Introduction: Navigating the Global Market for custom leather boots

In the fast-evolving landscape of international trade, sourcing high-quality custom leather boots poses a unique challenge for B2B buyers. As businesses in diverse sectors—from construction to fashion—seek reliable suppliers, understanding the nuances of custom leather boot manufacturing becomes paramount. This guide serves as your comprehensive resource, covering various types of custom leather boots, their applications across different industries, and essential criteria for vetting suppliers. Additionally, we delve into cost considerations and market trends that influence purchasing decisions.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—navigating the complexities of the global leather boot market is crucial. The demand for durable, stylish, and functional footwear is on the rise, making it imperative to partner with manufacturers that can deliver on quality and customization. By leveraging the insights and strategies outlined in this guide, you can make informed decisions that align with your business needs, ensuring that your investment in custom leather boots not only meets but exceeds expectations. Prepare to elevate your procurement strategy with actionable insights that empower you to thrive in a competitive marketplace.

Table Of Contents

- Top 9 Custom Leather Boots Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather boots

- Understanding custom leather boots Types and Variations

- Key Industrial Applications of custom leather boots

- 3 Common User Pain Points for ‘custom leather boots’ & Their Solutions

- Strategic Material Selection Guide for custom leather boots

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather boots

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather boots’

- Comprehensive Cost and Pricing Analysis for custom leather boots Sourcing

- Alternatives Analysis: Comparing custom leather boots With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather boots

- Navigating Market Dynamics and Sourcing Trends in the custom leather boots Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather boots

- Strategic Sourcing Conclusion and Outlook for custom leather boots

- Important Disclaimer & Terms of Use

Understanding custom leather boots Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Work Boots | Reinforced toe, slip-resistant soles, waterproof options | Construction, manufacturing, outdoor work | Pros: Durable, protective; Cons: Can be heavy, may require break-in period. |

| Logging Boots | High shaft for ankle support, steel toe options | Logging, forestry, heavy-duty tasks | Pros: Excellent support, rugged; Cons: Bulkiness can limit mobility. |

| Fire Boots | Flame-resistant materials, high-visibility features | Firefighting, rescue operations | Pros: Safety-focused, specialized protection; Cons: Higher cost, limited styles. |

| Tactical Boots | Lightweight, breathable materials, rugged design | Military, law enforcement, security | Pros: Comfort and agility; Cons: May lack waterproofing in some models. |

| Custom Dress Boots | Tailored fit, premium leather, stylish design | Corporate environments, formal events | Pros: Professional appearance, personalized fit; Cons: Higher price point, longer lead time. |

What Are the Key Characteristics of Work Boots for B2B Buyers?

