Introduction: Navigating the Global Market for microfiber by the yard

In the ever-evolving landscape of textiles, sourcing microfiber by the yard poses unique challenges for international B2B buyers. Whether you are in need of durable upholstery fabrics for high-traffic environments or comfortable apparel materials, understanding the nuances of microfiber is essential. This guide serves as a comprehensive resource, addressing various aspects such as types of microfiber, diverse applications, effective supplier vetting strategies, and cost considerations.

As the global market expands, buyers from regions like Africa, South America, the Middle East, and Europe—including key players in countries such as Saudi Arabia and Nigeria—face the critical task of making informed purchasing decisions. This guide empowers you to navigate the complexities of sourcing microfiber, offering insights that enhance your procurement process. From identifying the right fabric characteristics to evaluating supplier reliability, our goal is to equip you with actionable knowledge that fosters successful business outcomes.

By delving into the specifics of microfiber’s versatility—from its use in stylish decor to functional apparel—you will gain a clearer understanding of how to leverage this material effectively. Join us as we explore the intricacies of the microfiber market, ensuring that your business remains competitive and responsive to the demands of your clientele.

Table Of Contents

- Top 6 Microfiber By The Yard Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for microfiber by the yard

- Understanding microfiber by the yard Types and Variations

- Key Industrial Applications of microfiber by the yard

- 3 Common User Pain Points for ‘microfiber by the yard’ & Their Solutions

- Strategic Material Selection Guide for microfiber by the yard

- In-depth Look: Manufacturing Processes and Quality Assurance for microfiber by the yard

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber by the yard’

- Comprehensive Cost and Pricing Analysis for microfiber by the yard Sourcing

- Alternatives Analysis: Comparing microfiber by the yard With Other Solutions

- Essential Technical Properties and Trade Terminology for microfiber by the yard

- Navigating Market Dynamics and Sourcing Trends in the microfiber by the yard Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of microfiber by the yard

- Strategic Sourcing Conclusion and Outlook for microfiber by the yard

- Important Disclaimer & Terms of Use

Understanding microfiber by the yard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Microfiber Suede | Soft texture, resembles real suede, highly durable | Upholstery, apparel, accessories | Pros: Luxurious feel, stain-resistant. Cons: Can be more expensive than standard microfiber. |

| Microfiber Fleece | Thick, plush fabric, excellent insulation properties | Blankets, outerwear, home textiles | Pros: Warm, soft, and cozy. Cons: May pill over time. |

| Microfiber Velvet | Rich, soft surface with a slight sheen, luxurious look | High-end fashion, drapery, upholstery | Pros: Aesthetically pleasing, durable. Cons: Requires careful cleaning. |

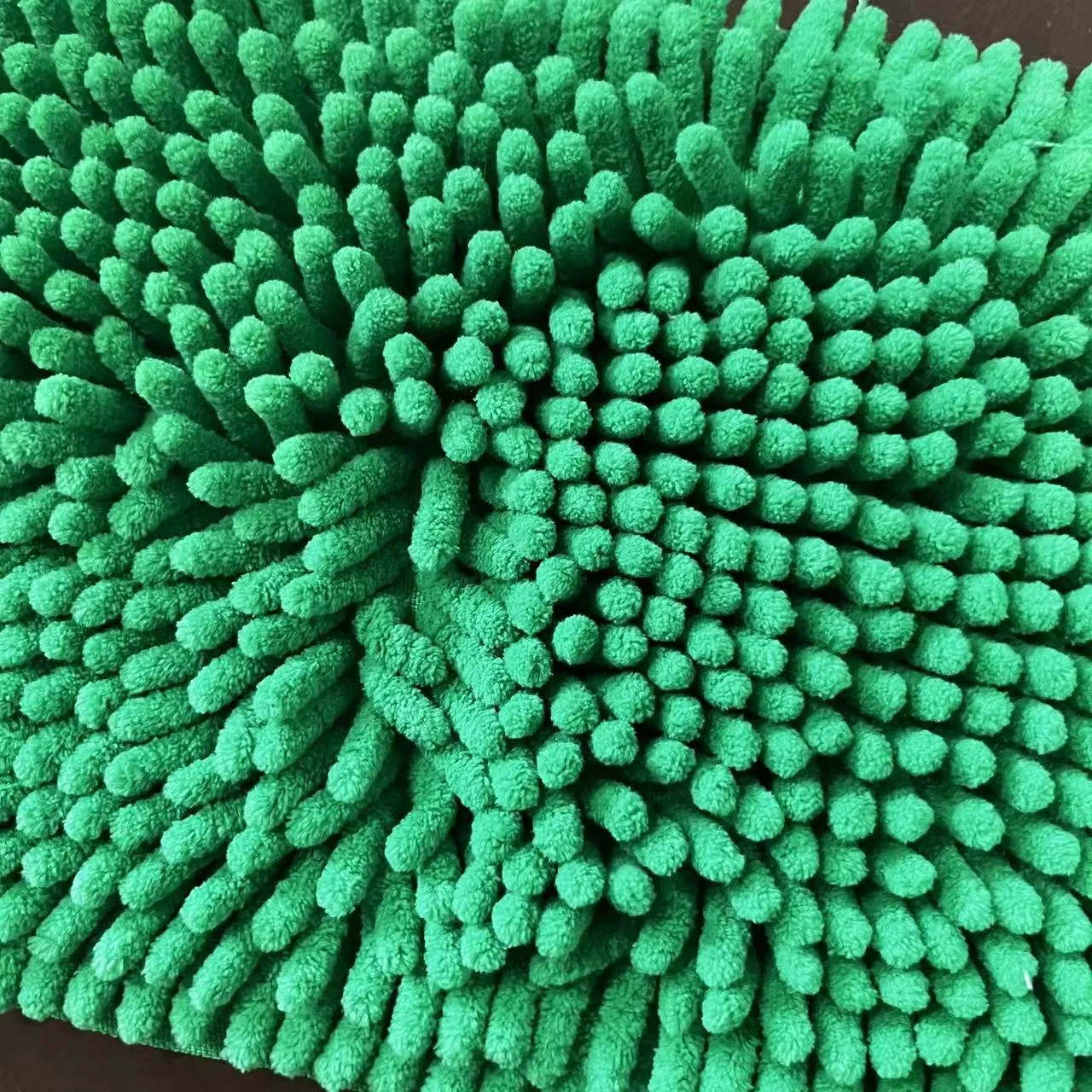

| Microfiber Terry Cloth | Looped texture, highly absorbent, soft | Towels, bathrobes, and cleaning cloths | Pros: Excellent absorbency, quick drying. Cons: Can be heavy and bulky. |

