Introduction: Navigating the Global Market for custom leather punch

In an increasingly competitive global market, sourcing custom leather punch solutions can pose significant challenges for B2B buyers, especially when aiming to meet specific branding or production needs. The demand for high-quality, durable leather punching tools is on the rise, driven by industries ranging from fashion to automotive. This guide serves as a comprehensive resource, offering insights into various types of custom leather punches, their applications, and the process of vetting suppliers across different regions, including Africa, South America, the Middle East, and Europe, particularly in markets like Saudi Arabia and Germany.

With a focus on empowering international buyers, this guide will delve into essential factors such as the cost implications of custom tooling, the importance of material quality, and design considerations tailored to unique production requirements. Readers will learn how to identify reputable manufacturers, understand the nuances of pricing structures, and leverage effective negotiation strategies. By equipping buyers with actionable insights and practical knowledge, this guide aims to facilitate informed purchasing decisions, ensuring that businesses can secure the best possible solutions for their leatherworking needs. Whether you are a seasoned leather artisan or a new entrant in the industry, navigating the complexities of custom leather punches has never been more straightforward.

Table Of Contents

- Top 6 Custom Leather Punch Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather punch

- Understanding custom leather punch Types and Variations

- Key Industrial Applications of custom leather punch

- 3 Common User Pain Points for ‘custom leather punch’ & Their Solutions

- Strategic Material Selection Guide for custom leather punch

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather punch

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather punch’

- Comprehensive Cost and Pricing Analysis for custom leather punch Sourcing

- Alternatives Analysis: Comparing custom leather punch With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather punch

- Navigating Market Dynamics and Sourcing Trends in the custom leather punch Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather punch

- Strategic Sourcing Conclusion and Outlook for custom leather punch

- Important Disclaimer & Terms of Use

Understanding custom leather punch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Punches | Made from unhardened steel; used for marking leather with logos | Branding leather goods, custom logos | Pros: Durable, precise marking; Cons: Limited to softer leathers |

| Clicker Dies | Pre-sharpened steel dies; customizable for various shapes | Mass production of leather parts | Pros: High accuracy, tailored designs; Cons: Higher initial cost |

| Electric Branding Irons | Electric heating for consistent branding; adjustable temperature | Branding leather products in bulk | Pros: Efficient, uniform results; Cons: Requires power source |

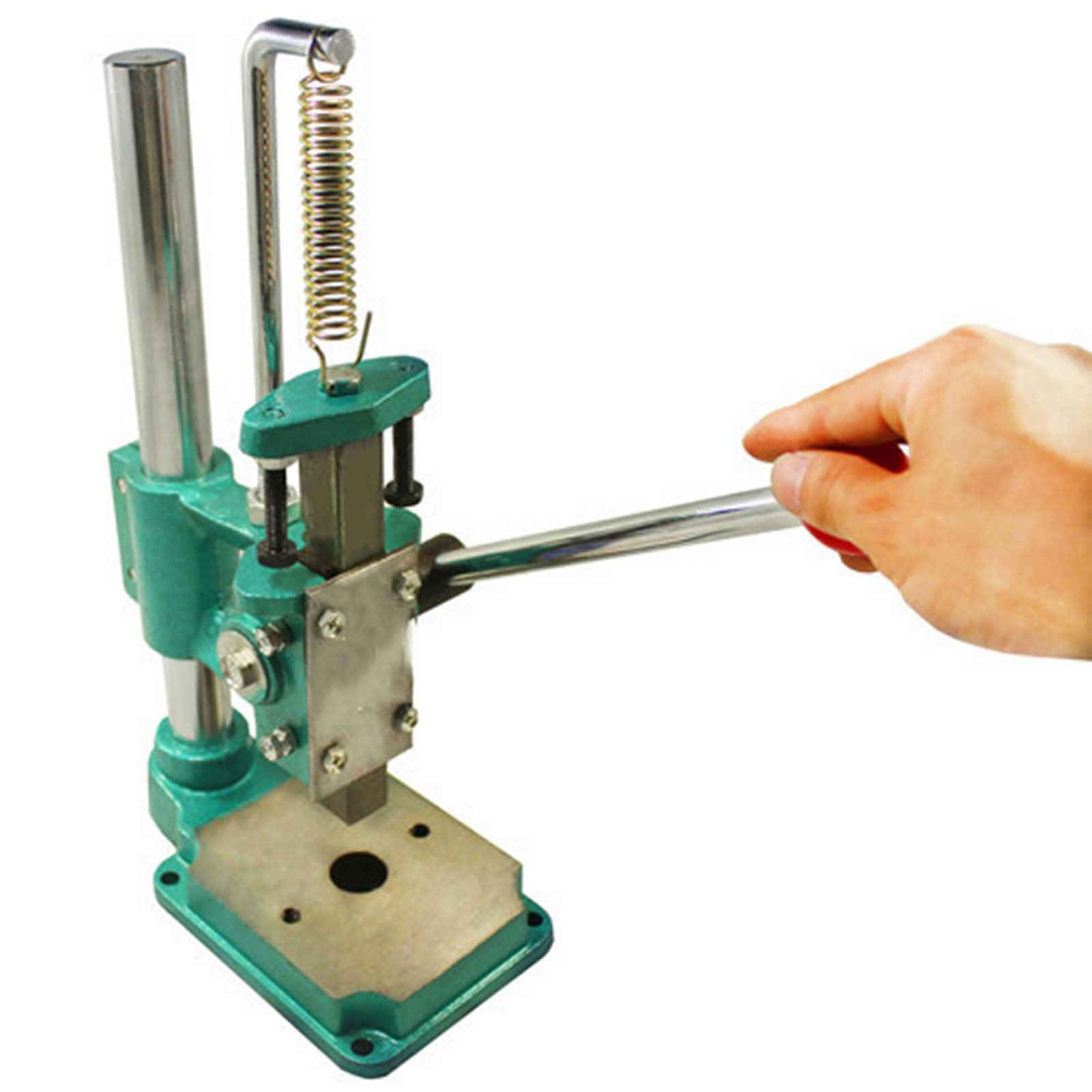

| Die Cutting Machines | Mechanical or hydraulic presses for cutting shapes | Large-scale leather crafting and production | Pros: Speedy production, versatile; Cons: Requires investment in machinery |

| Brass Stamps | Customizable with intricate designs; used for embossing | Personalized leather goods, gifts | Pros: High-quality impressions; Cons: Can be expensive for custom designs |

What Are Steel Punches and Their B2B Applications?

Steel punches are essential tools made from unhardened steel, designed primarily for marking leather with logos or designs. Their durability and precision make them ideal for small-scale branding tasks, particularly for businesses looking to personalize leather goods such as wallets, belts, and bags. When purchasing steel punches, B2B buyers should consider the hardness of the leather being used, as these punches are best suited for softer materials. Additionally, they should evaluate the potential for customization, as unique designs can enhance brand identity.

