Introduction: Navigating the Global Market for leather lining material

Navigating the global market for leather lining material presents a unique set of challenges for international B2B buyers, particularly when sourcing high-quality materials that meet specific project requirements. The complexity of selecting appropriate leather linings—whether for fashion, upholstery, or accessories—can be daunting, especially when considering varying standards across regions like Africa, South America, the Middle East, and Europe. This guide aims to demystify the process by providing an in-depth overview of leather lining materials, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

As buyers delve into this comprehensive resource, they will discover a variety of leather lining options, from economical fabric linings to premium lambskin and goatskin materials. Each section is designed to empower decision-makers with actionable insights that facilitate informed purchasing decisions. With a focus on quality and reliability, this guide not only aids in identifying reputable suppliers but also helps buyers understand the nuances of pricing and product specifications.

By addressing the key pain points in sourcing leather lining materials, this guide equips international B2B buyers with the knowledge necessary to navigate the complexities of the market confidently. Ultimately, it serves as a valuable tool in optimizing supply chains and enhancing product offerings across diverse industries.

Table Of Contents

- Top 7 Leather Lining Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather lining material

- Understanding leather lining material Types and Variations

- Key Industrial Applications of leather lining material

- 3 Common User Pain Points for ‘leather lining material’ & Their Solutions

- Strategic Material Selection Guide for leather lining material

- In-depth Look: Manufacturing Processes and Quality Assurance for leather lining material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather lining material’

- Comprehensive Cost and Pricing Analysis for leather lining material Sourcing

- Alternatives Analysis: Comparing leather lining material With Other Solutions

- Essential Technical Properties and Trade Terminology for leather lining material

- Navigating Market Dynamics and Sourcing Trends in the leather lining material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather lining material

- Strategic Sourcing Conclusion and Outlook for leather lining material

- Important Disclaimer & Terms of Use

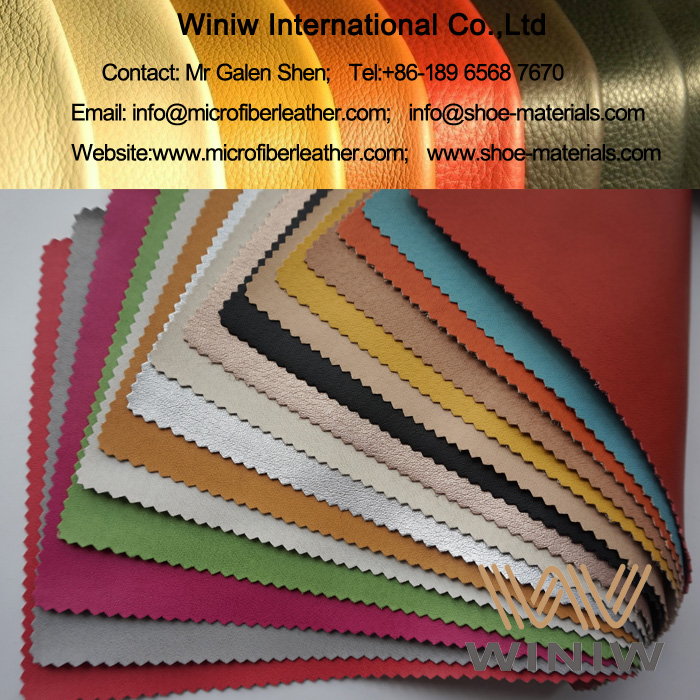

Understanding leather lining material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lambskin Leather | Soft, supple texture with a smooth finish; lightweight | High-end fashion, luxury goods, and accessories | Pros: Luxurious feel, excellent drape; Cons: Higher cost, less durable than thicker leathers. |

| Goatskin Leather | Durable yet flexible; good breathability; available in various finishes | Garments, bags, and upholstery | Pros: Versatile, lightweight; Cons: May be less resistant to wear than thicker options. |

| Pigskin Leather | Chrome-tanned, with a rich suede side; soft and pliable | Affordable linings for bags, wallets, and footwear | Pros: Cost-effective, good texture; Cons: Can lack the prestige of more expensive leathers. |

| Suede Leather | Soft, velvety texture; available in multiple colors | Fashion accessories, shoes, and upholstery | Pros: Attractive appearance, comfortable; Cons: Requires more maintenance, sensitive to stains. |

| Fabric Lining with Adhesive | Thin, lightweight fabric with a self-adhesive backing | DIY projects, cost-effective lining solutions | Pros: Easy to apply, budget-friendly; Cons: Limited durability compared to leather options. |

What Are the Key Characteristics of Lambskin Leather for B2B Buyers?

Lambskin leather is known for its luxurious softness and lightweight nature, making it a popular choice for high-end fashion and luxury goods. It features a smooth finish that enhances the aesthetic appeal of products such as bags and garments. B2B buyers should consider the cost implications, as lambskin is often more expensive than other leather types. Additionally, while it offers an exceptional drape, it may not be as durable as thicker leathers, making it essential to evaluate the intended use before purchasing.

How Does Goatskin Leather Stand Out in the Market?

Goatskin leather is recognized for its durability and flexibility, making it suitable for a wide range of applications, from garments to upholstery. Its breathability and ability to take on various finishes provide buyers with versatility in design. When sourcing goatskin, B2B buyers should assess the leather’s thickness and finish to ensure it meets their specific needs. While it is lightweight and offers good value, it may not withstand wear as effectively as thicker leather options, necessitating careful consideration based on product longevity.

What Are the Advantages of Using Pigskin Leather?

Pigskin leather is a cost-effective option that features a chrome-tanned finish, providing a rich suede side that adds texture to products. It is commonly used for linings in bags, wallets, and footwear, making it an attractive choice for budget-conscious B2B buyers. While it offers a good balance of affordability and quality, buyers should note that pigskin may lack the prestige associated with more premium leather types. Understanding the target market’s preferences is crucial when selecting pigskin for production.

