Introduction: Navigating the Global Market for leather distributors

In the dynamic landscape of global commerce, sourcing high-quality leather from reputable distributors poses a significant challenge for B2B buyers. With the increasing demand for leather goods across diverse industries—from fashion to automotive—the stakes are high. This guide aims to streamline the process of connecting with reliable leather distributors, offering insights into various types of leather, their applications, and essential factors for supplier vetting.

International buyers, particularly those from Africa, South America, the Middle East, and Europe (including Germany and Brazil), will benefit from a comprehensive analysis of sourcing strategies, cost considerations, and quality assessments. By understanding the nuances of leather types—such as vegetable-tanned and chrome-tanned options—and their specific uses, buyers can make informed decisions that align with their business needs.

Moreover, this guide emphasizes the importance of thorough supplier evaluation, helping you navigate potential risks and ensuring that your partnerships are both fruitful and sustainable. As you delve into the sections ahead, you will discover actionable insights and expert recommendations designed to empower your purchasing decisions in the global leather market. Whether you are a seasoned buyer or new to the industry, this resource equips you with the knowledge necessary to thrive in a competitive environment.

Table Of Contents

- Top 8 Leather Distributors Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather distributors

- Understanding leather distributors Types and Variations

- Key Industrial Applications of leather distributors

- 3 Common User Pain Points for ‘leather distributors’ & Their Solutions

- Strategic Material Selection Guide for leather distributors

- In-depth Look: Manufacturing Processes and Quality Assurance for leather distributors

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather distributors’

- Comprehensive Cost and Pricing Analysis for leather distributors Sourcing

- Alternatives Analysis: Comparing leather distributors With Other Solutions

- Essential Technical Properties and Trade Terminology for leather distributors

- Navigating Market Dynamics and Sourcing Trends in the leather distributors Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather distributors

- Strategic Sourcing Conclusion and Outlook for leather distributors

- Important Disclaimer & Terms of Use

Understanding leather distributors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather Distributors | Source high-quality, unaltered leather; retains natural grain and imperfections | Luxury goods, high-end furniture, automotive upholstery | Pros: Exceptional durability and aesthetics; Cons: Higher cost and limited availability. |

| Vegetable-Tanned Leather Distributors | Focus on eco-friendly tanning processes; offers a unique patina over time | Crafting, saddlery, and specialty leather goods | Pros: Environmentally friendly; ages beautifully; Cons: Longer production time and less water resistance. |

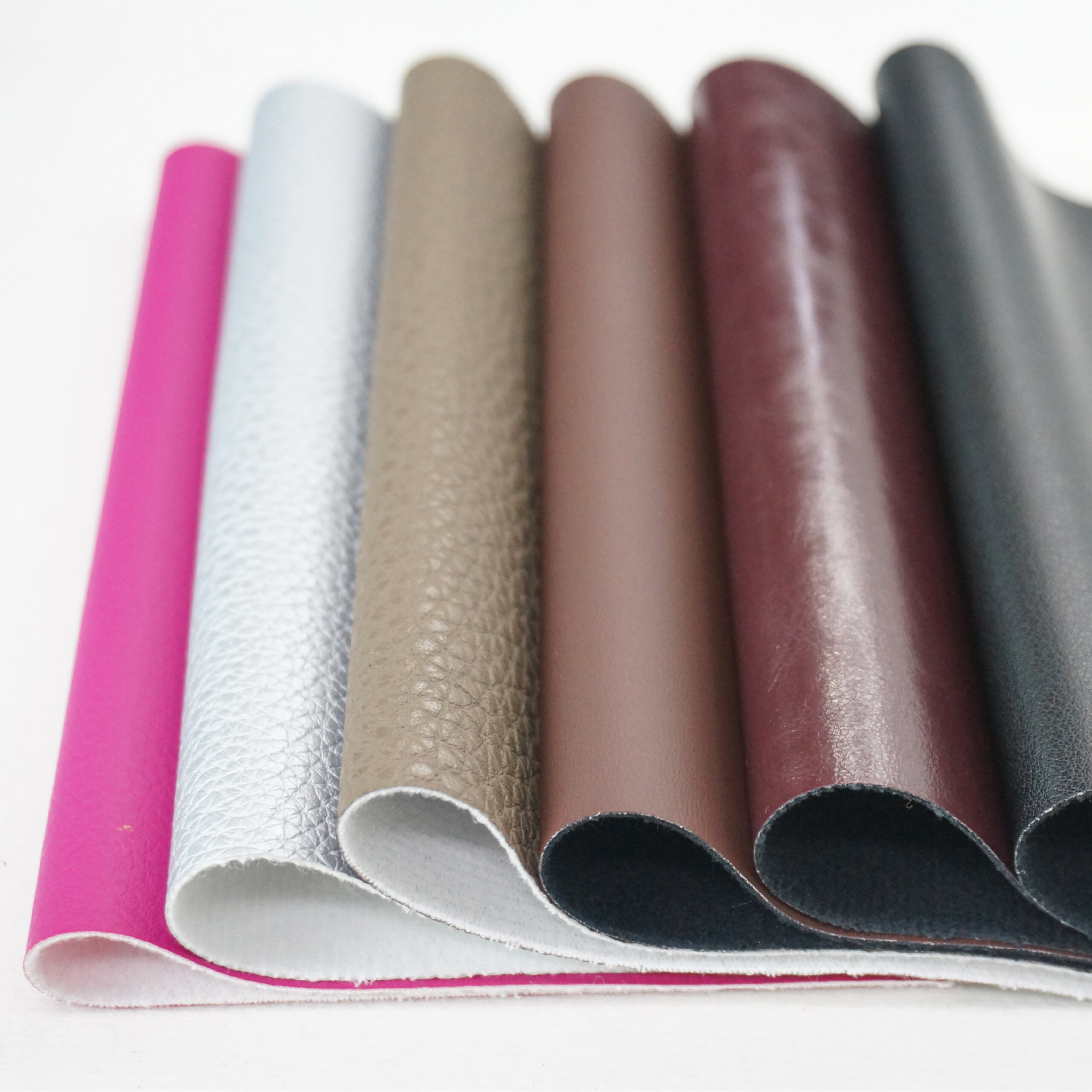

| Chrome-Tanned Leather Distributors | Utilize chromium salts for quicker tanning; softer and more pliable leather | Fashion, upholstery, and accessories | Pros: Quick production; wide range of colors; Cons: Less eco-friendly; can be less durable than vegetable-tanned options. |

