Introduction: Navigating the Global Market for leather working tools and supplies

In the increasingly competitive landscape of leatherworking, sourcing high-quality leather working tools and supplies can be a daunting challenge for international B2B buyers. From Africa to South America, and across the Middle East to Europe, businesses must navigate a complex web of suppliers, material types, and pricing structures. This comprehensive guide is designed to equip you with the essential knowledge and strategies needed to make informed purchasing decisions.

We will explore various categories of leather working tools—from cutting and stitching tools to specialized machinery—while also delving into the applications of these tools in different market sectors. Understanding how to vet suppliers effectively is crucial, particularly in regions where local availability may be limited. Additionally, we’ll provide insights into cost considerations, helping you to balance quality with budget constraints.

By leveraging the information presented in this guide, B2B buyers can enhance their procurement processes, optimize their supply chains, and ultimately improve product quality. Whether you are a seasoned leather craftsman or a newcomer to the industry, this resource will empower you to make strategic decisions that align with your business goals, ensuring a successful venture into the global market for leather working tools and supplies.

Table Of Contents

- Top 5 Leather Working Tools And Supplies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather working tools and supplies

- Understanding leather working tools and supplies Types and Variations

- Key Industrial Applications of leather working tools and supplies

- 3 Common User Pain Points for ‘leather working tools and supplies’ & Their Solutions

- Strategic Material Selection Guide for leather working tools and supplies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather working tools and supplies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather working tools and supplies’

- Comprehensive Cost and Pricing Analysis for leather working tools and supplies Sourcing

- Alternatives Analysis: Comparing leather working tools and supplies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather working tools and supplies

- Navigating Market Dynamics and Sourcing Trends in the leather working tools and supplies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather working tools and supplies

- Strategic Sourcing Conclusion and Outlook for leather working tools and supplies

- Important Disclaimer & Terms of Use

Understanding leather working tools and supplies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hand Tools | Manual operation, precision-focused | Crafting custom leather goods, repairs | Pros: Cost-effective, high control. Cons: Labor-intensive, slower production. |

| Sewing Machines | Automated stitching, various speed settings | Mass production of leather goods | Pros: High efficiency, consistent quality. Cons: Higher initial investment, requires maintenance. |

| Dyes and Finishes | Variety of colors and finishes, enhance leather appeal | Customization of leather products | Pros: Wide range of options, adds value. Cons: Requires knowledge for best results. |

| Hardware and Fasteners | Includes buckles, snaps, and rivets | Functional and decorative leather goods | Pros: Enhances durability, aesthetic appeal. Cons: Sourcing can be complex, quality varies. |

| Leather Crafting Kits | Bundled tools and materials for beginners | Educational purposes, entry-level crafting | Pros: Simplifies purchasing, ideal for training. Cons: Limited advanced options, may not suit all needs. |

What Are the Key Characteristics of Hand Tools for Leather Working?

Hand tools are essential for precise and detailed leather crafting. They include items such as knives, chisels, and edge tools, allowing artisans to have complete control over their work. These tools are particularly suitable for small-scale production or bespoke items, where quality and craftsmanship are paramount. B2B buyers should consider the brand reputation and tool durability, as these factors can significantly impact the overall quality of the finished product.

How Do Sewing Machines Enhance Leather Working Efficiency?

Sewing machines designed for leather working automate the stitching process, allowing for faster production rates without compromising quality. They come equipped with various features, such as adjustable speed settings and specialized needles suited for thicker materials. This makes them ideal for businesses engaged in mass production, such as bag and shoe manufacturers. When purchasing, B2B buyers should assess the machine’s compatibility with different leather types and its long-term maintenance requirements.

Why Are Dyes and Finishes Important in Leather Crafting?

Dyes and finishes are crucial for enhancing the aesthetic appeal of leather products. They come in a multitude of colors and finishes, allowing businesses to customize their offerings to meet market demands. Proper application can elevate the perceived value of leather goods, making them more appealing to consumers. B2B buyers must ensure they understand the application techniques and drying times to achieve the best results, as improper usage can lead to unsatisfactory finishes.

What Role Do Hardware and Fasteners Play in Leather Goods?

Hardware and fasteners, such as buckles, snaps, and rivets, are vital for both the functionality and aesthetics of leather products. They contribute to the durability of items like belts and bags while also serving as design elements. For businesses, sourcing high-quality hardware is essential to ensure the longevity of their products. Buyers should be mindful of the material quality and compatibility with their leather to avoid any issues during production.

How Do Leather Crafting Kits Support New Entrants in the Market?

Leather crafting kits offer a comprehensive solution for beginners and educational institutions. They typically include a selection of tools and materials needed to complete specific projects, making them an excellent choice for training programs. While these kits simplify the purchasing process, B2B buyers should consider the skill level of their target audience and whether the kits include advanced tools or materials that may not be suitable for entry-level crafters.

