Introduction: Navigating the Global Market for alcantara car seats

In an increasingly competitive automotive industry, sourcing high-quality Alcantara car seats presents a unique challenge for B2B buyers. As the demand for premium materials grows, understanding the intricacies of Alcantara—its applications, customization options, and maintenance—becomes essential for making informed purchasing decisions. This guide serves as a comprehensive resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany.

Throughout this guide, we will explore the various types of Alcantara car seats, detailing their applications in both luxury and performance vehicles. We will also provide insights on supplier vetting processes, ensuring that you partner with reliable manufacturers who meet rigorous quality standards. Additionally, we will discuss cost considerations, helping you to balance budget constraints with the need for excellence in vehicle interiors.

By empowering B2B buyers with actionable insights and practical knowledge, this guide aims to facilitate strategic sourcing decisions. Whether you are enhancing your product line or seeking to differentiate your offerings in a crowded marketplace, understanding Alcantara car seats will enable you to elevate your brand’s appeal while ensuring customer satisfaction.

Table Of Contents

- Top 5 Alcantara Car Seats Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara car seats

- Understanding alcantara car seats Types and Variations

- Key Industrial Applications of alcantara car seats

- 3 Common User Pain Points for ‘alcantara car seats’ & Their Solutions

- Strategic Material Selection Guide for alcantara car seats

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara car seats

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara car seats’

- Comprehensive Cost and Pricing Analysis for alcantara car seats Sourcing

- Alternatives Analysis: Comparing alcantara car seats With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara car seats

- Navigating Market Dynamics and Sourcing Trends in the alcantara car seats Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara car seats

- Strategic Sourcing Conclusion and Outlook for alcantara car seats

- Important Disclaimer & Terms of Use

Understanding alcantara car seats Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Alcantara Seats | Soft, suede-like texture; available in various colors | Mass-market vehicles, fleet sales | Pros: Cost-effective, versatile; Cons: May require frequent cleaning. |

| Performance Alcantara Seats | Enhanced durability; designed for high-performance vehicles | Luxury and sports car manufacturers | Pros: Lightweight, superior grip; Cons: Higher price point. |

| Custom Alcantara Seats | Tailor-made options with unique designs and finishes | High-end automotive brands | Pros: Exclusive appeal, brand differentiation; Cons: Longer lead times, higher costs. |

| Alcantara Eco-Friendly Seats | Made from sustainable materials; eco-conscious production | Green automotive brands | Pros: Appeals to eco-conscious consumers; Cons: Limited availability in some markets. |

| Alcantara Hybrid Seats | Combination of Alcantara with other materials (e.g., leather) | Luxury and custom vehicles | Pros: Enhanced comfort and aesthetics; Cons: More complex sourcing and production. |

What Are Standard Alcantara Seats and Their Applications?

Standard Alcantara seats are characterized by their soft, suede-like texture and come in a wide array of colors. These seats are primarily used in mass-market vehicles and fleet sales, making them a popular choice for manufacturers looking to balance quality with cost-effectiveness. When considering a purchase, B2B buyers should evaluate the material’s maintenance needs, as Alcantara can absorb oils and dirt, requiring regular cleaning to maintain its aesthetic appeal.

How Do Performance Alcantara Seats Stand Out?

Performance Alcantara seats are specifically designed for high-performance vehicles, offering enhanced durability and a superior grip. These seats are favored by luxury and sports car manufacturers who prioritize weight reduction and driver engagement. B2B buyers should consider the balance between cost and performance benefits when sourcing these seats, as they often come with a higher price point but provide significant advantages in premium automotive applications.

What Are the Benefits of Custom Alcantara Seats?

Custom Alcantara seats offer tailor-made options that allow for unique designs and finishes, catering to high-end automotive brands looking to differentiate their products. These seats not only enhance the vehicle’s interior but also elevate the brand’s image. B2B buyers should be prepared for longer lead times and higher costs associated with custom orders, but the exclusivity can justify the investment in competitive markets.

Why Choose Eco-Friendly Alcantara Seats?

Alcantara eco-friendly seats are produced using sustainable materials and environmentally conscious practices, appealing to brands focused on green initiatives. This type of seat is increasingly relevant as consumers become more eco-aware. B2B buyers should assess the availability of these options in their target markets, as they may not be as widely produced, but they can significantly enhance a brand’s reputation for sustainability.

What Are Alcantara Hybrid Seats and Their Key Features?

Alcantara hybrid seats combine Alcantara with other materials, such as leather, to create a luxurious and comfortable seating experience. This variation is often found in luxury and custom vehicles, providing an appealing aesthetic while maintaining durability. B2B buyers should consider the complexity of sourcing and production for hybrid seats, as they may require more intricate supply chain management, but the resulting product can offer significant value in high-end automotive markets.