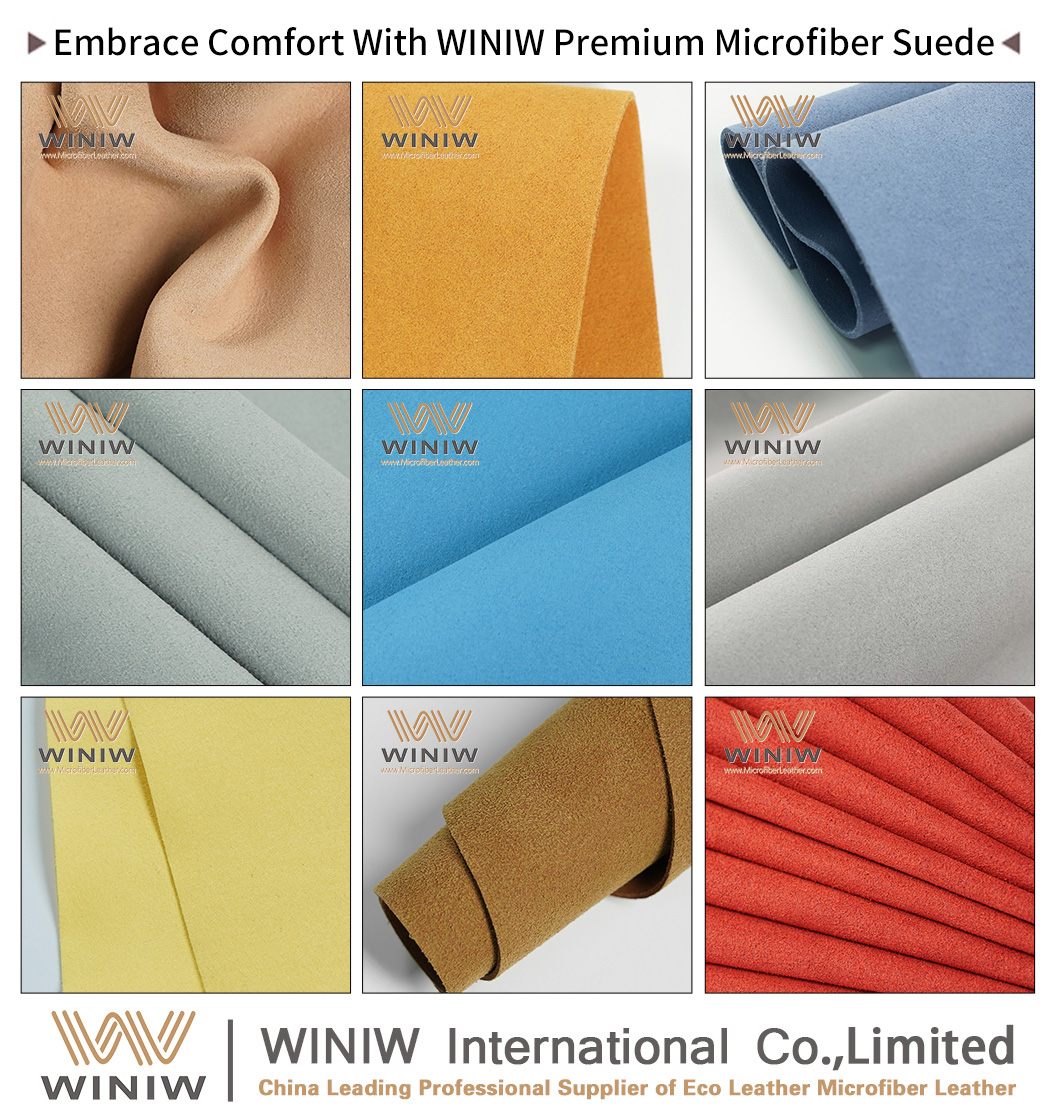

| Specialty Leather Distributors | Provide unique leathers like suede, nubuck, or exotic hides; often custom or limited runs | Fashion, bespoke items, and luxury accessories | Pros: Unique textures and appearances; Cons: Higher prices and potential sourcing challenges. |

| Wholesale Leather Distributors | Bulk suppliers catering to various leather types and grades; competitive pricing | Mass production for bags, shoes, and other goods | Pros: Cost-effective for large orders; Cons: Quality can vary; less personalized service. |

What Are the Characteristics of Full Grain Leather Distributors?

Full grain leather distributors specialize in sourcing high-quality leather that retains its natural grain and imperfections. This type of leather is often used in luxury goods, high-end furniture, and automotive upholstery due to its durability and aesthetic appeal. B2B buyers should consider the higher costs associated with full grain leather, as well as the limited availability of certain hides. However, the long-lasting nature and unique character of full grain leather make it a worthwhile investment for premium products.

How Do Vegetable-Tanned Leather Distributors Stand Out?

Vegetable-tanned leather distributors focus on eco-friendly tanning processes, using natural tannins derived from plant materials. This leather develops a unique patina over time, making it ideal for crafting, saddlery, and specialty leather goods. Buyers should be aware that while vegetable-tanned leather is environmentally friendly and ages beautifully, it typically has a longer production time and may lack water resistance compared to chrome-tanned alternatives.

Why Choose Chrome-Tanned Leather Distributors?

Chrome-tanned leather distributors utilize chromium salts for a quicker tanning process, resulting in softer and more pliable leather. This type is popular in fashion, upholstery, and accessories due to its wide range of colors and quick production times. While chrome-tanned leather is often more accessible and versatile, buyers should consider the environmental impact of chrome tanning and the fact that it may not offer the same durability as vegetable-tanned leather.

What Unique Options Do Specialty Leather Distributors Provide?

Specialty leather distributors offer unique leathers such as suede, nubuck, and exotic hides, often providing custom or limited-run options. These leathers are popular in fashion, bespoke items, and luxury accessories due to their distinctive textures and appearances. However, buyers should be prepared for higher prices and potential sourcing challenges, as these unique materials may not be as readily available as standard leather types.

How Do Wholesale Leather Distributors Cater to Mass Production?

