Introduction: Navigating the Global Market for custom leather stamp

In the competitive landscape of leather goods manufacturing, sourcing a reliable custom leather stamp can pose significant challenges for international B2B buyers. Whether you are a small artisan in Africa or a large-scale manufacturer in Germany, the need for high-quality, durable, and precise stamping solutions is critical. This guide on custom leather stamps offers an in-depth exploration of various types, applications, and sourcing options tailored to meet the unique requirements of businesses across diverse markets, including South America, the Middle East, and Europe.

As you navigate this essential resource, you will gain valuable insights into the different materials and designs available, such as brass and steel stamps, and their applications in leather embossing and branding. We’ll also cover supplier vetting processes to ensure that you partner with reputable manufacturers who can meet your specific needs, while also providing guidance on pricing structures and lead times.

By empowering you with the knowledge to make informed purchasing decisions, this guide aims to streamline your sourcing process for custom leather stamps. You will learn how to effectively assess your requirements, understand market trends, and leverage supplier capabilities to enhance your product offerings. Whether you are looking to create a unique brand identity or enhance your production capabilities, this comprehensive resource is designed to support your business objectives in a global marketplace.

Table Of Contents

- Top 7 Custom Leather Stamp Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather stamp

- Understanding custom leather stamp Types and Variations

- Key Industrial Applications of custom leather stamp

- 3 Common User Pain Points for ‘custom leather stamp’ & Their Solutions

- Strategic Material Selection Guide for custom leather stamp

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp’

- Comprehensive Cost and Pricing Analysis for custom leather stamp Sourcing

- Alternatives Analysis: Comparing custom leather stamp With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather stamp

- Navigating Market Dynamics and Sourcing Trends in the custom leather stamp Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp

- Strategic Sourcing Conclusion and Outlook for custom leather stamp

- Important Disclaimer & Terms of Use

Understanding custom leather stamp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Brass Leather Stamp | Durable, corrosion-resistant, excellent heat conductivity | Branding, embossing, marking | Pros: Longevity, high-quality finish. Cons: Higher cost compared to aluminum. |

| Handheld Steel Stamp | Versatile for multiple materials, sturdy construction | Small batch production, artisan use | Pros: Strong and durable. Cons: Requires manual effort and skill. |

| Custom Leather Roll Dies | Designed for high-volume production, continuous stamping | Mass production of leather goods | Pros: Efficient for large runs. Cons: Initial setup costs can be high. |

| Branding Irons | Uses heat for deep impressions, suitable for various leathers | Branding logos, special designs | Pros: Creates a permanent mark. Cons: Requires careful temperature control. |

| Leather Cutting Dies | Cuts shapes and designs, used with mechanical presses | Custom shapes for products | Pros: Precision cutting, flexible designs. Cons: Requires compatible press. |

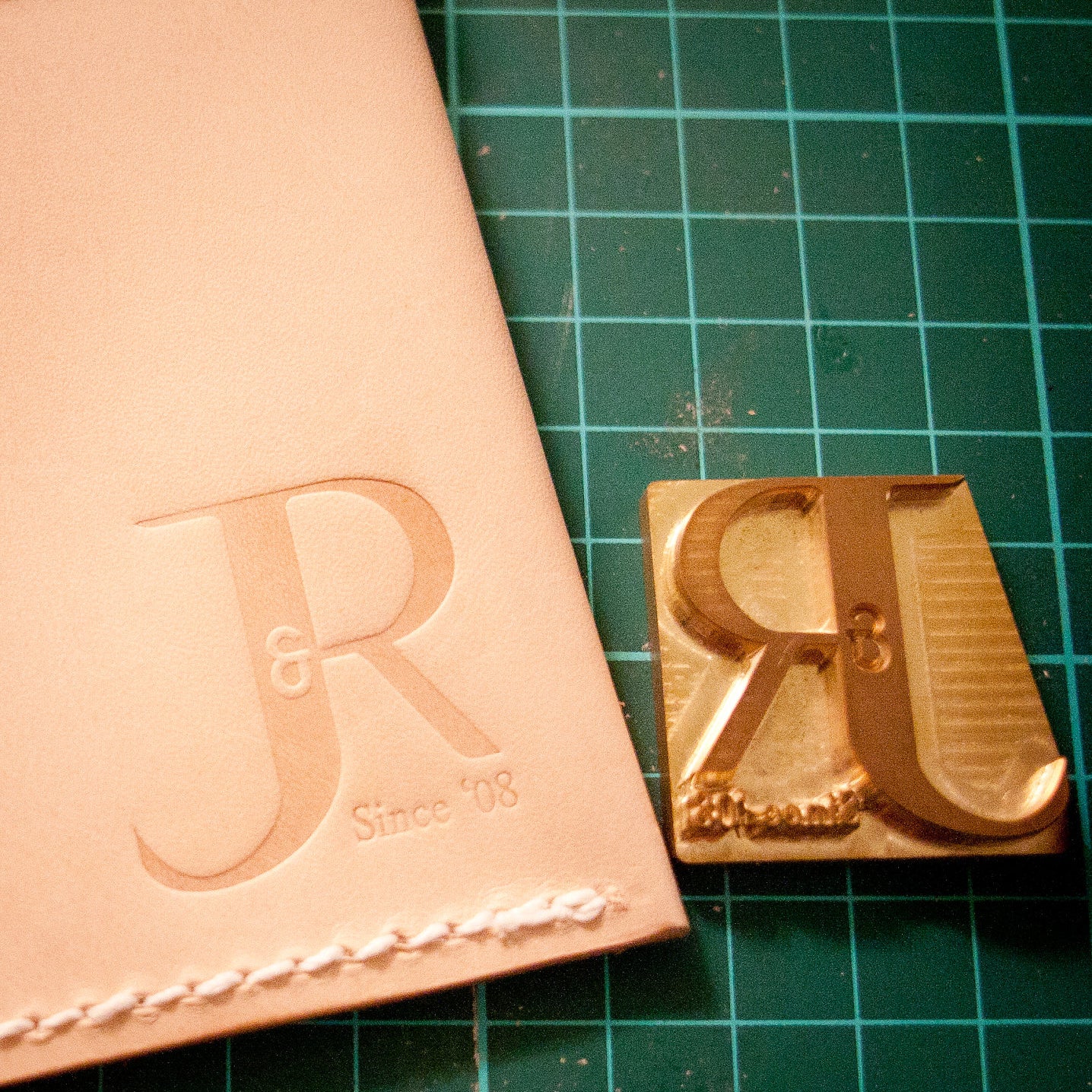

What Are the Key Characteristics of Custom Brass Leather Stamps?