Illustrative image related to leather lining material

Why Choose Suede Leather for Fashion Applications?

Suede leather is characterized by its soft, velvety texture and is available in a variety of colors, making it ideal for fashion accessories and shoes. It provides a unique aesthetic that appeals to consumers seeking comfort and style. However, B2B buyers should be aware that suede requires more maintenance than other leathers, as it is sensitive to stains and moisture. This makes it essential to educate end-users on proper care to maintain the product’s quality over time.

What Are the Benefits of Fabric Lining with Adhesive for B2B Projects?

Fabric lining with an adhesive backing offers a lightweight and budget-friendly solution for various DIY projects. Its ease of application makes it a popular choice among manufacturers looking to streamline production processes. However, while it is cost-effective, buyers should consider its limited durability compared to traditional leather linings. Assessing the specific project requirements will help determine whether this option meets the necessary standards for quality and longevity.

Key Industrial Applications of leather lining material

| Industry/Sector | Specific Application of Leather Lining Material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Lining for jackets, coats, and handbags | Enhances durability and aesthetic appeal of products | Quality of leather, weight, and thickness for specific designs |

| Automotive | Interior upholstery and seat covers | Provides luxury feel and long-lasting wear resistance | Compliance with automotive standards and fire resistance |

| Footwear | Inner linings for shoes and boots | Improves comfort and breathability for end-users | Sourcing sustainable and eco-friendly materials |

| Furniture | Upholstery lining for sofas and chairs | Adds comfort and enhances the overall look of furniture | Color options and matching with existing materials |

| Sporting Goods | Lining for bags and protective gear | Increases durability and user comfort | Weight specifications and compatibility with other materials |

How is Leather Lining Material Used in Fashion and Apparel?

In the fashion and apparel industry, leather lining material is predominantly used for jackets, coats, and handbags. This material not only elevates the aesthetic appeal but also enhances the durability of the products. Buyers from regions like Europe and the Middle East often look for high-quality leather that meets specific design requirements, such as weight and thickness. Additionally, they may seek eco-friendly options to align with current sustainability trends.

What Role Does Leather Lining Material Play in Automotive Interiors?

In the automotive sector, leather lining material is crucial for interior upholstery and seat covers. It provides a luxurious feel while ensuring durability against wear and tear. International buyers, particularly from Africa and South America, must consider compliance with stringent automotive standards, including fire resistance and environmental regulations. Sourcing leather that meets these criteria ensures safety and enhances the overall driving experience.

How is Leather Lining Material Utilized in Footwear?

Leather lining material is widely utilized in the footwear industry, particularly for inner linings in shoes and boots. Its natural breathability and comfort significantly enhance the wearer’s experience. When sourcing leather for footwear, buyers must prioritize sustainable options and consider the specific weight and thickness that align with their design needs. This focus on comfort and sustainability is increasingly important to consumers across various markets.

Illustrative image related to leather lining material

What Benefits Does Leather Lining Provide in Furniture?

In the furniture industry, leather lining is often used for upholstery in sofas and chairs. This material not only adds a touch of elegance but also increases the comfort level of the furniture. Buyers should focus on color options and the ability to match the leather lining with existing materials to maintain a cohesive look. Additionally, sourcing high-quality leather ensures longevity, making it a worthwhile investment for furniture manufacturers.

How is Leather Lining Material Applied in Sporting Goods?

In the sporting goods sector, leather lining material is commonly used in bags and protective gear. Its durability and comfort enhance the user experience, making it a preferred choice for manufacturers. When sourcing leather for this application, businesses should consider weight specifications and compatibility with other materials to ensure optimal performance. This attention to detail can differentiate products in a competitive market, appealing to both amateur and professional athletes.

3 Common User Pain Points for ‘leather lining material’ & Their Solutions

Scenario 1: Sourcing Quality Leather Lining Materials Efficiently

The Problem: B2B buyers often face challenges in sourcing high-quality leather lining materials that meet their specifications and price points. In regions like Africa and South America, buyers may struggle with limited supplier options or inconsistent product quality. This can lead to delays in production, increased costs, and ultimately dissatisfied customers. Additionally, the vast array of leather types and grades available can make it difficult for buyers to identify which materials will best suit their specific applications, whether it’s for luxury handbags, footwear, or upholstery.

The Solution: To overcome sourcing challenges, buyers should prioritize building relationships with reputable suppliers who offer transparency in their product specifications and sourcing practices. Conducting thorough research on potential suppliers, including checking reviews and requesting samples, can help ensure quality. It’s advisable to establish a clear communication channel with suppliers to discuss specific needs, such as thickness, finish, and durability. Buyers should also consider leveraging online platforms that specialize in leather goods, which often provide detailed descriptions and customer feedback, aiding in informed decision-making. Engaging in trade shows or leather fairs can also provide valuable networking opportunities and firsthand experience with new materials.

Illustrative image related to leather lining material

Scenario 2: Managing Costs While Maintaining Quality

The Problem: Cost management is a critical concern for B2B buyers, particularly in competitive markets. Buyers often feel pressured to reduce costs while still providing high-quality products, leading to a dilemma when selecting leather lining materials. Opting for cheaper alternatives can compromise the product’s quality, affecting brand reputation and customer satisfaction. In regions like Europe, where consumers expect superior craftsmanship, this balancing act becomes even more pronounced.

