Introduction: Navigating the Global Market for custom leather work gloves

In today’s competitive landscape, sourcing high-quality custom leather work gloves can be a daunting task for B2B buyers, particularly those operating across diverse markets in Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying the right suppliers but also in ensuring that the gloves meet specific industry standards for durability, comfort, and functionality. This comprehensive guide is designed to navigate you through the complexities of the global market for custom leather work gloves, providing insights into various types of gloves, their applications across different sectors, and effective supplier vetting processes.

From understanding the nuances of leather types to exploring customization options that cater to your unique needs, this guide empowers international B2B buyers to make informed purchasing decisions. We will delve into critical factors such as cost considerations, production timelines, and quality assurance practices that are essential for maintaining competitive advantage in your industry. With a focus on regions like Saudi Arabia and Germany, where industrial standards may vary, this guide serves as a valuable resource to help you streamline your procurement process and enhance your operational efficiency. By equipping you with actionable insights, we aim to transform your sourcing experience into a strategic advantage, ensuring you select the best custom leather work gloves for your business.

Table Of Contents

- Top 4 Custom Leather Work Gloves Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather work gloves

- Understanding custom leather work gloves Types and Variations

- Key Industrial Applications of custom leather work gloves

- 3 Common User Pain Points for ‘custom leather work gloves’ & Their Solutions

- Strategic Material Selection Guide for custom leather work gloves

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather work gloves

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather work gloves’

- Comprehensive Cost and Pricing Analysis for custom leather work gloves Sourcing

- Alternatives Analysis: Comparing custom leather work gloves With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather work gloves

- Navigating Market Dynamics and Sourcing Trends in the custom leather work gloves Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather work gloves

- Strategic Sourcing Conclusion and Outlook for custom leather work gloves

- Important Disclaimer & Terms of Use

Understanding custom leather work gloves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Roper Gloves | Durable leather, flexible fit, often lined | Ranching, rodeo, heavy-duty work | Pros: Excellent dexterity; Cons: May require break-in period. |

| Welding Gloves | Heat-resistant, reinforced stitching, longer cuffs | Construction, metal fabrication | Pros: High protection against heat; Cons: Bulkiness may reduce dexterity. |

| Garden Gloves | Lightweight, breathable leather, often with added grip | Horticulture, landscaping | Pros: Comfort during prolonged use; Cons: Less durable than heavier gloves. |

| Heavy-Duty Work Gloves | Thick leather, reinforced palms, rugged design | Construction, heavy machinery | Pros: Exceptional durability; Cons: Can be stiff initially. |

| Touchscreen Gloves | Leather with touchscreen-compatible fingertips | Logistics, outdoor work | Pros: Allows for device use without removal; Cons: May sacrifice some durability. |

What are Roper Gloves and Their Key B2B Considerations?

Roper gloves are characterized by their durable leather construction and flexible fit, often lined for added warmth. They are ideal for B2B applications in ranching, rodeo, and other heavy-duty work environments where dexterity is crucial. Buyers should consider the glove’s fit and comfort, as a proper fit enhances performance. Although they provide excellent dexterity, buyers should be aware that some models may require a break-in period to achieve optimal comfort.

How Do Welding Gloves Stand Out in the Market?

Welding gloves are specifically designed for high-heat environments, featuring reinforced stitching and longer cuffs to protect the forearms. Commonly used in construction and metal fabrication, these gloves prioritize safety over flexibility. B2B buyers should evaluate the level of heat resistance required for their specific tasks, as well as the glove’s overall fit. While they offer exceptional protection, their bulkiness might limit dexterity, which is a critical consideration for tasks requiring precision.

What Makes Garden Gloves Suitable for Horticulture?

Garden gloves are lightweight and often made from breathable leather, providing comfort during extended use. They are primarily utilized in horticulture and landscaping applications, where a balance of protection and dexterity is essential. B2B buyers should consider the glove’s grip and comfort features, as these can enhance productivity. However, it’s important to note that while these gloves are comfortable, they may not withstand the wear and tear of more demanding tasks as effectively as heavier-duty options.

Why Choose Heavy-Duty Work Gloves for Construction?

Heavy-duty work gloves are crafted from thick leather and designed with reinforced palms, making them suitable for construction and heavy machinery operations. These gloves offer exceptional durability and protection against abrasions and impacts. Buyers should assess the glove’s weight and initial stiffness, as they may require some time to break in. While these gloves are built to last, their bulkiness can be a drawback for tasks requiring fine motor skills.

How Do Touchscreen Gloves Enhance Efficiency in Logistics?

Touchscreen gloves integrate leather with fingertips designed for device compatibility, allowing users to operate smartphones and tablets without removing their gloves. This feature is particularly beneficial in logistics and outdoor work environments. B2B buyers should evaluate the balance between touchscreen functionality and the glove’s overall durability. While these gloves enhance efficiency by allowing seamless device interaction, they may sacrifice some durability compared to traditional work gloves, which is an important consideration for high-use scenarios.

Key Industrial Applications of custom leather work gloves

| Industry/Sector | Specific Application of custom leather work gloves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty tasks like demolition and masonry | Enhanced durability and protection against abrasions | Sourcing gloves with reinforced stitching and grip |

| Agriculture | Handling livestock and machinery | Improved grip and dexterity for intricate tasks | Consideration of materials that provide breathability |

| Manufacturing | Assembly line work and machine operation | Safety compliance and reduced hand fatigue | Customization options for fit and comfort |

| Oil & Gas | Rig operations and maintenance | Protection against chemicals and extreme conditions | Sourcing gloves with chemical resistance features |

| Mining | Handling tools and materials | Enhanced grip and durability in rugged environments | Consideration of heat resistance and insulation |

How Are Custom Leather Work Gloves Used in Construction?

