Introduction: Navigating the Global Market for alcantara fabric roll

In the fast-evolving landscape of the global textile market, sourcing Alcantara fabric rolls presents a unique challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. This premium fabric, renowned for its luxurious feel and versatility, is increasingly sought after in automotive, fashion, and interior design sectors. However, navigating the complexities of supply chains, quality standards, and pricing can be daunting.

This comprehensive guide delves into the various types of Alcantara fabric rolls available, including unbacked, backed, multilayer, and outdoor options, alongside their specific applications across industries. We will provide insights on how to effectively vet suppliers to ensure authenticity and quality, as well as strategies for negotiating costs to maximize value. By equipping international buyers with the knowledge to make informed purchasing decisions, this guide serves as a critical resource for those looking to integrate Alcantara into their product offerings.

Whether you are a manufacturer seeking high-performance textiles or a designer looking to elevate your creations, understanding the nuances of Alcantara fabric rolls will empower you to secure the best options tailored to your needs. Embrace the luxury and functionality of Alcantara while navigating the global market with confidence.

Table Of Contents

- Top 7 Alcantara Fabric Roll Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara fabric roll

- Understanding alcantara fabric roll Types and Variations

- Key Industrial Applications of alcantara fabric roll

- 3 Common User Pain Points for ‘alcantara fabric roll’ & Their Solutions

- Strategic Material Selection Guide for alcantara fabric roll

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric roll

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric roll’

- Comprehensive Cost and Pricing Analysis for alcantara fabric roll Sourcing

- Alternatives Analysis: Comparing alcantara fabric roll With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara fabric roll

- Navigating Market Dynamics and Sourcing Trends in the alcantara fabric roll Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric roll

- Strategic Sourcing Conclusion and Outlook for alcantara fabric roll

- Important Disclaimer & Terms of Use

Understanding alcantara fabric roll Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Panel | Unbacked, lightweight, and highly workable fabric | Vehicle headliners, door panels, dashboards | Pros: Lightweight, flexible; Cons: Less durable compared to backed options. |

| Alcantara Cover | Backed with a laminated 65/35 Poly Cotton scrim | Automotive seats, high-wear areas | Pros: Enhanced durability; Cons: Slightly heavier than unbacked options. |

| Alcantara Multilayer | Soft lamination for added thickness, stretchable in one direction | Steering wheels, car seats | Pros: Good grip and stretch; Cons: Limited to specific applications. |

| Alcantara EXO | Water-repellent and UV-resistant properties | Outdoor furniture, marine upholstery, motorcycle seats | Pros: Durable for outdoor use; Cons: Higher cost due to specialized treatment. |

| Alcantara Avant | Fire-rated with burn certifications available | Aviation interiors, high-risk environments | Pros: Meets safety regulations; Cons: May have longer lead times for certification. |

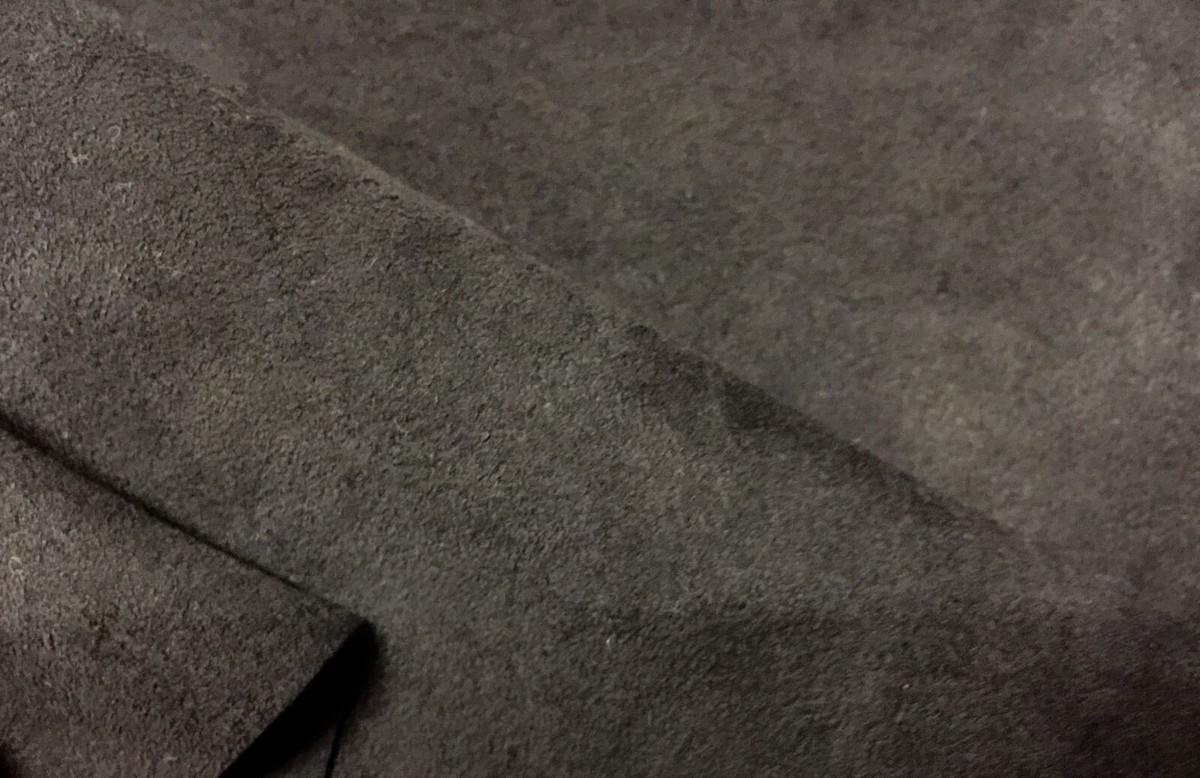

What Are the Characteristics of Alcantara Panel Fabric Rolls?

Alcantara Panel fabric is an unbacked, lightweight textile that offers exceptional workability. It is particularly suitable for applications where flexibility and stretch are essential, such as vehicle headliners, door panels, and dashboards. This type is favored in the automotive industry for its aesthetic appeal and ease of installation. However, buyers should consider its lower durability compared to backed fabrics, making it less ideal for high-wear areas.

