Introduction: Navigating the Global Market for white leather fabric

Navigating the complexities of sourcing white leather fabric can be a daunting task for international B2B buyers, especially when aiming to meet diverse market demands across continents such as Africa, South America, the Middle East, and Europe. The challenge often lies in identifying reliable suppliers who offer high-quality materials that cater to specific applications, whether for fashion, upholstery, or accessories. This guide serves as a comprehensive resource, addressing the various types of white leather fabric available, their numerous applications, and essential factors for vetting suppliers.

Within these pages, you will discover insights into the durability, aesthetic appeal, and versatility of white leather fabric, allowing you to make informed purchasing decisions. We delve into the intricacies of pricing structures, helping you navigate the cost implications associated with bulk orders and the benefits of establishing long-term supplier relationships. Additionally, we provide actionable tips on quality assessment and trends that are shaping the global market.

By empowering B2B buyers with this knowledge, we aim to streamline your sourcing process and enhance your competitive edge in the marketplace. Whether you’re based in Brazil, Nigeria, or elsewhere, this guide is designed to equip you with the tools necessary to confidently navigate the global market for white leather fabric, ensuring that you meet your business objectives effectively.

Table Of Contents

- Top 7 White Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for white leather fabric

- Understanding white leather fabric Types and Variations

- Key Industrial Applications of white leather fabric

- 3 Common User Pain Points for ‘white leather fabric’ & Their Solutions

- Strategic Material Selection Guide for white leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for white leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘white leather fabric’

- Comprehensive Cost and Pricing Analysis for white leather fabric Sourcing

- Alternatives Analysis: Comparing white leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for white leather fabric

- Navigating Market Dynamics and Sourcing Trends in the white leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of white leather fabric

- Strategic Sourcing Conclusion and Outlook for white leather fabric

- Important Disclaimer & Terms of Use

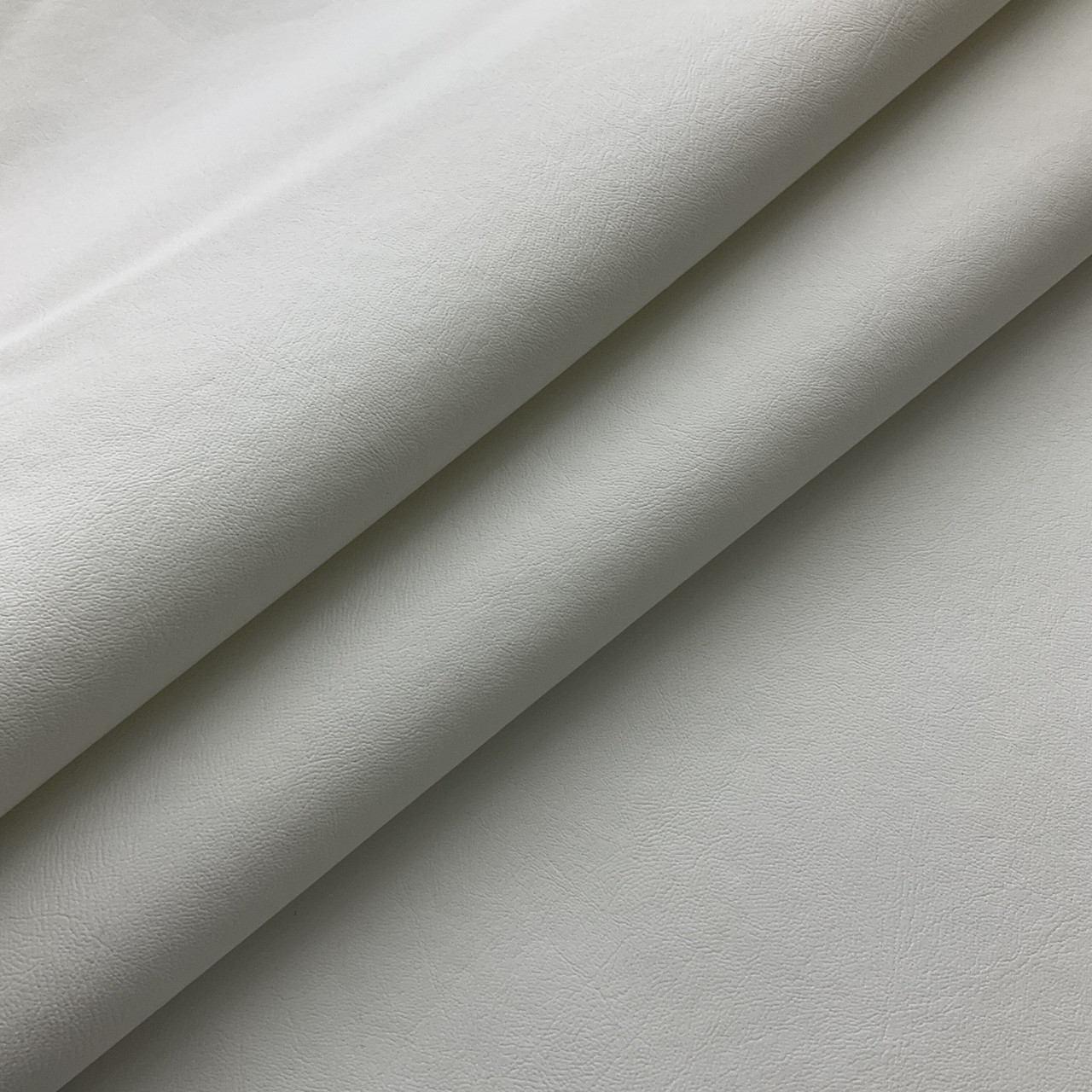

Understanding white leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather | Retains the natural grain and imperfections; highly durable and breathable. | High-end furniture, luxury apparel, accessories. | Pros: Exceptional quality and durability. Cons: Higher cost; may require special care. |