Key Industrial Applications of leather working tools and supplies

| Industry/Sector | Specific Application of leather working tools and supplies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom leather garments and accessories | Enhances product differentiation and brand identity | Quality of leather, tooling precision, and design adaptability |

| Automotive | Upholstery and interior leatherwork | Improves vehicle aesthetics and comfort | Durability of materials, compliance with safety standards |

| Furniture Manufacturing | Leather upholstery for furniture | Adds luxury appeal and durability | Availability of various textures and colors, bulk pricing options |

| Craft and Hobby | DIY leathercraft kits and tools | Engages customers in creative projects | Variety of tools, ease of use, and educational resources |

| E-commerce and Retail | Online sales of leather goods and supplies | Expands market reach and customer base | Shipping logistics, product authenticity, and customer service |

How Are Leather Working Tools and Supplies Utilized in the Fashion and Apparel Industry?

In the fashion and apparel sector, leather working tools and supplies are essential for creating custom garments and accessories. Designers utilize specialized tools like cutting dies, stitching machines, and embossing tools to craft unique leather products that stand out in a competitive market. This not only enhances product differentiation but also helps brands establish a strong identity. International buyers should consider the quality of leather and the precision of tooling to ensure that the final products meet their design expectations.

What Role Do Leather Working Tools Play in Automotive Upholstery?

In the automotive industry, leather working tools are crucial for upholstery and interior leatherwork. Manufacturers use high-quality leather and specialized stitching tools to enhance the aesthetics and comfort of vehicles. The use of durable materials ensures longevity and customer satisfaction, while compliance with safety standards is paramount. For international buyers, sourcing considerations include the durability of materials and the availability of specific colors and textures that align with regional preferences.

How Is Leather Used in Furniture Manufacturing?

Leather is a popular choice for upholstery in furniture manufacturing, providing a blend of luxury and durability. Tools such as sewing machines, edge tools, and cutting implements are used to create high-quality leather upholstery that appeals to consumers. The luxurious feel and long-lasting nature of leather furniture can significantly enhance market appeal. Buyers should focus on the availability of various textures and colors, as well as bulk pricing options, to optimize their sourcing strategies.

Why Are Leathercraft Kits Important for the Craft and Hobby Sector?

In the craft and hobby industry, leather working tools and supplies are vital for DIY enthusiasts. Leathercraft kits, which include essential tools and materials, allow individuals to engage in creative projects, fostering a sense of accomplishment and satisfaction. These kits often come with instructional materials, making them accessible for beginners. Buyers should prioritize variety in tools, ease of use, and the availability of educational resources to cater to different skill levels.

How Do Leather Working Supplies Benefit E-commerce and Retail?

For e-commerce and retail businesses, leather working tools and supplies are essential for expanding market reach. Online platforms can offer a wide range of leather goods and crafting supplies, appealing to a diverse customer base. Ensuring product authenticity and high-quality customer service is critical for maintaining a positive reputation in the digital marketplace. International buyers must consider shipping logistics and the reliability of suppliers to ensure timely delivery and customer satisfaction.

3 Common User Pain Points for ‘leather working tools and supplies’ & Their Solutions

Scenario 1: Sourcing Quality Leather Tools in Diverse Markets

The Problem: B2B buyers often struggle to source high-quality leather working tools and supplies that meet their specific needs, especially when operating across diverse international markets like Africa, South America, and the Middle East. Variability in product quality, inconsistent supplier reliability, and challenges in logistics can lead to significant delays and increased costs. Buyers may also face difficulty in verifying the authenticity and quality of the materials, which can compromise the final product’s integrity and craftsmanship.

The Solution: To effectively source quality leather tools, buyers should establish relationships with reputable suppliers who have a proven track record in the leather industry. Utilizing platforms that connect buyers with verified manufacturers can help mitigate risks. For instance, conducting thorough due diligence, such as requesting samples, can provide tangible insights into the product quality. Additionally, leveraging trade shows or industry-specific exhibitions can facilitate direct communication with suppliers, allowing for clearer specifications and better understanding of product offerings. It’s also advisable to create a standardized checklist for evaluating suppliers based on factors such as quality certifications, customer reviews, and warranty terms.

Scenario 2: Navigating Tool Compatibility and Functionality

The Problem: Many B2B buyers encounter difficulties in ensuring that the leather working tools they purchase are compatible with their existing machinery or specific project requirements. This issue is particularly pronounced for businesses that may be transitioning from manual to machine-driven processes. Incompatibility can lead to increased operational downtime and inefficient production, ultimately affecting profitability and project timelines.

The Solution: To navigate these compatibility challenges, buyers should conduct comprehensive research on the tools’ specifications before making a purchase. This includes understanding the type of leather being worked on and the specific requirements of their machinery. Engaging with suppliers who offer technical support can be invaluable; they can provide insights on which tools are best suited for specific applications. Additionally, maintaining an open dialogue with tool manufacturers can lead to tailored solutions that align with the buyer’s unique processes. Consider investing in versatile tools that can serve multiple functions, which can help streamline operations and reduce the need for multiple purchases.

