers should consider the maintenance requirements, as suede-like fabrics can be susceptible to staining, which may affect long-term durability.

What Role Does Acoustic Foam Play in Vehicle Design?

Acoustic foam is specifically engineered for sound dampening, making it a preferred choice in luxury vehicles where noise reduction is a priority. While it enhances passenger comfort by minimizing external noise, B2B buyers must consider its weight, as it may add to the overall vehicle weight, potentially impacting performance.

Key Industrial Applications of fabric for car roof

| Industry/Sector | Specific Application of fabric for car roof | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom headliner production | Enhances vehicle aesthetics and resale value | Quality, durability, and color options; compliance with safety standards |

| Automotive Repair | Headliner replacement kits | Cost-effective restoration of vehicle interiors | Availability of vehicle-specific sizes and adhesive compatibility |

| Recreational Vehicles | RV and boat interior refurbishment | Improves comfort and appearance for end-users | Weather resistance and UV stability; lightweight materials for ease of installation |

| Automotive Aftermarket | Upholstery for luxury vehicles | Adds premium feel and customization for clients | High-quality fabrics with a variety of textures and colors; sourcing from reliable suppliers |

| Construction and Fleet | Fleet vehicle interior upgrades | Enhances brand image and employee comfort | Bulk purchasing options and durability to withstand wear and tear |

How is Fabric for Car Roof Used in Automotive Manufacturing?

In automotive manufacturing, fabric for car roofs plays a crucial role in producing custom headliners. These fabrics enhance the aesthetic appeal of vehicles, contributing to their overall market value. Manufacturers require high-quality, durable materials that can withstand various environmental conditions while complying with safety regulations. For international buyers, particularly from regions with extreme climates like Africa or the Middle East, sourcing fabrics that resist fading and wear is essential to ensure longevity and customer satisfaction.

What Role Does Fabric Play in Automotive Repair?

Automotive repair shops frequently utilize headliner replacement kits that include foam-backed fabric to restore vehicle interiors. This application is vital for maintaining the functionality and appearance of older vehicles, offering a cost-effective solution for customers. Buyers in this sector should focus on sourcing materials that match specific vehicle models, ensuring a seamless fit. Additionally, compatibility with adhesives and ease of installation are critical considerations for repair professionals looking to optimize their workflow.

How is Fabric Used in Recreational Vehicle and Boat Refurbishment?

In the recreational vehicle (RV) and boating industries, fabric for car roofs is essential for refurbishing interiors. These fabrics not only improve the visual appeal but also enhance user comfort during travel. For buyers in these sectors, it is crucial to select materials that are weather-resistant and UV-stable to withstand outdoor conditions. Lightweight options can facilitate easier installation, making them attractive to manufacturers and repair services focusing on consumer satisfaction.

Why is Fabric Important in the Automotive Aftermarket?

In the automotive aftermarket, upholstery made from high-quality fabric is integral to customizing luxury vehicles. This application allows businesses to offer unique interior designs that cater to consumer preferences, thus enhancing customer loyalty and brand reputation. Buyers should prioritize sourcing fabrics with diverse textures and colors to meet varying client demands. Establishing relationships with reliable suppliers ensures a steady flow of high-grade materials that can elevate the overall vehicle experience.

How Can Fleet Vehicles Benefit from Upgraded Interior Fabrics?

For companies managing fleet vehicles, upgrading interior fabrics can significantly enhance brand image and employee comfort. Investing in durable, easy-to-clean materials can lead to lower maintenance costs and a more professional appearance. When sourcing these fabrics, businesses should consider bulk purchasing options to reduce costs and ensure consistency across their fleet. Selecting materials that can withstand heavy use is also crucial to maintaining a high standard of quality and comfort for drivers and passengers alike.

3 Common User Pain Points for ‘fabric for car roof’ & Their Solutions

Scenario 1: Sourcing Quality Fabric for Diverse Vehicle Models

The Problem: B2B buyers often struggle to find high-quality fabric that fits a wide range of vehicle models. This challenge is particularly pronounced when dealing with older or less common vehicles, where specifications for the fabric may be hard to come by. Additionally, sourcing from multiple suppliers can lead to inconsistencies in quality and color, impacting the overall aesthetics and functionality of the finished product. This inconsistency can be frustrating, especially when buyers are under pressure to meet customer demands quickly.