| Microfiber Nylon | Lightweight, strong, and water-resistant | Activewear, outdoor gear, automotive | Pros: Durable, resistant to wear and tear. Cons: Less soft than other types. |

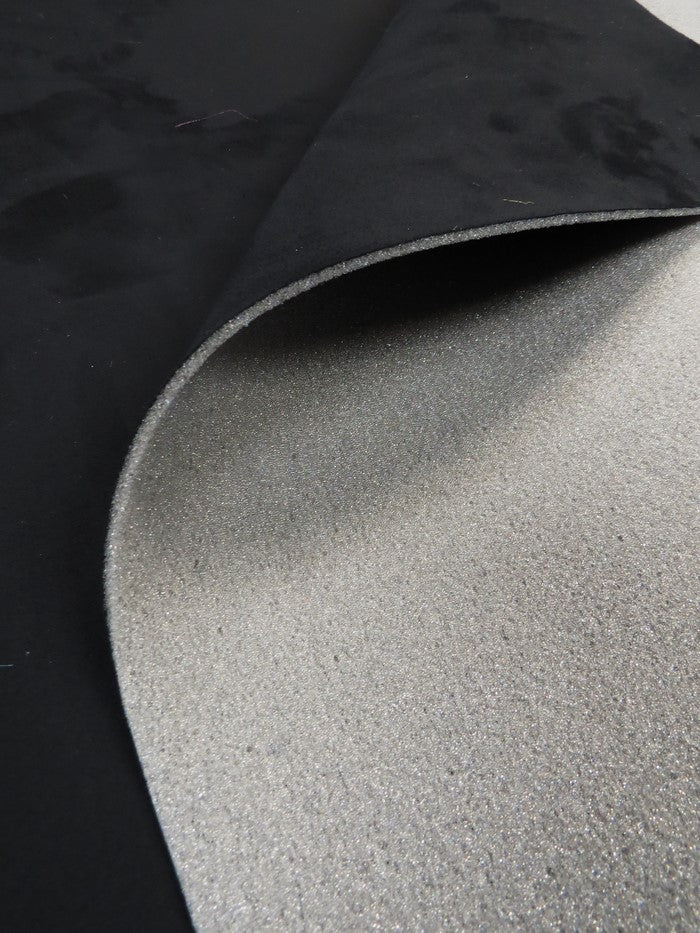

What are the Characteristics and Suitability of Microfiber Suede?

Microfiber suede offers a soft texture that closely mimics real suede while providing superior durability. This type of microfiber is often used in upholstery for furniture, as well as in clothing and accessories due to its luxurious feel. B2B buyers should consider the cost implications, as microfiber suede may be pricier than traditional options, but its longevity and aesthetic appeal can justify the investment.

How Does Microfiber Fleece Stand Out in B2B Applications?

Microfiber fleece is characterized by its thick, plush texture and exceptional insulation properties. It is ideal for products requiring warmth, such as blankets and outerwear. Buyers in the textile industry should evaluate the potential for pilling, which can affect the fabric’s appearance over time. However, its comfort and warmth make it a popular choice for consumer goods in colder climates.

Why Choose Microfiber Velvet for High-End Applications?

Microfiber velvet is known for its rich texture and slight sheen, making it a favored option for high-end fashion and drapery. Its luxurious appearance adds value to products, appealing to a market that prioritizes aesthetics. While it is durable, B2B buyers should be aware of the maintenance requirements, as microfiber velvet can require specialized cleaning to maintain its look.

Illustrative image related to microfiber by the yard

What Advantages Does Microfiber Terry Cloth Offer for Functional Products?

Microfiber terry cloth features a looped texture that provides excellent absorbency, making it perfect for towels, bathrobes, and cleaning cloths. Its quick-drying properties make it a practical choice for both personal and commercial use. However, buyers should consider that the bulkiness of terry cloth can be a drawback in terms of shipping and storage, particularly for large orders.

What Makes Microfiber Nylon a Practical Choice for Activewear?

Microfiber nylon is lightweight yet incredibly strong, making it a popular choice for activewear and outdoor gear. Its water-resistant properties are particularly beneficial in climates that require durable, weather-resistant fabrics. While it may lack the softness of other microfiber types, its durability and resistance to wear and tear make it an excellent investment for B2B buyers focused on performance-driven products.

Key Industrial Applications of microfiber by the yard

| Industry/Sector | Specific Application of microfiber by the yard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel & Fashion | Activewear and athleisure garments | High moisture-wicking properties, comfort, and durability | Look for lightweight, breathable options; consider colorfastness and stretchability. |

| Automotive | Interior upholstery and headliners | Enhanced durability, stain resistance, and aesthetic appeal | Ensure compliance with safety standards; consider custom colors and patterns. |

| Home Textiles | Bedding and drapery | Softness, easy care, and hypoallergenic properties | Check for certifications like OEKO-TEX; inquire about bulk purchasing options. |

| Hospitality | Linens for hotels and restaurants | Cost-effective, easy to clean, and luxurious feel | Focus on durability and washability; ensure availability of various colors and patterns. |

| Healthcare | Patient gowns and bedding | Soft, hypoallergenic, and easy to sterilize | Verify medical-grade certifications; consider bulk purchasing for cost efficiency. |

How is Microfiber by the Yard Used in Apparel and Fashion?