Illustrative image related to leather working tools and supplies

Scenario 3: Managing Inventory and Supply Chain Disruptions

The Problem: Inventory management poses a significant challenge for B2B buyers in the leather working sector, particularly when faced with supply chain disruptions. Fluctuations in demand, unforeseen shortages, and delays in shipping can lead to stockouts, affecting production schedules and customer satisfaction. This is especially critical for businesses operating in regions with limited access to reliable supply chains.

The Solution: To effectively manage inventory and mitigate supply chain risks, buyers should adopt a proactive inventory management strategy. Implementing a just-in-time (JIT) inventory system can help reduce holding costs while ensuring that essential materials are available when needed. Additionally, diversifying suppliers across different regions can create a buffer against localized disruptions. Buyers should also consider establishing long-term contracts with key suppliers to secure better terms and consistent availability of materials. Utilizing technology, such as inventory management software, can provide real-time data and analytics, allowing businesses to make informed decisions about stock levels and reorder points, thereby enhancing overall operational efficiency.

Strategic Material Selection Guide for leather working tools and supplies

When selecting materials for leather working tools and supplies, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: steel, aluminum, plastic, and wood. Each material has unique characteristics that can significantly impact the performance and suitability of leatherworking tools for international B2B buyers.

What Are the Key Properties of Steel in Leather Working Tools?

Steel is a popular choice for leather working tools due to its exceptional strength and durability. It typically offers high-temperature resistance and can withstand significant pressure without deforming. Corrosion-resistant coatings can enhance its lifespan, making it suitable for various environments, including humid conditions often found in regions like South America and Africa.

Pros: Steel tools are robust, providing longevity and reliability in performance. They maintain sharp edges well, which is crucial for precision cutting and tooling.

Cons: The primary drawback is that steel can be heavy, which may affect handling during extended use. Additionally, high-quality steel tools can be more expensive than alternatives, potentially raising initial investment costs for buyers.

How Does Aluminum Compare as a Material for Leather Working Tools?

Aluminum is lightweight and corrosion-resistant, making it an attractive option for certain leather working tools. It is particularly useful for tools that require frequent handling, such as stitching awls and edge tools.

Pros: The low weight of aluminum tools reduces fatigue during use, allowing for extended periods of crafting. They are also generally less expensive than steel counterparts, making them a cost-effective choice for businesses.

Cons: However, aluminum lacks the hardness of steel, which can lead to quicker wear and tear. This material may not be suitable for heavy-duty applications where durability is paramount.

Illustrative image related to leather working tools and supplies

What Role Does Plastic Play in Leather Working Supplies?

Plastic is often used in various leather working supplies, including templates, tool racks, and even some hand tools. Its versatility and resistance to moisture make it a practical choice.

Pros: Plastic tools are typically lightweight and affordable, appealing to budget-conscious buyers. They are resistant to corrosion and can be molded into complex shapes, enhancing usability.

Cons: The downside is that plastic may not withstand high temperatures or heavy pressure, limiting its application in more demanding tasks. Additionally, plastic tools may not provide the same tactile feedback as metal tools, which can affect precision.

Why is Wood Still Relevant in Leather Working Tools?

Wood has a long-standing tradition in leather working, especially for tools like mauls and mallets. Its natural properties provide a unique feel that many artisans prefer.

Pros: Wooden tools are often aesthetically pleasing and can offer a good grip. They are also less likely to damage leather surfaces compared to harder materials, making them ideal for delicate tasks.

Cons: However, wood can absorb moisture, leading to warping or cracking over time. It may also require more maintenance compared to metal or plastic tools, which could be a consideration for international buyers in varying climates.

Summary Table of Material Selection for Leather Working Tools

| المواد | Typical Use Case for leather working tools and supplies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Cutting tools, punches, and knives | High durability and edge retention | Heavy and potentially costly | عالية |

| Aluminum | Lightweight tools like awls and edge tools | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Plastic | Templates and tool racks | Affordable and versatile | Limited durability under pressure | منخفضة |

| Wood | Mallets and handles for tools | Good grip and less damaging to leather | Susceptible to moisture and requires maintenance | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions regarding material selection for leather working tools and supplies. Understanding the properties and implications of each material can enhance product performance and customer satisfaction in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for leather working tools and supplies

What Are the Key Stages in the Manufacturing Process of Leather Working Tools and Supplies?

The manufacturing process for leather working tools and supplies typically consists of several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring the final product meets the quality expectations of B2B buyers.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials, such as stainless steel for tools and premium leather for supplies. Suppliers often select materials based on durability, performance, and compatibility with various leather crafting techniques. For instance, leather may undergo tanning processes to enhance its longevity and aesthetic qualities. Proper storage and handling are crucial during this stage to prevent material degradation.