The Solution: To effectively source quality fabric for car roofs, buyers should prioritize suppliers that offer customizable headliner fabric replacement kits. These kits are typically tailored to specific vehicle models and come in a variety of colors and textures. When selecting a supplier, look for those that provide detailed product specifications and sample options. Requesting free samples allows you to compare fabrics directly with your vehicle’s interior, ensuring a perfect match. Establishing relationships with suppliers who specialize in automotive upholstery will also streamline the sourcing process and help you gain insights into upcoming trends or materials that may suit your needs.

Scenario 2: Managing Installation Challenges for Upholstery Projects

The Problem: Many B2B buyers face difficulties when it comes to the installation of roof fabric in vehicles. The challenges can range from choosing the right adhesive to ensuring a smooth application without wrinkles or air bubbles. These issues can lead to increased labor costs, project delays, and unsatisfactory results, which ultimately affect client satisfaction. Furthermore, lack of proper installation knowledge can result in rework or damage to the vehicle’s interior, compounding the costs.

Illustrative image related to fabric for car roof

The Solution: To mitigate installation challenges, buyers should invest in comprehensive training for their upholstery teams. This includes understanding the best practices for applying foam-backed fabrics and using the right adhesives. Suppliers often provide installation guides or training sessions that can be immensely beneficial. Additionally, using high-quality, heat-resistant adhesive specifically designed for automotive applications can significantly improve the outcome. Consider investing in tools like roller applicators to smooth out the fabric during installation, which can help prevent air bubbles and ensure a tight fit. Ensuring that your team is well-trained and equipped can lead to faster, cleaner installations and higher quality finishes.

Scenario 3: Dealing with Environmental Conditions Affecting Fabric Durability

The Problem: Buyers in regions with extreme weather conditions—such as high temperatures, humidity, or heavy rainfall—often find that the durability of car roof fabrics is a significant concern. Fabrics that are not adequately resistant to these environmental factors can lead to fading, peeling, or mold growth, which compromises the vehicle’s interior and the buyer’s reputation. This issue is particularly pertinent for businesses operating in markets like Africa or South America, where climate conditions can vary dramatically across regions.

The Solution: To address durability concerns, it is critical to select fabrics specifically designed for automotive use that offer resistance to UV rays, moisture, and temperature fluctuations. Look for fabrics that have been treated with protective coatings or are made from synthetic fibers known for their resilience. Additionally, suppliers that provide clear labeling regarding the fabric’s resistance capabilities can be invaluable. Incorporating regular maintenance and care instructions for end-users can also prolong the life of the fabric. Educating customers about the importance of protective measures, such as using sunshades or parking in shaded areas, can help mitigate environmental impacts and enhance customer satisfaction.

Strategic Material Selection Guide for fabric for car roof

When selecting fabrics for car roofs, several materials stand out due to their unique properties and suitability for various applications. This guide analyzes four common materials: polyester, vinyl, nylon, and cotton blends. Each material is evaluated based on key properties, advantages and disadvantages, and considerations for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyester for Car Roof Fabrics?

Polyester is a synthetic fabric known for its excellent durability and resistance to shrinking and stretching. It has a high temperature tolerance, making it suitable for various climates, including the heat of the Middle East and the humidity of South America. Polyester is also resistant to mildew and fading, which is essential for maintaining the aesthetic appeal of car interiors.

Pros: Polyester is relatively cost-effective and easy to manufacture, allowing for mass production. Its lightweight nature contributes to fuel efficiency in vehicles.

Cons: While durable, polyester can be less breathable compared to natural fabrics, which may affect comfort in hotter climates.

Impact on Application: Polyester can be treated with additional coatings for enhanced UV resistance, making it compatible with various automotive applications.

Illustrative image related to fabric for car roof

Considerations for International Buyers: Compliance with international standards such as ASTM for textile performance is crucial. Buyers should also consider the local climate, as polyester may not be ideal for extremely humid environments without proper treatment.

Why Choose Vinyl for Automotive Roof Fabrics?

Vinyl is a versatile and waterproof material often used in automotive applications. It offers excellent resistance to moisture, making it ideal for regions with high rainfall or humidity. Vinyl also has a high tolerance for temperature fluctuations, ensuring it maintains its integrity in diverse climates.

Pros: Vinyl is easy to clean and maintain, making it a popular choice for car interiors. Its durability against wear and tear is another significant advantage.

Illustrative image related to fabric for car roof

Cons: The primary drawback of vinyl is its tendency to become brittle over time, especially when exposed to extreme temperatures. Additionally, it can be less breathable, potentially leading to discomfort in hot weather.

Impact on Application: Vinyl can be used in a variety of automotive settings, including headliners and upholstery, but may require specific adhesives for installation.