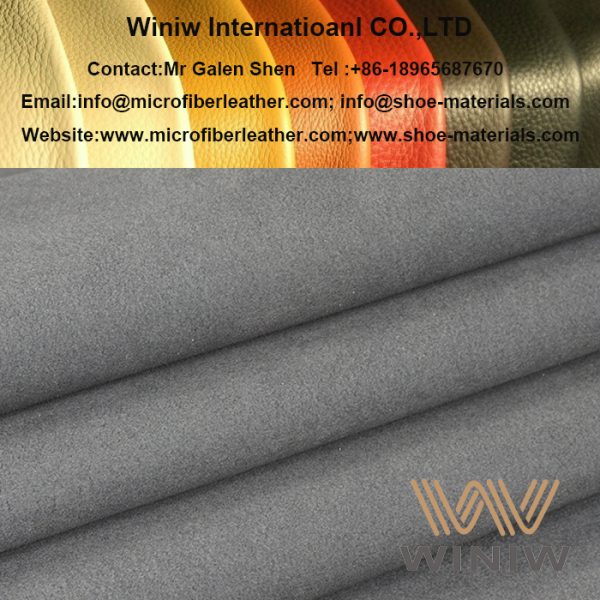

Illustrative image related to alcantara fabric roll

How Does Alcantara Cover Enhance Durability in Automotive Applications?

Alcantara Cover features a laminated backing of 65/35 Poly Cotton, significantly enhancing its strength and durability. This type is primarily used in automotive seats and other areas subject to frequent use. The backing provides additional resistance to wear and tear, making it an excellent choice for high-traffic environments. While it offers superior durability, buyers should be aware that it is slightly heavier than unbacked options, which may affect application methods.

Why Choose Alcantara Multilayer for Specialized Automotive Needs?

Alcantara Multilayer is designed with a soft lamination that allows for one-directional stretch, making it ideal for steering wheels and car seats. This type provides excellent grip and comfort, essential for performance-oriented automotive applications. While it excels in specific uses, its limited versatility may restrict its appeal to broader markets, which buyers should consider when making procurement decisions.

What Makes Alcantara EXO Suitable for Outdoor Applications?

Alcantara EXO is engineered for outdoor use, featuring water-repellent and UV-resistant properties. It is commonly utilized in marine upholstery, outdoor furniture, and motorcycle seats, where exposure to the elements is a concern. While this fabric offers remarkable durability for such applications, it typically comes at a higher price point due to its specialized treatment. B2B buyers should assess their budget against the long-term benefits of investing in this durable option.

Illustrative image related to alcantara fabric roll

How Does Alcantara Avant Meet Fire Safety Standards?

Alcantara Avant is specifically treated to meet fire safety regulations, making it suitable for aviation interiors and other high-risk environments. This type comes with burn certifications, providing peace of mind for buyers in industries where safety is paramount. However, the need for certification may lead to longer lead times, which buyers must factor into their procurement timelines.

Key Industrial Applications of alcantara fabric roll

| Industry/Sector | Specific Application of alcantara fabric roll | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior Upholstery for Luxury Vehicles | Enhances aesthetic appeal and increases perceived value | Ensure compliance with automotive standards and certifications |

| Aviation | Aircraft Interior Finishing | Lightweight, durable, and fire-resistant material | Verify fire rating certifications (FAR 25.853) and weight limits |

| Furniture & Interior Design | Upholstery for High-End Furniture | Provides a luxurious look and feel while being durable | Assess colorfastness and texture options for design compatibility |

| Fashion & Apparel | Clothing and Accessories | Offers a premium feel and unique style | Confirm fabric weight and stretch properties for garment design |

| Marine & Outdoor | Upholstery for Boats and Outdoor Furniture | Weather-resistant and UV-protected for longevity | Evaluate water repellency and maintenance requirements |

How is Alcantara Fabric Roll Utilized in Automotive Applications?

In the automotive sector, Alcantara fabric roll is primarily used for interior upholstery in luxury vehicles. This includes applications on seats, dashboards, and door panels, where its suede-like texture enhances both aesthetics and functionality. By providing a high grip surface, Alcantara improves driver control and comfort, solving issues related to wear and tear in high-traffic areas. For international buyers, especially from regions like Brazil and Saudi Arabia, it’s essential to source Alcantara that meets strict automotive standards, ensuring durability and compliance with safety regulations.

What Role Does Alcantara Play in Aviation Interior Design?

Alcantara’s application in aviation is pivotal for enhancing the passenger experience within aircraft interiors. Its lightweight nature contributes to overall aircraft efficiency, while its fire-resistant properties meet stringent aviation safety standards. This fabric is commonly used in seating, cabin panels, and other high-touch areas, offering a luxurious feel that aligns with premium airline branding. Buyers from the Middle East and Europe should prioritize sourcing Alcantara with verified fire ratings (FAR 25.853) to ensure compliance and safety in their aircraft interiors.

Illustrative image related to alcantara fabric roll

How is Alcantara Used in High-End Furniture Design?

In the furniture and interior design industry, Alcantara is favored for upholstery on high-end furniture pieces. It provides a luxurious aesthetic while maintaining durability against everyday wear. The fabric is versatile, suitable for sofas, chairs, and decorative accents, and enhances the overall design without compromising on comfort. For B2B buyers in Europe and South America, it is crucial to consider colorfastness and texture options to match specific design themes and client requirements.

What Advantages Does Alcantara Offer in Fashion and Apparel?

Alcantara fabric roll is increasingly utilized in the fashion industry for clothing and accessories, offering a premium feel and distinctive look. Its ability to be dyed in vibrant colors and patterns makes it a popular choice for high-fashion items, including jackets and bags. For international buyers, particularly in emerging markets, confirming the fabric’s weight and stretch properties is vital to ensure it meets design specifications and customer expectations.

How is Alcantara Beneficial for Marine and Outdoor Upholstery?

In marine and outdoor applications, Alcantara is used for upholstery on boats, outdoor furniture, and recreational vehicles. Its weather-resistant and UV-protected qualities ensure longevity and performance even in harsh environments. This fabric helps maintain the aesthetic appeal of outdoor spaces while providing comfort and ease of maintenance. Buyers in regions with extreme weather conditions should focus on sourcing Alcantara that offers superior water repellency and durability to withstand the elements.