The Solution: To effectively manage costs while ensuring quality, buyers should explore bulk purchasing options or long-term contracts with suppliers. This can lead to significant discounts and better pricing stability over time. Additionally, buyers should evaluate the total cost of ownership rather than just the initial purchase price. This includes considering factors like material longevity, maintenance needs, and potential returns or failures. Implementing a strict quality control process to assess the leather’s performance in real-world applications can also help avoid costly mistakes down the line. Investing in training for staff on how to properly handle and utilize leather lining materials can further enhance product quality and reduce waste.

Scenario 3: Ensuring Compliance with Regional Regulations

The Problem: As international trade in leather goods expands, compliance with various regional regulations regarding material sourcing and processing has become increasingly complex. For B2B buyers, especially those operating in the Middle East and Europe, navigating these regulations can be daunting. Non-compliance not only risks hefty fines but can also damage relationships with customers who prioritize ethically sourced and environmentally friendly materials.

The Solution: Buyers should proactively educate themselves on the specific regulations that pertain to leather sourcing in their target markets. This may involve familiarizing themselves with standards related to chemical treatments, environmental impact, and animal welfare. Partnering with suppliers who are certified and can provide documentation of compliance is crucial. Establishing a compliance checklist that includes verifying supplier certifications and conducting regular audits can help mitigate risks. Furthermore, engaging with industry associations or legal advisors specializing in trade regulations can provide valuable insights and keep buyers informed about changes in compliance requirements. Investing in sustainable and ethically sourced materials can also enhance brand reputation and appeal to a growing market segment that values corporate social responsibility.

Strategic Material Selection Guide for leather lining material

What Are the Key Properties of Common Leather Lining Materials?

When selecting leather lining materials, it is essential to consider their properties, performance, and suitability for various applications. Here, we analyze four common materials used for leather lining: lambskin, goatskin, pigskin, and synthetic fabric linings.

1. Lambskin Leather

Key Properties: Lambskin leather is known for its softness and fine grain, providing an elegant finish. It typically has a thickness of 0.8mm to 2mm, offering good flexibility while maintaining strength.

Pros & Cons: The primary advantage of lambskin is its luxurious feel and aesthetic appeal, making it ideal for high-end products. However, it is less durable than other leathers and may be susceptible to scratches and wear, limiting its use in rugged applications. Additionally, lambskin can be more expensive, which may affect cost-sensitive projects.

Impact on Application: Lambskin is particularly suitable for luxury goods, fashion items, and high-quality accessories. Its compatibility with various dyes and finishes allows for a wide range of design options.

Illustrative image related to leather lining material

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer lambskin for its premium quality. Compliance with EU regulations on leather sourcing and sustainability practices is crucial, as is adherence to standards such as DIN for product safety.

2. Goatskin Leather

Key Properties: Goatskin leather is known for its durability and resistance to wear. Typically ranging from 0.6mm to 1.2mm in thickness, it offers a balance between softness and strength.

Pros & Cons: One of the key advantages of goatskin is its excellent breathability and moisture-wicking properties, making it suitable for various applications, including garments and upholstery. However, it may not have the same luxurious feel as lambskin, which could be a drawback for high-end products. Goatskin is generally more affordable than lambskin, making it a cost-effective option.

Illustrative image related to leather lining material

Impact on Application: Goatskin is versatile and can be used in clothing, bags, and various accessories. Its durability makes it suitable for items that require frequent use.

Considerations for International Buyers: Buyers in Africa and South America may find goatskin appealing due to its affordability and availability. It is essential to ensure compliance with local leather quality standards and environmental regulations.

3. Pigskin Leather

Key Properties: Pigskin leather is characterized by its robust nature and is often thicker than other leathers, typically ranging from 1.5mm to 2mm. It has a unique texture that can provide an appealing aesthetic.

Pros & Cons: The primary advantage of pigskin is its durability and resistance to moisture, making it suitable for a variety of applications, including workwear and outdoor gear. However, its thickness may limit its use in products requiring a more refined finish. Pigskin is generally less expensive than lambskin and goatskin, making it an economical choice.

Impact on Application: Pigskin is often used in rugged applications, including bags, footwear, and work gear. Its durability ensures longevity, which is a significant consideration for end-users.

Considerations for International Buyers: Buyers from regions with harsh climates, such as the Middle East, may favor pigskin for its moisture resistance. Understanding local market preferences and compliance with international leather standards is vital.

4. Synthetic Fabric Linings

Key Properties: Synthetic fabric linings, such as polyester or nylon, are lightweight and often feature a self-adhesive backing for easy application. They typically have a thickness of around 0.1mm.

Pros & Cons: The main advantage of synthetic linings is their cost-effectiveness and ease of use. They are resistant to moisture and easy to clean, making them suitable for various applications. However, they may not provide the same aesthetic appeal or durability as natural leather options, which can be a limitation for high-end products.

Illustrative image related to leather lining material

Impact on Application: Synthetic linings are commonly used in budget-friendly products and can be ideal for items that require frequent cleaning or exposure to moisture.

Considerations for International Buyers: Buyers from cost-sensitive markets in Africa and South America may find synthetic linings appealing. It’s important to ensure compliance with local regulations regarding synthetic materials and their environmental impact.

Summary Table of Leather Lining Materials

| المواد | Typical Use Case for leather lining material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lambskin Leather | Luxury goods, fashion items | Luxurious feel and aesthetic | Less durable, higher cost | عالية |

| Goatskin Leather | Garments, bags, accessories | Durable and breathable | Less luxurious feel | Medium |

| Pigskin Leather | Workwear, outdoor gear | Highly durable and moisture-resistant | Thicker, less refined finish | منخفضة |

| Synthetic Fabric | Budget-friendly products | Cost-effective and easy to use | Lacks aesthetic appeal, less durable | منخفضة |

This guide aims to equip international B2B buyers with the insights necessary for making informed decisions regarding leather lining materials, ensuring that they select the right product for their specific applications and market demands.