Considerations for International Buyers: Buyers should ensure that the vinyl meets local and international safety standards, as well as consider the environmental impact of vinyl production and disposal.

What Advantages Does Nylon Offer for Car Roof Fabrics?

Nylon is another synthetic fabric that is known for its strength and elasticity. It has excellent abrasion resistance, making it suitable for high-wear areas in vehicles. Nylon also performs well in various temperatures, retaining its shape and integrity.

Pros: The elasticity of nylon allows it to stretch without losing its original shape, making it ideal for custom applications. It also has good resistance to chemicals and oils, which is beneficial in automotive environments.

Cons: Nylon can be more expensive than other synthetic options, which may deter budget-conscious buyers. Its susceptibility to UV damage can also limit its lifespan if not treated properly.

Impact on Application: Nylon is compatible with various automotive finishes and can be used in headliners and other interior applications.

Considerations for International Buyers: Buyers should consider the availability of nylon in their region and ensure compliance with relevant textile standards.

How Do Cotton Blends Compare for Car Roof Fabrics?

Cotton blends, often mixed with synthetic fibers, offer a natural feel combined with improved durability. They are breathable and comfortable, making them suitable for various climates, especially in hotter regions.

Illustrative image related to fabric for car roof

Pros: Cotton blends provide excellent comfort and aesthetic appeal, often preferred for luxury vehicles. They can also be treated for water resistance, enhancing their usability.

Cons: Cotton blends may not be as durable as synthetic options, particularly in terms of resistance to fading and mildew. They may also require more maintenance to keep them looking fresh.

Impact on Application: Cotton blends are suitable for upscale automotive interiors but may not be ideal for all climates without proper treatment.

Considerations for International Buyers: Buyers should ensure that cotton blends meet local environmental and safety standards, especially regarding pesticide use in cotton production.

Summary Table of Material Selection for Car Roof Fabrics

| Material | Typical Use Case for fabric for car roof | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General automotive interiors | Durable and resistant to mildew | Less breathable | Medium |

| Vinyl | Waterproof automotive upholstery | Easy to clean and maintain | Can become brittle over time | Medium |

| Nylon | High-wear automotive applications | Strong and elastic | Higher cost and UV susceptibility | High |

| Cotton Blends | Luxury automotive interiors | Comfortable and aesthetically pleasing | Less durable and requires maintenance | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with regional preferences and standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric for car roof

What Are the Main Stages of Manufacturing Fabric for Car Roofs?

The manufacturing process of fabric for car roofs involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages is vital for B2B buyers looking to source high-quality automotive fabrics.

Material Preparation: How Are Raw Materials Processed?

The first stage in manufacturing car roof fabric is material preparation. This involves selecting high-quality fibers—often polyester or nylon—that offer durability, resistance to environmental factors, and aesthetic appeal. The selected fibers are subjected to various treatments, such as dyeing and finishing, to enhance their properties. Buyers should inquire about the sourcing of these materials, as quality can vary significantly. Sustainable practices in material sourcing can also be a selling point for many buyers.

Illustrative image related to fabric for car roof

Forming: What Techniques Are Used to Shape the Fabric?

In the forming stage, the prepared materials are transformed into the desired fabric structure. Techniques such as weaving or knitting are commonly employed, depending on the specific requirements of the car roof fabric. Foam backing is often added during this stage to provide insulation and sound deadening properties. B2B buyers should consider the manufacturing techniques used, as these impact the fabric’s performance and suitability for various automotive applications.

Assembly: How Is the Fabric Constructed for Specific Applications?

Once the fabric is formed, it enters the assembly phase. This involves cutting the fabric into appropriate shapes and sizes to fit specific vehicle models. Manufacturers often offer custom solutions to meet the unique needs of different automotive brands. For buyers, understanding the assembly process can help ensure that the fabric they procure will fit seamlessly in the intended application.

Finishing: What Treatments Are Applied for Quality and Durability?

The final stage of manufacturing is finishing, where additional treatments are applied to enhance the fabric’s performance. This can include water repellency, UV protection, and flame retardant treatments. Quality finishing processes ensure the fabric can withstand the rigors of automotive use, such as temperature fluctuations and exposure to sunlight. Buyers should inquire about the specific finishing processes used and their impact on longevity and maintenance.

What Quality Assurance Measures Are Essential for Automotive Fabrics?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for automotive applications where safety and durability are paramount. International and industry-specific standards guide these QA measures.

Which International Standards Should B2B Buyers Be Aware Of?