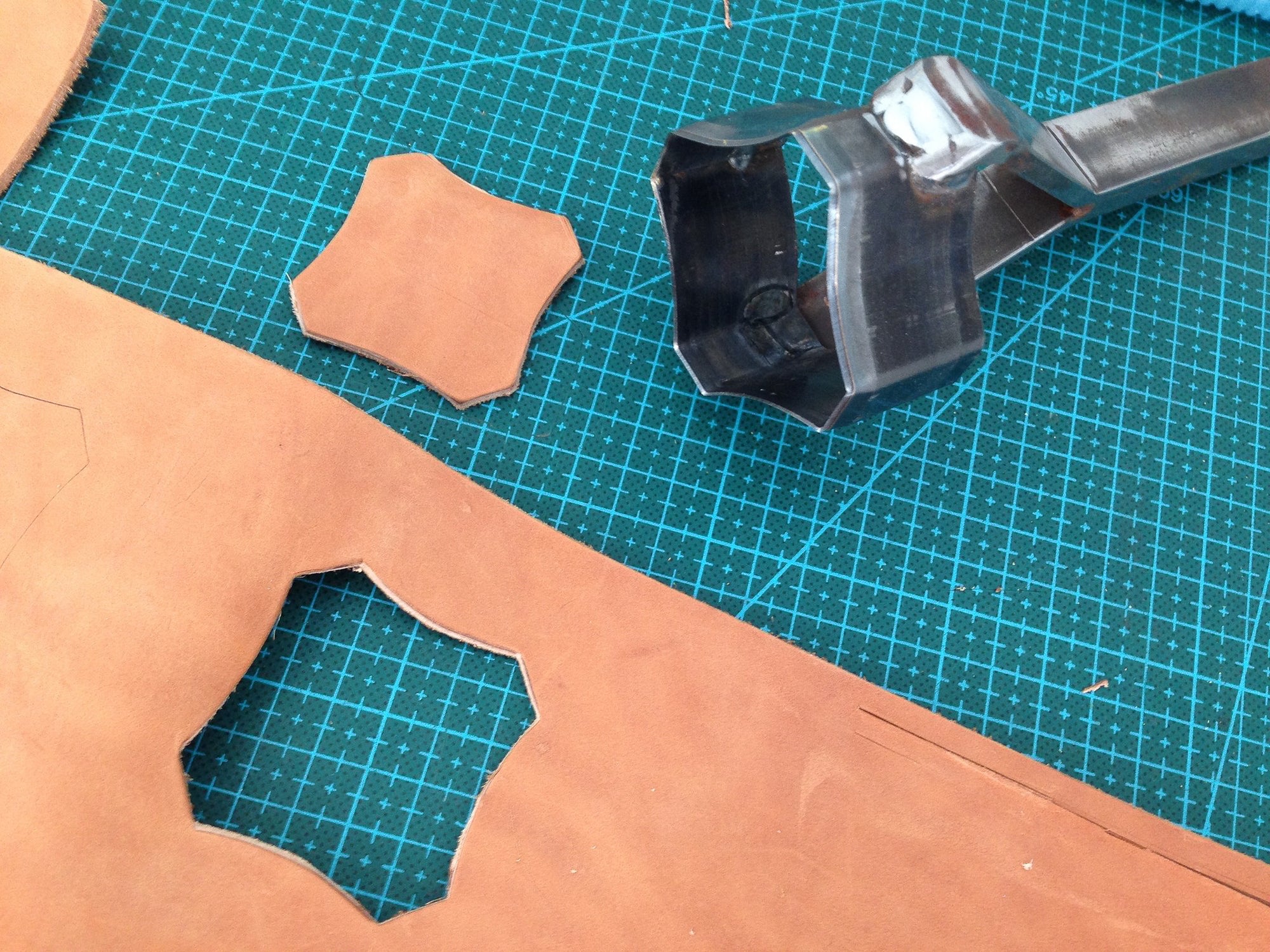

How Do Clicker Dies Benefit Mass Production?

Clicker dies are specialized tools crafted from pre-sharpened steel, allowing for the cutting of various shapes and patterns in leather. They are particularly useful in mass production scenarios where consistency and accuracy are paramount. B2B buyers should look for suppliers that offer customization options to ensure the dies meet specific design requirements. The initial investment may be higher, but the long-term efficiency gained through precise cuts can lead to significant cost savings in large-scale manufacturing.

What Advantages Do Electric Branding Irons Offer?

Electric branding irons are designed to deliver consistent branding results through electric heating, which allows for adjustable temperature settings. This feature is particularly beneficial for businesses that require uniform branding across multiple products. B2B buyers should assess the power requirements and portability of these tools, especially if they plan to use them in various locations. While the upfront cost may be higher than traditional methods, the efficiency and quality of branding can justify the investment.

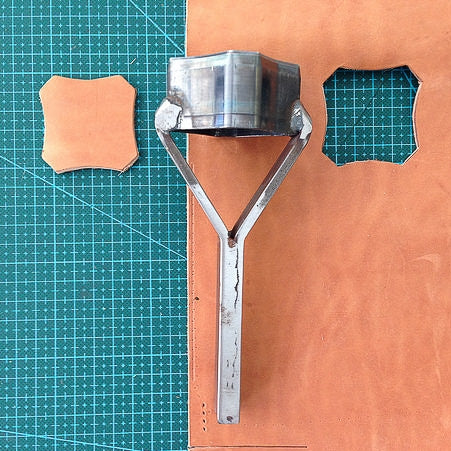

Illustrative image related to custom leather punch

Why Choose Die Cutting Machines for Leather Crafting?

Die cutting machines, which can be mechanical or hydraulic, are invaluable for businesses engaged in large-scale leather crafting and production. They enable quick and efficient cutting of intricate shapes, making them ideal for producing components like straps, tags, and decorative elements. When considering a die cutting machine, B2B buyers should evaluate the machine’s capacity, the variety of materials it can handle, and its compatibility with existing production processes. Although the initial investment is significant, the scalability and speed of production often lead to increased profitability.

What Makes Brass Stamps Ideal for Personalization?

Brass stamps are customizable tools that provide high-quality impressions for embossing leather products. They are particularly suited for businesses that want to offer personalized items such as gifts, custom wallets, or branded merchandise. When purchasing brass stamps, B2B buyers should consider the design complexity and the potential for multiple uses. While the cost may be higher for custom designs, the quality of the impressions and the ability to create unique products can enhance customer satisfaction and brand loyalty.

Key Industrial Applications of custom leather punch

| Industry/Sector | Specific Application of custom leather punch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Leather Goods Manufacturing | Custom branding on leather products like bags and wallets | Enhances brand identity and product value | Material quality, precision in design, and production capabilities |

| Automotive | Leather detailing and custom upholstery in vehicles | Improves aesthetics and customer satisfaction | Durability of the punch, compatibility with various leather types |

| Fashion and Apparel | Creating intricate designs for clothing and accessories | Differentiates products in a competitive market | Customization options, turnaround time, and cost-effectiveness |

| Craft and Hobby | DIY leather projects and custom crafts | Encourages creativity and personal expression | Ease of use, availability of various sizes, and user support |

| Footwear | Custom patterns for shoe manufacturing | Streamlines production and enhances design precision | Material strength, heat resistance, and compatibility with machinery |

How is Custom Leather Punch Used in Leather Goods Manufacturing?