Wholesale leather distributors cater to businesses looking to purchase leather in bulk, offering a variety of types and grades at competitive prices. This option is ideal for mass production of bags, shoes, and other goods. While wholesale purchasing can be cost-effective for large orders, buyers should be cautious about the quality variability and the potential lack of personalized service that comes with bulk transactions.

Key Industrial Applications of leather distributors

| Industry/Sector | Specific Application of leather distributors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Sourcing high-quality leather for garments | Enhances brand image and product quality | Leather type, sourcing origin, compliance with regulations |

| Automotive | Supplying leather for car interiors | Improves customer satisfaction and vehicle aesthetics | Durability, color options, and compliance with safety standards |

| Furniture and Upholstery | Providing leather for sofas and chairs | Increases product lifespan and customer appeal | Texture, color variety, and fire safety certifications |

| Footwear | Distributing leather for shoe manufacturing | Supports comfort and style, enhancing market competitiveness | Thickness, flexibility, and moisture resistance |

| Leather Goods | Supplying leather for bags, wallets, and accessories | Diversifies product offerings and boosts sales | Cost-effectiveness, customization options, and ethical sourcing |

How Do Leather Distributors Support the Fashion and Apparel Industry?

In the fashion and apparel sector, leather distributors play a crucial role by providing high-quality leather for garments. This leather is often used in jackets, skirts, and accessories, significantly enhancing the brand image and product quality. Buyers from regions like Europe and South America should consider the type of leather, its sourcing origin, and compliance with labor and environmental regulations. This ensures that the materials not only meet aesthetic standards but also align with ethical sourcing practices.

Illustrative image related to leather distributors

What Role Do Leather Distributors Play in the Automotive Sector?

In the automotive industry, leather distributors supply premium leather for car interiors, enhancing both aesthetics and comfort. High-quality leather seats can significantly improve customer satisfaction and contribute to a vehicle’s overall appeal. International buyers, particularly from the Middle East and Europe, should focus on durability, color options, and compliance with safety standards when sourcing leather for automotive applications. This attention to detail ensures a superior end product that meets consumer expectations.

Why Are Leather Distributors Essential for Furniture and Upholstery?

For the furniture and upholstery industry, leather distributors provide materials essential for crafting sofas, chairs, and other furnishings. The use of leather in these products increases their lifespan and enhances customer appeal due to the luxurious feel and look of leather. Buyers, especially from Africa and South America, should prioritize sourcing leather that offers a variety of textures and colors, along with necessary fire safety certifications. This approach ensures compliance with local regulations while meeting consumer preferences.

How Do Leather Distributors Contribute to the Footwear Industry?

In the footwear industry, leather distributors are vital for sourcing leather used in shoe manufacturing. The right leather enhances comfort and style, making products more competitive in the market. Buyers from regions like Europe and South America need to consider the leather’s thickness, flexibility, and moisture resistance when selecting materials. These factors directly impact the performance and longevity of the footwear, making informed sourcing decisions critical for success.

What Benefits Do Leather Distributors Offer for Leather Goods Production?

Leather distributors support the production of various leather goods such as bags, wallets, and accessories, providing a diverse range of materials that enhance product offerings. This diversification can lead to increased sales and market reach. B2B buyers should look for cost-effective options, customization possibilities, and ethical sourcing when selecting leather for these applications. Such considerations not only optimize production costs but also align with growing consumer demand for sustainable products.

Illustrative image related to leather distributors

3 Common User Pain Points for ‘leather distributors’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather in Bulk

The Problem: B2B buyers often struggle with sourcing high-quality leather in bulk, especially when dealing with varying quality standards from different suppliers. This inconsistency can lead to discrepancies in production, affecting the final product’s quality. Buyers may find themselves receiving leather that does not meet their specifications, leading to potential financial losses and delays in delivery.

The Solution: To overcome this challenge, buyers should establish clear quality benchmarks and communicate them effectively to potential distributors. Before placing a large order, request samples from multiple suppliers to assess the quality firsthand. Establishing a strong relationship with a reliable distributor who can guarantee quality consistency is crucial. Consider creating a checklist based on leather types, finishes, and intended uses to standardize your requirements. Additionally, explore certifications that indicate quality assurance, such as ISO certifications or compliance with environmental standards. This proactive approach will mitigate risks and ensure a steady supply of high-quality leather.

Scenario 2: Navigating Diverse Leather Types and Specifications

The Problem: With a myriad of leather types available, B2B buyers often find it daunting to select the appropriate leather for their specific applications. This confusion can lead to selecting an unsuitable material, which can compromise product functionality and appeal. For instance, using vegetable-tanned leather for a product requiring high durability can result in increased wear and tear.

Illustrative image related to leather distributors

The Solution: Educating oneself about the different leather types and their characteristics is essential. Buyers should take advantage of resources provided by distributors, such as detailed descriptions of leather types—vegetable-tanned, chrome-tanned, full-grain, etc.—and their respective applications. Engaging with knowledgeable representatives from leather distributors can provide valuable insights tailored to your needs. Furthermore, attending trade shows or workshops focused on leather products can enhance understanding. Creating a decision matrix that maps leather types to specific project requirements can also streamline the selection process, ensuring the right material is chosen for each application.

Scenario 3: Managing Inventory and Supply Chain Disruptions

The Problem: Fluctuations in supply and demand can significantly impact a buyer’s ability to maintain inventory levels, especially in industries where leather is a critical component. This challenge can be exacerbated by global supply chain disruptions, which can lead to delays in receiving materials, ultimately affecting production timelines and customer satisfaction.

The Solution: To manage inventory effectively, buyers should implement a just-in-time (JIT) inventory system that allows for flexibility and responsiveness to market demands. Establishing a strong communication line with distributors can provide insight into lead times and inventory levels. Additionally, buyers should consider diversifying their supplier base to reduce dependency on a single source. This strategy can safeguard against disruptions caused by geopolitical issues or natural disasters. Furthermore, utilizing inventory management software can help track stock levels and predict future needs based on sales trends. Regularly reviewing supplier performance and maintaining a buffer stock of essential materials can also mitigate risks associated with supply chain disruptions, ensuring smoother operations.

Strategic Material Selection Guide for leather distributors

What Are the Key Properties of Common Leather Materials for Distributors?

Leather distributors often deal with various types of leather, each possessing unique properties that affect their performance in different applications. Understanding these materials is crucial for making informed purchasing decisions. Here, we analyze four common leather types: Vegetable-Tanned Leather, Chrome-Tanned Leather, Suede, and Full Grain Leather.