One of the key international standards relevant to automotive fabrics is ISO 9001, which focuses on quality management systems. Compliance with this standard indicates that a manufacturer has established processes to consistently deliver quality products. Additionally, industry-specific certifications, such as CE marking for safety and environmental compliance, and API standards for automotive components, can further assure buyers of the product’s quality.

What Are the Key Quality Control Checkpoints in Fabric Manufacturing?

Quality control in the manufacturing process typically involves several checkpoints:

-

Incoming Quality Control (IQC): This is the initial inspection of raw materials upon arrival at the manufacturing facility. Ensuring that materials meet specified standards is crucial for the overall quality of the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to ensure that each stage adheres to quality standards. This includes monitoring the forming and assembly processes to catch any deviations early.

-

Final Quality Control (FQC): Once the fabric is completed, a final inspection is conducted to assess its overall quality, including dimensional accuracy and compliance with specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure they are sourcing high-quality automotive fabrics. Here are several methods to conduct this verification:

What Auditing Options Are Available for Buyers?

Audits are a critical tool for assessing a supplier’s manufacturing capabilities and quality control practices. Buyers can request third-party audits to obtain an unbiased evaluation of the supplier’s processes and compliance with international standards. This is particularly important for buyers from regions like Africa, South America, the Middle East, and Europe, where local regulations may differ.

How Can Buyers Use Quality Reports for Supplier Evaluation?

Requesting detailed quality reports from suppliers can provide insights into their quality assurance processes. These reports should include data on material sourcing, testing results, and compliance with relevant standards. Buyers should look for transparency in these reports, which can indicate a supplier’s commitment to quality.

What Role Do Third-Party Inspections Play?

Third-party inspections serve as an additional layer of quality assurance. These inspections can be scheduled at various stages of the manufacturing process, providing buyers with peace of mind regarding the quality of the fabric they are sourcing. It is advisable for buyers to establish relationships with reputable inspection agencies to facilitate this process.

What Are the Unique QC Considerations for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality control. Differences in regulations, standards, and quality expectations can impact sourcing decisions.

How Do Regional Standards Affect Sourcing Decisions?

B2B buyers should be aware of the specific regulations and quality standards applicable in their regions. For example, automotive fabrics sold in the European market must meet stringent environmental and safety standards, while buyers in Africa and South America may face different compliance requirements. Understanding these regional differences is essential for effective sourcing.

What Are the Best Practices for Ensuring Consistent Quality Across Borders?

To ensure consistent quality when sourcing internationally, buyers should establish clear communication channels with suppliers. This includes discussing quality expectations upfront and setting up regular check-ins throughout the manufacturing process. Additionally, leveraging technology for real-time tracking and quality monitoring can enhance transparency and accountability.

In conclusion, the manufacturing processes and quality assurance measures for fabric used in car roofs are complex and multifaceted. By understanding these elements, B2B buyers can make informed decisions that align with their quality standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric for car roof’

The following guide is designed to assist B2B buyers in effectively sourcing fabric for car roofs. By following this step-by-step checklist, you can ensure that your procurement process is thorough, efficient, and tailored to your specific needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications for the fabric you require. Consider factors such as durability, weight, texture, and color options. This step is vital as it ensures that the selected fabric meets the functional and aesthetic needs of the automotive application.

- Durability: Look for fabrics that can withstand various environmental conditions, including UV exposure and temperature fluctuations.

- Weight and Texture: Ensure the fabric is lightweight yet robust, facilitating easy installation while maintaining a high-quality finish.

Step 2: Research Available Fabric Types

Familiarize yourself with the different types of fabrics suitable for car roofs, such as foam-backed headliners and specialized automotive upholstery materials. Understanding the characteristics of each type will help you make informed decisions that align with your project’s requirements.

- Foam-Backed Fabrics: These are ideal for sound absorption and insulation, enhancing the overall comfort of the vehicle.

- Color and Design Options: Assess the variety of colors and patterns available, as this can significantly impact the vehicle’s interior aesthetics.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure reliability and quality. Look for suppliers with a proven track record in the automotive sector and request case studies or references from similar businesses.

Illustrative image related to fabric for car roof

- Company Reputation: Check online reviews and testimonials to gauge the supplier’s credibility and service quality.

- Sample Requests: Always request fabric samples to assess the quality and suitability before making bulk orders.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you consider have the necessary certifications, such as ISO or industry-specific quality standards. This validation is crucial to guarantee that the fabric meets safety and performance regulations.

- Environmental Compliance: Check if the fabrics are sourced sustainably and comply with environmental regulations, which is increasingly important for international trade.

- Material Safety: Confirm that the materials used are free from harmful substances, ensuring safety for end-users.

