Introduction: Navigating the Global Market for leather factory florence italy

In an increasingly competitive global market, sourcing high-quality leather products from a reputable leather factory in Florence, Italy, presents unique challenges for international B2B buyers. With a rich heritage of craftsmanship and a commitment to quality, Florence stands as a beacon for businesses seeking premium leather goods. However, navigating the complexities of supplier selection, customization options, and pricing structures can be daunting, especially for buyers from diverse regions such as Africa, South America, the Middle East, and Europe, including emerging markets like Vietnam and Saudi Arabia.

This comprehensive guide aims to demystify the process of engaging with Florence’s leather factories, offering valuable insights into various types of leather products, from handbags to clothing and accessories. We will delve into key considerations for supplier vetting, including quality assurance practices and ethical sourcing, ensuring that your purchases align with both your brand’s values and customer expectations. Additionally, the guide will cover cost factors and potential for customization, enabling you to make informed decisions tailored to your specific market needs.

By equipping you with essential knowledge and actionable strategies, this guide empowers B2B buyers to confidently engage with Florence’s leather manufacturers, fostering successful partnerships that elevate your product offerings and enhance your competitive edge in the global marketplace.

Table Of Contents

- Top 8 Leather Factory Florence Italy Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather factory florence italy

- Understanding leather factory florence italy Types and Variations

- Key Industrial Applications of leather factory florence italy

- 3 Common User Pain Points for ‘leather factory florence italy’ & Their Solutions

- Strategic Material Selection Guide for leather factory florence italy

- In-depth Look: Manufacturing Processes and Quality Assurance for leather factory florence italy

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather factory florence italy’

- Comprehensive Cost and Pricing Analysis for leather factory florence italy Sourcing

- Alternatives Analysis: Comparing leather factory florence italy With Other Solutions

- Essential Technical Properties and Trade Terminology for leather factory florence italy

- Navigating Market Dynamics and Sourcing Trends in the leather factory florence italy Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather factory florence italy

- Strategic Sourcing Conclusion and Outlook for leather factory florence italy

- Important Disclaimer & Terms of Use

Understanding leather factory florence italy Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Handbag Manufacturing | Customizable designs, high-quality materials | Wholesalers, retail chains | Pros: High customization; Cons: Longer lead times |

| High-End Leather Clothing | Artisan craftsmanship, premium leather types | Fashion boutiques, luxury retailers | Pros: Unique, high-quality products; Cons: Higher costs |

| Artistic Leather Goods | Hand-decorated, traditional techniques | Art galleries, gift shops | Pros: Unique artistic appeal; Cons: Limited scalability |

| Leather Accessories Production | Variety of small items like wallets and belts | Corporate gifting, promotional items | Pros: High demand for accessories; Cons: Price sensitivity |

| Private Label Leather Goods | Custom branding options, bulk production capabilities | Retailers looking for brand exclusivity | Pros: Brand recognition; Cons: Minimum order quantities |

What are the Key Characteristics of Handbag Manufacturing in Florence?

Florence is renowned for its handbag manufacturing, which combines traditional craftsmanship with modern design techniques. Factories often offer extensive customization options, allowing B2B buyers to specify materials, colors, and branding elements. This is particularly appealing to wholesalers and retail chains looking to differentiate their product offerings. However, buyers should be aware that this customization can lead to longer production times, which may affect inventory management.

Illustrative image related to leather factory florence italy

How Does High-End Leather Clothing Production Stand Out?

High-end leather clothing production in Florence emphasizes artisanal craftsmanship, using premium materials such as nappa and washed leather. This type of production caters to fashion boutiques and luxury retailers that prioritize quality and exclusivity. Buyers can expect unique products with meticulous attention to detail, but they should also consider the higher price point associated with such premium offerings. Understanding the target market’s willingness to pay is crucial for successful procurement.

What Makes Artistic Leather Goods Unique?

Artistic leather goods from Florence are characterized by their hand-decorated finishes and traditional crafting methods. These products often draw inspiration from historical Italian art, making them highly sought after in art galleries and gift shops. While they offer a unique aesthetic appeal, the scalability of production can be a challenge, making them less suited for mass-market applications. B2B buyers should evaluate their customer base’s preferences for artistic versus functional items when considering these products.

Why are Leather Accessories Production Opportunities Valuable?

Leather accessories production encompasses a wide range of items, including wallets, belts, and small bags. This sector is ideal for corporate gifting and promotional items, as there is a consistent demand for stylish yet practical accessories. B2B buyers can capitalize on this demand, but they must be mindful of price sensitivity among consumers. Offering competitive pricing while maintaining quality is essential for success in this market.

Illustrative image related to leather factory florence italy

What Benefits Does Private Label Leather Goods Offer?

Private label leather goods manufacturing allows businesses to create exclusive products under their own brand. This option is ideal for retailers seeking to enhance brand recognition and customer loyalty. Florence’s skilled artisans can produce high-quality items tailored to the buyer’s specifications, but minimum order quantities may apply. Buyers should assess their sales forecasts to ensure they can meet these requirements while maintaining a profitable margin.

Key Industrial Applications of leather factory florence italy

| Industry/Sector | Specific Application of leather factory florence italy | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom high-end leather handbags and accessories | Unique, luxury products that cater to affluent clientele | Quality assurance, customization options, lead times |

| Automotive | Leather upholstery for luxury vehicles | Enhanced aesthetics and comfort for premium vehicles | Material specifications, durability, compliance standards |

| Hospitality | Leather furnishings for hotels and restaurants | Elegant and durable decor that elevates guest experience | Design flexibility, bulk ordering, maintenance requirements |

| Sports and Recreation | Leather goods for sports equipment | Durable products that enhance performance and style | Sizing options, material quality, branding opportunities |

| Personal Accessories | Custom leather wallets and belts | High-quality, personalized items that drive customer loyalty | Design specifications, production timelines, pricing |

How Are High-End Leather Handbags and Accessories Used in Fashion Retail?