Illustrative image related to leather distributors

How Does Vegetable-Tanned Leather Perform in Various Applications?

Vegetable-tanned leather is renowned for its natural tanning process, utilizing tannins from plant sources. This type of leather is biodegradable and exhibits excellent durability, making it suitable for a variety of products, including belts, bags, and upholstery.

- Key Properties: High resistance to wear and tear, good breathability, and a natural finish that ages beautifully.

- Pros: Environmentally friendly, strong, and develops a unique patina over time.

- Cons: Prone to water damage if not treated; longer tanning process can increase costs.

- Impact on Application: Ideal for high-quality leather goods but requires careful handling to maintain its appearance.

- Considerations for International Buyers: Compliance with environmental regulations is essential, especially in regions with stringent eco-standards like Germany. Buyers should also verify adherence to ASTM standards for quality assurance.

What Advantages Does Chrome-Tanned Leather Offer?

Chrome-tanned leather is processed using chromium salts, resulting in a more pliable and water-resistant material. It is commonly used in the fashion and automotive industries due to its versatility.

- Key Properties: High resistance to water and heat, with a smooth finish that allows for vibrant dye applications.

- Pros: Quick tanning process, excellent durability, and a wide range of colors.

- Cons: Less environmentally friendly due to chemical use; potential for allergic reactions in sensitive individuals.

- Impact on Application: Suitable for products exposed to moisture, but care must be taken to ensure proper disposal of waste materials.

- Considerations for International Buyers: Buyers from the Middle East and Africa should consider local regulations regarding chemical use and waste management, ensuring compliance with JIS or DIN standards.

Why Choose Suede for Specific Leather Applications?

Suede, made from the underside of the animal hide, offers a soft and luxurious texture. It is often used in fashion accessories, upholstery, and footwear.

- Key Properties: Soft texture, good insulation, and a unique aesthetic appeal.

- Pros: Lightweight, flexible, and available in various colors.

- Cons: Less durable than other leather types; susceptible to staining and water damage.

- Impact on Application: Best suited for indoor applications or items that do not require heavy-duty use.

- Considerations for International Buyers: In regions like South America, where humidity can be high, buyers should consider protective treatments to enhance durability.

What Makes Full Grain Leather a Preferred Choice?

Full grain leather is the highest quality leather available, made from the top layer of the hide, retaining its natural grain. It is often used in premium products like high-end handbags and furniture.

Illustrative image related to leather distributors

- Key Properties: Exceptional durability, breathability, and a natural look that improves with age.

- Pros: Highly resistant to wear and tear; develops a rich patina over time.

- Cons: Higher cost and requires regular maintenance to preserve its appearance.

- Impact on Application: Ideal for luxury items where quality is paramount.

- Considerations for International Buyers: Buyers in Europe, particularly Germany, may look for certifications that ensure the leather meets high-quality standards, such as the EU Ecolabel.

Summary Table of Leather Materials for Distributors

| المواد | Typical Use Case for leather distributors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Belts, bags, upholstery | Environmentally friendly | Prone to water damage | Medium |

| Chrome-Tanned Leather | Fashion items, automotive interiors | Quick tanning process | Less eco-friendly | Medium |

| Suede | Fashion accessories, upholstery | Soft texture | Less durable | Medium |

| Full Grain Leather | High-end handbags, luxury furniture | Exceptional durability | Higher cost | عالية |

Understanding these materials and their implications will empower leather distributors to make strategic purchasing decisions that align with their business goals and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for leather distributors

What Are the Main Stages of the Leather Manufacturing Process?

The manufacturing process for leather involves several key stages that transform raw hides into finished products suitable for various applications. Understanding these stages is crucial for B2B buyers to ensure they partner with reliable suppliers.

-

Material Preparation: The journey begins with the selection of raw hides, which can be sourced from various animals, including cattle, goats, and sheep. The hides undergo a rigorous cleaning process to remove hair, flesh, and other impurities. This step is critical to prevent defects in the final product. After cleaning, the hides are preserved using methods such as salting or drying to inhibit bacterial growth until they are processed further.

-

Tanning: This is a pivotal step where raw hides are transformed into leather through chemical processes. The two most common tanning methods are vegetable tanning, which uses natural tannins from plants, and chrome tanning, which employs chromium salts. Each method yields different characteristics in the leather, affecting its durability, flexibility, and appearance. For example, vegetable-tanned leather is often favored for its eco-friendliness and ability to develop a rich patina over time.

-

Forming and Finishing: After tanning, the leather is subjected to various processes to achieve the desired thickness and texture. Techniques such as splitting, shaving, and buffing refine the hide. Following this, finishing processes like dyeing, coating, and polishing enhance the leather’s aesthetic appeal and protective qualities. Finishing can also include the application of water-repellent treatments and color dyes, which are crucial for products that will face environmental challenges.

-

Assembly: The final stage involves cutting the leather into specific shapes and assembling the components. This can include stitching, riveting, or bonding, depending on the product being manufactured. Quality craftsmanship is vital during this phase to ensure that the final product meets both functional and aesthetic standards.

How Is Quality Assurance Implemented in Leather Manufacturing?

Quality assurance (QA) in leather manufacturing is essential for maintaining high standards and ensuring customer satisfaction. B2B buyers should be familiar with the various international and industry-specific standards that govern quality in leather production.

-

International Standards: Many manufacturers adhere to ISO 9001, which outlines requirements for a quality management system (QMS). This standard helps organizations ensure consistent quality in their products and services, enhancing customer satisfaction. Compliance with ISO standards is often a key criterion for B2B buyers when selecting suppliers.

-

Industry-Specific Certifications: Additional certifications may apply depending on the intended use of the leather. For instance, leather products aimed at the European market may require CE marking, indicating compliance with health, safety, and environmental protection standards. Buyers should inquire about these certifications to ensure the leather meets the necessary regulatory requirements.

What Are the Key Quality Control Checkpoints?

Effective quality control (QC) involves several checkpoints throughout the manufacturing process, ensuring that any defects are identified and rectified early on.