Step 5: Negotiate Pricing and Terms

Once you have narrowed down your options, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Being informed about the market rates can empower you during this phase.

- Bulk Discounts: Inquire about pricing for larger orders, as many suppliers offer discounts for bulk purchases.

- Payment Flexibility: Discuss payment terms that suit your cash flow, such as net 30 or net 60 options.

Step 6: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the fabric once it arrives. This step is essential to verify that the materials meet the agreed-upon specifications and standards.

- Inspection Protocols: Develop a checklist for inspecting the fabric upon arrival, including checks for defects and color consistency.

- Feedback Loop: Create a system for providing feedback to the supplier to address any issues promptly and maintain a strong relationship.

Step 7: Plan for Future Sourcing Needs

As your business grows, consider establishing a long-term relationship with your chosen supplier. Planning for future needs can lead to better pricing and priority service.

Illustrative image related to fabric for car roof

- Supplier Development: Engage in discussions about potential future projects to align your sourcing strategy with supplier capabilities.

- Market Trends: Stay informed about emerging trends in automotive fabrics to adapt your sourcing strategy accordingly.

By following this checklist, B2B buyers can navigate the complexities of sourcing fabric for car roofs effectively, ensuring a successful procurement process that meets both quality and budgetary requirements.

Comprehensive Cost and Pricing Analysis for fabric for car roof Sourcing

What Are the Key Cost Components in Sourcing Car Roof Fabrics?

When sourcing fabrics for car roofs, various cost components must be considered to form a comprehensive cost structure. The primary components include:

-

Materials: The type of fabric chosen—whether foam-backed headliner materials or specialized automotive fabrics—will significantly influence costs. High-quality, durable fabrics that meet automotive standards typically command higher prices.

-

Labor: Labor costs are incurred during the manufacturing process, which can vary based on the complexity of the fabric production and the skill level of the workforce. In regions where labor is more affordable, such as parts of South America and Africa, overall costs may be lower.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and administrative expenses. Factories with modern equipment and streamlined processes may have lower overhead costs, contributing to overall cost efficiency.

-

Tooling: Initial tooling costs can be significant, especially for customized fabric designs or sizes. These costs are often amortized over larger production runs, making it essential for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring the fabric meets industry standards requires a quality assurance process, which adds to the overall cost. Rigorous QC can prevent costly returns and rework.

-

Logistics: Shipping and handling costs vary widely based on the geographical location of the supplier and the buyer. International shipping may involve customs duties and tariffs, particularly for buyers in regions like the Middle East or Africa.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition, supplier reputation, and buyer relationships.

How Do Price Influencers Affect the Cost of Car Roof Fabrics?

Several factors can influence the pricing of car roof fabrics, including:

-

Volume/MOQ: Bulk orders often lead to significant cost savings. Suppliers are generally more willing to offer discounts for larger quantities, making it advantageous for businesses to consolidate orders.

-

Specifications and Customization: Custom fabrics tailored to specific vehicle models or unique designs will typically incur higher costs. Buyers should evaluate whether customization is necessary or if standard options suffice.

-

Materials and Quality Certifications: Fabrics that are certified for automotive use, such as those resistant to UV light and wear, tend to be more expensive. Buyers should weigh the long-term benefits of investing in high-quality materials against initial costs.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers with a proven track record may charge higher prices but can offer better service, quality assurance, and timely delivery.

-

Incoterms: The terms of shipping and delivery (Incoterms) can affect total costs. Buyers should be aware of who is responsible for shipping costs, insurance, and customs duties to avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Car Roof Fabrics?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, can adopt several strategies to optimize their sourcing process:

-

Negotiate Effectively: Engage suppliers in discussions regarding pricing, especially for larger orders. Building a strong relationship may lead to better terms and discounts.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess factors like durability, maintenance, and potential rework costs. A higher upfront investment in quality fabric may result in lower TCO.

-

Understand Pricing Nuances: Recognize that prices may vary based on regional economic conditions, currency fluctuations, and local demand. Stay informed about market trends to make educated purchasing decisions.

-

Request Samples: Before committing to a large order, request samples to assess fabric quality, color accuracy, and suitability for your specific applications. This step can prevent costly mistakes.

-

Evaluate Logistics Options: Compare shipping options, timelines, and costs from different suppliers. Consider local suppliers to reduce logistics costs and simplify supply chain management.

