Catalog

Material Insight: Upholstery Material For Cars

Premium Upholstery Material for Automotive Interiors: The Definitive Choice

In the highly competitive automotive sector, interior upholstery is far more than an aesthetic element—it is a critical component defining brand perception, passenger experience, and long-term vehicle value. With consumers demanding uncompromising quality, safety, and sustainability, selecting the right material is a strategic decision impacting durability, comfort, and market differentiation. Among available options, high-performance automotive leather stands as the superior solution for premium and mass-market vehicles alike, engineered to withstand the unique rigors of the automotive environment while elevating the driving experience.

Why Automotive Leather is the Optimal Choice for Vehicle Upholstery

- Unmatched Durability & Resilience: Automotive leather is specifically formulated to endure extreme conditions, including prolonged UV exposure, temperature fluctuations (-30°C to +80°C), abrasion from daily use, and chemical resistance to oils, cleaning agents, and perspiration. This ensures longevity and maintains aesthetic integrity over the vehicle’s lifecycle, reducing warranty claims and enhancing resale value.

- Enhanced Safety Compliance: Meets stringent global flammability standards (e.g., FMVSS 302, ECE R118) without compromising breathability or comfort. Its non-toxic composition and low VOC emissions contribute to healthier cabin air quality, aligning with evolving regulatory requirements.

- Premium Sensory Experience: Delivers the tactile luxury, softness, and natural breathability expected in high-end vehicles. Unlike generic alternatives, it develops a refined patina over time, reinforcing brand prestige and customer satisfaction.

- Sustainability Integration: Modern automotive leather leverages closed-loop production, water-based coatings, and recycled content without sacrificing performance. It supports circular economy goals through end-of-life recyclability and reduced carbon footprint versus conventional materials.

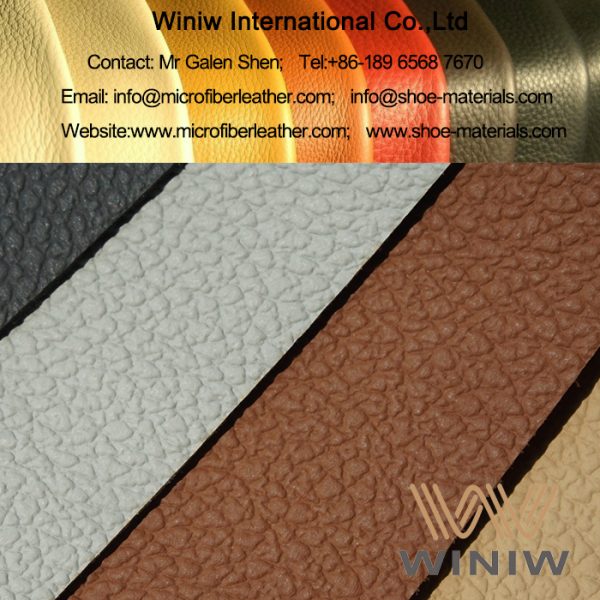

- Design Versatility: Offers extensive customization in texture, color, stitching, and embossing to align with brand identity, while maintaining consistent thickness and dimensional stability for seamless manufacturing integration.

WINIW: Engineering Excellence in Sustainable Automotive Upholstery

For over 20 years, WINIW has been a trusted innovation partner to leading global automotive OEMs and Tier-1 suppliers. We specialize in developing eco-conscious, high-performance synthetic leather solutions that meet and exceed the exacting demands of modern vehicle interiors. Rooted in a commitment to sustainability, our materials are crafted using:

– Proprietary bio-based polyurethanes and recycled polyester backings.

– Zero-DMA/DMF solvent-free production, certified by OEKO-TEX® and ISO 14001.

– Advanced technologies for superior UV resistance, tear strength, and colorfastness.

WINIW’s R&D-driven approach ensures our upholstery materials not only deliver the luxury and resilience of premium leather but also advance the automotive industry’s sustainability mission—proving that environmental responsibility and uncompromised quality coexist. Partner with us to transform interior aesthetics into enduring value.

Technical Performance & Standards

WINIW Automotive Upholstery Material – B2B Product Technical Guide

WINIW specializes in high-performance synthetic leather solutions engineered specifically for automotive interior applications. Our upholstery materials are developed to meet the rigorous demands of modern vehicle manufacturing, combining durability, safety, and environmental responsibility. Designed for OEMs and Tier-1 suppliers, WINIW’s automotive upholstery delivers superior technical performance across key industry benchmarks.