-

Incoming Quality Control (IQC): This initial checkpoint focuses on the quality of raw materials received. Inspectors assess the hides for defects, measuring factors such as thickness, texture, and color consistency. This step is crucial, as the quality of the raw materials directly impacts the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves monitoring the processes, including tanning and finishing. Regular inspections help identify deviations from established standards, allowing for immediate corrective actions. Techniques such as statistical process control (SPC) may be employed to track variations and maintain quality.

-

Final Quality Control (FQC): This final checkpoint occurs before products are shipped. Inspectors evaluate the finished leather for overall quality, checking for defects in stitching, color, and finish. FQC ensures that only products meeting the highest standards reach the customer.

What Testing Methods Are Commonly Used in Leather Quality Assurance?

Various testing methods are employed to assess the quality and durability of leather products. B2B buyers should be aware of these methods to verify the quality of the leather they purchase.

-

Physical Testing: This includes tests for tensile strength, tear strength, and abrasion resistance. These tests help determine how well the leather will perform in real-world applications, such as in footwear or upholstery.

-

Chemical Testing: Chemical analyses are conducted to ensure that the leather complies with safety standards, particularly regarding the presence of harmful substances. Tests for chromium levels, pH balance, and the presence of volatile organic compounds (VOCs) are essential for ensuring safety and compliance.

-

Aesthetic Testing: This includes evaluations of colorfastness, texture, and finish quality. Aesthetic tests ensure that the leather not only meets functional requirements but also aligns with customer expectations regarding appearance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is crucial for ensuring product reliability. Here are some effective strategies:

-

Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes and quality control measures firsthand. This can include reviewing records, inspecting facilities, and observing production practices.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes. These reports should outline testing results, non-conformance issues, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These organizations typically conduct thorough inspections and testing, offering additional assurance to buyers.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should consider several nuances in quality control:

Illustrative image related to leather distributors

-

Cultural Differences: Understanding cultural differences in quality expectations is crucial. For instance, European buyers may have stricter standards compared to buyers from other regions, necessitating clear communication about quality requirements.

-

Logistical Challenges: Shipping and handling can affect leather quality. Buyers should ensure that suppliers have robust packaging and shipping protocols to protect the leather during transit.

-

Regulatory Compliance: Different regions may have varying regulations regarding leather products. Buyers must ensure that their suppliers comply with local regulations, which may include specific testing and certification requirements.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing leather products, ensuring they partner with suppliers who uphold the highest standards of quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather distributors’

مقدمة

In the competitive landscape of leather distribution, sourcing the right supplier is crucial for ensuring quality, consistency, and value in your products. This checklist provides a practical, step-by-step approach to help international B2B buyers effectively navigate the procurement process and establish fruitful partnerships with leather distributors.

1. Identify Your Specific Needs

Begin by clearly defining your leather requirements, including type, grade, thickness, and intended use. Different applications, such as upholstery, garment making, or accessories, will necessitate different specifications. Understanding your needs upfront will streamline your search and help you communicate effectively with potential suppliers.

2. Research Potential Suppliers

Conduct thorough research to compile a list of potential leather distributors. Utilize industry directories, trade shows, and online platforms to identify reputable suppliers. Pay attention to their market presence, years of operation, and product range, as this can indicate reliability and experience in the industry.

3. Verify Supplier Certifications

Ensure that your chosen suppliers possess relevant certifications and adhere to industry standards. Certifications may include environmental compliance (like ISO 14001), quality management (ISO 9001), and ethical sourcing practices. These credentials not only guarantee product quality but also promote responsible business practices, which can be vital for your brand reputation.

4. Request Samples for Quality Assessment

Before making a bulk purchase, always request samples of the leather. This allows you to evaluate the texture, durability, color, and overall quality. Examine how the leather responds to dyeing or finishing processes, especially if customization is part of your product offering. Quality assessment upfront can prevent costly mistakes later.

5. Review Pricing and Payment Terms

Discuss pricing models and payment terms with your potential suppliers. Understanding the cost structure, including shipping and handling fees, is crucial for budgeting. Look for transparency in pricing and be wary of suppliers who offer prices significantly lower than competitors, as this could indicate inferior quality.

6. Assess Communication and Support

Evaluate the level of communication and support provided by the supplier. A responsive supplier will facilitate smoother transactions and address any concerns promptly. Assess their willingness to provide technical support and after-sales service, which can be crucial for long-term partnerships.

7. Establish Clear Contract Terms

Once you have selected a supplier, ensure that all terms and conditions are documented in a formal contract. This should include delivery timelines, quality expectations, payment schedules, and return policies. Clear contracts not only protect your interests but also set the foundation for a transparent and professional relationship.

By following this structured checklist, B2B buyers can enhance their sourcing strategy, mitigate risks, and establish solid partnerships with leather distributors, ultimately contributing to the success of their business operations.

Comprehensive Cost and Pricing Analysis for leather distributors Sourcing

When analyzing the cost structure and pricing for leather distributors, it’s essential to break down the various cost components and price influencers that play a crucial role in the overall pricing strategy. Understanding these elements can help international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

What Are the Key Cost Components in Leather Distribution?

-

Materials: The primary cost driver for leather distributors is the cost of raw materials. This includes the type of leather being sourced—such as vegetable-tanned, chrome-tanned, or exotic leathers. Each type has its own price range, influenced by factors such as sourcing location and quality. For example, Italian leather often commands a premium due to its reputation for quality.

-

Labor: Labor costs encompass the wages of skilled artisans involved in processing and finishing the leather. This can vary significantly based on the region. For instance, labor costs might be higher in Europe compared to South America, affecting the overall pricing structure.

-

Manufacturing Overhead: This includes expenses related to the facilities, utilities, and equipment used in production. Distributors that invest in advanced machinery or eco-friendly production methods may incur higher overhead costs, which can be reflected in the pricing.

-

Tooling: The cost of specialized tools and molds for custom designs can add to the overall expense. Customization options often lead to increased tooling costs, which should be factored into price negotiations.

-

Quality Control (QC): Maintaining high-quality standards through rigorous QC processes incurs additional costs. Buyers should look for suppliers that prioritize quality assurance, as this can minimize defects and returns.

-

Logistics: Shipping and transportation costs are critical, particularly for international buyers. Factors such as distance, mode of transport, and any import duties or tariffs can significantly impact the final price.

-

Margin: Finally, distributors will add a profit margin to cover their operational costs and generate profit. This margin can vary based on market demand, competition, and the perceived value of the product.