Custom brass leather stamps are renowned for their durability and resistance to corrosion, making them ideal for long-term use in various leather applications. Their excellent thermal conductivity allows for effective heat embossing, producing crisp and clear designs. B2B buyers should consider these stamps for branding, embossing, and marking leather products. While the initial investment is higher than aluminum options, the longevity and quality of the impressions often justify the cost, especially for businesses focused on premium leather goods.

How Do Handheld Steel Stamps Stand Out?

Handheld steel stamps are versatile tools that can mark not only leather but also wood and metals. Their sturdy construction ensures they withstand repeated use, making them suitable for artisans and small-scale producers. However, they require a certain level of skill for effective application, as the user must apply consistent pressure. This type of stamp is particularly beneficial for businesses that produce small batches of customized items, allowing for flexibility in design without the need for large-scale machinery.

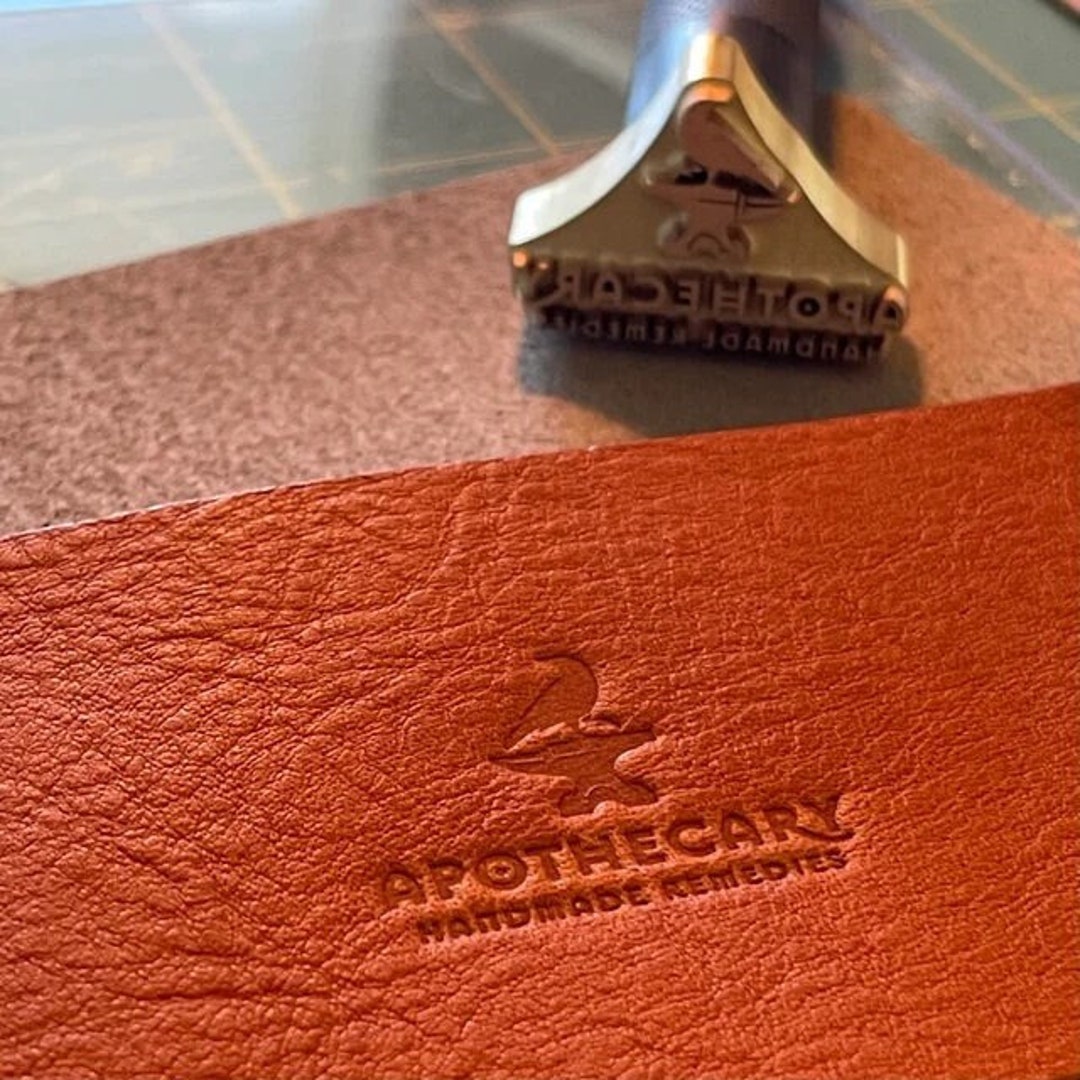

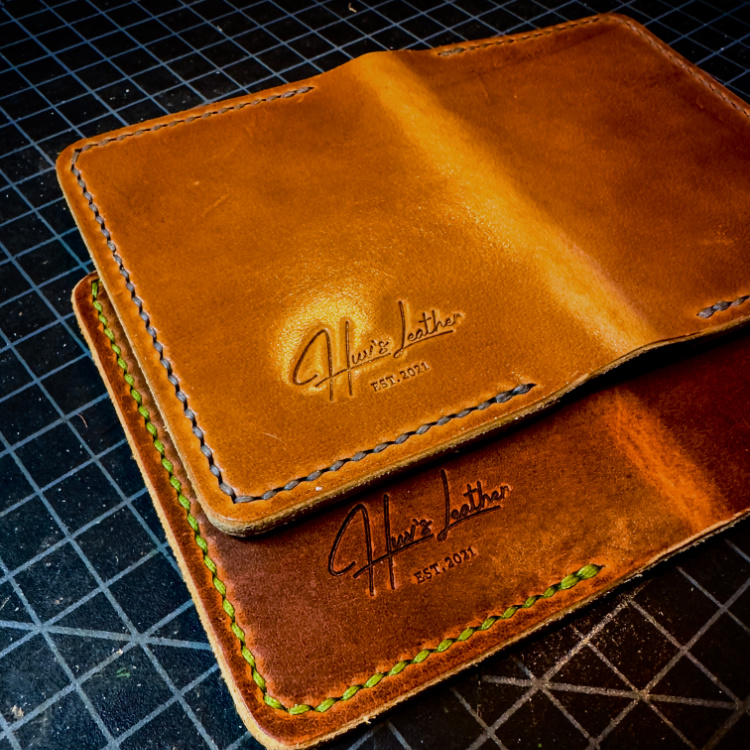

Illustrative image related to custom leather stamp

What Are Custom Leather Roll Dies Used For?

