Introduction: Navigating the Global Market for smooth faux leather

In the ever-evolving landscape of the global market, sourcing high-quality smooth faux leather presents a unique challenge for B2B buyers. With the increasing demand for sustainable and cost-effective materials, understanding the nuances of faux leather—including its types, applications, and supplier reliability—becomes crucial. This guide delves into the various facets of smooth faux leather, providing an in-depth analysis of its benefits, such as affordability and ease of maintenance, while highlighting its versatility across industries ranging from automotive to furniture upholstery.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, will find this guide indispensable in making informed purchasing decisions. By offering insights into supplier vetting processes, pricing structures, and material specifications, we aim to empower businesses to navigate the complexities of sourcing faux leather with confidence. Whether you are in Nigeria looking for durable upholstery options or in Saudi Arabia seeking eco-friendly alternatives for automotive applications, this comprehensive resource will equip you with the knowledge needed to select the right suppliers and products that meet your unique needs.

Join us as we explore the dynamic world of smooth faux leather, ensuring that your purchasing decisions are not only informed but also strategically aligned with market trends and consumer demands.

Table Of Contents

- Top 6 Smooth Faux Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for smooth faux leather

- Understanding smooth faux leather Types and Variations

- Key Industrial Applications of smooth faux leather

- 3 Common User Pain Points for ‘smooth faux leather’ & Their Solutions

- Strategic Material Selection Guide for smooth faux leather

- In-depth Look: Manufacturing Processes and Quality Assurance for smooth faux leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘smooth faux leather’

- Comprehensive Cost and Pricing Analysis for smooth faux leather Sourcing

- Alternatives Analysis: Comparing smooth faux leather With Other Solutions

- Essential Technical Properties and Trade Terminology for smooth faux leather

- Navigating Market Dynamics and Sourcing Trends in the smooth faux leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of smooth faux leather