Key Industrial Applications of alcantara car seats

| Industry/Sector | Specific Application of Alcantara Car Seats | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom luxury car interiors | Enhances brand prestige and customer satisfaction | Quality assurance, customization options, lead times |

| Motorsports | Race car interiors | Provides lightweight, high-performance solutions | Durability, fire resistance, material weight |

| Luxury Vehicle Rentals | Premium rental car fleet | Attracts high-end clientele, improves rental experience | Maintenance requirements, aesthetic appeal |

| Aviation | Private jet interiors | Elevates luxury experience, enhances comfort | Compliance with aviation standards, fire resistance |

| Marine | Yacht interiors | Combines aesthetics with durability in harsh environments | Water resistance, maintenance, customization options |

How Are Alcantara Car Seats Used in Automotive Manufacturing?

In the automotive manufacturing sector, Alcantara car seats are utilized to create custom luxury interiors that enhance the overall aesthetics and comfort of vehicles. By incorporating this high-quality material, manufacturers can significantly elevate their brand prestige and customer satisfaction. Buyers in this sector must consider quality assurance practices, customization options, and lead times to ensure that their products meet the expectations of discerning consumers, particularly in regions like Europe and the Middle East, where luxury is highly valued.

What is the Role of Alcantara in Motorsports?

Motorsports teams leverage Alcantara car seats to provide lightweight and high-performance solutions that are essential for competitive racing. The material is prized for its durability and fire resistance, making it ideal for the extreme conditions faced on the track. For international buyers, particularly from South America and Africa, it is crucial to assess the material’s performance under high-stress scenarios and ensure compliance with relevant safety regulations, as well as sourcing from reputable suppliers.

How Do Luxury Vehicle Rentals Benefit from Alcantara?

Luxury vehicle rental companies integrate Alcantara car seats into their fleets to attract high-end clientele and enhance the rental experience. The luxurious feel and visual appeal of Alcantara can significantly influence customer choices, leading to increased bookings and customer loyalty. Buyers in this sector should focus on maintenance requirements and the overall aesthetic appeal of the material, ensuring that it aligns with the expectations of affluent customers, especially in regions with a growing luxury market like the Middle East.

Why is Alcantara Preferred for Aviation Interiors?

In the aviation industry, Alcantara car seats are used to furnish private jets, providing an elevated luxury experience for passengers. The material’s comfort and aesthetic qualities enhance the overall cabin environment, making it a preferred choice for high-end aircraft interiors. Buyers must ensure compliance with aviation standards, particularly regarding fire resistance and durability, while also considering the aesthetic aspects that appeal to affluent travelers, particularly in Europe and the Middle East.

How is Alcantara Used in Marine Applications?

In the marine sector, Alcantara car seats are employed in yacht interiors, where they combine aesthetics with durability to withstand harsh marine environments. The material is resistant to water and UV rays, making it an ideal choice for boat manufacturers looking to enhance the luxury appeal of their vessels. Buyers must prioritize sourcing materials that offer water resistance and low maintenance, ensuring that the final product meets the expectations of luxury yacht owners, particularly in regions with vibrant maritime industries like South America and Europe.

3 Common User Pain Points for ‘alcantara car seats’ & Their Solutions

Scenario 1: Difficulty in Maintaining Cleanliness of Alcantara Car Seats

The Problem:

B2B buyers, particularly those in the automotive industry, often face significant challenges when it comes to the maintenance and cleanliness of Alcantara car seats. Given the material’s tendency to absorb oils, dirt, and other contaminants, maintaining the pristine appearance and feel of these seats can be daunting. This is especially true in regions with high humidity or dust, where seats can quickly become grimy. Buyers may worry about customer satisfaction and the longevity of the product, leading to potential reputational damage if the seats degrade in appearance and feel over time.

Illustrative image related to alcantara car seats

The Solution:

To effectively maintain Alcantara car seats, it is crucial to establish a routine cleaning protocol. Buyers should source specialized cleaning kits designed specifically for Alcantara, which typically include a gentle cleaning solution and a soft brush. Regularly scheduled cleanings—ideally once a month—can help prevent the buildup of grime. Additionally, educating end-users about the importance of using only recommended cleaning methods can enhance the longevity of the seats. Offering training sessions or informational materials on how to care for Alcantara can also improve customer satisfaction and protect your investment in this high-quality material.

Scenario 2: Concerns About Durability in High-Usage Environments

The Problem:

For B2B buyers involved in fleet management or high-usage vehicle manufacturing, the durability of Alcantara car seats presents a significant concern. In environments where vehicles are used extensively, such as in taxi services or delivery fleets, the wear and tear on seats can be accelerated. This raises questions about whether Alcantara can withstand the daily rigors of use without losing its aesthetic appeal or structural integrity, leading to potential increases in replacement costs and customer complaints.

The Solution:

To mitigate concerns about durability, buyers should specify Alcantara with enhanced durability features, such as a protective coating that improves its resistance to wear and staining. Partnering with manufacturers who offer warranties on their Alcantara products can also provide peace of mind. Additionally, conducting a thorough assessment of the intended use environment can help in selecting the appropriate grade of Alcantara. Engaging in pilot testing within a controlled fleet can allow for real-world evaluation of performance and durability before full-scale implementation.

Scenario 3: Navigating the Challenges of Color and Design Choices

The Problem:

B2B buyers often struggle with selecting the right colors and designs for Alcantara car seats that will appeal to their target markets. With the extensive range of colors and textures available, making a choice can be overwhelming. Furthermore, trends in automotive interiors can shift quickly, making it crucial to choose options that remain appealing over time. Buyers may fear that poor choices could lead to unsold inventory or dissatisfaction among consumers.

