Introduction: Navigating the Global Market for custome leather jacket

In the competitive landscape of fashion, sourcing custom leather jackets poses a unique challenge for B2B buyers seeking high-quality, tailored solutions. With an increasing demand for personalized apparel across diverse markets, including Africa, South America, the Middle East, and Europe, understanding the intricacies of this niche can significantly impact your purchasing decisions. This guide serves as a comprehensive resource, delving into various aspects of custom leather jackets—from the types of materials available and their applications to the critical process of supplier vetting and cost considerations.

Navigating the global market for custom leather jackets requires insight into regional preferences and trends, as well as a clear understanding of what distinguishes reputable suppliers. Buyers will find practical information on design options, including embroidery and printing, to ensure products resonate with their target audience. Additionally, this guide emphasizes the importance of quality assurance and fit, providing strategies to mitigate risks and enhance customer satisfaction.

By equipping international B2B buyers with actionable insights and a structured approach to sourcing, this guide empowers companies to make informed decisions that align with their brand identity and market demands. Whether you’re a retailer in Germany looking to expand your product line or a fashion entrepreneur in Brazil aiming for a unique offering, understanding the nuances of the custom leather jacket market is crucial for success.

Table Of Contents

- Top 6 Custome Leather Jacket Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custome leather jacket

- Understanding custome leather jacket Types and Variations

- Key Industrial Applications of custome leather jacket

- 3 Common User Pain Points for ‘custome leather jacket’ & Their Solutions

- Strategic Material Selection Guide for custome leather jacket

- In-depth Look: Manufacturing Processes and Quality Assurance for custome leather jacket

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custome leather jacket’

- Comprehensive Cost and Pricing Analysis for custome leather jacket Sourcing

- Alternatives Analysis: Comparing custome leather jacket With Other Solutions

- Essential Technical Properties and Trade Terminology for custome leather jacket

- Navigating Market Dynamics and Sourcing Trends in the custome leather jacket Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custome leather jacket

- Strategic Sourcing Conclusion and Outlook for custome leather jacket

- Important Disclaimer & Terms of Use

Understanding custome leather jacket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Biker Jacket | Rugged design, often with zippers and studs | Motorcycle gear, fashion retailers | Pros: Durable, stylish; Cons: May not suit all markets. |

| Bomber Jacket | Shorter length, fitted waist, often with ribbed cuffs | Casual wear, military-themed apparel | Pros: Versatile, timeless; Cons: Limited functionality in cold weather. |

| Blazer Jacket | Tailored fit, structured design, often with lapels | Corporate wear, upscale fashion lines | Pros: Professional appearance; Cons: Higher price point. |

| Varsity Jacket | Sporty look, often featuring patches or embroidery | Educational institutions, sports teams | Pros: Customizable, appealing to youth; Cons: Limited market appeal outside sports. |

| Custom Printed Jacket | Personal artwork or logos printed on leather | Promotional items, branding | Pros: Unique branding opportunities; Cons: Longer production time. |

What Are the Key Characteristics of Biker Jackets for B2B Buyers?

Biker jackets are characterized by their rugged construction, typically featuring zippers, studs, and a close-fitting design. They appeal to motorcycle enthusiasts and fashion retailers looking to tap into edgy, youthful markets. When purchasing, B2B buyers should consider the durability of the leather, the quality of hardware used, and the potential for customization in design and fit. These jackets are often a staple in motorcycle gear, but their fashion appeal makes them versatile across various sectors.

Illustrative image related to custome leather jacket

How Do Bomber Jackets Stand Out in the Market?

Bomber jackets are shorter in length, featuring a fitted waist and ribbed cuffs, which give them a stylish yet casual appearance. This type of jacket is suitable for both men and women and is often used in military-themed apparel and casual wear. B2B buyers should focus on the quality of the leather and lining, as well as the potential for customization in color and design. Their timeless appeal can attract a broad audience, though functionality in colder climates might be a concern for some buyers.

What Makes Blazer Jackets Suitable for Corporate Wear?

Blazer jackets are tailored with a structured design, often including lapels and a fitted silhouette, making them ideal for corporate environments. They are commonly used in upscale fashion lines and professional settings. B2B buyers should prioritize high-quality leather and precise tailoring to ensure a polished look. While they offer a professional appearance, the higher price point may limit their appeal to budget-conscious buyers.

Why Choose Varsity Jackets for Educational Institutions?

Varsity jackets are known for their sporty aesthetic, frequently featuring patches or embroidery representing schools or teams. This type of jacket is popular among educational institutions and sports teams, providing a sense of community and pride. B2B buyers should consider the customization options available, as this can significantly enhance the jacket’s appeal. However, the market for varsity jackets may be limited primarily to school-related events and sports, potentially restricting broader sales.

How Do Custom Printed Jackets Offer Unique Branding Opportunities?

Custom printed jackets allow for personal artwork, logos, or designs to be printed directly onto the leather, making them an excellent choice for promotional items and branding. This type of jacket can help businesses stand out in competitive markets. B2B buyers should evaluate the printing technology used and the lead times for production, as these factors can impact overall satisfaction. While they offer unique branding opportunities, the longer production times may be a drawback for urgent needs.

Key Industrial Applications of custome leather jacket

| Industry/Sector | Specific Application of Custom Leather Jacket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom designer jackets for fashion brands | Unique branding opportunities and differentiation in the market | Quality of leather, customization options, and production timelines |

| Automotive | Branded jackets for automotive dealerships | Enhances brand visibility and customer loyalty | Material durability, customization for branding, and size variety |

| Entertainment & Media | Costumes for film, theater, and events | Authentic representation and enhanced audience engagement | Design accuracy, material quality, and quick turnaround times |

| Corporate Gifts & Promotions | Custom jackets for corporate giveaways | Strengthens brand image and employee morale | Bulk order capabilities, customization options, and pricing |

| Outdoor & Adventure Sports | Specialized jackets for adventure companies | Increased safety and comfort for users | Weather resistance, material performance, and customization features |

How Are Custom Leather Jackets Used in the Fashion & Apparel Industry?