- Strategic Sourcing Conclusion and Outlook for smooth faux leather

- Important Disclaimer & Terms of Use

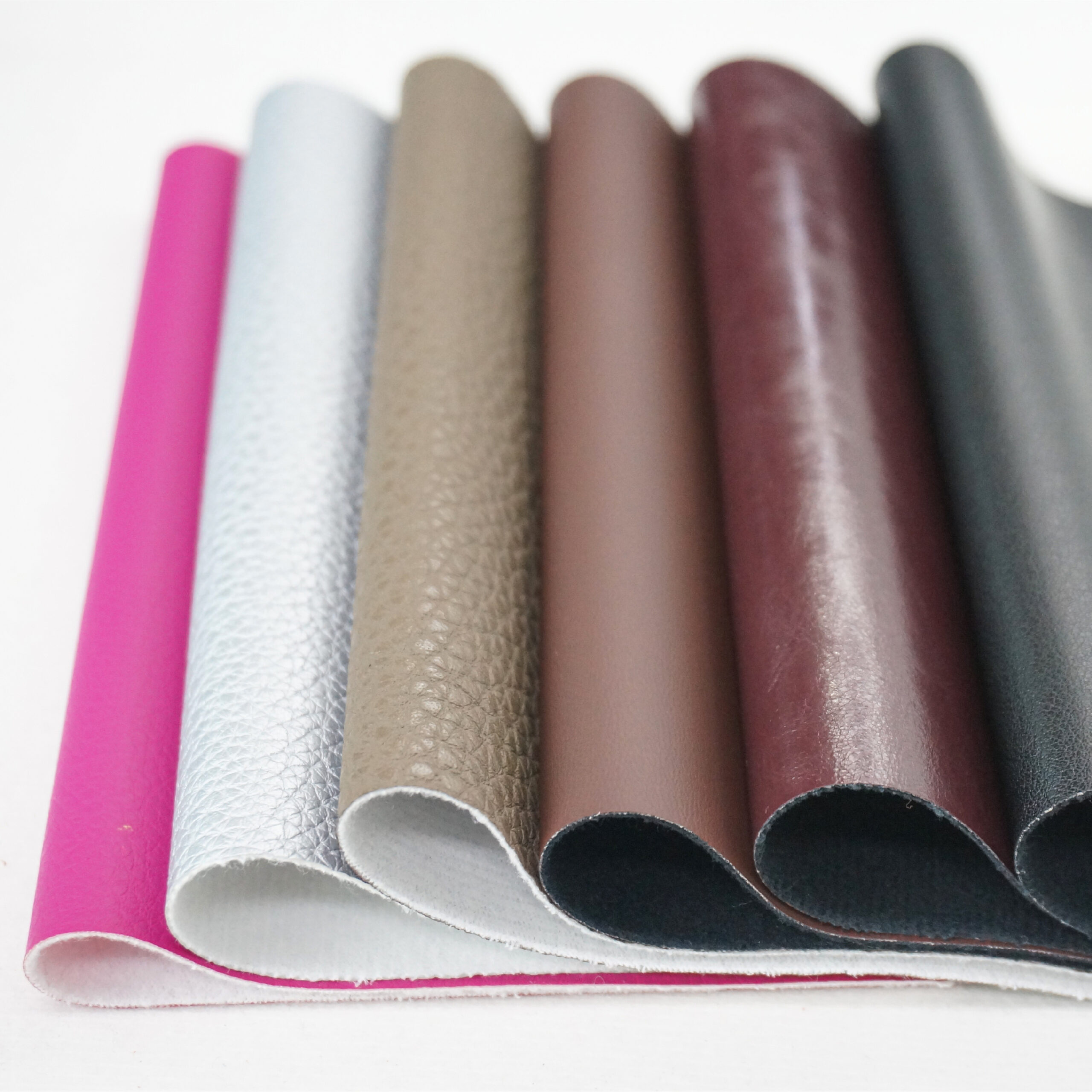

Understanding smooth faux leather Types and Variations

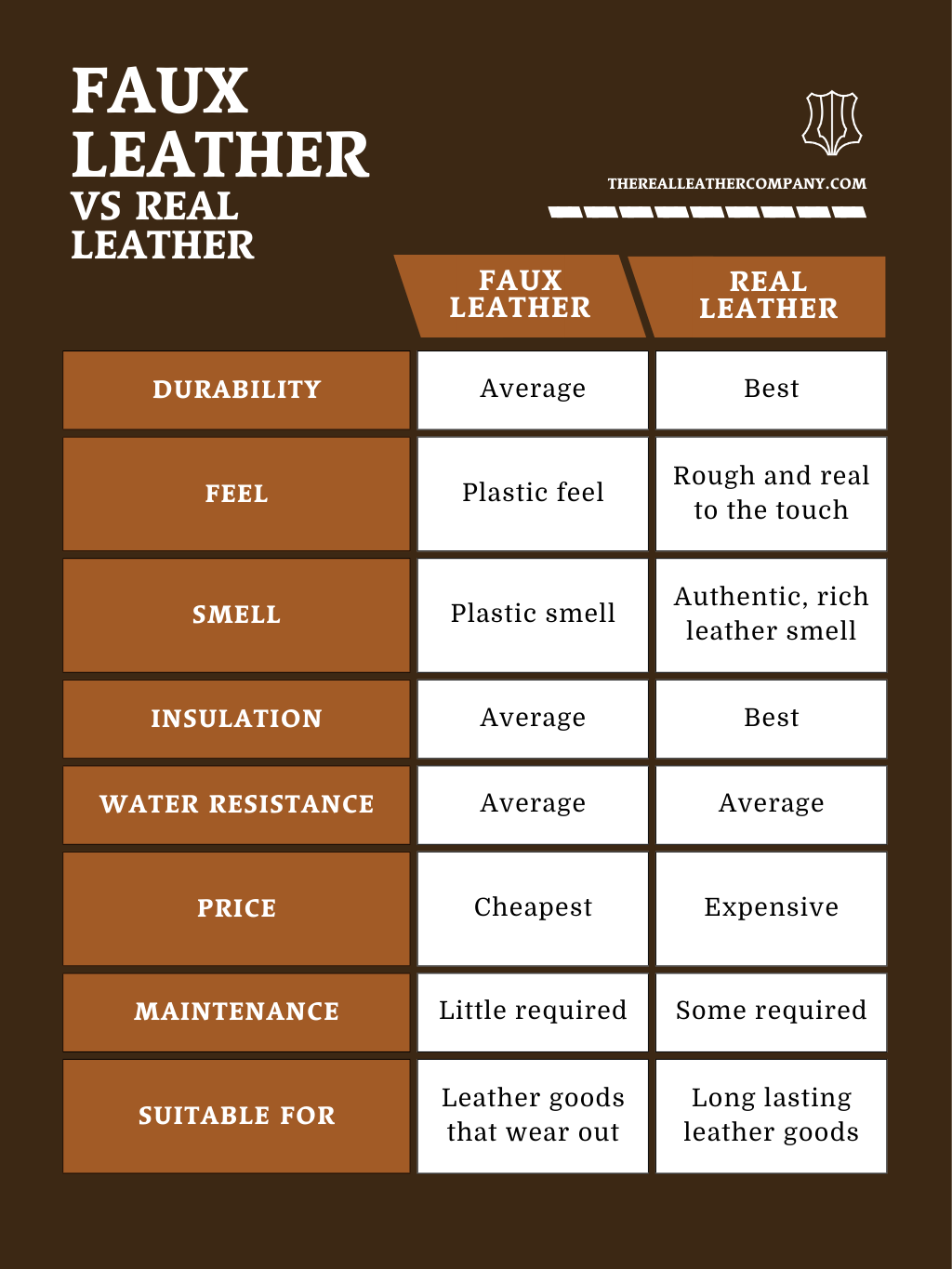

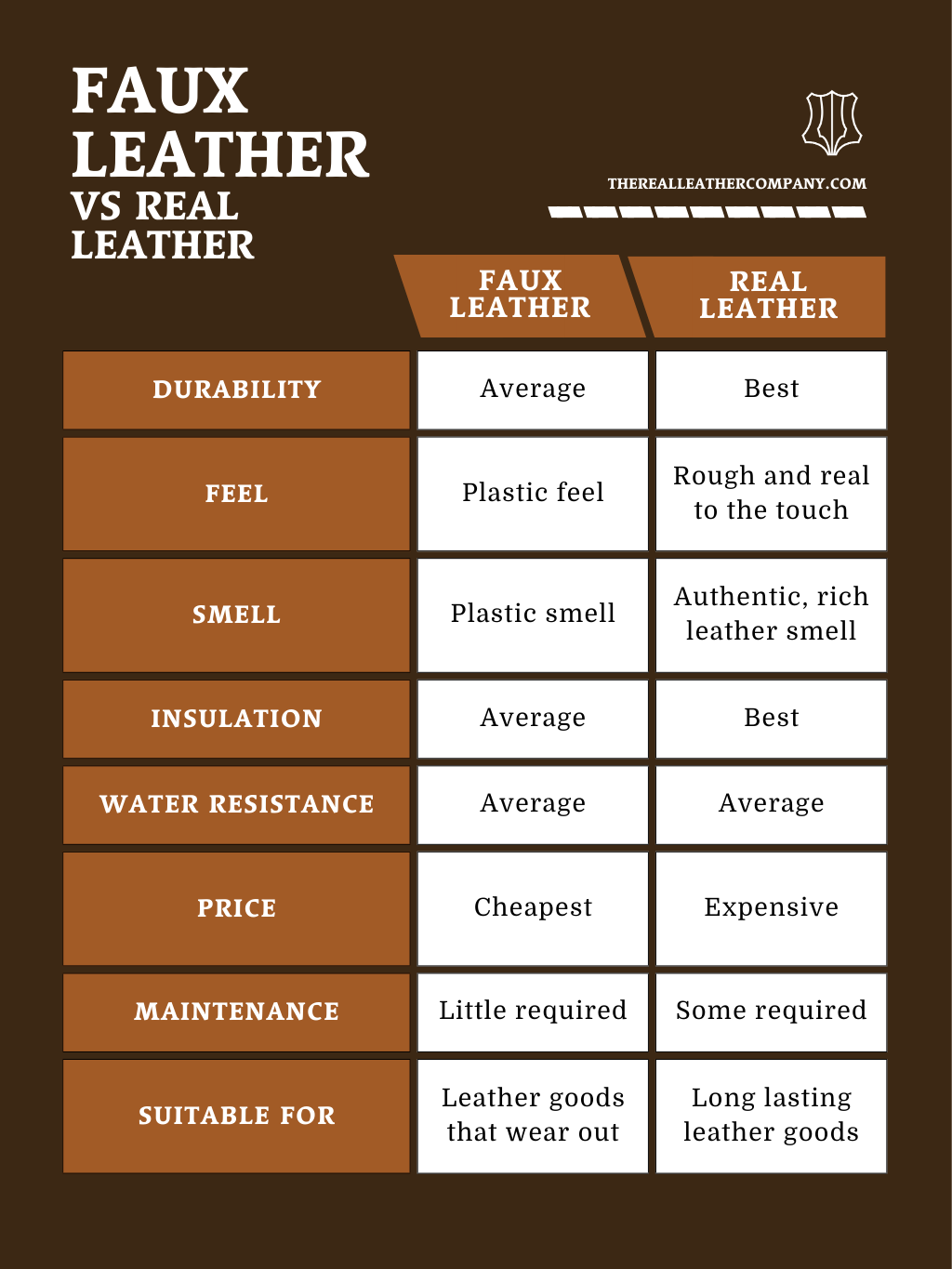

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather | Soft, supple texture; resembles genuine leather closely | Furniture upholstery, automotive interiors | Pros: Affordable, easy to clean. Cons: May not be as durable as PVC options. |

| PVC Leather | More rigid; often less expensive; water-resistant | Outdoor furniture, marine upholstery | Pros: Highly resistant to water and stains. Cons: Can be less breathable. |

| Leatherette | Glossy finish; available in various colors; lightweight | Fashion accessories, tote bags | Pros: Versatile, lightweight. Cons: May wear out faster than other types. |

| Microfiber Leather | Ultra-soft texture; often mimics suede; durable | Upholstery for high-end furniture, automotive | Pros: Luxurious feel, durable. Cons: Higher price point compared to other faux leathers. |

| Eco-Friendly Faux Leather | Made from recycled materials; sustainable production | Eco-conscious brands, luxury goods | Pros: Environmentally friendly, unique aesthetic. Cons: Limited availability, often higher cost. |

What Are the Characteristics of PU Leather for B2B Buyers?

PU leather, or polyurethane leather, is a popular choice among B2B buyers due to its softness and ability to closely mimic the appearance of genuine leather. This type is particularly well-suited for furniture upholstery and automotive interiors, where a luxurious look is desired without the associated costs of real leather. When purchasing PU leather, buyers should consider factors such as the thickness and grain pattern, as these can affect the material’s durability and aesthetic appeal. Additionally, its easy maintenance and affordability make it a practical option for bulk purchases.

How Does PVC Leather Stand Out in Various Applications?

PVC leather, known for its rigidity and water resistance, is a practical choice for outdoor furniture and marine upholstery. Its affordability makes it attractive for businesses looking to minimize costs while still providing quality products. However, B2B buyers should be aware of its less breathable nature, which may affect comfort in certain applications. When selecting PVC leather, it is essential to consider the intended use, as its durability and resistance to the elements can significantly enhance product longevity.