In the apparel and fashion industry, microfiber by the yard is predominantly utilized for creating activewear and athleisure garments. The fabric’s moisture-wicking properties keep wearers comfortable during physical activities, while its durability ensures long-lasting use. For B2B buyers, especially from regions like Africa and South America, sourcing microfiber that is lightweight yet robust is essential. Additionally, considerations regarding colorfastness and stretchability are vital to meet the diverse demands of consumers in these markets.

What Role Does Microfiber Play in Automotive Applications?

In the automotive sector, microfiber by the yard is commonly used for interior upholstery and headliners. This fabric offers enhanced durability and stain resistance, making it suitable for high-traffic areas within vehicles. For international buyers, particularly in the Middle East where luxury vehicles are prevalent, sourcing microfiber that meets specific safety standards is crucial. Furthermore, customization options in colors and patterns can help businesses cater to regional preferences effectively.

Illustrative image related to microfiber by the yard

Why is Microfiber Important in Home Textiles?

Microfiber by the yard is a popular choice in the home textiles industry for applications such as bedding and drapery. Its softness and hypoallergenic properties make it an attractive option for consumers seeking comfort and health-conscious materials. For B2B buyers, particularly in Europe, checking for certifications like OEKO-TEX is important to ensure the fabric is free from harmful substances. Additionally, bulk purchasing options can provide significant cost savings for businesses catering to the home decor market.

How is Microfiber Beneficial for the Hospitality Industry?

In the hospitality sector, microfiber is widely used for linens in hotels and restaurants due to its cost-effectiveness and luxurious feel. The fabric is easy to clean and maintain, which is a significant advantage for businesses that require high turnover in linen supplies. For buyers in regions like Saudi Arabia, focusing on the durability and washability of microfiber is essential to withstand frequent laundering. Additionally, ensuring a variety of colors and patterns can help businesses create a unique ambiance for their establishments.

What are the Healthcare Applications of Microfiber?

Microfiber by the yard finds critical applications in the healthcare industry for items such as patient gowns and bedding. Its soft texture and hypoallergenic properties make it ideal for sensitive skin, while its ease of sterilization is crucial in medical settings. For B2B buyers, verifying medical-grade certifications is paramount to ensure compliance with health regulations. Furthermore, considering bulk purchasing options can lead to cost efficiency, especially in regions where healthcare facilities are expanding rapidly.

3 Common User Pain Points for ‘microfiber by the yard’ & Their Solutions

Scenario 1: Sourcing Quality Microfiber Fabric for Diverse Applications

The Problem: B2B buyers often struggle with sourcing high-quality microfiber fabric that meets their specific needs, particularly when dealing with international suppliers. This challenge is compounded by varying standards for quality, which can lead to discrepancies in the fabric’s performance, such as durability, absorbency, and softness. For instance, a buyer in Nigeria might require microfiber for automotive upholstery, while a buyer in Saudi Arabia may seek it for high-end fashion apparel. Without a reliable quality assurance process, buyers risk receiving subpar materials that can negatively affect their production timelines and product quality.

Illustrative image related to microfiber by the yard

The Solution: To ensure the procurement of quality microfiber fabric, buyers should establish clear specifications based on their intended applications. This includes identifying the desired fiber composition (e.g., polyester vs. nylon), weight, and texture. Engaging in pre-purchase sampling is critical; request swatches from potential suppliers to evaluate the fabric firsthand. Additionally, buyers should consider suppliers that provide certifications or third-party testing results, which can serve as benchmarks for quality assurance. Building a strong relationship with suppliers can also facilitate more transparent communication regarding quality standards, leading to improved sourcing outcomes.

Scenario 2: Managing Inventory and Storage of Microfiber by the Yard

The Problem: B2B buyers frequently face challenges in managing inventory levels and storage of microfiber by the yard. Due to its lightweight nature and bulk packaging, improper storage can lead to damage or deterioration, particularly in humid climates such as those found in South America. Furthermore, overstocking can tie up valuable capital, while understocking may lead to delays in fulfilling customer orders, disrupting business operations.

The Solution: Implementing an effective inventory management system is essential for optimizing storage and minimizing waste. Buyers should analyze sales patterns to forecast demand accurately and adjust their orders accordingly. When receiving microfiber fabric, ensure it is stored in a climate-controlled environment to prevent moisture damage. Utilizing shelving systems that allow for easy access and visibility can also help in maintaining an organized inventory. Moreover, consider establishing a Just-In-Time (JIT) inventory system to align orders closely with production schedules, reducing the need for large storage spaces and minimizing excess stock.

Scenario 3: Addressing Color Matching and Customization Challenges

The Problem: Color matching is a significant pain point for B2B buyers when ordering microfiber fabric by the yard, especially for businesses involved in fashion, upholstery, or branding. Inconsistent dye lots can lead to variations in color, which may affect product aesthetics and brand integrity. For buyers in Europe, where seasonal fashion trends are crucial, the inability to match colors accurately can result in unsold inventory and financial losses.

The Solution: To tackle color matching challenges, buyers should prioritize suppliers that offer consistent dye lots and provide color cards or samples prior to placing bulk orders. It’s advisable to specify the color codes from recognized color standards (like Pantone) to ensure uniformity across different production batches. If customization is required, consider collaborating with suppliers that have in-house dyeing capabilities, allowing for greater control over color outcomes. Establishing a clear communication channel with suppliers regarding color expectations and setting up regular quality checks during production can further enhance the reliability of color matching.

Illustrative image related to microfiber by the yard

Strategic Material Selection Guide for microfiber by the yard

What Are the Key Properties of Polyester Microfiber for B2B Applications?

Polyester microfiber is one of the most common materials used in the production of microfiber fabrics. It is known for its excellent durability, high absorbency, and resistance to shrinking and stretching. Polyester microfiber can withstand a wide range of temperatures, making it suitable for various applications, from apparel to upholstery. Its fine fibers create a plush texture that enhances comfort in clothing and bedding.