| Top-Grain Leather | Sanded and refinished surface; softer than full-grain. | Upholstery, fashion items, automotive interiors. | Pros: Good balance of quality and price. Cons: Less durable than full-grain. |

| جلد صناعي | Made from man-made materials; often more affordable. | Fashion items, upholstery, budget-friendly applications. | Pros: Cost-effective and versatile. Cons: Less breathable and can wear out faster. |

| Suede Leather | Soft texture with a napped finish; can be dyed easily. | Apparel, accessories, and decorative items. | Pros: Luxurious feel and aesthetic appeal. Cons: Less durable; can stain easily. |

| جلد صناعي | Eco-friendly alternative; mimics the look of real leather. | Fashion, upholstery, and budget-conscious markets. | Pros: Vegan-friendly and often easier to clean. Cons: May lack the longevity of genuine leather. |

What Are the Key Characteristics of Full-Grain Leather?

Full-grain leather is the highest quality leather available, showcasing the natural grain and imperfections of the hide. This type is highly valued for its durability and breathability, making it suitable for high-end applications such as luxury furniture and premium apparel. When considering full-grain leather, B2B buyers should note its higher price point, which reflects its quality and longevity. Proper maintenance is essential to preserve its appearance, making it a long-term investment.

Illustrative image related to white leather fabric

How Does Top-Grain Leather Compare to Full-Grain Leather?

Top-grain leather is sanded and refinished to remove imperfections, resulting in a softer texture than full-grain leather. It strikes a balance between quality and affordability, making it popular for upholstery, fashion items, and automotive interiors. Buyers should consider that while top-grain leather offers a more accessible price point, it may not be as durable as full-grain, necessitating careful use in high-traffic areas.

Why Consider Synthetic Leather for B2B Applications?

Synthetic leather, crafted from man-made materials, is often more affordable and versatile than genuine leather. It is widely used in fashion items and budget-friendly upholstery applications. B2B buyers should weigh the cost benefits against potential downsides, such as lower breathability and durability compared to real leather. However, it can be a practical choice for businesses looking to offer stylish products at a lower price.

What Makes Suede Leather Unique for Buyers?

Suede leather features a soft texture with a napped finish, which can easily be dyed to various colors, enhancing its aesthetic appeal. This type is commonly used in apparel and accessories, providing a luxurious feel. However, B2B buyers should be cautious of its durability; suede can stain easily and may require special care. Its unique texture can elevate product offerings, but the maintenance considerations are crucial for long-term use.

Is Faux Leather a Viable Option for Sustainable B2B Solutions?

Faux leather presents an eco-friendly alternative to traditional leather, mimicking its look while being vegan-friendly. This material is increasingly popular in fashion and upholstery, appealing to budget-conscious markets. Buyers should recognize that while faux leather is easier to clean and maintain, it may not offer the same longevity as genuine leather. It is an excellent option for businesses aiming to attract environmentally aware consumers without compromising on style.

Key Industrial Applications of white leather fabric

| Industry/Sector | Specific Application of White Leather Fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | High-end clothing, jackets, and footwear | Elevates brand image through luxury appeal | Ensure color consistency, durability, and ethical sourcing practices. |

| Automotive | Upholstery for luxury vehicles | Enhances aesthetic and comfort for premium market segment | Verify resistance to wear and tear, as well as ease of cleaning. |

| Furniture & Interior Design | Upholstery for sofas and chairs | Provides a sophisticated look while ensuring durability | Assess fire-retardant properties and colorfastness for longevity. |

| Accessories & Handbags | Luxury bags and cases | Creates standout products that attract high-end consumers | Focus on weight, texture, and compatibility with other materials. |

| Marine Industry | Boat interiors and seating | Combines style with water resistance and durability | Check for UV protection and waterproof treatments for longevity. |

How is White Leather Fabric Used in Fashion & Apparel?

In the fashion industry, white leather fabric is utilized to create high-end clothing, jackets, and footwear. Its luxurious appearance enhances the brand image, making products more appealing to consumers seeking premium items. For B2B buyers, it’s crucial to source leather that maintains color consistency and durability, especially when catering to diverse markets in Africa, South America, the Middle East, and Europe. Ethical sourcing practices are also increasingly important, aligning with consumer preferences for responsible production.

What Role Does White Leather Fabric Play in the Automotive Sector?

In the automotive sector, white leather fabric is often used for upholstery in luxury vehicles. This application not only enhances the aesthetic appeal of the vehicle but also contributes to passenger comfort. B2B buyers should prioritize sourcing leather that is resistant to wear and tear, ensuring that the product can withstand the rigors of daily use. Additionally, ease of cleaning is a significant consideration, particularly in regions with varying climates, such as Nigeria and Brazil, where vehicles may be exposed to harsh conditions.

How is White Leather Fabric Applied in Furniture & Interior Design?

White leather fabric is a popular choice for upholstery in sofas and chairs within the furniture and interior design sector. Its sophisticated look offers a timeless appeal while ensuring durability. For international buyers, it’s vital to assess the fire-retardant properties and colorfastness of the leather to ensure compliance with safety standards and to maintain the product’s longevity. This is particularly important in markets like Europe, where regulations on materials used in furniture can be stringent.