Illustrative image related to smooth faux leather

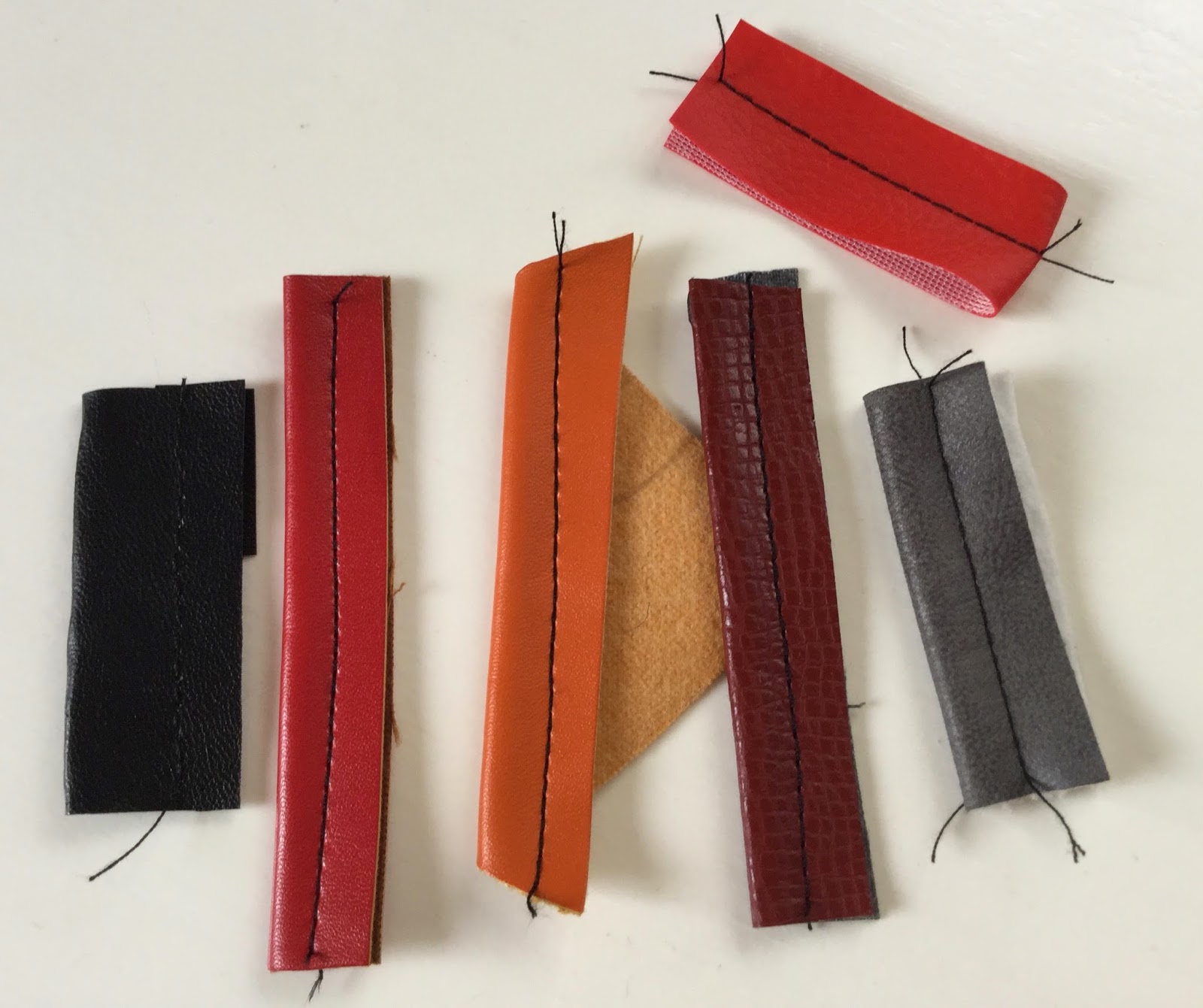

Why Choose Leatherette for Fashion Accessories?

Leatherette is characterized by its glossy finish and lightweight nature, making it ideal for fashion accessories and tote bags. Its versatility allows for a wide range of colors and designs, appealing to brands looking to offer trendy products. Buyers should keep in mind that while leatherette provides a stylish appearance, it may not be as durable as other faux leather options. Therefore, understanding the target market’s expectations for wear and longevity is crucial when opting for leatherette materials.

What Makes Microfiber Leather a Premium Option?

Microfiber leather offers an ultra-soft texture that mimics suede, making it a luxurious choice for high-end furniture and automotive applications. Its durability and resistance to wear make it suitable for environments requiring a sophisticated aesthetic. However, B2B buyers should consider its higher price point compared to other faux leathers. When purchasing microfiber leather, evaluating the supplier’s quality certifications can ensure that the material meets the necessary standards for durability and appearance.

How Can Eco-Friendly Faux Leather Benefit Brands?

Eco-friendly faux leather, made from recycled materials, appeals to brands focused on sustainability. Its unique aesthetic and environmentally conscious production processes can enhance brand image and attract eco-conscious consumers. However, availability may be limited, and costs can be higher than traditional faux leathers. B2B buyers should assess their target market’s values and consider eco-friendly options as part of their product offerings, potentially differentiating their brand in competitive markets.

Illustrative image related to smooth faux leather

Key Industrial Applications of smooth faux leather

| Industry/Sector | Specific Application of smooth faux leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Seat covers and interior upholstery | Enhances aesthetic appeal while being cost-effective | Ensure durability, color fastness, and compliance with safety standards. |

| Hospitality | Furniture upholstery for hotels and restaurants | Provides a luxurious look at a lower cost, easy to maintain | Look for stain resistance and variety in colors and textures. |

| Marine | Upholstery for boat interiors and exterior cushions | Water-resistant, durable, and easy to clean | Focus on UV resistance and mildew prevention for longevity. |

| Healthcare | Upholstery for medical furniture and equipment | Offers hygienic, easy-to-clean surfaces for patient care | Verify antimicrobial properties and compliance with health regulations. |

| Fashion and Accessories | Production of bags, wallets, and apparel | Allows for creative designs while being animal-friendly | Assess material flexibility, color options, and sourcing ethics. |

How is Smooth Faux Leather Used in the Automotive Sector?

In the automotive industry, smooth faux leather is extensively used for seat covers and interior upholstery. This material not only provides an aesthetically pleasing look that can rival genuine leather but also offers significant cost savings—up to 75% less than traditional leather. For international buyers, especially from regions like Africa and the Middle East, sourcing faux leather that meets local safety and durability standards is crucial. Additionally, it must be resistant to wear and fading, ensuring longevity in various climate conditions.

What Role Does Smooth Faux Leather Play in Hospitality?

In the hospitality sector, smooth faux leather is favored for furniture upholstery in hotels and restaurants. Its luxurious appearance enhances the ambiance of dining and lodging spaces while being easy to maintain, an essential factor for busy establishments. Buyers should consider the material’s stain resistance and variety of design options, as these features contribute to a lasting impression on guests. Sourcing from reputable manufacturers ensures that the material complies with industry standards, particularly in high-traffic areas.

Why is Smooth Faux Leather Important for Marine Upholstery?

Marine applications benefit significantly from smooth faux leather due to its water resistance and durability. Used for both interior and exterior upholstery in boats, this material stands up to harsh marine environments while remaining easy to clean. For B2B buyers in South America and Europe, it is vital to source faux leather that offers UV protection and mildew resistance, ensuring that the upholstery maintains its integrity and appearance over time. These features are essential for enhancing the longevity of marine vessels.

How is Smooth Faux Leather Utilized in Healthcare?

In healthcare settings, smooth faux leather is employed for upholstery on medical furniture and equipment, providing hygienic surfaces that are easy to clean. This is particularly important in environments where cleanliness is paramount. Buyers must ensure that the materials sourced possess antimicrobial properties and comply with health regulations. The ability to maintain a clean and sterile environment while offering comfort to patients makes faux leather an ideal choice in this sector.

What Are the Fashion and Accessory Applications of Smooth Faux Leather?