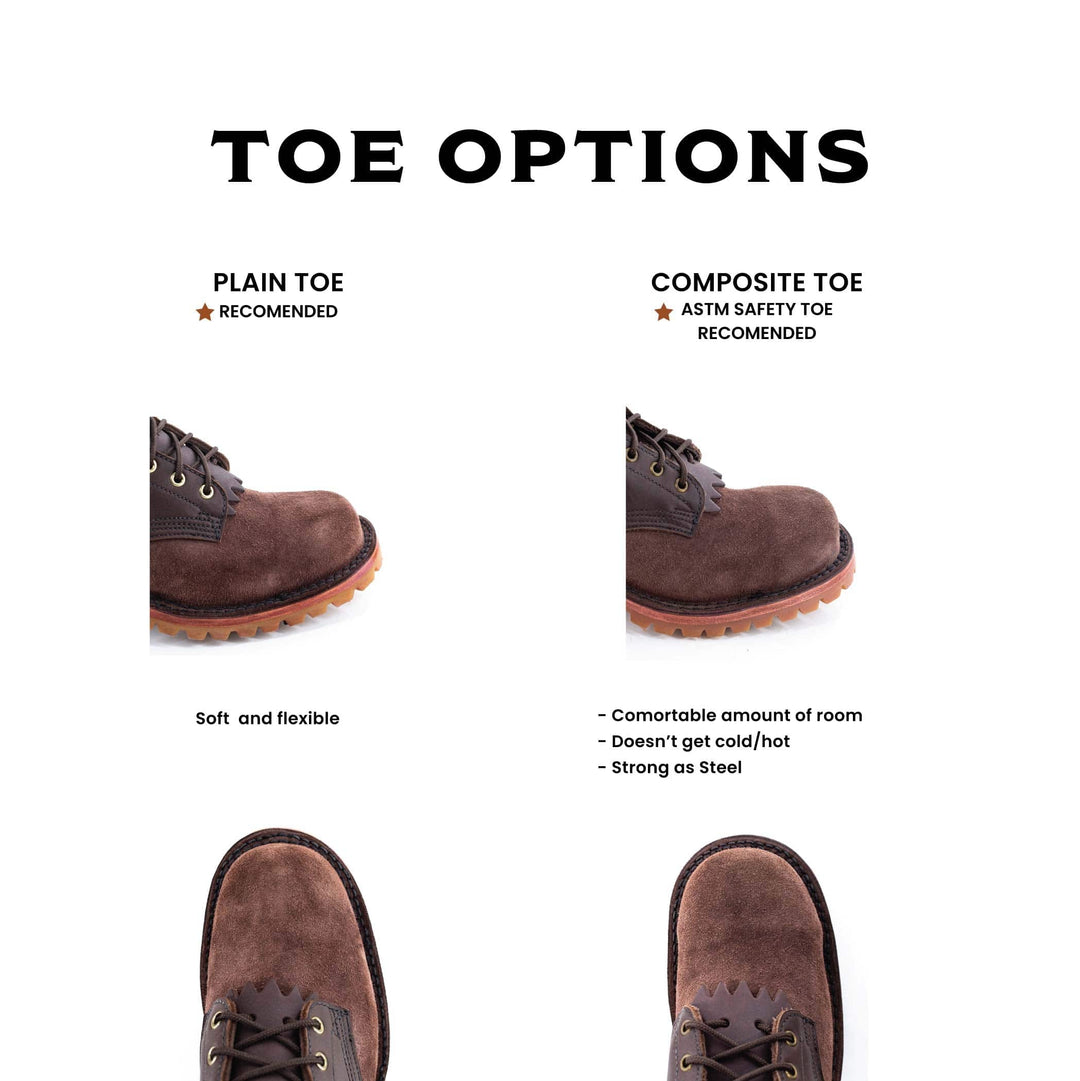

Work boots are designed for rugged use, featuring reinforced toes and slip-resistant soles, making them ideal for construction and manufacturing environments. Their waterproof options provide added protection against various weather conditions. B2B buyers should consider durability and comfort, as these boots often require a break-in period but are essential for ensuring employee safety on job sites.

How Do Logging Boots Provide Support in Challenging Environments?

Logging boots typically have a high shaft to offer superior ankle support and may include steel toe options for added safety. These boots are crucial for forestry and heavy-duty tasks where foot protection is paramount. Buyers should evaluate the balance between ruggedness and mobility, as the bulkiness of these boots can sometimes hinder agility in challenging terrains.

What Makes Fire Boots Essential for Emergency Services?

Fire boots are crafted from flame-resistant materials and often feature high-visibility elements to ensure safety during emergency operations. They are indispensable for firefighting and rescue missions, providing specialized protection against extreme conditions. While they offer critical safety benefits, B2B buyers should be aware of the higher cost and limited styles available in this category.

Why Are Tactical Boots a Preferred Choice for Military and Security?

Tactical boots are lightweight and breathable, designed for agility and comfort in demanding situations. They are commonly used by military personnel, law enforcement, and security professionals. Buyers should focus on the boot’s flexibility and overall fit, but also consider that some models may not offer waterproofing, which could be a limitation in certain environments.

How Do Custom Dress Boots Enhance Professional Appearance?

Custom dress boots are tailored to provide a perfect fit and are often made from premium leather, offering a stylish option for corporate settings and formal events. B2B buyers should appreciate the value of personalized footwear that enhances professional appearance, though they should also factor in the higher price point and longer lead time associated with custom orders.

Key Industrial Applications of custom leather boots

| Industry/Sector | Specific Application of custom leather boots | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Safety and work boots for construction workers | Enhanced safety and durability for labor-intensive tasks | Compliance with safety standards, comfort for long hours, custom fit |

| Agriculture | Custom boots for farm and ranch workers | Improved foot protection and support in rugged environments | Weather resistance, waterproof options, easy maintenance |

| Military & Law Enforcement | Tactical and service boots | Operational effectiveness and durability under extreme conditions | Availability of custom specifications, lightweight materials, and breathability |

| Outdoor Recreation | Hiking and hunting boots | Enhanced performance and comfort for outdoor activities | Customization for terrain-specific needs, moisture-wicking properties |

| Manufacturing | Industrial boots for factory workers | Increased productivity and safety in manufacturing environments | Compliance with industry standards, resoleable options, and customization for fit |

How are Custom Leather Boots Used in the Construction Industry?

In the construction industry, custom leather boots are essential for ensuring worker safety and comfort on job sites. These boots are designed to meet rigorous safety standards, offering features like steel toe caps, slip-resistant soles, and waterproof materials. The unique requirements of construction work, such as prolonged standing and exposure to harsh environments, necessitate a customized fit that can alleviate discomfort and prevent injuries. For international buyers, sourcing boots that comply with local safety regulations while providing durability and comfort is crucial.

What Role Do Custom Leather Boots Play in Agriculture?

For agricultural workers, custom leather boots provide critical foot protection and support in challenging conditions. These boots are often designed to be waterproof, which is essential for those working in wet or muddy environments. They also offer features like reinforced toe caps and slip-resistant soles to enhance safety during long hours of labor. Buyers from regions like Africa and South America may prioritize sourcing boots that are not only durable but also breathable to combat heat and humidity, ensuring comfort throughout the workday.

How Are Custom Leather Boots Beneficial for Military and Law Enforcement?

In military and law enforcement applications, custom leather boots are vital for operational effectiveness. These boots must withstand extreme conditions while providing comfort and support during prolonged use. Features such as lightweight materials, tactical designs, and moisture-wicking capabilities are essential for performance. For international buyers in the Middle East or Europe, ensuring that boots meet specific operational requirements and local regulations is key to maintaining the safety and effectiveness of personnel in the field.

Illustrative image related to custom leather boots

Why Are Custom Leather Boots Important for Outdoor Recreation?

For outdoor enthusiasts, custom leather boots are tailored to enhance performance during hiking, hunting, and other outdoor activities. These boots are often designed with specific terrain in mind, offering features like ankle support, waterproofing, and advanced traction. Buyers in regions with diverse landscapes, such as mountainous areas in Europe or the rugged terrains of South America, will benefit from sourcing boots that meet their specific outdoor needs. Customization options can include fit adjustments and material choices to ensure maximum comfort and functionality.

How Do Custom Leather Boots Improve Safety in Manufacturing?

In the manufacturing sector, custom leather boots play a crucial role in ensuring worker safety and productivity. These boots are often required to meet industry safety standards, including slip resistance and electrical hazard protection. Customization allows for a perfect fit, which is essential for workers who spend long hours on their feet. B2B buyers in Europe or Africa should consider sourcing boots that not only comply with safety regulations but also offer features like durability and ease of maintenance, ensuring long-lasting use in demanding environments.