What Are the Benefits of Using White Leather Fabric for Accessories & Handbags?

In the accessories and handbags industry, white leather fabric is favored for creating luxury bags and cases. Its standout appearance attracts high-end consumers, making it a profitable choice for businesses. Buyers should focus on the weight and texture of the leather, ensuring it complements other materials used in the product. Additionally, compatibility with various manufacturing processes is crucial, especially for businesses in regions like the Middle East, where craftsmanship is highly valued.

Why is White Leather Fabric Important in the Marine Industry?

In the marine industry, white leather fabric is used for boat interiors and seating, combining style with necessary durability and water resistance. This application is essential for creating an inviting atmosphere on boats while ensuring that the materials can withstand exposure to elements. B2B buyers should verify that the leather has UV protection and waterproof treatments to ensure longevity, especially in regions where boats are frequently used, such as coastal areas in South America and Africa.

Illustrative image related to white leather fabric

3 Common User Pain Points for ‘white leather fabric’ & Their Solutions

Scenario 1: Ensuring Durability in Diverse Climates

The Problem: B2B buyers often face the challenge of sourcing white leather fabric that can withstand varying environmental conditions, particularly in regions with high humidity or extreme temperatures. For instance, a buyer in Brazil may worry that the leather will degrade or discolor when exposed to high moisture levels. Similarly, those in arid regions may find that their leather dries out and cracks, leading to product failures and increased costs.

The Solution: To mitigate these risks, it’s crucial to choose white leather fabric that has been treated for enhanced durability. Buyers should seek out suppliers that offer waterproof or moisture-resistant options. Additionally, requesting samples to test in local climate conditions can provide invaluable insights. When specifying orders, explicitly indicate the intended use and environmental conditions. This helps manufacturers suggest appropriate treatments or finishes that enhance the leather’s performance, ensuring longevity and maintaining its aesthetic appeal.

Scenario 2: Addressing Stains and Maintenance Challenges

The Problem: White leather fabric is notoriously susceptible to staining, which can deter buyers from investing in it for high-traffic applications like upholstery or fashion accessories. A buyer in Nigeria may find that dirt, oils, and other substances easily mar the surface, leading to costly cleaning and maintenance efforts.

The Solution: To combat staining issues, buyers should prioritize sourcing white leather with a protective coating designed to resist spills and stains. Additionally, establishing a clear care and maintenance protocol can greatly enhance the fabric’s lifespan. Suppliers can provide guidelines on appropriate cleaning agents and methods for upkeep. Consider also investing in protective sprays or treatments that create an additional barrier against stains. Regular maintenance schedules, including cleaning and conditioning, can help preserve the leather’s appearance and functionality, minimizing the long-term impact of stains.

Scenario 3: Sourcing Sustainable and Ethical Options

The Problem: An increasing number of B2B buyers are concerned about the ethical implications of sourcing leather, particularly in regions like Europe where sustainability is a significant purchasing factor. Buyers may struggle to find white leather fabric that meets ethical standards and is sourced responsibly, impacting their brand image and compliance with local regulations.

The Solution: To address these concerns, buyers should engage suppliers who are transparent about their sourcing practices and can provide certifications for sustainability. Look for options such as leather sourced from tanneries that adhere to environmental regulations and animal welfare standards. Additionally, consider alternative materials that mimic the look and feel of leather while being more sustainable, such as vegan leather made from recycled materials. Engaging in discussions with suppliers about their production methods can help ensure that the materials align with your company’s values, enhancing brand integrity and appealing to eco-conscious consumers.

Strategic Material Selection Guide for white leather fabric

What Are the Key Properties of Natural Leather for White Leather Fabric?

Natural leather, derived from animal hides, is renowned for its strength, durability, and aesthetic appeal. Key properties include excellent tensile strength, which allows it to withstand significant pressure and wear. It also has a natural breathability that helps regulate temperature, making it comfortable for wearables. However, natural leather can be sensitive to moisture and may require additional treatments to enhance its water resistance.

Pros and Cons: The primary advantage of natural leather is its durability and luxurious appearance, making it suitable for high-end fashion and upholstery. However, it tends to be more expensive than synthetic alternatives and may involve complex manufacturing processes, including tanning and finishing. Additionally, ethical considerations regarding animal sourcing may pose challenges in certain markets.

Impact on Application: Natural leather is often preferred for premium products, such as luxury handbags and high-quality furniture. Buyers in regions like Europe may prioritize ethically sourced materials, while those in Africa and South America might focus on cost-effectiveness and local availability.

How Does Synthetic Leather Compare for White Leather Fabric?

Synthetic leather, commonly made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to natural leather. It is generally more resistant to moisture and stains, making it easier to clean and maintain. Synthetic leather also provides a consistent appearance and texture, which can be advantageous for mass production.

Pros and Cons: The key advantage of synthetic leather is its affordability and versatility, allowing for a wide range of applications from fashion to automotive upholstery. However, it may lack the breathability and durability of natural leather, leading to a shorter lifespan in high-use environments. Additionally, concerns about environmental impact and recyclability are increasingly relevant in global markets.

Impact on Application: Synthetic leather is commonly used in fashion items and furniture where cost is a primary concern. Buyers in the Middle East may favor synthetic options for their resilience against heat and humidity, while European buyers may scrutinize the environmental credentials of synthetic materials.

What Are the Benefits of Faux Leather for White Leather Fabric?