In the construction industry, custom leather work gloves are essential for heavy-duty tasks such as demolition, masonry, and carpentry. These gloves provide enhanced durability, protecting workers’ hands from abrasions and cuts. Buyers in this sector should prioritize gloves with reinforced stitching and superior grip features to ensure safety and efficiency on-site. Additionally, gloves that allow for dexterity and comfort can significantly reduce hand fatigue during long working hours, making them a valuable investment for construction companies.

What Role Do Custom Leather Work Gloves Play in Agriculture?

In agriculture, custom leather work gloves are vital for tasks such as handling livestock and operating machinery. They offer improved grip and dexterity, enabling workers to perform intricate tasks safely. For international buyers, particularly in regions with varying climates, sourcing gloves made from breathable materials is crucial to ensure comfort during extended use. Gloves that can withstand wear and tear while providing adequate protection against animal bites or cuts from tools are highly sought after in this industry.

Why Are Custom Leather Work Gloves Important in Manufacturing?

Manufacturing environments often require workers to operate machinery and handle materials on assembly lines. Custom leather work gloves are designed to meet safety compliance standards while reducing hand fatigue, making them ideal for such applications. Businesses should consider customization options that ensure a perfect fit for their employees, as this can enhance productivity and safety. Furthermore, gloves that offer resistance to oil and other substances commonly found in manufacturing settings can help maintain the integrity of the product and the safety of the workers.

How Do Custom Leather Work Gloves Benefit the Oil & Gas Industry?

In the oil and gas sector, custom leather work gloves are indispensable for rig operations and maintenance tasks. These gloves protect against harsh chemicals and extreme environmental conditions, ensuring worker safety. When sourcing gloves for this industry, businesses should look for options with chemical resistance and enhanced grip features. The right gloves can significantly reduce the risk of accidents and injuries, making them a critical component of safety gear in this high-risk industry.

What Are the Advantages of Custom Leather Work Gloves in Mining?

Mining operations often involve handling heavy tools and materials, where durability is paramount. Custom leather work gloves provide the necessary protection against sharp objects and abrasive surfaces. Buyers in the mining sector should focus on gloves that offer heat resistance and insulation, especially for tasks performed in high-temperature environments. By investing in high-quality gloves, mining companies can enhance worker safety and comfort, ultimately improving operational efficiency.

3 Common User Pain Points for ‘custom leather work gloves’ & Their Solutions

Scenario 1: Difficulty in Sizing and Fit for Diverse Workforce

The Problem: One of the most significant challenges B2B buyers face when procuring custom leather work gloves is ensuring that the gloves fit a diverse workforce. In industries such as construction, agriculture, and manufacturing, employees come in various hand sizes and shapes. Poorly fitted gloves can lead to discomfort, reduced dexterity, and ultimately decreased productivity. Moreover, when gloves are too tight, they can cause blisters and fatigue, while overly loose gloves may compromise safety and grip.

The Solution: To address sizing issues, buyers should implement a standardized sizing chart that accounts for the unique hand dimensions of their workforce. Conducting a simple survey or measurement session can help gather data on hand sizes, ensuring that the right sizes are ordered. Additionally, consider sourcing gloves that offer adjustable features, such as wrist straps or elastic bands, to accommodate various hand shapes. Collaborating with manufacturers who provide a range of sizes and styles can ensure that all employees are equipped with gloves that enhance their performance while minimizing the risk of injury.

Scenario 2: Concerns Over Durability and Wear

The Problem: B2B buyers often encounter issues with the durability of custom leather work gloves, particularly in demanding environments. Gloves that wear out quickly can lead to increased costs due to frequent replacements, not to mention the potential for safety hazards when employees are left without adequate hand protection. The challenge lies in balancing the need for high-quality materials with budget constraints.

The Solution: When sourcing custom leather work gloves, it is crucial to prioritize material quality. Buyers should look for gloves made from high-grade leather, such as cowhide or goatskin, which offer superior durability and resistance to wear and tear. Engaging with suppliers who provide detailed specifications on their materials can help buyers make informed decisions. Additionally, consider investing in gloves that are designed for specific tasks, as these will often feature reinforced stitching or additional layers in high-wear areas. Establishing long-term relationships with reputable manufacturers can also lead to better product warranties and support, ensuring that the gloves perform well over time.

Scenario 3: Inadequate Protection Against Environmental Factors

The Problem: Many industries require workers to operate in harsh environments, where exposure to elements such as extreme temperatures, chemicals, or abrasives is common. B2B buyers may struggle to find custom leather work gloves that provide adequate protection against these environmental factors while still allowing for dexterity and comfort. Failing to provide appropriate hand protection can result in injuries and compliance issues.

The Solution: To overcome this challenge, buyers should seek custom leather work gloves that are specifically designed for the environmental conditions faced by their workforce. For instance, gloves with thermal insulation are ideal for cold environments, while those with chemical-resistant coatings are necessary for workers handling hazardous materials. It is beneficial to consult with manufacturers who specialize in gloves tailored to specific industries, as they can offer expert advice on the best materials and designs for particular applications. Additionally, conducting thorough testing of gloves in real-world conditions before full-scale deployment can help ensure that the selected products meet safety and performance expectations. Regular feedback from employees using the gloves can also aid in refining future orders to better suit their needs.