3 Common User Pain Points for ‘custom leather boots’ & Their Solutions

Scenario 1: Sizing Discrepancies Leading to Discomfort

The Problem: Many B2B buyers face challenges with sizing when ordering custom leather boots, particularly when dealing with international suppliers. Variations in sizing standards across different countries can lead to significant discomfort for end-users. Buyers may receive boots that are too tight or too loose, resulting in dissatisfaction and potential returns. This not only impacts employee morale but can also incur additional costs for the business due to shipping and restocking.

The Solution: To mitigate sizing discrepancies, B2B buyers should establish a clear communication channel with suppliers regarding sizing standards. It’s crucial to provide detailed foot measurements (including length, width, and arch type) to the manufacturer. Consider utilizing a standardized sizing chart that aligns with the supplier’s specifications. Additionally, requesting samples or utilizing a fitting program before placing a bulk order can ensure a proper fit. This proactive approach can enhance user satisfaction and reduce the likelihood of returns.

Scenario 2: Durability Concerns for Heavy-Duty Use

The Problem: Custom leather boots are often expected to endure rigorous conditions, especially in industries such as construction, logging, or emergency services. B2B buyers may worry about the durability and longevity of the boots, particularly when investing in custom orders that can be significantly more expensive than standard options. A lack of confidence in the product’s durability can lead to hesitance in placing large orders, as buyers fear the potential for high failure rates and subsequent replacement costs.

Illustrative image related to custom leather boots

The Solution: To address durability concerns, buyers should thoroughly research the materials and construction methods used by potential suppliers. Look for boots made from high-quality full-grain leather and those constructed with techniques like Goodyear welting, which allows for resoling. Request detailed information about warranty policies and the manufacturer’s history in producing heavy-duty footwear. Engaging in direct conversations with suppliers about the specific use cases and stress testing their products can also provide insights into durability. Finally, consider implementing a trial period for bulk purchases, allowing end-users to evaluate performance in real-world conditions before committing to larger orders.

Scenario 3: Limited Customization Options Hindering Brand Identity

The Problem: In a competitive marketplace, B2B buyers often seek to differentiate their brand through unique and customized footwear options. However, many suppliers may offer limited customization features, which can hinder a company’s ability to create a distinct brand identity. This limitation is particularly felt in sectors where brand representation is crucial, such as in hospitality or corporate environments. Buyers may find themselves compromising on their brand’s image if the available custom options do not align with their vision.

The Solution: To ensure that the final product aligns with brand identity, B2B buyers should actively seek suppliers that offer extensive customization options. This includes not just color and material choices but also personalized features such as logo embossing, unique sole designs, and customizable fits. Requesting a portfolio of past custom projects can help gauge the supplier’s flexibility and creativity. Additionally, engaging in a collaborative design process with the manufacturer can lead to innovative solutions that reflect the brand’s ethos. By prioritizing suppliers that can provide tailored solutions, buyers can enhance their brand visibility and ensure that the footwear resonates with their target audience.

Strategic Material Selection Guide for custom leather boots

When selecting materials for custom leather boots, international B2B buyers must consider various factors that influence product performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the production of custom leather boots, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in diverse markets.

Illustrative image related to custom leather boots

What Are the Key Properties of Full Grain Leather for Custom Leather Boots?

Full grain leather is renowned for its durability and natural appearance. It retains the original texture and imperfections of the hide, providing a unique aesthetic. This material is breathable and develops a rich patina over time, enhancing its visual appeal. Full grain leather can withstand high temperatures and is resistant to moisture, making it suitable for various environments.

Pros: Full grain leather is extremely durable, offers excellent breathability, and ages beautifully. It is ideal for high-performance boots that require longevity and comfort.

Cons: The cost of full grain leather is relatively high, and its manufacturing process can be complex due to the need for careful selection and treatment of the hides.

Impact on Application: Full grain leather is suitable for rugged environments, making it ideal for work boots in construction or outdoor activities. It is compatible with various weather conditions, ensuring reliable performance.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with leather sourcing standards, such as REACH in the EU. Additionally, they should consider the environmental impact of leather production and seek suppliers with sustainable practices.

Illustrative image related to custom leather boots

How Does Suede Compare to Other Materials for Custom Leather Boots?

Suede, a type of leather made from the underside of the hide, is softer and more pliable than full grain leather. It offers a unique texture and is often used in fashion-oriented designs. Suede is less durable than full grain leather but provides a comfortable fit.

Pros: Suede is lightweight, offers a luxurious feel, and is available in various colors. It is ideal for casual or fashion boots.

Cons: Suede is more susceptible to stains and water damage, requiring regular maintenance. Its durability is lower compared to full grain leather.

Impact on Application: Suede is best suited for casual wear and less demanding environments. It may not be ideal for heavy-duty applications but works well in fashion-centric markets.

Illustrative image related to custom leather boots

Considerations for International Buyers: Buyers in South America and Africa should be aware of the climate’s impact on suede. Proper care products must be considered to maintain the material’s appearance and longevity.

What Are the Benefits of Using Synthetic Leather in Custom Leather Boots?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers an alternative to traditional leather. It is designed to mimic the look and feel of real leather while being more affordable and easier to maintain.

Pros: Synthetic leather is cost-effective, water-resistant, and available in a wide range of colors and textures. It is also easier to clean and maintain compared to natural leather.

Cons: While synthetic leather can be durable, it typically does not offer the same level of breathability and longevity as full grain leather. It may also lack the unique character that natural leather develops over time.

Impact on Application: Synthetic leather is suitable for budget-conscious markets and applications where moisture resistance is crucial, such as in regions with high humidity.

Illustrative image related to custom leather boots

Considerations for International Buyers: Buyers in regions like Saudi Arabia and Germany should consider the environmental implications of synthetic materials and ensure compliance with local regulations regarding the use of chemicals in production.

How Does Nubuck Leather Enhance Custom Leather Boots?

Nubuck leather is similar to suede but is made from the outer side of the hide, giving it a more durable finish. It has a soft, velvety texture and is often used in high-quality footwear.