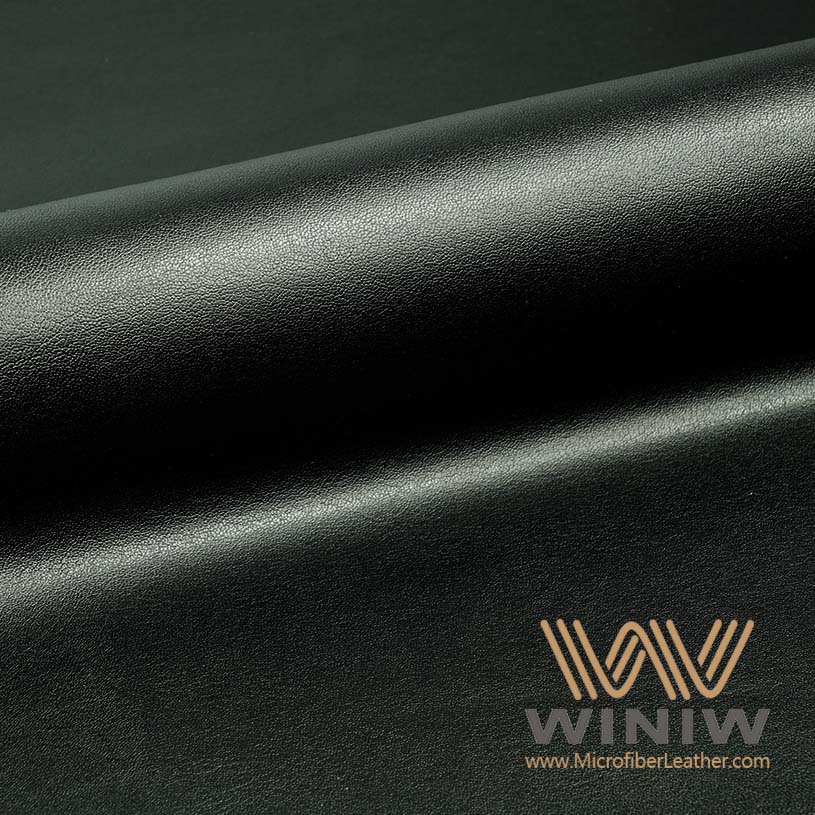

In-depth Look: Manufacturing Processes and Quality Assurance for leather lining material

What Are the Key Stages in the Manufacturing Process of Leather Lining Material?

The manufacturing process of leather lining material involves several crucial stages that ensure the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing of leather lining material involves sourcing high-quality hides and skins. Depending on the desired characteristics, such as softness, durability, and breathability, manufacturers may choose from various types of leather, including lambskin, goatskin, and pigskin. The hides undergo initial processing, which may involve soaking, liming, and fleshing to remove impurities and prepare them for tanning.

Once the hides are processed, they are tanned using either chrome or vegetable tanning methods. Chrome tanning is faster and produces a more supple leather, while vegetable tanning is more environmentally friendly and offers greater longevity. This stage is crucial as it determines the leather’s final properties.

What Techniques Are Used in Forming Leather Lining Materials?

Forming involves cutting the tanned leather into the desired shapes and sizes. Manufacturers utilize advanced cutting technologies such as die-cutting and laser cutting to achieve precise dimensions. This accuracy is essential for ensuring that the lining fits perfectly within the final product, whether it be a handbag, wallet, or garment.

After cutting, the leather pieces may undergo various treatments, such as embossing or surface finishing, to enhance their aesthetic appeal. Techniques such as aniline dyeing can be employed to add color while maintaining the natural texture of the leather.

Illustrative image related to leather lining material

How Is Leather Lining Material Assembled?

During the assembly stage, the cut leather pieces are stitched together using high-quality threads. This process often involves using specialized sewing machines that can handle various thicknesses of leather. Manufacturers may also apply adhesives, particularly for self-adhesive linings, which simplify the application process for end-users.

Quality at this stage is paramount, as improper stitching can lead to durability issues in the final product. For instance, double stitching may be employed in high-stress areas to enhance strength and longevity.

What Finishing Processes Are Critical for Leather Lining Materials?

The finishing stage encompasses a variety of treatments designed to enhance the leather’s appearance and performance. This may include applying protective coatings to improve water and stain resistance. Additionally, a final inspection is conducted to ensure that the leather meets the desired quality standards.

Finishing also involves conditioning the leather to maintain its suppleness and prevent cracking. This is particularly important for products intended for high-end markets, where the tactile quality of leather is crucial.

What International Quality Assurance Standards Are Relevant for Leather Lining Materials?

Quality assurance is a critical aspect of the leather lining material manufacturing process. International standards such as ISO 9001 ensure that manufacturers implement effective quality management systems. Compliance with these standards demonstrates a commitment to consistent quality and customer satisfaction.

For specific applications, industry standards such as CE (Conformité Européenne) certification may be necessary, particularly for products sold in Europe. CE certification indicates that the product meets safety and environmental requirements.

What Are the Key Quality Control Checkpoints in Leather Lining Production?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established to ensure product quality. These checkpoints include:

-

Incoming Quality Control (IQC): Raw materials, including leather hides, are inspected upon arrival to verify their quality and compliance with specifications.

-

In-Process Quality Control (IPQC): Inspections occur at various stages of production, such as during cutting, stitching, and finishing. This ensures any defects are identified early in the process.

-

Final Quality Control (FQC): The completed products undergo a thorough inspection to confirm they meet all quality standards before shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers. Conducting audits of the manufacturing facility is one effective method. These audits allow buyers to assess the supplier’s adherence to quality standards and their overall manufacturing processes.