Faux leather, similar to synthetic leather, is designed to mimic the appearance of real leather while being made from a variety of synthetic materials. It is often more affordable and can be produced in a wide range of colors and textures.

Pros and Cons: Faux leather is lightweight and easy to clean, making it suitable for various applications, including clothing and accessories. However, it may not offer the same level of durability or luxury feel as natural leather. Additionally, the manufacturing process can involve harmful chemicals, raising concerns among environmentally conscious buyers.

Impact on Application: Faux leather is popular in fast fashion and budget-friendly home decor. In regions like Brazil, where fashion trends can change rapidly, faux leather provides a cost-effective solution for trendy items. However, buyers should consider the long-term implications of using faux leather in terms of durability and environmental impact.

What Should International Buyers Consider When Selecting White Leather Fabric?

When selecting white leather fabric, international buyers must consider compliance with local regulations and standards, such as ASTM, DIN, or JIS. In Africa and South America, buyers might prioritize cost and availability, while those in Europe may focus on sustainability and ethical sourcing. Additionally, understanding local market preferences can help in selecting the most suitable materials for specific applications.

Illustrative image related to white leather fabric

| المواد | Typical Use Case for white leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Leather | Luxury handbags, high-end upholstery | Exceptional durability and aesthetics | Higher cost and ethical sourcing issues | عالية |

| جلد صناعي | Fashion apparel, automotive interiors | Cost-effective and moisture-resistant | Less durable and potential environmental concerns | Medium |

| جلد صناعي | Trendy clothing, budget home decor | Lightweight and easy to clean | Lacks durability and may involve harmful chemicals | منخفضة |

In-depth Look: Manufacturing Processes and Quality Assurance for white leather fabric

What Are the Main Stages in the Manufacturing Process of White Leather Fabric?

The manufacturing of white leather fabric involves several critical stages, each contributing to the final product’s quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality raw materials, which can be either animal hides or synthetic alternatives. For animal hides, the tanning process is essential to preserve the leather and enhance its durability. This can involve vegetable tanning, chrome tanning, or synthetic tanning methods. Each method affects the leather’s texture, flexibility, and environmental impact. Synthetic materials, on the other hand, are produced using polymers and undergo processes like extrusion and coating to achieve the desired properties.

-

Forming: Once the materials are prepared, they are cut into desired shapes based on specific patterns. Advanced techniques such as laser cutting and die cutting are often employed for precision. This stage may also involve embossing or printing patterns onto the leather, adding aesthetic value and uniqueness to the fabric.

-

Assembly: After forming, the pieces are assembled. This stage typically involves stitching or bonding the leather components together. High-quality threads and adhesives are selected to ensure durability and strength. Assembly techniques may vary based on the intended use of the leather, whether for apparel, upholstery, or accessories.

-

Finishing: The final stage of manufacturing is finishing, which enhances the leather’s appearance and functionality. This may include applying protective coatings for water resistance, UV protection, or anti-stain treatments. The finishing process also involves polishing and coloring to achieve the desired shade of white, ensuring consistency across batches.

How Is Quality Assurance Implemented in White Leather Fabric Manufacturing?

Quality assurance (QA) in the manufacturing of white leather fabric is crucial for ensuring that the final products meet international standards and customer expectations. Various quality control measures are implemented throughout the production process.

-

International Standards for Quality Control: Many manufacturers adhere to international standards such as ISO 9001, which provides a framework for effective quality management systems. Compliance with these standards ensures that processes are efficient and meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for specific applications may be relevant.

-

Quality Control Checkpoints: Quality control is typically segmented into several checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This includes checking for defects in hides or inconsistencies in synthetic materials.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to identify any deviations from quality standards. This can involve monitoring stitching quality, color consistency, and adherence to design specifications.

– Final Quality Control (FQC): Once the products are completed, a final inspection is conducted to ensure that they meet all quality and performance criteria before being shipped to buyers. -

Common Testing Methods for Leather Quality: Various testing methods are employed to assess the quality of white leather fabric. These may include:

– Physical Tests: Assessing properties such as tensile strength, tear resistance, and abrasion resistance.

– Chemical Tests: Ensuring that the leather is free from harmful substances and adheres to environmental regulations.

– Aesthetic Evaluations: Checking for color uniformity, surface defects, and overall appearance.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, it is vital to have confidence in the quality assurance practices of suppliers. Here are actionable steps to verify supplier quality control:

-

Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request to see their quality management systems and the results of any internal or external audits.

-

Reviewing Quality Reports: Suppliers should be able to provide comprehensive quality reports that detail their testing results, compliance with international standards, and any corrective actions taken for non-conformance. Buyers should review these documents carefully.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of production, offering assurance that the products meet specified standards.

-

Understanding Quality Control Nuances: Buyers should be aware of the specific quality control nuances that may exist in different regions. For example, regulations in Europe may be more stringent compared to those in other regions. Understanding these nuances can help buyers make informed decisions and mitigate risks associated with non-compliance.

How Do Regional Differences Impact Quality Assurance Practices?

Regional differences can significantly influence the quality assurance practices adopted by manufacturers of white leather fabric. Buyers from Africa, South America, the Middle East, and Europe should consider the following factors:

-

Regulatory Compliance: Different countries have varying regulations regarding environmental impact, chemical usage, and labor practices. Buyers should ensure that their suppliers comply with local and international regulations to avoid legal complications and ensure product safety.

-

Cultural Expectations: Quality perceptions can differ based on cultural expectations. For instance, buyers in Europe may prioritize eco-friendliness and ethical sourcing more than buyers from other regions. Understanding these expectations can help manufacturers tailor their quality assurance practices accordingly.