In the leather goods manufacturing sector, custom leather punches are essential for branding and marking products like bags and wallets. Businesses can create unique logos and designs that enhance brand identity, allowing them to stand out in a competitive market. Buyers should consider the quality of materials used in the punch, as well as the precision of the design to ensure a consistent and professional finish. For international buyers, especially from Africa and Europe, understanding the local preferences for branding can also influence the punch design.

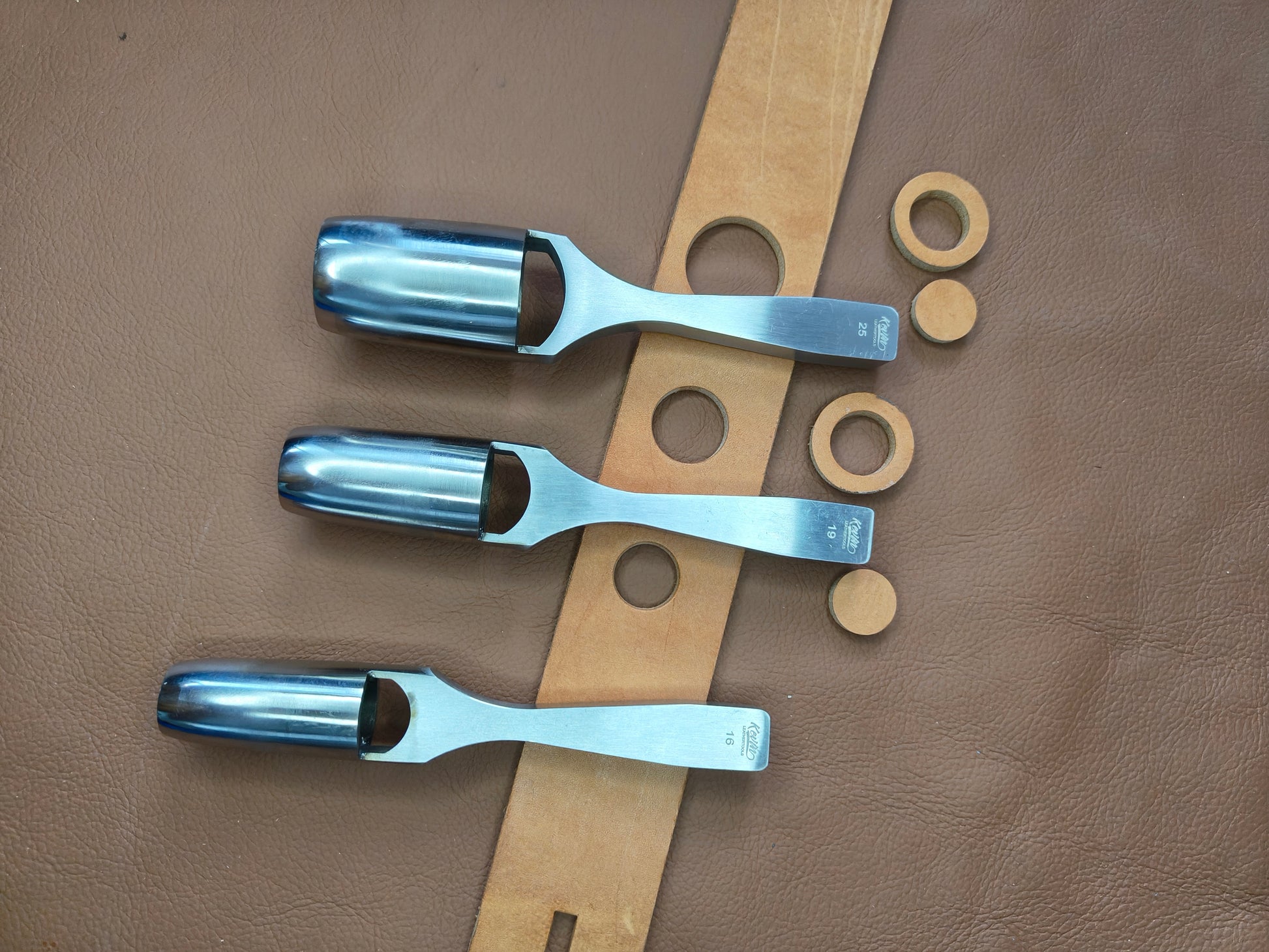

Illustrative image related to custom leather punch

What Role Does Custom Leather Punch Play in Automotive Upholstery?

In the automotive industry, custom leather punches are utilized for creating detailed designs and patterns in vehicle upholstery. This application not only improves the aesthetic appeal of the vehicle but also increases customer satisfaction through personalized options. Buyers in this sector must prioritize the durability of the punch to withstand the rigors of automotive use, as well as its compatibility with various types of leather. For businesses in the Middle East and South America, recognizing regional design trends can further enhance product offerings.

How is Custom Leather Punch Beneficial in Fashion and Apparel?

The fashion and apparel industry leverages custom leather punches to create intricate designs on clothing and accessories, enabling brands to differentiate their products. The ability to produce unique patterns allows businesses to cater to niche markets and personal styles. Buyers should focus on customization options and the turnaround time for orders to ensure they meet seasonal demands. For European buyers, aligning with fashion trends is critical, making it essential to source punches that can accommodate diverse design requirements.

What Advantages Does Custom Leather Punch Offer to Craft and Hobby Enthusiasts?

In the craft and hobby sector, custom leather punches are popular for DIY projects, allowing individuals to create personalized leather items. This fosters creativity and personal expression among crafters. Buyers should look for punches that are easy to use and available in various sizes to accommodate different project needs. For international buyers, especially from regions like Africa, sourcing locally can reduce shipping costs and support local artisans.

How Does Custom Leather Punch Streamline Footwear Production?

Custom leather punches play a crucial role in the footwear industry by enabling manufacturers to create precise patterns for shoe production. This not only streamlines the manufacturing process but also enhances design accuracy, ultimately leading to better-quality products. Buyers should consider the material strength of the punches and their heat resistance, especially when working with various leather types. For South American buyers, understanding the local footwear styles can help in selecting the right punch designs.

3 Common User Pain Points for ‘custom leather punch’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Marking Quality

The Problem: B2B buyers in the leather goods industry often face the challenge of inconsistent marking quality when using custom leather punches. This inconsistency can lead to poor branding results, where logos or patterns appear uneven or faint, negatively impacting the product’s perceived quality. Buyers may find that some punches don’t create clear impressions on various leather types, especially when switching between thicker and thinner materials. This inconsistency can lead to wasted materials and increased labor costs as they attempt to achieve a satisfactory finish.

The Solution: To ensure consistent marking quality, it is crucial for buyers to invest in high-quality, precision-engineered custom leather punches. When sourcing these tools, look for manufacturers that provide detailed specifications and testing results. Opt for punches made from hardened steel, as these are less likely to dull over time, leading to clearer impressions. Additionally, consider ordering samples or prototypes before committing to a bulk order. This approach allows you to test the punch on different leather types and thicknesses, ensuring that it meets your branding requirements. Finally, ensure proper maintenance of the punches, including regular cleaning and sharpening, to preserve their effectiveness over time.