Disclaimer on Pricing

Prices for car roof fabrics are subject to fluctuations based on market conditions, material availability, and economic factors. It is advisable for buyers to conduct thorough market research and obtain updated quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing fabric for car roof With Other Solutions

Introduction: Exploring Alternatives to Fabric for Car Roofs

When considering solutions for car roof upholstery, it’s essential to evaluate various materials and technologies that can meet the specific needs of automotive interiors. While traditional fabric remains a popular choice due to its aesthetic appeal and versatility, alternative solutions such as vinyl, synthetic leather, and headliner kits offer distinct advantages and disadvantages. This analysis will compare these options, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Fabric For Car Roof | Vinyl Upholstery | Synthetic Leather |

|---|---|---|---|

| Performance | Good durability; breathable | Highly durable; water-resistant | Durable; good aesthetic appeal |

| Cost | Moderate pricing | Generally lower cost | Higher cost than vinyl but lower than real leather |

| Ease of Implementation | Requires skilled labor for installation | Easy to install; can be self-applied | Requires skilled labor for installation |

| Maintenance | Requires periodic cleaning | Easy to wipe clean | Easy to maintain; resistant to stains |

| Best Use Case | Custom restorations; luxury vehicles | Budget-friendly restorations | High-end vehicles; luxury applications |

Detailed Breakdown of Alternatives

Vinyl Upholstery

Vinyl is a popular alternative to fabric for car roofs, known for its durability and water resistance. It is often more cost-effective than traditional fabric, making it a suitable choice for budget-conscious buyers. The installation of vinyl is relatively straightforward, allowing for DIY applications. However, it may not provide the same level of breathability and comfort as fabric, which can be a drawback in warmer climates. Vinyl is best suited for budget restorations and vehicles where durability is prioritized over luxury.

Synthetic Leather

Synthetic leather, or faux leather, offers a balance of aesthetics and durability. It mimics the appearance of genuine leather while being more affordable and easier to maintain. This material is resistant to stains and can withstand wear and tear, making it ideal for high-end vehicles that require a sophisticated look without the associated costs of real leather. However, the installation process can be complex, often requiring professional help. Synthetic leather is best for luxury applications where visual appeal is paramount, but the higher initial cost may deter some buyers.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right material for car roof upholstery, B2B buyers should carefully assess their specific requirements, including budget constraints, desired aesthetics, and durability needs. Traditional fabric may be ideal for custom restorations in luxury vehicles, while vinyl serves well in budget-friendly applications. Synthetic leather strikes a balance between luxury and practicality but may require a higher investment. By understanding the strengths and weaknesses of each alternative, buyers can make an informed decision that aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for fabric for car roof

What Are the Key Technical Properties of Fabric Used for Car Roofs?

When selecting fabric for car roofs, several critical technical properties should be considered to ensure durability, performance, and aesthetic appeal. Understanding these properties is essential for B2B buyers to make informed purchasing decisions.

-

Material Grade

The material grade refers to the quality and type of fabric used in headliners, typically including polyester, nylon, or blends. High-grade materials offer superior durability, resistance to fading, and improved insulation properties. B2B buyers should prioritize high-quality materials to enhance the longevity of their products, especially in regions with extreme weather conditions. -

Foam Backing

Many automotive headliner fabrics come with a foam backing, which adds cushioning and structural support. This backing improves sound insulation and enhances the overall comfort of the vehicle interior. Buyers should assess the density and thickness of the foam to ensure it meets their specific needs, as a higher density usually translates to better performance and longevity. -

UV Resistance

UV resistance is a critical property for automotive fabrics, particularly in regions with high sun exposure. Fabrics treated with UV inhibitors can withstand prolonged sunlight without degrading or discoloring. B2B buyers should verify UV resistance ratings to ensure the fabric maintains its appearance and functionality over time. -

Flame Retardancy

Safety is paramount in automotive applications, and flame retardant fabrics help mitigate fire risks. Fabrics that meet industry standards for flame resistance provide an added layer of security for vehicle occupants. Buyers should seek certifications that confirm compliance with relevant safety regulations, especially when supplying to markets with stringent safety requirements. -

Colorfastness

Colorfastness refers to the ability of the fabric to retain its color when exposed to washing, light, and other environmental factors. Fabrics with high colorfastness ratings will maintain their aesthetic appeal longer, which is crucial for customer satisfaction and brand reputation. Buyers should inquire about colorfastness testing results to ensure their chosen fabrics will meet long-term performance expectations. -

Tensile Strength

Tensile strength measures the fabric’s resistance to being pulled apart. A higher tensile strength indicates a more durable fabric that can withstand wear and tear. This property is particularly important for automotive applications where the fabric will experience stress from everyday use. Buyers should consider tensile strength specifications to ensure they select materials that can endure the rigors of automotive environments.