Florence’s leather factories are renowned for crafting bespoke handbags and accessories that appeal to high-end fashion retailers. These products not only offer unique designs but also leverage Italy’s rich leather craftsmanship to attract affluent customers. International B2B buyers from regions like Africa and the Middle East can benefit from the ability to customize products, ensuring they meet specific market demands. Buyers must consider quality assurance and lead times, as timely delivery is crucial for maintaining retail schedules.

What Role Does Leather Upholstery Play in the Automotive Industry?

In the automotive sector, leather from Florence is used for upholstery in luxury vehicles, enhancing both aesthetic appeal and comfort. High-quality leather elevates the overall interior experience, making vehicles more desirable to consumers. B2B buyers in South America and Europe should focus on material specifications and durability when sourcing, as these factors significantly impact customer satisfaction. Compliance with industry standards is also essential to ensure product longevity and safety.

How Do Leather Furnishings Enhance Hospitality Experiences?

Leather furnishings crafted in Florence are increasingly popular in the hospitality industry, where aesthetics and durability are paramount. Items such as leather chairs, sofas, and decorative elements not only provide a sophisticated look but also withstand the rigors of heavy use in hotels and restaurants. For international buyers, understanding design flexibility and bulk ordering processes is vital. Additionally, maintenance requirements should be discussed upfront to ensure long-term satisfaction with the products.

Illustrative image related to leather factory florence italy

Why Are Leather Goods Important in Sports and Recreation?

Leather factories in Florence produce durable leather goods for sports equipment, enhancing both performance and style. Items such as gloves, bags, and protective gear benefit from the material’s strength and flexibility, making them ideal for athletes. B2B buyers from regions like Vietnam should prioritize sizing options and material quality when sourcing these products. Opportunities for branding on sports equipment can also create unique selling points in competitive markets.

How Do Custom Leather Wallets and Belts Drive Personal Accessory Sales?

The production of custom leather wallets and belts in Florence meets the growing demand for personalized accessories. These high-quality items are not only functional but also serve as fashion statements, driving customer loyalty. International buyers must consider design specifications and production timelines to align with market trends. Pricing strategies should also be evaluated to ensure competitiveness in diverse global markets, particularly in regions with a strong demand for luxury goods.

3 Common User Pain Points for ‘leather factory florence italy’ & Their Solutions

Scenario 1: Navigating Customization Options for Diverse Markets

The Problem: B2B buyers often struggle with the complexity of customizing leather products to meet the diverse preferences of their target markets. For instance, a buyer from South America may require specific color palettes and styles that resonate with local trends, while a buyer from Europe may prioritize sustainability and artisanal craftsmanship. This dissonance can lead to confusion and delays in production, as well as potential misalignment with customer expectations.

The Solution: To effectively navigate customization, buyers should engage with manufacturers in Florence who prioritize flexibility and communication. When initiating contact, clearly outline your market’s specific needs regarding design, materials, and branding. Leverage the expertise of Florentine artisans who can suggest options based on current trends and the latest materials. Request samples or prototypes to ensure alignment before full production. This proactive approach not only streamlines the customization process but also fosters a collaborative relationship with the manufacturer, enhancing product relevance in the target market.

Scenario 2: Ensuring Quality Control Across International Shipments

The Problem: Quality assurance becomes a significant concern when importing leather goods from Florence to various international destinations. Buyers may encounter issues such as inconsistencies in product quality, unexpected damages during transit, or discrepancies in order fulfillment. Such challenges can lead to increased costs, customer dissatisfaction, and potential damage to the buyer’s brand reputation.

Illustrative image related to leather factory florence italy

The Solution: To mitigate these risks, B2B buyers should implement a comprehensive quality control checklist before shipment. This includes verifying the quality of materials, ensuring that products meet the agreed specifications, and conducting final inspections. Establishing a clear communication channel with the manufacturer regarding packaging and handling procedures is also crucial. Additionally, consider working with logistics partners who specialize in handling delicate goods to ensure safe and timely delivery. By taking these steps, buyers can significantly reduce the likelihood of quality-related issues and maintain their brand integrity.

Scenario 3: Understanding Lead Times and Production Capacities

The Problem: Buyers often face unpredictability regarding lead times and production capacities, particularly when placing large orders or during peak seasons. This uncertainty can disrupt supply chains, making it difficult for businesses to meet customer demand and plan for inventory management effectively. Buyers from regions with high demand, such as the Middle East or Europe, may find themselves in a race against time to secure their orders.

The Solution: To tackle this challenge, it is essential for buyers to develop a clear understanding of the manufacturer’s production processes and capacities. Initiate discussions about lead times early in the procurement process and inquire about the factors that could affect these timelines. Establishing a partnership approach allows for better forecasting and planning. Additionally, consider placing orders well in advance of peak seasons and exploring options for smaller, staggered shipments to manage cash flow and inventory levels effectively. By fostering open communication and strategic planning, buyers can better align their operations with the production capabilities of Florentine leather factories.

Strategic Material Selection Guide for leather factory florence italy

What Are the Key Materials Used in Leather Production in Florence?

Florence is renowned for its high-quality leather goods, and the selection of materials plays a pivotal role in determining the performance and appeal of these products. Below, we analyze four common materials used in leather production, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Full-Grain Leather Perform in Leather Goods Manufacturing?

Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain, which provides durability and breathability.

Illustrative image related to leather factory florence italy

- Key Properties: Full-grain leather boasts exceptional strength and resistance to wear and tear. It can withstand high temperatures and is less susceptible to moisture damage compared to other types of leather.

- Pros & Cons: The durability of full-grain leather makes it ideal for high-end products, but it comes at a higher cost. Its manufacturing process is complex, requiring skilled artisans, which can increase production time.

- Impact on Application: Full-grain leather is suitable for luxury handbags and accessories, as it ages beautifully and develops a unique patina.

- Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for quality assurance. Markets in Africa and the Middle East may prefer products that showcase authenticity and craftsmanship.

What Are the Benefits of Top-Grain Leather for Fashion Accessories?

Top-grain leather is the second-highest quality leather, made from the inner layer of the hide. It is sanded and refinished to remove imperfections, resulting in a smooth surface.