Scenario 2: Challenges in Custom Design Specifications

The Problem: Another common pain point for B2B buyers is the difficulty in effectively communicating custom design specifications to manufacturers of leather punches. Misunderstandings regarding dimensions, design intricacies, or required materials can lead to products that do not meet expectations, resulting in costly delays and potential rework. For companies looking to create unique designs for branding or product differentiation, this challenge can significantly hinder their production timelines.

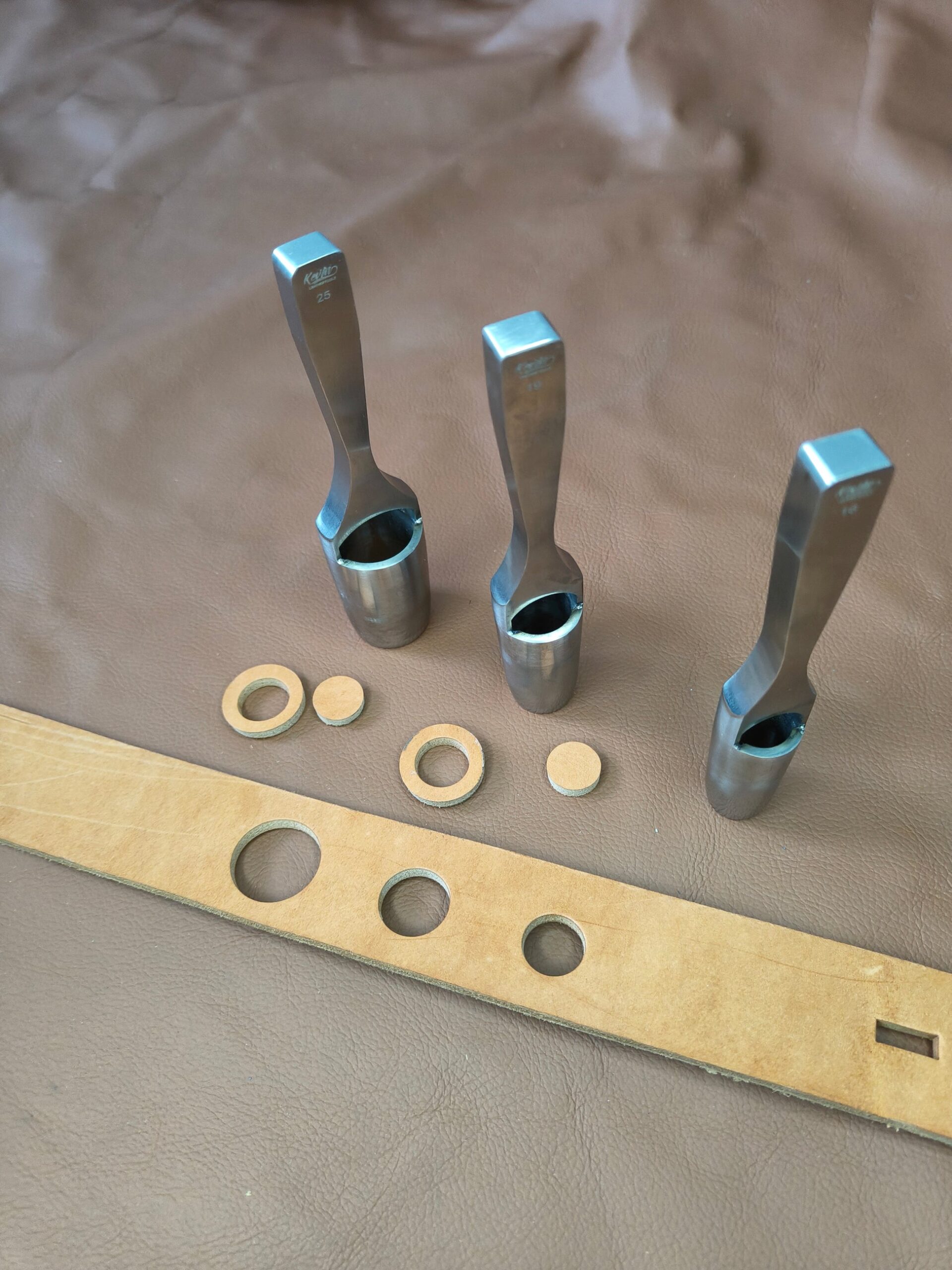

Illustrative image related to custom leather punch

The Solution: To mitigate these issues, B2B buyers should adopt a proactive approach to communication and design submission. Utilize CAD software to create precise digital representations of the desired design, including exact measurements and any specific requirements for the punch. When submitting designs to manufacturers, include multiple angles and detailed notes to clarify your vision. Additionally, establish a clear feedback loop with the manufacturer, allowing for adjustments and revisions before finalizing the order. This collaboration can significantly reduce the risk of errors and ensure that the final product aligns closely with the original concept.

Scenario 3: High Costs Associated with Custom Punch Production

The Problem: Many B2B buyers encounter high costs when ordering custom leather punches, particularly when they require low-volume production runs. Custom tooling can be expensive due to setup fees, material costs, and the time required for production. This financial burden can make it challenging for smaller businesses or startups to invest in custom solutions, potentially forcing them to compromise on quality or design.

The Solution: To address the cost issue, buyers should explore options for bulk purchasing or partnering with other businesses to share the costs of custom punches. Some manufacturers offer discounts for larger orders or repeat business, so establishing a long-term relationship can lead to better pricing. Additionally, consider utilizing alternative manufacturing techniques, such as 3D printing for prototypes or smaller runs, which can be more cost-effective. Finally, evaluate the potential return on investment by analyzing how high-quality custom punches can enhance branding and product appeal, justifying the initial expenditure. By strategically managing costs and exploring collaborative opportunities, buyers can optimize their investments in custom leather punches.

Strategic Material Selection Guide for custom leather punch

What Are the Key Materials for Custom Leather Punches?

When selecting materials for custom leather punches, B2B buyers must consider several factors, including the intended application, durability, and cost. Below, we analyze four common materials used in the manufacturing of custom leather punches, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

1. Steel

Key Properties: Steel is known for its high tensile strength and durability, making it an excellent choice for custom leather punches. It can withstand high pressure and temperature, which is essential during the punching process.

Illustrative image related to custom leather punch

Pros & Cons: The primary advantage of steel is its robustness, ensuring longevity and reliability. However, it is susceptible to corrosion if not treated or coated appropriately. The manufacturing process can be complex, especially for intricate designs, which may increase costs.

Impact on Application: Steel punches are highly effective for marking and cutting various leather types, including thicker hides. They perform well in both manual and machine-operated settings.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with ASTM or DIN standards for steel quality. Additionally, they should be aware of local regulations regarding the import of metal products, particularly concerning corrosion resistance treatments.

2. Brass

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and resistance to corrosion, making it suitable for custom leather punches that require intricate designs.

Pros & Cons: The main advantage of brass is its aesthetic appeal and resistance to tarnishing, which is beneficial for branding applications. However, brass is generally softer than steel, which may limit its use in high-volume production environments.

Impact on Application: Brass punches are ideal for decorative stamping and branding on leather, providing clear impressions without damaging the material. They are particularly effective for softer leathers.