In the fashion sector, custom leather jackets serve as a canvas for designers to express creativity and individuality. By offering bespoke designs, brands can cater to niche markets, ensuring that their products stand out. B2B buyers from Europe and South America may seek high-quality leather, unique designs, and reliable production times to meet consumer demands. The ability to incorporate logos or specific branding elements further enhances the value proposition, allowing businesses to create a distinct identity.

Illustrative image related to custome leather jacket

What Role Do Custom Leather Jackets Play in the Automotive Sector?

Automotive dealerships often use custom leather jackets as promotional items or uniforms for staff. These jackets not only enhance the dealership’s brand visibility but also instill a sense of professionalism among employees. For international buyers, particularly in Africa and the Middle East, sourcing durable materials that withstand various climates is crucial. Customization options for branding are also essential, as they allow dealerships to maintain a cohesive brand image.

How Are Custom Leather Jackets Utilized in the Entertainment & Media Industry?

In the entertainment sector, custom leather jackets are frequently used as costumes in films, theater productions, and promotional events. These jackets help create authentic character portrayals, which can significantly enhance audience engagement. B2B buyers in this industry need to prioritize design accuracy and quality materials to ensure that jackets not only look good on screen but also withstand the rigors of production. Quick turnaround times are also vital, as productions often operate on tight schedules.

Why Are Custom Leather Jackets Important for Corporate Gifts & Promotions?

Custom leather jackets serve as premium corporate gifts that can elevate brand image and foster employee loyalty. They are often given during events or as part of incentive programs. For businesses in Europe and South America, the ability to source jackets that reflect corporate branding through logos or custom embroidery is essential. Additionally, buyers should consider bulk order capabilities and pricing, ensuring that they receive quality products without compromising on budget.

How Do Outdoor & Adventure Sports Companies Benefit from Custom Leather Jackets?

Adventure and outdoor sports companies utilize custom leather jackets for safety and comfort during activities. These jackets can be tailored to include weather-resistant materials and functional features that enhance user experience. For B2B buyers, especially from regions with diverse climates, it’s crucial to source jackets that are not only stylish but also durable and functional. Customization options, such as adding insulation or special pockets, can further cater to specific user needs, enhancing the overall value of the product.

3 Common User Pain Points for ‘custome leather jacket’ & Their Solutions

Scenario 1: Quality Assurance Challenges in Custom Leather Jackets

The Problem: B2B buyers often face significant challenges ensuring the quality of custom leather jackets. When sourcing jackets from international suppliers, discrepancies in leather quality, stitching, and overall craftsmanship can lead to subpar products that do not meet the expectations of their clients. This can be particularly problematic for retailers and brands that pride themselves on delivering premium goods, as poor quality can damage their reputation and result in financial losses.

Illustrative image related to custome leather jacket

The Solution: To mitigate quality assurance issues, buyers should establish stringent quality control measures before placing bulk orders. This includes requesting samples of different leather types and craftsmanship techniques prior to finalizing the order. Additionally, buyers should consider visiting the manufacturing facility, if feasible, to conduct an on-site inspection of production processes. Partnering with suppliers who offer guarantees on the leather quality and craftsmanship can also provide added assurance. Furthermore, investing in third-party quality assurance services can help in verifying the quality before the jackets are shipped. Documenting quality expectations in contracts can set clear standards for suppliers to meet.

Scenario 2: Sizing and Fit Consistency for Custom Orders

The Problem: One of the most common pain points for B2B buyers in the custom leather jacket market is ensuring consistent sizing and fit across different orders. Variability in measurements and production methods can lead to products that do not fit as expected, resulting in high return rates and dissatisfied customers. This is especially crucial for brands that cater to diverse body types and require a wide range of sizes, including plus sizes.

The Solution: To address sizing issues, buyers should work closely with suppliers who offer detailed measurement guides and consultation services. It is advisable to establish a standardized size chart that aligns with the target market’s body types and preferences. Utilizing technology such as 3D fitting solutions can also enhance accuracy in sizing, allowing customers to visualize how the jacket will fit before production. Implementing a sample order process can help in assessing fit before committing to large quantities. Additionally, suppliers should be encouraged to provide a fitting guarantee, allowing for alterations or remakes if the fit does not meet the specified requirements.

Scenario 3: Long Lead Times and Delivery Delays

The Problem: B2B buyers frequently encounter issues with long lead times and delivery delays when ordering custom leather jackets, which can disrupt their inventory management and affect sales. This is particularly problematic for seasonal collections or promotional launches, where timing is crucial. Delays can lead to missed opportunities and customer dissatisfaction, which can have long-term repercussions for business relationships.

The Solution: To combat lead time challenges, buyers should prioritize suppliers who have a reputation for reliability and efficient production processes. Establishing clear timelines and milestones in the order process can help manage expectations. Buyers should also consider diversifying their supplier base to include local manufacturers who may offer faster turnaround times for urgent orders. Implementing a just-in-time inventory system can help in managing stock levels more effectively, reducing reliance on long lead times. Additionally, maintaining open lines of communication with suppliers can provide early warnings of potential delays, allowing buyers to make informed decisions regarding inventory and sales strategies.

Strategic Material Selection Guide for custome leather jacket

What Are the Key Properties of Common Materials for Custom Leather Jackets?

When selecting materials for custom leather jackets, it’s essential to understand the properties of each type of leather, as they directly influence the jacket’s performance, durability, and suitability for various climates and applications. Here, we analyze four common materials used in the production of custom leather jackets: lambskin, cowhide, goatskin, and suede.

How Does Lambskin Perform as a Material for Custom Leather Jackets?

Lambskin is renowned for its softness and lightweight nature, making it an excellent choice for fashion-forward designs. It has a moderate temperature rating, providing comfort in cooler weather without being overly heavy. However, lambskin is less durable than other leather types, making it more susceptible to wear and tear over time.

Pros: The key advantages of lambskin include its luxurious feel and aesthetic appeal, which can enhance the perceived value of the jacket. It is also relatively easy to dye, allowing for a wide range of color options.

Cons: The primary drawback is its lower durability compared to thicker leathers. It may not withstand harsh conditions or heavy usage, which could be a concern for buyers in regions with extreme weather or rugged environments.

Illustrative image related to custome leather jacket

What Are the Benefits of Cowhide for Custom Leather Jackets?