Pros: Nubuck is durable, offers a luxurious feel, and is more resistant to wear and tear compared to suede. It provides a good balance between comfort and durability.

Illustrative image related to custom leather boots

Cons: Like suede, nubuck is susceptible to staining and requires regular maintenance to preserve its appearance.

Impact on Application: Nubuck is suitable for both casual and semi-formal boots, appealing to fashion-conscious consumers.

Considerations for International Buyers: Buyers should be aware of the specific care requirements for nubuck and ensure that suppliers provide appropriate maintenance products. Compliance with local leather quality standards is also essential.

Summary Table of Material Selection for Custom Leather Boots

| Material | Typical Use Case for custom leather boots | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Heavy-duty work boots | Exceptional durability | High cost and complex mfg process | High |

| Suede | Casual or fashion boots | Luxurious feel and lightweight | Less durable and stain-prone | Medium |

| Synthetic Leather | Budget-friendly and moisture-resistant boots | Cost-effective and easy maintenance | Lacks breathability and character | Low |

| Nubuck Leather | Casual to semi-formal boots | Durable with a luxurious feel | Stain susceptibility and care needed | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials available for custom leather boots, helping them make informed decisions that align with their specific market needs and compliance requirements.

Illustrative image related to custom leather boots

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather boots

What Are the Key Stages in the Manufacturing Process of Custom Leather Boots?

The manufacturing of custom leather boots involves multiple intricate stages, each critical to ensuring the final product meets quality standards and customer specifications. The main stages of production include material preparation, forming, assembly, and finishing.

Material Preparation

The journey begins with selecting high-quality leather and other materials. Tannery processes can vary, with options like vegetable tanning or chrome tanning affecting the leather’s durability, flexibility, and aesthetic. Once selected, the leather is cut into various shapes and sizes, tailored to the specific design of the boot. This stage may also involve treating the leather with oils or waxes to enhance water resistance and longevity.

Forming

In this stage, the prepared leather is shaped to fit the desired boot design. Techniques such as lasting involve stretching the leather over a foot-shaped mold (the last) to create the boot’s shape. Hand-sewn methods, as seen in high-end brands, require skilled artisans to stitch the leather together, ensuring a perfect fit and strong seams. This step is crucial for achieving the comfort and durability that custom boots are known for.

Assembly

Once the boot components are formed, they move to the assembly stage. This involves attaching the upper part of the boot to the sole, often using methods like Goodyear welting or cementing. Each method has its advantages: Goodyear welted boots are generally more durable and can be resoled, while cemented boots may offer a lighter weight and lower cost. The assembly process also includes adding features such as eyelets, laces, and insoles, tailored to customer specifications.

Finishing

The final stage is finishing, where the boots undergo quality checks, polishing, and any additional treatments such as waterproofing. This stage ensures the boots not only look appealing but are also functional and ready for use. Quality assurance practices during this phase are vital, as they help identify any defects that may have occurred during production.

How Is Quality Assurance Implemented in Custom Leather Boot Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for custom leather boots, especially for B2B buyers who require reliability and consistency in their products. Implementing robust QA procedures involves adhering to international standards and conducting thorough inspections throughout the production process.

International Standards for Quality Assurance

Many manufacturers comply with international quality standards such as ISO 9001, which outlines requirements for quality management systems. This certification demonstrates a commitment to quality and customer satisfaction. Additionally, industry-specific standards such as CE marking for safety and environmental compliance can be relevant, depending on the intended use of the boots, such as in industrial or hazardous environments.

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure adherence to quality standards. Key checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality before they enter production. This includes verifying leather quality, checking for defects, and ensuring compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are performed at various stages to catch defects early. For example, checks may be conducted after the lasting and assembly stages to ensure proper fit and construction.

-

Final Quality Control (FQC): Once production is complete, the finished boots undergo a final inspection. This includes checking for overall appearance, functionality, and comfort. Any boots that do not meet the established criteria are either repaired or discarded.

Common Testing Methods for Quality Assurance

Several testing methods are employed to evaluate the quality of custom leather boots. These may include:

Illustrative image related to custom leather boots

-

Durability Testing: Assessing how well the boots withstand wear and tear, often through simulated conditions.

-

Water Resistance Testing: Ensuring that the leather and seams can repel moisture effectively.

-

Comfort Testing: Evaluating the fit and comfort of the boots through wear trials.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control practices of potential suppliers is essential to ensure product reliability and compliance with local regulations.

Conducting Supplier Audits

One of the most effective methods for verifying quality control practices is through supplier audits. These audits can be conducted on-site or remotely and should assess the manufacturer’s adherence to quality standards, production processes, and overall operational efficiency. Buyers should look for suppliers with a proven track record of compliance with international standards.

Requesting Quality Reports and Certifications

B2B buyers should request quality reports and certifications from their suppliers. These documents provide insights into the manufacturer’s quality assurance processes and compliance with industry standards. Certifications such as ISO 9001, CE, and any relevant local certifications can serve as indicators of a supplier’s commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These services can conduct inspections at various stages of production, providing detailed reports on compliance with specifications and standards.

Illustrative image related to custom leather boots

What Are the Unique Quality Control Considerations for International Buyers?

When sourcing custom leather boots internationally, buyers must navigate several quality control nuances that can vary by region. This includes understanding local regulations, cultural expectations, and logistical challenges.

Cultural Expectations and Standards

Different regions may have varying expectations regarding quality and craftsmanship. For instance, European buyers may prioritize artisanal techniques and heritage craftsmanship, while Middle Eastern buyers may focus on durability and performance in harsh environments. Understanding these cultural nuances can help buyers select suppliers that align with their market needs.

Regulatory Compliance

Buyers must also consider regulatory compliance related to materials used in the boots. For instance, certain countries may have restrictions on specific types of leather or chemicals used in tanning processes. Ensuring that suppliers adhere to these regulations is crucial for avoiding legal issues and ensuring product safety.