Illustrative image related to leather lining material

Additionally, requesting quality control reports can provide insights into the supplier’s QC history, including defect rates and corrective actions taken. Third-party inspections are another option, offering an unbiased assessment of the supplier’s quality practices.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of regional differences in quality standards and regulations. For instance, European buyers may have stricter compliance requirements compared to those in other regions.

It is also essential for buyers to consider language barriers and cultural differences that may affect communication regarding quality expectations. Establishing clear specifications and quality agreements upfront can mitigate misunderstandings and ensure that the final product aligns with the buyer’s expectations.

In conclusion, understanding the manufacturing processes and quality assurance mechanisms for leather lining materials is vital for B2B buyers. By focusing on the key stages of production, relevant quality standards, and effective verification methods, buyers can make informed decisions when sourcing leather lining materials, ensuring that they receive products that meet their quality and performance requirements.

Illustrative image related to leather lining material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather lining material’

When sourcing leather lining material, it’s essential to follow a systematic approach to ensure you make informed decisions that align with your business needs. This checklist will guide you through the key steps to procure high-quality leather lining materials effectively.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your leather lining material. Consider factors such as thickness, texture, and color that match your product design.

– السُمك: For instance, materials can range from 0.1mm to 1.2mm, influencing the durability and flexibility of your final product.

– Texture and Finish: Decide whether you need a smooth finish for a high-end product or a suede texture for casual items.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers that specialize in leather lining materials. Look for companies with a solid reputation in the industry.

– Online Reviews: Check platforms for reviews and feedback from other B2B buyers.

– Industry Connections: Leverage your network to gather recommendations for reliable suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Certifications: Ensure suppliers have relevant certifications that guarantee the quality and sustainability of their materials.

– Samples: Ask for material samples to assess the quality firsthand before making bulk purchases.

Step 4: Compare Pricing and Terms

Gather pricing information from multiple suppliers to ensure you receive competitive offers. Pay attention not just to the base price but also to the terms of sale.

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

– Shipping and Returns: Clarify shipping costs and return policies to avoid unexpected expenses.

Step 5: Assess Quality Control Processes

Inquire about the quality control measures that suppliers have in place. Understanding their processes will help ensure that the materials meet your standards.

– Testing Procedures: Ask about any testing conducted on the materials, including durability and wear resistance.

– Production Standards: Ensure the supplier adheres to industry standards, which can be crucial for your brand’s reputation.

Step 6: Negotiate Terms and Place Orders

Once you’ve selected a supplier, negotiate terms that work for both parties. Discuss lead times, payment terms, and any specific requirements you may have.

– Flexibility: Be clear about your needs, especially if you expect fluctuations in order sizes.

– Contractual Agreements: Consider drafting a contract that outlines all agreed terms to protect your interests.

Step 7: Monitor and Evaluate Supplier Performance

After placing your order, continuously monitor the supplier’s performance and the quality of the materials received.

– Feedback Loop: Establish a feedback mechanism to communicate any issues or concerns that arise post-purchase.

– Long-term Relationships: Building a strong relationship with your supplier can lead to better service and terms in future transactions.

By following these steps, you can streamline your sourcing process for leather lining materials, ensuring that you make well-informed decisions that contribute to the success of your business.

Comprehensive Cost and Pricing Analysis for leather lining material Sourcing

In the competitive landscape of leather lining material sourcing, understanding the cost structure and pricing dynamics is vital for international B2B buyers. This analysis delves into the various cost components, price influencers, and practical tips for negotiating favorable terms, particularly for buyers in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Leather Lining Materials?

The cost structure of leather lining materials encompasses several critical components:

-

Materials: The primary cost driver, this includes the type of leather (e.g., lambskin, goatskin, pigskin) and any additional features like adhesive backing or specialized finishes. High-quality, certified materials often come at a premium but can enhance the product’s durability and aesthetics.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. Skilled labor is essential for processing high-quality leather, impacting the overall cost.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Efficient production processes can help reduce overhead costs and improve pricing for bulk orders.

-

Tooling and Customization: Custom tooling for specific designs or specifications can increase initial costs. Buyers should assess whether customization is necessary, as standard options may provide cost savings.

-

Quality Control (QC): Ensuring that materials meet quality standards can involve additional testing and inspections. This is particularly important for international shipments, where compliance with various regulations is crucial.

-

Logistics: Shipping costs, including freight and insurance, play a significant role in the total cost. Factors such as distance, mode of transport, and Incoterms will affect logistics expenses.

-

Margin: Suppliers will typically add a margin to cover risks and profit. Understanding the average margins in your specific market can assist in evaluating supplier pricing.

How Do Price Influencers Impact Leather Lining Material Costs?

Several factors influence the pricing of leather lining materials:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders can lead to significant discounts. Suppliers often provide better pricing for larger quantities, which can be a decisive factor for businesses with high demand.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should weigh the benefits of tailored products against standard options that may be more cost-effective.

-

Material Quality and Certifications: Higher-quality leathers with certifications (e.g., eco-friendly or cruelty-free) often command higher prices. Buyers should consider the value these certifications add to their brand.

-

Supplier Factors: Reliability, reputation, and customer service are critical. A well-established supplier may charge a premium but can offer assurance regarding quality and delivery timelines.

-

Incoterms: Understanding the terms of sale (e.g., FOB, CIF) is essential as they define who bears shipping costs and risks. This can significantly impact the total cost.

What Negotiation Strategies Can Buyers Use to Enhance Cost-Efficiency?

-

Research and Benchmarking: Before entering negotiations, buyers should research market prices and competitor offerings. This knowledge allows for informed discussions and better negotiation leverage.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms. Frequent communication and trust can result in more favorable negotiations.

-

Total Cost of Ownership (TCO): Buyers should consider not just the initial purchase price but the overall TCO, including maintenance, durability, and potential resale value. This perspective can guide purchasing decisions.