Pros & Cons: The primary advantage of polyester microfiber is its durability, which allows it to maintain its appearance and functionality over time. However, it can be more expensive compared to other synthetic fibers, which may affect cost-sensitive projects. Additionally, while it is generally easy to clean, improper washing can lead to pilling or loss of softness.

Impact on Application: Polyester microfiber is compatible with dye sublimation printing, making it an excellent choice for custom designs. This feature is particularly appealing for businesses looking to create branded apparel or promotional items.

Considerations for International Buyers: When sourcing polyester microfiber, B2B buyers should ensure compliance with international standards such as ASTM and ISO for textile safety and performance. Buyers in regions like Africa and South America should also consider local climate conditions, which may affect the fabric’s performance in specific applications.

How Does Nylon Microfiber Compare in Terms of Performance?

Nylon microfiber offers a unique combination of strength and elasticity, making it highly resistant to wear and tear. This material is particularly valued in applications requiring flexibility, such as activewear and outdoor gear. Nylon microfiber has a lower moisture absorption rate than polyester, which can be advantageous in high-humidity environments.

Illustrative image related to microfiber by the yard

Pros & Cons: The key advantage of nylon microfiber is its superior tensile strength, which allows for lightweight yet durable products. However, it may be less breathable than polyester, making it less suitable for certain clothing applications. Additionally, nylon can be prone to static electricity, which could be a consideration for end-users.

Impact on Application: Nylon microfiber is particularly effective in applications that require abrasion resistance, such as automotive upholstery and outdoor gear. Its ability to withstand harsh conditions makes it a preferred choice for businesses targeting these markets.

Considerations for International Buyers: Buyers should verify that nylon microfiber meets relevant safety and environmental standards, particularly in regions like the Middle East where regulations around synthetic materials can be stringent.

What Are the Advantages of Acrylic Microfiber for Specific Uses?

Acrylic microfiber is known for its softness and warmth, making it a popular choice for products like blankets and plush toys. It is lightweight and has good thermal insulation properties, which can be beneficial in colder climates.

Pros & Cons: The primary advantage of acrylic microfiber is its softness, which enhances comfort in end products. However, it is generally less durable than polyester or nylon, leading to potential issues with longevity. Additionally, acrylic can be more susceptible to fading when exposed to sunlight.

Illustrative image related to microfiber by the yard

Impact on Application: Acrylic microfiber is often used in applications where comfort and warmth are prioritized, such as in home textiles and children’s apparel. Its ability to mimic wool without the associated weight makes it appealing for various markets.

Considerations for International Buyers: B2B buyers should ensure that acrylic microfiber complies with local regulations regarding flammability and chemical safety, especially in European markets where standards can be strict.

How Do Blended Microfibers Enhance Versatility in Applications?

Blended microfibers, which combine different synthetic fibers like polyester and nylon, offer a balance of properties that can enhance product versatility. These blends can be engineered to provide specific characteristics, such as increased durability or improved moisture-wicking capabilities.

Illustrative image related to microfiber by the yard

Pros & Cons: The key advantage of blended microfibers is their adaptability to various applications, allowing manufacturers to tailor products to specific market needs. However, the complexity of manufacturing blended fabrics can lead to higher production costs and potential quality control challenges.

Impact on Application: Blended microfibers are suitable for a wide range of applications, including activewear, upholstery, and home textiles. Their customizable nature allows businesses to cater to niche markets effectively.

Considerations for International Buyers: Buyers should consider the sourcing of raw materials for blended microfibers, ensuring they meet compliance standards in their respective regions, especially in countries like Nigeria and Saudi Arabia where local sourcing may be preferred.

Illustrative image related to microfiber by the yard

Summary Table of Microfiber Material Selection

| Material | Typical Use Case for microfiber by the yard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Apparel, upholstery, bedding | High durability and absorbency | Higher cost compared to other fibers | Medium |

| Nylon | Activewear, outdoor gear | Superior tensile strength | Less breathable, prone to static | Medium |

| Acrylic | Blankets, plush toys | Softness and warmth | Less durable, fades in sunlight | Medium |

| Blended | Activewear, upholstery, home textiles | Versatile and customizable | Higher production complexity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for microfiber by the yard

What are the Key Stages in the Manufacturing Process of Microfiber by the Yard?

The manufacturing of microfiber fabric involves several critical stages, ensuring the final product meets the high standards required by B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of raw materials, typically polyester and nylon, which are chosen for their durability and absorbency. These synthetic fibers are processed to create extremely fine filaments, often measuring less than one denier. Once the fibers are produced, they undergo a process known as splitting or fibrillation, where they are divided into smaller strands. This increases the surface area and enhances the fabric’s ability to absorb moisture, making it ideal for various applications.

Forming Techniques

After preparation, the fibers are spun into yarn. The most common methods include ring spinning or open-end spinning, which produce a strong and smooth yarn suitable for weaving or knitting. In the case of woven microfiber, the yarn is then interlaced on a loom to form the fabric. Knitted microfiber, on the other hand, employs a different technique where the yarn is looped to create a stretchable fabric. The choice between weaving and knitting depends on the intended application, with woven microfiber typically used for upholstery and knitted microfiber favored for apparel.

Illustrative image related to microfiber by the yard

Assembly and Finishing

Following the forming stage, the fabric undergoes various finishing processes to enhance its performance characteristics. These may include treatments for water resistance, stain resistance, or antimicrobial properties. The fabric is then dyed and printed according to the specifications of the buyer. Quality control checks are implemented at each stage to ensure that the finished product meets the required standards.

How is Quality Assurance Implemented in Microfiber Fabric Manufacturing?

Quality assurance is paramount in the manufacturing of microfiber fabric, especially for international B2B buyers who expect high standards. The quality control process typically adheres to international standards such as ISO 9001, which outlines criteria for an effective quality management system.