Smooth faux leather is increasingly popular in the fashion industry for creating bags, wallets, and apparel. This material allows designers to explore innovative styles while being environmentally friendly and cruelty-free. For international buyers, especially those in Europe and Africa, the flexibility in design, availability of various colors, and ethical sourcing practices are key factors to consider. Understanding the market demand for sustainable fashion can also provide a competitive edge in sourcing decisions.

Illustrative image related to smooth faux leather

3 Common User Pain Points for ‘smooth faux leather’ & Their Solutions

Scenario 1: Sourcing Quality Faux Leather for Diverse Applications

The Problem: B2B buyers often struggle to source smooth faux leather that meets specific quality standards required for different applications, such as upholstery, automotive interiors, or marine environments. The challenge lies in distinguishing high-quality faux leather from inferior products, which can lead to premature wear, discoloration, or even peeling. This concern is particularly acute for businesses in sectors like hospitality and automotive, where durability and aesthetics are paramount.

The Solution: To ensure the sourcing of quality smooth faux leather, B2B buyers should establish relationships with reputable manufacturers and suppliers known for their commitment to quality. Request samples to evaluate the texture, flexibility, and durability before making bulk purchases. Additionally, inquire about the material’s specifications, such as its resistance to stains, UV rays, and water. Buyers should also consider suppliers that offer certifications or performance guarantees, which can provide added assurance of the material’s longevity and suitability for intended uses. Leveraging industry connections and attending trade shows can also help in identifying trusted suppliers and discovering innovative products.

Scenario 2: Overcoming Cleaning and Maintenance Challenges

The Problem: Although smooth faux leather is generally easier to maintain than genuine leather, B2B buyers frequently encounter difficulties related to cleaning and stain resistance. In commercial environments, such as restaurants or hotels, where spills and stains are inevitable, the inability to effectively clean faux leather can lead to unsightly appearances and increased replacement costs.

Illustrative image related to smooth faux leather

The Solution: To mitigate cleaning and maintenance issues, businesses should educate staff on the proper care techniques for smooth faux leather. This includes using appropriate cleaning agents—preferably mild soap and water—as harsher chemicals can damage the material. Establish a routine cleaning schedule and consider investing in additional protective coatings that enhance stain resistance. Suppliers often offer guidance on the best maintenance practices, so it’s beneficial to consult them during the purchasing process. For high-traffic areas, opting for faux leather with a higher grade of stain resistance can further extend the lifespan and appearance of the material.

Scenario 3: Addressing Environmental and Sustainability Concerns

The Problem: With increasing consumer awareness regarding sustainability, B2B buyers face pressure to select materials that align with eco-friendly practices. Faux leather, often made from synthetic materials, can raise concerns about its environmental impact, particularly when sourced from suppliers with inadequate sustainability measures. Buyers may worry about how their choice will affect their brand image and customer perception.

The Solution: To address sustainability concerns, B2B buyers should seek out suppliers that prioritize eco-friendly manufacturing processes and materials. Look for faux leather options made from recycled or low-impact materials and inquire about the environmental certifications the supplier holds. Additionally, consider the end-of-life options for the product, such as recyclability or biodegradability, which can enhance the overall sustainability profile of the material. Transparent communication about these practices in marketing materials can also help improve brand perception among environmentally conscious consumers, reinforcing the business’s commitment to sustainability. By prioritizing sustainable sourcing, companies can not only meet regulatory requirements but also appeal to a growing demographic of eco-conscious customers.

Strategic Material Selection Guide for smooth faux leather

When selecting materials for smooth faux leather, international B2B buyers must consider various factors that impact product performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in the production of smooth faux leather, focusing on their properties, advantages, disadvantages, and considerations for buyers in diverse markets, including Africa, South America, the Middle East, and Europe.

What are the Key Properties of Polyurethane (PU) Leather?

Polyurethane leather, commonly referred to as PU leather, is a popular choice for smooth faux leather due to its soft texture and durability. Its key properties include excellent flexibility, water resistance, and a high level of abrasion resistance. PU leather can withstand temperatures ranging from -30°C to 70°C, making it suitable for various climates.

Pros & Cons: The primary advantage of PU leather is its affordability, typically costing up to 75% less than genuine leather. It is also easy to clean and maintain, making it ideal for high-traffic areas. However, PU leather may have a shorter lifespan than genuine leather, particularly in extreme conditions, and can be less environmentally friendly due to its petroleum-based components.

Impact on Application: PU leather is widely used in upholstery, automotive interiors, and fashion accessories. Its compatibility with various dyes and finishes allows for a broad range of aesthetic options.

Considerations for International Buyers: Buyers should ensure that PU leather complies with international standards such as ASTM and REACH, particularly regarding chemical safety and environmental impact. In regions like Nigeria and Saudi Arabia, buyers may also need to consider local regulations regarding synthetic materials.

Illustrative image related to smooth faux leather

How Does Polyvinyl Chloride (PVC) Compare as a Material for Faux Leather?

Polyvinyl chloride, or PVC, is another common material used in faux leather production. It is known for its durability and resistance to moisture, making it suitable for outdoor applications.

Pros & Cons: PVC is highly resistant to wear and tear, making it a good choice for products that require longevity. It is also less expensive than PU leather. However, PVC can be less breathable, leading to discomfort in certain applications, such as clothing. Additionally, it may emit harmful chemicals during production and disposal, raising environmental concerns.

Impact on Application: PVC is often used for marine upholstery, outdoor furniture, and commercial applications where durability is paramount. Its resistance to UV light makes it suitable for outdoor environments.

Considerations for International Buyers: Buyers should be aware of compliance with environmental regulations, especially in Europe where PVC usage may be restricted. Understanding local preferences for sustainable materials is crucial, particularly in markets that prioritize eco-friendly products.

What are the Benefits of Using Microfiber as a Smooth Faux Leather Alternative?

Microfiber is a synthetic material made from polyester and polyamide fibers, often used as a high-end alternative to traditional faux leather. Its key properties include softness, high tensile strength, and excellent stain resistance.

Illustrative image related to smooth faux leather

Pros & Cons: The main advantage of microfiber is its luxurious feel, which closely mimics genuine leather. It is also easy to clean and maintain. However, microfiber can be more expensive than PU and PVC, which may deter cost-sensitive buyers.

Impact on Application: Microfiber is commonly used in high-end furniture, automotive interiors, and fashion accessories. Its compatibility with various dyes allows for vibrant color options.

Considerations for International Buyers: Buyers should consider the sourcing and manufacturing processes of microfiber to ensure ethical practices. In markets like South America, where sustainability is gaining traction, environmentally friendly microfiber options may be preferred.

Why is Recycled Leather a Sustainable Option for Faux Leather Products?

Recycled leather, made from scraps of genuine leather and synthetic materials, is an innovative option for faux leather. Its key properties include durability and a unique texture that can enhance product appeal.

Pros & Cons: The primary advantage of recycled leather is its sustainability, reducing waste and the demand for new materials. It also offers a unique aesthetic. However, the variability in quality can make it challenging for manufacturers to maintain consistency.

Impact on Application: Recycled leather is suitable for a wide range of applications, including upholstery, bags, and accessories. Its unique texture can add value to products.

Considerations for International Buyers: Buyers should verify the sourcing and quality standards of recycled leather to ensure compliance with local regulations. In regions like Europe, where sustainability is a key focus, recycled leather can enhance brand reputation.

Summary Table of Material Selection for Smooth Faux Leather

| Material | Typical Use Case for smooth faux leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Upholstery, automotive interiors | Soft texture, affordable | Shorter lifespan than genuine leather | Medium |

| Polyvinyl Chloride | Marine upholstery, outdoor furniture | Highly durable, moisture-resistant | Less breathable, environmental concerns | Low |

| Microfiber | High-end furniture, automotive interiors | Luxurious feel, stain-resistant | Higher cost | High |

| Recycled Leather | Upholstery, bags, accessories | Sustainable, unique aesthetic | Variable quality | Medium |

This comprehensive analysis provides B2B buyers with actionable insights into the various materials available for smooth faux leather, enabling informed decision-making based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for smooth faux leather

What Are the Main Stages of Smooth Faux Leather Manufacturing?