Illustrative image related to custom leather boots

Logistical Challenges

Finally, international buyers should consider logistical challenges that may impact quality control, such as shipping delays or variations in climate that can affect material properties. Establishing clear communication channels and contingency plans with suppliers can help mitigate these risks.

In summary, the manufacturing processes and quality assurance of custom leather boots are intricate and multi-faceted. For B2B buyers, understanding these processes, implementing rigorous quality checks, and verifying supplier compliance are essential steps to ensure the procurement of high-quality footwear that meets their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather boots’

Introduction

This guide provides a comprehensive checklist for B2B buyers seeking to procure custom leather boots. It highlights essential steps to ensure you source high-quality products tailored to your specific requirements. By following this checklist, you can streamline the procurement process, minimize risks, and enhance your overall satisfaction with the purchase.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to establish clear technical specifications for the custom leather boots you need. Consider factors such as material type (e.g., full-grain leather, suede), boot style (e.g., work, tactical, fashion), and specific features (e.g., waterproofing, insulation). A well-defined specification helps suppliers understand your needs and ensures that the final product meets your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather boots. Look for manufacturers with a proven track record in quality and craftsmanship. Utilize online marketplaces, industry directories, and trade shows to gather a list of suppliers. Pay attention to reviews, ratings, and any available case studies that can give insight into their reliability and product quality.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify that your selected suppliers meet industry standards and possess relevant certifications. Certifications such as ISO 9001 for quality management or sustainability certifications can indicate a commitment to quality and ethical practices. Request documentation and validate these credentials to ensure you partner with reputable suppliers who prioritize compliance and quality.

Step 4: Request Samples and Prototypes

Before making a bulk order, request samples or prototypes of the custom leather boots. This step allows you to evaluate the quality, fit, and craftsmanship firsthand. Assess the materials used, stitching quality, and overall comfort. Ensure that the samples align with your initial specifications and that any necessary adjustments can be made before final production.

Step 5: Discuss Customization Options

Engage in detailed discussions with your chosen supplier about available customization options. This may include choices in leather color, boot height, sole type, and additional features like waterproofing or insulation. Clear communication about these options ensures that the final product meets your specific needs and can enhance your brand’s identity.

Step 6: Establish Clear Terms and Conditions

Prior to finalizing your order, establish clear terms and conditions regarding pricing, lead times, and payment methods. Ensure that you discuss minimum order quantities, shipping logistics, and return policies. A well-defined agreement protects both parties and sets clear expectations for the procurement process.

Illustrative image related to custom leather boots

Step 7: Implement Quality Control Measures

Once the order is placed, establish quality control measures to monitor the production process. This can include regular updates from the supplier, on-site inspections, or third-party quality assurance services. Implementing these measures helps catch any issues early and ensures that the final product adheres to your specifications and quality standards.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom leather boots effectively, ensuring a successful procurement process that meets their specific requirements.

Comprehensive Cost and Pricing Analysis for custom leather boots Sourcing

What Are the Key Cost Components for Sourcing Custom Leather Boots?

When considering the sourcing of custom leather boots, it is essential to understand the cost structure involved. The primary cost components include:

-

Materials: High-quality leather, lining, insoles, and soles are fundamental to the production of custom boots. The choice of leather significantly impacts the overall cost; for instance, premium leathers like Horween Chromexcel or full-grain leather can raise prices substantially due to their durability and aesthetic appeal.

-

Labor: Skilled labor is crucial for crafting custom boots, especially when hand-sewn techniques are employed. The labor cost can vary significantly based on the country of production, with regions like Europe often commanding higher wages compared to some areas in Africa or South America.

-

Manufacturing Overhead: This includes costs related to the factory’s operation, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom boots often require specific molds and tools for their production. The initial tooling investment can be high, especially for unique designs, but is amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure that each pair of boots meets the required standards. This can add to the overall cost, but it is essential for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs should not be overlooked. Factors such as distance, shipping method, and customs duties can significantly influence final costs, especially for international buyers.

-

Margin: Suppliers will typically add a margin on top of their costs to ensure profitability. This can vary based on market demand and competition.

What Influences the Pricing of Custom Leather Boots?

Several factors can influence the pricing of custom leather boots:

-

Volume/MOQ (Minimum Order Quantity): Larger orders can lead to reduced per-unit costs, making it advantageous for businesses to negotiate for bulk purchases.

-

Specifications and Customization: The level of customization required—such as unique designs, colors, or materials—can raise costs. Buyers should clearly communicate their specifications to get accurate quotes.

-

Material Quality and Certifications: Boots made from high-quality materials and those that comply with safety standards or eco-certifications may come at a premium price.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and location can also affect pricing. Established suppliers may offer reliability and quality assurance, which can justify higher costs.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

What Negotiation Tips Can Help Buyers Secure Better Prices?

-

Understand Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, longevity, and potential resale value when assessing costs.

-

Leverage Relationships: Building a long-term relationship with suppliers can lead to better pricing, as they may offer discounts for repeat business.

-

Be Clear on Specifications: Providing detailed requirements upfront can help avoid misunderstandings that lead to additional costs later.

-

Explore Multiple Suppliers: Comparing quotes from several suppliers can provide leverage during negotiations and help identify the best value.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, trade tariffs, and shipping costs, which can all affect the final price.

Conclusion

Navigating the cost structure and pricing of custom leather boots requires a clear understanding of various components and influences. By focusing on TCO and employing strategic negotiation tactics, B2B buyers can optimize their sourcing decisions, ensuring they secure quality products that meet their needs while remaining cost-effective. Keep in mind that prices can vary widely based on specifications and supplier factors, so always request detailed quotes and be prepared to discuss your requirements thoroughly.