Considerations for International Buyers: Buyers should verify that brass products meet the relevant standards in their regions, such as JIS in Japan or EN in Europe. Additionally, they should consider the availability of brass in their local markets, as sourcing can vary significantly.

3. Aluminum

Key Properties: Aluminum is lightweight and resistant to corrosion, making it a popular choice for custom leather punches that require frequent handling.

Pros & Cons: The lightweight nature of aluminum makes it easier to use, especially in manual applications. However, it is less durable than steel and brass, which may lead to wear over time. Its lower strength limits its effectiveness in high-pressure applications.

Impact on Application: Aluminum punches are suitable for lighter leather materials and are often used for creating patterns rather than heavy-duty cutting. They are ideal for small-scale operations or hobbyist applications.

Considerations for International Buyers: Buyers should ensure that aluminum punches comply with local regulations regarding metal products. In regions like Africa and South America, where sourcing may be more challenging, buyers should consider local suppliers who can provide aluminum punches that meet their quality standards.

4. High Carbon Steel

Key Properties: High carbon steel offers enhanced hardness and wear resistance compared to standard steel, making it suitable for demanding applications.

Pros & Cons: The primary advantage of high carbon steel is its durability, allowing for prolonged use without significant wear. However, it can be more brittle than other materials, which may lead to breakage under extreme conditions.

Impact on Application: High carbon steel punches are ideal for heavy-duty leatherworking, capable of cutting through thick hides and producing clean impressions. They are particularly effective in industrial settings.

Illustrative image related to custom leather punch

Considerations for International Buyers: Buyers should be aware of the specific grades of high carbon steel and their compliance with international standards. In Europe, for example, adherence to EN standards is crucial for ensuring product quality and safety.

Summary Table

| Material | Typical Use Case for custom leather punch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty marking and cutting | High durability and strength | Susceptible to corrosion | Medium |

| Brass | Decorative stamping and branding | Aesthetic appeal and corrosion resistance | Softer, may not withstand high volume | Medium |

| Aluminum | Lightweight applications and patterns | Lightweight and easy to handle | Less durable, not suitable for heavy use | Low |

| High Carbon Steel | Industrial leatherworking | Enhanced hardness and wear resistance | More brittle, risk of breakage | High |

This material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions when sourcing custom leather punches.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather punch

What Are the Main Stages of Manufacturing Custom Leather Punches?

The manufacturing process of custom leather punches involves several critical stages that ensure the final product meets the specifications and quality standards required by B2B buyers. Each stage plays a vital role in transforming raw materials into high-quality tools that can withstand the rigors of leatherworking.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in the manufacturing process is material preparation, where high-grade steel or brass is selected based on the design and intended use of the punch. Steel is often favored for its durability and ability to hold a sharp edge, while brass may be used for specific applications like branding.

Once the material is chosen, it undergoes processes such as cutting and shaping. This often involves precision machining to create the basic form of the punch. The material is typically cut into manageable sizes and then heated or treated to enhance its mechanical properties, ensuring it can handle the pressures involved in leather punching without deforming.

How Is the Forming Process Conducted for Custom Leather Punches?

After material preparation, the next stage is forming, where the punch is shaped to the desired specifications. This often involves techniques such as:

- Forging: This process uses compressive forces to shape the steel, resulting in a dense and strong product.

- Casting: For more complex shapes, casting may be employed, where molten metal is poured into a mold.

- Machining: CNC (Computer Numerical Control) machines are commonly used for precise cutting and shaping, ensuring high accuracy in dimensions.

The forming stage is critical because it determines the punch’s functionality, including its sharpness, design, and ability to create clean cuts in leather.

What Assembly Processes Are Typical for Custom Leather Punches?

Once the individual components are formed, the assembly process begins. For custom leather punches, this may involve:

- Fitting: Different parts are aligned and fitted together, ensuring that all components interact seamlessly.

- Welding or Soldering: In cases where multiple pieces are used, welding may be required to ensure a permanent and robust connection.

- Finishing: This includes polishing and coating to enhance the appearance and protect against corrosion. Techniques such as anodizing or applying a protective finish may be utilized to improve durability.

The assembly stage is crucial for ensuring that the punch operates effectively, providing a reliable tool for leatherworking.

What Finishing Techniques Are Employed in Custom Leather Punch Manufacturing?

Finishing techniques are essential for the aesthetic and functional quality of custom leather punches. Common finishing processes include:

- Grinding: This method sharpens the edges of the punch, ensuring it can cut through leather with ease.

- Polishing: A polished surface not only enhances the visual appeal but also reduces friction during use, allowing for a smoother operation.

- Coating: Protective coatings can be applied to prevent rust and wear, significantly extending the lifespan of the punch.

Quality finishing is a hallmark of a well-manufactured leather punch, as it directly impacts performance and longevity.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance (QA) is vital in the manufacturing of custom leather punches, as it ensures that products meet international and industry-specific standards. B2B buyers should look for compliance with standards such as:

- ISO 9001: This international standard sets criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In some applications, particularly those involving tools used in conjunction with other machinery, adherence to American Petroleum Institute (API) standards may be relevant.

These standards provide a framework for assessing the reliability and quality of the manufacturing processes.

What Are Key Quality Control Checkpoints in Custom Leather Punch Manufacturing?

Effective quality control (QC) checkpoints throughout the manufacturing process help ensure that each custom leather punch meets the required specifications. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for defects or inconsistencies before they enter the production line.

- In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to ensure that each stage adheres to the specified parameters.

- Final Quality Control (FQC): The finished products undergo rigorous testing to verify that they meet all quality and performance standards before being shipped.

By implementing these QC checkpoints, manufacturers can identify and address issues early in the production cycle, reducing the risk of defects in the final product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some strategies:

- Supplier Audits: Conducting audits of the manufacturing facility can provide insights into the production processes, quality control measures, and overall operational practices.

- Quality Reports: Requesting detailed quality reports can help buyers understand how the supplier monitors and maintains quality throughout the manufacturing process.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing processes and the quality of the finished products.

These measures are particularly important for international buyers from regions such as Africa, South America, the Middle East, and Europe, where varying standards and practices may exist.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control that can affect their purchasing decisions. These include:

Illustrative image related to custom leather punch

- Cultural Differences: Understanding the cultural context of a supplier can impact communication and expectations regarding quality.

- Regulatory Variations: Different countries have varying regulations regarding product safety and quality, which can affect compliance and certification processes.

- Logistics and Shipping: Quality control does not end at manufacturing; ensuring the integrity of products during shipping and handling is also crucial.

By considering these factors, buyers can better navigate the complexities of sourcing custom leather punches from international suppliers, ensuring they receive high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather punch’

In the competitive world of leather goods manufacturing, sourcing a custom leather punch requires careful planning and execution. This checklist will guide B2B buyers through the essential steps to ensure that they procure the right tool for their business needs, enhancing their production capabilities and product quality.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s vital to outline your specific requirements for the custom leather punch. Consider dimensions, material type (such as hardened steel), and design features that cater to your production needs. Understanding these details will help you communicate effectively with suppliers and ensure that the final product aligns with your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of custom leather punches. Utilize industry directories, trade shows, and online platforms to compile a list of potential partners. Focus on suppliers with proven experience in your specific market and those who have received positive feedback from previous clients.