Cowhide is one of the most durable leather options available, offering excellent resistance to abrasions and tears. It has a high temperature rating, making it suitable for colder climates. This material is often used in motorcycle jackets due to its protective qualities.

Pros: Cowhide’s durability means it can withstand significant wear and tear, making it ideal for heavy-duty applications. It also has a classic look that appeals to a broad audience.

Cons: The main disadvantage is its weight and stiffness, which may not be as comfortable for all-day wear. Additionally, cowhide can be more expensive than other leather types, impacting cost considerations for B2B buyers.

Illustrative image related to custome leather jacket

How Does Goatskin Compare as a Material for Custom Leather Jackets?

Goatskin is another popular choice, known for its balance between durability and softness. It offers good abrasion resistance and has a unique grain pattern that adds character to the finished product. Goatskin is also lighter than cowhide, making it comfortable for various applications.

Pros: The key advantage of goatskin is its versatility; it can be used in both fashion and functional designs. It is also more affordable than cowhide while still offering a premium look and feel.

Cons: While goatskin is durable, it may not provide the same level of protection as cowhide in extreme conditions. Buyers should consider the intended use when selecting this material.

What Role Does Suede Play in Custom Leather Jacket Manufacturing?

Suede, derived from the underside of the animal hide, is known for its soft texture and unique appearance. It is less durable than full-grain leather but offers a distinctive aesthetic that appeals to fashion-conscious consumers.

Illustrative image related to custome leather jacket

Pros: Suede’s softness and luxurious feel make it a popular choice for stylish jackets. It also comes in various colors and can be easily manipulated into different designs.

Cons: The primary limitation of suede is its susceptibility to staining and water damage, which can be a concern in regions with high humidity or rainfall. B2B buyers must consider the maintenance requirements associated with this material.

Summary Table of Material Selection for Custom Leather Jackets

| Material | Typical Use Case for custome leather jacket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lambskin | Fashion jackets, lightweight designs | Luxurious feel and aesthetic appeal | Lower durability, prone to wear | Medium |

| Cowhide | Heavy-duty jackets, motorcycle gear | High durability and abrasion resistance | Heavier and stiffer than other leathers | High |

| Goatskin | Versatile jackets for fashion and function | Good balance of softness and durability | Less protective than cowhide | Medium |

| Suede | Stylish, fashion-forward jackets | Soft texture and unique appearance | Susceptible to stains and water damage | Low |

This strategic material selection guide provides valuable insights for B2B buyers, helping them to make informed decisions based on the properties, advantages, and limitations of each leather type. Understanding these factors is crucial for ensuring that the final product meets the expectations of end-users across diverse markets, including Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for custome leather jacket

What Are the Key Stages in the Manufacturing Process of Custom Leather Jackets?

The manufacturing process of custom leather jackets involves several critical stages, each contributing to the final product’s quality and uniqueness. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to custome leather jacket

How Is Material Prepared for Custom Leather Jackets?

Material preparation is the first step in the manufacturing process. High-quality leather is sourced from reputable tanneries, which may include lambskin, sheepskin, goatskin, buffalo hide, and cow hide. Each type of leather offers distinct characteristics, such as durability, texture, and weight, which affect the jacket’s final look and feel.

Before production, leather undergoes thorough inspection to identify any defects or inconsistencies. Suppliers often provide swatches for B2B buyers to evaluate the leather quality. This step is crucial for ensuring that the material meets the specifications and aesthetic requirements of the client.

What Techniques Are Used in Forming Custom Leather Jackets?

The forming stage involves cutting the leather into the required patterns based on the design specifications. Advanced techniques such as laser cutting may be utilized to ensure precision and minimize material waste. Skilled artisans then shape the leather through methods like molding or stretching to achieve the desired fit.

In addition to leather, other materials such as linings, zippers, and hardware are selected during this stage. Choosing high-quality components, like YKK zippers, can significantly enhance the jacket’s durability and functionality.

How Are Custom Leather Jackets Assembled?

Assembly is the stage where all the components come together. Expert craftsmen stitch the leather pieces using industrial sewing machines, ensuring strong seams that will withstand wear and tear. Attention to detail is paramount; therefore, techniques such as double-stitching or reinforced seams may be employed, especially in high-stress areas like the shoulders and elbows.

Illustrative image related to custome leather jacket

Customization options, including embroidery and sublimation printing, are integrated into the assembly process. This allows B2B clients to incorporate logos, graphics, or personal designs, further enhancing the product’s uniqueness.

What Finishing Touches Are Applied to Custom Leather Jackets?

Finishing involves several steps to ensure that the jacket meets the highest quality standards. This includes trimming excess threads, applying protective coatings, and conducting a final quality check. The jackets may undergo conditioning treatments to enhance the leather’s softness and longevity.

Lastly, each jacket is meticulously inspected for quality and consistency before packaging. This step is essential to ensure that every product meets the buyer’s expectations.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance in the manufacturing of custom leather jackets is critical to maintaining consistency and reliability. B2B buyers should be aware of relevant international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards can indicate a supplier’s commitment to quality and customer satisfaction.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints should be integrated at various stages of production.

-

Incoming Quality Control (IQC): This is the initial checkpoint where the quality of raw materials, including leather and other components, is assessed. Ensuring that materials meet specified standards is crucial for the overall quality of the final product.

-

In-Process Quality Control (IPQC): Throughout the assembly and finishing processes, regular inspections are conducted to identify and rectify any issues that may arise. This can include checking stitching quality, alignment, and overall craftsmanship.

-

Final Quality Control (FQC): At this stage, a comprehensive inspection of the finished jackets is carried out. This includes checking for defects, fit, and adherence to the client’s specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify a supplier’s quality control processes. Here are some effective methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, observe the production processes, and verify adherence to quality standards. Audits can be performed by the buyer’s team or third-party inspection services.

-

Quality Assurance Reports: Requesting detailed QC reports from suppliers can provide insights into their quality control practices. These reports should outline inspection results, defect rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can perform independent checks at various stages of production, providing unbiased evaluations of the quality.