Illustrative image related to alcantara car seats

The Solution:

To navigate the complexities of color and design selection, buyers should leverage trend forecasting services and market research to understand the preferences of their target demographics. Conducting surveys or focus groups with potential end-users can provide valuable insights into color preferences and design aesthetics. Additionally, collaborating with design professionals who specialize in automotive interiors can lead to informed decisions. Offering customizable options in Alcantara seats can also attract a wider audience, allowing buyers to cater to diverse tastes while minimizing the risk of unsold inventory.

Strategic Material Selection Guide for alcantara car seats

What Materials Are Commonly Used for Alcantara Car Seats?

When selecting materials for Alcantara car seats, it is essential to consider various options that can complement or enhance the properties of Alcantara itself. The following analysis examines four common materials used in conjunction with Alcantara for automotive seating, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Leather in Car Seat Applications?

Leather is a traditional choice for car interiors, known for its luxurious feel and durability. It offers excellent temperature resistance and is relatively easy to clean. Leather can withstand high pressure and is resistant to wear, making it suitable for high-performance vehicles.

Illustrative image related to alcantara car seats

Pros: Leather provides a premium aesthetic, is durable, and can be treated for additional water and stain resistance. Its natural breathability enhances comfort during long drives.

Cons: The cost of high-quality leather can be prohibitive, and it may require regular maintenance to prevent cracking or fading. Additionally, leather is less environmentally friendly compared to synthetic alternatives.

Impact on Application: Leather works well with Alcantara, often used in high-end models where luxury is paramount. However, B2B buyers should consider local preferences for sustainable materials, especially in regions where animal welfare is a concern.

How Does Fabric Compare to Alcantara for Car Seats?

Fabric is another common material, often used for its affordability and variety. It can be engineered to provide good durability and comfort, with moisture-wicking properties that enhance breathability.

Illustrative image related to alcantara car seats

Pros: Fabric is generally less expensive than leather and Alcantara, making it suitable for mass-market vehicles. It can also be produced in various colors and patterns, allowing for customization.

Cons: Fabric may not offer the same level of durability as leather or Alcantara and can absorb stains and odors more readily. It may also require more frequent cleaning to maintain its appearance.

Impact on Application: Fabric can be a good choice for budget-friendly vehicles, but B2B buyers should ensure that the fabric meets local standards for flammability and durability, particularly in regions with stringent automotive regulations.

What Role Does Vinyl Play in Alcantara Car Seat Manufacturing?

Vinyl is a synthetic alternative that mimics the look and feel of leather but at a lower cost. It is resistant to moisture and can be easily cleaned, making it suitable for automotive applications.

Pros: Vinyl is cost-effective, durable, and available in a wide range of colors and finishes. It is also resistant to UV damage, which is crucial for vehicles exposed to harsh sunlight.

Illustrative image related to alcantara car seats

Cons: Vinyl lacks the breathability of natural materials, which can lead to discomfort in hot climates. It may also not provide the same luxurious feel as Alcantara or leather.

Impact on Application: Vinyl can be used in conjunction with Alcantara to create a visually appealing and functional car seat. Buyers in warmer regions should consider the thermal properties of vinyl when selecting materials for their vehicles.

How Does Alcantara Itself Enhance Car Seat Performance?

Alcantara is a synthetic material known for its soft, suede-like texture. It is lightweight, breathable, and offers excellent grip, making it a popular choice for performance vehicles.

Pros: Alcantara is highly customizable in terms of color and texture, and it is also fire-resistant. Its unique properties make it suitable for high-end applications where aesthetics and performance are critical.

Cons: Alcantara can absorb oils and dirt, requiring regular maintenance to keep it looking new. It may not be the best choice for high-contact areas like steering wheels due to its tendency to become grimy.

Illustrative image related to alcantara car seats

Impact on Application: Alcantara is often used in luxury and performance vehicles, appealing to buyers looking for a premium interior. International buyers should be aware of the cleaning and maintenance requirements, especially in regions with high humidity or dust.

Summary Table of Material Selection for Alcantara Car Seats

| Material | Typical Use Case for alcantara car seats | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Luxury vehicles, high-end models | Premium aesthetic, durability | High cost, maintenance required | High |

| Fabric | Mass-market vehicles, budget-friendly options | Cost-effective, customizable | Less durable, absorbs stains | Low |

| Vinyl | Budget models, easy-to-clean interiors | Affordable, moisture-resistant | Lacks breathability, less luxurious | Medium |

| Alcantara | Luxury and performance vehicles | Lightweight, customizable | Requires maintenance, can absorb dirt | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse markets, ensuring they make informed decisions that align with regional preferences and standards.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara car seats

What Are the Key Stages in the Manufacturing Process of Alcantara Car Seats?