-

Market Demand: The demand for specific qualities in leather products can vary by region. For example, while some markets may prioritize durability, others may focus on aesthetics. Manufacturers should adapt their quality assurance processes to align with these regional demands.

In summary, the manufacturing and quality assurance processes for white leather fabric are multifaceted and require careful consideration by B2B buyers. By understanding the stages of production, quality control measures, and regional nuances, buyers can make informed decisions and build strong partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘white leather fabric’

This guide provides a comprehensive checklist for B2B buyers looking to source white leather fabric effectively. By following these steps, you can ensure a successful procurement process that meets your quality and business needs.

Step 1: Define Your Technical Specifications

Clearly outline your requirements for the white leather fabric. Consider factors such as thickness, texture, and intended use, whether for apparel, upholstery, or accessories. Specific specifications help you avoid misunderstandings and ensure that suppliers provide exactly what you need.

- السُمك: Determine the gauge of the leather suitable for your application.

- Texture: Decide if you prefer a smooth finish or a more textured surface.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Use industry directories, trade shows, and online platforms to compile a list of potential vendors. This step is essential for discovering suppliers who specialize in white leather fabric and can meet your specific needs.

- Verify Experience: Look for suppliers with a strong track record in your industry.

- Check Reviews: Read testimonials and reviews from previous clients to gauge reliability.

Step 3: Evaluate Potential Suppliers

Vetting suppliers is crucial before making a commitment. Request company profiles, production capabilities, and references from buyers in similar markets. This process helps ensure that the supplier can deliver high-quality products consistently.

- Quality Assurance: Inquire about their quality control processes.

- Certifications: Check for relevant industry certifications that demonstrate compliance with standards.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality, color consistency, and overall feel of the fabric. Analyzing samples can prevent costly mistakes in your final purchase.

- Test Durability: Evaluate the fabric’s strength and resistance to wear.

- Inspect Color: Ensure the white color meets your expectations in various lighting conditions.

Step 5: Negotiate Terms and Pricing

Engage in negotiations to establish favorable terms. Discuss pricing, payment terms, and delivery timelines to ensure they align with your budget and schedule. Effective negotiation can lead to better pricing and flexibility in your order.

- Bulk Discounts: Inquire about discounts for larger orders.

- Delivery Terms: Clarify shipping options and costs to avoid unexpected fees.

Step 6: Confirm Compliance with Regulations

Ensure that the white leather fabric complies with relevant regulations. Depending on your market, there may be specific standards for materials used in textiles. Compliance is essential to avoid legal issues and ensure product safety.

- Environmental Standards: Verify that the supplier adheres to environmental regulations regarding leather production.

- Safety Standards: Ensure the fabric meets safety requirements for its intended application.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your supplier. Effective communication ensures that you can address any issues or changes promptly throughout the procurement process. Establishing points of contact and regular updates can facilitate smoother transactions.

- Regular Updates: Schedule check-ins to monitor progress on your order.

- Issue Resolution: Agree on a protocol for addressing any potential issues during production or delivery.

By following these steps, you can streamline the sourcing process for white leather fabric and secure a reliable supply for your business needs.

Comprehensive Cost and Pricing Analysis for white leather fabric Sourcing

What Are the Key Cost Components of Sourcing White Leather Fabric?

When evaluating the total cost of sourcing white leather fabric, several key components must be considered. The primary cost factors include:

-

Materials: The type of leather—whether genuine or synthetic—significantly influences the cost. Genuine leather tends to be more expensive due to sourcing challenges and the quality of the material, while synthetic options may offer lower price points but can vary widely in quality.

-

Labor: Labor costs can vary depending on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can sometimes impact the quality of craftsmanship.

-

Manufacturing Overhead: This includes utilities, equipment depreciation, and facility maintenance. Efficient manufacturing processes can help mitigate these costs, making the final product more competitively priced.

-

Tooling: Custom tooling may be necessary for specific designs, which can add to initial costs. However, once the tooling is established, it can be amortized over larger production runs.

-

Quality Control (QC): Implementing rigorous QC processes ensures the final product meets the required standards. While this may incur additional costs, it is essential for maintaining a reputable brand and avoiding costly returns.

-

Logistics: Shipping costs can vary significantly based on the origin of the leather and the destination market. International shipping may involve tariffs and duties, which should be factored into the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the standard markup for the industry can help buyers negotiate more effectively.

How Do Price Influencers Affect the Cost of White Leather Fabric?

Several factors influence the pricing of white leather fabric:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can greatly affect pricing. Larger orders generally lead to lower per-unit costs, but buyers must balance this with their inventory capabilities.

-

Specifications and Customization: Custom specifications, such as specific colors, finishes, or treatments (e.g., waterproofing), can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., eco-friendly or cruelty-free) often come at a premium. Buyers should evaluate whether these certifications align with their brand values.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more but often provide better quality assurance and customer service.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can influence the overall cost. Understanding these terms helps buyers assess their responsibilities for shipping and insurance.

What Negotiation Strategies Can B2B Buyers Use for Cost-Efficient Sourcing?

B2B buyers should adopt a strategic approach to negotiation to enhance cost efficiency:

-

Research Market Prices: Understanding the market rates for white leather fabric will empower buyers during negotiations. This knowledge can help identify suppliers offering competitive prices.

-

Build Long-Term Relationships: Establishing strong relationships with suppliers can lead to better pricing and favorable terms. Loyalty often results in priority treatment during production and shipping.