3 Common User Pain Points for ‘alcantara fabric roll’ & Their Solutions

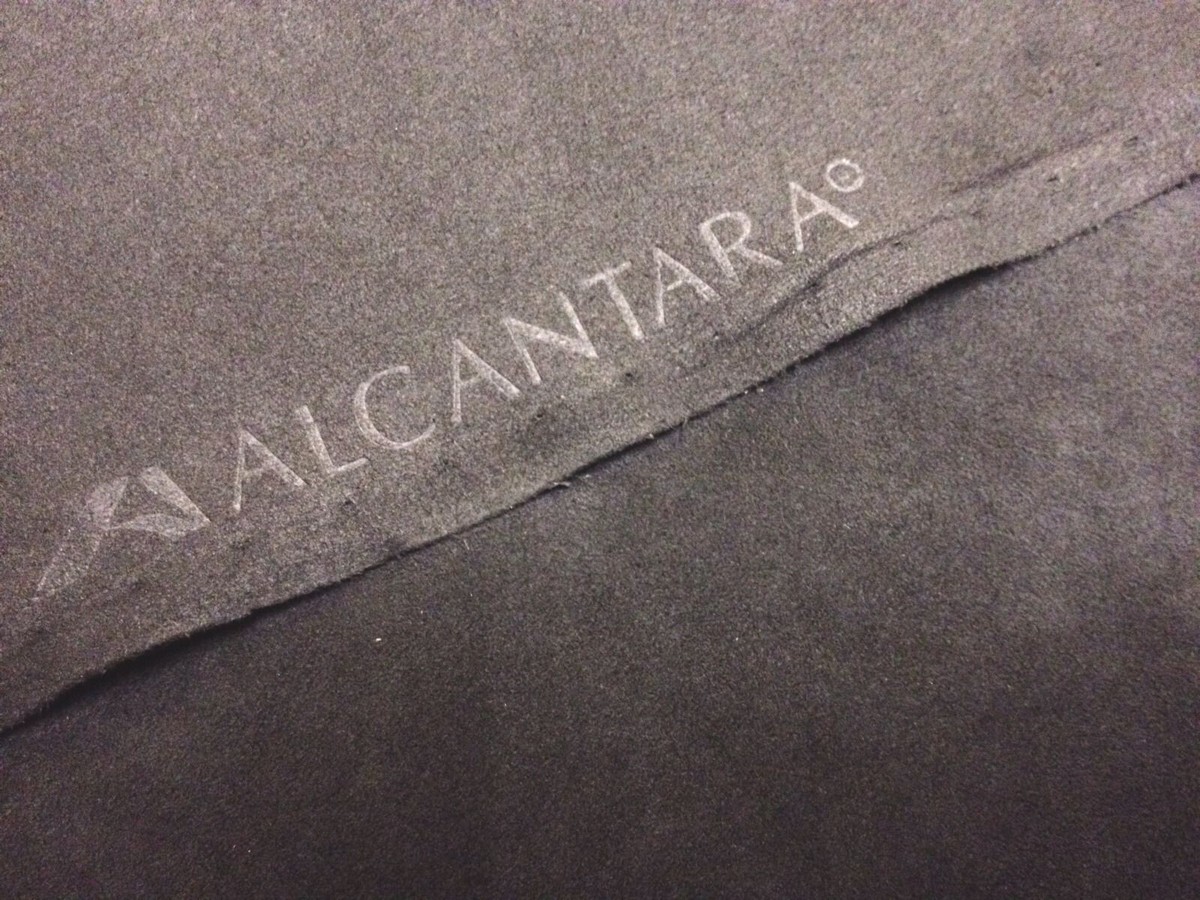

Scenario 1: Sourcing Genuine Alcantara Fabric Rolls for High-Quality Production

The Problem: Many B2B buyers face the challenge of sourcing genuine Alcantara fabric rolls. The market is flooded with imitations and low-quality substitutes that do not meet the high standards required for luxury applications, especially in the automotive and fashion industries. Buyers often struggle with verifying the authenticity of the material, leading to potential quality issues in their end products. This can result in costly reworks, project delays, and damage to brand reputation.

The Solution: To ensure you are sourcing authentic Alcantara fabric rolls, partner with certified distributors who have a strong reputation in the industry. Before making a purchase, request documentation that verifies the material’s authenticity, such as certificates of origin and performance testing results. Additionally, consider ordering samples from multiple suppliers to assess the texture, durability, and color accuracy. Establishing a long-term relationship with a reputable supplier can also provide ongoing support and assurance of quality, including regular updates on new product lines and innovations in Alcantara fabric.

Scenario 2: Understanding the Different Types of Alcantara Fabric Rolls

The Problem: With various types of Alcantara fabric rolls available—such as Panel, Cover, Multilayer, and EXO—buyers often find it overwhelming to choose the right type for their specific applications. Misunderstanding the properties and intended uses of each variant can lead to incorrect purchases, resulting in performance issues in the final product, such as inadequate durability or improper fit for the intended use, particularly in high-stress environments like automotive interiors.

The Solution: To navigate the different types of Alcantara fabric effectively, create a detailed specification document that outlines the requirements for your projects, such as the intended application, environmental factors (e.g., UV exposure for outdoor use), and desired aesthetic qualities. Consult with your supplier for expert advice on which Alcantara variant best meets your needs. Additionally, leverage product datasheets that include information on weight, stretchability, and durability to make informed decisions. Training sessions or workshops hosted by suppliers can also enhance your team’s understanding of the material, leading to better procurement strategies.

Illustrative image related to alcantara fabric roll

Scenario 3: Managing Inventory and Minimizing Waste in Alcantara Fabric Rolls

The Problem: Effective inventory management is a critical concern for B2B buyers dealing with Alcantara fabric rolls. Over-ordering can lead to excess stock, while under-ordering may cause production delays. Furthermore, the unique cutting requirements of Alcantara fabric can result in significant material waste if not handled properly, impacting cost efficiency and sustainability efforts.

The Solution: Implement an inventory management system that tracks usage patterns and forecasts demand based on historical data. This system can help determine the optimal order quantities for Alcantara fabric rolls while reducing excess inventory. Consider utilizing just-in-time (JIT) inventory practices to align orders with production schedules, minimizing storage costs and waste. Additionally, work with your suppliers to establish a flexible ordering system that allows for smaller, more frequent shipments, which can help adapt to changing production needs without compromising quality or availability. Training your team on efficient cutting techniques can also help reduce waste during the production process, ensuring that every yard of fabric is used to its fullest potential.