The manufacturing of Alcantara car seats involves several critical stages, each designed to ensure that the final product meets the high standards expected by both manufacturers and consumers. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with the sourcing of Alcantara, a synthetic, suede-like material known for its durability and aesthetic appeal. The production process starts with the careful selection of raw materials, ensuring compliance with sustainability standards, as Alcantara is a brand that emphasizes eco-friendliness. The material is then cut to specific dimensions based on the design requirements of each car model.

-

Forming: Once the material is prepared, it undergoes forming processes where it is shaped into the required components of the car seat. This may involve techniques such as molding or stitching, depending on the design specifications. Advanced machinery is often used to ensure precision in cutting and shaping the Alcantara fabric, which allows for intricate designs that enhance the car’s interior aesthetics.

-

Assembly: Following the forming stage, the individual components of the seat, such as the seat cover, foam padding, and frame, are assembled. Skilled artisans typically oversee this process, ensuring that each piece fits seamlessly together. The assembly process is crucial for maintaining the structural integrity of the seat while ensuring that comfort and ergonomics are prioritized.

-

Finishing: The final stage involves adding finishing touches to the car seats. This can include additional stitching, quality checks for defects, and treatments to enhance the material’s properties, such as stain resistance or improved durability. This stage ensures that the seats not only look premium but also perform well over time.

How Is Quality Assurance Implemented in Alcantara Car Seat Manufacturing?

Quality assurance is paramount in the manufacturing of Alcantara car seats, ensuring that they meet international standards and consumer expectations. Several quality control processes and checkpoints are integrated throughout the manufacturing stages.

-

International Standards Compliance: To maintain high quality, manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. This certification assures B2B buyers that the manufacturing processes are consistently monitored and improved. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are often pursued to address specific regulatory requirements.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints during the production process:

– Incoming Quality Control (IQC): Raw materials, including Alcantara fabric, are inspected upon arrival to ensure they meet the required specifications and standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, quality checks are performed to identify defects early. This includes monitoring stitching quality and material integrity during the forming and assembly phases.

– Final Quality Control (FQC): After assembly, the completed car seats undergo rigorous testing to ensure they meet all design and functional specifications. This may include stress testing and visual inspections. -

Common Testing Methods for Alcantara Seats: Various testing methods are employed to evaluate the performance of Alcantara car seats. These include:

– Durability Tests: Assessing the wear and tear of the fabric under various conditions to ensure longevity.

– Stain Resistance Tests: Evaluating how well the material withstands spills and stains, which is crucial for maintaining the aesthetic appeal of car interiors.

– Comfort Tests: Measuring the ergonomic support provided by the seats to ensure passenger comfort.

What Strategies Can B2B Buyers Use to Verify Supplier Quality Control?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are strategies to ensure that suppliers adhere to high standards.

-

Conducting Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance protocols. This may involve on-site visits to assess production capabilities and compliance with international standards.

-

Requesting Quality Assurance Reports: Buyers should request detailed quality assurance reports from suppliers. These reports should outline the quality control measures implemented, results from testing, and any certifications obtained. This documentation helps buyers understand the reliability of the supplier.

-

Engaging Third-Party Inspection Services: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These services can conduct inspections at various stages of production, ensuring that the final products meet the required standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances related to quality control when sourcing Alcantara car seats. Understanding these nuances can significantly impact the success of procurement strategies.

-

Cultural and Regulatory Differences: Buyers should be aware of the cultural differences that may influence manufacturing practices and quality standards. Regulatory requirements can vary significantly across regions, necessitating thorough research into local compliance standards.

-

Language Barriers: Language can pose challenges in communication regarding quality expectations and standards. It is advisable for buyers to establish clear communication channels and utilize translation services when necessary to avoid misunderstandings.

-

Logistical Considerations: The logistics of transporting materials and finished products across borders can affect quality. Buyers should ensure that suppliers have robust logistics strategies in place to maintain product integrity during shipping.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for Alcantara car seats is essential for B2B buyers. By focusing on quality control measures and establishing strong relationships with suppliers, buyers can ensure they procure high-quality products that meet their specifications and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara car seats’

When sourcing Alcantara car seats, it is essential to navigate through a process that ensures you find a supplier who meets your specific needs while adhering to quality and sustainability standards. This guide provides a structured approach to streamline your procurement process.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your Alcantara car seats. Consider factors such as the desired color palette, texture, durability, and intended use (e.g., luxury vehicles vs. performance cars). This step is crucial as it will guide your supplier discussions and ensure that you align with your target market’s expectations.

- Material Properties: Identify necessary attributes like breathability and ease of cleaning.

- Compliance Standards: Ensure specifications meet regional automotive regulations.

Step 2: Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers who specialize in Alcantara materials. Look for manufacturers with a proven track record in the automotive industry, especially those who have collaborated with recognized automotive brands.

- Industry Reputation: Review online ratings and testimonials from previous B2B clients.

- Experience: Focus on suppliers with experience in producing Alcantara car seats for specific vehicle types.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, it’s critical to verify their certifications and adherence to quality standards. Look for ISO certifications, sustainability credentials, and compliance with automotive industry standards.

- Quality Assurance: Certifications indicate a commitment to maintaining high manufacturing standards.

- Sustainability Practices: Ensure the supplier follows eco-friendly practices, aligning with growing consumer demand for sustainable products.