Alternatives Analysis: Comparing custom leather boots With Other Solutions

Exploring Alternatives to Custom Leather Boots for B2B Buyers

When considering custom leather boots, it’s essential to evaluate alternative footwear solutions that might meet your specific operational needs. These alternatives can offer various benefits, such as cost savings, specialized performance, or ease of maintenance. Below, we compare custom leather boots with two viable alternatives: synthetic work boots and ready-made leather boots.

Illustrative image related to custom leather boots

| Comparison Aspect | Custom Leather Boots | Synthetic Work Boots | Ready-Made Leather Boots |

|---|---|---|---|

| Performance | Excellent durability, tailored for specific tasks | Good durability, often lightweight and water-resistant | Decent durability, may lack task-specific features |

| Cost | High initial investment ($400 – $850) | Moderate cost ($100 – $300) | Lower cost ($150 – $400) |

| Ease of Implementation | Requires fitting and customization, longer lead times | Readily available in various sizes | Available off-the-shelf, quick procurement |

| Maintenance | High maintenance; can be resoled and refurbished | Low maintenance; typically easy to clean | Moderate maintenance; may require occasional polishing |

| Best Use Case | Heavy-duty tasks in rugged environments requiring specific features | General work environments needing lightweight and moisture-resistant options | Occasional use where style and comfort are prioritized |

What Are the Pros and Cons of Synthetic Work Boots?

Synthetic work boots are designed for versatility and comfort. They are often made from materials such as nylon or polyurethane, providing water resistance and lightweight properties. The primary advantage of synthetic boots is their cost-effectiveness, making them an attractive option for businesses operating on tight budgets. However, they may lack the durability and support required for heavy-duty tasks, which could lead to higher replacement costs in the long run. Additionally, synthetic materials may not offer the same level of breathability and comfort as custom leather options.

How Do Ready-Made Leather Boots Compare?

Ready-made leather boots present a middle ground between custom options and synthetic alternatives. They are generally more affordable than custom leather boots and can be found in a variety of styles and sizes, making them accessible for immediate purchase. While they offer decent durability and a classic aesthetic, they may not provide the tailored fit or specialized features that custom boots do. As a result, they may not be suitable for all tasks, particularly in demanding work environments where fit and functionality are critical.

How Can B2B Buyers Make the Right Choice?

When selecting the right footwear solution, B2B buyers should consider their specific operational requirements, including the nature of the work, budget constraints, and the importance of comfort and durability. Custom leather boots may be ideal for industries where performance and fit are paramount, such as logging or construction. Conversely, for businesses needing a cost-effective and flexible solution, synthetic work boots or ready-made leather options may provide adequate protection and comfort without the high investment. Ultimately, the choice should align with the specific demands of the workforce and the environment in which they operate, ensuring both safety and efficiency.

Essential Technical Properties and Trade Terminology for custom leather boots

What Are the Key Technical Properties of Custom Leather Boots?

When considering custom leather boots for your business, understanding the technical properties is crucial for ensuring quality, durability, and fit. Here are some essential specifications to look for:

1. Material Grade

The quality of leather used in custom boots is paramount. Common grades include full-grain, top-grain, and corrected grain leather. Full-grain leather is the highest quality, retaining the natural grain and durability. Top-grain is slightly less robust but offers a refined appearance, while corrected grain is treated to hide imperfections. For B2B buyers, selecting the appropriate material grade ensures the longevity and performance of the boots, aligning with customer expectations and end-use conditions.

Illustrative image related to custom leather boots

2. Last Specifications

The “last” refers to the mold that determines the boot’s shape and fit. Different lasts cater to various foot shapes and activities, such as work or casual wear. A well-designed last can enhance comfort and support, reducing fatigue during extended wear. For businesses, understanding last specifications helps in offering tailored solutions that meet the specific needs of their clientele, thereby enhancing customer satisfaction.

3. Construction Method

Boot construction methods, such as Goodyear welt, Blake stitch, or stitchdown, significantly impact durability and reparability. The Goodyear welt method, for example, allows for resoling, extending the lifespan of the boot. Understanding these methods enables buyers to select boots that not only meet immediate needs but also provide long-term value through the possibility of repair.

4. Sole Composition

The sole material, whether rubber, leather, or synthetic, affects traction, flexibility, and comfort. Vibram soles are popular for their superior grip and durability, making them ideal for rugged environments. For B2B transactions, specifying sole composition ensures that the final product meets the operational demands of the end-user, particularly in challenging work conditions.

Illustrative image related to custom leather boots

5. Waterproofing and Breathability

Many custom leather boots feature waterproofing treatments and breathable linings. These properties are essential for users exposed to wet or humid environments. Understanding the balance between waterproofing and breathability can help buyers select boots that maintain comfort while providing necessary protection, a critical factor for customer satisfaction.

What Are Common Trade Terms in the Custom Leather Boot Industry?

Navigating the custom leather boot market requires familiarity with industry-specific terminology. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then sold under another company’s brand. In the custom boot industry, OEM relationships can help brands offer high-quality products without investing in manufacturing facilities. For buyers, understanding OEM partnerships can guide their sourcing strategies and ensure product authenticity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers to understand, as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases and negotiate favorable terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the custom leather boot sector, submitting an RFQ can streamline the procurement process, allowing buyers to compare options and make informed decisions based on cost and specifications.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and delivery. Familiarity with these terms is essential for B2B buyers engaged in global trade, ensuring clarity in contractual obligations and reducing the risk of disputes.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is vital for inventory planning and meeting customer demands. In the custom boot industry, lead times can vary based on materials and complexity, making this knowledge crucial for effective supply chain management.