The manufacturing process for smooth faux leather involves several critical stages, each designed to ensure the final product meets high standards of quality and durability. Understanding these stages will help B2B buyers identify reliable suppliers and make informed purchasing decisions.

Illustrative image related to smooth faux leather

1. Material Preparation: What Raw Materials Are Used?

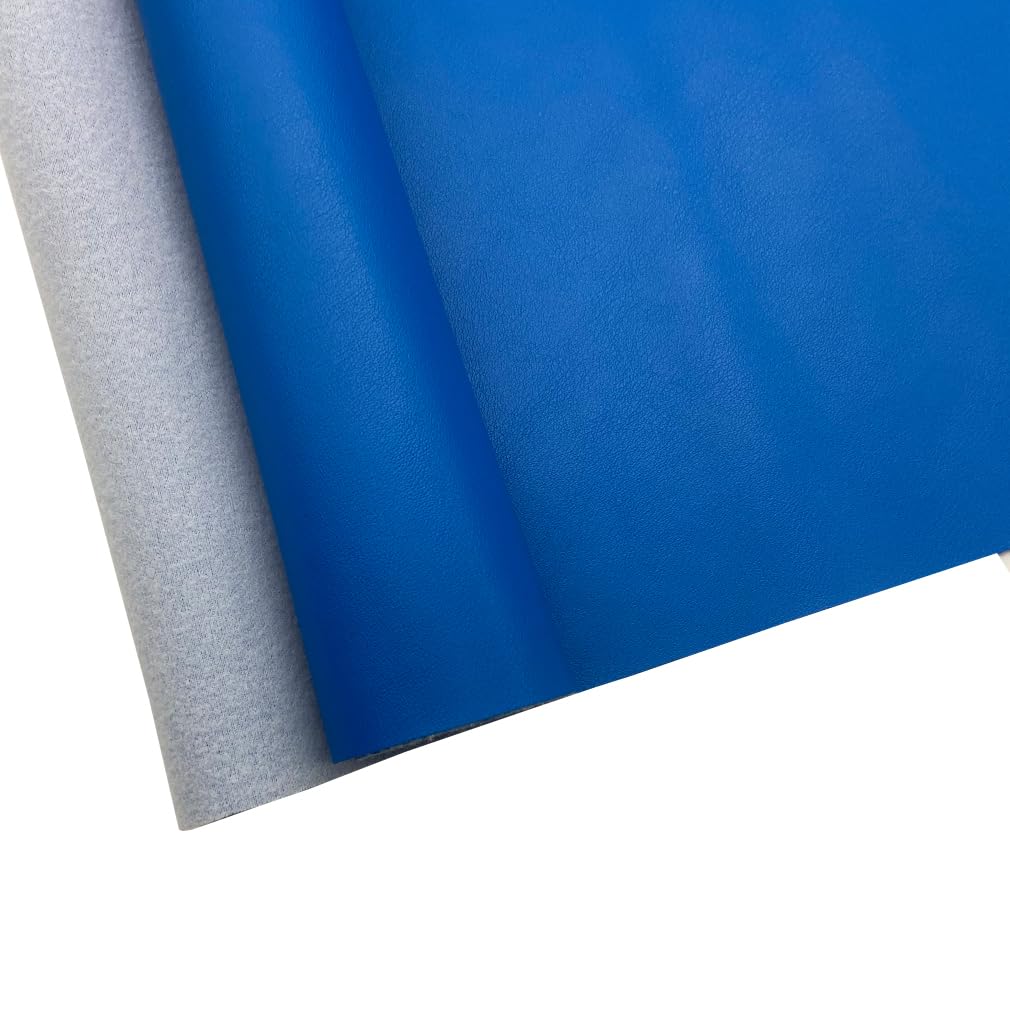

The first stage in the manufacturing process involves the selection and preparation of raw materials. The primary material used in the production of smooth faux leather is vinyl, often in the form of polyvinyl chloride (PVC) or polyurethane (PU). These materials are chosen for their flexibility, durability, and ability to mimic the appearance of genuine leather.

During material preparation, the vinyl is typically blended with various additives to enhance properties such as UV resistance, water repellency, and color fastness. This stage may also involve the treatment of the base fabric, which serves as the substrate for the faux leather. Common substrates include polyester or cotton, which provide the necessary strength and support.

2. Forming: How Is Faux Leather Created?

The forming stage is where the magic happens. The prepared vinyl is coated onto the substrate through a process known as calendaring. In this technique, the substrate is passed through rollers that apply heat and pressure, allowing the vinyl to adhere evenly. The thickness of the vinyl layer can be adjusted to meet specific requirements, resulting in a variety of textures and finishes.

Embossing is another key technique used in this stage. Manufacturers often emboss the vinyl surface to create a leather-like grain, enhancing the aesthetic appeal of the faux leather. This process not only contributes to the visual quality but also affects the tactile feel, making it challenging to distinguish from genuine leather.

Illustrative image related to smooth faux leather

3. Assembly: What Happens After Forming?

Once the faux leather is formed, it is cut into specific shapes and sizes for various applications, such as upholstery, automotive interiors, or fashion items. The assembly stage may involve sewing the faux leather pieces together or applying it to pre-manufactured items like furniture frames or car seats.

During this stage, manufacturers pay close attention to stitching quality, seam strength, and overall craftsmanship. This attention to detail is crucial, especially for products that require durability and longevity under regular use.

4. Finishing: How Is Quality Enhanced?

The finishing stage encompasses various processes aimed at enhancing the faux leather’s appearance and performance. This may include applying protective coatings that improve resistance to stains, scratches, and UV light. Additionally, manufacturers may add dyes and pigments to achieve the desired color and texture.

Quality control checks are often conducted at this stage to ensure that the finished product meets specifications. These checks can include visual inspections for color consistency and surface defects, as well as physical tests for strength and flexibility.

What International Standards and Quality Assurance Practices Are Relevant?

Quality assurance is a critical component of the manufacturing process for smooth faux leather. B2B buyers must understand the relevant international standards and practices to ensure they are sourcing high-quality materials.

ISO 9001: What Does It Mean for Faux Leather Production?

ISO 9001 is an internationally recognized standard that outlines the requirements for a quality management system (QMS). Manufacturers who adhere to this standard demonstrate their commitment to consistent quality and customer satisfaction. This certification ensures that suppliers have established processes for monitoring and improving their production systems.

Illustrative image related to smooth faux leather

CE Marking: Why Is It Important for European Markets?

For suppliers targeting the European market, CE marking signifies that a product meets EU safety, health, and environmental protection requirements. This is particularly important for faux leather used in applications like upholstery and automotive interiors, where safety standards are stringent.

API Standards: How Do They Apply to Specific Applications?

The American Petroleum Institute (API) sets standards for products used in the oil and gas industry, including certain types of synthetic materials. If faux leather is being used in applications related to this sector, verifying compliance with API standards is essential.

What Quality Control Checkpoints Should Buyers Be Aware Of?

Quality control (QC) checkpoints are integral to ensuring that the manufacturing process yields a high-quality product. B2B buyers should be familiar with the various stages of QC to assess supplier reliability.

Incoming Quality Control (IQC): What Is Its Role?

IQC involves inspecting raw materials upon arrival at the manufacturing facility. This step ensures that the materials meet predetermined quality standards before production begins. Buyers should inquire about the supplier’s IQC processes to confirm that only high-quality materials are used.

In-Process Quality Control (IPQC): How Is It Implemented?

During the manufacturing process, IPQC checks are performed to monitor quality at various stages. This includes evaluating the consistency of the vinyl coating, the integrity of seams, and the effectiveness of finishing treatments. Suppliers should be able to provide records of IPQC checks as part of their quality assurance documentation.