Strategic Material Selection Guide for alcantara fabric roll

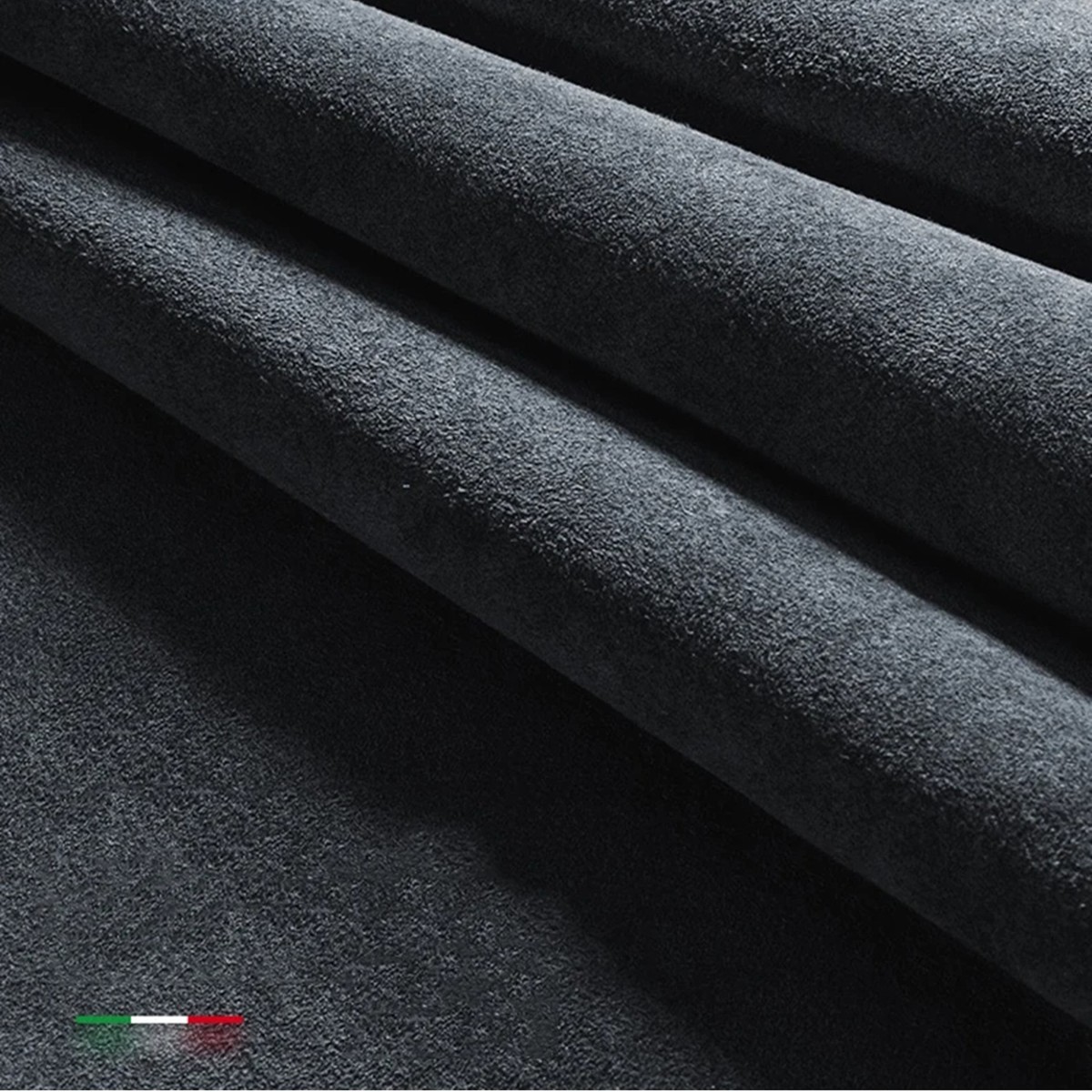

What Are the Key Properties of Alcantara Fabric Rolls?

Alcantara fabric rolls are made from a unique blend of polyester and polyurethane, offering a luxurious feel akin to suede while maintaining high durability. This synthetic material is known for its excellent temperature resistance, making it suitable for various applications, especially in automotive interiors. Alcantara can withstand a wide range of temperatures, typically from -30°C to 80°C, ensuring it performs well in diverse climates, which is particularly relevant for international buyers in regions like Africa and the Middle East.

What Are the Advantages and Disadvantages of Using Alcantara Fabric Rolls?

1. Alcantara Panel (Unbacked)

Key Properties: The Alcantara Panel is a single-layer, unbacked textile that is lightweight and flexible. It is known for its high stretchability and durability, making it ideal for applications requiring a premium finish.

Pros: This material is easy to work with and can be used in various applications, including vehicle headliners and door panels. Its aesthetic appeal and tactile quality make it a favored choice for luxury automotive brands.

Illustrative image related to alcantara fabric roll

Cons: While it offers great performance, the lack of backing can limit its application in high-stress areas. Additionally, it may require careful handling during installation to avoid tearing.

Impact on Application: The Alcantara Panel is particularly suited for automotive interiors, providing a high-end look while being functional. However, it may not be suitable for outdoor applications due to its limited weather resistance.

Considerations for International Buyers: Buyers should ensure compliance with local automotive standards, such as ASTM or DIN, particularly in regions with stringent regulations like Europe.

2. Alcantara Cover (Backed)

Key Properties: The Alcantara Cover features a laminated backing, enhancing its strength and durability. This makes it particularly suitable for high-wear applications like car seats.

Pros: The backing provides additional support, making it less prone to stretching and tearing. It also enhances the fabric’s lifespan, making it a cost-effective choice for manufacturers.

Illustrative image related to alcantara fabric roll

Cons: The added backing may slightly increase the weight of the material, which could be a consideration for certain applications where weight is critical.

Impact on Application: This material is ideal for automotive seating and other high-traffic areas, ensuring longevity and performance.

Considerations for International Buyers: Buyers from regions like South America and the Middle East should consider the climate impact on the fabric’s longevity and ensure that the backing meets local fire safety standards.

3. Alcantara EXO (Outdoor)

Key Properties: The EXO variant is specially designed for outdoor applications, featuring enhanced UV protection and water resistance. This makes it suitable for use in marine upholstery and outdoor furniture.

Pros: Its weather-resistant properties make it an excellent choice for outdoor settings, where exposure to elements is a concern. The material is also easy to clean and maintain.

Cons: While it performs well outdoors, it may not have the same luxurious feel as other Alcantara options, which could be a drawback for high-end applications.

Impact on Application: The EXO fabric is perfect for marine environments, ensuring that it withstands sun, rain, and other harsh conditions without degrading.

Considerations for International Buyers: Buyers in coastal regions should prioritize this variant for its durability against saltwater and UV exposure. Compliance with marine safety standards is also essential.

Summary Table of Alcantara Fabric Rolls

| Material | Typical Use Case for alcantara fabric roll | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Panel (Unbacked) | Vehicle headliners, door panels | Lightweight and flexible | Limited durability in high-stress areas | Medium |

| Alcantara Cover (Backed) | Automotive seats | Enhanced durability and strength | Slightly heavier due to backing | High |

| Alcantara EXO (Outdoor) | Marine upholstery, outdoor furniture | Weather-resistant and easy to clean | Less luxurious feel compared to others | Medium |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them navigate their options in the Alcantara fabric market effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric roll

What Are the Key Stages in the Manufacturing Process of Alcantara Fabric Roll?