Step 3: Evaluate Supplier Certifications and Quality Standards

It’s crucial to verify the certifications and quality standards of potential suppliers. Look for ISO certifications or industry-specific quality assurances that demonstrate a commitment to excellence. This step ensures that the products you receive will meet international quality and safety standards, thereby reducing the risk of defects in your manufacturing process.

Step 4: Request Samples and Product Specifications

Once you have shortlisted suppliers, request samples of their custom leather punches. Analyzing these samples allows you to assess the craftsmanship and durability of the tools. Additionally, ask for detailed product specifications, including material composition and manufacturing processes, to confirm that they meet your requirements.

Illustrative image related to custom leather punch

Step 5: Assess Production Capabilities and Lead Times

Understanding a supplier’s production capabilities is essential for planning your orders effectively. Inquire about their manufacturing capacity and average lead times for producing custom punches. Reliable suppliers should be able to provide clear timelines, allowing you to synchronize your inventory and production schedules accordingly.

Step 6: Negotiate Pricing and Payment Terms

Before finalizing your order, negotiate pricing and payment terms with your chosen supplier. Consider factors such as bulk order discounts, payment methods, and delivery costs. Establishing favorable terms can significantly impact your overall project budget and cash flow management.

Step 7: Finalize Your Order and Establish Communication

Once all details are agreed upon, finalize your order with the supplier. Ensure that you have a clear contract that outlines all specifications, pricing, and delivery timelines. Establish a communication plan for updates throughout the production process to maintain transparency and address any potential issues promptly.

Illustrative image related to custom leather punch

By following this checklist, B2B buyers can ensure a streamlined and effective sourcing process for custom leather punches, ultimately leading to better product quality and customer satisfaction.

Comprehensive Cost and Pricing Analysis for custom leather punch Sourcing

What are the Key Cost Components for Custom Leather Punch Sourcing?

When sourcing custom leather punches, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The type of materials used significantly impacts pricing. For instance, high-quality steel offers durability but comes at a higher cost compared to lower-grade options. Additionally, the choice between brass and stainless steel can also affect the price.

-

Labor: Skilled labor is required for the precision manufacturing of custom leather punches. Labor costs can vary by region, with higher wages in developed countries compared to emerging markets. It is essential to consider the expertise required for customization and the associated labor costs.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including utilities, equipment depreciation, and factory rent. Manufacturers with efficient operations may offer lower overhead costs, which can translate to better pricing for buyers.

-

Tooling: Initial tooling costs for custom designs can be significant, particularly for unique or complex shapes. Buyers should inquire about tooling fees upfront, as they can be a substantial part of the initial investment.

-

Quality Control (QC): Ensuring the quality of the punches involves testing and inspection, which adds to the overall cost. Manufacturers with robust QC processes may charge more, but they ensure that the products meet specified standards.

-

Logistics: Shipping costs can vary widely based on the supplier’s location and the buyer’s destination. Factors such as shipping method, weight, and distance play a crucial role in logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on their market position and competition. Understanding this margin can help buyers negotiate more effectively.

How Do Price Influencers Affect Custom Leather Punch Pricing?

Several factors can influence the pricing of custom leather punches:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing, which can significantly reduce the per-unit cost. Buyers should assess their needs and consider placing larger orders to benefit from economies of scale.

-

Specifications/Customization: Highly customized designs or specific dimensions can increase costs due to the additional time and resources required for production. Clear communication of design requirements can help avoid unexpected charges.

-

Materials: The choice of materials not only affects the price but also the durability and functionality of the leather punches. Buyers should weigh the benefits of premium materials against their budget constraints.

-

Quality and Certifications: Products that meet specific quality standards or certifications may come at a premium. However, investing in certified products can lead to long-term savings through increased durability and reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their experience and quality assurances, while newer suppliers may offer lower prices to gain market entry.

-

Incoterms: The terms of trade can significantly affect total costs. Understanding who is responsible for shipping, insurance, and duties can help buyers avoid unexpected expenses.

What Are the Best Negotiation and Cost-Efficiency Tips for Buyers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can enhance cost efficiency:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, durability, and potential replacement costs. A lower upfront cost may lead to higher long-term expenses if the product is not durable.

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better pricing and terms. Regular communication can lead to favorable negotiations and loyalty discounts.

-

Be Transparent: Sharing your volume expectations and potential future orders can encourage suppliers to provide better pricing. Transparency can foster trust and lead to more favorable terms.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers allows for comparison and can provide leverage during negotiations. This practice can also reveal market trends and pricing standards.

-

Stay Informed about Market Trends: Understanding market dynamics, such as material shortages or labor costs, can help buyers negotiate better prices and terms.

Disclaimer

The prices and cost components discussed are indicative and can vary based on market conditions, supplier practices, and specific buyer requirements. Always consult with multiple suppliers and perform due diligence to ensure you receive the best pricing for your unique needs.

Illustrative image related to custom leather punch

Alternatives Analysis: Comparing custom leather punch With Other Solutions

When evaluating the best tools for leatherworking, it’s essential to explore various alternatives to the custom leather punch. Each method or tool has unique features, advantages, and limitations that can affect production quality, cost, and operational efficiency. This analysis will compare the custom leather punch with alternative solutions to help B2B buyers make informed decisions.

| Comparison Aspect | Custom Leather Punch | Steel Rule Die Cut | Electric Branding Irons |

|---|---|---|---|

| Performance | High precision for intricate designs | Excellent for mass production with consistent results | Ideal for branding and marking with heat |

| Cost | Moderate to high depending on customization | Moderate, typically lower for bulk orders | Varies widely, generally higher due to technology |

| Ease of Implementation | Requires manual effort and skills | Quick setup for mass production | Easy to use but needs a power source |

| Maintenance | Low, occasional sharpening needed | Low, durable and long-lasting | Moderate, requires cleaning and maintenance |

| Best Use Case | Custom designs and unique branding | High-volume, uniform shapes and designs | Branding leather products with logos or designs |

What Are the Benefits and Drawbacks of Using Steel Rule Die Cuts?

Steel rule die cuts are particularly suited for mass production, offering high precision and consistency. They are made from durable materials, ensuring longevity and reliability in high-volume applications. The major advantage of using steel rule die cuts is the ability to produce large quantities of the same design quickly. However, they may not be suitable for smaller runs or custom designs, as the initial setup cost can be high, and modifications to designs may require new dies.

How Do Electric Branding Irons Compare for Leather Marking?

Electric branding irons offer a different approach to marking leather. They utilize heat to imprint designs or logos directly onto the leather, which can be particularly effective for branding purposes. The major advantage is the ability to create a deep, lasting mark with less manual effort compared to traditional methods. However, the initial investment for quality electric branding irons can be significant, and they require a power source, which may not be practical in all settings. Additionally, they are less versatile for cutting or shaping leather compared to custom punches.

How Can B2B Buyers Choose the Right Leatherworking Solution?

When selecting the best leatherworking tool, B2B buyers must consider their specific operational needs, such as production volume, design complexity, and budget constraints. For businesses focusing on custom, low-volume projects, the custom leather punch may be the most effective choice. Conversely, for those engaged in high-volume production where uniformity is key, steel rule die cuts offer efficiency and consistency. Electric branding irons serve well for businesses prioritizing branding and marking over cutting or shaping leather. Ultimately, understanding the unique requirements of the leatherwork project will guide buyers to the most suitable solution for their needs.