Custom leather roll dies are specifically engineered for high-volume production, allowing businesses to stamp consistent designs across multiple items swiftly. These dies are ideal for manufacturers focusing on mass production of leather goods, such as bags and belts. While they offer efficiency and speed, the upfront investment can be significant, as they require specialized machinery. B2B buyers should evaluate their production needs and volume to determine if this option aligns with their operational goals.

Why Choose Branding Irons for Leather Marking?

Branding irons utilize heat to create deep impressions on leather, making them an excellent choice for businesses looking to create lasting marks with logos or unique designs. They are particularly effective on thicker or chrome-tanned leather. While branding irons can produce a permanent mark, they require careful temperature management to avoid damaging the leather. Buyers should consider the specific leather types they work with and ensure they have the necessary equipment to operate these tools effectively.

What Benefits Do Leather Cutting Dies Provide?

Leather cutting dies are essential for businesses that need to create specific shapes and designs in leather. Used with mechanical or hydraulic presses, these dies enable precise cutting, making them ideal for custom product shapes. B2B buyers should assess their production capabilities and ensure compatibility with their existing machinery. The flexibility in design and the potential for high-volume production make cutting dies a valuable investment for manufacturers looking to streamline their processes.

Key Industrial Applications of custom leather stamp

| Industry/Sector | Specific Application of custom leather stamp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Branding leather goods with logos or designs | Enhances brand recognition and customer loyalty | Material quality (brass vs. steel), design complexity, lead time |

| Automotive | Custom stamps for leather upholstery in vehicles | Adds value and personalization to vehicle interiors | Compatibility with different leather types, durability, precision |

| Furniture & Interior Design | Embossing designs on leather furniture | Distinguishes products in a competitive market | Customization options, size specifications, production timelines |

| Crafts & Hobby | Stamping on handmade leather goods | Provides unique selling points for artisans | Design assistance, ease of use, cost-effectiveness |

| Pet Products | Custom stamps for branding pet accessories | Builds brand loyalty and unique product identity | Sizing for small items, durability, shipping options |

How is Custom Leather Stamp Used in the Fashion & Accessories Industry?

In the fashion sector, custom leather stamps are essential for branding leather goods such as handbags, belts, and wallets. By imprinting logos or unique designs, businesses can enhance brand recognition and foster customer loyalty. Buyers in this industry should consider the quality of materials—brass is often preferred for its durability and resistance to rust. Additionally, the intricacy of the design and lead time for production are critical factors that can influence the overall branding strategy.

What Role Does Custom Leather Stamp Play in the Automotive Sector?

The automotive industry employs custom leather stamps to personalize leather upholstery in vehicles, providing a unique touch that enhances the overall aesthetic. This application not only adds value to the vehicle but also appeals to consumers seeking luxury and individuality. Buyers must assess the compatibility of stamps with various types of leather, ensuring durability and precision in the stamping process, which is crucial for maintaining high-quality standards in automotive interiors.

How Can Custom Leather Stamps Elevate Furniture & Interior Design?

In furniture and interior design, custom leather stamps are used to emboss designs on leather sofas, chairs, and other furnishings. This application helps to distinguish products in a competitive market, allowing businesses to showcase their unique style. When sourcing custom stamps, considerations include customization options, the size of the designs, and production timelines to ensure timely delivery for interior projects.

Why Are Custom Leather Stamps Important for Crafts & Hobby?

Artisans and crafters utilize custom leather stamps to create unique handmade leather goods, providing distinct selling points in a crowded marketplace. These stamps enable creators to imprint personal designs or logos, enhancing the perceived value of their products. Buyers should focus on design assistance offered by suppliers, the ease of use of the stamps, and overall cost-effectiveness to ensure profitability in their craft endeavors.

How Do Custom Leather Stamps Benefit the Pet Products Industry?

In the pet products sector, custom stamps are increasingly used for branding accessories like collars and leashes, allowing businesses to create a strong brand identity. By incorporating unique designs or logos, companies can build brand loyalty among pet owners. Key sourcing considerations include sizing for small items, the durability of the stamps, and shipping options, especially for international buyers looking to streamline their supply chain.

Illustrative image related to custom leather stamp

3 Common User Pain Points for ‘custom leather stamp’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality in Stamping

The Problem: One of the most significant challenges B2B buyers face when sourcing custom leather stamps is ensuring the quality and consistency of the stamped designs. Inconsistent impressions can lead to product rejections, wasted materials, and ultimately, a loss of revenue. Buyers may find that different manufacturers produce varying levels of detail or depth, which can severely impact the final product’s aesthetic and perceived value, particularly for high-end leather goods.

The Solution: To combat this issue, B2B buyers should prioritize working with manufacturers that offer samples or prototypes before committing to a bulk order. Requesting a test stamp can help evaluate the quality, detail, and overall execution of the design. Additionally, it’s essential to communicate specific requirements clearly, such as the type of leather being used, the desired depth of the stamp, and any special finishing processes. Opting for manufacturers that utilize CNC machining for precision can also ensure a more consistent output. Furthermore, establishing a quality control process that includes regular checks during production can help maintain standards across batches.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: In many cases, B2B buyers encounter lengthy lead times when ordering custom leather stamps, which can disrupt production schedules and delay product launches. This issue is particularly pronounced for businesses operating in fast-paced markets or those that require seasonal designs, as delays can lead to missed opportunities and increased costs.

The Solution: To minimize lead times, buyers should seek out suppliers that emphasize expedited processing and shipping options. Many reputable manufacturers now offer quick turnaround times, sometimes within 2-3 business days for rush orders. When placing an order, clearly communicate any urgent timelines and confirm the expected delivery date upfront. Establishing a relationship with a reliable supplier can also facilitate quicker responses for future orders. Consider creating a catalog of frequently used designs, allowing for faster reorders. This proactive approach ensures that the production process remains uninterrupted and aligns with business goals.