-

Forming: In this phase, raw materials are shaped into their intended forms. For tools, this may involve cutting, stamping, or forging processes. Techniques like CNC machining ensure precision in creating components such as blades, handles, or dies. For leather supplies, die cutting and molding are common methods used to produce consistent shapes and sizes. The forming stage is vital for ensuring that each item meets design specifications, which directly impacts usability and customer satisfaction.

-

Assembly: The assembly stage involves putting together the various components of tools and supplies. This may include attaching handles to cutting tools or stitching leather pieces together for crafting kits. Skilled artisans often oversee this process to ensure quality workmanship. Automated assembly lines may also be employed for mass production, but manual oversight remains essential for quality assurance, especially in intricate designs.

-

Finishing: The final stage focuses on enhancing the product’s appearance and functionality. This can include polishing metal surfaces, applying protective coatings, dyeing leather, or adding branding elements. Quality control measures are implemented during this stage to ensure that each product not only looks appealing but also meets performance standards.

How Is Quality Assurance Ensured in Leather Working Tools and Supplies Manufacturing?

Quality assurance (QA) is integral to the manufacturing of leather working tools and supplies. The process typically adheres to various international standards and industry-specific regulations to guarantee product reliability and safety.

-

International Standards: Many manufacturers comply with ISO 9001, a standard that outlines criteria for a quality management system. This certification indicates that a company has established consistent processes for improving product quality. Additionally, other certifications like CE marking are relevant for products sold in Europe, indicating compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified standards before production begins. Any defective materials are rejected, preventing downstream issues.

– In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor processes and identify any deviations from quality standards. This proactive approach allows for immediate corrective actions.

– Final Quality Control (FQC): After production, finished products undergo rigorous testing to ensure they meet all specifications. This can include functional testing, visual inspections, and stress tests for durability. -

Common Testing Methods: Manufacturers may utilize various testing methods, including tensile strength tests for tools and color fastness tests for leather. These tests verify that products can withstand the rigors of use and maintain their aesthetic qualities over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing practices firsthand. This process includes reviewing production methods, quality control systems, and compliance with international standards. Audits can help identify potential risks and establish a supplier’s credibility.

-

Requesting Quality Reports: Buyers can request documentation such as quality control reports, testing certifications, and compliance documents. These records provide insights into a supplier’s quality assurance practices and help buyers make informed decisions.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These organizations can conduct inspections at various stages of the manufacturing process, ensuring adherence to agreed-upon specifications and international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the quality control and certification landscape can be challenging for international B2B buyers. Here are some nuances to consider:

-

Regional Standards and Regulations: Different regions may have specific standards that products must meet. For instance, while CE marking is essential for products in Europe, buyers in the Middle East may look for Gulf Conformity Mark (G Mark) certification. Understanding these regional requirements is crucial for compliance and market access.

-

Cultural and Market Expectations: Quality perceptions may vary across cultures and markets. Buyers from Africa or South America may prioritize durability and functionality, while European buyers might emphasize aesthetics and compliance with environmental standards. Tailoring procurement strategies to meet these expectations can enhance buyer-supplier relationships.

-

Building Long-term Relationships: Establishing a partnership with suppliers who prioritize quality can yield long-term benefits. Engaging in continuous dialogue regarding quality expectations, feedback mechanisms, and collaborative improvement initiatives can foster trust and enhance product quality over time.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing leather working tools and supplies, ensuring that they receive products that meet their operational needs and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather working tools and supplies’

مقدمة

Sourcing leather working tools and supplies requires a strategic approach to ensure quality, cost-effectiveness, and supplier reliability. This checklist will guide B2B buyers through the essential steps to procure the right tools and materials for their leathercrafting needs, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the tools and materials you require is crucial. This includes detailing the types of leather (e.g., vegetable-tanned, chrome-tanned), tool functionalities (e.g., cutting, stitching, tooling), and any specific dimensions or features. Having precise specifications helps streamline the sourcing process and ensures that suppliers understand your exact needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in leather working tools and supplies. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential vendors. Pay attention to supplier reviews and their history in the market to gauge reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it’s essential to verify that suppliers meet relevant industry certifications and standards. Look for certifications such as ISO (International Organization for Standardization) or specific leather industry standards that indicate quality control and ethical practices. This step is vital for ensuring that the materials you source are compliant with safety and environmental regulations.

Illustrative image related to leather working tools and supplies

Step 4: Request Samples and Product Catalogs

Always request product samples and detailed catalogs from your shortlisted suppliers. Evaluating samples allows you to assess the quality of materials and tools firsthand. Additionally, comprehensive catalogs provide insights into the range of products available, enabling you to make informed decisions about your purchases.

Step 5: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing effectively. Consider not only the cost of the products but also shipping fees, bulk discounts, and payment terms. Understanding the total cost of procurement will help you budget accurately and identify the best value for your investment.