-

Certifications: Buyers should look for suppliers with relevant certifications, such as CE marking for compliance with European safety standards or other industry-specific certifications. These certifications can indicate a commitment to quality and safety.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Cultural differences, regulatory requirements, and market expectations can impact the quality assurance process.

-

Regulatory Compliance: Buyers should familiarize themselves with local regulations regarding leather goods, including environmental and safety standards. Compliance with these regulations is crucial for market entry and sustainability.

-

Communication and Collaboration: Establishing clear communication channels with suppliers is essential. Regular updates and feedback can help address quality concerns promptly and build a collaborative relationship.

-

Cultural Sensitivity: Understanding cultural differences in business practices can enhance collaboration. For example, approaches to negotiation, timelines, and quality expectations may vary between regions.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring that they receive high-quality custom leather jackets that meet their specifications and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custome leather jacket’

Introduction

Sourcing custom leather jackets for your business requires careful consideration and planning. This guide provides a structured checklist to help B2B buyers navigate the complexities of procuring high-quality, bespoke leather jackets tailored to their specific needs. Each step is designed to ensure that you select the right supplier and product for your market, while also safeguarding your investment.

Illustrative image related to custome leather jacket

Step 1: Identify Your Target Market Needs

Understanding your target market is critical when sourcing custom leather jackets. Conduct market research to identify preferences regarding styles, colors, and price points. This insight will guide your design specifications and ensure that your offerings resonate with potential customers.

- Consider regional preferences: Different markets may have unique tastes; for instance, European buyers may favor classic styles, while South American markets might lean towards vibrant colors.

- Evaluate competitive offerings: Analyze what competitors are providing to find gaps you can fill.

Step 2: Define Your Technical Specifications

Clearly outlining the technical specifications of the jackets you want is essential for effective communication with suppliers. This includes material types, design elements, and any customization options.

- Select leather types: Decide whether you prefer lambskin, cowhide, or other materials, considering their durability and texture.

- Outline design features: Specify details like zippers, pockets, and linings to ensure the final product meets your expectations.

Step 3: Research and Verify Potential Suppliers

Before entering any agreements, it’s vital to thoroughly investigate potential suppliers. Look for manufacturers with a solid reputation and proven track record in producing high-quality leather products.

- Request samples: Ask for product samples to evaluate the quality and craftsmanship.

- Check certifications: Verify that the supplier adheres to international quality standards and ethical sourcing practices.

Step 4: Request Customization Options

Customization is a key selling point for leather jackets, so ensure your supplier can accommodate specific requests. This may include embroidery, logos, or unique color combinations.

- Discuss design flexibility: Confirm that the supplier can handle custom designs and modifications based on your requirements.

- Inquire about production timelines: Understand how customization might affect lead times to manage customer expectations.

Step 5: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, it’s time to negotiate the terms of your agreement. This includes pricing, minimum order quantities, and payment terms.

Illustrative image related to custome leather jacket

- Clarify payment structures: Discuss whether payments will be made upfront, upon delivery, or based on milestones.

- Establish a return policy: Ensure there is a clear understanding of how returns and alterations will be handled, particularly for custom items.

Step 6: Evaluate Shipping and Logistics

Understanding the logistics of shipping your custom leather jackets is crucial for timely delivery. Ensure your supplier can provide reliable shipping options that align with your business model.

- Choose your shipping method: Depending on urgency, decide between standard and expedited shipping.

- Assess international shipping capabilities: If you are sourcing globally, confirm the supplier’s experience with customs and international regulations.

Step 7: Plan for Quality Control and Feedback

Implement a robust quality control process to ensure that the jackets meet your specifications upon arrival. Establish a feedback loop with your supplier for continuous improvement.

- Conduct inspections: Arrange for quality checks at various production stages.

- Gather customer feedback: After the jackets are sold, collect customer insights to guide future sourcing decisions and adjustments.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing custom leather jackets, ensuring that their final products meet market demands while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for custome leather jacket Sourcing

What Are the Key Cost Components for Custom Leather Jacket Sourcing?

When sourcing custom leather jackets, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of leather significantly impacts costs. Premium materials like lambskin or buffalo hide will be more expensive than lower-grade options. Additionally, sourcing materials from reputable tanneries ensures quality but can drive up prices.

-

Labor: Skilled craftsmanship is vital in the production of custom leather jackets. Labor costs will vary based on the complexity of the design and the expertise required. Customization often requires more skilled labor, which can increase costs.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses related to the production facility. Efficient operations can help keep these costs down.

-

Tooling: Custom designs may necessitate unique tools or molds, which can add to the initial investment. However, once established, these tools can be used for multiple orders, spreading the cost over time.

-

Quality Control (QC): Ensuring that each jacket meets quality standards is crucial. This may involve inspections at various stages of production, which can add to overall costs but is necessary to maintain brand reputation.

-

Logistics: Shipping costs can vary widely based on the destination and shipping method. Buyers should consider potential tariffs and duties, especially when sourcing internationally.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market demand and competition.

How Do Price Influencers Impact Custom Leather Jacket Costs?

Several factors influence the pricing of custom leather jackets. Understanding these can help buyers negotiate better deals.

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing significantly. Larger orders often qualify for bulk discounts, reducing the per-unit cost.

-

Specifications and Customization: The more customized the jacket, the higher the price. Features like unique designs, embroidery, or specialized fittings will increase production complexity and cost.

-

Materials and Quality Certifications: Jackets made from high-quality materials with certifications (e.g., eco-friendly leather) may come at a premium. Buyers should weigh the benefits of these investments against the added costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their assurance of quality and timely delivery.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect shipping costs and responsibilities, impacting the overall price structure. Buyers should clarify these terms to avoid unexpected charges.

What Negotiation Tips Can Help B2B Buyers Secure Better Pricing?

-

Understand Total Cost of Ownership (TCO): Beyond the initial price, consider long-term costs, including maintenance, durability, and potential alterations. A higher upfront cost for a quality jacket may save money in the long run.

-

Leverage Volume Discounts: If planning to order in bulk, use this as leverage in negotiations. Suppliers are often willing to reduce prices for larger orders.

-

Request Detailed Quotes: Ensure quotes include a breakdown of all cost components. This transparency allows for more informed negotiations and highlights areas where costs can be cut.