Step 4: Request Samples and Conduct Quality Checks

Once you have shortlisted potential suppliers, request samples of their Alcantara car seats. Conduct thorough quality checks to assess the material’s texture, durability, and overall finish.

- Testing for Performance: Evaluate how the material performs under various conditions, such as exposure to sunlight and moisture.

- Aesthetic Appeal: Ensure the colors and textures meet your design specifications.

Step 5: Understand Pricing and Terms of Sale

Engage suppliers in discussions about pricing structures, minimum order quantities, and payment terms. Understanding the financial aspects early can prevent surprises later in the procurement process.

Illustrative image related to alcantara car seats

- Cost Transparency: Request a detailed breakdown of costs, including shipping and handling.

- Negotiation Flexibility: Assess if suppliers are open to negotiating terms based on your order size.

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the logistics capabilities of your chosen supplier, including their ability to meet delivery timelines and handle international shipping if necessary. This is particularly important for B2B buyers in regions like Africa and South America, where logistics can be complex.

- Lead Times: Inquire about typical lead times for orders to plan your production schedules.

- Shipping Options: Explore available shipping methods and their associated costs.

Step 7: Establish a Long-Term Relationship

After selecting a supplier, work on building a long-term partnership. Maintaining open lines of communication can lead to improved collaboration and better pricing in future orders.

- Regular Check-ins: Schedule periodic reviews to discuss performance and any necessary adjustments.

- Feedback Mechanism: Implement a system for providing feedback on product quality and service.

By following these steps, B2B buyers can effectively source high-quality Alcantara car seats that meet their specific requirements while ensuring a reliable and sustainable supply chain.

Comprehensive Cost and Pricing Analysis for alcantara car seats Sourcing

What Are the Key Cost Components for Alcantara Car Seats?

When sourcing Alcantara car seats, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of Alcantara itself is a significant factor. As a synthetic suede-like material, it is priced higher than traditional fabrics due to its unique properties, such as durability, breathability, and aesthetic appeal. Buyers should also consider the cost of additional materials used for seat construction, such as foam and frame materials.

-

Labor: The manufacturing process for Alcantara car seats often requires skilled labor, particularly for custom designs. Labor costs can vary significantly based on the region and the complexity of the seat design.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, maintenance, and equipment depreciation. Given the specialized nature of Alcantara production, overhead costs can be substantial.

-

Tooling: If custom molds or specialized tools are required for production, tooling costs can add a significant upfront expense. This is particularly relevant for bespoke designs or limited-edition models.

-

Quality Control (QC): Ensuring that the Alcantara seats meet the required standards involves QC processes that can incur additional costs. This is especially important for international buyers who need to comply with various safety and quality certifications.

-

Logistics: Transportation costs to deliver Alcantara seats from the manufacturing facility to the buyer’s location can fluctuate based on distance, shipping method, and current market conditions. This is a critical consideration for international sourcing.

-

Margin: Suppliers will add their profit margin to the total cost, which can vary based on the competitiveness of the market and the supplier’s positioning.

How Do Price Influencers Affect Alcantara Car Seat Sourcing?

Several factors influence the pricing of Alcantara car seats, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders, making it essential for buyers to consider their purchasing volume. Negotiating for lower MOQs can also yield better pricing structures.

-

Specifications and Customization: Customized designs can lead to increased costs. Buyers should clearly outline their specifications to avoid unexpected expenses. Tailoring options such as color, stitching, and additional features can significantly impact the final price.

-

Material Quality and Certifications: Higher quality Alcantara materials or those with specific certifications (e.g., eco-friendly or fire-resistant) may come at a premium. Buyers should weigh the benefits of these features against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their perceived quality and service reliability.

-

Incoterms: The terms of shipping can also influence costs. Buyers should be aware of the different Incoterms (e.g., FOB, CIF) as they define the responsibilities and liabilities of both the buyer and seller during transportation.

What Are Effective Buyer Tips for Negotiating Alcantara Car Seat Prices?

Navigating the procurement process for Alcantara car seats requires strategic planning. Here are some tips for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe:

-

Negotiate Wisely: Always approach negotiations with a clear understanding of your budget and the market rates for Alcantara seats. Building a relationship with suppliers can lead to more favorable terms and pricing.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider long-term durability and maintenance costs associated with Alcantara compared to alternative materials.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations and import tariffs that can affect the final cost. Conducting thorough market research in your region can help in setting realistic budget expectations.

-

Request Samples: Before committing to a large order, request samples to assess the quality of the Alcantara material. This can also serve as a basis for negotiation regarding material costs.

Disclaimer on Indicative Prices

Prices for Alcantara car seats can vary widely based on the factors outlined above. Buyers are encouraged to conduct thorough market research and consult multiple suppliers to obtain accurate and competitive pricing.