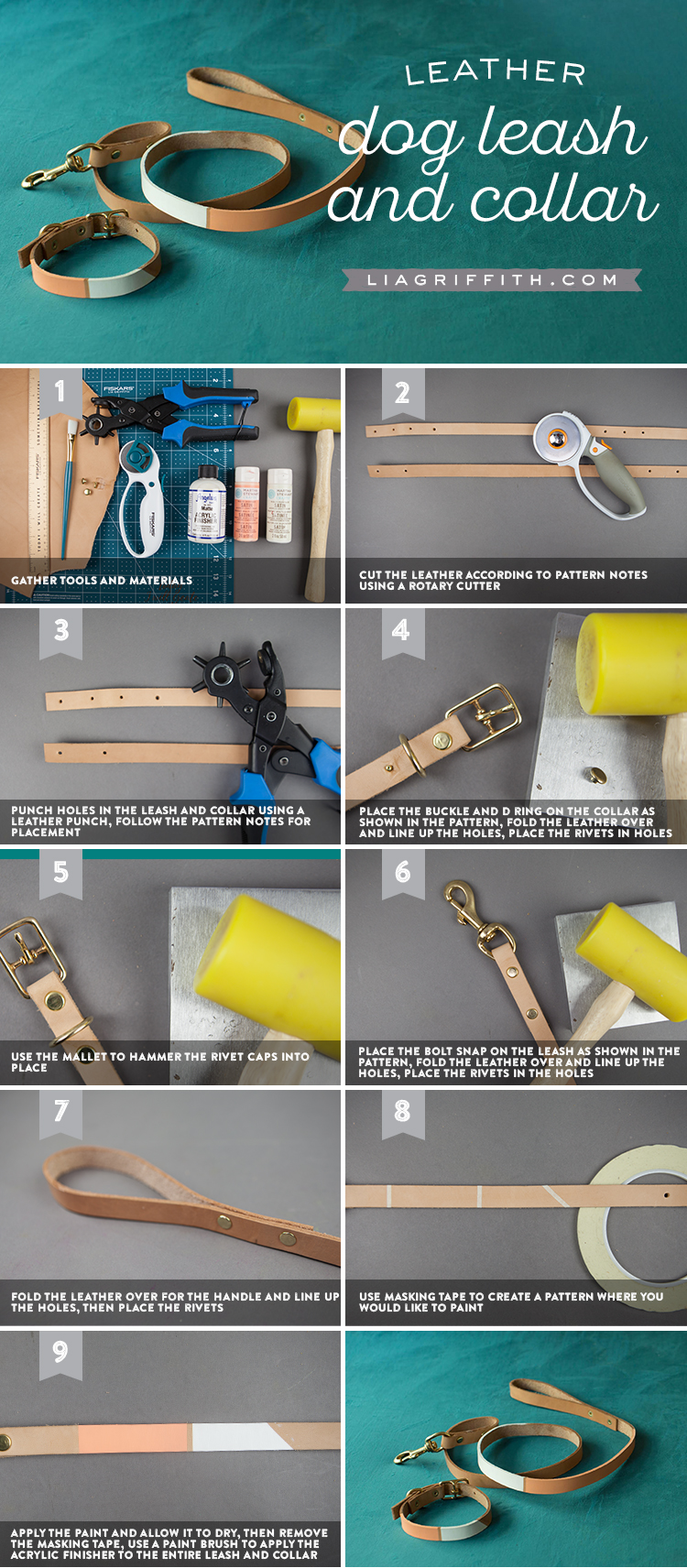

Illustrative image related to custom leather work gloves

Strategic Material Selection Guide for custom leather work gloves

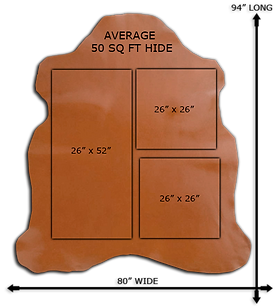

When selecting materials for custom leather work gloves, understanding the properties, advantages, and limitations of various types of leather is crucial for B2B buyers. This guide focuses on four common materials used in glove manufacturing: cowhide, goatskin, deerskin, and buffalo leather. Each material has unique characteristics that influence performance, durability, and suitability for specific applications.

What Are the Key Properties of Cowhide Leather for Work Gloves?

Cowhide leather is one of the most widely used materials for work gloves due to its strength and durability. It typically offers excellent abrasion resistance and can withstand high temperatures, making it suitable for heavy-duty applications such as construction and welding. However, it can be heavier and less flexible than other leathers, which may affect dexterity.

Pros: Cowhide gloves are highly durable and provide good protection against cuts and abrasions. They are generally cost-effective, making them a popular choice for bulk purchases.

Illustrative image related to custom leather work gloves

Cons: The weight can hinder dexterity, and they may not be as breathable as other materials, leading to discomfort in warmer climates.

Impact on Application: Cowhide is compatible with a range of industrial applications, especially where heavy machinery is involved. However, buyers in hotter regions, such as parts of Africa and the Middle East, may find them less suitable without additional ventilation features.

How Does Goatskin Leather Compare for Custom Gloves?

Goatskin leather is known for its softness and flexibility, which allows for greater dexterity compared to cowhide. It is also resistant to water and has a natural elasticity, making it ideal for tasks requiring precision, such as in the automotive or electronics industries.

Illustrative image related to custom leather work gloves

Pros: Goatskin gloves are lightweight and provide a high level of tactile sensitivity, making them suitable for intricate tasks. They also offer good abrasion resistance.

Cons: While durable, goatskin may not withstand extreme temperatures as well as cowhide. Additionally, it can be more expensive, which may be a consideration for budget-conscious buyers.