Illustrative image related to custom leather boots

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that their investments in custom leather boots align with their business objectives and customer needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather boots Sector

Market Overview & Key Trends

The custom leather boots market is witnessing significant evolution driven by a blend of consumer demand for personalization, sustainability, and technological advancements. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, engage with this sector, understanding key trends is essential. The rise of e-commerce platforms has reshaped sourcing strategies, enabling buyers to access a wider range of manufacturers and styles, often with customizable options.

Emerging technologies such as 3D printing and digital fitting solutions are enhancing the customization experience, allowing buyers to offer tailored products that meet specific consumer needs. Additionally, the increasing influence of social media and digital marketing has created a more informed customer base that prioritizes quality and craftsmanship in their purchases.

Illustrative image related to custom leather boots

In markets like Germany and Saudi Arabia, there is a growing preference for local artisans and manufacturers who emphasize traditional craftsmanship, aligning with the global trend toward supporting small businesses and local economies. This shift not only enhances brand loyalty but also provides buyers with unique selling propositions in competitive markets. Moreover, as global supply chains become more interconnected, B2B buyers must remain vigilant about geopolitical factors and trade regulations that could impact sourcing strategies.

Sustainability & Ethical Sourcing in B2B

In today’s market, sustainability is not just a buzzword but a critical factor influencing purchasing decisions. The environmental impact of leather production, particularly in terms of water usage and chemical processing, necessitates a focus on ethical sourcing practices. B2B buyers are increasingly seeking suppliers who can provide transparency in their supply chains and demonstrate commitment to sustainable practices.

Green certifications, such as the Leather Working Group (LWG) certification, are becoming essential for manufacturers aiming to appeal to environmentally conscious buyers. These certifications not only validate the sustainability of the leather used but also assure buyers of ethical labor practices throughout the production process.

Moreover, the adoption of eco-friendly materials, such as vegetable-tanned leather and recycled components, is gaining traction. Buyers looking to differentiate their offerings can capitalize on this trend by sourcing boots that highlight these sustainable materials, thereby meeting the demand from consumers who prioritize ethical consumption.

Brief Evolution/History

The custom leather boots sector has roots that trace back centuries, with craftsmanship evolving from artisanal production to more industrialized methods while still retaining the essence of personalized service. Initially, boots were custom-made for individuals, reflecting personal style and functional needs. Over time, the advent of mass production introduced standardized sizes and styles, diminishing the bespoke nature of footwear.

Illustrative image related to custom leather boots

However, the resurgence of interest in custom leather boots in recent years signifies a return to craftsmanship and individuality. This evolution has been fueled by the desire for unique, high-quality products that resonate with consumers’ values of authenticity and sustainability. Today, B2B buyers are positioned at the forefront of this renaissance, as they seek to offer products that cater to a discerning clientele looking for both style and substance.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather boots

-

How do I ensure the quality of custom leather boots from international suppliers?

To ensure the quality of custom leather boots, start by conducting thorough research on potential suppliers. Look for certifications, customer testimonials, and case studies that highlight their manufacturing processes. Request samples to evaluate the craftsmanship, materials, and comfort. Consider setting up virtual or in-person audits to inspect their facilities and processes. Engage in clear communication about your quality standards and expectations, and inquire about their quality assurance protocols to ensure compliance with international standards. -

What customization options are available for B2B buyers of leather boots?

B2B buyers can typically customize various aspects of leather boots, including material type, color, sole type, heel height, and additional features like waterproofing or insulation. Many suppliers offer bespoke services that allow you to specify measurements for a perfect fit. It’s beneficial to request a detailed catalog of customization options and to communicate your specific requirements clearly to ensure the final product aligns with your business needs. -

What are the minimum order quantities (MOQs) for custom leather boots?

Minimum order quantities can vary significantly between suppliers, often depending on the complexity of the customization and the materials used. For many manufacturers, MOQs for custom leather boots may range from 50 to 200 pairs. It’s advisable to negotiate these terms upfront, especially if you are a smaller business. Some suppliers may offer flexibility or discounts for larger orders, so be prepared to discuss your anticipated demand and future needs. -

What payment terms should I expect when sourcing custom leather boots internationally?

Payment terms can differ widely among suppliers, but common practices include a deposit (usually 30-50%) upfront, with the balance due upon completion or before shipping. Some suppliers may offer net payment terms, allowing you to pay within a specified period after delivery. Always clarify payment methods accepted (e.g., wire transfer, credit card) and discuss any potential fees. Establishing clear payment terms in a written contract can help protect both parties and ensure a smooth transaction. -

How can I vet potential suppliers for custom leather boots?

Vetting suppliers involves multiple steps, including checking their reputation through online reviews and industry references. Conduct background checks to confirm their business legitimacy and experience in producing custom leather boots. Requesting samples can also help assess their craftsmanship. Additionally, consider visiting their manufacturing site if feasible or utilizing third-party inspection services to verify compliance with international standards. -

What logistics considerations should I keep in mind when importing custom leather boots?

Logistics play a crucial role in importing custom leather boots. Consider the shipping methods and costs, as air freight is faster but more expensive than sea freight. Factor in customs duties and tariffs, which can vary based on the country of origin and destination. Work with a reliable freight forwarder who understands international trade regulations and can facilitate smooth customs clearance. Also, ensure that you have a reliable plan for inventory management upon receipt. -

What are the common challenges faced when sourcing custom leather boots internationally?

Common challenges include communication barriers, cultural differences, and varying quality standards. Time zone differences can complicate coordination, leading to delays. Additionally, understanding international trade regulations and customs requirements can be daunting. To mitigate these challenges, establish clear lines of communication, consider hiring a local representative or agent, and engage in thorough planning and documentation to ensure compliance and smooth operations. -

How can I ensure timely delivery of custom leather boots?

To ensure timely delivery, establish clear timelines with your supplier from the outset. Confirm production lead times and set realistic delivery expectations based on shipping methods. Regularly communicate with the supplier to monitor progress and address any potential delays proactively. Building a good relationship with the supplier can also facilitate better communication and responsiveness, helping to ensure that your orders are prioritized and delivered on time.