Illustrative image related to smooth faux leather

Final Quality Control (FQC): What Does It Involve?

FQC is the last checkpoint before products are shipped to customers. This process involves thorough inspections of the finished faux leather, checking for defects, color consistency, and compliance with specifications. B2B buyers should request FQC reports to validate the quality of the products they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control practices is essential for B2B buyers, particularly those operating in international markets. Here are several strategies to ensure supplier reliability:

Conducting Audits: What to Look For?

Auditing potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Buyers should assess the supplier’s adherence to ISO 9001 and other relevant standards, as well as their internal QC procedures. A thorough audit can reveal whether the supplier is committed to maintaining high quality.

Requesting Quality Reports: What Should Be Included?

Buyers should request quality control reports that detail the results of IQC, IPQC, and FQC checks. These reports should include information on testing methods, pass/fail rates, and any corrective actions taken for non-conforming products.

Illustrative image related to smooth faux leather

Engaging Third-Party Inspectors: How Can They Help?

Hiring third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspectors can perform on-site evaluations and product inspections, offering buyers peace of mind when sourcing materials from international suppliers.

What Are the QC Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate unique challenges when sourcing smooth faux leather. Understanding these nuances can help buyers make informed decisions.

Regional Regulations: What Should Buyers Consider?

Different regions may have specific regulations regarding the use of synthetic materials. Buyers should familiarize themselves with local laws and standards to ensure compliance, particularly in industries such as automotive and furniture manufacturing.

Cultural Considerations: How Do They Impact Sourcing?

Cultural factors may influence supplier relationships and communication. Building trust and understanding local business practices can significantly enhance collaboration between buyers and suppliers.

Illustrative image related to smooth faux leather

Currency and Payment Risks: What to Be Aware Of?

International transactions may involve currency fluctuations and payment risks. Buyers should consider using secure payment methods and negotiating terms that protect against exchange rate volatility.

By understanding the manufacturing processes and quality assurance practices associated with smooth faux leather, B2B buyers can make informed decisions and build strong partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘smooth faux leather’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to procure smooth faux leather. As demand for cost-effective, durable, and aesthetically pleasing materials continues to rise globally, understanding the nuances of sourcing faux leather is essential for making informed purchasing decisions. Whether you’re in Africa, South America, the Middle East, or Europe, following these steps will help you streamline your procurement process.

Illustrative image related to smooth faux leather

Step 1: Define Your Technical Specifications

Understanding your specific needs is crucial before initiating any sourcing process. This includes determining the intended application—be it for upholstery, automotive, or marine use.

– Consider factors like thickness, texture, and color to ensure the faux leather meets your project requirements.

– Document these specifications to provide potential suppliers with clear guidelines.

Step 2: Research and Identify Potential Suppliers

Begin by compiling a list of suppliers who specialize in faux leather. Utilize industry directories, trade shows, and online marketplaces to find reputable vendors.

– Focus on suppliers with a strong presence in your target regions (e.g., Africa, Europe) to minimize logistics issues.

– Look for companies that offer a variety of options, including different types of faux leather, to ensure flexibility in your sourcing.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request company profiles, product samples, and references from previous clients.

– Assess their production capabilities to ensure they can meet your volume and quality requirements.

– Investigate their reputation within the industry by checking reviews and seeking feedback from peers.

Step 4: Verify Supplier Certifications

Quality assurance is paramount when sourcing materials. Verify that suppliers have the necessary certifications to ensure compliance with industry standards.

– Look for certifications related to safety, environmental impact, and manufacturing processes.

– This not only protects your business but also enhances your brand’s credibility by ensuring that your materials are ethically sourced.

Step 5: Request Samples for Quality Assessment

Before finalizing your order, always request samples of the faux leather. This step allows you to physically assess the material’s quality, texture, and color accuracy.

– Evaluate how the material feels and behaves under stress to ensure it meets your durability requirements.

– Testing samples also provides insight into the cleaning and maintenance of the material, which is crucial for your end-users.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, the next step is to negotiate pricing and terms. This is an opportunity to ensure you are getting the best value for your investment.

– Discuss bulk discounts, payment terms, and lead times to avoid any surprises later in the process.

– Be clear about your expectations regarding delivery schedules and quality assurance protocols.

Step 7: Establish a Long-Term Relationship

Building a strong partnership with your supplier can yield benefits beyond a single transaction. Consider creating a long-term relationship to enhance collaboration and communication.

– Regularly communicate your needs and any changes in specifications to foster a proactive relationship.

– A reliable supplier can offer insights into market trends and innovations in faux leather, keeping your business competitive.

Following this checklist will empower you to make informed sourcing decisions for smooth faux leather, ultimately enhancing your product offerings and operational efficiency.

Illustrative image related to smooth faux leather

Comprehensive Cost and Pricing Analysis for smooth faux leather Sourcing

What Are the Key Cost Components in Smooth Faux Leather Sourcing?

When sourcing smooth faux leather, it’s crucial to understand the various cost components that contribute to the overall price. These include:

-

Materials: The primary cost driver for faux leather is the raw materials used in its production, such as polyurethane (PU) or polyvinyl chloride (PVC). PU leather is generally more expensive due to its superior quality and softness compared to PVC.

-

Labor: Labor costs vary by region and can significantly impact the final price. Skilled labor is often required for quality assurance and manufacturing processes, especially for custom designs.

-

Manufacturing Overhead: This includes expenses related to the factory’s operational costs, such as utilities, equipment maintenance, and administrative costs. High overhead can lead to increased pricing for buyers.

-

Tooling: For customized faux leather products, tooling costs can be significant. This includes the expense of creating molds or other equipment necessary for producing specific designs or patterns.

-

Quality Control (QC): Ensuring that the faux leather meets the required standards incurs additional costs. Effective QC processes are vital for maintaining quality, especially in markets that demand high standards.

-

Logistics: Transportation costs can fluctuate based on distance, shipping methods, and freight terms. This is particularly relevant for international buyers who may face additional tariffs or shipping delays.

-

Margin: Suppliers typically add a markup to cover their costs and earn a profit. The margin can vary significantly based on the supplier’s market positioning and the volume of the order.

How Do Price Influencers Affect Faux Leather Sourcing?

Several factors can influence the pricing of smooth faux leather, particularly for B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit prices due to economies of scale. Understanding a supplier’s MOQ is essential for negotiating better rates.

-

Specifications and Customization: Custom designs, colors, or finishes can increase costs. Buyers should be clear about their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., eco-friendly certifications) can command higher prices. Buyers should assess whether these certifications are necessary for their target market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their reliability and service.

-

Incoterms: Understanding international shipping terms (Incoterms) is crucial for calculating the total cost. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can impact overall expenses.

What Are Effective Buyer Tips for Sourcing Smooth Faux Leather?

To optimize sourcing strategies for smooth faux leather, B2B buyers should consider the following tips:

-

Negotiation: Engage in open negotiations with suppliers. Don’t hesitate to discuss pricing, especially when ordering in bulk or establishing long-term partnerships. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, storage, and potential waste. Understanding TCO can help buyers make informed decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and import duties. This knowledge can help in budgeting and negotiating better terms.

-

Request Samples: Before placing large orders, request samples to evaluate quality. This can prevent costly mistakes and ensure that the product meets your specifications.

-

Stay Informed: Market trends and material costs can fluctuate. Regularly review industry reports and maintain communication with suppliers to stay informed about potential price changes.

Disclaimer on Indicative Prices

Pricing for smooth faux leather can vary widely based on the factors outlined above. The prices mentioned in various sources are indicative and should not be considered fixed. Buyers are encouraged to conduct thorough market research and engage with multiple suppliers to determine the best pricing for their specific needs.