-

Be Aware of Pricing Nuances: Different regions may have varying standards for quality and service, which can affect pricing. Understanding these nuances can aid in negotiations, particularly when dealing with suppliers from Africa, South America, the Middle East, or Europe.

-

Build Relationships with Suppliers: Establishing a long-term relationship can lead to better pricing and priority service. Suppliers are often more willing to negotiate with clients they know and trust.

Conclusion: What Should Buyers Keep in Mind?

B2B buyers should approach custom leather jacket sourcing with a comprehensive understanding of the cost structure, price influencers, and effective negotiation strategies. With careful planning and strategic purchasing, buyers can optimize their sourcing processes while ensuring quality and cost-effectiveness. Always remember that indicative prices can fluctuate based on market conditions, so stay informed and flexible in your sourcing strategy.

Alternatives Analysis: Comparing custome leather jacket With Other Solutions

Exploring Alternatives to Custom Leather Jackets

In the realm of bespoke fashion, custom leather jackets are a popular choice for businesses seeking high-quality, personalized outerwear. However, there are several alternatives that may also meet the needs of B2B buyers. This section provides a comparative analysis of custom leather jackets against other viable solutions, helping businesses make informed decisions based on their specific requirements.

| Comparison Aspect | Custom Leather Jacket | Alternative 1: Tailored Fabric Jackets | Alternative 2: Synthetic Leather Jackets |

|---|---|---|---|

| Performance | High durability and quality | Good durability, varies with fabric | Moderate durability, less breathable |

| Cost | Higher price range ($367+) | Moderate price range ($150-$400) | Lower price range ($50-$200) |

| Ease of Implementation | Requires measurements; time-consuming | Requires measurements; faster than leather | Ready-made options available; quick to procure |

| Maintenance | Requires special care | Easier to clean, machine washable | Low maintenance; wipe clean |

| Best Use Case | Luxury, fashion-forward brands | Casual and business casual wear | Budget-conscious brands, promotional items |

What Are the Pros and Cons of Tailored Fabric Jackets?

Tailored fabric jackets offer a versatile alternative to custom leather jackets. These jackets can be made from various materials, including cotton, polyester, and blends, allowing for a wide range of styles and fits. One of the significant advantages is their moderate price point, making them accessible for businesses looking to outfit employees or create a uniform. Additionally, they are typically easier to clean and maintain, as many fabric jackets are machine washable. However, they may not provide the same level of durability or prestige as leather, making them less suitable for high-end branding.

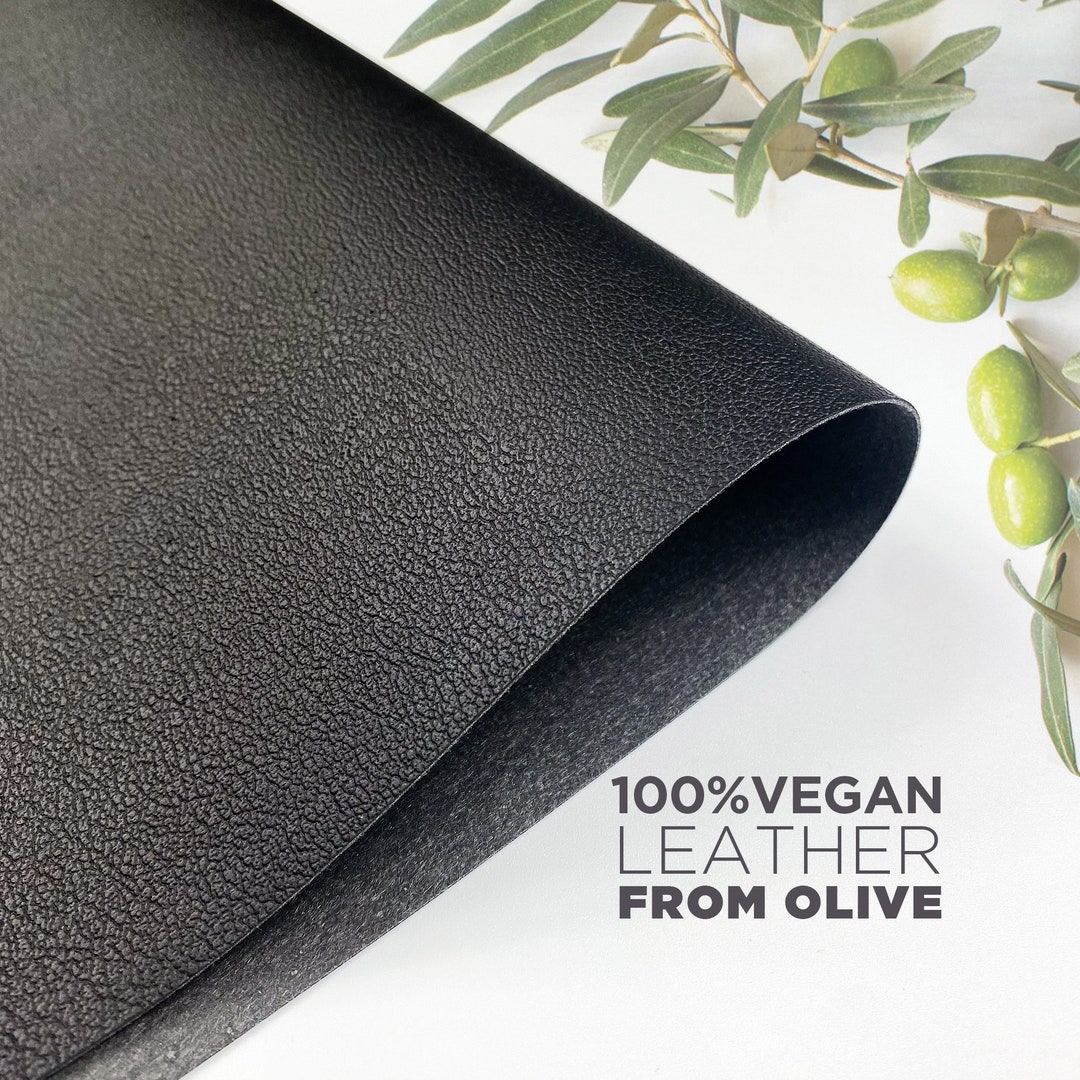

How Do Synthetic Leather Jackets Compare?