What Influences the Pricing of Leather Products?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to bulk pricing discounts. Buyers should negotiate MOQs that align with their needs to maximize cost efficiency.

-

Specifications and Customization: Customized leather products, while appealing, come with additional costs for design and tooling. Buyers should weigh the benefits of customization against the increased price.

-

Quality Certifications: Certifications, such as those ensuring sustainable sourcing or adherence to specific quality standards, can affect pricing. Buyers should consider the long-term benefits of purchasing certified products.

-

Supplier Factors: Supplier reputation, reliability, and relationship history can influence pricing. Long-term partnerships may lead to better pricing due to established trust and consistent orders.

-

Incoterms: Understanding international shipping terms is crucial. Buyers should clarify responsibilities for shipping costs, insurance, and risk during transit, as these can affect the total cost.

How Can Buyers Negotiate for Better Prices in Leather Sourcing?

-

Conduct Market Research: Familiarize yourself with current market rates for different leather types and suppliers. This knowledge empowers you during negotiations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can foster loyalty and trust.

-

Consider Total Cost of Ownership (TCO): Assess not just the purchase price, but also the long-term costs associated with the leather, including maintenance, durability, and potential resale value.

-

Be Flexible with Specifications: If possible, consider adjusting specifications to match available stock or lower-cost options, which can result in substantial savings.

-

Explore Alternative Suppliers: Don’t hesitate to source from multiple suppliers. This competitive approach can lead to better pricing and options.

الخاتمة

The complexity of the leather sourcing landscape necessitates a thorough understanding of cost structures and pricing influencers. By strategically navigating these factors, international B2B buyers can enhance their procurement strategies, ensuring they receive the best value for their investments. Remember, while prices may vary, focusing on quality, sustainability, and long-term relationships can yield significant advantages in the leather market.

Disclaimer: Prices mentioned in this analysis are indicative and may vary based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing leather distributors With Other Solutions

Understanding Alternative Solutions for Leather Sourcing

In the dynamic landscape of leather procurement, international B2B buyers often seek alternatives to traditional leather distributors. This section explores viable options, allowing businesses to make informed decisions based on their specific needs, such as performance, cost, and ease of implementation.

Comparison of Leather Distributors and Alternatives

| Comparison Aspect | Leather Distributors | Online Marketplaces | Synthetic Leather Suppliers |

|---|---|---|---|

| Performance | High-quality, authentic leather | Variable quality, depends on sellers | Durable, consistent quality |

| Cost | Moderate to high (depending on type) | Often lower due to competition | Generally lower than genuine leather |

| Ease of Implementation | Streamlined ordering process, established relationships | Easy to set up and order from various sellers | Simple ordering, but may require education on care |

| Maintenance | Requires specific care for longevity | Varies by product; can be inconsistent | Low maintenance, easy to clean |

| Best Use Case | High-end products needing authenticity | Budget-friendly options for varied applications | Eco-conscious products or cost-sensitive projects |

Detailed Breakdown of Alternatives

Online Marketplaces: Are They a Viable Option?

Online marketplaces like Alibaba or Etsy provide access to a vast range of leather products from various sellers. The pros include competitive pricing and diverse selections, allowing buyers to find unique materials. However, quality can be inconsistent, and buyers must exercise caution in vetting sellers to ensure product authenticity and reliability. This option is ideal for businesses seeking budget-friendly alternatives or niche products but may not suit those requiring uniform quality and reliability.

Synthetic Leather Suppliers: What Are Their Advantages?

Synthetic leather, or vegan leather, is gaining traction as an alternative to traditional leather. Suppliers offer products that are often more affordable and less resource-intensive to produce. The advantages include a lower environmental impact and ease of maintenance, as synthetic materials are typically easier to clean and care for. However, they may lack the tactile qualities and durability of genuine leather, making them less suitable for high-end applications. Businesses focused on sustainability or cost reduction may find synthetic leather to be an attractive option.

Conclusion: How to Choose the Right Leather Sourcing Solution

When selecting the appropriate leather sourcing solution, B2B buyers must assess their specific requirements, including the desired quality, budget constraints, and application needs. Leather distributors are ideal for companies prioritizing quality and authenticity, especially in high-end markets. In contrast, online marketplaces can serve budget-conscious buyers seeking a variety of options, while synthetic leather suppliers cater to eco-conscious firms looking for innovative alternatives. By evaluating these factors, businesses can make an informed choice that aligns with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for leather distributors

What Are the Key Technical Properties of Leather Relevant to Distributors?

Understanding the technical properties of leather is crucial for distributors to ensure they meet the specific needs of their clients. Here are some essential specifications to consider:

-

Material Grade

Material grade refers to the quality classification of leather, which can range from full-grain to split leather. Full-grain leather, made from the top layer of the hide, retains its natural texture and durability, making it ideal for high-end products. In contrast, lower grades like corrected grain leather may have a synthetic finish, affecting both appearance and longevity. For distributors, knowing the grade helps in sourcing appropriate materials that align with customer expectations and market demands. -

Thickness and Weight

Thickness is often measured in ounces (oz) or millimeters (mm) and can significantly influence the application of the leather. For instance, heavier leathers (8-10 oz) are typically used for belts and saddlery, while lighter leathers (2-4 oz) are preferred for garments and accessories. Understanding weight specifications allows distributors to recommend suitable products for specific applications, enhancing customer satisfaction and reducing returns. -

Tanning Method

Leather can be tanned through various methods, such as vegetable tanning and chrome tanning, each imparting distinct characteristics. Vegetable-tanned leather is eco-friendly and develops a rich patina over time, while chrome-tanned leather is more pliable and water-resistant. Distributors should be knowledgeable about these processes to guide clients in selecting the right leather type based on their product requirements and sustainability goals. -

Finish Type

The finish of leather affects its appearance and usability. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather, with its natural look, is more susceptible to stains, while pigmented leather offers greater durability and color consistency. Familiarity with finish types empowers distributors to provide tailored recommendations based on the desired aesthetics and functional needs of their customers. -

Physical Properties

Key physical properties such as tensile strength, elongation, and tear resistance are essential in assessing leather’s performance. Tensile strength measures how much force leather can withstand before breaking, while elongation indicates its flexibility. These properties are critical for applications requiring durability, such as upholstery and heavy-duty goods. Distributors must understand these metrics to ensure that their leather products can meet industry standards and customer expectations.