Top 9 Custom Leather Boots Manufacturers & Suppliers List

1. Whites Boots – Key Products

Domain: whitesboots.com

Registered: 1997 (28 years)

Introduction: Key product details include: 55 Arch-Ease™ Last C350 Cruiser ($640.00), 55 Arch-Ease™ Last C350 Cutter ($640.00), 55 Arch-Ease™ Last C350-CS ($650.00), 1972 Arch-Ease™ Last Perry 6″ Select ($400.00), 55 Arch-Ease™ Last The Original 350 Cruiser ($750.00), 55 Arch-Ease™ Last The Original 350 Cutter ($750.00), 690 Arch-Ease™ Last The Original Packer ($725.00). White’s Boots are hand-sewn stitchdown b…

2. Baker’s – Custom Bounty Hunter

Domain: bakershoe.com

Registered: 1999 (26 years)

Introduction: Custom Boots available from brands like White’s, Wesco, and more. Options include: Baker’s Custom Bounty Hunter ($749.95), Custom White’s MP Service Boot ($729.95), Custom Smokejumper ($724.95), Custom Classic Semi Dress ($739.95), Baker’s Custom Horsehide Bounty Hunter ($849.95), Custom Boss Wesco ($549.95), Custom Jobmaster Wesco ($519.95), Custom Semi Dress – Horsehide ($849.95), Custom Nomad E…

3. Atitlan Leather – Custom Made Boots

Domain: atitlanleather.com

Registered: 2012 (13 years)

Introduction: Custom Made Boots | Handmade Boots Just for You. Regular price for Custom Tall Boots: $219.95. Regular price for Custom Handmade Lace Up Victorian Boots: $199.95. Regular price for Custom Chukka Boots: $199.95. Regular price for Custom Biker Boots: $199.95. All Natural Leather Balm starting from $8.99. Features include handcrafted design, Goodyear welt construction for resoling, upgraded insoles f…

4. JK Boots – Fast Delivery & Easy Returns

Domain: jkboots.com

Registered: 2012 (13 years)

Introduction: This company, JK Boots – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Custom Waterproof Leather Boots – Comfortable and Grippy

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for custom boots that are comfortable, waterproof (at least up to the ankle), preferably leather, and have decent grippy tread. Budget is preferably under $400. Previous experience with Merrell boots was comfortable but waterproof coating wore off and showed accelerated wear.

6. Nicks Handmade Boots – Quality Footwear

Domain: nicksboots.com

Registered: 1997 (28 years)

Introduction: Nicks Handmade Boots offers a variety of boot types including work boots, heritage boots, fire boots, tactical boots, western boots, hiking boots, and more. Key features include padded collars for comfort, notched uppers for flexibility, and Honey Vibram Unit Lug soles for flexibility. Popular models include Falcon, Americana, Overlander, BuilderPro HD, and Moc Toe Wedge, with prices ranging from …

7. Jim Green – Custom Made Boots

Domain: jimgreenfootwear.com

Registered: 2020 (5 years)

Introduction: Custom Made Boots by Jim Green

**Upper Styles:**

– AR8

– AR08

– Razorback

– B6

– Baobab

– AM30

– Numzaan

– AM31

– Stockman

– F3

– 719

– CM719

– African Trooper

– AR10

– African Ranger

– AR01

– Vellie

– V1

– Turbo Vellie

– S5

– Shoellie

– AM01

– Workhorse Moc Toe

– MT01

– Meander Moc Toe

– MT02

**Last Types:**

– JG Last (Wide last with low toe box)

– Zero Drop Last

– Barefoot Last

– STC Last (Wid…

8. Fillies and Boots – Custom-Made Luxury Riding Boots

Domain: filliesandboots.com

Registered: 2017 (8 years)

Introduction: Fillies and Boots offers custom-made luxury boots tailored to individual calf measurements for maximum comfort. Key product features include:

– Custom fitting based on calf circumference, calf height, and foot size.

– Dalia boots: Classic riding boots with a 4 cm hidden wedge, crafted from fine leather by Italian artisans.

– Unique, made-to-order pieces ensuring comfort and style.

– Positive c…

9. Frank’s Handmade Boots – The Patriot Collection

Domain: franksboots.com

Registered: 2016 (9 years)

Introduction: Frank’s Handmade Boots offers a variety of products including Originals, Wildland Firefighting Work Boots, Casual Boots, and Accessories. Key features include:

– The Patriot Collection: Limited edition leather, designed for various professions (wildland firefighter, construction worker, etc.), with a 3/4″ thick sole for flexibility, made from 7.5 to 8 oz. full grain water resistant leather, highe…

Strategic Sourcing Conclusion and Outlook for custom leather boots

In the competitive landscape of custom leather boots, strategic sourcing emerges as a pivotal factor for international buyers aiming to maximize value and quality. By prioritizing partnerships with manufacturers that emphasize craftsmanship, such as those employing traditional hand-sewing techniques and customizable options, businesses can ensure they meet their clients’ diverse needs while maintaining high standards of durability and comfort.

Furthermore, understanding regional preferences and market trends across Africa, South America, the Middle East, and Europe allows for tailored offerings that resonate with local consumers. This insight not only enhances customer satisfaction but also fosters long-term loyalty and brand recognition.

As the demand for customized footwear continues to rise, B2B buyers are encouraged to leverage strategic sourcing practices that prioritize quality and sustainability. Engaging with reputable suppliers who offer comprehensive customization options will not only set your business apart but also position you favorably in a burgeoning market.

Embrace this opportunity to elevate your product offerings and strengthen your supply chain. Connect with leading manufacturers today to explore innovative designs and enhance your portfolio of custom leather boots for tomorrow’s discerning clientele.

Illustrative image related to custom leather boots

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather boots