-

Flexibility in Specifications: Being open to standard products instead of custom solutions can yield significant savings. Suppliers are often more willing to negotiate on items that don’t require bespoke manufacturing.

-

Payment Terms and Conditions: Negotiating favorable payment terms can help manage cash flow. Discounts for upfront payments or extended payment terms can enhance financial flexibility.

الخاتمة

Navigating the complexities of leather lining material sourcing requires a comprehensive understanding of cost components, price influencers, and effective negotiation strategies. By leveraging these insights, B2B buyers in diverse markets can make informed decisions that optimize their procurement processes. As a final note, prices can vary significantly based on market conditions, so always verify current pricing with suppliers to ensure accuracy in budgeting.

Alternatives Analysis: Comparing leather lining material With Other Solutions

Exploring Alternatives to Leather Lining Material

When selecting materials for product lining, it’s essential to consider various alternatives to leather that may fit specific needs and budgets. While leather lining is renowned for its durability and aesthetic appeal, other materials can provide competitive advantages in terms of cost, performance, and ease of use. Below, we explore two viable alternatives: fabric lining with a self-adhesive backing and synthetic suede.

| Comparison Aspect | Leather Lining Material | Fabric Lining (Self-Adhesive) | Synthetic Suede |

|---|---|---|---|

| Performance | High durability and breathability | Moderate durability, lightweight | Good durability, soft feel |

| Cost | Generally higher (varies by type) | Lower cost (approx. $14.99) | Moderate cost (varies widely) |

| Ease of Implementation | Requires skilled labor for cutting and sewing | Easy to apply, DIY-friendly | Moderate; may require adhesives |

| Maintenance | Requires regular conditioning | Easy to clean, less upkeep | Easy to maintain, washable |

| Best Use Case | Luxury products, high-end items | Budget-friendly applications | Apparel, accessories, and home decor |

What Are the Benefits and Drawbacks of Fabric Lining with Self-Adhesive Backing?

Fabric lining with a self-adhesive backing offers a cost-effective and user-friendly alternative to leather. It provides moderate durability and is lightweight, making it suitable for projects where bulk reduction is essential, such as wallets or lightweight bags. Its easy application process allows manufacturers to save on labor costs, as it can be applied quickly without specialized skills. However, it may not provide the same aesthetic appeal or longevity as leather, potentially limiting its use in high-end products.

How Does Synthetic Suede Compare to Leather Lining Material?

Synthetic suede is another alternative that mimics the look and feel of real suede while often being more affordable. It boasts good durability and a soft texture, making it appealing for a range of applications, from clothing to accessories. Additionally, synthetic suede is generally easier to maintain, as it can often be washed without the need for special conditioners. However, its performance may not match the breathability and longevity of leather, and the synthetic material may not appeal to consumers seeking natural products.

Illustrative image related to leather lining material

How Can B2B Buyers Choose the Right Lining Material?

When deciding between leather lining and its alternatives, B2B buyers should consider the specific requirements of their products and target market. For luxury items where durability and aesthetics are paramount, leather remains the top choice. Conversely, for budget-sensitive projects or those requiring quick application, self-adhesive fabric lining may be more suitable. Synthetic suede offers a balanced approach, appealing to buyers looking for a soft, durable option that is easier to maintain. Ultimately, evaluating these factors will help buyers select the most appropriate lining material for their needs, ensuring both quality and cost-effectiveness in their offerings.

Essential Technical Properties and Trade Terminology for leather lining material

What Are the Key Technical Properties of Leather Lining Material?

When selecting leather lining materials, B2B buyers must understand specific technical properties that influence product quality, durability, and application suitability. Here are essential specifications to consider:

-

Material Grade

Material grade refers to the quality classification of the leather used in lining. Higher grades, such as full-grain or top-grain leather, are generally more durable and aesthetically pleasing, making them suitable for premium products. Understanding material grade is crucial for buyers looking to position their products in a specific market segment or meet customer expectations for quality. -

Thickness

Thickness is typically measured in ounces (oz) or millimeters (mm). For instance, a 2 oz leather lining is approximately 0.8 mm thick. The thickness of the lining material affects its weight, flexibility, and overall appearance. Buyers must choose the right thickness based on the intended use, as thicker materials may offer more durability, while thinner options can provide a sleeker finish. -

Tolerance

Tolerance refers to the allowable variation in the thickness or dimensions of the leather lining. A tolerance of +/- 0.15 mm is common for many leather products. Understanding tolerance is vital for manufacturers to ensure consistency in production, which directly impacts the quality and fit of the final product. -

Breathability

Breathability is a key property of leather lining, especially in applications such as footwear or garments. It refers to the material’s ability to allow moisture and air to pass through. Breathable linings help regulate temperature and moisture, enhancing comfort for the end user. Buyers should prioritize breathable materials to ensure product longevity and user satisfaction. -

Adhesive Properties

Many leather linings come with self-adhesive backings, allowing for easier assembly and application. The strength and durability of the adhesive are crucial, particularly in high-wear applications. Understanding adhesive properties helps buyers assess the ease of use and potential longevity of the finished product. -

Environmental Considerations

With growing awareness of sustainability, buyers should consider the environmental impact of leather production. Terms like “chrome-free” or “vegetable-tanned” indicate more eco-friendly processes. Choosing environmentally sustainable options can enhance brand reputation and appeal to eco-conscious consumers.