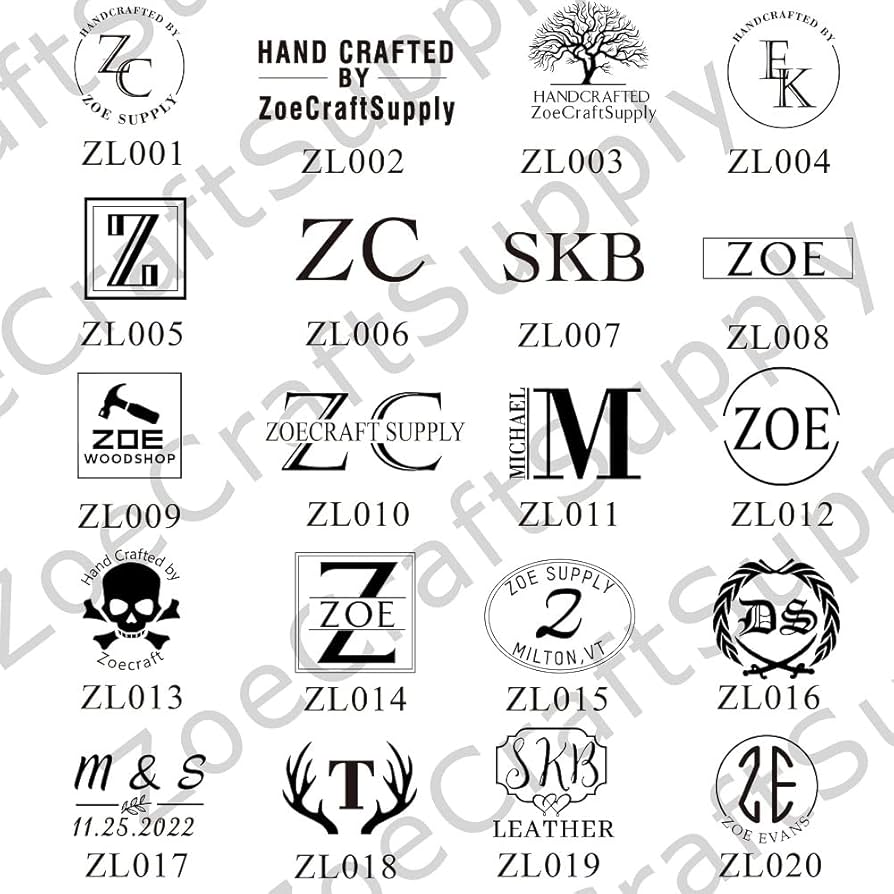

Scenario 3: Uncertainty in Custom Design Capabilities

The Problem: B2B buyers often struggle with uncertainty regarding the design capabilities of custom leather stamp manufacturers. Questions about whether a supplier can accurately replicate a logo or intricate design can create hesitation in the purchasing process. This uncertainty can lead to buyers feeling overwhelmed and uncertain about their choices, especially when trying to differentiate their products in a competitive market.

The Solution: To alleviate these concerns, buyers should engage in open dialogues with potential suppliers about their design capabilities. Requesting case studies or portfolios of previous work can provide insights into the manufacturer’s ability to handle complex designs. Additionally, seeking suppliers that offer design consultations can be beneficial, as they can provide guidance on optimizing designs for stamping. Ensuring that the supplier can work with high-resolution vector files (like AI or PDF formats) will also enhance the chances of achieving a precise and detailed final product. Establishing a clear communication channel for revisions and feedback during the design process can further help in aligning expectations and achieving a satisfactory outcome.

Strategic Material Selection Guide for custom leather stamp

What Are the Key Materials for Custom Leather Stamps?

When selecting materials for custom leather stamps, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and cost-effectiveness of the stamping process. Below, we analyze four common materials used in the manufacturing of custom leather stamps: brass, steel, aluminum, and copper.

How Does Brass Perform as a Material for Custom Leather Stamps?

Brass is a popular choice for custom leather stamps due to its excellent thermal conductivity and corrosion resistance. It performs well under high temperatures, making it suitable for both wet and heat stamping applications. Brass stamps are durable and can maintain their sharpness over time, allowing for detailed impressions.

Pros: Brass offers a long lifespan and is resistant to rust, making it ideal for repeated use in various leather types, including vegetable-tanned leather. Its aesthetic appeal also adds value to the final product.

Cons: The primary downside of brass is its higher cost compared to aluminum, which may be a consideration for budget-conscious buyers. Additionally, while brass is durable, it can be softer than steel, leading to potential wear over time if not properly maintained.

Impact on Application: Brass is particularly effective for applications requiring precision and detail, such as branding logos or intricate designs. Its compatibility with various leather types, including chrome-tanned leather, enhances its versatility.

What Are the Benefits of Using Steel for Custom Leather Stamps?

Steel is another robust option for custom leather stamps, known for its strength and durability. It can withstand high pressure and is less prone to deformation compared to brass. Steel stamps are often used for heavy-duty applications and can produce clear, lasting impressions.

Pros: The durability of steel makes it suitable for high-volume production, ensuring that stamps maintain their integrity over time. Steel can also be treated to enhance its corrosion resistance.

Cons: The main drawback of steel is its susceptibility to rust if not properly cared for, especially in humid environments. Additionally, steel stamps can be more expensive to manufacture due to the complexity involved in machining.

Impact on Application: Steel is ideal for heavy-duty stamping, particularly in industries where high-pressure applications are common. Its strength makes it suitable for marking thicker leather materials.

Why Choose Aluminum for Custom Leather Stamps?

Aluminum is a lightweight and cost-effective option for custom leather stamps. While it may not have the same durability as brass or steel, aluminum is resistant to corrosion and can be machined easily, allowing for quick production.

Pros: The low cost of aluminum makes it an attractive option for startups or businesses looking to minimize expenses. Its lightweight nature facilitates ease of handling during the stamping process.

Illustrative image related to custom leather stamp

Cons: Aluminum stamps may wear out more quickly than their brass or steel counterparts, leading to a shorter lifespan. They may also lack the detailed impression quality that heavier materials can provide.

Impact on Application: Aluminum is best suited for less demanding applications where cost is a primary concern. It works well for marking lighter leather types but may not be ideal for intricate designs requiring high precision.

What Role Does Copper Play in Custom Leather Stamps?

Copper is less common but still a viable option for custom leather stamps. It offers excellent thermal conductivity and can produce high-quality impressions. However, it is generally more expensive and less durable than brass and steel.

Illustrative image related to custom leather stamp

Pros: Copper stamps can create very detailed impressions and are often used in artistic applications where aesthetics are crucial. They also resist corrosion well.

Cons: The primary limitation of copper is its cost and tendency to wear down more quickly than other materials. Additionally, it can tarnish over time, requiring regular maintenance to maintain its appearance.

Impact on Application: Copper is suitable for specialized applications, particularly in artistic leatherworking where detailed designs are essential. However, its cost may limit its use in high-volume production settings.

Summary Table of Material Selection for Custom Leather Stamps

| المواد | Typical Use Case for custom leather stamp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Branding logos on vegetable-tanned leather | Excellent thermal conductivity and corrosion resistance | Higher cost than aluminum | عالية |

| Steel | Heavy-duty stamping for thick leather | Exceptional durability and strength | Susceptible to rust without care | Medium |

| Aluminum | Cost-effective stamping for lighter leather | Lightweight and easy to handle | Shorter lifespan and less detail | منخفضة |

| Copper | Artistic applications requiring detail | High-quality impressions and aesthetic appeal | Higher cost and tarnishing issues | عالية |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on application requirements, cost considerations, and material properties.