Key Technical Advantages

-

Abrasion Resistant

WINIW’s upholstery material is engineered with a reinforced polyurethane (PU) coating and high-tenacity backing fabric, providing exceptional resistance to wear and tear. It withstands over 50,000 cycles in Martindale abrasion testing, ensuring long-term durability even in high-contact areas such as seats, armrests, and door panels. -

UV Resistant

The material incorporates advanced UV stabilizers and light-fast pigments that prevent color fading and surface degradation under prolonged sun exposure. Tested under accelerated weathering conditions (Xenon arc, 1,000 hours), it maintains over 90% color retention, making it ideal for vehicles in high-sunlight regions. -

VOC Free

WINIW’s production process eliminates the use of volatile organic compounds (VOCs). Our materials are independently tested and certified to emit less than 10 µg/g of total VOCs, contributing to healthier cabin air quality and compliance with strict automotive interior air standards. -

REACH Compliant

All chemicals used in WINIW’s upholstery materials are fully compliant with the European REACH regulation (EC 1907/2006). The product is free from SVHCs (Substances of Very High Concern), ensuring safe handling throughout the supply chain and end-of-life processing. -

ISO 9001 Certified Manufacturing

WINIW’s production facilities are ISO 9001 certified, ensuring consistent quality control, process traceability, and continuous improvement. This certification supports reliable batch-to-batch consistency and on-time delivery for global automotive manufacturers.

Technical Specifications

| Property | المواصفات | Test Standard |

|---|---|---|

| Abrasion Resistance | >50,000 cycles (Martindale) | ISO 12947-2 |

| Colorfastness to UV Light | Grade 7–8 (on Blue Scale) after 1,000h exposure | ISO 105-B02 / SAE J2412 |

| Total VOC Emissions | <10 µg/g | VDA 276 |

| REACH Compliance | Fully compliant, no SVHCs declared | EC 1907/2006 |

| Tensile Strength | ≥25 N/cm (warp), ≥23 N/cm (weft) | ISO 1421 |

| Tear Strength | ≥3.5 N (Elmendorf) | ISO 9073-9 |

| Cold Crack Temperature | ≤ -30°C | ISO 14362-1 |

| Flame Resistance | Meets FMVSS 302, DIN 75200 | FMVSS 302 |

| Density | 0.95–1.05 g/cm³ | ISO 2781 |

| Thickness | 1.0 – 1.8 mm (customizable) | ISO 2589 |

WINIW’s automotive upholstery material is a sustainable, high-performance alternative to traditional leather and low-grade synthetic fabrics. By integrating advanced material science with eco-conscious manufacturing, WINIW supports automotive brands in achieving durability, regulatory compliance, and environmental leadership.

Why Choose Synthetic over Real Leather

B2B Product Guide: Automotive Upholstery Material Comparison

Selecting the right upholstery material is critical for automotive OEMs and Tier-1 suppliers balancing performance, cost, and sustainability. While real leather remains a traditional choice, advanced synthetic leather (particularly eco-engineered variants like WINIW’s offerings) delivers compelling advantages for modern vehicle interiors. Below is a factual comparison focused on core decision-driving attributes.

Key benefits of high-performance synthetic leather for automotive applications include:

– Consistent texture and color batch-to-batch, minimizing production waste

– Enhanced resistance to UV degradation and color fading in sun-exposed interiors

– Customizable thickness, breathability, and tactile properties to meet specific design requirements

– Streamlined manufacturing with fewer processing steps compared to leather finishing

– Inherent resistance to mold, mildew, and microbial growth in humid climates

Comparative Analysis: Synthetic Leather vs. Real Leather

| Attribute | Synthetic Leather (Eco-Engineered) | Real Leather |

|---|---|---|

| Cost | $18–$35/m² (lower total cost of ownership due to higher yield rates and reduced waste) | $30–$60+/m² (significant price volatility; 30–40% material waste during cutting) |

| المتانة | 50,000+ double-rub cycles (ASTM D4157); superior tear strength; consistent performance in extreme temperatures (-30°C to 85°C) | 25,000–40,000 double-rub cycles; prone to cracking/drying in arid conditions; variable grain integrity |

| Eco-Friendliness | 60–75% lower CO2e footprint; water-based, PFC-free production; 30–100% recycled content options; fully recyclable at end-of-life | High water/land use (15,000L+ water per hide); toxic tanning chemicals (chromium); non-recyclable; methane emissions from livestock |

Strategic Implications for Automotive Partners

Synthetic leather addresses escalating B2B priorities: supply chain resilience (stable pricing, no agricultural dependencies), compliance with evolving global EPR (Extended Producer Responsibility) regulations, and alignment with OEM sustainability mandates (e.g., EU Green Deal). Real leather’s ecological burden—particularly water consumption, chemical pollution from tanneries, and methane emissions—increasingly conflicts with net-zero commitments. WINIW’s eco-synthetics further advance circularity through closed-loop water systems and traceable recycled feedstocks, offering OEMs verifiable ESG metrics without compromising luxury aesthetics or longevity.