The production of Alcantara fabric rolls involves a sophisticated process that combines advanced technology with traditional craftsmanship. The main stages in the manufacturing process include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The initial phase involves sourcing high-quality raw materials. Alcantara is primarily made from a blend of polyester and polyurethane, which are selected for their durability, softness, and aesthetic appeal. These materials undergo rigorous testing to ensure they meet specific quality standards before moving to the next stage. -

Forming:

In this stage, the raw materials are processed into the desired fabric form. This involves spinning the polyester and polyurethane into fibers, which are then woven or non-woven into a fabric. The formation technique varies based on the intended application, such as automotive interiors or fashion accessories. Advanced techniques such as needle punching and chemical bonding may be employed to enhance fabric properties like strength and texture. -

Assembly:

After the fabric is formed, it is cut into rolls or panels according to client specifications. This is a critical stage where precision is essential, as inconsistencies can lead to material wastage and affect the final product’s quality. The assembly process may also involve additional layers, such as backing materials for added durability in specific applications, like automotive seating. -

Finishing:

The final stage includes a series of treatments to enhance the fabric’s performance characteristics. This can involve dyeing for color consistency, applying protective coatings for stain resistance, or treatments to improve UV stability for outdoor applications. The fabric is then inspected for quality and prepared for packaging.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is integral to the Alcantara manufacturing process, ensuring that the final product meets both customer expectations and international standards. The following are key aspects of QA:

-

International Standards Compliance:

The production of Alcantara fabric rolls is often guided by international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures consistent quality in products and services, enhancing customer satisfaction. -

Industry-Specific Certifications:

Depending on the application, additional certifications may be necessary. For instance, automotive applications might require adherence to standards set by the Automotive Industry Action Group (AIAG) or the European Committee for Standardization (CEN). Certifications such as CE marking are crucial for products sold within the European market, indicating compliance with health, safety, and environmental protection standards. -

Quality Control Checkpoints:

The manufacturing process incorporates multiple quality control checkpoints, including:

– Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to catch defects early.

– Final Quality Control (FQC): A thorough inspection of finished products before shipping, assessing factors such as color accuracy, dimensional stability, and overall appearance.

What Testing Methods Are Commonly Used in the QC of Alcantara Fabric?

To ensure that Alcantara fabric rolls meet industry standards, several testing methods are employed:

-

Physical Testing:

This includes assessments of tensile strength, tear resistance, and abrasion resistance. These tests help determine the durability and longevity of the fabric, especially for high-traffic applications like automotive interiors. -

Chemical Testing:

Chemical resistance tests evaluate how well the fabric withstands exposure to various substances, including oils, solvents, and cleaning agents. This is particularly important for automotive and upholstery applications, where spills are common. -

Environmental Testing:

Tests for UV resistance and color fastness to light help determine how well the fabric will perform in outdoor settings. This is vital for Alcantara products intended for use in marine or outdoor furniture contexts.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure that the products meet required standards. Here are several approaches:

-

Supplier Audits:

Conducting on-site audits can provide insights into the supplier’s manufacturing processes, quality control practices, and adherence to international standards. This can help buyers assess the supplier’s commitment to quality. -

Quality Assurance Reports:

Requesting detailed quality assurance reports can offer transparency into the supplier’s testing procedures, results, and compliance with relevant standards. These reports should detail each stage of the manufacturing process and any corrective actions taken in response to quality issues. -

Third-Party Inspections:

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production, ensuring that products meet agreed-upon specifications before shipment. -

Certification Verification:

Buyers should verify the authenticity of certifications claimed by suppliers. This can involve checking with certifying bodies to confirm that the supplier is in good standing and adheres to the required standards.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is essential for international buyers. Different regions may have varying standards and expectations regarding quality assurance.

Illustrative image related to alcantara fabric roll

-

Regional Standards:

Buyers should familiarize themselves with specific regional standards that may apply to Alcantara products. For instance, European buyers might prioritize CE marking, while buyers in the Middle East may have different regulatory requirements. -

Cultural Considerations:

Cultural differences can influence how quality is perceived and prioritized. Buyers should consider the local business practices and expectations of their suppliers to foster effective communication and collaboration. -

Supply Chain Transparency:

Ensuring transparency throughout the supply chain is vital for maintaining quality. Buyers should inquire about the entire production process, from raw material sourcing to final product delivery, to understand how quality is maintained at each stage.

In conclusion, the manufacturing and quality assurance processes for Alcantara fabric rolls are critical to ensuring the product meets the high standards expected by B2B buyers. By understanding these processes and implementing robust verification methods, buyers can confidently source quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric roll’

To assist B2B buyers in successfully procuring Alcantara fabric rolls, this guide provides a structured checklist that outlines essential steps in the sourcing process. By following these steps, buyers can ensure they make informed decisions, leading to high-quality purchases and strong supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is vital to determine the specific technical requirements for the Alcantara fabric. Consider factors such as thickness, type (e.g., unbacked, backed, or multilayer), and intended applications (automotive, upholstery, etc.). This clarity will streamline communication with suppliers and help you select the right product that meets your needs.

Illustrative image related to alcantara fabric roll

Step 2: Identify Reliable Suppliers

Research potential suppliers who specialize in Alcantara fabric. Look for companies that have a proven track record in supplying this material, particularly to your industry. Consider factors such as their geographic location, customer reviews, and industry certifications to gauge their reliability and reputation.

Step 3: Request Product Samples

Always request samples of the Alcantara fabric before making bulk purchases. This step allows you to assess the quality, texture, and color accuracy of the fabric firsthand. Additionally, it provides an opportunity to evaluate how the material performs in your specific application, ensuring it meets your standards.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications for the Alcantara fabric they provide. Look for certifications related to sustainability, quality assurance, and compliance with industry standards. This verification helps mitigate risks associated with sourcing inferior or non-compliant products, particularly in highly regulated markets.

Step 5: Assess Pricing and Terms of Sale

Compare pricing structures among different suppliers to ensure you are getting a fair deal. Consider not just the unit price but also minimum order quantities, shipping costs, and payment terms. Understanding the total cost of ownership will help you make a more informed financial decision.

Step 6: Evaluate Customer Support and After-Sales Service

Strong customer support and after-sales service are crucial for a successful procurement experience. Assess how responsive the supplier is to inquiries and whether they offer support for issues such as returns, warranties, or product guidance. A supplier with robust support can significantly enhance your purchasing experience and provide peace of mind.