- Key Properties: This leather is slightly less durable than full-grain but offers a good balance of durability and affordability. It has a moderate resistance to moisture and is easier to clean.

- Pros & Cons: Top-grain leather is versatile and can be used for a variety of products, including handbags and wallets. However, it may not develop the same character as full-grain leather over time, which can be a drawback for luxury markets.

- Impact on Application: It is particularly suitable for fashion accessories that require a polished look without the premium price tag of full-grain leather.

- Considerations for International Buyers: Buyers from Europe may prioritize top-grain leather for its aesthetic appeal, while those from South America may focus on its ease of maintenance.

Why Choose Suede Leather for Unique Textures in Leather Goods?

Suede leather, made from the underside of the hide, offers a soft texture and a distinct aesthetic.

- Key Properties: Suede is less durable than full-grain and top-grain leather but provides excellent flexibility and comfort. It is sensitive to moisture and can be easily stained.

- Pros & Cons: The unique texture of suede makes it popular for fashion-forward products, but its maintenance requirements can be a drawback. It is generally less expensive than full-grain leather but may require more frequent replacement.

- Impact on Application: Suede is often used in clothing and accessories where a soft touch is desired, such as jackets and bags.

- Considerations for International Buyers: Buyers should be aware of the climate in their regions, as suede may not perform well in humid environments. Compliance with local standards for textile products is also essential.

How Does Vegetable-Tanned Leather Compare to Other Types?

Vegetable-tanned leather is produced using natural tannins from plants, making it a sustainable choice.

- Key Properties: This type of leather is biodegradable and has a unique, rustic appearance. It is generally more rigid and less water-resistant than chrome-tanned leather.

- Pros & Cons: Vegetable-tanned leather is favored for its eco-friendliness and ability to develop a rich patina. However, its rigidity can limit its use in more flexible products, and it typically requires more care.

- Impact on Application: It is ideal for artisanal products and custom leather goods, where sustainability is a selling point.

- Considerations for International Buyers: Buyers from environmentally conscious markets in Europe may prefer vegetable-tanned leather, while those from regions with different sustainability standards may need to adjust their expectations.

Summary Table of Material Selection for Leather Goods

| المواد | Typical Use Case for leather factory florence italy | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury handbags and high-end accessories | Exceptional durability and breathability | Higher cost and complex manufacturing | عالية |

| Top-Grain Leather | Fashion accessories and everyday handbags | Good balance of durability and affordability | Less character than full-grain | Medium |

| Suede Leather | Clothing and soft-touch accessories | Unique texture and aesthetic | Sensitive to moisture and stains | Medium |

| Vegetable-Tanned Leather | Artisanal products and custom leather goods | Eco-friendly and develops rich patina | More rigid and requires care | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers looking to source high-quality leather products from Florence, Italy. Understanding the properties, advantages, and limitations of each material will enable informed purchasing decisions that align with market demands and customer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for leather factory florence italy

What Are the Key Stages in the Manufacturing Process of Leather Goods in Florence?

The manufacturing of leather goods in Florence, a city renowned for its craftsmanship, involves several meticulous stages that ensure the highest quality products.

Illustrative image related to leather factory florence italy

Material Preparation: How Is Leather Selected and Prepared?

The process begins with the careful selection of leather, typically sourced from reputable tanneries that adhere to strict European regulations. Artisans choose high-quality vegetable-tanned leather, known for its durability and eco-friendliness. The leather is then cut into predetermined shapes using precision tools, ensuring minimal waste. This stage is crucial as the quality of the leather directly impacts the final product.

Forming: What Techniques Are Used to Shape Leather?

Once the leather is prepared, it undergoes forming, where it is shaped into the desired product. This often involves wetting the leather and mounting it onto wooden molds, which helps maintain the intended design. The artisans skillfully manipulate the leather, utilizing traditional techniques such as hand-stitching and tooling, which not only enhance the aesthetics but also strengthen the seams. This craftsmanship is a hallmark of Florentine leather goods, emphasizing both form and function.

Assembly: How Are Leather Goods Assembled?

The assembly stage involves stitching together various components of the product. Artisans use high-quality threads and advanced stitching techniques to ensure durability. This phase may also include the attachment of hardware such as zippers, buckles, and clasps. Quality control is integral at this point, with artisans checking for alignment and overall craftsmanship before moving on to the finishing stage.

Finishing: What Final Touches Are Applied to Leather Products?

The finishing stage is where the leather goods are refined and polished. This includes dyeing, edge painting, and applying protective coatings to enhance the product’s longevity and aesthetic appeal. Artisans pay close attention to detail, ensuring that every piece meets the high standards expected from Florentine leather goods. The final inspection is critical, as it determines the readiness of the product for distribution.

What Quality Assurance Measures Are Implemented in Florentine Leather Factories?

Quality assurance (QA) is paramount in maintaining the reputation of Florentine leather factories. Various international standards and industry-specific certifications guide their QA processes.

How Do International Standards Like ISO 9001 Influence Quality Control?

Florentine leather factories often adhere to ISO 9001 standards, which establish a framework for effective quality management systems. This certification emphasizes continuous improvement, customer satisfaction, and process consistency. Factories must regularly review their processes and implement corrective actions as needed, ensuring that they consistently meet or exceed customer expectations.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This initial check ensures that the raw materials meet quality standards before production begins.

- In-Process Quality Control (IPQC): During various stages of production, artisans perform checks to identify any defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): Once production is complete, a thorough inspection of the finished products is conducted to ensure they meet all specifications and standards.

What Common Testing Methods Are Used to Ensure Quality in Leather Goods?

To guarantee the durability and performance of leather products, several testing methods are employed:

- Tensile Strength Tests: These assess the strength of the leather, ensuring it can withstand everyday use.

- Colorfastness Tests: These determine how well the leather holds its color when exposed to light, water, or friction.

- Flexibility Tests: This evaluates how well the leather can bend without cracking, a crucial factor for bags and clothing.