Step 6: Check Lead Times and Delivery Options

Inquire about the suppliers’ lead times for order fulfillment and their shipping options. Understanding delivery timelines is critical, especially if you have project deadlines to meet. Look for suppliers who can accommodate your schedule and offer reliable shipping methods to your region.

Step 7: Establish a Communication Plan

Finally, set up a clear communication plan with your chosen suppliers. Define points of contact, preferred communication channels, and response times to ensure smooth interactions. Effective communication helps prevent misunderstandings and facilitates a productive relationship with your suppliers.

Illustrative image related to leather working tools and supplies

By following this checklist, B2B buyers can navigate the complexities of sourcing leather working tools and supplies, ensuring they select the best options for their business needs.

Comprehensive Cost and Pricing Analysis for leather working tools and supplies Sourcing

What Are the Key Cost Components in Leather Working Tools and Supplies?

When sourcing leather working tools and supplies, understanding the cost structure is crucial for B2B buyers. Key cost components include:

-

Materials: The quality of leather, tools, and supplies directly influences costs. High-quality leather, such as vegetable-tanned or exotic leathers, typically commands higher prices. Additionally, specialized tools may require premium materials, impacting overall expenses.

-

Labor: Labor costs are significant, especially in regions where skilled artisans are involved in production. Labor rates vary by country, affecting the final pricing. In regions like Europe and the Middle East, higher labor costs may be offset by superior craftsmanship.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and equipment maintenance. Suppliers in regions with higher operational costs may pass these expenses onto buyers, making it essential to consider the supplier’s location.

-

Tooling: Custom tooling or specialized equipment for unique designs can add substantial costs. Buyers should inquire about tooling fees when requesting custom items.

-

Quality Control (QC): Ensuring that products meet quality standards incurs additional costs. Suppliers with rigorous QC processes may charge more, but this can save buyers from future issues related to defective products.

-

Logistics: Shipping and handling are often overlooked in pricing analysis. The cost of transporting goods varies significantly based on distance, mode of transport, and Incoterms selected. For international buyers, understanding these logistics is vital to avoid unexpected costs.

-

Margin: Supplier profit margins can vary widely. Analyzing the margin can provide insights into the competitiveness of a supplier’s pricing.

What Influences Prices for Leather Working Tools and Supplies?

Several factors influence pricing in this market, and understanding them can help buyers make informed decisions:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for bulk purchases. Negotiating lower MOQs can lead to cost savings, especially for small businesses.

-

Specifications and Customization: Customized tools or supplies usually come at a premium. Buyers should assess whether customization is essential or if standard products can meet their needs.

-

Materials and Quality Certifications: Products with certifications (e.g., eco-friendly, ethically sourced) may carry higher prices. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and location can significantly impact pricing. Established suppliers may charge more due to perceived quality, while new entrants may offer competitive pricing to gain market share.

-

Incoterms: Different Incoterms can affect total costs. For instance, choosing terms that place the burden of shipping and insurance on the seller can lead to higher prices but may offer more predictability.

What Are the Best Negotiation Tips for Buyers in International Markets?

When navigating the complexities of international sourcing, consider these strategies:

-

Understand Total Cost of Ownership (TCO): TCO encompasses all costs associated with a product, not just the initial purchase price. Include logistics, potential tariffs, and long-term maintenance when evaluating suppliers.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and more favorable terms. Trust can often open doors to negotiations that benefit both parties.

-

Be Aware of Pricing Nuances: Prices can fluctuate based on exchange rates, local economic conditions, and seasonal demand. Staying informed about these factors can provide leverage in negotiations.

-

Conduct Market Research: Understanding the competitive landscape and price points in your region can empower you during negotiations. Knowing what similar products are priced at can help in discussions about value and cost.

-

Explore Alternative Suppliers: Don’t hesitate to seek multiple quotes. Exploring various suppliers can yield better prices and terms, allowing for more informed decision-making.

In conclusion, a comprehensive understanding of cost components, price influencers, and effective negotiation strategies is essential for international B2B buyers in the leather working tools and supplies market. This knowledge can lead to more strategic sourcing decisions and ultimately improve profitability.

Alternatives Analysis: Comparing leather working tools and supplies With Other Solutions

Introduction to Alternative Solutions in Leather Working

In the realm of leather crafting, selecting the right tools and supplies is crucial for achieving high-quality results. However, various alternatives exist that can fulfill similar roles in the leatherworking process. This analysis will explore how traditional leather working tools and supplies compare against other methods and technologies, such as synthetic leather materials and digital fabrication techniques. Understanding these alternatives can empower international B2B buyers to make informed purchasing decisions tailored to their specific operational needs.