What Are Common Trade Terms Used in the Leather Lining Industry?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather lining industry, this term indicates that a company provides custom leather solutions tailored to the specifications of another brand, enhancing product differentiation. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively and ensure they are meeting supplier requirements without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This process is essential for buyers to compare options and negotiate the best deal while ensuring that all necessary specifications are met. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is vital for ensuring clarity on shipping costs, risks, and responsibilities, which can significantly impact the total cost of procurement. -

Lead Time

Lead time refers to the amount of time from placing an order to its delivery. Understanding lead times helps buyers plan their production schedules and manage customer expectations effectively. -

Sample Approval

Sample approval is the process by which buyers evaluate and approve a physical sample of the leather lining before full-scale production. This step is critical for ensuring that the materials meet quality and design specifications, thereby reducing the risk of costly errors in large orders.

By grasping these technical properties and trade terminologies, B2B buyers in the leather lining market can make informed decisions that align with their business objectives and customer needs.

Navigating Market Dynamics and Sourcing Trends in the leather lining material Sector

What Are the Key Market Dynamics and Trends Influencing the Leather Lining Material Sector?

The leather lining material sector is experiencing significant growth driven by rising demand for high-quality, durable materials in various applications, including fashion, automotive, and furniture industries. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe (notably Germany and Brazil), are increasingly focused on sourcing materials that offer both functionality and aesthetic appeal. The shift towards customization and personalization in product offerings has led manufacturers to seek specialized leather lining materials, such as lambskin and goatskin, which provide unique textures and finishes.

Illustrative image related to leather lining material

Emerging technologies are also reshaping the sourcing landscape. Digital platforms and e-commerce solutions facilitate smoother transactions and better inventory management, allowing buyers to source leather lining materials directly from manufacturers worldwide. Furthermore, advancements in synthetic and eco-friendly alternatives are becoming more prominent, catering to a market that increasingly values sustainability without compromising on quality.

The impact of global economic conditions cannot be overlooked. Fluctuations in raw material prices, trade regulations, and geopolitical tensions influence supply chains, making it essential for buyers to stay informed about market dynamics. As a result, strategic partnerships and long-term relationships with suppliers are becoming critical for securing consistent quality and pricing.

How Important Is Sustainability and Ethical Sourcing in the Leather Lining Material Sector?

Sustainability and ethical sourcing are paramount in the leather lining material sector, reflecting a growing awareness among consumers and businesses alike regarding environmental impacts. Traditional leather production methods often raise concerns about pollution and animal welfare, prompting a shift towards more sustainable practices. B2B buyers are increasingly prioritizing suppliers that adhere to ethical standards and sustainable practices, such as using chrome-free tanning processes and sourcing from farms that practice humane animal husbandry.

The demand for ‘green’ certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification, is on the rise. These certifications provide assurance that the leather has been produced with minimal environmental impact and adheres to strict social compliance standards. Buyers looking to enhance their brand reputation and meet consumer expectations must consider these factors when sourcing leather lining materials.

Moreover, the integration of recycled and bio-based materials into leather production is gaining traction. This trend not only reduces waste but also appeals to eco-conscious consumers. By investing in sustainable sourcing practices, B2B buyers can differentiate their offerings in a competitive marketplace while contributing positively to environmental conservation.

What Is the Historical Context of Leather Lining Materials in B2B Transactions?

The use of leather as a lining material has a rich history, dating back centuries when it was prized for its durability and versatility. Initially utilized in luxury goods, leather linings have evolved alongside technological advancements and changing consumer preferences. The industrial revolution marked a significant turning point, as mass production techniques made leather more accessible to a broader market.

In recent decades, the leather lining sector has seen a transformation driven by globalization and the rise of fast fashion. B2B transactions have shifted from traditional brick-and-mortar exchanges to digital platforms, enhancing the ability for international buyers to source materials from diverse suppliers. As consumer preferences lean towards sustainable and ethically sourced products, the leather lining industry continues to adapt, ensuring that it meets the demands of modern markets while honoring its storied heritage.

Frequently Asked Questions (FAQs) for B2B Buyers of leather lining material

-

How do I choose the right leather lining material for my products?

Selecting the right leather lining material involves assessing your specific product requirements, such as durability, weight, and aesthetic appeal. Consider the type of leather (e.g., lambskin, pigskin, goatskin) based on the intended use—lambskin is softer and more luxurious, while pigskin offers robust durability. Additionally, evaluate thickness, breathability, and finish options. It’s also wise to request samples from suppliers to gauge quality firsthand before making a bulk purchase. -

What are the common thicknesses available for leather lining materials?

Leather lining materials typically range from 0.4mm to 2.0mm in thickness, depending on the type and intended application. For example, lambskin linings are usually around 0.8mm to 1.2mm, providing a balance of softness and strength, while heavier options like full-grain leather may exceed 2mm. When selecting thickness, consider the product’s end use, as thicker materials offer more durability but may add bulk. -

What should I consider when vetting suppliers for leather lining materials?

When vetting suppliers, prioritize their reputation, production capacity, and quality certifications. Check for customer reviews and request references to verify reliability. Ensure the supplier can meet your specific needs regarding customization, minimum order quantities (MOQs), and shipping capabilities. Additionally, assess their transparency regarding sourcing practices and material sustainability, as these factors can impact your brand’s reputation. -

What are the typical minimum order quantities (MOQs) for leather lining materials?

Minimum order quantities can vary significantly by supplier and material type. Generally, MOQs range from 50 to 500 square feet, depending on the leather’s rarity and the supplier’s production scale. For specialized or custom orders, MOQs may be higher. Discuss your needs with potential suppliers to negotiate terms that fit your business model while ensuring you meet their minimum requirements. -

What payment terms should I expect when sourcing leather lining materials internationally?

Payment terms for international transactions typically involve upfront deposits ranging from 30% to 50% of the total order value, with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or other secure payment methods, especially for large orders. Always clarify payment terms before finalizing contracts to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality control for my leather lining materials?