Step 7: Finalize the Contract and Order Confirmation

Once you’ve selected a supplier, ensure that all terms are clearly outlined in a formal contract. This should include delivery timelines, payment terms, product specifications, and quality assurances. Confirm the order details before proceeding to payment to avoid any misunderstandings and ensure a smooth transaction.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing Alcantara fabric rolls, ensuring they acquire the right products from reputable suppliers while maintaining quality and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for alcantara fabric roll Sourcing

What Are the Key Cost Components in Sourcing Alcantara Fabric Rolls?

When sourcing Alcantara fabric rolls, understanding the cost structure is crucial for effective budgeting and planning. The primary cost components include:

Illustrative image related to alcantara fabric roll

-

Materials: Alcantara is a premium synthetic fabric made primarily from polyester and polyurethane, which contributes significantly to the overall cost. The sourcing of high-quality raw materials impacts the fabric’s durability, texture, and aesthetic appeal.

-

Labor: Skilled labor is necessary for the manufacturing and quality control processes. Labor costs can vary based on the production location, with regions like Italy (where Alcantara is produced) generally having higher labor costs compared to other manufacturing hubs.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Efficient manufacturing processes can mitigate overhead costs, but these are often fixed and must be accounted for in pricing.

-

Tooling: Depending on the specifications and customizations required, tooling costs can vary. These costs are associated with molds and machinery needed for specific fabric designs or features.

-

Quality Control (QC): Ensuring the fabric meets industry standards and customer specifications requires rigorous QC processes. This adds to the overall cost but is essential for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping and handling costs can significantly impact the final price, especially for international buyers. Factors like distance, freight options, and customs duties play a role in logistics expenses.

-

Margin: Suppliers typically apply a profit margin to cover their costs and ensure profitability. This margin can vary widely among suppliers based on their brand reputation, service levels, and market positioning.

How Do Price Influencers Affect Alcantara Fabric Roll Costs?

Several factors can influence the pricing of Alcantara fabric rolls, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often come with discounts, making it more cost-effective to order larger quantities. Understanding supplier MOQs is crucial for negotiating favorable terms.

-

Specifications and Customization: Custom colors, patterns, or performance specifications (like fire resistance or UV protection) can increase costs. Buyers should clearly define their needs to avoid unexpected charges.

-

Quality and Certifications: Alcantara that meets specific quality standards or certifications (such as ISO or fire safety ratings) may command higher prices. Buyers should consider these factors when evaluating suppliers.

-

Supplier Factors: The supplier’s reputation, reliability, and service levels can affect pricing. Established suppliers may charge a premium for their experience and customer support.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can impact total costs, especially in terms of responsibilities for shipping, insurance, and duties. Buyers should negotiate Incoterms that align with their logistical capabilities.

What Are the Best Practices for Negotiating Alcantara Fabric Roll Prices?

To ensure cost-efficiency and maximize value, consider the following buyer tips:

-

Conduct Market Research: Understand the market rates for Alcantara fabric rolls by comparing multiple suppliers. This knowledge can empower you during negotiations.

-

Negotiate Volume Discounts: If your business can commit to larger orders, leverage this potential for volume discounts. Suppliers are often willing to reduce prices for guaranteed sales.

-

Evaluate Total Cost of Ownership (TCO): Consider all associated costs, including shipping, duties, and potential waste during production. A lower upfront price may not always equate to lower overall costs.

-

Establish Long-term Relationships: Building a strong relationship with suppliers can lead to better pricing and terms in the future. Consistent orders may also incentivize suppliers to offer favorable pricing.

-

Be Aware of Pricing Nuances for International Sourcing: International buyers, particularly from regions like Africa, South America, and the Middle East, should account for currency fluctuations, trade tariffs, and local regulations that may impact overall costs.

Disclaimer on Indicative Prices

Prices for Alcantara fabric rolls can vary significantly based on the factors outlined above. The figures provided in various sources may serve as a guideline but should be verified through direct communication with suppliers for the most accurate and current pricing. Always ensure that you receive formal quotes that reflect your specific requirements and conditions.

Alternatives Analysis: Comparing alcantara fabric roll With Other Solutions

When considering materials for automotive and interior applications, Alcantara fabric rolls stand out due to their unique blend of style, durability, and functionality. However, there are alternative solutions that may also meet the diverse needs of B2B buyers. This analysis will compare Alcantara fabric rolls with two viable alternatives: synthetic suede and genuine leather.

| Comparison Aspect | Alcantara Fabric Roll | Synthetic Suede | Genuine Leather |

|---|---|---|---|

| Performance | Excellent durability, stain-resistant, and versatile | Good durability, less resistant to stains than Alcantara | High durability, excellent breathability, but prone to scratches |

| Cost | Moderate to high price range, varies by type | Generally lower cost, making it budget-friendly | Higher price point, especially for premium grades |

| Ease of Implementation | Easy to cut and sew, lightweight | Easy to work with, similar to Alcantara | Requires specialized tools and skills for installation |

| Maintenance | Low maintenance, easy to clean with mild detergent | Moderate maintenance, requires careful cleaning to avoid damage | High maintenance, needs regular conditioning to prevent drying and cracking |

| Best Use Case | Luxury automotive interiors, high-end furniture | Budget-conscious projects, casual upholstery | Premium products, high-end furniture, and luxury vehicles |

What Are the Advantages and Disadvantages of Synthetic Suede Compared to Alcantara Fabric Roll?

Synthetic suede is a popular alternative to Alcantara, particularly in budget-sensitive projects. It mimics the soft feel and aesthetic appeal of Alcantara but is generally more affordable. The performance of synthetic suede is commendable, offering good durability and a variety of colors. However, it tends to be less resistant to stains and may not provide the same level of luxury feel as Alcantara. For projects where budget is a primary concern and luxury is less critical, synthetic suede can be a viable option.

How Does Genuine Leather Compare to Alcantara Fabric Roll in Terms of Usability?

Genuine leather is revered for its timeless elegance and durability. It offers excellent breathability and develops a unique patina over time, enhancing its aesthetic appeal. However, genuine leather can be significantly more expensive than Alcantara and requires more maintenance, including regular conditioning to prevent drying out. Its installation often demands specialized skills and tools, making it less accessible for all projects. For high-end applications where quality and prestige are paramount, genuine leather may be the preferred choice.

How Can B2B Buyers Choose the Right Fabric for Their Needs?

When selecting the ideal fabric for their projects, B2B buyers should consider several factors, including the intended use, budget constraints, and desired aesthetic. Alcantara fabric rolls are ideal for luxury applications where performance and style are critical. Synthetic suede offers a budget-friendly alternative for less demanding environments, while genuine leather appeals to those seeking the ultimate in quality and prestige, despite the higher costs and maintenance requirements. By evaluating these aspects, buyers can make informed decisions that align with their project goals and market demands.