Comparison Table

| Comparison Aspect | Leather Working Tools and Supplies | Synthetic Leather Materials | Digital Fabrication Techniques |

|---|---|---|---|

| Performance | High durability and craftsmanship | Moderate durability, often less authentic feel | High precision, customizable designs |

| Cost | Moderate to high initial investment | Generally lower cost | Higher initial investment, but cost-effective for bulk production |

| Ease of Implementation | Requires skill and training | Easy to cut and assemble | Requires technical knowledge and software |

| Maintenance | Regular maintenance needed | Low maintenance | Occasional software and machine upkeep |

| Best Use Case | Custom, high-end leather goods | Mass production of fashion items | Prototyping and complex designs |

Detailed Breakdown of Alternatives

Synthetic Leather Materials

Synthetic leather, often made from polyurethane or PVC, serves as a popular alternative to traditional leather. It offers a lower cost, making it appealing for mass production and budget-conscious businesses. However, while it is easier to work with and does not require the same level of skill as traditional leather, synthetic options often lack the durability and unique aesthetic that natural leather provides. For businesses focused on producing high-volume fashion items where authenticity is less critical, synthetic leather can be an effective choice.

Digital Fabrication Techniques

Digital fabrication, which includes technologies like laser cutting and 3D printing, represents a cutting-edge approach to leatherworking. This method allows for high precision and customization, enabling intricate designs that might be challenging to achieve manually. However, the initial investment in equipment and the need for specialized software can be significant drawbacks. Digital fabrication is ideal for businesses that prioritize innovation and design flexibility, particularly in prototyping or producing complex products.

Conclusion: Choosing the Right Solution for Your Leatherworking Needs

When selecting between leather working tools and supplies, synthetic leather materials, and digital fabrication techniques, B2B buyers should consider several factors, including their specific business model, production capacity, and desired product quality. Leather tools are best suited for artisans focused on craftsmanship and bespoke goods, while synthetic materials may benefit companies aiming for lower costs and higher volume. Digital fabrication offers unparalleled design possibilities but requires technical expertise and investment. By assessing these elements against their operational goals, businesses can make informed decisions that align with their strategic objectives in the leatherworking industry.

Essential Technical Properties and Trade Terminology for leather working tools and supplies

What Are the Key Technical Properties of Leather Working Tools and Supplies?

When sourcing leather working tools and supplies, understanding specific technical properties is essential for making informed purchasing decisions. Here are some critical specifications:

Illustrative image related to leather working tools and supplies

-

Material Grade

The material grade of tools and supplies can significantly impact their durability and performance. For example, high-grade stainless steel is commonly used in cutting tools and stitching needles due to its resistance to corrosion and wear. In contrast, lower-grade materials may be more cost-effective but can lead to premature wear and replacement costs. Buyers should prioritize tools made from higher-grade materials to ensure longevity and reliability in production. -

Tolerance

Tolerance refers to the allowable deviation from a specified measurement. In leather working, precise tolerances are crucial, especially for tools like cutting dies and stitching chisels. A tighter tolerance ensures a better fit and finish, which is vital for high-quality leather goods. For B2B buyers, understanding tolerance levels can help in selecting tools that meet their production standards and reduce waste from poorly fitting components. -

Finish Type

The finish type of leather supplies can affect both aesthetics and functionality. For instance, tools with a polished finish can reduce friction during use, leading to smoother operation and better results. Additionally, the finish on leather itself, whether it be top grain, full grain, or suede, can influence the final product’s look and feel. Buyers should consider the intended application and select finishes that align with their project requirements. -

Weight and Balance

The weight and balance of tools, such as mauls or knives, play a critical role in usability and ergonomics. Heavier tools may offer more striking force, while lighter tools can reduce user fatigue during prolonged use. Understanding the balance can help buyers select tools that enhance productivity and comfort for their teams. -

Durability Rating

This rating indicates how well a tool or supply can withstand wear and tear over time. For example, tools that are rated for high durability can withstand extensive use without losing effectiveness. When negotiating with suppliers, buyers should inquire about durability ratings to ensure they are investing in tools that will deliver value over their expected lifespan.

What Are Common Trade Terms in the Leather Working Industry?

Navigating the leather working industry requires familiarity with specific jargon and trade terms. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In leather working, an OEM may provide tools or supplies that are then branded and sold by another company. Understanding OEM relationships can help buyers identify quality sources for tools. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers looking to manage inventory and costs effectively. Knowing the MOQ can help businesses plan their purchases and avoid overstocking or understocking situations. -

RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For leather working supplies, submitting an RFQ can help buyers receive competitive pricing and terms from multiple vendors, facilitating better procurement decisions. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for B2B buyers to understand shipping costs and responsibilities, helping to avoid misunderstandings during the procurement process. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. In leather working, understanding lead times is critical for planning production schedules and ensuring timely delivery of finished goods. Buyers should always clarify lead times with suppliers to avoid delays in their supply chain.

By mastering these technical properties and trade terms, B2B buyers in the leather working industry can make informed decisions that enhance their operations and product quality.

Navigating Market Dynamics and Sourcing Trends in the leather working tools and supplies Sector

What Are the Current Market Dynamics and Key Trends in Leather Working Tools and Supplies?