International and Industry-Specific Standards

ISO 9001 provides a framework for consistent quality management, while additional certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the application of the microfiber. These standards help ensure that the materials used are safe and effective for their intended purpose.

Quality Control Checkpoints

Quality control is integrated into the manufacturing process at various checkpoints:

Illustrative image related to microfiber by the yard

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet predefined specifications. Suppliers must provide certificates of compliance to verify the quality of their materials.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process and identify any deviations from quality standards. This includes evaluating the yarn’s strength, fabric weight, and consistency.

-

Final Quality Control (FQC): Once production is complete, the finished microfiber fabric undergoes thorough inspections. This includes testing for colorfastness, durability, and any specific performance attributes required by the buyer.

What Testing Methods are Commonly Used in Microfiber Quality Control?

Several testing methods are employed to ensure that microfiber fabrics meet quality standards. These may include:

-

Physical Testing: This involves assessing the fabric’s tensile strength, tear strength, and abrasion resistance. Such tests ensure that the fabric can withstand everyday use and maintain its integrity.

-

Chemical Testing: This includes tests for colorfastness to washing, light, and rubbing, which help determine how well the fabric retains its color and appearance over time.

-

Performance Testing: Depending on the intended use, microfiber may undergo tests for water repellency, moisture-wicking properties, and antimicrobial effectiveness.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide invaluable insight into their manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards firsthand.

-

Requesting Quality Reports: Buyers should ask for detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These documents should outline any discrepancies and how they were addressed.

-

Third-Party Inspections: Engaging third-party inspection services can help verify that the supplier adheres to industry standards and that the products meet specified quality criteria before shipment.

What are the Nuances in Quality Control for International B2B Buyers?

When dealing with international suppliers, there are several nuances to consider in quality control:

-

Cultural Differences: Quality expectations may vary by region. Understanding the local manufacturing culture can help buyers set realistic expectations and establish clear communication regarding quality standards.

-

Regulatory Compliance: Different countries may have unique regulations regarding textile products. Buyers must ensure that their suppliers are compliant with local laws and international standards to avoid potential legal issues.

-

Logistics and Shipping Considerations: Quality control does not end with the manufacturing process. Buyers should consider how the fabric is packaged and shipped, as improper handling can lead to damage or defects.

By understanding these critical aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing microfiber fabric by the yard, ensuring they receive products that meet their quality and performance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘microfiber by the yard’

In the competitive landscape of sourcing microfiber fabric by the yard, having a structured approach is essential for B2B buyers. This checklist serves as a practical guide to navigate the procurement process effectively, ensuring that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the intended applications for the microfiber, such as upholstery, apparel, or cleaning products. Be specific about the weight, texture, and durability required, as these factors will influence both the performance and cost of the fabric.

- Key considerations:

- Fabric weight (e.g., GSM)

- Fiber content (e.g., polyester vs. nylon)

- Finish and treatment (e.g., moisture-wicking, stain-resistant)

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in microfiber fabric. Look for companies with a strong reputation in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize online platforms, industry directories, and trade shows to compile a list of candidates.

- Where to look:

- Online B2B marketplaces

- Industry-specific trade fairs

- Recommendations from industry peers

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications to ensure compliance with industry standards. This is crucial for maintaining quality and sustainability in your supply chain. Look for certifications such as OEKO-TEX, ISO, or specific environmental certifications relevant to your market.

- Important certifications:

- OEKO-TEX Standard 100 for harmful substances

- ISO certifications for quality management

- GRS (Global Recycled Standard) for sustainable sourcing

Step 4: Request Samples

Always request fabric samples before making bulk purchases. This step allows you to assess the quality, feel, and color accuracy of the microfiber. Evaluate how well the samples meet your specifications and consider conducting performance tests if applicable.

- Testing aspects:

- Colorfastness and durability

- Texture and softness

- Absorbency and stain resistance

Step 5: Negotiate Terms and Pricing

Once you’ve selected potential suppliers, engage in negotiations to secure favorable terms. Discuss pricing, minimum order quantities, lead times, and payment terms. Establishing a good rapport with your supplier can lead to better pricing and service in the long run.

- Negotiation tips:

- Compare quotes from multiple suppliers

- Be clear about your budget constraints

- Consider long-term partnerships for volume discounts

Step 6: Assess Logistics and Shipping Options

Evaluate the logistics of shipping microfiber fabric from the supplier to your location. Understand the shipping costs, timelines, and potential customs issues that may arise. Effective logistics management can significantly impact your overall project timelines and costs.

- Logistics considerations:

- Shipping methods (air vs. sea)

- Customs clearance processes

- Insurance options for high-value shipments

Step 7: Establish a Quality Control Process

Implement a quality control protocol to ensure that the delivered microfiber meets your specifications. This step can include inspections during production and upon receipt. A robust quality assurance process minimizes the risk of defects and returns, safeguarding your business reputation.

Illustrative image related to microfiber by the yard

- Quality control measures:

- On-site inspections during manufacturing

- Random sampling upon delivery

- Clear return and replacement policies

By following these steps, B2B buyers can streamline their sourcing process for microfiber fabric, ensuring they procure high-quality materials that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for microfiber by the yard Sourcing

What Are the Key Cost Components in Microfiber Fabric Sourcing?

When sourcing microfiber by the yard, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include:

-

Materials: Microfiber is typically made from synthetic fibers like polyester and nylon, which can fluctuate in price based on global oil prices and availability. The quality of the materials directly impacts the fabric’s performance characteristics, such as durability and softness.

-

Labor: Labor costs vary widely depending on the geographic location of the manufacturing facility. Regions with lower labor costs, such as parts of Asia, may offer cheaper production but could compromise on quality. Conversely, manufacturers in Europe may provide higher quality but at increased labor costs.

-

Manufacturing Overhead: This includes costs associated with running the factory, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help lower these costs, making it crucial to evaluate potential suppliers on their operational efficiency.