What Are Common Trade Terms Used in the Leather Industry?

Navigating the leather distribution landscape also requires familiarity with industry jargon. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In leather distribution, this term is often used when suppliers provide leather components for brands that manufacture finished goods, such as handbags or shoes. Understanding OEM relationships can help distributors forge valuable partnerships and expand their market reach. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of goods that a supplier is willing to sell. For leather distributors, knowing the MOQ is vital for inventory management and cost-effectiveness. It allows them to assess whether they can meet client demands without incurring excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer requesting a quote from suppliers for specific products or services. This term is essential in the B2B landscape, as it streamlines the procurement process and helps distributors accurately price their offerings based on customer specifications. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is crucial for leather distributors engaged in international trade, as they clarify who bears the risk and costs at various stages of the shipping process. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For leather distributors, understanding lead times is critical for managing client expectations and planning inventory. Clear communication about lead times can enhance customer satisfaction and improve supply chain efficiency.

By mastering these technical properties and trade terms, leather distributors can better serve their clients, foster strong relationships, and navigate the complexities of the leather industry effectively.

Navigating Market Dynamics and Sourcing Trends in the leather distributors Sector

What Are the Current Market Dynamics and Key Trends in the Leather Distributors Sector?

The leather distributors sector is experiencing significant evolution, driven by various global factors. The demand for leather products is escalating due to the rising popularity of luxury goods, fashion items, and bespoke leather products, particularly in emerging markets across Africa, South America, and the Middle East. Countries like Brazil and Germany are notable players, with Brazil’s rich biodiversity offering unique leather types and Germany being a hub for high-quality craftsmanship.

Key trends shaping the market include the integration of advanced B2B technologies such as Artificial Intelligence (AI) and blockchain for supply chain transparency. These technologies facilitate real-time tracking of materials, ensuring authenticity and ethical sourcing, which are critical for international buyers. Additionally, e-commerce platforms are becoming increasingly popular, allowing buyers to access a wide range of products from various suppliers, thus enhancing market competition and driving down prices.

Furthermore, there is a notable shift towards customization and personalization in leather goods, driven by consumer demand for unique products. This trend encourages distributors to invest in flexible manufacturing processes and diversified product offerings to meet specific client needs. Overall, international buyers should remain aware of these dynamics to navigate the complexities of the leather market effectively.

How Is Sustainability Shaping Sourcing Trends in the Leather Industry?

Sustainability and ethical sourcing have become paramount in the leather industry, reflecting a growing awareness of environmental impacts. Traditional tanning processes often involve harmful chemicals, leading to significant ecological damage. As a result, both consumers and B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices. This includes using vegetable-tanned leather, which is less harmful to the environment, and sourcing hides from responsible farms.

Certifications such as the Leather Working Group (LWG) and other eco-labels are becoming essential for distributors aiming to appeal to conscious buyers. These certifications ensure that the leather is produced with minimal environmental impact and adheres to ethical labor practices. Furthermore, there is a rising trend toward upcycling and recycling materials, with companies looking to reduce waste and promote circular economy principles.

For B2B buyers, aligning with suppliers who prioritize sustainability not only enhances their brand image but also opens doors to new market opportunities as eco-conscious consumers continue to demand responsibly sourced products. This shift is reshaping sourcing strategies and encouraging distributors to innovate in their supply chains.

What Is the Historical Context of Leather Distribution and Its Evolution?

The leather distribution sector has a rich history dating back thousands of years, with leather being one of the first materials used by humans for clothing and protection. Historically, leather was sourced locally, with artisans and small workshops dominating the market. The Industrial Revolution marked a significant turning point, introducing mechanization and large-scale production methods, which expanded the availability and diversity of leather products.

Illustrative image related to leather distributors

In recent decades, globalization has transformed the leather industry, allowing for cross-border trade and the sourcing of hides from various regions, including Africa and South America, known for their unique leather types. The rise of fast fashion has also influenced the sector, prompting a shift towards rapid production cycles and lower-cost materials. However, the current focus on sustainability and ethical sourcing reflects a re-evaluation of these practices, pushing the industry towards more responsible and transparent operations. This historical context is crucial for B2B buyers to understand the evolution of sourcing strategies and market dynamics in the leather distributors sector.

Frequently Asked Questions (FAQs) for B2B Buyers of leather distributors

-

How do I assess the quality of leather from distributors?

Evaluating leather quality involves several factors. Request samples to examine the texture, thickness, and finish. Look for consistent grain patterns and minimal blemishes. Additionally, inquire about the tanning process, as vegetable-tanned leather typically offers durability and environmental benefits. Certifications or quality standards from recognized bodies can also serve as indicators of quality. Lastly, establishing a relationship with the supplier allows for better insights into their sourcing practices and product reliability. -

What are the best types of leather for various applications?

The ideal leather type depends on your specific application. For upholstery, consider full-grain or top-grain leather for durability and aesthetic appeal. Vegetable-tanned leather is excellent for crafting belts and bags due to its natural properties. Suede offers a soft texture, suitable for garments, while chrome-tanned leather is often preferred for waterproof applications. Always assess the leather’s weight and thickness in relation to its intended use to ensure optimal performance. -

How can I verify the credibility of a leather distributor?

To verify a distributor’s credibility, start by checking their online presence, including reviews and testimonials from previous clients. Request references and case studies to understand their track record with other businesses. Additionally, inquire about their certifications and adherence to industry standards. A visit to their facility or showroom can provide firsthand insight into their operations. Engaging in direct communication about your requirements and their processes can also reveal their professionalism and reliability. -

What are typical minimum order quantities (MOQs) for leather supplies?

Minimum order quantities can vary widely among leather distributors, typically ranging from 10 to 100 square feet or more, depending on the type of leather and the supplier’s policies. Some distributors may offer flexibility for first-time buyers or smaller businesses. It’s advisable to discuss your needs upfront to negotiate MOQs that align with your budget and production goals. Consider the implications of bulk purchasing on storage and cash flow when evaluating MOQs. -

What payment terms should I expect from leather distributors?

Payment terms with leather distributors often vary, but common practices include net 30 or net 60 terms. Some suppliers may require upfront deposits, especially for custom orders or large quantities. It’s crucial to clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit, particularly for international transactions. Negotiating favorable terms can improve cash flow, so don’t hesitate to discuss options that work best for your business. -

How can I ensure the leather meets my specifications?