Essential Technical Properties and Trade Terminology for custom leather punch

What Are the Key Technical Properties of Custom Leather Punches?

When sourcing custom leather punches, understanding their technical properties is essential for ensuring product quality and compatibility with your manufacturing processes. Here are some critical specifications to consider:

Illustrative image related to custom leather punch

-

Material Grade: The most common materials for leather punches include hardened steel and brass. Hardened steel offers durability and resistance to wear, making it ideal for high-volume production. In contrast, brass is often used for branding stamps due to its excellent heat conductivity. Choosing the right material affects the punch’s longevity and the quality of the imprint.

-

Tolerance: Tolerance refers to the allowable deviation from a specified dimension. In leather punching, tight tolerances are crucial for ensuring that the punch fits properly into the intended machinery and produces accurate cuts or imprints. High tolerance levels (e.g., ±0.01 mm) are especially important for precision work, where even minor discrepancies can affect the final product.

-

Size and Dimensions: Custom leather punches come in various sizes, typically defined by the maximum marking area or cutting capacity. For example, a punch with a maximum marking area of 30×30 mm may be suitable for small logos or designs. Understanding the required size is vital for achieving the desired visual impact on your leather products.

-

Blade Height: The height of the blade protrusion is another important specification. It determines how deep the punch will cut into the leather. A blade height of 6 mm is common for standard applications, but heavier materials may require longer blades for effective penetration. Selecting the appropriate blade height ensures clean cuts and prevents damage to the leather.

-

Production Time: Knowing the lead time for manufacturing custom punches is essential for planning your production schedule. Many suppliers offer a turnaround time of 3-5 business days for custom designs. Timely delivery is crucial for maintaining workflow and meeting customer demands.

What Are Common Trade Terms Related to Custom Leather Punches?

Navigating the landscape of custom leather punches involves familiarizing yourself with industry-specific terminology. Here are some common trade terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are used in another company’s end products. If you’re sourcing custom leather punches, you may engage with OEMs that specialize in producing high-quality tooling for the leather industry.

-

MOQ (Minimum Order Quantity): MOQ defines the smallest order size that a supplier is willing to accept. Understanding MOQ is vital for budgeting and inventory management, especially if you are a smaller business or just starting. Suppliers may offer different MOQs for different products or custom designs.

-

RFQ (Request for Quotation): An RFQ is a formal document issued by buyers to solicit price quotes from suppliers. In the context of custom leather punches, submitting an RFQ helps you gather competitive pricing and terms from multiple manufacturers, allowing for informed decision-making.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), is crucial for understanding shipping costs and liabilities when sourcing custom leather punches from overseas suppliers.

-

Die Cutting: This refers to the process of using a die to cut or shape materials, including leather. Die cutting is a common application for custom leather punches, particularly for creating intricate designs or specific shapes in leather goods.

-

Heat Resistance: This property indicates the ability of a punch to withstand high temperatures, particularly important for branding irons. A punch with high heat resistance ensures consistent branding quality without warping or losing effectiveness over time.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing custom leather punches, ultimately enhancing product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the custom leather punch Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Punch Sector?

The custom leather punch market is experiencing significant growth driven by increasing demand for personalized leather products across various sectors, including fashion, automotive, and accessories. As international trade flourishes, particularly in regions such as Africa, South America, the Middle East, and Europe, B2B buyers are keenly interested in sourcing high-quality, customizable leather tools that enable them to stand out in a competitive landscape.

Technological advancements are reshaping the industry, with innovations in manufacturing processes such as CNC machining and laser cutting enhancing precision and efficiency. Moreover, the rise of e-commerce platforms has simplified sourcing, allowing businesses to connect directly with manufacturers and suppliers worldwide. This trend is particularly relevant for buyers in regions like Saudi Arabia and Germany, where quality and customization are paramount.

Emerging trends also highlight a growing preference for multifunctional tools. Buyers are increasingly looking for leather punches that can serve multiple purposes, from embossing to die-cutting, to optimize their investment. Additionally, the demand for rapid prototyping and short-run production is leading suppliers to offer more flexible and responsive services, catering to the dynamic needs of international buyers.

How Is Sustainability Shaping the Sourcing of Custom Leather Punches?

Sustainability and ethical sourcing have become critical considerations in the custom leather punch sector. Environmental concerns regarding traditional leather production methods have prompted buyers to seek suppliers who prioritize eco-friendly practices. This includes sourcing leather from tanneries that adhere to sustainable practices, minimizing water usage and chemical waste.

Illustrative image related to custom leather punch

Furthermore, B2B buyers are increasingly interested in suppliers that offer green certifications, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification. These certifications assure buyers of a product’s environmental impact and ethical production processes.

The importance of transparent supply chains cannot be overstated. Buyers are keen to understand the sourcing journey of their materials, ensuring that they are not only environmentally responsible but also socially ethical. This demand for transparency is driving many suppliers to adopt more sustainable practices, such as using vegetable-tanned leather and reducing carbon footprints in production.

What Is the Evolution of the Custom Leather Punch Sector?

The custom leather punch sector has evolved significantly over the decades, transitioning from manual craftsmanship to highly sophisticated manufacturing techniques. Historically, leatherworking tools were predominantly handmade, with skilled artisans crafting punches that reflected individual creativity and regional styles.

With the advent of industrialization, mass production techniques were introduced, allowing for greater consistency and availability of leather tools. Today, the integration of technology has further transformed the sector, enabling precision manufacturing and customization at scale. This evolution has opened new avenues for B2B buyers, allowing them to source high-quality, tailored leather punches that meet specific business needs while maintaining the artisanal quality that many end consumers desire.

In conclusion, the custom leather punch market is characterized by dynamic growth influenced by technological advancements, sustainability considerations, and a rich historical context. International B2B buyers must navigate these complexities to effectively source products that align with their business goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather punch

-

How do I ensure the quality of a custom leather punch supplier?

To verify the quality of a custom leather punch supplier, start by checking their certifications and industry standards compliance. Request samples to evaluate craftsmanship and materials used. Investigate customer reviews and testimonials, focusing on their experiences regarding product durability and service reliability. Additionally, inquire about their manufacturing processes and quality control measures. Establishing a clear communication channel can also help you gauge their professionalism and responsiveness, which are crucial for long-term partnerships. -

What is the typical lead time for custom leather punches?

Lead times for custom leather punches can vary significantly based on the complexity of the design, the supplier’s production capacity, and order volume. Generally, expect a timeframe of 2 to 4 weeks from order confirmation to delivery. For urgent requirements, discuss expedited options with your supplier, which may incur additional fees. Always confirm the lead time during the negotiation phase to align your production schedules accordingly. -

What customization options are available for leather punches?

Customization options for leather punches typically include size, shape, and design elements such as logos or specific patterns. Most suppliers will work with you to create a unique design that meets your specifications, using CAD software for precision. Additionally, you may have choices regarding materials—such as steel or brass—and finishes. Ensure you provide high-quality artwork or files for accurate production. Discuss these options upfront to avoid miscommunication later in the process. -

What are the minimum order quantities (MOQs) for custom leather punches?