Impact on Application: Goatskin is particularly favored in Europe and North America for applications requiring precision. However, in regions with extreme heat, buyers should ensure that the gloves are treated for additional heat resistance.

What Are the Benefits of Using Deerskin Leather?

Deerskin leather is renowned for its softness and comfort, making it an excellent choice for gloves that require extended wear. It has natural insulating properties, making it suitable for colder climates, while also being breathable.

Illustrative image related to custom leather work gloves

Pros: Deerskin gloves are exceptionally comfortable and conform well to the hand, providing a custom fit. They also offer good resistance to moisture.

Cons: Deerskin is generally more expensive than cowhide and goatskin and may not be as durable under heavy abrasion.

Impact on Application: These gloves are ideal for outdoor activities and industries requiring comfort, such as agriculture and landscaping. Buyers in colder regions, such as Germany, may find deerskin gloves particularly appealing.

Why Choose Buffalo Leather for Heavy-Duty Applications?

Buffalo leather is thicker and more robust than other types, making it ideal for heavy-duty applications. It offers excellent abrasion resistance and durability, which is crucial in industries like construction and mining.

Illustrative image related to custom leather work gloves

Pros: Buffalo leather gloves are highly durable and provide excellent protection against cuts and abrasions. They are suitable for rugged environments.

Cons: The thickness of buffalo leather can limit dexterity, and it may take longer to break in compared to softer leathers.

Impact on Application: Buffalo leather is well-suited for industries where heavy wear is expected. However, buyers should consider the balance between durability and dexterity, especially in regions where precision is also required.

Illustrative image related to custom leather work gloves

Summary Table of Material Selection for Custom Leather Work Gloves

| Material | Typical Use Case for custom leather work gloves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Construction, welding | Highly durable and cost-effective | Less flexible, heavier | Medium |

| Goatskin | Automotive, electronics | Excellent dexterity and softness | Higher cost, less heat resistance | High |

| Deerskin | Outdoor activities, agriculture | Exceptional comfort and fit | More expensive, less durable | High |

| Buffalo | Heavy-duty applications (construction, mining) | Excellent durability and protection | Limited dexterity, longer break-in | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to procure custom leather work gloves tailored to their specific industry needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather work gloves

What Are the Key Stages in the Manufacturing Process of Custom Leather Work Gloves?

The manufacturing process of custom leather work gloves is intricate and requires attention to detail at every stage. It typically includes four main stages: material preparation, forming, assembly, and finishing.

1. Material Preparation: How Are Leather Materials Selected and Processed?

The quality of custom leather work gloves starts with the selection of the leather. Different types of leather—such as cowhide, deerskin, goat leather, or buffalo hide—are chosen based on their intended use, durability, and comfort.

Once selected, the leather undergoes processing to enhance its properties. This can involve tanning (vegetable or chrome tanning), dyeing, and conditioning, which contribute to the leather’s flexibility and resistance to wear. Proper storage and handling of the leather are crucial to prevent any damage or defects that could affect the final product.

Illustrative image related to custom leather work gloves

2. Forming: What Techniques Are Used to Shape the Gloves?

After material preparation, the next step is forming. This involves cutting the leather into specific patterns that match the glove design. Advanced technologies, such as computer-aided design (CAD) and laser cutting, are often employed to ensure precision and minimize waste.

Additionally, techniques like pre-curving the leather can be used to enhance comfort and fit. This is particularly important for gloves intended for heavy-duty work, as it allows for better dexterity and reduces hand fatigue.

3. Assembly: How Are the Components Joined Together?

The assembly stage is where the glove takes its final shape. Skilled workers or automated machines stitch together the cut pieces, ensuring that seams are strong and durable. Techniques such as double stitching and reinforced seams are common to enhance the glove’s longevity.

Quality checks during assembly are crucial. Inspectors often examine stitching patterns, alignment, and overall craftsmanship to ensure that each glove meets the required standards. Any defects found at this stage can be addressed before moving on to the finishing process.

4. Finishing: What Processes Enhance the Final Product?

Finishing is the final step in the manufacturing process, where gloves are treated to improve their appearance and performance. This can involve applying water-resistant coatings, polishing the leather, or adding features like insulation or touchscreen compatibility.

The finishing stage also includes final inspections to ensure that the gloves meet aesthetic and functional standards. Gloves may be packaged at this point, ready for distribution to B2B buyers.

What Quality Assurance Measures Are Essential for Custom Leather Work Gloves?

Quality assurance (QA) is vital in the production of custom leather work gloves, ensuring that each product meets both customer expectations and international standards.

1. What International Standards Apply to Leather Work Gloves?

For B2B buyers, understanding international quality standards is essential. ISO 9001 is a key standard that outlines quality management systems. Compliance with this standard indicates that a manufacturer has robust processes in place for maintaining quality throughout production.

Illustrative image related to custom leather work gloves

Additionally, industry-specific certifications such as CE marking (for products sold in Europe) and API (American Petroleum Institute) standards may also apply depending on the gloves’ intended use. These certifications ensure that the gloves meet specific safety and performance criteria relevant to various industries.

2. What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are critical throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Conducting inspections during the manufacturing process to identify defects early on. This may involve checking stitching quality, material integrity, and overall craftsmanship.

- Final Quality Control (FQC): Performing thorough inspections on finished products to ensure they meet all specified requirements before packaging and shipping.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to ensure high-quality products can take several steps to verify a supplier’s quality control practices:

Illustrative image related to custom leather work gloves

1. What Documentation Should Be Requested?

Buyers should request documentation that demonstrates compliance with international standards, such as ISO certificates and industry-specific certifications. Additionally, quality audit reports can provide insights into the supplier’s QC processes.