-

Tooling: Customizing microfiber fabrics may require specific tooling, which can be a significant upfront investment. Understanding whether tooling costs are included in the price or charged separately is essential for accurate budgeting.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the fabric meets specified standards, which can incur additional costs. However, investing in quality control reduces the risk of defects and returns, ultimately leading to cost savings.

-

Logistics: Shipping costs can vary based on distance, mode of transport, and volume. International buyers should consider the total cost of logistics, including customs duties and tariffs, which can significantly affect the final price.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding this margin can help buyers negotiate better prices, especially when placing larger orders.

How Do Price Influencers Affect Microfiber Fabric Pricing?

Several factors influence the pricing of microfiber fabrics:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom fabrics with specific colors, patterns, or performance features (e.g., moisture-wicking, UV-resistant) may incur additional costs. Clearly defining specifications upfront can prevent unexpected expenses.

-

Material Quality and Certifications: Higher-quality microfiber fabrics or those that come with certifications (e.g., eco-friendly, hypoallergenic) may command premium prices. Buyers should weigh the long-term benefits against initial costs.

-

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers may offer better service and quality assurance, justifying higher prices.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they dictate the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. Incorrect assumptions about these terms can lead to unexpected costs.

What Tips Can Help International Buyers Optimize Their Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing efficiency:

-

Negotiate Effectively: Leverage volume commitments or long-term contracts to negotiate better pricing and terms. Establishing a good relationship with suppliers can also lead to better deals over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront price but also the long-term implications of sourcing decisions, including maintenance, durability, and potential waste.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures based on local demand and supply dynamics. Researching market trends in specific regions can provide valuable insights for negotiation.

-

Utilize Technology: Platforms that aggregate supplier information can streamline the sourcing process, allowing buyers to compare prices, quality, and delivery times efficiently.

-

Stay Informed on Global Trends: Keeping abreast of global economic trends, such as changes in oil prices or trade policies, can help buyers anticipate cost fluctuations and plan accordingly.

Disclaimer on Indicative Prices

Prices for microfiber by the yard can vary significantly based on the factors outlined above. It is essential for buyers to conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing microfiber by the yard With Other Solutions

In the diverse landscape of fabric solutions, B2B buyers often seek alternatives to ‘microfiber by the yard’ for various applications. Understanding these alternatives can help businesses make informed decisions that align with their specific needs and operational goals. Below, we compare ‘microfiber by the yard’ with two viable alternatives: cotton fabric and polyester blends.

| Comparison Aspect | Microfiber By The Yard | Cotton Fabric | Polyester Blends |

|---|---|---|---|

| Performance | Highly absorbent, durable, and resistant to stains | Naturally breathable but less durable | Strong, durable, and wrinkle-resistant |

| Cost | Moderate price point | Generally lower cost | Competitive pricing |

| Ease of Implementation | Easy to sew and work with | Standard sewing techniques required | Similar to cotton, easy to work with |

| Maintenance | Machine washable, quick drying | Requires more care; prone to wrinkling | Easy to care for, often wrinkle-resistant |

| Best Use Case | Ideal for apparel, upholstery, and home decor | Suitable for everyday clothing and bedding | Great for activewear and outdoor gear |

What Are the Advantages and Disadvantages of Cotton Fabric Compared to Microfiber?

Cotton fabric is a popular alternative known for its natural breathability and softness, making it a staple in everyday clothing and bedding. Its lower cost can be appealing for budget-conscious buyers. However, cotton is less durable than microfiber and may require more frequent replacements, particularly in high-wear applications. Additionally, it is prone to wrinkling and may require ironing, which can increase maintenance efforts.

How Do Polyester Blends Stack Up Against Microfiber?

Polyester blends offer a robust alternative, providing a balance of durability and performance. They are often wrinkle-resistant and quick-drying, making them suitable for activewear and outdoor applications. While polyester blends can be competitively priced, they may not offer the same level of comfort as microfiber. Additionally, the synthetic nature of polyester can lead to less breathability, which may be a concern for certain applications such as bedding or summer apparel.

How Should B2B Buyers Choose Between These Fabric Options?

When selecting the right fabric solution, B2B buyers should consider several factors, including the specific application, target market, and budget constraints. Microfiber by the yard excels in versatility and performance, making it an excellent choice for high-end upholstery and activewear. Cotton fabric may be the best option for products prioritizing comfort and natural materials. Polyester blends could be ideal for businesses focusing on durability and ease of maintenance in activewear or industrial applications.

Illustrative image related to microfiber by the yard

Ultimately, the decision should align with the operational needs and customer expectations. By evaluating these alternatives and understanding their respective advantages and disadvantages, buyers can make strategic choices that enhance their product offerings and meet market demands effectively.

Essential Technical Properties and Trade Terminology for microfiber by the yard

What Are the Key Technical Properties of Microfiber Fabric by the Yard?

Microfiber fabric, known for its versatility and durability, has several essential technical properties that B2B buyers should consider:

-

Material Composition

Microfiber is typically made from a blend of polyester and polyamide (nylon). This combination gives the fabric its unique softness, strength, and absorbency. Understanding the material composition is crucial for buyers who need specific qualities in their products, such as enhanced durability or moisture-wicking capabilities. -

Weight (GSM – Grams per Square Meter)

The weight of microfiber is often measured in GSM, which indicates the density of the fabric. A higher GSM typically denotes a thicker, more durable fabric, suitable for upholstery or heavy-duty applications. Buyers must consider GSM to ensure the fabric meets the performance requirements of their intended use, whether for apparel, drapery, or other applications. -

Fabric Width

Microfiber fabric is available in various widths, commonly ranging from 54 to 60 inches. The width affects how much fabric is needed for large projects, impacting both cost and efficiency. B2B buyers should assess the width to optimize their material usage for specific applications, such as large upholstery pieces or custom garments. -

Durability and Abrasion Resistance

Microfiber is renowned for its durability, often exceeding that of traditional fabrics. It can withstand extensive use without fraying or losing its structure. For B2B buyers, understanding the abrasion resistance of microfiber is vital, especially for products that will undergo heavy wear, such as automotive upholstery or commercial furnishings. -

Moisture Management

One of the standout properties of microfiber is its ability to wick moisture away from the skin, making it ideal for activewear and home textiles. This feature is particularly important for buyers in markets focused on performance fabrics, as it enhances comfort and usability in various environments. -

Colorfastness

The ability of microfiber to retain its color after washing is known as colorfastness. High colorfastness ensures that the fabric maintains its aesthetic appeal over time, which is crucial for retail applications. Buyers should prioritize this property to ensure customer satisfaction and product longevity.