- Chemical Tests: These check for harmful substances, ensuring compliance with safety regulations.

How Can B2B Buyers Verify the Quality Control Processes of Leather Suppliers?

For international B2B buyers, verifying the quality control processes of leather suppliers is essential. Here are several actionable steps:

What Role Do Audits and Reports Play in Supplier Verification?

Buyers should request audits of the supplier’s quality management system and production processes. These audits can be conducted by third-party organizations that specialize in quality assurance. Additionally, suppliers should provide detailed reports outlining their QC measures, inspection results, and any corrective actions taken. Regular communication and transparency from suppliers can build trust and ensure that quality remains a priority.

How Important Are Third-Party Inspections for Quality Assurance?

Engaging third-party inspectors is a prudent step for B2B buyers, particularly when sourcing from international markets. These inspectors can conduct on-site evaluations of the manufacturing process, ensuring compliance with both industry standards and buyer specifications. This independent verification serves as an additional layer of assurance for buyers, mitigating risks associated with product quality.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

When engaging with suppliers in Florence, international buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several nuances:

- Cultural Differences in Quality Expectations: Different markets may have varying expectations regarding quality and craftsmanship. Buyers should clearly communicate their requirements to avoid misunderstandings.

- Import Regulations and Compliance: Each region has its own regulations regarding leather products, including environmental and safety standards. Buyers must ensure that their suppliers comply with these regulations to avoid potential legal issues.

- Customs and Duties: Understanding the customs regulations and potential duties associated with importing leather goods can help buyers manage costs effectively.

By understanding the manufacturing processes and quality assurance measures in Florentine leather factories, B2B buyers can make informed decisions that align with their business needs and market expectations. This comprehensive insight not only aids in supplier selection but also helps in building long-term partnerships rooted in quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather factory florence italy’

This guide is designed to assist international B2B buyers in effectively sourcing leather products from factories in Florence, Italy. With its rich heritage in leather craftsmanship, Florence offers an array of options for high-quality leather goods. This checklist will help streamline your procurement process, ensuring you make informed decisions.

Step 1: Define Your Product Requirements

Before reaching out to suppliers, clearly outline what you need. Specify the types of leather goods (e.g., handbags, clothing, accessories) and any design specifications or quality standards. This will help suppliers understand your needs and provide accurate quotes.

- Customization Needs: Determine if you require custom designs, branding, or specific materials.

- Volume Requirements: Clarify the quantity you intend to order, as this can influence pricing and lead times.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable leather factories in Florence. Look for companies with a strong online presence, customer reviews, and portfolios showcasing their craftsmanship.

- Industry Experience: Seek out suppliers with a proven track record in your specific product category.

- Certifications: Verify if the factory meets industry standards, such as ISO certifications or compliance with environmental regulations.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist of potential suppliers, assess their production capabilities. This includes understanding their manufacturing processes, lead times, and flexibility in accommodating your requirements.

- الطاقة الإنتاجية: Ensure the supplier can handle your order volume within your required timeframe.

- Craftsmanship Quality: Request samples to evaluate the quality of materials and craftsmanship.

Step 4: Request Quotes and Compare Offers

Reach out to your shortlisted suppliers with a detailed request for quotation (RFQ). Compare quotes not only on price but also on terms of delivery, payment conditions, and after-sales service.

- Transparent Pricing: Look for clear breakdowns of costs to avoid hidden fees.

- Negotiation Opportunities: Be open to negotiating terms that work best for both parties.

Step 5: Assess Communication and Support

Effective communication is crucial in any B2B transaction. Evaluate how responsive and supportive each supplier is during your initial interactions.

- Language and Cultural Considerations: Ensure there are no language barriers that could complicate negotiations or order fulfillment.

- Customer Service: Gauge their willingness to assist you with queries or issues that may arise.

Step 6: Conduct Factory Visits if Possible

If feasible, visit the factories in Florence to gain firsthand insight into their operations. This can provide a deeper understanding of their craftsmanship and working conditions.

- Observing Production Processes: Witnessing the production process can help you assess the quality control measures in place.

- Building Relationships: Establishing personal connections can foster trust and facilitate smoother transactions.

Step 7: Finalize Contracts and Place Orders

Once you’ve chosen a supplier, finalize the contract details, ensuring all terms are clear and agreed upon. Include specifications on quality, delivery timelines, and payment terms.

- Legal Considerations: Consider consulting with a legal expert to review the contract, ensuring your interests are protected.

- Order Confirmation: Confirm all details before placing the order to avoid misunderstandings later on.

By following this checklist, you can navigate the complexities of sourcing leather goods from Florence, ensuring you partner with a supplier that meets your business needs and standards.

Comprehensive Cost and Pricing Analysis for leather factory florence italy Sourcing

What Are the Key Cost Components in Sourcing from Leather Factories in Florence, Italy?

Sourcing leather goods from factories in Florence involves several cost components that contribute to the final price. The primary elements include:

Illustrative image related to leather factory florence italy

-

Materials: The quality of leather is paramount. Factories often use premium, vegetable-tanned leather sourced from certified tanneries, which can significantly affect costs. High-quality materials not only enhance product durability but also elevate perceived value.

-

Labor: Italian craftsmanship is renowned for its skill and artistry, which translates to higher labor costs. Skilled artisans in Florence command competitive wages due to their expertise and the labor-intensive nature of leather crafting. This is a key factor in the overall cost structure.

-

Manufacturing Overhead: This includes operational expenses such as facility maintenance, utilities, and equipment depreciation. Italian factories often maintain high standards of production, which can lead to increased overhead costs.

-

Tooling: Custom tooling for specific designs or products incurs additional costs. This is particularly relevant for businesses seeking unique or tailored items, as the initial investment in molds and tools can be substantial.

-

Quality Control (QC): Ensuring that each product meets strict quality standards is essential in the leather industry. Comprehensive QC processes can increase costs but are necessary to maintain brand reputation and customer satisfaction.

-

Logistics: Shipping costs, including international freight and customs duties, can vary significantly depending on the destination. Buyers should factor in these logistics expenses, which can be substantial when importing goods.