Synthetic leather jackets, often made from polyurethane or PVC, present a budget-friendly option for companies aiming to provide stylish outerwear without the higher costs associated with genuine leather. They are easy to maintain, requiring only a simple wipe-down to keep them clean, and are often available in a wide range of colors and styles. However, synthetic leather can lack the breathability and durability of natural leather, which could affect comfort and longevity, particularly in diverse climates. This makes them more suitable for promotional items or lower-tier fashion lines rather than luxury branding.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the right solution for custom leather jackets or alternatives, B2B buyers should consider their specific needs, budget, and brand image. Custom leather jackets are ideal for businesses seeking a high-quality, durable product that conveys a sense of luxury and exclusivity. On the other hand, tailored fabric jackets can provide a balance between style and cost-effectiveness for more casual settings. Lastly, synthetic leather jackets are a viable option for those prioritizing budget over durability and brand prestige. By weighing these factors, businesses can make a decision that aligns with their objectives and resonates with their target audience.

Essential Technical Properties and Trade Terminology for custome leather jacket

What Are the Key Technical Properties of Custom Leather Jackets?

When sourcing custom leather jackets, understanding the technical properties is crucial for ensuring quality and meeting customer expectations. Here are some essential specifications to consider:

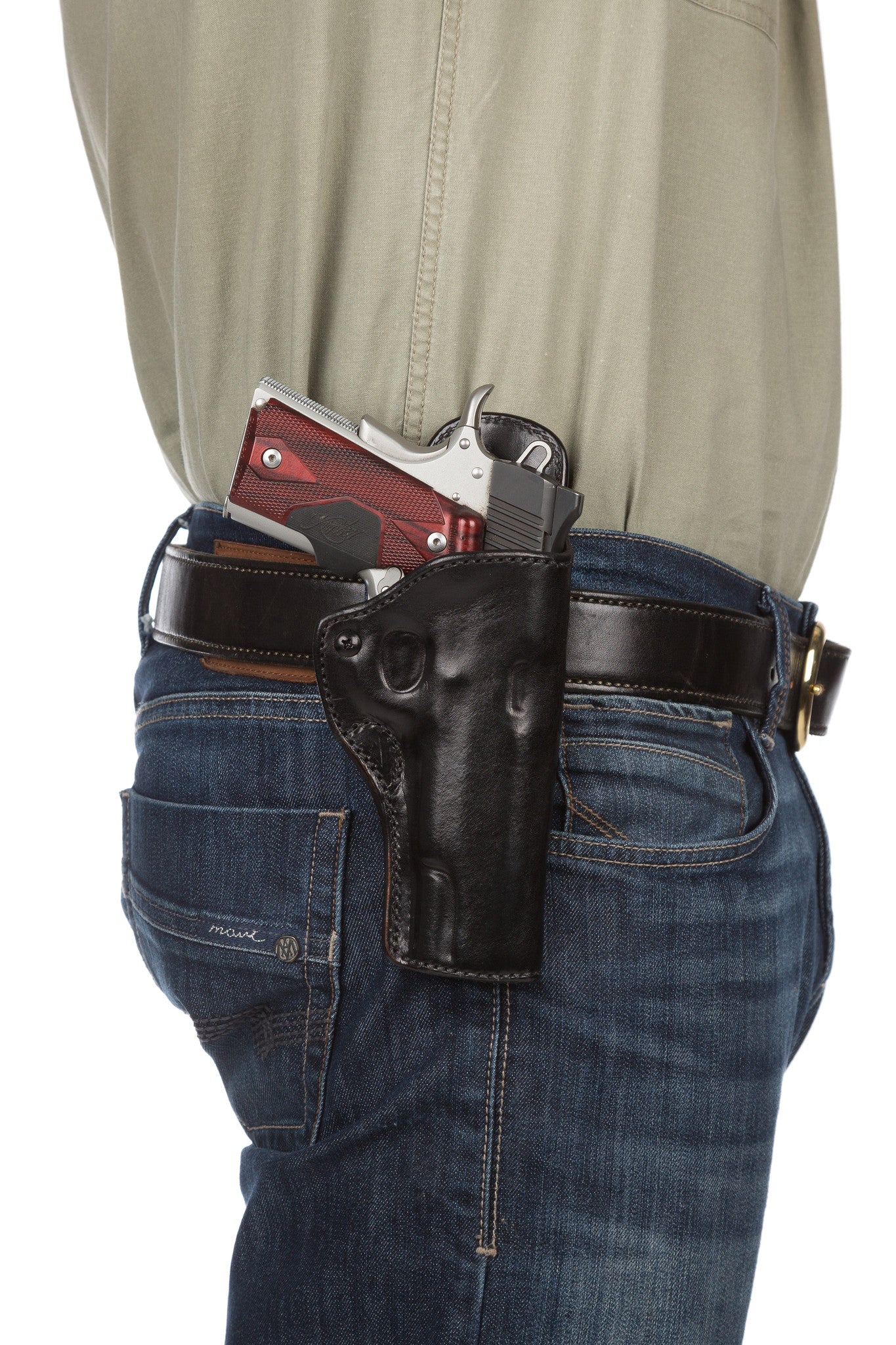

1. Material Grade

The material grade of leather is a primary determinant of the jacket’s durability, appearance, and feel. Common grades include full-grain, top-grain, and corrected grain leather. Full-grain leather is the highest quality, retaining the natural grain and imperfections, making it both durable and aesthetically appealing. B2B buyers must prioritize material grade to ensure that the final product meets market standards and customer satisfaction.

2. Tolerance Levels

Tolerance levels refer to the acceptable variations in size, shape, and fit of the leather jacket during production. For custom orders, maintaining tight tolerances is essential to achieve the desired fit and design. This is particularly important for bespoke items, where precision in measurements can significantly impact customer satisfaction. Suppliers should provide clear tolerances to avoid costly returns and alterations.