Minimum order quantities (MOQs) for custom leather punches can vary widely among suppliers, often ranging from 50 to several hundred units. Factors influencing MOQs include the manufacturing process, materials used, and the complexity of the design. It’s advisable to discuss your needs with potential suppliers, as some may offer flexibility for smaller orders, especially for new business relationships or product testing. Always confirm MOQs before placing an order to ensure it aligns with your business capabilities. -

What payment terms should I expect when ordering custom leather punches?

Payment terms for custom leather punches can vary by supplier and may include options like upfront payment, partial payment upon order confirmation, or payment upon delivery. Commonly, a 30% deposit is required, with the balance due before shipping. Ensure you clarify payment methods accepted (e.g., bank transfer, credit card) and any associated fees. Additionally, understand the implications of international transactions, such as currency exchange rates and transaction fees, especially when dealing with suppliers in different regions. -

How can I effectively communicate my design specifications to a supplier?

Effective communication of design specifications begins with preparing detailed documentation, including sketches, dimensions, and any specific materials. Utilize CAD files or high-resolution images to convey your vision clearly. Schedule a meeting or call with the supplier to discuss your requirements, allowing them to ask clarifying questions. Encourage feedback from the supplier to ensure they fully understand your expectations, and consider requesting a prototype or sample before finalizing the order. -

What logistics considerations should I keep in mind for international shipments?

When sourcing custom leather punches internationally, consider logistics aspects such as shipping methods, costs, and estimated delivery times. Discuss with your supplier whether they offer freight services or if you need to arrange your own shipping. Be aware of customs duties and regulations that may apply to your order upon arrival in your country. It’s advisable to work with a logistics partner experienced in international trade to navigate these complexities effectively. -

What are the best practices for inspecting custom leather punches upon delivery?

Upon delivery, inspect custom leather punches carefully for quality and accuracy. Check for any discrepancies between the received products and your specifications, including dimensions and design details. Use a checklist to document your findings, noting any defects or issues. If discrepancies arise, contact the supplier immediately to address them. Establishing a clear inspection protocol can prevent misunderstandings and ensure that the products meet your quality standards before use in production.

Top 6 Custom Leather Punch Manufacturers & Suppliers List

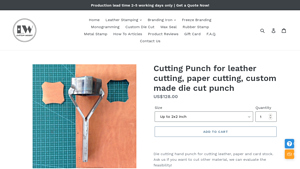

1. LW Leathers – Cutting Punches

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: Cutting Punch for leather cutting, paper cutting, custom made die cut; Regular price: US$128.00; Sizes available: Up to 2×2 inch, Up to 3×3 inch; Larger sizes available as Steel Rule Die Cuts; Production lead time: 2-5 working days, rush orders can ship in 2 working days (additional cost applies); Suitable for cutting leather, paper, and card stock; Custom designs accepted; Preferred file formats:…

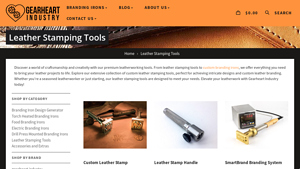

2. Gearheart Industry – Custom Leather Stamping Tools

Domain: gearheartindustry.com

Registered: 2013 (12 years)

Introduction: Custom Leather Stamping Tools, Made in the USA; Branding Irons: Torch Heated, Electric, Food, Mounted; Branding Iron Design Generator; Leather Stamping Tools; Accessories; Custom Leather Stamp: Starting at $119.00; Leather Stamp Handle: $21.00; SmartBrand Branding System: Starting at $412.00; SmartBrand Drill Press Branding System: Starting at $522.00; Extra Branding Iron Plates: $65.00.

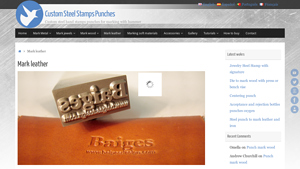

3. Punzonesomella – Custom Steel Stamps

Domain: punzonesomella.com

Registered: 2010 (15 years)

Introduction: Mark leather – Custom Steel Stamps Punches for marking leather or skin. Maximum size: 30x30x120mm. Max marking area: 30x30mm. Material: Steel unhardened. Designed for hammer use. Suitable for marking wet or dry leather, but not for feather or very thin skins. Solid, single USA piece construction for durability and precision.

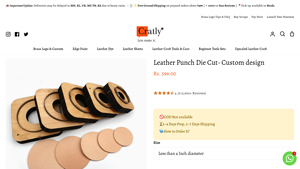

4. Cratly – Leather Punch Die Cut

Domain: cratly.com

Registered: 2014 (11 years)

Introduction: Product Name: Leather Punch Die Cut – Custom design

Price: ₹599.00

Rating: 4.75 (1,900+ Reviews)

Shipping: 3–4 Days Prep, 5–7 Days Shipping

Material: Steel + Wood

Die Cut Height: 24mm (Blade Protrusion Height: 6mm)

Sizes Available: Less than 4 Inch diameter, Less than 8 Inch diameter

Production Time: Ships in 3-5 business days after artwork approval

Usage: Suitable for leather patterns, tags, spec…

5. Instructables – Leather Tooling Punches

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Leather Tooling Punches are homemade tools created from nails, designed for crafting leather. The process involves shaping the nail head using metal files and a junior hacksaw to create various designs such as squares, triangles, and custom shapes like Pacman. Essential materials include nails, while tools required are metal files, a junior hacksaw, a hammer, a sturdy wood block for striking, and …

6. Weaver Leather Supply – Custom Leather Belt End Dies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Using Custom Leather Belt End Dies – Weaver Leather Supply. Custom Polycarb Leather Cutting Dies help save time in the belt-making process. Featured products include: #1555 2-Tongue Roller Buckles (Sale price from $3.38), #2200 Double Cap Rivet and Insta-Rivet Setter ($5.00), CHAHINLEATHER® English Bridle Sides (from $290.00), English Bridle Belt Blank, Plain ($16.80), Exotic Wood Leather Slicker …

Strategic Sourcing Conclusion and Outlook for custom leather punch

The strategic sourcing of custom leather punches presents a significant opportunity for B2B buyers across diverse markets, especially in Africa, South America, the Middle East, and Europe. Key takeaways highlight the importance of quality, customization, and supplier reliability in ensuring that your leather products stand out in a competitive landscape. By investing in high-quality, precision-engineered tools, businesses can enhance their production capabilities, ensuring both efficiency and superior craftsmanship.

Furthermore, leveraging strategic sourcing not only reduces costs but also opens avenues for innovation through collaboration with specialized manufacturers. As you explore partnerships with suppliers who understand your unique needs—whether for branding, intricate designs, or mass production—you’re positioning your business for sustained growth and market relevance.

Illustrative image related to custom leather punch

Looking ahead, the demand for custom leather solutions is set to rise, driven by trends in personalization and sustainable practices. Now is the time to engage with reliable suppliers who can meet your specifications and help you capitalize on emerging opportunities. Take the next step in your sourcing journey—connect with manufacturers today to elevate your leather offerings and secure your competitive edge.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.