-

Margin: Factories will include a profit margin in their pricing, which can range based on their business model and the exclusivity of the products.

How Do Price Influencers Affect the Cost of Leather Goods?

Several factors influence the pricing of leather goods from Florence:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. Buyers should negotiate for better pricing based on their purchasing power.

-

Specifications and Customization: Custom designs or specific requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected price escalations.

-

Material Choices: Opting for specialty leathers or finishes can impact pricing. Understanding the material options available can help buyers make informed decisions.

-

Quality Certifications: Products that come with certifications for quality and sustainability may carry a premium. Buyers should assess the importance of these certifications relative to their target market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established factories with a history of quality may charge more due to their proven track record.

-

Incoterms: Understanding shipping terms and responsibilities can affect total costs. Buyers should clarify whether prices include shipping, insurance, and duties.

What Are the Best Negotiation and Cost-Efficiency Tips for International Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Engage in open discussions about pricing and seek to understand the factory’s cost structure. Building a relationship can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, durability, and potential returns. Investing in higher-quality products may yield savings over time.

-

Pricing Nuances: Be aware of seasonal fluctuations in pricing and any potential tariffs or trade agreements that could impact costs. Understanding the broader economic landscape can inform purchasing decisions.

-

Payment Terms: Favorable payment terms can ease cash flow. Explore options like staggered payments or letters of credit to mitigate upfront costs.

-

Sample Orders: Before committing to large orders, request samples to evaluate quality and craftsmanship, ensuring alignment with your expectations.

Disclaimer on Indicative Prices

Pricing for leather goods can vary widely based on the aforementioned factors, and the costs provided by suppliers should be viewed as indicative rather than fixed. Buyers are encouraged to conduct thorough market research and engage directly with suppliers to obtain accurate quotes tailored to their specific needs.

Alternatives Analysis: Comparing leather factory florence italy With Other Solutions

Exploring Alternatives to Leather Factory Florence, Italy

In the competitive landscape of leather production, international B2B buyers have various options for sourcing high-quality leather goods. While the Florence leather factories are renowned for their craftsmanship and heritage, it is essential to consider alternative solutions that may also meet business needs. Below is a comparative analysis of ‘Leather Factory Florence, Italy’ against other viable options in the leather manufacturing sector.

Illustrative image related to leather factory florence italy

| Comparison Aspect | Leather Factory Florence Italy | Alternative 1 Name: Asian Leather Manufacturers | Alternative 2 Name: Local Artisan Workshops |

|---|---|---|---|

| Performance | High-quality, handcrafted goods | Variable quality; some manufacturers offer high standards | Exceptional craftsmanship; quality varies widely |

| Cost | Moderate to high | Generally lower costs; competitive pricing | Higher prices for bespoke items |

| Ease of Implementation | Requires longer lead times due to customization | Faster turnaround times, especially for bulk orders | Limited capacity; longer lead times for complex designs |

| Maintenance | Durable products with proper care | Varies; some may require more upkeep | Typically high maintenance; handcrafted items need care |

| Best Use Case | Luxury markets; high-end retail | Mass market; budget-conscious buyers | Niche markets; custom, unique pieces |

What Are the Pros and Cons of Asian Leather Manufacturers?

Asian leather manufacturers, primarily located in countries like Vietnam and China, offer a competitive edge in terms of pricing and production speed. They often utilize modern machinery, which allows for mass production and lower costs, making them attractive for businesses looking to meet high-volume demands. However, the trade-off can be variability in quality. While some manufacturers maintain high standards, others may compromise on craftsmanship, leading to inconsistency in the final product. Additionally, the cultural nuances in leather crafting may lack the traditional artistry found in Italian products.

How Do Local Artisan Workshops Compare?

Local artisan workshops provide an intimate and personalized approach to leather goods production. They focus on bespoke items, often incorporating unique designs and high-quality materials. This method appeals to niche markets that value originality and craftsmanship. However, the downsides include higher costs and potentially longer lead times. As artisans typically have limited production capacity, scaling up orders may be challenging. Furthermore, while the quality is often superior, the reliance on individual skill can introduce variability in the end product.

Making the Right Choice for Your B2B Leather Needs

When deciding on the best solution for sourcing leather goods, B2B buyers should consider their specific requirements. If the goal is to offer luxury products that reflect Italian craftsmanship, opting for a leather factory in Florence is ideal. However, businesses targeting a broader market or those with tighter budgets may find Asian manufacturers more appealing. Conversely, if uniqueness and artisan craftsmanship are priorities, local workshops may be the best fit despite higher costs and longer turnaround times. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their brand values and market demands.

Illustrative image related to leather factory florence italy

Essential Technical Properties and Trade Terminology for leather factory florence italy

What Are the Key Technical Properties of Leather from Florence?

When sourcing leather products from Florence, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that play a significant role in the quality and durability of leather goods:

-

Material Grade

The grade of leather significantly influences the final product’s appearance and longevity. Full-grain leather, for instance, is the highest quality, retaining the natural surface of the hide, making it more durable and resistant to wear. Buyers should prioritize full-grain or top-grain leather for premium products, as these grades are associated with superior craftsmanship and aesthetic appeal. -

Tanning Process

The tanning process determines the leather’s softness, color, and resistance to moisture. Vegetable tanning, commonly used in Florence, employs natural tannins from plants, resulting in environmentally friendly leather that develops a rich patina over time. This process is essential for buyers who value sustainability and traditional craftsmanship. -

Thickness (Weight)

Leather thickness is measured in ounces or millimeters, affecting both the product’s weight and durability. Thicker leather is generally more robust and suitable for items like bags and belts, while thinner leather is often used for garments. Understanding thickness helps buyers choose products that meet their specific application needs, whether for fashion or functional use. -

Finish Type

The finish of leather can vary widely, impacting its texture and appearance. Common finishes include aniline (natural look) and pigmented (more uniform and protective). Buyers should assess finish types based on desired aesthetics and functional requirements, such as stain resistance and ease of maintenance. -

Colorfastness

This property indicates how well the leather retains its color when exposed to light and moisture. High colorfastness is essential for products intended for outdoor use or those subject to frequent handling. Buyers should inquire about colorfastness ratings to ensure the longevity of the product’s appearance.