Illustrative image related to custom leather stamp

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather stamp

What Are the Main Stages in the Manufacturing Process of Custom Leather Stamps?

The manufacturing of custom leather stamps involves several critical stages that ensure the final product meets the high standards expected by B2B buyers. Understanding these stages can help buyers assess potential suppliers and make informed decisions.

Material Preparation: How Are Materials Selected and Processed?

The first step in the manufacturing process is material preparation. Custom leather stamps are typically made from materials such as brass, steel, or aluminum, each offering unique advantages. Brass is favored for its durability and resistance to rust, making it ideal for wet stamping applications. Steel offers strength and longevity, while aluminum provides a cost-effective alternative.

Once the material is selected, it undergoes a series of preparations, including cutting to size and surface treatment. This ensures that the materials are free from impurities and defects, which is essential for achieving high-quality stamps. Suppliers often use CNC (Computer Numerical Control) machines to achieve precise cuts and engravings, significantly enhancing the accuracy of the final product.

Which Techniques Are Employed in the Forming Stage?

The forming stage is where the design of the custom leather stamp is brought to life. This process typically involves the use of CNC milling, which allows for intricate designs and high levels of detail. The stamp’s engraving depth and thickness are carefully controlled to ensure that the stamp will leave a clear impression on the leather.

For B2B buyers, understanding the forming techniques is crucial. Some manufacturers may offer additional options, such as heat stamping or branding, which require different tools and techniques. Buyers should inquire about the specific methods used by suppliers to ensure they meet their project’s requirements.

How Is the Assembly Process Conducted for Custom Leather Stamps?

In the assembly stage, the various components of the stamp are brought together. For handheld stamps, this may involve attaching a durable handle to the engraved die. Press stamps may require integration with hydraulic or clicker presses, which necessitates precise alignment to ensure consistent stamping results.

Quality assurance begins during this stage, as manufacturers must ensure that all components fit together seamlessly. Misalignment can lead to poor impressions on the leather, affecting the overall quality of the product. B2B buyers should consider suppliers that emphasize meticulous assembly processes, as this can significantly impact the performance of the stamps.

What Finishing Techniques Are Used to Ensure High-Quality Custom Leather Stamps?

Finishing processes are vital to the overall quality of custom leather stamps. This stage may include polishing, coating, or additional engraving to enhance the stamp’s durability and appearance. A well-finished stamp will not only perform better but also provide an aesthetically pleasing result on the leather.

Buyers should pay attention to the finishing techniques used by suppliers. High-quality finishes can prevent rust and wear, extending the lifespan of the stamp. Suppliers that adhere to strict quality standards in finishing will typically produce more reliable products, which is essential for maintaining a professional image in B2B transactions.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is a critical component of the manufacturing process for custom leather stamps. Reputable manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This ensures that the manufacturing process is consistently monitored and improved.

Illustrative image related to custom leather stamp

What Are the Key QC Checkpoints in the Manufacturing Process?

QC checkpoints are implemented at various stages of production:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for defects before production begins. Suppliers should have a robust IQC process to ensure only high-quality materials are used.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, IPQC checks are performed to monitor the manufacturing process. This includes verifying dimensions and ensuring that the engraving meets specifications.

-

Final Quality Control (FQC): Once the stamps are finished, FQC involves a comprehensive inspection of the final product. This includes testing the stamps on leather to ensure they produce clear and precise impressions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s QC practices is essential to ensure they receive high-quality products. Here are some effective methods for conducting this verification:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes, equipment, and quality control measures. This hands-on approach allows buyers to assess whether the supplier meets their standards.

-

Quality Reports: Requesting quality control reports from suppliers can help buyers understand their QC processes and the results of recent inspections. These reports should include information on defect rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s products. These organizations can perform inspections at various stages of production to ensure compliance with international standards.

What Are the Quality Control Nuances for International Buyers?

When purchasing from suppliers in different regions, B2B buyers must be aware of various quality control nuances. Different countries may have distinct standards and regulations that affect the manufacturing and quality assurance processes. For instance, suppliers in Europe may adhere to CE marking standards, while those in the Middle East may follow local regulations.

Buyers should familiarize themselves with these regional standards and ensure their suppliers comply. Additionally, language barriers and cultural differences can impact communication regarding quality expectations, so establishing clear communication channels is vital.

الخاتمة

Understanding the manufacturing processes and quality assurance measures for custom leather stamps is crucial for B2B buyers. By familiarizing themselves with the stages of production, key techniques, and quality control practices, buyers can make informed decisions and select suppliers that meet their specific needs. Investing time in this due diligence can lead to successful partnerships and high-quality products that enhance their business offerings.

Illustrative image related to custom leather stamp

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather stamp’

In the competitive world of leather crafting, sourcing a custom leather stamp can significantly enhance your branding and product quality. This guide provides a step-by-step checklist to assist international B2B buyers in effectively procuring custom leather stamps that meet their unique requirements.

Step 1: Define Your Technical Specifications

Begin by outlining the technical specifications for your custom leather stamp. Consider the design, size, depth of engraving, and material (e.g., brass, steel, or aluminum). This clarity will help you communicate your needs effectively to suppliers and ensure that the final product aligns with your expectations.

- Design Requirements: Specify the artwork, logo, or text you want on the stamp.

- Dimensions: Determine the maximum size for your stamp, as larger designs may incur additional costs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather stamps. Look for manufacturers with experience in your specific type of leather and stamping techniques.

- Check Reviews and Testimonials: Look for feedback from other B2B buyers, particularly those from your target regions like Africa, South America, the Middle East, and Europe.

- Compare Offerings: Evaluate multiple suppliers to understand their product range and customization options.

Step 3: Request Samples and Quotes

Before making a decision, request samples of previous work along with detailed quotes. This will give you a tangible sense of the quality you can expect.

- Ask for Different Materials: If possible, request samples in various materials (e.g., brass vs. aluminum) to assess durability and performance.

- Analyze Pricing Structures: Ensure the quote includes all potential costs, such as shipping and rush order fees.

Step 4: Evaluate Production Capabilities

Assess the supplier’s production capabilities to ensure they can meet your timelines and volume requirements.

Illustrative image related to custom leather stamp

- Lead Times: Inquire about the typical turnaround time for orders, especially if you need a rush order.