Essential Technical Properties and Trade Terminology for alcantara fabric roll

What Are the Key Technical Properties of Alcantara Fabric Rolls?

When evaluating Alcantara fabric rolls for B2B applications, understanding the essential technical properties is crucial for making informed purchasing decisions. Below are some critical specifications that buyers should consider:

-

Material Composition

Alcantara is a synthetic textile made primarily from polyester and polyurethane. This unique blend provides the fabric with a suede-like feel, high durability, and excellent resistance to wear and tear. For B2B buyers, knowing the material composition is vital as it directly affects the fabric’s performance in various applications, especially in high-end automotive interiors. -

Roll Width and Length

Standard Alcantara fabric rolls typically have a width of 54 to 56 inches and can be ordered in lengths of up to 55 yards. Understanding roll dimensions is essential for manufacturers and upholstery businesses, as it impacts cutting and application processes. Accurate measurements help in minimizing waste and ensuring that production timelines are met. -

Thickness

Alcantara fabric generally ranges from 0.7 mm to 1.0 mm in thickness, depending on the type (e.g., Panel, Cover). Thickness influences both the tactile experience and the fabric’s suitability for specific applications. For instance, thicker variants are preferred for seats, while thinner options may be more suitable for headliners or dashboards. B2B buyers must assess thickness based on their project requirements to ensure compatibility. -

Weight per Square Meter

The weight of Alcantara fabric, which can vary between 250 to 350 grams per square meter, is a significant consideration. Heavier fabrics tend to offer more durability, making them suitable for high-traffic areas in vehicles, while lighter options may be chosen for less demanding applications. Understanding weight helps buyers gauge the quality and longevity of the fabric. -

Color Fastness and UV Resistance

Alcantara fabric is known for its color retention and UV resistance, making it suitable for both indoor and outdoor use. These properties are particularly important for automotive applications exposed to sunlight, as they ensure that the fabric maintains its aesthetic appeal over time. Buyers should prioritize these attributes when sourcing materials for projects that will face environmental challenges.

What Are Common Trade Terms Related to Alcantara Fabric Rolls?

In addition to technical properties, familiarity with industry terminology is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of Alcantara, many luxury car brands source their interior fabrics from OEM suppliers. Understanding OEM relationships can help B2B buyers identify trusted suppliers and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand as it influences purchasing decisions and inventory management. Knowing the MOQ helps businesses plan their orders and manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. For B2B buyers of Alcantara fabric rolls, issuing an RFQ can facilitate competitive pricing and better understanding of supplier capabilities. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, risk, and insurance. Familiarity with these terms is crucial for B2B buyers, especially those involved in cross-border transactions, as they outline who is responsible for costs and liabilities at different stages of shipping. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is a critical factor for project timelines, and understanding lead times can help B2B buyers plan their production schedules accordingly.

By grasping these essential technical properties and trade terms, international B2B buyers can enhance their procurement strategies, ensuring that they select the right Alcantara fabric rolls for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the alcantara fabric roll Sector

What Are the Current Market Dynamics and Key Trends in the Alcantara Fabric Roll Sector?

The Alcantara fabric roll sector is experiencing a robust growth trajectory, propelled by several global drivers. The increasing demand for high-quality, luxury materials in automotive, fashion, and interior design industries underscores the fabric’s versatility and premium appeal. As brands emphasize quality, Alcantara’s unique blend of aesthetics and functionality positions it as a preferred choice. Additionally, the rise of e-commerce platforms is reshaping B2B purchasing behaviors, enabling international buyers, especially from Africa, South America, the Middle East, and Europe, to access a broader range of products with ease.

Emerging technologies are also transforming the sourcing landscape. Digital platforms and supply chain management software are facilitating real-time inventory tracking and streamlined ordering processes, which are critical for B2B buyers aiming to maintain efficient operations. Moreover, advancements in manufacturing techniques are allowing for customized solutions that cater to specific client needs, such as tailored color options and textures, enhancing the competitive edge for suppliers.

Market dynamics are shifting as buyers increasingly prioritize suppliers who can demonstrate reliability and responsiveness. This trend is particularly vital in regions like Brazil and Saudi Arabia, where the luxury market is expanding rapidly. Understanding these dynamics will enable international buyers to make informed sourcing decisions that align with their business objectives.

Illustrative image related to alcantara fabric roll

How Is Sustainability Influencing the Alcantara Fabric Roll Market?

Sustainability has become a cornerstone of B2B purchasing decisions, particularly in the Alcantara fabric roll sector. The environmental impact of textile production is under scrutiny, compelling businesses to adopt more responsible sourcing practices. Alcantara, known for its ethical production processes, stands out in this regard. The fabric is 100% made in Italy, utilizing renewable resources and employing energy-efficient manufacturing practices, which resonate with environmentally-conscious buyers.

The importance of ethical supply chains cannot be overstated. B2B buyers are increasingly seeking suppliers who can provide certifications demonstrating their commitment to sustainability. This includes ‘green’ certifications that validate eco-friendly materials and processes, ensuring that the products meet stringent environmental standards. For instance, Alcantara’s commitment to using recycled materials and reducing waste aligns with the growing trend of circular economy practices, making it a compelling choice for brands looking to enhance their sustainability credentials.

As international buyers navigate the sourcing landscape, prioritizing suppliers that champion sustainability will not only mitigate environmental impact but also appeal to a consumer base that values ethical consumption. This strategic alignment can ultimately enhance brand reputation and foster long-term customer loyalty.

What Is the Evolution of Alcantara Fabric in the B2B Sector?

Alcantara’s evolution is rooted in its inception in the late 1970s, when it was introduced as a synthetic alternative to suede. Initially, it found its niche in luxury automotive interiors, quickly gaining traction among premium car manufacturers like Lamborghini and BMW. Over the decades, its application expanded beyond automotive to encompass fashion, interior design, and even aviation, showcasing its versatility and appeal.

The fabric’s unique properties—durability, softness, and ease of maintenance—have made it a favored choice among luxury brands. As sustainability concerns have risen, Alcantara has adapted by incorporating eco-friendly practices into its production processes, solidifying its position as a leader in both quality and ethical sourcing. This historical perspective is crucial for B2B buyers to understand the brand’s commitment to excellence and innovation, ensuring they make informed decisions when sourcing Alcantara fabric rolls.

Illustrative image related to alcantara fabric roll

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric roll

-

How do I choose the right Alcantara fabric for my project?