What Are Common Trade Terms Associated with Microfiber Fabric?

Familiarity with industry jargon is essential for B2B transactions. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of microfiber, OEMs might provide fabric for apparel manufacturers or furniture makers. Understanding OEM relationships can help buyers navigate sourcing and production partnerships more effectively. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest amount of product that a supplier is willing to sell. For microfiber fabric, this can vary significantly based on the manufacturer. Knowing the MOQ is essential for buyers to ensure they can meet production needs without incurring unnecessary costs. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing information from suppliers. When purchasing microfiber, submitting an RFQ allows buyers to compare offers from multiple suppliers and make informed decisions based on quality, price, and delivery terms. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international transactions. They cover aspects such as shipping costs, insurance, and liability. Understanding Incoterms is crucial for B2B buyers importing microfiber fabric, as they clarify who is responsible for various logistics throughout the supply chain. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. In the context of microfiber fabrics, lead times can vary based on production schedules and shipping logistics. Buyers should factor in lead time when planning inventory to avoid disruptions in their supply chain. -

Sample Order

A sample order allows buyers to evaluate the quality and characteristics of microfiber fabric before committing to a larger purchase. This practice is particularly beneficial for businesses that require specific fabric properties for their applications, ensuring that the final product meets their standards.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing microfiber fabric, ensuring their products meet market demands and quality standards.

Navigating Market Dynamics and Sourcing Trends in the microfiber by the yard Sector

What Are the Key Market Dynamics and Trends Affecting Microfiber by the Yard?

The microfiber by the yard sector is experiencing significant growth, fueled by global demand across multiple industries, including apparel, home decor, automotive, and healthcare. Key drivers include the increasing consumer preference for durable, lightweight, and versatile materials. Moreover, the rising trend of online shopping has made it easier for international buyers from regions such as Africa, South America, the Middle East, and Europe to source microfiber fabric efficiently. B2B technology trends, such as e-commerce platforms and digital supply chain management systems, are facilitating seamless transactions and improving supplier visibility.

Illustrative image related to microfiber by the yard

Emerging trends in the microfiber market include the adoption of innovative manufacturing techniques that enhance fabric performance, such as moisture-wicking and stain-resistant technologies. Buyers are also increasingly interested in customization options, such as color, pattern, and texture, to meet specific market demands. For instance, in regions like Saudi Arabia, where climate can be extreme, sourcing microfiber that offers UV protection is becoming essential. Furthermore, the trend towards sustainable materials is reshaping purchasing decisions, with buyers favoring suppliers who provide transparency and traceability in their supply chains.

How Is Sustainability and Ethical Sourcing Impacting the Microfiber Industry?

Sustainability and ethical sourcing are becoming non-negotiable aspects of the microfiber by the yard sector. The environmental impact of synthetic fibers, including microfiber, is significant; it contributes to plastic pollution and can be detrimental to marine life. As such, many B2B buyers are prioritizing suppliers who demonstrate a commitment to reducing their ecological footprint. This includes sourcing recycled materials or using manufacturing processes that minimize waste and energy consumption.

Ethical supply chains are also gaining prominence, with buyers increasingly scrutinizing labor practices within the textile industry. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming crucial for demonstrating compliance with environmental and social responsibility. Suppliers who can provide these certifications not only enhance their credibility but also align with the values of conscious consumers in markets across Africa, South America, and Europe. By focusing on sustainable practices, B2B buyers can better position themselves in a marketplace that is rapidly evolving towards eco-friendliness.

How Has the Microfiber Market Evolved Over Time?

The evolution of the microfiber market can be traced back to its inception in the 1970s when it was first developed in Japan. Initially used in cleaning products due to its superior absorbency and softness, microfiber has since expanded its applications dramatically. In the late 20th century, advancements in textile technology allowed for the mass production of microfiber fabrics, making them accessible for use in clothing, upholstery, and various other applications.

Today, the microfiber by the yard market is characterized by diverse offerings, catering to an array of consumer needs, from fashion to functionality. The continuous innovation in fabric technology and the growing awareness of sustainability have transformed microfiber into a material that not only meets practical demands but also aligns with modern ethical standards. As the market continues to evolve, international B2B buyers must stay informed about trends and adapt their sourcing strategies accordingly to remain competitive.

Illustrative image related to microfiber by the yard

Frequently Asked Questions (FAQs) for B2B Buyers of microfiber by the yard

-

How do I ensure the quality of microfiber fabric before purchasing?

To guarantee the quality of microfiber fabric, request samples from potential suppliers before placing bulk orders. Evaluate the texture, durability, and absorbency of the fabric to ensure it meets your specifications. Additionally, inquire about the manufacturing process, including the type of fibers used and quality control measures in place. Certifications such as OEKO-TEX or ISO can also indicate adherence to quality standards, providing further assurance of the fabric’s performance. -

What are the minimum order quantities (MOQs) for microfiber by the yard?

Minimum order quantities for microfiber fabric can vary significantly among suppliers, typically ranging from 10 to 100 yards. It’s essential to clarify MOQs during negotiations, as some suppliers may offer flexibility based on your needs or frequency of orders. Additionally, consider the impact of MOQs on your inventory management and cash flow, especially if you’re entering a new market or testing product lines. -

What payment terms should I expect when sourcing microfiber fabric internationally?