2. How Important Are Audits and Third-Party Inspections?

Conducting regular audits of suppliers is crucial for maintaining quality assurance. Buyers can either perform these audits themselves or hire third-party inspection services to evaluate the supplier’s manufacturing processes and QC practices.

Third-party inspections provide an unbiased assessment of the supplier’s capabilities and adherence to quality standards. This can be particularly beneficial for B2B buyers in regions like Africa, South America, and the Middle East, where local suppliers may vary significantly in their manufacturing practices.

What Are the Unique Challenges in Quality Control for International Buyers?

For international B2B buyers, navigating quality control can come with challenges. Factors such as varying quality standards, shipping logistics, and cultural differences in manufacturing practices can impact the final product’s quality.

Buyers must be proactive in establishing clear communication channels with suppliers to set expectations regarding quality and compliance. Additionally, understanding the local regulations and certifications required in the supplier’s country can help mitigate risks associated with quality discrepancies.

Illustrative image related to custom leather work gloves

In summary, the manufacturing processes and quality assurance measures for custom leather work gloves are crucial for ensuring that products meet the high standards expected by international B2B buyers. By understanding these processes and implementing thorough verification methods, buyers can make informed decisions and secure reliable partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather work gloves’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure custom leather work gloves. Understanding the nuances of sourcing these gloves is essential for ensuring quality, durability, and suitability for specific applications. Follow these steps to streamline your procurement process and make informed decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications for the leather work gloves you need. Consider factors such as material type (e.g., cowhide, goatskin), glove size, intended use (e.g., construction, welding), and any special features like waterproofing or insulation. This clarity helps suppliers understand your requirements and enables you to compare products effectively.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather work gloves. Look for companies with a strong reputation in the industry, positive customer reviews, and a portfolio showcasing their products. Utilize online platforms, trade shows, and industry publications to gather information and narrow down your options.

Illustrative image related to custom leather work gloves

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers to ensure they meet industry standards. Look for certifications such as ISO, CE, or specific safety standards relevant to your region and industry. This step is crucial as it reflects the supplier’s commitment to quality and safety, which directly impacts the reliability of the products you procure.

Step 4: Request Samples for Testing

Always request samples of the gloves before making a bulk order. Testing samples allows you to assess the glove’s comfort, fit, and durability in real-world conditions. Pay attention to the stitching quality, leather thickness, and overall craftsmanship, as these factors will influence the gloves’ longevity and performance.

Step 5: Inquire About Customization Options

Discuss customization options with potential suppliers to ensure you can tailor the gloves to your specific needs. This could include features like logo branding, color choices, and modifications in design. Understanding the supplier’s capabilities in customization can enhance your brand’s visibility and ensure the gloves meet your operational requirements.

Step 6: Review Pricing and Payment Terms

Evaluate the pricing structure and payment terms offered by each supplier. Compare quotes from multiple suppliers to ensure you’re getting a competitive rate, while also considering the quality of the gloves. Negotiate payment terms that align with your cash flow, such as payment upon delivery or installment options.

Illustrative image related to custom leather work gloves

Step 7: Establish a Communication Plan

Develop a clear communication plan with your chosen supplier to facilitate smooth interactions throughout the procurement process. Set expectations for response times, updates on production status, and handling any issues that may arise. Effective communication fosters a strong partnership and ensures timely delivery of your custom leather work gloves.

By following these steps, B2B buyers can navigate the complexities of sourcing custom leather work gloves, ensuring they select the right products that meet their specific needs while fostering solid supplier relationships.

Comprehensive Cost and Pricing Analysis for custom leather work gloves Sourcing

What Are the Key Cost Components in Custom Leather Work Gloves?

When sourcing custom leather work gloves, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of leather (e.g., cowhide, deerskin, goatskin) significantly influences the price. Higher-quality leathers typically come at a premium. Additionally, any lining materials, waterproofing treatments, or specialized features (like touchscreen compatibility) will add to the overall cost.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs may offer competitive pricing, but this can impact quality. Skilled labor is essential for crafting durable gloves, particularly those with intricate designs or custom features.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help lower these costs, providing better pricing for buyers.

-

Tooling: Custom designs often require specific molds or tools, which can be a significant initial investment. These costs may be amortized over larger production runs, making it crucial to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring that gloves meet quality standards involves additional costs. This can include testing for durability, comfort, and compliance with safety certifications, which are particularly relevant for B2B buyers in sectors like construction and manufacturing.

-

Logistics: Shipping and handling costs can vary widely based on the supplier’s location and the destination. Incoterms (International Commercial Terms) play a vital role in determining who bears these costs, impacting the overall pricing.

-

Margin: Finally, the supplier’s desired profit margin will influence the final price. Buyers should inquire about pricing structures to understand how margins affect costs.

How Do Price Influencers Affect Custom Leather Work Gloves?

Several factors can influence the pricing of custom leather work gloves:

-

Volume/MOQ: Larger orders typically attract lower per-unit prices due to economies of scale. Establishing a long-term relationship with suppliers can also lead to better pricing on future orders.

-

Specifications and Customization: Custom features, such as branding or specific design elements, can increase costs. It’s essential to define your needs clearly to avoid unexpected charges.

-

Material Selection: The choice of leather and additional features (like reinforced fingertips) can significantly impact pricing. Buyers should evaluate the trade-off between cost and quality based on their specific requirements.