Selecting the appropriate Alcantara fabric depends on the intended application. For automotive interiors, consider Alcantara Cover or Multilayer for durability, whereas Alcantara Panel is ideal for headliners and door trims due to its lightweight properties. If your project involves outdoor use, Alcantara EXO offers UV protection and water resistance. Always evaluate the fabric’s backing, thickness, and texture to ensure it meets your design and functional requirements. -

What is the minimum order quantity (MOQ) for Alcantara fabric rolls?

MOQs for Alcantara fabric rolls can vary by supplier. Generally, many suppliers require a minimum order of one full roll, typically around 55 yards. However, some may allow smaller quantities, such as cuts by the yard. It’s essential to communicate with suppliers to understand their specific terms, especially for international orders, as shipping costs can influence your purchasing decisions. -

How do I verify the quality of Alcantara fabric before placing a bulk order?

To ensure the quality of Alcantara fabric, request samples before making a bulk order. Most reputable suppliers will provide swatches or small cuts for evaluation. Additionally, inquire about the fabric’s certifications and performance standards, particularly for automotive applications, where compliance with safety regulations is crucial. Check for testimonials and reviews from other businesses to assess the supplier’s reliability. -

What payment terms should I expect when ordering Alcantara fabric internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, deposits, or net 30/60 terms upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify the payment terms in advance and ensure they align with your cash flow and financial policies. -

How can I customize Alcantara fabric for my specific needs?

Customization options for Alcantara fabric often include color selection, backing type, and texture variations. Many suppliers offer a range of colors and finishes, allowing you to tailor the fabric to match your brand or design specifications. Discuss your requirements with suppliers, as they may also provide bespoke solutions, including custom patterns or sizes, depending on your project needs. -

What are the logistics considerations when importing Alcantara fabric rolls?

When importing Alcantara fabric rolls, consider shipping methods, customs regulations, and import duties specific to your country. Air freight may be faster but more expensive, while sea freight is more economical for larger orders. Ensure your supplier provides the necessary documentation for customs clearance and check for any restrictions or certifications required for textile imports in your region. -

How do I ensure compliance with international quality standards for Alcantara fabric?

To ensure compliance with international quality standards, request documentation from your supplier regarding the fabric’s certifications. Alcantara, being a premium textile, often adheres to strict guidelines related to durability, safety, and environmental impact. Familiarize yourself with relevant standards such as ISO certifications or industry-specific regulations to ensure the fabric meets your market’s requirements. -

What are the common applications for Alcantara fabric in various industries?

Alcantara fabric is widely used across several industries, particularly in automotive for seats, dashboards, and headliners due to its luxurious feel and durability. In the fashion sector, it’s popular for handbags and footwear, while in interior design, it’s favored for upholstery and home decor. Understanding these applications can help you identify opportunities for incorporating Alcantara into your product offerings, enhancing both aesthetics and functionality.

Top 7 Alcantara Fabric Roll Manufacturers & Suppliers List

1. Relicate – Alcantara® Upholstery Options

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Alcantara® upholstery options available: OEM Auto Colors, Unbacked Alcantara Panel, Foam Backed Alcantara Cover, Marine/Outdoor Alcantara EXO, Perforated Alcantara, Multilayer Plaid Seat Fabrics. Various plaid designs including Highlander/Overlander, Spirit of Le Mans, VW, Porsche, BMW, Mercedes, and Spec Series. Other textiles include Houndstooth & Pepita Seat Fabric and NappaTek™ Synthetic Black…

2. Keystone Bros – Alcantara Suede Automotive Fabric

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Alcantara Suede – Automotive Fabric. Product options include: Alcantara Cover, Alcantara Soft, Alcantara Pannel, Alcantara EXO, Alcantara Pannel MB-4 Perf, Alcantara Pannel S-2000 Perf. Pricing requires login to view. Additional details such as roll size, cleaning code, abrasion, UFAC class, and color number are available but not specified in the text.

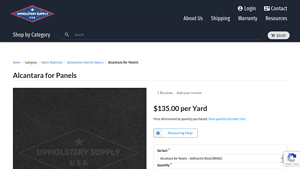

3. Upholstery Supply USA – Alcantara for Panels – Anthracite Black

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Alcantara for Panels – Anthracite Black (#9002)”, “Price”: {“1 to 9 yards”: “$135.00”, “10 to 24 yards”: “$130.00”, “25+ yards”: “$125.00”}, “Material Type”: “Genuine Alcantara Textile”, “Origin”: “Made in Italy”, “Product Description”: “Alcantara Automotive Panel (Unbacked) is a premium suede-like textile fabric, superior in craftsmanship and its workability for automotive appli…

4. Hydes Leather – Alcantara Products

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather is the official distributor of Alcantara in North America, offering a complete range of Alcantara products used by luxury auto brands in Europe. Alcantara is known for its style, elegance, functionality, and environmental ethics, being 100% made in Italy. The product range includes:

1. Alcantara Panel (unbacked, thin, used for headliners, doors, dashboards)

2. Alcantara Cover (backe…

5. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Available colors include Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, Raw Amber, Dark Brown, Brombeer,…

6. Alcantara – Craft Fabric Rolls

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Alcantara Craft Fabric for sale on eBay. Categories include various types of craft fabrics, with specific mentions of Alcantara fabric rolls, black Alcantara, and self-adhesive options. The fabric is noted for its use in car headlining, with a width of 150 cm. Prices range from $16.77 to $1,183.78, with free shipping available. Related searches include Alcantara leather, trim, and wrap.

7. OEM Auto Fabric – Alcantara Black

Strategic Sourcing Conclusion and Outlook for alcantara fabric roll

In the realm of strategic sourcing for Alcantara fabric rolls, understanding the diverse applications and benefits of this premium material is vital for B2B buyers. Alcantara, with its exceptional durability, aesthetic appeal, and environmental credentials, is a preferred choice across various industries, particularly in luxury automotive and high-end upholstery. By sourcing from reputable suppliers, businesses can secure not only high-quality materials but also customized solutions tailored to specific project needs.

Furthermore, the availability of different Alcantara types—such as unbacked panels, backed covers, and outdoor EXO variants—allows buyers to select the most appropriate product for their applications, ensuring optimal performance and longevity. This strategic approach to sourcing enables businesses to enhance their product offerings while maintaining a commitment to sustainability and ethical practices.

As international buyers from Africa, South America, the Middle East, and Europe seek to elevate their product lines, leveraging the unique qualities of Alcantara fabric will be crucial. Engage with trusted suppliers today to explore the extensive range of Alcantara products available, and position your business at the forefront of innovation and quality in your respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.