What Common Trade Terms Should B2B Buyers Know?

Navigating the leather market in Florence requires familiarity with specific trade terminology. Here are some common jargon terms that are essential for effective communication and negotiation:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end products. For B2B buyers, understanding OEM relationships is critical for identifying potential partnerships and ensuring product quality and consistency. -

MOQ (Minimum Order Quantity)

MOQ denotes the minimum number of units a supplier is willing to sell in a single order. This term is vital for buyers as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchasing strategy effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products or services. B2B buyers should utilize RFQs to obtain competitive pricing and clarify specifications, ensuring they receive the best possible offers. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs and risk management. Familiarity with these terms helps buyers negotiate better shipping agreements and understand their liability in the delivery process. -

Private Label

This term refers to products manufactured by one company for sale under another company’s brand. For B2B buyers, private labeling can offer opportunities for brand expansion and customization while leveraging the manufacturer’s expertise. -

Lead Time

Lead time indicates the time required from placing an order to receiving the goods. Understanding lead times is crucial for inventory planning and ensuring that products arrive on schedule, particularly in fast-paced markets.

By grasping these technical properties and trade terms, international B2B buyers can navigate the leather market in Florence more effectively, ensuring they make informed purchasing decisions that align with their business needs.

Illustrative image related to leather factory florence italy

Navigating Market Dynamics and Sourcing Trends in the leather factory florence italy Sector

What are the Current Market Dynamics and Key Trends in the Leather Sector from Florence, Italy?

The leather sector in Florence, Italy, is experiencing a renaissance fueled by global demand for high-quality, artisanal products. International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking unique leather goods that blend traditional craftsmanship with contemporary design. Key drivers include the rising popularity of luxury goods and a growing appreciation for handmade, customizable products. B2B tech trends like digital marketplaces and e-commerce platforms are reshaping how buyers source products, allowing for streamlined transactions and greater access to diverse product offerings.

Emerging trends such as personalization and sustainable practices are also influencing market dynamics. Buyers are looking for manufacturers that can offer customization options—from design to branding—ensuring products meet specific customer needs. Additionally, the integration of technology in production processes, such as automated cutting and stitching, is enhancing efficiency while maintaining the artisanal quality that Florence is renowned for. This blend of tradition and innovation is crucial for international buyers looking to differentiate their offerings in competitive markets.

How are Sustainability and Ethical Sourcing Shaping the Leather Industry in Florence?

Sustainability and ethical sourcing are becoming non-negotiable aspects of the leather industry, particularly for B2B buyers who are increasingly concerned about the environmental impact of their purchases. Florentine leather factories are responding by adopting eco-friendly practices, such as using vegetable-tanned leather sourced from certified tanneries that adhere to stringent European regulations. This not only minimizes environmental damage but also ensures the safety and quality of the materials used.

Ethical supply chains are gaining traction, with many manufacturers emphasizing transparency and traceability in their sourcing practices. Buyers are encouraged to seek out suppliers who can demonstrate commitment to sustainability through certifications and eco-labels. The move towards “green” materials, such as recycled leather and low-impact dyes, is not just a trend but a necessity for attracting conscientious consumers. By prioritizing sustainable sourcing, international buyers can enhance their brand reputation and appeal to a growing segment of eco-aware customers.

Illustrative image related to leather factory florence italy

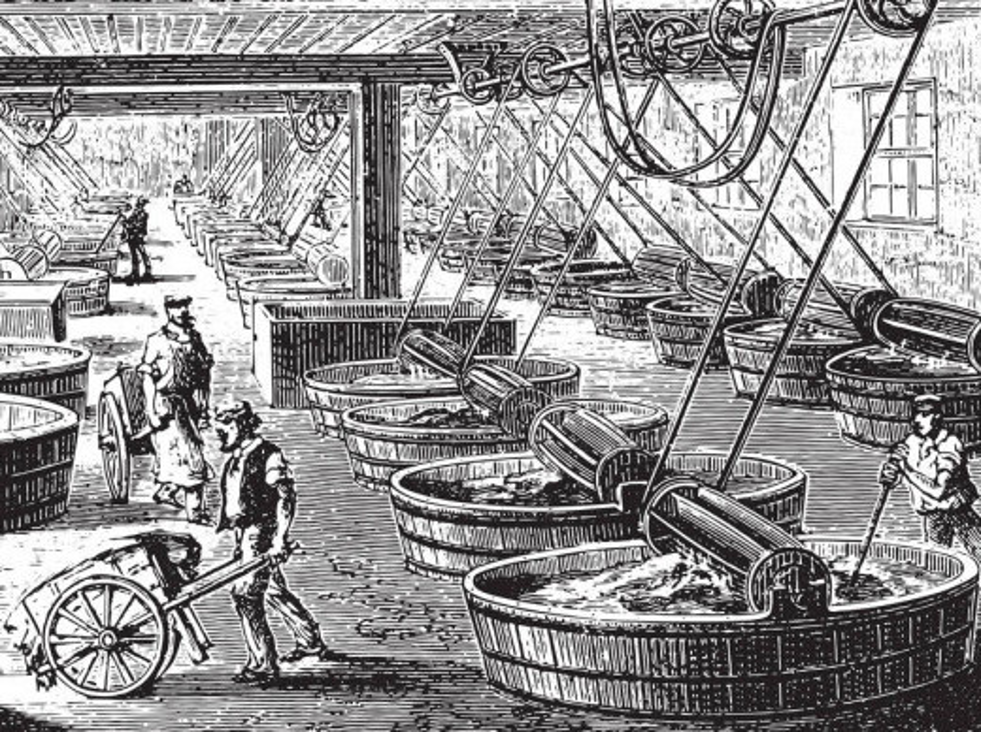

How Has the Leather Industry in Florence Evolved Over Time?