To ensure quality control, establish clear specifications and standards with your supplier before production begins. Request samples for initial evaluation, and consider conducting third-party inspections at various production stages. Additionally, maintaining open communication with your supplier can help address any concerns promptly. Implementing a comprehensive quality assurance protocol will safeguard your investment and ensure product consistency. -

What are the best shipping options for leather lining materials?

The best shipping options depend on your budget, urgency, and destination. Air freight is faster but more expensive, making it suitable for urgent needs, while sea freight is cost-effective for larger orders but takes longer. Consider working with logistics partners experienced in handling leather goods to navigate customs and ensure compliance with international shipping regulations. Always compare quotes and delivery times from multiple carriers to find the best solution. -

Can I customize leather lining materials to fit my brand’s needs?

Many suppliers offer customization options, including color, texture, and even specific thicknesses to align with your brand’s identity. Discuss your requirements with potential suppliers to explore available options. Keep in mind that customization may involve higher MOQs and longer lead times. Establishing a clear design brief will help streamline the process and ensure the final product meets your expectations.

Top 7 Leather Lining Material Manufacturers & Suppliers List

1. Avetco – Lining Leather

Domain: avetcoinc.com

Registered: 2005 (20 years)

مقدمة: Lining Leather from Avetco is soft, lightweight, and specifically selected for interior use in footwear, handbags, garments, and accessories. It is known for its smooth finish and breathability, adding comfort, structure, and a refined touch to any finished product. Available in a variety of colors and textures, it delivers both function and luxury to every design.

2. Lining Leather – Quality & Versatility

Domain: buyleatheronline.com

Registered: 2015 (10 years)

مقدمة: Lining Leather category offers quality and versatility for enhancing interiors of various products. It is thin yet resilient, providing a smooth surface for shoes, bags, wallets, belts, and bookbinding. The selection includes top-quality hides with refined finishes. Key features include:

– Price Range: $0.00 – $50.00

– Color Options: White, Beige, Pink, Green, Yellow, Red, Blue, Brown, Grey, Black…

3. Ivan – Premium Lining Fabric

Domain: ivan.tw

Registered: 2005 (20 years)

مقدمة: [{‘name’: ‘Premium Lining Fabric’, ‘dimensions’: ‘145cm x 90cm (57″x36″)’, ‘price’: ‘$12.99’, ‘description’: ‘This premium lining fabric offers excellent durability thanks to its resistant to stretching, tight weave and subtle rigidity.’}, {‘name’: ‘Goatskin Lining’, ‘thickness’: ‘0.8mm~1.2mm (2/3oz)’, ‘color’: ‘Pearl White’, ‘price’: ‘$14.99’, ‘description’: ‘Strong and thin with a smooth, tight …

4. Lusso Leather – Leather Jacket Linings

Domain: lussoleather.com

Registered: 2016 (9 years)

مقدمة: Lining for leather jackets is the layer of cloth sewn inside the jacket to provide comfort and protection. It helps prevent the leather from clinging to the skin, adds insulation for warmth, and increases the jacket’s longevity. Common lining materials include polyester, viscose, cotton, silk, and nylon. Each material has its own benefits: cotton is breathable and cozy, polyester is strong and wri…

5. Honghu Leather – Handbag Linings Guide

Domain: honghuleather.com

Registered: 2023 (2 years)

مقدمة: The five most common handbag linings are cotton, polyester, nylon, suede, and leather. Each material offers different benefits in terms of durability, feel, and ease of care, suitable for various bag styles and uses. Handbag lining serves to cover construction, protect the outer material, keep belongings organized, and maintain cleanliness. Cotton is soft, breathable, and affordable, often used in…

6. Nagaba – Natural Leather Lining & Felt Solutions

Domain: nagaba.eu

مقدمة: Types of lining:

1. SKU – 00: NATURAL LEATHER LINING

– Description: Natural pig leather lining from the best Polish tanneries, thickness 0.7 – 0.9 mm, moisture management.

2. SKU – 01: FELT

– Colour: Black

– Composition: 100% PL – POLYESTER

– Description: Synthetic black felt, flexible, high permeability to water vapor, ideal for autumn and early spring.

3. SKU – 03: CHECK

…

7. Pidigi – Kardak 700 WR & Kardak 1200

Domain: pidigi.com

Registered: 1996 (29 years)

مقدمة: [{‘name’: ‘Kardak 700 WR’, ‘features’: ‘High abrasion resistance: over 70,000 cycles with the Martindale method, water-repellent fabric’, ‘technical_data’: {‘composition’: ‘100% polyester’, ‘weight’: ‘200 g/m² ± 5%’}}, {‘name’: ‘Kardak 1200’, ‘features’: ‘High resistance to abrasion and tearing: over 100,000 cycles with the Martindale method, water-repellent fabric’, ‘technical_data’: {‘compositio…

Strategic Sourcing Conclusion and Outlook for leather lining material

In the dynamic landscape of leather lining materials, strategic sourcing emerges as a critical component for B2B buyers aiming to enhance their product offerings while optimizing costs. By leveraging high-quality materials, such as self-adhesive fabric linings and various leather types like lambskin and pigskin, companies can ensure durability and aesthetic appeal in their finished products. Buyers are encouraged to consider factors such as thickness, breathability, and price when evaluating options, as these elements directly impact product performance and consumer satisfaction.

Moreover, the rise of eco-friendly materials and innovative sourcing strategies can not only reduce environmental impact but also align with global market trends favoring sustainability. As international buyers from Africa, South America, the Middle East, and Europe navigate this evolving market, establishing strong supplier relationships and staying informed about material advancements will be vital.

Looking ahead, the demand for quality leather lining materials is set to grow. Buyers should seize the opportunity to explore new suppliers and materials that align with their business objectives. By prioritizing strategic sourcing, companies can enhance their competitive edge and meet the diverse needs of their customer base effectively.

Illustrative image related to leather lining material

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.