The global leather working tools and supplies market is experiencing a notable shift driven by a combination of technological advancements, evolving consumer preferences, and sustainability considerations. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly leveraging e-commerce platforms to source high-quality leather products and tools. The rise of digital marketplaces has streamlined procurement processes, enabling buyers to access a wider range of products from diverse suppliers, often at competitive prices.

Emerging technologies such as automation and 3D printing are also reshaping the landscape, allowing manufacturers to produce customized tools and components efficiently. Buyers are increasingly looking for suppliers who can offer innovative products that improve productivity and reduce lead times. Additionally, there is a growing trend towards integrated supply chains that emphasize transparency and traceability, which is particularly important for discerning buyers focused on quality and ethical sourcing.

Illustrative image related to leather working tools and supplies

Furthermore, as the demand for artisanal and bespoke leather goods rises, the market is witnessing an increase in interest towards specialized tools and high-quality materials. This trend is particularly pronounced in regions with a rich tradition of craftsmanship, where buyers seek tools that enhance skill development and enable artisans to create intricate designs.

How Does Sustainability Influence Sourcing Decisions in the Leather Working Sector?

Sustainability and ethical sourcing are paramount considerations for B2B buyers in the leather working tools and supplies sector. The environmental impact of leather production has come under scrutiny, prompting buyers to prioritize suppliers who adhere to sustainable practices. This includes sourcing leather from tanneries that utilize eco-friendly processes, such as vegetable tanning, which minimizes harmful chemical usage.

Buyers are also increasingly interested in suppliers that offer ‘green’ certifications, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification. These certifications not only assure buyers of the environmental integrity of their products but also enhance their brand reputation in a market that values responsible practices.

Moreover, ethical supply chains are becoming a key differentiator in the competitive landscape. Buyers are looking for suppliers who can demonstrate a commitment to fair labor practices and community engagement. This focus on ethics not only aligns with consumer values but also mitigates risks associated with reputational damage and supply chain disruptions.

How Has the Leather Working Tools and Supplies Market Evolved Over Time?

The evolution of the leather working tools and supplies market can be traced back to traditional craftsmanship, where artisans relied on hand tools and locally sourced materials. Over the decades, technological advancements have introduced machinery that enhances efficiency and precision, transforming the landscape of leather production.

Illustrative image related to leather working tools and supplies

The advent of synthetic materials in the mid-20th century posed challenges for the leather industry; however, it also spurred innovation in tool design and manufacturing processes. Today, the market is characterized by a blend of traditional techniques and modern technology, catering to a diverse range of consumers from hobbyists to professional artisans.

As global trends shift towards sustainability and ethical practices, the sector continues to adapt, ensuring that it meets the demands of conscious consumers while preserving the artistry and heritage of leather craftsmanship. This ongoing evolution provides a rich opportunity for international B2B buyers to engage with suppliers who are not only focused on quality and innovation but also committed to responsible sourcing practices.

Frequently Asked Questions (FAQs) for B2B Buyers of leather working tools and supplies

-

How do I choose the right leather working tools for my business needs?

Selecting the right leather working tools involves understanding your specific applications, production volume, and the type of leather you will be using. Start by assessing the projects you plan to undertake—whether it’s crafting bags, belts, or custom items. Invest in essential tools like cutting knives, stitching supplies, and finishing tools suited for your level of expertise. Additionally, consider the durability and ergonomics of the tools, as they can significantly impact productivity and quality in the long run. -

What are the essential supplies for leathercrafting?

Essential leathercrafting supplies include quality leather hides, cutting tools, stitching materials, dyes, and finishes. Depending on your project, you might also need hardware such as buckles, snaps, and rivets. It’s beneficial to purchase from reputable suppliers who offer a variety of products to ensure compatibility and quality. Additionally, consider investing in leathercrafting kits for beginners, which often include the basic tools and materials needed to start crafting immediately. -

What should I consider when vetting international suppliers for leather tools?

When vetting international suppliers, prioritize their reputation, product quality, and compliance with industry standards. Look for suppliers with positive customer reviews and certifications that indicate adherence to safety and quality regulations. Evaluate their communication responsiveness and willingness to provide samples before committing to large orders. Additionally, confirm their ability to meet your volume requirements and delivery timelines to avoid disruptions in your production process. -

What are the typical minimum order quantities (MOQs) for leather supplies?

Minimum order quantities (MOQs) can vary widely depending on the supplier and the specific products. Many suppliers set MOQs to ensure cost-effectiveness for both parties; commonly, these can range from 10 to 100 units per item. It is advisable to discuss MOQs upfront during negotiations, especially if you are a small business. Some suppliers may offer flexibility for first-time orders or bulk purchases, so it’s worth inquiring about these options. -

What payment terms are standard for B2B transactions in the leather industry?