-

Quality and Certifications: Gloves that meet industry standards or possess certifications (e.g., EN388 for cut resistance) may command higher prices. However, these certifications can provide assurance of safety and durability, justifying the investment.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers with a history of quality may charge more, but they can offer peace of mind regarding product consistency.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Costs associated with shipping, insurance, and customs duties can add significantly to the total price.

What Are Effective Tips for B2B Buyers Sourcing Custom Leather Work Gloves?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiation: Don’t hesitate to negotiate terms and pricing with suppliers. Building a good rapport can often lead to better deals, especially for repeat orders.

-

Cost-Efficiency: Assess the total cost of ownership (TCO), which includes purchase price, shipping, maintenance, and potential replacement costs. A lower initial price may not always equate to savings in the long run if the product requires frequent replacement.

-

Pricing Nuances: Be aware of currency fluctuations and their impact on pricing, especially when dealing with international suppliers. It’s advisable to lock in prices when possible to mitigate risks.

-

Quality Assurance: Prioritize suppliers who can provide samples or detailed product specifications. This helps ensure that the gloves meet your quality standards before placing larger orders.

-

Cultural Considerations: Understanding the business culture of your supplier’s country can facilitate smoother negotiations and partnerships. Building trust is often essential in many regions, which can lead to better pricing and collaboration.

By carefully analyzing these components and influences, B2B buyers can make strategic decisions that align with their operational needs while ensuring cost-effectiveness in sourcing custom leather work gloves.

Illustrative image related to custom leather work gloves

Alternatives Analysis: Comparing custom leather work gloves With Other Solutions

In the realm of protective gear for industrial and manual labor applications, custom leather work gloves have established themselves as a premium choice. However, buyers in international markets, particularly from Africa, South America, the Middle East, and Europe, may benefit from exploring various alternatives to ensure they select the most suitable option for their specific needs. This analysis will compare custom leather work gloves with two viable alternatives: synthetic work gloves and cotton canvas gloves.

Comparison Table

| Comparison Aspect | Custom Leather Work Gloves | Synthetic Work Gloves | Cotton Canvas Gloves |

|---|---|---|---|

| Performance | High durability and protection; excellent grip | Good flexibility; moderate durability | Lightweight; basic protection |

| Cost | $75 – $175 per pair | $20 – $60 per pair | $10 – $30 per pair |

| Ease of Implementation | Requires fitting for customization; longer lead time | Readily available; off-the-shelf options | Readily available; off-the-shelf options |

| Maintenance | Requires regular conditioning; longer lifespan with care | Low maintenance; replace when worn | Low maintenance; replace when worn |

| Best Use Case | Heavy-duty tasks; industries like construction and agriculture | Light to medium-duty tasks; industries like warehousing | Light tasks; gardening and general use |

Analyzing the Alternatives: What Are Their Strengths and Weaknesses?

What Are the Advantages and Disadvantages of Synthetic Work Gloves?

Synthetic work gloves, often made from materials such as nitrile or polyurethane, offer flexibility and a decent level of protection. They tend to be lighter than leather gloves, making them comfortable for prolonged wear. Their cost-effectiveness is another advantage, appealing to budget-conscious buyers. However, synthetic gloves generally lack the durability and protective qualities of leather, particularly in heavy-duty environments. They may wear out faster and provide less insulation in colder conditions, making them less suitable for outdoor work in harsh climates.

How Do Cotton Canvas Gloves Compare to Custom Leather Work Gloves?

Cotton canvas gloves are an economical choice for light-duty tasks. They are breathable, making them comfortable for warm-weather activities, and are easily washable, which is a plus for maintenance. However, their performance in terms of protection and durability is significantly lower than that of custom leather work gloves. They are not ideal for heavy lifting or work that involves sharp tools or hazardous materials. Buyers looking for robust hand protection for intensive labor might find cotton gloves insufficient.

How Should B2B Buyers Choose the Right Solution?

When selecting the right hand protection solution, B2B buyers should consider the specific demands of their industry and the tasks at hand. Custom leather work gloves excel in durability, protection, and comfort for heavy-duty applications, making them ideal for construction, agriculture, and industrial use. Conversely, synthetic and cotton options offer budget-friendly solutions for lighter tasks but may not meet the rigorous standards required in more demanding environments. Assessing factors such as cost, ease of implementation, and maintenance will guide buyers toward the most appropriate choice for their operational needs. Ultimately, aligning the glove type with the specific use case will ensure optimal performance and worker safety.

Essential Technical Properties and Trade Terminology for custom leather work gloves

What Are the Key Technical Properties of Custom Leather Work Gloves?

When sourcing custom leather work gloves, understanding the technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that buyers should consider:

Illustrative image related to custom leather work gloves

1. Material Grade

The quality of leather used in work gloves is a primary determinant of their durability and performance. Common grades include full-grain, top-grain, and split leather. Full-grain leather, the highest quality, retains the natural grain and is known for its strength and longevity. Top-grain leather, while slightly less durable, is more pliable and often treated for a softer feel. Split leather, derived from the lower layers, is less expensive but may not offer the same level of protection. Selecting the right material grade ensures that the gloves meet the specific demands of the intended work environment.

2. Thickness

The thickness of the leather, typically measured in ounces, directly influences durability and dexterity. Thicker leather offers greater protection but can reduce flexibility, making it essential to balance thickness with the required dexterity for tasks such as handling tools or machinery. In B2B contexts, understanding the appropriate thickness for specific applications can prevent costly glove replacements and enhance worker safety.

3. Stitching Quality

The quality of stitching is vital for the glove’s overall strength and longevity. Double stitching or reinforced seams can significantly improve durability, especially in high-stress areas. Buyers should inquire about the type of stitching used, as high-quality stitching can prevent seams from ripping or tearing, ensuring the gloves withstand rigorous use over time.