Alternatives Analysis: Comparing alcantara car seats With Other Solutions

Exploring Alternatives to Alcantara Car Seats: A Comparative Analysis

When considering car seat materials, Alcantara has gained significant traction in the automotive industry due to its unique blend of aesthetics and performance. However, various alternatives can serve similar purposes, each with its own set of advantages and drawbacks. This analysis aims to provide B2B buyers with insights into viable options for car seat materials, allowing for informed decision-making based on specific needs and use cases.

| Comparison Aspect | Alcantara Car Seats | Leather Car Seats | Synthetic Leather Car Seats |

|---|---|---|---|

| Performance | Lightweight, breathable, and durable; offers a premium feel. | High durability and classic aesthetics; can be less breathable. | Good durability; offers a leather-like appearance at a lower cost. |

| Cost | Premium pricing due to brand and quality; higher upfront investment. | Generally high cost, especially for genuine leather; can vary based on grade. | More affordable; offers a budget-friendly alternative to leather. |

| Ease of Implementation | Requires skilled labor for installation; custom options available. | Installation can be complex, requiring specialized skills; custom options available. | Easier to install; often available in pre-fabricated designs. |

| Maintenance | Requires regular cleaning to prevent staining; can absorb oils and dirt. | Easy to clean but may require conditioning to maintain appearance; can crack over time. | Low maintenance; easier to clean and resistant to stains. |

| Best Use Case | Ideal for high-end vehicles seeking luxury aesthetics and performance. | Suited for luxury cars and high-performance vehicles; provides a classic touch. | Best for budget-conscious manufacturers looking for a leather-like finish without the cost. |

Leather Car Seats: A Traditional Choice

Leather car seats have long been a staple in the automotive industry, known for their durability and timeless appeal. The primary advantage of leather is its classic look and feel, which conveys luxury and sophistication. However, high-quality leather can come with a significant price tag and may require regular maintenance to prevent cracking and fading. Additionally, leather can be less breathable than Alcantara, potentially leading to discomfort in warmer climates.

Synthetic Leather Car Seats: A Cost-Effective Alternative

Synthetic leather, often referred to as “pleather,” is an increasingly popular alternative to traditional leather and Alcantara. It offers a similar aesthetic at a much lower price point, making it an attractive option for budget-conscious automotive manufacturers. Synthetic leather is generally easier to maintain, as it is resistant to stains and does not require conditioning. However, it may lack the premium feel of Alcantara and genuine leather, which can be a drawback for high-end vehicles where luxury is paramount.

Illustrative image related to alcantara car seats

Conclusion: Choosing the Right Car Seat Material for Your Needs

For B2B buyers in the automotive industry, selecting the appropriate car seat material is crucial for meeting customer expectations and enhancing vehicle value. Alcantara car seats excel in luxury and performance, making them ideal for high-end models. However, alternatives like leather and synthetic leather can provide valuable options depending on budget constraints and desired aesthetics. Assessing the specific needs of the target market, including cost, maintenance requirements, and performance characteristics, will guide buyers in making informed choices that align with their business objectives.

Essential Technical Properties and Trade Terminology for alcantara car seats

What Are the Essential Technical Properties of Alcantara Car Seats?

Alcantara is a premium synthetic material that stands out for its versatility and performance in automotive applications. Understanding its technical properties is crucial for B2B buyers in the automotive sector, especially those involved in sourcing materials for high-end vehicle interiors. Here are some key specifications:

1. Material Composition

Alcantara is composed of 68% polyester and 32% polyurethane. This unique blend offers a suede-like texture while maintaining durability and resistance to wear and tear. For B2B buyers, knowing the composition is essential for evaluating the material’s performance in various climates and usage scenarios, particularly in regions like Africa and the Middle East, where extreme temperatures can impact interior materials.

2. Durability and Abrasion Resistance

Alcantara exhibits excellent durability, often rated for over 100,000 Martindale cycles in abrasion tests. This property is vital for automotive applications, as it ensures that the seats can withstand everyday use without degrading. Buyers should consider this specification when assessing the long-term value of Alcantara versus other materials, such as leather or vinyl.

3. Breathability and Comfort

The breathability of Alcantara contributes to a comfortable seating experience, particularly in warmer climates. It allows air circulation, reducing heat buildup during hot weather, which is particularly beneficial for regions with high temperatures. B2B purchasers should prioritize this feature when sourcing materials for markets that demand high comfort levels in vehicle interiors.

4. Fire Resistance

Alcantara is inherently fire-resistant, meeting automotive safety standards. This property is crucial for compliance with safety regulations in various countries, including those in Europe and the Middle East. Understanding fire resistance specifications can help B2B buyers ensure that their products meet local safety standards and enhance consumer trust.

5. Cleaning and Maintenance Requirements

Alcantara is washable and easy to maintain, which is a significant advantage for both manufacturers and end-users. It can be cleaned with mild detergents and does not require specialized care like some leather materials. For B2B buyers, emphasizing ease of maintenance can be a selling point in markets where vehicle upkeep is a concern.

What Are Common Trade Terms Related to Alcantara Car Seats?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are some common terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Alcantara car seats, understanding OEM relationships helps buyers identify suppliers that meet specific quality and branding standards.