- Production Capacity: Confirm that the supplier can handle your expected order volume, particularly for larger projects.

Step 5: Verify Certifications and Quality Standards

Ensure that the supplier adheres to relevant quality standards and certifications. This is crucial for maintaining product consistency and safety.

- ISO Certifications: Check if the supplier has ISO certifications, which indicate adherence to international quality management standards.

- Material Sourcing: Ask about the sourcing of materials to ensure they meet industry standards for leather stamping.

Step 6: Communicate Your Needs Clearly

Establish open communication with your chosen supplier. Provide them with clear instructions, design files, and any specific requirements you have.

- Design Formats: Ensure that your design files are in the correct format (preferably AI or PDF) for ease of engraving.

- Feedback Loop: Maintain a feedback loop during the production process to address any issues or modifications.

Step 7: Finalize Payment and Shipping Arrangements

Once you’ve agreed on the specifications and timelines, finalize the payment and shipping arrangements.

- Payment Terms: Understand the payment terms and ensure they align with your company’s policies.

- Shipping Options: Discuss shipping methods and costs, especially if you require expedited shipping for your order.

By following these steps, you can streamline the sourcing process for custom leather stamps, ensuring that you receive high-quality products tailored to your specifications.

Comprehensive Cost and Pricing Analysis for custom leather stamp Sourcing

What Are the Key Cost Components in Custom Leather Stamp Sourcing?

When sourcing custom leather stamps, understanding the cost structure is crucial for B2B buyers to make informed decisions. The primary cost components include:

Illustrative image related to custom leather stamp

-

Materials: The choice of materials significantly impacts the overall cost. Common materials like solid brass and steel are popular for their durability and quality. Brass, while slightly more expensive, is favored for its resistance to rust and superior thermal conductivity, making it ideal for stamping applications.

-

Labor: Skilled labor is required for the design and manufacturing of custom stamps. The complexity of the design can influence labor costs, particularly for intricate or high-detail stamps.

-

Manufacturing Overhead: This includes costs associated with the facility, utilities, and equipment used in the production process. Efficient manufacturing practices can help reduce these overhead costs.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs are typically amortized over the production run, meaning larger orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring that each stamp meets quality standards is essential, particularly for B2B applications where precision is critical. QC processes may add to costs but are necessary for maintaining product reliability.

-

Logistics: Shipping and handling costs can vary greatly depending on the destination and shipping method. International shipping may involve additional fees, tariffs, and longer lead times.

-

Margin: Suppliers typically mark up prices to cover their costs and ensure profitability. Understanding the supplier’s margin can aid in negotiations.

How Do Price Influencers Affect the Cost of Custom Leather Stamps?

Several factors can influence the pricing of custom leather stamps:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specific dimensions can increase costs. The more complex the design, the more labor and material are required, which can raise the overall price.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., environmental or safety standards) may come at a premium. Buyers should assess whether the added cost aligns with their quality requirements.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can influence pricing. Established suppliers may charge more due to their experience and reliability, while new entrants may offer competitive pricing to gain market share.

-

Incoterms: The agreed terms of delivery can significantly impact costs. For example, “Free on Board” (FOB) pricing means the buyer is responsible for shipping costs once the product is loaded onto a vessel, while “Delivered Duty Paid” (DDP) includes all shipping and customs fees.

What Negotiation Tips Can Help Buyers Secure Better Pricing?

B2B buyers can employ several strategies to negotiate more favorable terms when sourcing custom leather stamps:

-

Research and Benchmarking: Understand the market rates and compare quotes from multiple suppliers. This can provide leverage during negotiations.

-

Discuss Total Cost of Ownership (TCO): Emphasize the long-term value rather than just the upfront cost. Highlighting factors such as durability and reduced replacement frequency can justify a higher initial investment.

-

Leverage Volume Discounts: If feasible, consider consolidating orders across different product lines to meet minimum order quantities for discounts.

-

Be Transparent About Needs: Clearly communicating your requirements can foster trust and lead to better terms. Suppliers are more likely to accommodate requests when they understand the buyer’s specific needs.

-

Consider Payment Terms: Negotiate payment terms that can ease cash flow, such as extended payment periods or installment payments.

What Should International Buyers Consider When Sourcing Custom Leather Stamps?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific challenges and opportunities:

-

Currency Fluctuations: Be mindful of exchange rates, as they can affect the total cost. Consider locking in prices or using hedging strategies.

-

Customs and Duties: Understand the import regulations and potential tariffs that may apply to leather goods in your country. This knowledge can help avoid unexpected costs.

-

Cultural Sensitivities: Building relationships and understanding cultural nuances can enhance negotiations and foster long-term partnerships with suppliers.

-

Lead Times: Factor in longer lead times for international shipments, and plan accordingly to avoid disruptions in production schedules.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing custom leather stamp With Other Solutions

When evaluating options for marking or branding leather, B2B buyers must consider various methods beyond the traditional custom leather stamp. While custom leather stamps offer a reliable solution for branding, alternative technologies and methods can provide additional benefits depending on the specific requirements of a business. Below is a comparative analysis of custom leather stamps alongside two alternative solutions: laser engraving and branding irons.

Illustrative image related to custom leather stamp

| Comparison Aspect | Custom Leather Stamp | Laser Engraving | Branding Iron |

|---|---|---|---|

| Performance | High detail and durability for stamping | Extremely precise with intricate designs | Effective for quick, bold impressions |

| Cost | Moderate ($68 – $250) | Higher initial investment ($200 – $5,000) | Moderate ($50 – $500) |

| Ease of Implementation | Simple setup; requires manual effort | Requires trained personnel and software | Easy to use; can be operated by anyone |

| Maintenance | Low; occasional cleaning needed | Medium; requires software updates | Low; durable and long-lasting |

| Best Use Case | Ideal for small to medium production runs | Best for detailed designs on various materials | Perfect for high-volume applications |

How Does Laser Engraving Compare to Custom Leather Stamps?

Laser engraving technology utilizes a focused laser beam to etch designs onto the leather surface. This method excels in precision, allowing for complex and intricate designs that are difficult to achieve with traditional stamping. While the initial cost of laser engraving equipment can be significantly higher than that of custom leather stamps, the long-term benefits include faster production times and the ability to customize designs without the need for physical stamps. However, the requirement for trained personnel and ongoing software maintenance can pose challenges for some businesses.

What Are the Advantages of Using Branding Irons Over Custom Leather Stamps?