Illustrative image related to custom leather work gloves

4. Grip and Texture

A glove’s grip and texture can greatly impact its usability in various applications. Leather can be treated or textured to enhance grip, which is essential for tasks requiring precision, such as assembly work or handling slippery materials. A better grip reduces the risk of accidents and improves overall productivity, making it a significant consideration for B2B buyers.

5. Lining and Insulation

Depending on the work environment, gloves may require additional lining or insulation. For cold climates, Thinsulate or fleece linings provide warmth without sacrificing dexterity. Conversely, breathable linings can enhance comfort in warmer conditions. Understanding the specific insulation needs can help companies optimize worker comfort and performance across different climates.

What Are Common Trade Terms Used in Custom Leather Work Gloves?

Familiarizing oneself with industry jargon can streamline the procurement process and enhance communication between buyers and suppliers. Here are several key trade terms relevant to custom leather work gloves:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products based on specifications provided by another company. In the context of leather gloves, an OEM might create custom designs for a brand that sells them under its label. Understanding OEM relationships can help buyers identify potential manufacturers for custom orders.

Illustrative image related to custom leather work gloves

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. This is crucial for B2B buyers to know, as it can affect inventory management and cash flow. Buyers should negotiate MOQs based on their operational needs and sales forecasts.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing, terms, and conditions for a specific quantity of goods. In the context of custom leather gloves, issuing an RFQ allows buyers to compare quotes from different manufacturers, ensuring competitive pricing and favorable terms.

4. Incoterms (International Commercial Terms)

These are standardized trade terms used in international shipping that define the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities. For example, “FOB” (Free on Board) indicates that the seller is responsible for shipping costs until the goods are loaded onto the transport vessel.

Illustrative image related to custom leather work gloves

5. Customization

This refers to the ability to modify gloves according to specific client requirements, such as size, color, or additional features. Customization can enhance branding and ensure that the gloves meet the precise needs of end-users.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing custom leather work gloves, ultimately enhancing their operational efficiency and safety standards.

Navigating Market Dynamics and Sourcing Trends in the custom leather work gloves Sector

What Are the Key Trends Shaping the Custom Leather Work Gloves Market?

The global market for custom leather work gloves is experiencing dynamic growth, driven by several key factors. Firstly, the increasing demand for personal protective equipment (PPE) across various industries—such as construction, agriculture, and manufacturing—highlights the essential nature of durable work gloves. Buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on sourcing high-quality gloves that offer protection without compromising dexterity. Emerging technologies in glove manufacturing, such as 3D knitting and automated cutting, are enhancing the fit and function of gloves, enabling suppliers to meet specific client requirements more efficiently.

Moreover, customization is becoming a significant trend, with businesses seeking gloves tailored to their unique operational needs. This trend is evident in the rise of companies offering bespoke services, allowing clients to choose materials, designs, and features that align with their brand identity. Additionally, e-commerce platforms are transforming the purchasing process, allowing international buyers to easily compare products and suppliers, streamline transactions, and improve supply chain efficiency. This shift is particularly advantageous for B2B buyers in developing markets who may not have access to extensive local resources.

How Is Sustainability Influencing the Sourcing of Custom Leather Work Gloves?

Sustainability is a critical consideration for B2B buyers in the custom leather work gloves sector, as the environmental impact of leather production comes under increasing scrutiny. Ethical sourcing practices are gaining traction, with buyers prioritizing suppliers who demonstrate commitment to environmentally friendly methods, such as using vegetable-tanned leather or recycled materials.

Moreover, certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® provide assurance that products meet stringent environmental and social criteria. Buyers are increasingly inclined to partner with manufacturers who have transparent supply chains and can prove adherence to sustainability standards. The push for greener products not only enhances brand reputation but also caters to the growing consumer demand for responsible sourcing, especially in markets like Europe where regulations are becoming stricter.

Illustrative image related to custom leather work gloves

What Is the Historical Context of Custom Leather Work Gloves in B2B Sourcing?

The evolution of custom leather work gloves can be traced back to their origins as basic protective gear for laborers and craftsmen. Historically, leather was prized for its durability and ability to provide a barrier against physical hazards. Over the decades, technological advancements in tanning and manufacturing processes have transformed the glove industry, allowing for the incorporation of diverse materials and designs.

As markets expanded, so did the need for customization to cater to specific industries, such as agriculture and construction. This shift towards tailored solutions marked a significant turning point, enabling businesses to enhance worker safety while promoting brand identity through unique glove designs. Today, the legacy of craftsmanship continues, with modern manufacturers blending traditional techniques with innovative technologies to meet the demands of a global marketplace.

In conclusion, understanding these market dynamics and sourcing trends is essential for international B2B buyers navigating the custom leather work gloves sector. By aligning their procurement strategies with current trends in customization, sustainability, and technological advancement, companies can secure reliable partnerships and enhance their operational efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather work gloves

-

How do I choose the right custom leather work gloves for my business needs?

Choosing the right custom leather work gloves involves assessing the specific tasks your workforce will perform. Consider factors such as the type of leather (e.g., cowhide, goatskin, deerskin) for durability and comfort, the glove’s design for flexibility and dexterity, and additional features like insulation or water resistance for environmental conditions. Engage with suppliers who offer samples or prototypes to ensure the gloves meet your operational requirements before placing a bulk order. -

What are the benefits of customizing leather work gloves for my workforce?