Illustrative image related to custome leather jacket

3. Stitching Techniques

The type and quality of stitching used in leather jackets can greatly affect their durability and overall appearance. Common stitching techniques include double-stitching and reinforced stitching, which enhance strength and longevity. For B2B buyers, understanding the stitching technique can help in assessing the quality of craftsmanship and ensuring that the jackets can withstand wear and tear.

4. Leather Finish

The finish applied to the leather can alter its look, feel, and performance. Options include matte, glossy, or distressed finishes. Each finish not only affects the aesthetic appeal but also influences the jacket’s resistance to elements like moisture and UV rays. Buyers must consider the intended use of the jackets to select the appropriate finish that aligns with customer preferences.

5. Lining Materials

The choice of lining material is crucial for comfort and functionality. Common options include cotton, polyester, and silk, each providing different levels of warmth and breathability. Buyers should evaluate lining options based on climate considerations and target markets, ensuring that the final product meets the expected comfort standards.

6. Hardware Quality

The quality of zippers, buttons, and other hardware components is often overlooked but plays a vital role in the jacket’s functionality and style. High-quality hardware, such as YKK zippers, ensures smooth operation and enhances the jacket’s overall durability. B2B buyers should insist on premium hardware to minimize returns and enhance customer satisfaction.

What Are Common Trade Terms in the Custom Leather Jacket Industry?

Understanding industry jargon is essential for effective communication and successful transactions in the custom leather jacket market. Here are some key terms:

Illustrative image related to custome leather jacket

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of custom leather jackets, an OEM can create jackets based on a buyer’s specifications, allowing brands to offer unique products without investing in production infrastructure.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it influences inventory management and pricing strategies. Understanding MOQ helps buyers negotiate better deals and plan their procurement effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to suppliers to request pricing and terms for specific products or services. In the custom leather jacket industry, an RFQ allows buyers to gather competitive offers and assess supplier capabilities, ensuring they make informed purchasing decisions.

Illustrative image related to custome leather jacket

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They outline aspects such as shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to avoid misunderstandings and ensure smooth logistics when sourcing custom leather jackets globally.

5. Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is essential for B2B buyers to manage their supply chain effectively and meet market demand without delays.

6. Customization Options

Customization options refer to the various choices available to buyers in designing their leather jackets, including style, color, materials, and additional features. Knowledge of customization options allows buyers to cater to diverse customer preferences and enhance product offerings.

By grasping these technical properties and trade terms, B2B buyers can navigate the custom leather jacket market more effectively, ensuring they make informed decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the custome leather jacket Sector

What Are the Key Trends Shaping the Custom Leather Jacket Market?

The custom leather jacket market is witnessing significant growth driven by several global factors. Increasing disposable incomes and the rise of the middle class in regions such as Africa and South America are fueling demand for premium, personalized products. Additionally, the growing trend of self-expression through fashion is leading consumers to seek unique, custom-designed pieces that reflect their individuality. This trend is particularly pronounced among younger demographics who prioritize authenticity and personal branding.

Emerging B2B technologies are also reshaping the sourcing landscape. Companies are leveraging advanced design software and 3D modeling to create virtual prototypes, allowing buyers to visualize their custom jackets before production. Furthermore, online consultation platforms facilitate direct communication between manufacturers and international buyers, streamlining the design process. The adoption of e-commerce solutions is essential for businesses aiming to tap into global markets, particularly in Europe and the Middle East, where online shopping is increasingly popular.

Market dynamics indicate a shift towards small-batch production, as brands recognize the value of limited editions and the appeal of artisanal craftsmanship. This trend aligns with consumer demand for quality over quantity, encouraging manufacturers to focus on bespoke offerings that cater to specific customer needs. As the market evolves, international B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with consumer preferences.

Illustrative image related to custome leather jacket

How Can Sustainability and Ethical Sourcing Impact B2B Operations in the Custom Leather Jacket Sector?

Sustainability is becoming a cornerstone of the custom leather jacket market, with increasing awareness regarding the environmental impact of leather production. B2B buyers are now prioritizing suppliers who adhere to sustainable practices, such as sourcing leather from tanneries that use eco-friendly processes. The importance of ethical supply chains cannot be overstated, as consumers are increasingly scrutinizing the origins of their products.

Brands that invest in ‘green’ certifications and sustainable materials not only enhance their reputation but also attract environmentally conscious consumers. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) provide assurance that the leather used is sourced responsibly. Additionally, the use of alternative materials, such as plant-based leathers and recycled textiles, is gaining traction, offering innovative solutions that align with sustainability goals.

For international B2B buyers, collaborating with suppliers committed to ethical practices not only strengthens their supply chain but also positions them favorably in the marketplace. As regulations around sustainability tighten globally, companies that proactively adopt these practices will be better equipped to navigate future challenges and meet consumer expectations.

What Is the Historical Context of the Custom Leather Jacket Market?

The custom leather jacket industry has evolved significantly over the decades. Initially popularized in the early 20th century by aviators and later embraced by motorcycle enthusiasts, leather jackets have transcended their utilitarian roots to become symbols of rebellion and style. The rise of Hollywood in the mid-20th century further cemented their status as fashion staples, with iconic figures like Marlon Brando and James Dean showcasing leather jackets in films.

As consumer preferences shifted towards personalization in the late 20th century, the demand for custom leather jackets surged. Today, advancements in manufacturing technology and design capabilities allow for highly individualized products, catering to diverse markets globally. This evolution reflects broader trends in fashion, where bespoke and unique items are increasingly valued, making the custom leather jacket a significant player in the contemporary apparel landscape.

Illustrative image related to custome leather jacket

Understanding this historical context provides B2B buyers with valuable insights into consumer behavior and market dynamics, informing their sourcing strategies in the custom leather jacket sector.

Frequently Asked Questions (FAQs) for B2B Buyers of custome leather jacket

1. How can I ensure the quality of custom leather jackets from suppliers?

To ensure quality, it’s crucial to vet suppliers thoroughly. Request samples of their leather and craftsmanship before placing bulk orders. Look for certifications or quality assurances from recognized bodies. Additionally, consider visiting the supplier’s facility if possible, or arrange for third-party inspections to verify standards. Establishing a clear communication channel regarding your quality expectations and conducting regular audits can further enhance your confidence in the supplier’s capabilities.