What Are Common Trade Terms in the Automotive Fabric Industry?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms related to automotive fabrics.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of automotive fabrics, it signifies materials that are made to the specifications of a vehicle manufacturer. Buyers should ensure that the fabrics they source meet OEM standards for compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for buyers to understand their purchasing commitments and budget constraints. Suppliers often set MOQs to ensure profitability, so buyers should clarify these terms upfront to avoid unexpected costs. -

RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to potential suppliers requesting price estimates for specific products or services. This process helps buyers compare options and negotiate terms effectively. Including detailed specifications in an RFQ can lead to more accurate quotes and better supplier responses. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery responsibilities, which is critical when sourcing fabrics from international suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for buyers to manage inventory and production schedules effectively. Suppliers should provide clear lead time estimates to help buyers plan accordingly. -

Color Match

Color match refers to the process of ensuring that fabric colors are consistent with a specific design or vehicle interior. This term is essential for buyers looking to maintain brand consistency and aesthetic appeal. Requesting color samples and utilizing color matching services can help achieve the desired results.

Navigating Market Dynamics and Sourcing Trends in the fabric for car roof Sector

What Are the Current Market Dynamics and Key Trends in the Fabric for Car Roof Sector?

The global fabric for car roof market is witnessing a transformative phase driven by several factors. Increased consumer demand for vehicle customization and interior aesthetics is pushing automotive manufacturers and suppliers to explore a diverse range of headliner fabrics. Key trends include the growing popularity of foam-backed headliners, which offer enhanced durability and ease of installation, making them attractive for both manufacturers and end-users. Additionally, the rise of e-commerce platforms is reshaping the sourcing landscape, allowing international B2B buyers from regions such as Africa, South America, the Middle East, and Europe to access a broader selection of automotive fabrics directly from manufacturers.

Technological advancements are also influencing sourcing strategies. Innovations in fabric production, such as digital printing and advanced textile treatments, are enabling suppliers to offer customized solutions that meet specific client requirements. Moreover, the increasing importance of local sourcing in response to supply chain disruptions has led buyers to seek partnerships with regional suppliers who can provide timely deliveries and reduce lead times.

How Is Sustainability and Ethical Sourcing Impacting the Fabric for Car Roof Market?

Sustainability is becoming a critical consideration for B2B buyers in the automotive fabric sector. As consumers and manufacturers alike become more environmentally conscious, the demand for sustainable materials is rising. The fabric for car roof suppliers are increasingly turning to eco-friendly textiles and processes, such as organic cotton, recycled polyester, and low-impact dyes. These materials not only reduce environmental impact but also enhance brand reputation.

Ethical sourcing practices are also gaining traction. Buyers are now prioritizing suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are essential for ensuring that sourced materials meet environmental and social criteria. This shift not only helps mitigate risks associated with unethical practices but also aligns with the growing consumer preference for brands that demonstrate corporate social responsibility.

What Is the Brief Evolution of the Fabric for Car Roof Sector?

The fabric for car roof sector has evolved significantly over the past few decades. Initially dominated by basic materials, the industry has transitioned towards more sophisticated fabrics that offer enhanced functionality, aesthetics, and comfort. The introduction of foam-backed headliner fabrics in the 1990s marked a pivotal moment, providing better insulation and durability.

In recent years, the focus has shifted toward customization and sustainability, reflecting broader trends in consumer behavior and corporate responsibility. As the automotive industry continues to innovate, the fabric for car roof sector is expected to expand further, integrating advanced materials and sustainable practices to meet the evolving demands of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric for car roof

-

How do I choose the right fabric for car roofs?

Selecting the appropriate fabric for car roofs involves considering factors such as durability, weight, and appearance. Look for materials that are UV resistant, water-repellent, and easy to clean. Foam-backed headliners are popular for their cushioning properties, providing comfort and sound insulation. Additionally, evaluate color options to ensure compatibility with the vehicle’s interior. Requesting samples can help you assess the quality and feel of the fabric before making a bulk purchase. -

What is the best type of fabric for automotive headliners?

The best type of fabric for automotive headliners is typically a foam-backed material that offers durability and ease of installation. Common choices include polyester and nylon blends, which provide good resistance to wear and tear. These fabrics are designed to withstand temperature variations and moisture, ensuring longevity. When selecting a fabric, also consider the specific vehicle model and the intended use, whether for repairs or custom installations. -

What are the typical minimum order quantities (MOQs) for car roof fabrics?