WINIW delivers ISO 14001-certified, automotive-grade synthetic leather engineered for the lifecycle demands of premium EVs and ICE vehicles. Our solutions meet FMVSS 302, ISO 105-X12, and OE-specific abrasion standards while reducing environmental impact by design.

WINIW: Engineering Sustainable Interiors for the Future of Mobility

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, sustainable materials. Our vertically integrated production ecosystem is built on strong industrial capabilities, advanced R&D, and uncompromising quality standards.

Our state-of-the-art manufacturing facility spans over 100,000 square meters, making it one of the largest synthetic leather production bases in Asia. This extensive infrastructure enables us to maintain high output capacity while ensuring operational efficiency and scalability to meet the demands of international partners.

Key strengths of the WINIW factory include:

- Advanced production lines equipped with automated control systems for consistent material quality and reduced environmental impact

- In-house R&D team composed of material scientists and engineers dedicated to developing eco-friendly, high-performance synthetic leather solutions

- Continuous investment in innovation, including water-based, solvent-free, and recycled materials to align with global sustainability trends

- Strict quality control protocols implemented at every stage—from raw material selection to final product inspection—ensuring compliance with international standards (REACH, RoHS, OEKO-TEX, etc.)

- Dedicated testing laboratory for physical performance, color fastness, and environmental safety validation

WINIW products are exported globally, with a strong presence in Europe and the USA. Our clients include leading brands in fashion, automotive, furniture, and sports industries who rely on our materials for their durability, aesthetic precision, and environmental responsibility.

Through a combination of scale, innovation, and quality, WINIW delivers synthetic leather solutions that support the evolving needs of global markets—driving performance and sustainability in tandem.

Contact Us for Samples

WINIW Automotive Upholstery Solutions: Premium Synthetic Leather for Vehicle Interiors

WINIW delivers engineered microfiber leather specifically formulated for automotive upholstery applications. Our materials meet the rigorous durability, safety, and sustainability demands of modern vehicle manufacturing while offering exceptional aesthetic versatility. As a trusted partner to global Tier 1 suppliers and OEMs, we provide eco-conscious performance without compromise.

Key Advantages for Automotive Applications

- Superior Durability: Engineered to withstand 50,000+ double-rub cycles (Martindale test), resisting abrasion, tearing, and UV degradation for long-term cabin integrity.

- Eco-Certified Production: OEKO-TEX® STANDARD 100 Class I certified (skin-safe), GRS-certified recycled content options (up to 40%), and 100% solvent-free manufacturing.

- Design Flexibility: Customizable thickness (0.6–1.2mm), textures (Nappa, grain, suede), and color matching (Pantone®/RAL) to align with brand-specific interior concepts.

- Enhanced Functionality: Breathable structures, anti-microbial treatment, and low-VOC emissions (<5μg/g) ensuring cabin air quality compliance (ISO 12219-2).

Technical Performance Specifications

| Property | Test Standard | WINIW Automotive Grade | Industry Benchmark |

|---|---|---|---|

| Abrasion Resistance | ISO 12947-2 | ≥50,000 cycles | 30,000 cycles |

| Color Fastness to Rubbing | ISO 105-X12 | Grade 4-5 | Grade 4 |

| Tensile Strength | ISO 1798 | ≥30 N/mm² | ≥20 N/mm² |

| VOC Emissions | ISO 12219-2 | <5 μg/g | <10 μg/g |

| Recycled Content | GRS v4.0 | Up to 40% | 0–25% |

Why Automotive Leaders Choose WINIW

- End-to-End Traceability: Blockchain-enabled material journey tracking from raw inputs to finished roll.

- Scalable Production: 15M+ meters annual capacity with JIT delivery support across NA, EU, and APAC.

- Regulatory Assurance: Compliant with FMVSS 302, REACH, and ELV directives; full material disclosure (IMDS-ready).

- Circularity Focus: Take-back program for pre-consumer waste to support closed-loop manufacturing goals.

Elevate your vehicle interiors with sustainable performance that exceeds passenger expectations and environmental mandates. WINIW microfiber leather delivers the tactile luxury and engineering resilience demanded by premium automotive brands.

Request Technical Documentation & Free Samples

Evaluate WINIW’s automotive upholstery solutions against your specifications. Contact our technical sales team for material swatches, test reports, and customization support:

MKT88@MicrofiberLeather.com

Free physical samples available for qualified automotive projects.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.