2. What are the typical minimum order quantities (MOQs) for custom leather jackets?

Minimum order quantities can vary significantly among suppliers, often ranging from 50 to 500 units per design. Some manufacturers may accommodate lower MOQs for first-time buyers, especially if you’re willing to pay a premium. It’s advisable to discuss your needs upfront to find a supplier who can meet your order size without compromising quality. Always factor in the potential for future orders when negotiating MOQs to establish a long-term partnership.

3. What customization options are available for B2B buyers of leather jackets?

Customization options typically include selecting the type of leather, color, style, and design elements such as logos or embroidery. Some suppliers offer personalized fitting based on specific measurements, allowing for tailored designs that meet unique buyer specifications. You may also have the option to choose linings, zippers, and other hardware. Engaging in a detailed consultation with the supplier can help clarify available options and refine your design vision.

4. How do payment terms work when sourcing custom leather jackets internationally?

Payment terms can vary by supplier but often include options like a deposit upfront (usually 30-50%) with the balance due upon completion or shipment. Some suppliers may offer letters of credit or payment through escrow services to protect both parties. It’s important to discuss and agree on terms that suit both your cash flow and the supplier’s requirements, ensuring clarity on payment methods, timelines, and consequences for late payments.

5. What shipping options should I consider when importing custom leather jackets?

When importing, consider air freight for faster delivery or sea freight for cost savings on larger shipments. Many suppliers offer various shipping options, including express services for urgent needs. Ensure that you understand the total landed cost, which includes shipping, customs duties, and taxes. Discuss with your supplier the best shipping methods based on your location and urgency, and consider logistics partners that specialize in international shipping for smoother transactions.

6. How can I handle customs duties and regulations when importing leather jackets?

Understanding customs duties and regulations is critical in international trade. Research the specific tariff classifications for leather jackets in your country, as they can significantly affect your overall costs. Engage a customs broker to facilitate the clearance process, ensuring compliance with all import regulations. It’s advisable to maintain accurate documentation, including invoices and certificates of origin, to avoid delays and additional charges upon arrival.

7. What are common pitfalls to avoid when sourcing custom leather jackets?

Common pitfalls include failing to conduct thorough supplier vetting, neglecting to clarify customization details, and not being aware of hidden costs such as shipping and duties. Additionally, overlooking the importance of quality control can lead to unsatisfactory products. To mitigate these risks, ensure clear communication, set realistic timelines, and engage in detailed contracts that outline expectations for quality, delivery, and payment terms.

8. How can I establish a long-term relationship with my leather jacket supplier?

Building a long-term relationship with your supplier involves consistent communication, timely payments, and providing constructive feedback. Regularly discussing future orders and potential collaborations can also strengthen the partnership. Attend trade shows or industry events to engage with your supplier personally, fostering a sense of trust and mutual understanding. Establishing a clear framework for resolving disputes and adapting to changes in market demands can also ensure a sustainable relationship.

Illustrative image related to custome leather jacket

Top 6 Custome Leather Jacket Manufacturers & Suppliers List

1. The Jacket Maker – Custom Leather Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom Leather Jackets & Coats available for men and women. Options include Bomber Jackets, Biker Jackets, Suede Jackets, Varsity Jackets, Fur & Shearling Leather Blazers, Aviator Jackets, Hooded Leather Jackets, Leather Vests, and more. Customization options include embroidery, logos, and color selection. Available in various sizes and styles, with a focus on personalized design. Corporate gifts …

2. Magnoli Clothiers – Custom Leather Jackets

Domain: magnoliclothiers.com

Registered: 2006 (19 years)

Introduction: Custom made leather jackets by Magnoli Clothiers, offering personalized fit and style options.

3. Lusso Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Product Name: Custom Leather Jackets

Regular Price: $484.00

Sale Price: $367.00

Free Shipping: Yes

Return Policy: 30 days for Returns/Alterations

Available Sizes: XSmall, Small, Medium, Large, Xlarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $431.00

Customization Options: Custom embroidery, sublimation printing, logos, graphics, lettering, monograms, quotes

Fit Guarantee: 94% cus…

4. Vanson – Handcrafted Leather Motorcycle Jackets

Domain: vansonleathers.com

Registered: 1997 (28 years)

Introduction: This company, Vanson – Handcrafted Leather Motorcycle Jackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

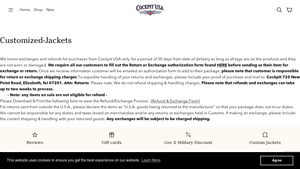

5. Cockpit USA – Custom Leather Bomber Jackets

Domain: cockpitusa.com

Registered: 2004 (21 years)

Introduction: Custom Jacket Maker for Leather Bomber Flight Jackets. Customized jackets available. Return policy: exchanges and refunds for purchases from Cockpit USA only for a period of 30 days from date of delivery, provided all tags are on the products and they are not worn or damaged. Customers must fill out a Return or Exchange authorization form. Refunds and exchanges can take up to two weeks to process….

6. The Cast – Custom Leather Jackets & Vests

Domain: thecast.com

Registered: 1999 (26 years)

Introduction: This company, The Cast – Custom Leather Jackets & Vests, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custome leather jacket

In the rapidly evolving market for custom leather jackets, strategic sourcing is crucial for B2B buyers aiming to leverage quality and brand differentiation. Key takeaways include the importance of selecting suppliers who prioritize high-quality materials, such as lambskin and buffalo-hide, and offer customization options that reflect your brand identity. Collaborating with manufacturers that facilitate a bespoke design process not only enhances product appeal but also fosters customer loyalty.

As international buyers from regions like Africa, South America, the Middle East, and Europe seek to tap into the lucrative fashion segment, understanding local market trends and consumer preferences will empower your sourcing decisions. Establishing strong partnerships with reliable manufacturers can significantly reduce lead times and enhance product quality.

Looking ahead, the demand for unique, personalized leather goods is set to grow. Buyers are encouraged to embrace innovation in design and sustainability, ensuring that their offerings resonate with modern consumers. By actively engaging in the strategic sourcing process, you can position your brand for success in a competitive landscape. Start exploring your options today and secure your place in the thriving custom leather jacket market.

Illustrative image related to custome leather jacket

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custome leather jacket