The leather industry in Florence has a rich history that dates back centuries, deeply rooted in the city’s artisanal traditions. Initially, leather goods were crafted for local markets, showcasing the skills of skilled artisans who utilized techniques passed down through generations. The rise of luxury fashion brands in the 20th century propelled Florence onto the global stage, transforming it into a hub for high-quality leather production.

Today, the industry has evolved to meet modern demands while preserving its artisanal roots. With advancements in technology, many Florentine factories have integrated innovative practices that enhance production without compromising craftsmanship. As global markets continue to evolve, the focus on quality, customization, and sustainability remains at the forefront, positioning Florence as a leading destination for international B2B buyers seeking exceptional leather products.

Frequently Asked Questions (FAQs) for B2B Buyers of leather factory florence italy

1. How do I find reliable leather factories in Florence, Italy?

Finding a reliable leather factory in Florence involves thorough research. Start by checking online directories and trade platforms dedicated to the leather industry. Look for factories with a solid reputation, positive customer reviews, and a portfolio showcasing their craftsmanship. Attending trade shows or industry events in Italy can also provide opportunities to meet manufacturers directly. Additionally, consider requesting samples to evaluate quality before making any commitments.

2. What are the customization options available for leather products from Florence?

Many Florentine leather manufacturers offer extensive customization options, including materials, colors, sizes, and designs. You can often request personalized features such as inner labels, tags, and specific finishes. Some factories allow for custom shapes or styles based on your specifications. It’s advisable to communicate your requirements clearly during initial discussions to ensure that the factory can meet your needs effectively.

Illustrative image related to leather factory florence italy

3. What is the minimum order quantity (MOQ) for leather products from Florence?

The MOQ can vary significantly among different manufacturers in Florence. Typically, smaller artisan workshops may have higher MOQs due to the labor-intensive nature of their craftsmanship, while larger factories might offer more flexible MOQs. It’s essential to discuss your order size during your initial inquiry to find a supplier that aligns with your purchasing capabilities.

4. How can I ensure quality assurance when sourcing leather goods?

To ensure quality assurance, consider implementing a multi-step process. Start with factory audits to assess their production capabilities and quality control measures. Request samples to evaluate craftsmanship, materials, and durability. Establish clear quality standards in your purchase agreement and consider third-party inspections before shipment. Maintaining ongoing communication with the manufacturer throughout the production process can also help address any issues proactively.

5. What payment terms should I expect when working with leather factories in Florence?

Payment terms can vary widely, but many factories require a deposit upfront (typically 30-50%) with the balance due upon completion or prior to shipping. It’s advisable to negotiate terms that are favorable to your cash flow while ensuring that the factory feels secure in their transaction. Always use secure payment methods to protect your investment and consider using escrow services for larger orders.

6. What logistics considerations should I keep in mind when importing leather goods?

When importing leather goods from Florence, consider freight options, customs regulations, and potential tariffs. Research shipping methods that align with your timeline and budget, whether by air or sea. Ensure that the factory provides all necessary documentation for customs clearance. Additionally, consider working with a logistics partner who specializes in international trade to navigate complexities and ensure timely delivery.

7. Are there any specific certifications I should look for in leather suppliers?

When sourcing leather goods, look for suppliers with certifications that demonstrate their adherence to quality and ethical standards. Common certifications include ISO 9001 for quality management and certifications for environmentally friendly practices, such as the Leather Working Group (LWG) certification. These certifications can provide assurance that the factory meets high production standards and ethical sourcing practices.

Illustrative image related to leather factory florence italy

8. How can I build a long-term relationship with a leather supplier in Florence?

Building a long-term relationship with a leather supplier involves consistent communication, transparency, and mutual respect. Regularly provide feedback on products and service, and be open about your future needs and expectations. Consider visiting the factory periodically to strengthen your partnership and understand their processes better. Establishing trust and reliability will benefit both parties and lead to more favorable terms and collaborations in the future.

Top 8 Leather Factory Florence Italy Manufacturers & Suppliers List

1. Florence Leather Factory – Handbags, Suitcases, and Leather Belts

Domain: florenceleatherfactory.it

Registered: 2014 (11 years)

مقدمة: Manufacturer of handbags, suitcases, and leather belts since the early 80s. Located in Tuscany, Italy. Products include various handbags (SKU: 5140-5146), backpacks (SKU: 5138), travel bags (SKU: 5134), and shoulder bags (SKU: 5133). All items can be customized, including inner labels, tags, liners, or hot stamping. Export to Europe and America. Quality materials certified according to European re…