-

Leverage Volume Discounts: Consolidating orders can lead to volume discounts. Buyers should negotiate for better rates based on their purchasing potential.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes maintenance, logistics, and potential waste. This broader perspective can lead to more informed purchasing decisions.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of local market conditions and import regulations, which can affect pricing.

What Should International B2B Buyers Consider About Pricing Nuances?

International buyers need to navigate a complex landscape of pricing and procurement. Currency fluctuations can affect costs, and understanding local tariffs and import duties is crucial. Furthermore, cultural differences in negotiation styles can impact discussions, so it’s beneficial to approach negotiations with cultural sensitivity.

Disclaimer

Prices for white leather fabric can vary widely based on the factors mentioned above. This analysis serves as a guideline, and actual costs may differ based on specific supplier agreements and market conditions. Buyers are encouraged to conduct thorough market research and engage directly with suppliers to obtain accurate pricing.

Alternatives Analysis: Comparing white leather fabric With Other Solutions

When considering the use of white leather fabric for various applications, it’s essential to evaluate alternatives that can meet similar needs while offering distinct advantages and disadvantages. This comparison provides insights into the performance, cost, ease of implementation, maintenance, and ideal use cases for white leather fabric and its alternatives.

| Comparison Aspect | White Leather Fabric | جلد صناعي | Canvas |

|---|---|---|---|

| Performance | Durable, water-resistant when treated | Moderate durability, often less water-resistant | High durability, but less formal appearance |

| Cost | Higher initial investment | Generally lower cost | Low to moderate cost |

| Ease of Implementation | Requires specialized sewing techniques | Easy to work with, similar to fabric | Easy to cut and sew, widely available |

| Maintenance | Requires regular cleaning and conditioning | Easy to clean, less frequent maintenance | Machine washable, but may fade over time |

| Best Use Case | High-end fashion, luxury upholstery | Affordable fashion, casual upholstery | Outdoor furniture, durable bags |

What are the Pros and Cons of Using Faux Leather Instead of White Leather Fabric?

Faux leather, also known as synthetic leather or vegan leather, provides a cost-effective alternative to white leather fabric. It mimics the look of real leather while being more affordable and easier to maintain. However, faux leather may not offer the same level of durability and luxury feel as genuine leather. It is suitable for fashion items, casual upholstery, and products where budget constraints are significant. Its ease of cleaning makes it a popular choice for everyday items, but it may not withstand heavy wear as effectively as real leather.

How Does Canvas Compare to White Leather Fabric in Durability and Use Cases?

Canvas is a versatile fabric known for its durability and strength, making it an excellent choice for outdoor applications and rugged use cases. While it is cost-effective and easy to work with, canvas does not provide the same aesthetic appeal as white leather fabric. It is often used for bags, tents, and outdoor furniture due to its ability to withstand the elements. However, its more casual appearance may not be suitable for luxury items or high-end fashion.

Conclusion: How Should B2B Buyers Choose the Right Fabric for Their Needs?

When selecting between white leather fabric and its alternatives, B2B buyers should assess their specific requirements, including the intended use, budget constraints, and desired aesthetic. For high-end applications requiring durability and luxury, white leather fabric remains an excellent choice. However, for cost-sensitive projects or casual applications, faux leather or canvas may provide viable solutions. By carefully evaluating these factors, buyers can make informed decisions that align with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for white leather fabric

What Are the Key Technical Properties of White Leather Fabric?

When considering white leather fabric for your business needs, understanding its technical properties is essential. Here are some critical specifications to keep in mind:

-

Material Grade

The material grade indicates the quality of the leather. Grades typically range from full-grain, which is the highest quality and most durable, to corrected grain, which is more affordable but less durable. For B2B buyers, selecting the appropriate material grade is crucial, as it directly affects product lifespan, aesthetic appeal, and pricing. -

Thickness

Thickness is measured in millimeters or ounces and can vary significantly across different types of leather. A standard thickness for upholstery leather might range from 1.0 mm to 2.0 mm. For manufacturers, understanding thickness is vital for ensuring the leather is suitable for its intended use, whether for clothing or furniture. -

Tensile Strength

This property refers to the maximum amount of tensile (pulling) stress that the leather can withstand before breaking. A higher tensile strength indicates better durability and performance, making it essential for items subject to wear and tear, such as bags and shoes. B2B buyers should prioritize tensile strength to ensure the longevity of their products. -

Water Resistance

Many white leather fabrics undergo treatments to enhance their water resistance. This property is particularly important for applications in outdoor or high-moisture environments. For buyers, opting for water-resistant leather can mean fewer returns and a better customer satisfaction rate. -

Finish Type

The finish applied to white leather can influence its texture and appearance. Common finishes include aniline (natural look) and semi-aniline (more protective). Understanding finish types helps buyers choose the right product for specific applications, affecting both aesthetics and functionality. -

Color Fastness

This property indicates how well the dye adheres to the leather and resists fading over time. High color fastness is crucial for maintaining the aesthetic appeal of white leather products, especially in sunlight-exposed environments. Buyers should verify color fastness ratings to ensure they meet their quality standards.

What Are Common Trade Terms Used in the White Leather Fabric Industry?