Customizing leather work gloves provides several advantages, including improved fit and comfort, which can enhance worker productivity and safety. Personalized gloves can also feature branding elements, increasing brand visibility and creating a sense of unity among team members. Additionally, customized gloves can be tailored to meet specific industry standards or environmental needs, ensuring optimal performance in various work conditions. -

What is the typical minimum order quantity (MOQ) for custom leather work gloves?

The minimum order quantity for custom leather work gloves can vary widely among suppliers, typically ranging from 100 to 500 pairs. Factors influencing MOQ include the complexity of the customization, the type of leather used, and the supplier’s production capacity. When negotiating with suppliers, clarify MOQ terms to ensure they align with your budget and inventory needs. -

How can I ensure the quality of custom leather work gloves from suppliers?

To ensure quality, conduct thorough research on potential suppliers, including checking their certifications and customer reviews. Request samples to evaluate the glove’s material, craftsmanship, and durability. Additionally, consider suppliers that offer quality assurance processes, such as inspections during production and before shipment, to mitigate risks associated with defective products. -

What payment terms should I expect when ordering custom leather work gloves?

Payment terms for custom leather work gloves often vary by supplier and region, but common practices include a deposit of 30-50% upfront, with the balance due upon delivery or before shipment. Some suppliers may offer flexible terms based on your relationship or order size. It is essential to negotiate clear payment terms in advance to avoid misunderstandings that could delay production or delivery. -

What are the shipping and logistics considerations for importing leather work gloves?

When importing leather work gloves, consider shipping options, costs, and transit times to your location. It’s crucial to work with suppliers experienced in international shipping and customs regulations to ensure compliance with import duties and taxes. Additionally, factor in potential delays due to customs clearance, especially in regions with stringent import regulations. -

How can I vet suppliers of custom leather work gloves effectively?

Vetting suppliers involves evaluating their manufacturing capabilities, quality control measures, and industry reputation. Request references from other businesses and check online reviews or ratings. You may also want to visit the supplier’s facility if possible or conduct a virtual tour to assess their production processes and working conditions, ensuring they align with your ethical standards and quality expectations. -

What customization options are typically available for leather work gloves?

Customization options for leather work gloves can include various features such as different types of leather, glove sizes, colors, and styles. You can also add functional elements like reinforced palms, touchscreen compatibility, or insulation for cold weather. Branding options, such as embroidery or printing your logo, are commonly available and can enhance your brand’s visibility while ensuring that the gloves meet your specific operational needs.

Top 4 Custom Leather Work Gloves Manufacturers & Suppliers List

1. Vermont Glove – The Vermonter

Domain: vermontglove.com

Registered: 2018 (7 years)

Introduction: {“products”:[{“name”:”The Vermonter”,”price”:”$115.00 USD”,”description”:”Our flagship work glove”},{“name”:”Custom Leather Work Glove – Gift Pack”,”price”:”$175.00 USD”,”description”:”The ultimate gift”},{“name”:”Flatlander”,”price”:”$115.00 USD”,”description”:”Our nimblest glove”},{“name”:”Uphill Skier”,”price”:”$150.00 USD”,”description”:”Versatile winter work glove”}],”brand”:”Vermont Glove”,”…

2. Sullivan Glove – Durable Work Gloves

Domain: sullivanglove.com

Registered: 1999 (26 years)

Introduction: This company, Sullivan Glove – Durable Work Gloves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Buy Bear Knuckles – Premier Leather Work Gloves

Domain: buybearknuckles.com

Registered: 2017 (8 years)

Introduction: Pre-Curved Premier Leather Work Gloves – Patented Design; Made to last; Comfort and durability; Available for various industries: Rodeo, Farm & Ranch, Construction, Welding & Fabrication; Best Sellers include: High Noon – D373 ($32.98), Old Faithful – D351 ($27.48), Bushwacker – HD361 ($29.98), Midnight – D409 ($32.98), Yellow Jacket – D367 ($30.86), Bodacious – D357 ($29.72), Redrock – D451 ($27….

4. Etch O Sketch – Personalized Leather Gloves

Domain: etchosketch.com

Registered: 2009 (16 years)

Introduction: {“product_name”:”Personalized Leather Gloves”,”material”:”100% deerskin leather”,”features”:”Ultimate everyday all day work gloves, suitable for gardening, oil field work, automobile tasks, and horseback riding.”,”personalization”:”Laser engraved monogram, name, logo, or ranch brand available. Men’s monogram is a 3-letter monogram (First, Middle, Last). Women’s monogram is a 3-letter monogram with…

Strategic Sourcing Conclusion and Outlook for custom leather work gloves

In the ever-evolving landscape of industrial workwear, custom leather work gloves stand out as a critical investment for businesses prioritizing safety, durability, and comfort. As highlighted throughout this guide, strategic sourcing is essential for international B2B buyers to ensure they partner with manufacturers who not only meet quality standards but also offer tailored solutions to their specific needs. Engaging with suppliers from diverse regions—such as Africa, South America, the Middle East, and Europe—can unlock opportunities for innovation, cost savings, and enhanced product offerings.

The unique attributes of custom leather gloves, including their flexibility, breathability, and resistance to wear, make them indispensable across various industries, from construction to agriculture. As you consider your sourcing strategies, focus on suppliers that provide comprehensive support, including customization options and after-sales services.

Looking ahead, the demand for high-quality leather work gloves is poised to increase, driven by a growing emphasis on workplace safety and ergonomic design. Now is the time to strengthen your supply chain by forging relationships with reputable manufacturers who can deliver exceptional products tailored to your requirements. Take the next step in enhancing your workforce’s safety and productivity by exploring strategic partnerships in the custom leather glove market today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.