Branding irons offer a straightforward method for marking leather by using heated metal plates to create impressions. This technique is especially effective for high-volume production environments where speed is crucial. Branding irons can be used with various types of leather and are generally easy to operate, making them accessible for businesses without specialized training. However, they may lack the intricate detail that custom leather stamps and laser engraving can provide, and they may not be suitable for delicate designs.

How Should B2B Buyers Choose the Right Leather Marking Solution?

When deciding between custom leather stamps, laser engraving, and branding irons, B2B buyers should consider several factors, including the nature of their projects, budget constraints, and desired outcomes. For businesses focused on intricate designs and versatility, laser engraving may be the best choice despite its higher costs. Conversely, for companies prioritizing speed and ease of use, branding irons can be an ideal option. Custom leather stamps remain a solid choice for those seeking durability and detailed impressions in smaller production runs. Ultimately, the right solution will align with the buyer’s specific needs and operational capabilities, ensuring effective branding and marking of leather products.

Essential Technical Properties and Trade Terminology for custom leather stamp

What Are the Key Technical Properties of Custom Leather Stamps?

When considering custom leather stamps, understanding their essential technical properties is crucial for ensuring that the final product meets your specific needs. Here are some critical specifications to keep in mind:

-

Material Composition

– Common materials for leather stamps include solid brass, aluminum, and steel. Brass is favored for its durability and resistance to rust when stamping wet leather. Steel offers longevity and can withstand heavy use, while aluminum is a cost-effective option for lighter applications. Choosing the right material can impact the quality of the imprint and the longevity of the stamp. -

Engraving Depth

– The engraving depth typically ranges from 2mm to 5mm. A deeper engraving allows for more intricate designs and clearer impressions on the leather. However, the optimal depth should be balanced with the type of leather being used, as too deep an engraving may damage thinner materials. -

Stamp Thickness

– Standard stamp thickness usually varies between 6mm to 10mm. A thicker stamp provides better durability and a more robust impression, making it ideal for high-volume stamping operations. Conversely, thinner stamps may be suitable for delicate designs but could wear out faster. -

Tolerance Levels

– Tolerance refers to the permissible limit of variation in the dimensions of the stamp. Precise tolerances are critical, especially when integrating stamps into automated production processes. Ensuring tight tolerances can lead to consistent results and minimize production errors. -

Size Specifications

– The size of the stamp is often defined in square centimeters. Most manufacturers offer standard sizes but can create custom dimensions based on client needs. For example, a design area of 10cm² is common, but larger sizes may incur additional costs. -

Production Lead Time

– Understanding the production lead time is vital, especially for businesses requiring quick turnarounds. Standard production times can range from a few days to several weeks, depending on the complexity of the design and the manufacturer’s workload.

What Are the Common Trade Terms Related to Custom Leather Stamps?

Familiarity with industry terminology is essential for effective communication and negotiation in the custom leather stamp market. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that manufacture products based on designs provided by another company. In the context of custom leather stamps, it often pertains to suppliers who create stamps tailored to a brand’s specifications. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest order quantity that a supplier is willing to accept. Understanding the MOQ is essential for budgeting and inventory planning, especially for businesses that may not require large quantities initially. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers asking for price estimates based on specific requirements. This process helps buyers compare costs and select the best supplier for their needs. -

Incoterms (International Commercial Terms)

– Incoterms are a series of international trade terms that define the responsibilities of buyers and sellers in shipping. They clarify who is responsible for transportation, insurance, and tariffs, which is crucial for international transactions. -

Customization Options

– This term refers to the various ways a leather stamp can be tailored to meet specific needs, including design alterations, size adjustments, and material choices. Clear communication about customization options can enhance customer satisfaction and ensure the final product aligns with expectations. -

Heat Embossing

– Heat embossing involves using heat and pressure to create raised designs on leather. It’s important for buyers to know if their chosen stamp is compatible with heat embossing techniques, as this can expand the range of applications for their products.

Understanding these technical properties and trade terms can empower B2B buyers to make informed decisions, ensuring they select the right custom leather stamps for their unique applications.

Navigating Market Dynamics and Sourcing Trends in the custom leather stamp Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Stamp Sector?

The custom leather stamp market is experiencing significant growth, driven by increasing demand for personalized leather goods across various industries, including fashion, automotive, and crafts. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for high-quality, customizable solutions to differentiate their products. Emerging technologies, such as CNC machining and 3D printing, are revolutionizing the production of leather stamps, enabling quicker turnaround times and more intricate designs. For instance, many suppliers now offer rapid production capabilities, with some able to ship custom stamps within 2-3 working days, catering to urgent requirements.

Moreover, the trend towards digitalization in sourcing processes is prominent. B2B platforms and e-commerce solutions are simplifying the procurement of custom leather stamps, allowing buyers to easily compare prices, specifications, and lead times. Additionally, there is a growing emphasis on multi-functionality in stamping tools, with many manufacturers offering stamps that can be used for both wet and heat stamping applications. This versatility appeals to manufacturers who wish to streamline their production processes and reduce equipment costs.

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Stamp Market?

Sustainability has become a cornerstone of purchasing decisions in the custom leather stamp sector. Buyers are increasingly aware of the environmental impact of leather production and are seeking suppliers who prioritize ethical sourcing practices. This includes using vegetable-tanned leather, which is less harmful to the environment compared to chrome-tanned alternatives, and sourcing materials from suppliers with transparent supply chains.

Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction among B2B buyers, as these credentials provide assurance regarding the sustainability and ethical practices of suppliers. Manufacturers are also adopting eco-friendly production methods, such as reducing water usage and minimizing waste during the stamping process. By aligning with suppliers that demonstrate a commitment to sustainability, B2B buyers can enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Historical Context of Custom Leather Stamps in the B2B Landscape?

The custom leather stamp has evolved significantly from its artisanal roots to a more industrialized production process. Initially, leather stamping was a manual craft, where artisans used basic tools to create designs. However, advancements in technology, such as CNC machining and laser engraving, have transformed the sector, allowing for high precision and the ability to produce complex designs at scale. This evolution has made custom leather stamps more accessible to a broader range of businesses, from small craftspeople to large manufacturers.