Familiarity with industry jargon can streamline negotiations and transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, this could mean a business sourcing white leather for branded products. Understanding OEM relationships can help buyers leverage better pricing and quality control. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. This term is essential for B2B buyers as it affects inventory management and cash flow. Negotiating MOQs can also lead to more favorable pricing structures. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to potential suppliers asking for price estimates for specific products. This term is crucial for B2B transactions, as it sets the stage for negotiations and helps buyers compare costs across different suppliers. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law. Incoterms define the responsibilities of buyers and sellers in shipping arrangements. Understanding these terms can help buyers mitigate risks associated with international shipping. -

Lead Time

Lead time refers to the time taken between placing an order and receiving the product. This term is critical for inventory planning and can affect production schedules. B2B buyers should always clarify lead times to ensure timely delivery. -

Quality Assurance (QA)

QA involves systematic processes to ensure that products meet specified quality standards. For white leather fabric, implementing QA measures is essential to minimize defects and ensure customer satisfaction. Buyers should inquire about a supplier’s QA processes before committing to orders.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing white leather fabric, ensuring quality and satisfaction in their product offerings.

Navigating Market Dynamics and Sourcing Trends in the white leather fabric Sector

What Are the Current Market Dynamics and Key Trends in the White Leather Fabric Sector?

The global market for white leather fabric is driven by several key factors, including a growing demand for luxury and durable materials in various applications, from fashion apparel to interior design. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly attracted to the aesthetic appeal and versatility of white leather. This trend is amplified by the rise of e-commerce platforms, making it easier for international buyers to source materials directly from manufacturers. Emerging technologies, such as digital printing and automated cutting, are also transforming how white leather is produced and distributed, allowing for more customization and efficiency.

Illustrative image related to white leather fabric

Additionally, sustainability has become a significant concern among B2B buyers. With consumers demanding eco-friendly products, suppliers of white leather fabric are adapting by offering sustainable options, including recycled and synthetic alternatives. The trend toward ethical sourcing is reshaping the supply chain dynamics, as buyers seek transparency and accountability from their suppliers. Companies that adopt innovative sourcing strategies, such as local procurement and direct trade relationships, can enhance their market competitiveness while meeting the increasing demand for ethically produced materials.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in White Leather Fabric?

The environmental impact of leather production is a critical consideration for B2B buyers in the white leather fabric sector. Traditional tanning processes often involve harmful chemicals that can damage ecosystems and pose health risks. Therefore, ethical sourcing practices are becoming essential for companies looking to enhance their brand reputation and comply with international regulations.

Buyers should prioritize suppliers that demonstrate a commitment to sustainability through certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG). These certifications ensure that the materials used meet stringent environmental and social criteria. Furthermore, opting for alternative materials, such as plant-based leathers or synthetics produced from recycled content, can significantly reduce the ecological footprint associated with traditional leather production.

Illustrative image related to white leather fabric

By fostering relationships with suppliers who prioritize ethical practices, B2B buyers can not only mitigate risks but also appeal to a growing segment of environmentally conscious consumers. This strategic alignment can lead to increased brand loyalty and market share in a competitive landscape.

What Is the Historical Context of White Leather Fabric in B2B Markets?

The use of leather dates back thousands of years, originally utilized for its durability and protective qualities. White leather, specifically, gained prominence in the 20th century as fashion and design trends began to emphasize lighter colors and luxurious materials. Initially sourced primarily from animal hides, advancements in technology have introduced synthetic alternatives that mimic the look and feel of genuine leather while offering enhanced durability and lower costs.

As consumer preferences evolved, so did the production methods, with a notable shift towards sustainability in recent decades. Today, white leather fabric is not only celebrated for its aesthetic appeal but also for its potential to align with modern values of environmental stewardship and ethical consumption. This evolution presents significant opportunities for B2B buyers to engage with suppliers who are at the forefront of these trends, ensuring they remain competitive in a rapidly changing market.

In conclusion, understanding the current market dynamics, prioritizing sustainability, and acknowledging the historical context of white leather fabric can empower B2B buyers to make informed sourcing decisions that align with both their business objectives and ethical standards.

Illustrative image related to white leather fabric

Frequently Asked Questions (FAQs) for B2B Buyers of white leather fabric

-

How do I choose the right white leather fabric for my project?

Choosing the right white leather fabric involves assessing the intended use, durability requirements, and aesthetic preferences. For apparel, opt for softer, more flexible leather that offers comfort, while upholstery projects may require thicker, more durable options. Consider whether you need genuine leather or synthetic alternatives, which can provide additional benefits like waterproofing and stain resistance. Always request samples to evaluate texture, finish, and weight before making a bulk purchase. -

What are the common applications of white leather fabric in B2B sectors?

White leather fabric is versatile and commonly used in various industries. In fashion, it serves as material for jackets, shoes, and accessories. In interior design, it is favored for upholstery on furniture and decorative items. Additionally, automotive industries utilize white leather for car interiors, while luxury brands may use it for high-end products. Understanding the specific application can guide you in selecting the appropriate type of leather. -

What is the minimum order quantity (MOQ) for white leather fabric?

The MOQ for white leather fabric can vary significantly between suppliers, typically ranging from 10 to 100 yards or more. Factors influencing MOQ include the type of leather, customization options, and the supplier’s production capabilities. When sourcing, communicate your project needs clearly and inquire about the possibility of lower MOQs for trial orders, especially if you are a new buyer or testing the market. -

How can I ensure the quality of white leather fabric before purchasing?

To ensure quality, request samples before placing a large order. Assess the leather’s texture, finish, and weight, and check for any defects such as discoloration or inconsistent grain. Additionally, inquire about the supplier’s quality assurance processes, including testing for durability, waterproofing, and colorfastness. Certifications or test results can provide further assurance of the leather’s quality and compliance with industry standards. -

What payment terms should I expect when sourcing white leather fabric internationally?