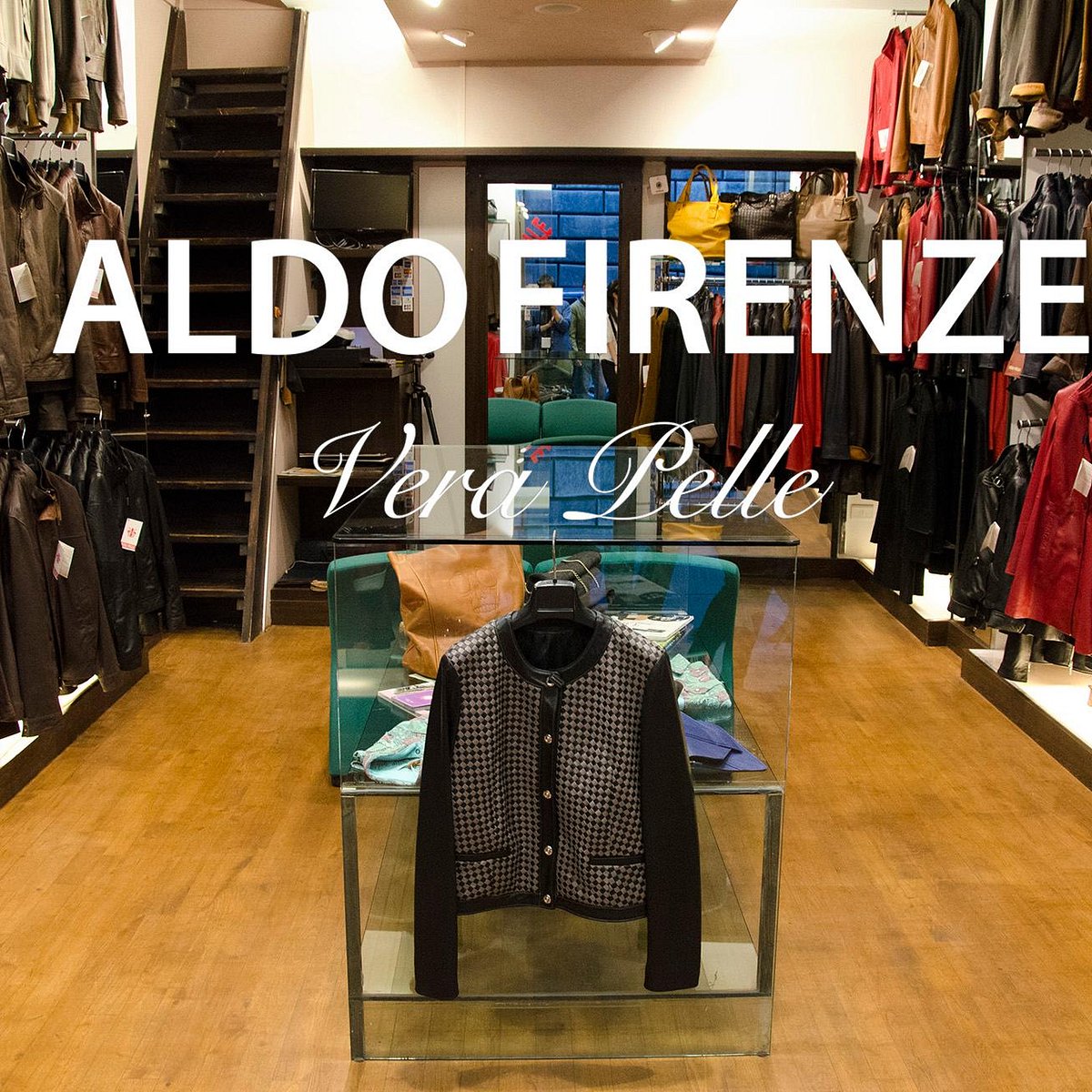

2. AJ Leather Factory – High-End Leather Clothing & Accessories

Domain: ajleatherfactory.it

Registered: 2014 (11 years)

مقدمة: AJ Leather Factory specializes in high-end leather clothing production for men and women, as well as handbags and craft accessories. The products are characterized by original and refined features, top-quality materials, and high-level manufacturing, appealing to a demanding clientele. Collections include ASTRONOMICA NATURAL (30 products), ASTRONOMICA VERNICETTA (18 products), ASTRONOMICA BASIC (1…

3. Yelp – Top Leather Shops in Florence

Domain: yelp.com

Registered: 2003 (22 years)

مقدمة: This company, Yelp – Top Leather Shops in Florence, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Peroni Firenze – Handcrafted Leather Goods

Domain: peronifirenze.com

Registered: 2016 (9 years)

مقدمة: Pelletteria Peroni specializes in handcrafted leather goods, including bags, suitcases, briefcases, handbags, iPad holders, folders, underarms, travel cases, accessories for shoes, belts, necklaces, bracelets, business and credit card holders, coin cases, wallets, keychains, eyeglasses cases, pen cases, gift items, smokers’ articles, gaming articles, sporting goods, flasks, furniture and office ac…

5. Pierotucci – Guided Leather Factory Tour

Domain: pierotucci.com

Registered: 1998 (27 years)

مقدمة: Free Guided Leather Factory Tour, Free shipping over 350 €, Ship to: USA, Available languages: EN, IT, RU, JP, CN, KO, Tour includes: observation of skilled artisans, explanation of production process, opportunity to shop at Pierotucci Leather Store (TAX FREE shopping), customization options available, located 15 minutes from Florence, factory tours available Monday to Friday, 9 am-5 pm, contact f…

6. Calzaiuoli Leather – High-End Leather Products

Domain: calzaiuolileather.com

Registered: 2001 (24 years)

مقدمة: This company, Calzaiuoli Leather – High-End Leather Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Florence Leather Market – Italian Leather Bags

Domain: florenceleathermarket.com

Registered: 2014 (11 years)

مقدمة: Italian Leather Bags Online | genuine leather bags and accessories handmade in Italy. Worldwide shipping by express courier without minimum order. Free shipping in Europe for orders from 500 € or 50 KG. 100% leather made in Italy. Secure and verified payments. Latest products include: Nadia Leather Bucket Bag ($99.83, sale price $69.88), Marina Leather Bucket Bag ($87.85, sale price $61.49), Savan…

8. Tripadvisor – Borgo Degli Albizi 45/R

Domain: tripadvisor.com

Registered: 1999 (26 years)

مقدمة: This company, Tripadvisor – Borgo Degli Albizi 45/R, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather factory florence italy

The leather industry in Florence presents a unique opportunity for international B2B buyers seeking high-quality, artisan-crafted products. Key takeaways from this guide emphasize the importance of strategic sourcing to access a diverse range of customizable leather goods, from handbags to apparel, all made with top-tier materials. The craftsmanship synonymous with Florentine leather factories not only ensures exceptional quality but also caters to the specific branding and personalization needs of buyers.

For businesses in Africa, South America, the Middle East, and Europe, collaborating with Florentine manufacturers can lead to enhanced product offerings that resonate with discerning consumers. The ability to customize products—from tags to design elements—allows for a tailored approach that can significantly boost market appeal.

Looking ahead, the future of sourcing from Florence is promising, with ongoing innovations in design and sustainability practices. International buyers are encouraged to engage with local artisans and manufacturers to leverage these advantages. Embrace the opportunity to explore partnerships that can elevate your product line and meet the evolving demands of your market. Reach out today to discover how Florence’s rich leather heritage can become a vital part of your business strategy.

Illustrative image related to leather factory florence italy

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.