Illustrative image related to alcantara car seats

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management, especially when entering new markets or launching new vehicle models.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to invite suppliers to bid on a specific quantity of goods or services. For those sourcing Alcantara car seats, submitting an RFQ can streamline the procurement process, ensuring competitive pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers importing Alcantara materials to ensure compliance and clarity regarding shipping, insurance, and delivery responsibilities.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is critical for supply chain management, especially in the automotive industry, where timing can significantly impact production schedules.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their sourcing strategies for Alcantara car seats, ensuring they meet market demands while maintaining high quality and compliance.

Navigating Market Dynamics and Sourcing Trends in the alcantara car seats Sector

What Are the Key Market Trends Impacting Alcantara Car Seats?

The Alcantara car seats market is influenced by several global drivers that shape buyer preferences and sourcing strategies. As automotive manufacturers increasingly prioritize lightweight materials for performance vehicles, Alcantara’s reputation as a premium alternative to traditional upholstery options like leather and vinyl is gaining traction. In regions such as Europe and the Middle East, there is a growing demand for high-end customizations, particularly in luxury and performance cars. This trend is mirrored in emerging markets in Africa and South America, where the appetite for premium automotive interiors is on the rise, driven by a burgeoning middle class and increased vehicle ownership.

Technologically, advancements in manufacturing processes are enabling more efficient and sustainable production of Alcantara. Digital tools such as AI and machine learning are enhancing supply chain management, allowing manufacturers to better predict demand and optimize inventory levels. Furthermore, the integration of IoT technologies in automotive design is fostering innovative applications of Alcantara, from smart seating solutions to enhanced user experiences. B2B buyers should be aware of these trends as they navigate sourcing decisions, ensuring they partner with suppliers who are at the forefront of these technological advancements.

How Is Sustainability Shaping the Alcantara Car Seats Market?

Sustainability is increasingly becoming a non-negotiable aspect of sourcing in the automotive industry. Alcantara is at the forefront of this movement, emphasizing its commitment to ethical sourcing and environmental stewardship. The material itself is a blend of polyester and polyurethane, produced with a focus on minimizing environmental impact. B2B buyers should seek suppliers who can demonstrate transparency in their supply chains and adherence to environmental regulations.

Illustrative image related to alcantara car seats

Moreover, certifications such as ISO 14001 for environmental management and Oeko-Tex for textile safety are becoming important indicators of a supplier’s commitment to sustainable practices. By sourcing Alcantara car seats that are certified ‘green,’ buyers can align their purchasing decisions with corporate sustainability goals, appealing to an increasingly eco-conscious consumer base. This not only enhances brand reputation but also helps in meeting regulatory requirements across different regions.

What Is the Historical Context Behind Alcantara in Automotive Interiors?

The integration of Alcantara into automotive interiors dates back to 1978, marking the beginning of its journey as a material of choice for luxury and performance vehicles. Initially adopted by high-end brands, Alcantara’s unique combination of durability, aesthetic appeal, and lightweight properties quickly established it as a favored option among automotive designers. Over the decades, it has adorned the interiors of iconic vehicles from brands such as Lamborghini, Maserati, and BMW, reinforcing its status as a premium material.

As the automotive industry evolves, so too does the application of Alcantara, which is now not only used for seats but also for dashboards, steering wheels, and door panels. This evolution reflects changing consumer preferences towards customization and luxury, as well as the increasing importance of sustainability in material selection. Understanding this historical context can provide B2B buyers with valuable insights into the evolving expectations of consumers and the strategic advantages of incorporating Alcantara into their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara car seats

-

How do I solve the issue of Alcantara seat maintenance in high-use environments?

Maintaining Alcantara seats in high-use environments, such as taxis or rental vehicles, requires a structured cleaning regimen. Regular vacuuming is essential to remove dirt and debris. For deeper cleaning, use a microfiber cloth and a gentle upholstery cleaner specifically designed for Alcantara to avoid damage. Implementing a routine schedule for cleaning can help mitigate staining from oils and dirt. Additionally, consider training staff on proper care techniques to prolong the material’s lifespan and maintain its aesthetic appeal. -

What is the best method for sourcing high-quality Alcantara car seats?

To source high-quality Alcantara car seats, begin by identifying reputable manufacturers known for their craftsmanship and material quality. Request samples to assess the texture, durability, and color options. Attend industry trade shows and exhibitions to meet suppliers face-to-face, which can help build trust and facilitate negotiations. Additionally, consider suppliers with positive reviews and strong certifications in sustainability and quality assurance, as these factors can enhance your brand’s reputation in the market. -

What customization options are available for Alcantara car seats?

Customization options for Alcantara car seats can include variations in color, texture, stitching patterns, and even the integration of logos or branding elements. Many manufacturers offer bespoke solutions to meet specific design requirements, enabling you to align the seats with your brand identity or vehicle aesthetics. Discuss your customization needs with potential suppliers early in the negotiation process to understand their capabilities and any associated costs. This approach ensures that your final product meets both functional and visual standards. -

What are the minimum order quantities (MOQ) for Alcantara car seats?

Minimum order quantities for Alcantara car seats can vary significantly depending on the manufacturer and the complexity of the customization required. Typically, MOQs may range from 50 to 500 units. It’s essential to discuss your projected volumes with suppliers to negotiate favorable terms. Additionally, consider the potential for future orders, as establishing a long-term partnership may provide leverage to lower MOQs, thereby enhancing your purchasing flexibility. -

What payment terms should I expect when ordering Alcantara car seats?