Payment terms can vary by supplier but generally include options such as wire transfers, letters of credit, or PayPal. It’s common to pay a deposit upfront, usually 30-50%, with the balance due upon delivery or before shipping. Ensure you clarify payment terms and methods during negotiations to avoid misunderstandings. Additionally, consider using escrow services for larger transactions to enhance security. -

How do I vet suppliers of white leather fabric for international trade?

Vetting suppliers involves several steps: review their business credentials, check for industry certifications, and read customer testimonials. Conduct background checks using platforms like Alibaba or global trade directories. Request references from previous clients, and consider visiting their facilities if possible. Engaging with suppliers through video calls can also help assess their operations and product quality. -

What logistics considerations should I keep in mind when importing white leather fabric?

When importing white leather fabric, consider shipping methods, customs regulations, and lead times. Evaluate whether air freight or ocean freight best suits your timeline and budget. Familiarize yourself with the import duties and taxes applicable in your country. Working with a reliable freight forwarder can streamline logistics, ensuring compliance with international shipping regulations and timely delivery. -

Can I customize white leather fabric according to my specifications?

Yes, many suppliers offer customization options for white leather fabric, including dyeing, embossing, or applying finishes. Discuss your specific requirements with potential suppliers, including color shades, texture preferences, and any patterns or prints. Keep in mind that customization may affect the MOQ and lead time, so plan accordingly to ensure your project timeline is met.

Top 7 White Leather Fabric Manufacturers & Suppliers List

1. Leather Hide Store – Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

مقدمة: White & Cream Upholstery Leather sold by the hide, not on rolls or sheets. Average size is 50 square feet. Used for furniture, automotive, and general leathercraft. Closeout items include: K1335-GLAZED PEARL (Available 25), K1282 WHITE LONG HAIR SHERPA (Available 22), K1262 SNOW WHITE (Available 9), K1446 ANTIQUE LACE (Available 7), K1444 CHAMPAGNE MIST (Available 4), K1104 IVORY MIST (Available 4…

2. Fabric Wholesale Direct – White Leather Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

مقدمة: This company, Fabric Wholesale Direct – White Leather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Hobby Lobby – Pearl White Castello Faux Leather Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

مقدمة: {‘name’: ‘Pearl White Castello Faux Leather Fabric’, ‘sku’: ‘1347699’, ‘original_price’: ‘$13.99’, ‘description’: ‘Pearl White Castello Faux Leather Fabric is a charming fabric that includes a felt-like backing and a vinyl-like crackled texture across the front. Available in 1-yard increments. Average bolt size is approximately 9 yards. Price displayed is for 1-yard. Enter the total number of yard…

4. Folio Fabrics – Versatile White Vinyl

Domain: foliofabrics.com

Registered: 2013 (12 years)

مقدمة: White and off-white-colored vinyl offers numerous advantages, making it a versatile and popular material for various applications. Its clean, neutral color provides a timeless and classic aesthetic that complements any design scheme, enhancing the brightness and perceived space of an area. The vinyl is stain-resistant, allowing for the enjoyment of its pristine beauty without concern for everyday …

5. Naugahyde – White Faux Leather Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

مقدمة: White Faux Leather Upholstery Vinyl available from various brands including Naugahyde and Boltaflex. Prices range from $6.97 to $33.95 per yard. Multiple colors and styles available, with stock quantities varying from 15 to 99 yards. Free shipping on most orders over $199. Products suitable for automotive, furniture, and marine use.

6. Kovi Fabrics – K8838 Oyster Outdoor/Indoor Vinyl

Domain: kovifabrics.com

Registered: 2010 (15 years)

مقدمة: {“Pattern number”: “K8838 Oyster”, “Recommended use”: [“Upholstery”, “Automotive”, “Contract”, “Home”, “Marine”, “Outdoors”], “Warranty”: “Limited lifetime warranty”, “Minimum order”: “1 yard”, “Collection”: “Outdoor/Indoor Vinyl Oasis”, “Color”: [“White”, “Ivory”], “Type”: [“Bacteria & Mildew Resistant”, “Fade Resistant”, “Performance Grade”, “Pet Friendly”, “Stain Resistant”, “Weather Resistant”…

7. Mood Fabrics – Premium White Leather

Domain: moodfabrics.com

Registered: 2001 (24 years)

مقدمة: This company, Mood Fabrics – Premium White Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for white leather fabric

How Can Strategic Sourcing Enhance Your White Leather Fabric Procurement?

In summary, strategic sourcing of white leather fabric offers B2B buyers a pathway to not only reduce costs but also enhance product quality and supplier reliability. By leveraging insights into market trends, material specifications, and supplier capabilities, businesses can secure high-quality materials that meet their specific needs. Whether for apparel, upholstery, or accessories, understanding the nuances of sourcing can lead to improved inventory management and better profit margins.

The value of white leather fabric lies in its versatility and durability, making it an attractive option across various industries. As global demand continues to rise, especially from regions such as Africa, South America, the Middle East, and Europe, it is crucial for buyers to establish robust relationships with reliable suppliers. This approach not only mitigates risks but also positions businesses to respond swiftly to market fluctuations.

Looking ahead, now is the time for international B2B buyers to evaluate their sourcing strategies and consider partnerships that prioritize quality and sustainability. Embrace the opportunity to innovate and differentiate your offerings with premium white leather fabric, and position your business for success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.