Today, the ability to create bespoke stamps tailored to specific branding needs is a crucial factor for many companies, reflecting a shift towards personalization in the leather goods market. This historical progression underscores the importance of adapting to technological advancements and consumer preferences in the custom leather stamp sector, making it a dynamic and evolving field for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather stamp

-

1. How do I choose the right custom leather stamp for my business needs?

Selecting the right custom leather stamp involves understanding your specific requirements, such as the type of leather you will be using, the design complexity, and the intended application (e.g., branding, embossing). Consider the material of the stamp—brass, steel, or aluminum—each offering different durability and heat conductivity. Additionally, consult with suppliers about the engraving depth and size to ensure the stamp meets your branding specifications. Engaging in a dialogue with your supplier can provide insights into the best options for your unique project. -

2. What is the typical turnaround time for custom leather stamps?

Turnaround times for custom leather stamps can vary based on the supplier and the complexity of your order. Generally, many suppliers offer a production time of 2-3 business days for standard orders. For rush orders, expedited processing is often available at an additional cost. Always confirm the expected delivery time with your supplier to align with your project deadlines, especially for international shipping, which may add to the overall time frame. -

3. What are the minimum order quantities (MOQs) for custom leather stamps?

Minimum order quantities for custom leather stamps vary by supplier and can depend on the type of stamp and the materials used. Some manufacturers may have MOQs as low as one stamp for simple designs, while others may require larger orders for custom projects. It’s essential to discuss your needs directly with suppliers to find the best fit for your budget and production capabilities, particularly if you’re sourcing internationally. -

4. How can I ensure the quality of custom leather stamps from suppliers?

To ensure the quality of custom leather stamps, conduct thorough research on potential suppliers. Look for customer reviews, request samples, and inquire about their manufacturing processes. Additionally, check if they provide guarantees on their products or offer to revise designs if they don’t meet your specifications. Establishing a clear communication channel with the supplier can help address any concerns and ensure that the final product aligns with your expectations. -

5. What payment terms should I expect when ordering custom leather stamps?

Payment terms for custom leather stamps can vary widely between suppliers. Common arrangements include upfront payments, deposits, or payment upon delivery. For international transactions, be aware of potential currency fluctuations and additional fees. It’s advisable to clarify payment options and terms early in the negotiation process to avoid misunderstandings. Using secure payment methods can also provide added protection for your transaction. -

6. How do I handle shipping and logistics for international orders of custom leather stamps?

When ordering custom leather stamps internationally, consider factors such as shipping costs, delivery times, and customs regulations. Discuss logistics with your supplier to determine the best shipping method for your needs. It’s also wise to familiarize yourself with import duties and taxes in your country to avoid unexpected costs. Establishing a reliable freight forwarder can streamline the shipping process and ensure timely delivery. -

7. Can I customize the design and specifications of my leather stamp?

Yes, most suppliers offer customization options for leather stamps, including the design, size, and material. You can provide your artwork or request assistance in creating a unique design that reflects your brand. Be clear about your specifications, such as engraving depth and stamp thickness, to ensure the final product meets your needs. Working closely with the supplier during the design phase can help ensure that the stamp aligns with your vision. -

8. What types of leather are best suited for custom stamping?

Custom leather stamps are most effective on vegetable-tanned leather, which is known for its ability to hold impressions well. However, they can also be used on other types of leather, such as chrome-tanned or Horween leather, depending on the stamping method. Discuss with your supplier the type of leather you plan to use to receive tailored recommendations on the best stamping techniques and materials for optimal results.

Top 7 Custom Leather Stamp Manufacturers & Suppliers List

1. Infinity Stamps – Leather Stamping Solutions

Domain: infinitystamps.com

Registered: 2001 (24 years)

مقدمة: Leather Stamps – Infinity Stamps Inc. offers a variety of leather stamping products including: Handheld Stamps, Plate Stamps, Pin Marking Devices, Roll Dies, Maker Stamps, Hot Stamps, and Steel Type Stamps & Holders specifically designed for leather. The company is family-owned and has been in business for over 25 years, emphasizing quality and American-made products.

2. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

مقدمة: Custom Leather Stamp for leather embossing & leather stamping\nRegular price: US$68.00\nSize options: Up to 1.25 x 1.25 inch / 3 x 3 cm, Up to 1.5 x 1.5 inch / 4 x 4 cm, Up to 2 x 2 inch / 5 x 5 cm, Up to 3 x 3 inch / 7.5 x 7.5 cm, Up to 4 x 4 inch / 10 x 10 cm\nProduction lead time: 2-5 working days, with rush orders available (additional cost)\nMaterial: Solid Brass\nStamp thickness: 8mm\nEngrav…

3. Buckeye Engraving – Custom Leather Stamps

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

مقدمة: Buckeye Engraving offers custom leather stamps, dies, and branding irons made in the USA. The stamps can be made from aluminum, steel, or brass, with brass being the most popular choice due to its durability and resistance to rust. The company provides high-detail stamps that are machined to specifications and hand-finished. Leather hand stamps come with a heavy-duty removable steel handle, while …

4. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

مقدمة: Custom Brass Leather Stamps, Cutting Dies, Lettersets; Made in the USA; Custom stamps CNC milled from solid brass; Thickness up to 1″; Compatible with branding irons and standard presses; Custom leather cutting dies made from solid steel; Requires simple outline and sizing information; Fast turnaround with all custom stamps shipping next business day; Customer testimonials highlight excellent serv…

5. Tandy Leather – Custom Stamps

Domain: tandyleather.com

Registered: 1996 (29 years)

مقدمة: This company, Tandy Leather – Custom Stamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Custom Brand – Leather Embossing Stamp

7. Steel Stamps Inc. – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

مقدمة: Custom Leather Stamps available at Steel Stamps Inc. include various categories such as Custom Jewelry Stamps, Custom Steel Stamps for Knife Makers, Blacksmiths, Farriers, and Custom Locksmith Stamps & Industrial Markings. The collection features Leather Design Stamps, including Sheridan Flowers/Leaves, Leather State Stamps, and various Pro Series Designs. Additionally, there are specialized stamp…

Strategic Sourcing Conclusion and Outlook for custom leather stamp

In the evolving landscape of custom leather stamps, strategic sourcing emerges as a pivotal element for B2B buyers looking to enhance their product offerings. Key takeaways include the importance of selecting high-quality materials, such as brass or steel, which not only ensure durability but also offer superior results for both embossing and stamping. Understanding the specifications of custom stamps, including design precision and material compatibility, is essential for maximizing investment.

Illustrative image related to custom leather stamp

For international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, establishing partnerships with reputable manufacturers can streamline the sourcing process. Leveraging advanced technologies like CNC machining allows for rapid production times, meeting the demands of fast-paced markets. Furthermore, engaging with suppliers that offer personalized service and support can lead to better customization options and overall satisfaction.

As we look to the future, the demand for customized leather products is expected to grow, driven by trends in personalization and craftsmanship. Now is the time for B2B buyers to explore strategic sourcing opportunities that will not only elevate their brand but also foster lasting relationships with reliable suppliers. Embrace the potential of custom leather stamps to leave a mark on your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom leather stamp

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.