Alternatives Analysis: Comparing smooth faux leather With Other Solutions

Exploring Alternatives to Smooth Faux Leather in Upholstery Solutions

In the competitive landscape of upholstery materials, smooth faux leather stands out as a popular choice due to its versatility and affordability. However, B2B buyers should consider a variety of alternatives that might better align with specific project needs, budget constraints, and aesthetic preferences. This section provides a comparison of smooth faux leather with two viable alternatives: genuine leather and PVC vinyl.

Illustrative image related to smooth faux leather

| Comparison Aspect | Smooth Faux Leather | Genuine Leather | PVC Vinyl |

|---|---|---|---|

| Performance | Durable, water-resistant, stain-resistant | Highly durable, ages well, luxurious feel | Durable, but less breathable than leather |

| Cost | Up to 75% less than genuine leather | Premium pricing, can be costly | Generally low-cost, competitive with faux leather |

| Ease of Implementation | Easy to cut and sew, versatile | Requires skilled labor for cutting and sewing | Simple to work with, often available in rolls |

| Maintenance | Easy to clean with a damp cloth | Requires regular conditioning and care | Low maintenance, easy to clean with soap and water |

| Best Use Case | Ideal for commercial and residential upholstery | High-end furniture, luxury items | Budget-friendly projects, temporary applications |

What Are the Pros and Cons of Genuine Leather Compared to Smooth Faux Leather?

Genuine leather is revered for its luxurious appearance and durability. It ages gracefully and develops a unique patina over time, making it a preferred choice for high-end furniture and luxury items. However, the costs associated with genuine leather can be significantly higher, making it less accessible for budget-conscious projects. Additionally, it requires ongoing maintenance to prevent cracking and drying out, which can be a deterrent for some buyers.

How Does PVC Vinyl Stack Up Against Smooth Faux Leather?

PVC vinyl is another alternative that offers a budget-friendly option for upholstery projects. Its low cost and availability in various colors and patterns make it appealing for temporary or high-traffic applications. However, while PVC is durable and easy to clean, it lacks the breathability and luxurious feel of both smooth faux leather and genuine leather. Buyers should consider the specific application and environment when choosing PVC, as it may not offer the same long-term value as other materials.

Making the Right Choice for Your Upholstery Needs

When evaluating upholstery solutions, B2B buyers must consider their specific requirements, including budget, intended use, and desired aesthetics. Smooth faux leather offers a compelling balance of performance, cost, and ease of maintenance, making it suitable for a wide range of applications. However, for projects that prioritize luxury and durability, genuine leather may be the ideal choice despite its higher price point. Conversely, for budget-sensitive projects or short-term applications, PVC vinyl could be the most practical solution. Ultimately, understanding the strengths and weaknesses of each option will empower buyers to make informed decisions that align with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for smooth faux leather

What Are the Key Technical Properties of Smooth Faux Leather?

Smooth faux leather, often regarded as a cost-effective alternative to genuine leather, is characterized by several essential technical properties that are crucial for B2B buyers to understand. Here are some of the most important specifications:

Illustrative image related to smooth faux leather

-

Material Composition

Smooth faux leather is primarily made from synthetic materials such as polyurethane (PU) or polyvinyl chloride (PVC). PU leather is favored for its softness and flexibility, making it difficult to differentiate from genuine leather. Understanding the material composition is vital for buyers, as it influences durability, aesthetics, and maintenance requirements. -

Thickness and Weight

The thickness of faux leather typically ranges from 0.8 mm to 1.5 mm, with weight varying based on the intended application. For instance, upholstery fabrics may require thicker materials for better durability. Buyers should consider the thickness and weight to ensure suitability for specific uses, such as furniture, automotive interiors, or fashion accessories. -

Abrasion Resistance

This property indicates how well the material can withstand wear and tear. Faux leather often undergoes testing based on the Martindale scale, where higher ratings signify better durability. For B2B buyers, selecting materials with high abrasion resistance is essential for applications where longevity is a priority, such as in high-traffic commercial settings. -

Water and Stain Resistance

Smooth faux leather is generally water-resistant and can be treated for enhanced stain resistance. This feature not only simplifies cleaning but also prolongs the material’s lifespan. Buyers in sectors like hospitality or automotive can benefit from these properties as they reduce maintenance costs and improve customer satisfaction. -

Colorfastness

This refers to the material’s ability to retain its color when exposed to light, water, and other environmental factors. High-quality faux leather should exhibit excellent colorfastness, ensuring that the product maintains its appearance over time. B2B buyers should prioritize colorfastness to avoid frequent replacements due to fading or discoloration. -

Flexibility and Softness

The tactile properties of smooth faux leather, such as its flexibility and softness, are critical for user comfort and aesthetic appeal. These characteristics can significantly influence the material’s marketability in consumer goods. Buyers should assess these properties to ensure they meet end-user expectations.

Which Trade Terminology Should B2B Buyers Know for Smooth Faux Leather?

Understanding industry jargon is essential for effective communication and negotiation. Here are some common trade terms relevant to smooth faux leather:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are marketed by another company. In the context of faux leather, buyers may work with OEMs to source custom materials for specific applications. This term is crucial for establishing partnerships and ensuring product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For smooth faux leather, MOQs can vary based on the supplier’s policies and the material’s production process. Understanding MOQ helps buyers plan their inventory and budget effectively. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for a specific quantity of materials. Utilizing RFQs can help businesses compare prices, negotiate terms, and ensure they are receiving competitive offers for faux leather materials. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping responsibilities, risk management, and cost implications associated with faux leather procurement. -

Lead Time

This term refers to the amount of time from placing an order to receiving the goods. In the faux leather industry, lead times can vary based on production schedules and shipping logistics. Buyers should consider lead times when planning their projects to avoid delays. -

Batch Testing

This refers to the process of testing a sample from a production batch to ensure quality and compliance with specifications. For faux leather suppliers, batch testing is essential to maintain product consistency. Buyers should inquire about batch testing practices to ensure the reliability of their sourced materials.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions when procuring smooth faux leather, leading to better product outcomes and enhanced business relationships.

Navigating Market Dynamics and Sourcing Trends in the smooth faux leather Sector

What Are the Current Market Dynamics and Key Trends in the Smooth Faux Leather Sector?

The global market for smooth faux leather is experiencing significant growth, driven by increasing consumer demand for sustainable and ethical alternatives to genuine leather. Key markets in Africa, South America, the Middle East, and Europe are witnessing a shift as businesses recognize the advantages of faux leather, including its cost-effectiveness—often up to 75% less than genuine leather—and its versatility across various applications, such as upholstery, automotive interiors, and fashion accessories.

Illustrative image related to smooth faux leather

Emerging B2B technologies are reshaping sourcing strategies, with companies leveraging online platforms to source high-quality faux leather materials directly from manufacturers. This trend is particularly relevant for international buyers from regions like Nigeria and Saudi Arabia, where direct access to suppliers can streamline procurement processes and reduce costs. Additionally, the rise of digital supply chain management tools is enhancing transparency and efficiency, enabling businesses to track orders, manage inventory, and optimize logistics in real-time.

Sourcing trends are also influenced by changing consumer preferences toward customization. Manufacturers are increasingly offering a wide range of colors and textures, allowing businesses to tailor products to meet specific market demands. The ability to purchase faux leather by the yard further supports this trend, enabling smaller businesses and startups to experiment with unique designs without the commitment of large quantities.

How Does Sustainability and Ethical Sourcing Impact the Faux Leather Industry?

Sustainability is a growing concern among B2B buyers, particularly in regions where environmental regulations are becoming stricter. The production of smooth faux leather has a lower environmental impact compared to traditional leather, as it avoids the harmful tanning processes associated with animal hides. This positions faux leather as an appealing alternative for companies looking to enhance their sustainability credentials.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers who adhere to ethical manufacturing practices, ensuring that the materials used in faux leather production are sourced responsibly. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® Standard 100 are becoming essential for suppliers aiming to demonstrate their commitment to sustainability and consumer safety.