To ensure the leather meets your specifications, establish clear communication with your distributor regarding your requirements. Provide detailed descriptions of color, texture, and thickness, and request samples for approval before finalizing orders. Implement a quality assurance process upon receipt of goods to check for compliance with your standards. If necessary, consider setting up a quality control agreement that outlines acceptable parameters and procedures for addressing discrepancies. -

What logistics considerations should I keep in mind when sourcing leather internationally?

When sourcing leather internationally, logistics play a crucial role in your supply chain. Consider shipping methods, transit times, and costs, as well as customs regulations that may impact delivery. Work with distributors who have experience in international shipping to navigate potential challenges. Additionally, ensure you have adequate insurance for your shipments and understand the implications of tariffs and taxes in your country to avoid unexpected expenses. -

How can I customize leather orders to fit my business needs?

Many leather distributors offer customization options, including color, texture, and size. Discuss your specific needs with potential suppliers to explore available options. Provide samples or sketches to communicate your vision clearly. Be prepared to meet minimum order quantities for custom requests and inquire about lead times, as custom orders may require additional processing time. Building a strong relationship with your distributor can facilitate better customization experiences in the future.

Top 8 Leather Distributors Manufacturers & Suppliers List

1. Hide & Leather House – Leather Hides & Products

Domain: hidehouse.com

Registered: 1996 (29 years)

مقدمة: The Hide & Leather House, Inc. offers a wide range of leather products including: 1. Leather Hides – Over 3,000 types in stock, including: – Bags & Personal Leather Gear – Belting & Strapping – Chap & Motorcycle Hides – Eco Friendly Tannage – Footwear & Shoe Hides – Garment Hides – Hair on Hides – Lining & Orthopedic Hides – Nonstock Leather Hides – Saddlery, Veg-Tan & Latigo Hides – Up…

2. Tandy Leather – Quality Leather Goods

Domain: tandyleather.com

Registered: 1996 (29 years)

مقدمة: This company, Tandy Leather – Quality Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Waterhouse Leather – Wholesale Leather Hides

Domain: waterhouseleather.com

Registered: 2006 (19 years)

مقدمة: Wholesale Leather Skins and Hides Supplier offers various categories of leather hides including: 1. New Leather – Recent offerings 2. Special & Closeout Leather – Lowest prices 3. Popular Leather – Most popular hides 4. Hides by Application: Upholstery, Belt & Strap, Handbag, Wallet, Patch & Badge, Journal & Book-covering, Holster, Knife Sheath, Laser Engraving, Carving & Tooling, Embossing, Moldi…

4. Maverick Leather Company – Leather Hides by the Side

Domain: maverickleathercompany.com

Registered: 2009 (16 years)

مقدمة: Leather Hides – Sold By The Side – Flat Rate Shipping. Leather Color Range: Black, Brown, Burgundy, Blue, Gray, Green, Metallic, Natural, Orange, Pink, Purple, Red, Tan, White, Yellow. Leather Weight Options: 1 oz / 0.4 mm, 2 oz / 0.8 mm, 3 oz / 1.2 mm, 4 oz / 1.6 mm, 5 oz / 2 mm, 6 oz / 2.4 mm, 7 oz / 2.8 mm, 8 oz / 3.2 mm, 9 oz / 3.6 mm, 10 oz / 4 mm, 11 oz / 4.4 mm and Up. Hide Types: Bison & B…

5. District Leather Supply – Key Product Details

Domain: districtleathersupply.com

Registered: 2017 (8 years)

مقدمة: Key product details include: 1. Leather Types: Laser Friendly (Vegetable Tanned), Smooth Grain, Pebbled/Textured Grain, Suede/Nubuck. 2. Leather Colors: Black, Blue, Brown, Burgundy, Gold, Green, Natural, Orange, Pink, Purple, Red, Silver, Tan, Yellow, White. 3. Tannery Sources: Artigiano del Cuoio (Italy), Conceria 800 (Italy), Conceria La Bretagna (Italy), Conceria La Perla Azzurra (Italy), Conc…

6. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

مقدمة: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies, including various types of leather such as ChahinLeather®, Hermann Oak® Veg Tan, and Chrome Tanned options. They provide leather cuts like double shoulders, backs, bends, and whole hides, as well as textures including top grain, pebbled, and smooth. The store features tools for cutting, hand stitching, toolin…

7. Leather Hide Store – Premium Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

مقدمة: Upholstery Leather Supplier | Leather Hide Store offers a wide range of premium upholstery hides in various colors and prints. All products are 100% genuine cowhide suitable for furniture, automotive, leathercraft, and more. The store features leather in colors such as Black, Blue, Brown & Gold, Dark Brown, Green, Grey, Metallic, Orange, Pink & Purple, Red & Burgundy, Tan & Beige, Taupe, White & C…

8. Buckleguy – Wholesale Leather Hides and Skins

Domain: buckleguy.com

Registered: 2002 (23 years)

مقدمة: Buckleguy offers a variety of leather hides and skins at wholesale prices, including top grain leather such as vegetable tanned, chrome tanned, and re-tans in cowhide, buffalo calf, and cordovan. The product range includes leather panels for smaller cut sheets and various cuts such as double shoulders, sides, and exotic skins. Key features include:

– Tannery options: Hermann Oak, Horween, Korba, L…

Strategic Sourcing Conclusion and Outlook for leather distributors

In today’s competitive landscape, strategic sourcing has emerged as a pivotal element for leather distributors aiming to enhance their operational efficiency and profitability. By leveraging a diverse range of suppliers, buyers can secure high-quality leather products while optimizing costs. Establishing strong relationships with reputable sources not only guarantees product availability but also fosters innovation and adaptability in response to market trends.

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional nuances and supplier capabilities can significantly influence procurement strategies. As global demand for leather products continues to rise, aligning with suppliers who prioritize sustainability and ethical practices will be crucial.

Looking ahead, the leather industry stands poised for growth, driven by evolving consumer preferences and advancements in leather technology. Now is the time for B2B buyers to engage proactively with distributors and suppliers, exploring partnerships that can lead to mutual success. Embrace the opportunities presented by strategic sourcing to not only meet current demands but also to anticipate future trends in the leather market.

Illustrative image related to leather distributors

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.