Payment terms for ordering Alcantara car seats generally depend on the supplier’s policies and your negotiation leverage. Common arrangements include a deposit upfront (usually 30-50%) with the balance due upon delivery or after a specified period. Some suppliers may offer credit terms based on your business relationship and order history. Always clarify payment terms in advance and ensure they are documented in the contract to avoid misunderstandings later on. -

How can I ensure quality assurance for Alcantara car seats?

To ensure quality assurance for Alcantara car seats, engage suppliers who have robust quality control processes in place. Request information on their testing procedures for durability, colorfastness, and overall material quality. Additionally, consider conducting regular inspections during production and upon delivery to verify compliance with your specifications. Establishing a clear quality agreement in your contract can also provide recourse if the delivered products do not meet your standards. -

What logistics considerations should I keep in mind for importing Alcantara car seats?

When importing Alcantara car seats, consider shipping methods, customs regulations, and potential tariffs that could affect your total costs. Work with logistics partners experienced in international shipping to navigate these complexities. Ensure that all necessary documentation, such as invoices and certificates of origin, is in order to facilitate smooth customs clearance. Additionally, assess the shipping times and plan your inventory accordingly to avoid stockouts and maintain customer satisfaction. -

How can I assess the reputation of an Alcantara car seat supplier?

Assessing the reputation of an Alcantara car seat supplier involves researching their history, customer reviews, and industry standing. Look for testimonials from other B2B buyers and check for any industry certifications or awards that signify quality. Engaging in discussions with existing clients can provide insights into their experiences. Additionally, consider the supplier’s responsiveness and willingness to address your inquiries, as these factors can indicate their commitment to customer service and reliability.

Top 5 Alcantara Car Seats Manufacturers & Suppliers List

1. Alcantara – Automotive Interiors

Domain: alcantara.com

Registered: 1996 (29 years)

Introduction: Alcantara is a 100% Italian brand known for its versatility and excellence in automotive applications. It has been a key player in the automotive industry since 1978, providing custom-made interiors for vehicles. Key features of Alcantara include durability, breathability, washability, and improved grip, making it ideal for car interiors. The brand has partnered with luxury automotive manufacturer…

2. Alcantara – Automotive Textile

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Alcantara is a synthetic textile that has gained popularity in the automotive industry, particularly in high-performance vehicles. It is often preferred over leather for certain applications due to its aesthetic appeal and versatility. However, opinions on its luxury status vary, with some users finding it less durable and less appealing for high-touch areas like steering wheels. Alcantara is comm…

3. Carwow – Alcantara Upholstery

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic textile made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is often used in car interiors for upholstery on seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic, flame retardant properties, …

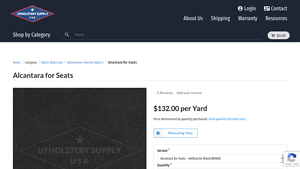

4. Upholstery Supply USA – Alcantara for Seats

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“name”: “Alcantara for Seats”,”color_options”: [“Anthracite Black (#9002)”, “Orion Grey (#2934)”],”price_per_yard”: {“1_to_9”: 132.00, “10_to_24”: 121.00, “25_plus”: 115.00},”material”: “Genuine Alcantara Textile, Made in Italy”,”description”: “Premium suede-like textile fabric, superior in craftsmanship for automotive applications. OEM for luxury vehicle interiors including Audi, Jaguar, Tesla, …

5. Mercedes-Benz GLA – AMG Line Alcantara vs. MB-Tex Seats

Domain: forum.leasehackr.com

Registered: 2015 (10 years)

Introduction: The discussion revolves around two Mercedes-Benz GLA models at a dealership: one equipped with AMG line alcantara seats and the other with base synthetic leather seats (MB-Tex). Key points include:

– AMG line alcantara seats are debated for their practicality, including concerns about staining and ease of cleaning.

– Base seats are synthetic leather (MB-Tex), which users report are durable and e…

Strategic Sourcing Conclusion and Outlook for alcantara car seats

Alcantara car seats represent a unique blend of luxury, functionality, and sustainability, making them an attractive choice for automotive manufacturers and B2B buyers alike. As a 100% Italian brand, Alcantara offers unparalleled customization options that cater to diverse market needs, from high-end luxury vehicles to more accessible models. This versatility, combined with the material’s durability and lightweight properties, positions Alcantara as a leading solution in the automotive interior segment.

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, strategic sourcing of Alcantara products can enhance brand value and consumer satisfaction. As the automotive industry increasingly prioritizes sustainable practices, partnering with Alcantara not only aligns with environmental goals but also elevates the perceived quality of vehicle interiors.

Looking ahead, the demand for innovative materials such as Alcantara is set to grow. Now is the opportune time for businesses to explore strategic partnerships that leverage this premium material. By investing in Alcantara car seats, you can differentiate your product offerings, meet evolving consumer expectations, and drive business growth in a competitive marketplace. Embrace the future of automotive design—consider Alcantara as your next strategic sourcing choice.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to alcantara car seats