Moreover, the development of innovative eco-friendly materials, such as bio-based polyurethane, is gaining traction. These materials are produced from renewable resources, further reducing the carbon footprint of faux leather products. B2B buyers are advised to prioritize suppliers who offer sustainable options, as this not only aligns with global trends but also caters to a growing segment of environmentally conscious consumers.

What Is the Historical Context of Faux Leather Development in the B2B Market?

The evolution of faux leather can be traced back to the early 20th century, with the introduction of synthetic materials that sought to replicate the aesthetics and functionality of genuine leather. The invention of Naugahyde in the 1920s marked a significant milestone, as it provided a durable, cost-effective alternative that quickly gained popularity in various industries, including upholstery and automotive manufacturing.

Over the decades, advancements in technology have led to the development of more sophisticated faux leather options, such as polyurethane (PU) leather, which closely mimics the softness and texture of genuine leather. Today, smooth faux leather is not only recognized for its affordability and durability but also for its potential to meet modern demands for sustainability and ethical production. As the market continues to evolve, B2B buyers can expect ongoing innovations that enhance the performance and appeal of faux leather products.

Frequently Asked Questions (FAQs) for B2B Buyers of smooth faux leather

-

How do I ensure the quality of smooth faux leather before purchasing?

To ensure the quality of smooth faux leather, request samples from suppliers before committing to a large order. Evaluate the texture, durability, and appearance to ensure it meets your specifications. Additionally, inquire about the manufacturing process and any certifications that indicate compliance with international quality standards. Establishing clear quality assurance protocols and conducting on-site inspections can further help in assessing the supplier’s capabilities and product integrity. -

What are the common applications of smooth faux leather in various industries?

Smooth faux leather is versatile and widely used in several industries, including furniture upholstery, automotive interiors, fashion accessories, and marine applications. Its durability, ease of cleaning, and aesthetic appeal make it suitable for residential and commercial projects alike. Specifically, it is often chosen for seating in restaurants and hotels, as well as for stylish totes and bags in the fashion sector, providing a leather-like appearance without the associated costs. -

What factors should I consider when choosing a supplier for smooth faux leather?

When selecting a supplier, consider factors such as their reputation, production capacity, and experience in the faux leather industry. Check for customer reviews and testimonials to gauge reliability. It’s also important to evaluate their compliance with international trade regulations, payment terms, and delivery capabilities. Establishing a strong communication channel and confirming their ability to provide customization options can enhance your sourcing experience. -

What are the minimum order quantities (MOQs) for smooth faux leather?

Minimum order quantities for smooth faux leather can vary significantly based on the supplier and the specific fabric type. Generally, MOQs can range from 10 yards to several hundred yards for bulk orders. It’s essential to discuss MOQs with suppliers upfront, especially if you are a smaller business or just starting. Some suppliers may offer flexible options or discounts for larger orders, which can be beneficial for cost management. -

What payment terms are typically offered by suppliers of smooth faux leather?

Payment terms can differ by supplier, but common practices include upfront payment, partial payment upon order confirmation, and the balance due upon shipment. Some suppliers may offer credit terms for established businesses. It’s crucial to clarify payment methods accepted, such as bank transfers or letters of credit, and to ensure that all terms are documented to avoid misunderstandings. Negotiating favorable terms can help in managing cash flow effectively. -

How do I handle shipping and logistics for my faux leather orders?

Shipping and logistics for faux leather orders involve coordinating with suppliers to ensure timely delivery. Confirm the shipping methods available, estimated delivery times, and associated costs. Depending on your location, consider whether the supplier can handle international logistics or if you need to engage a third-party logistics provider. Ensure that customs regulations are understood and complied with to avoid delays upon arrival in your country. -

Can I customize the color or texture of the smooth faux leather?

Yes, many suppliers offer customization options for color, texture, and even pattern designs in smooth faux leather. When discussing your requirements, provide clear specifications and any design samples you have. Custom orders may require larger MOQs and longer lead times, so it’s advisable to plan accordingly. Requesting a prototype or sample of the customized material can help ensure it meets your expectations before full production. -

What are the cleaning and maintenance requirements for smooth faux leather?

Smooth faux leather is known for its low maintenance and ease of cleaning. Typically, it can be cleaned with a damp cloth and mild soap to remove dirt and stains. Avoid harsh chemicals that could damage the surface. Regular care, such as wiping down surfaces and avoiding prolonged exposure to direct sunlight, can extend the life of the material. Understanding these maintenance requirements is vital for ensuring customer satisfaction in applications such as furniture and automotive interiors.

Top 6 Smooth Faux Leather Manufacturers & Suppliers List

1. PU Leather & Faux Leather – Vinyl Upholstery Fabric

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric

– Free Shipping Coupon Code: SHIPFREE for most $199 orders

– Available for wholesale purchase by the yard or full roll

– Brands: Naugahyde, Omnova Boltaflex, Nassimi, Spradling

– Applications: Furniture, Automotive, Marine, Commercial projects

– Features: Durable, easy to clean, available in rich colors, significantly lower cost than genuine leat…

2. All About Fabrics – Smooth Textured Faux Leather in Latte Tan

Domain: allaboutfabrics.com

Registered: 2002 (23 years)

Introduction: {‘name’: ‘Smooth Textured Faux Leather Fabric in Latte Tan’, ‘width’: ’55 inches’, ‘primary_fiber’: ‘100% Vinyl’, ‘description’: ‘This smooth textured faux leather fabric is featured in latte tan. Uses include upholstery, seat covers and totes.’, ‘cleaning_instructions’: ‘Spot clean with water and mild soap’, ‘sku’: ‘A47C 1/21’, ‘regular_price’: ‘$29.97’, ‘shipping_info’: ‘Shipping available to Ca…

3. Fashion Fabric LA – Soft Skin Faux Leather Vinyl Fabric

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Introduction: Soft Skin Faux Leather Upholstery Apparel Vinyl Fabric – Sold By The Yard

4. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather by Sallie Tomato is a vegan material that serves as an alternative to leather or cork fabric, available in various colors and textures. It is soft, pliable, and comes in eight different textures: Weave, Pebble, Legacy, Shimmer, Crocodile, Alligator, Ostrich, and Rugged. Select Faux Leathers are available in Lite Legacy, an ultra-thin material. The fabric is sold by quarter yard, and t…

5. Faux Leather Care – Wrinkle Removal Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Faux leather pieces, 100% polyester, arrived folded with wrinkles. Suggestions for removing wrinkles include laying flat for a few hours, using steam from a shower, or hovering an iron on the lowest setting with a towel in between. Caution advised to avoid melting or distorting the material.

6. PIP Supply – Cream Solid Smooth Faux Leather Sheets

Domain: pipsupply.com

Registered: 2018 (7 years)

Introduction: Cream Solid Smooth Faux Leather Sheets

Strategic Sourcing Conclusion and Outlook for smooth faux leather

In the evolving landscape of faux leather sourcing, the strategic advantages are clear. Smooth faux leather offers a cost-effective, durable, and versatile alternative to genuine leather, making it an attractive option for various industries, including automotive, upholstery, and fashion. By leveraging its affordability—up to 75% less than genuine leather—international B2B buyers can optimize their supply chains while maintaining high-quality standards. The ease of maintenance and wide range of colors and styles further enhance its appeal, enabling businesses to cater to diverse consumer preferences.

As you consider your sourcing strategies, prioritizing suppliers that offer reliable quality and competitive pricing will be essential. Engaging with manufacturers who understand the specific needs of your market—be it in Nigeria, Saudi Arabia, or beyond—will facilitate smoother transactions and foster long-term partnerships.

Looking ahead, the demand for sustainable and animal-friendly materials is likely to grow, making faux leather an even more relevant choice. Now is the time to explore new sourcing opportunities and align your procurement strategies with market trends. Embrace the potential of smooth faux leather to elevate your offerings and meet the evolving demands of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to smooth faux leather

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.