Standard payment terms in the leather industry often include options like net 30, net 60, or letter of credit for larger transactions. Many suppliers may require a deposit upfront, especially for custom orders. Ensure to clarify payment methods accepted, such as bank transfers or credit terms, and confirm the currency of transactions to avoid unexpected costs. Establishing clear payment terms can help maintain a smooth business relationship and avoid cash flow issues. -

How can I ensure quality assurance (QA) for the leather products I source?

To ensure quality assurance, start by requesting product samples before making a bulk purchase. Evaluate the samples for texture, thickness, and overall quality to ensure they meet your standards. Establish quality control protocols with your supplier, such as specifying acceptable tolerances and conducting inspections at various production stages. Additionally, consider third-party quality inspections if sourcing from overseas to verify compliance with your specifications and industry standards. -

What logistics considerations should I keep in mind when importing leather supplies?

Logistics play a crucial role in the timely delivery of leather supplies. Consider shipping options, customs regulations, and potential tariffs that may apply when importing goods. Work with a logistics partner experienced in international trade to navigate these complexities effectively. Ensure you have a clear understanding of lead times, shipping costs, and the documentation required for customs clearance. Proper planning can help mitigate delays and unexpected expenses. -

Can I customize leather tools and supplies for my business?

Yes, many suppliers offer customization options for leather tools and supplies. Customization can include branding tools with your logo, selecting specific colors or finishes, and adjusting sizes to fit your business needs. When discussing customization, provide detailed specifications to ensure the supplier can meet your requirements. Be aware that custom orders may have different MOQs and longer lead times, so factor this into your planning process.

Top 5 Leather Working Tools And Supplies Manufacturers & Suppliers List

1. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

مقدمة: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies including various types of leather (ChahinLeather®, Hermann Oak® Veg Tan, Natural Veg Tan, Dyed Chrome Tanned, Water Buffalo Leather, Specialty Leather), leather cuts (Double Shoulders, Backs & Bends, Single Shoulders, Panels, Half Sides, Whole Hide, Bellies, Belt Blanks, Laces & Strapping), textures (Top Grai…

2. Tandy Leather – Essential Hand Tools

Domain: tandyleather.com

Registered: 1996 (29 years)

مقدمة: Essential Leather Hand Tools for precise crafting, free shipping on orders over $149.

3. Buckleguy – Quality Hardware

Domain: buckleguy.com

Registered: 2002 (23 years)

مقدمة: This company, Buckleguy – Quality Hardware, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

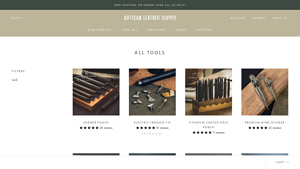

4. Artisan Leather Supply – Corner Punch

Domain: artisanleathersupply.com

Registered: 2020 (5 years)

مقدمة: [{‘name’: ‘Corner Punch’, ‘reviews’: ’28 reviews’, ‘price’: ‘From $14’}, {‘name’: ‘Electric Creaser Tip’, ‘reviews’: ’10 reviews’, ‘price’: ‘From $17’}, {‘name’: ‘Titanium-Coated Hole Punch’, ‘reviews’: ’11 reviews’, ‘price’: ‘From $5.50’}, {‘name’: ‘Premium Wing Divider’, ‘reviews’: ’33 reviews’, ‘price’: ‘From $32’}, {‘name’: ‘Locking Pins (pack of 5)’, ‘reviews’: ’13 reviews’, ‘price’: ‘From $5…

5. Slice Products – Swivel Knife & Awls

Domain: sliceproducts.com

Registered: 2006 (19 years)

مقدمة: 1. Swivel Knife: Ideal for intricate details and outlining; features an indented finger rest for control, zirconium oxide blade that never needs sharpening, ergonomic design, and cross-hatched grip.

2. Awls: Used for poking holes in leather; includes various types like collar awl, curved awl, lacing awl, diamond tip awl, and needle awl for different functions.

3. Burnisher and Slicker Tools: Used …

Strategic Sourcing Conclusion and Outlook for leather working tools and supplies

In the dynamic landscape of leatherworking tools and supplies, strategic sourcing emerges as a pivotal element for international B2B buyers. By prioritizing quality, durability, and innovation, businesses can secure a competitive edge in their markets. Engaging with reputable suppliers not only ensures access to premium materials and tools but also fosters long-term partnerships that can lead to cost efficiencies and better supply chain management.

Furthermore, understanding regional market trends and consumer preferences can significantly enhance sourcing strategies. Buyers from Africa, South America, the Middle East, and Europe should leverage local insights to tailor their offerings, ensuring they meet the diverse needs of their clientele. As the demand for customized and high-quality leather goods continues to rise, the importance of sourcing the right tools and supplies cannot be overstated.

Looking ahead, we encourage international buyers to explore emerging trends in the leatherworking industry, invest in advanced tooling technologies, and engage with suppliers who prioritize sustainable practices. By doing so, businesses can not only enhance their product offerings but also contribute to a more sustainable future in leathercrafting. Take the next step in your sourcing journey and partner with suppliers who align with your vision for growth and quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.