Payment terms can vary by supplier and region. Common practices include upfront payments, letters of credit, or payment upon delivery. For international transactions, it’s wise to negotiate terms that protect your interests, such as partial payments before shipment and the remainder upon receipt. Always ensure that payment methods are secure and that you have clear documentation of the transaction to avoid disputes. -

How can I customize microfiber fabric to meet my specific needs?

Many suppliers offer customization options for microfiber fabric, including color, pattern, and texture. When seeking customization, provide detailed specifications and, if possible, samples of desired materials. Discuss lead times for production and any additional costs associated with customization. Establishing a strong communication channel with your supplier can facilitate a smoother design process and ensure that the final product aligns with your expectations. -

What logistics considerations should I keep in mind when importing microfiber fabric?

Logistics play a crucial role in sourcing microfiber fabric internationally. Consider shipping methods, transit times, and potential customs regulations in your destination country. Work with logistics partners who have experience in textile shipments to navigate any complexities. Additionally, understand the incoterms (e.g., FOB, CIF) that dictate responsibility for shipping costs and risks, which can impact your overall budget and delivery timelines. -

How do I vet potential suppliers for microfiber fabric?

To effectively vet suppliers, start by researching their reputation through reviews and testimonials from other clients. Request references and check their track record in delivering quality products on time. Visit their manufacturing facilities if possible, or conduct virtual assessments to gauge production capabilities. It’s also beneficial to ask for certifications and compliance with international standards to ensure they meet your quality and ethical sourcing requirements. -

What types of microfiber fabric are available for different applications?

Microfiber fabric is versatile and available in various types suitable for different applications, including apparel, upholstery, and cleaning products. For fashion items, look for softer blends, while heavier grades are ideal for upholstery and home décor. Understanding your specific application will help you choose the right fabric type, ensuring it meets performance and aesthetic requirements for your end products. -

What are the common uses for microfiber fabric in the B2B sector?

Microfiber fabric is widely used across various industries due to its durability and absorbency. In the apparel sector, it’s popular for activewear, loungewear, and uniforms. In home textiles, microfiber is used for upholstery, curtains, and bedding. Additionally, its cleaning properties make it a preferred choice for commercial cleaning products. Identifying your target market and application will help you leverage the advantages of microfiber fabric effectively.

Top 6 Microfiber By The Yard Manufacturers & Suppliers List

1. Fabric Wholesale Direct – Microfiber Fabric by the Yard

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: Microfiber Fabric By The Yard | Free Shipping On Orders $99+ | Available in various colors and patterns | Suitable for multiple applications including apparel, activewear, automotive, bedding, and upholstery | Characteristics include moisture wicking, stretch, and UV resistance.

2. Fabric Warehouse – Microfiber Fabric

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Microfiber Fabric By The Yard – Faux Suede for Upholstery

– SHIPS FREE OVER $100

– Categories: Microfiber Fabric, Upholstery Fabric

– Available in Remnants and Yards

– Yards Available: 1+, 10+, 20+, 30+

– Colors Available: Beige, Black, Blue, Bronze, Brown, Gold, Gray, Green, Ivory, Khaki, Orange, Pink, Purple, Red, Silver

– Upholstery Fabric Weight Options: Extra Heavy Weight, Heavy Weight, Light…

3. Rocky Woods – SunScreen50™ UPF50+ Fabric

Domain: rockywoods.com

Registered: 1998 (27 years)

Introduction: SunScreen50™ UPF50+ Polyester Microfiber Fabric (Sold per Yard)

4. Wazoodle – Zorb® Microfiber Loop Terry

Domain: wazoodle.com

Registered: 2002 (23 years)

Introduction: Zorb® Microfiber Loop Terry is designed for rapid absorption. It is part of the Zorb fabric collection, known for its super absorbent properties. The fabric is suitable for various applications including activewear, medical gowns, nursing pads, and reusable bags. It features functions such as being absorbent, antimicrobial, food safe, waterproof, and hook-compatible. Zorb Microfiber Terry is avail…

5. My Textile Fabric – Microfiber Towel Fabric

Domain: mytextilefabric.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “Microfiber Towel Fabric”,”Description”: “Ultra-Soft & Absorbent microfiber fabric designed for maximum absorbency, softness, and durability.”,”Material”: “80% Polyester, 20% Polyamide”,”Width”: “60 inches”,”Texture”: “Ultra-soft, plush, and absorbent”,”Colors Available”: [“White”, “Baby Blue”],”Durability”: “Quick-drying, lint-free, and long-lasting”,”Versatile Uses”: [“Towels”, …

6. eBay – Microfiber Craft Fabrics

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: By the Yard Microfiber Craft Fabrics available in various colors including Orange, Beige, and Brown. Products include a range of microfiber fabrics suitable for upholstery, apparel, and crafts. Notable listings include microsuede upholstery fabric, cotton microfiber blends, and faux suede options, with widths typically around 56″ to 66″. Prices vary from approximately $2.49 to $72.00, with shippin…

Strategic Sourcing Conclusion and Outlook for microfiber by the yard

As the demand for microfiber by the yard continues to grow across diverse industries—from apparel to home decor—strategic sourcing becomes crucial for international buyers. Understanding the unique properties of microfiber, including its durability, absorbency, and versatility, allows businesses to make informed purchasing decisions that align with their operational needs. Sourcing high-quality microfiber not only enhances product offerings but also supports sustainable practices by providing materials that can be utilized across various applications, from upholstery to activewear.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, establishing reliable supply chains is essential. Engaging with suppliers who offer competitive pricing, fast international shipping, and excellent customer service can lead to significant cost savings and improved product quality.

Looking ahead, the future of microfiber sourcing is promising. By prioritizing strategic partnerships and staying abreast of market trends, businesses can harness the full potential of this innovative fabric. Now is the time to explore the vast opportunities microfiber presents—seize the moment and enhance your inventory with high-quality microfiber by the yard to meet the evolving needs of your customers.

Illustrative image related to microfiber by the yard

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.