Minimum order quantities (MOQs) for car roof fabrics can vary significantly between suppliers. Generally, MOQs may range from 10 to 100 yards, depending on the manufacturer and the specific fabric type. It’s essential to discuss your requirements with potential suppliers to negotiate MOQs that align with your business needs. Establishing a good relationship with suppliers can also lead to more favorable terms on future orders. -

How can I ensure quality assurance (QA) when sourcing fabrics?

To ensure quality assurance when sourcing fabrics, conduct thorough vetting of suppliers. Request certifications that demonstrate compliance with industry standards, such as ISO or ASTM. It’s advisable to ask for samples to assess the fabric’s quality firsthand. Additionally, consider setting up a quality control process that includes inspections during production and before shipment to verify that the fabrics meet your specifications. -

What payment terms should I expect when sourcing internationally?

Payment terms for international fabric sourcing often include options like advance payment, letters of credit, or payment upon delivery. Standard practices may require a deposit (30-50%) at the time of order confirmation, with the balance due before shipment. Ensure you discuss and agree upon payment terms upfront to avoid misunderstandings. Also, consider using secure payment methods that provide buyer protection to mitigate risks. -

How do I handle logistics and shipping for fabric orders?

Handling logistics and shipping for fabric orders involves planning and coordination with your supplier. Discuss shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Ensure you understand the incoterms (like FOB or CIF) that govern the shipping process. It’s also crucial to factor in customs duties and regulations specific to your country to avoid delays in delivery. -

What customization options are available for car roof fabrics?

Many suppliers offer customization options for car roof fabrics, including color matching, printing, and specific sizing to fit different vehicle models. You may also be able to request unique textures or patterns to align with your brand identity. Discuss your specific needs with suppliers to determine what customization services they can provide, as this can enhance the value of your offerings in the market. -

How can I find reliable suppliers for car roof fabrics?

To find reliable suppliers for car roof fabrics, leverage online platforms like trade directories, industry-specific websites, and trade shows. Networking within industry associations can also yield valuable leads. Evaluate potential suppliers based on their experience, customer reviews, and product offerings. Conducting site visits or requesting references can further validate their reliability and quality standards, ensuring you partner with trustworthy manufacturers.

Top 3 Fabric For Car Roof Manufacturers & Suppliers List

1. Fabric Warehouse – Foam-Backed Vinyl Fabric Headliner

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Automotive Headliners available in various colors and materials. Key products include: 1. Foam-Backed Vinyl Fabric Headliner in Black – 1/32″ Thick, 54″ Wide, priced from $19.98. 2. Foam-Backed Vinyl Fabric Headliner in Light Grey – 1/32″ Thick, 54″ Wide, priced from $19.98. 3. Arctic Whisper Beige Foam-Backed Fabric Headliner – 1/8th Thick, 60″ Wide, priced from $21.98. 4. Lyric Light Sandstone F…

2. MooN Auto Tops – Headliner Fabric Replacement Kits

Domain: moonautotops.com

Registered: 2014 (11 years)

Introduction: Headliner Fabric Replacement Kits are designed to replace the old fabric on your vehicle’s original headliner board. Each kit is cut as a single roll of foam-backed material, specifically sized to fit various vehicle models. Available in a wide selection of colors, free color samples can be requested to compare against your vehicle’s interior. Compatible manufacturers include Acura, Buick, Cadilla…

3. Reddit – Super 77 Spray Adhesive

Strategic Sourcing Conclusion and Outlook for fabric for car roof

In the evolving landscape of automotive upholstery, strategic sourcing of fabric for car roofs presents significant opportunities for international B2B buyers. Key takeaways include the importance of selecting high-quality, durable materials that not only enhance aesthetics but also provide functionality such as sound insulation and heat resistance. Suppliers offering customized solutions, such as foam-backed headliner kits tailored to specific vehicle models, are invaluable for businesses looking to streamline their operations and meet diverse customer needs.

As the demand for vehicle interior renovations grows in regions like Africa, South America, the Middle East, and Europe, it is essential for buyers to forge strong partnerships with reliable fabric suppliers. This strategic collaboration can lead to cost savings, improved product quality, and faster turnaround times, ultimately enhancing customer satisfaction and loyalty.

Looking ahead, the market for automotive fabrics will continue to expand, driven by trends in sustainability and personalization. Now is the time for B2B buyers to assess their sourcing strategies and explore innovative fabric solutions that align with their business goals. Engage with trusted suppliers today to stay ahead in this competitive industry and elevate your automotive offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to fabric for car roof

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.