Introduction: Navigating the Global Market for nubuck leather material

In the competitive landscape of B2B sourcing, navigating the global market for nubuck leather material presents unique challenges for international buyers. Whether you are looking to procure high-quality leather for footwear, upholstery, or fashion accessories, understanding the nuances of nubuck leather—its characteristics, applications, and care requirements—is essential. This guide serves as a comprehensive resource, addressing key considerations such as the different types of nubuck leather, supplier vetting processes, pricing structures, and maintenance tips.

For buyers from regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Saudi Arabia—making informed purchasing decisions is crucial to ensure quality and sustainability. As nubuck leather is renowned for its luxurious texture and durability, recognizing the differences between nubuck and other leathers, such as suede, can influence your project’s success.

This guide empowers B2B buyers by providing actionable insights, helping you navigate supplier options and understand market trends. By arming yourself with this knowledge, you can confidently select the right nubuck leather that aligns with your business needs, ensuring that your final products meet both aesthetic and functional demands.

Table Of Contents

- Top 2 Nubuck Leather Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for nubuck leather material

- Understanding nubuck leather material Types and Variations

- Key Industrial Applications of nubuck leather material

- 3 Common User Pain Points for ‘nubuck leather material’ & Their Solutions

- Strategic Material Selection Guide for nubuck leather material

- In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leather material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leather material’

- Comprehensive Cost and Pricing Analysis for nubuck leather material Sourcing

- Alternatives Analysis: Comparing nubuck leather material With Other Solutions

- Essential Technical Properties and Trade Terminology for nubuck leather material

- Navigating Market Dynamics and Sourcing Trends in the nubuck leather material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leather material

- Strategic Sourcing Conclusion and Outlook for nubuck leather material

- Important Disclaimer & Terms of Use

Understanding nubuck leather material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Nubuck | Soft, velvety texture with natural grain marks | Footwear, handbags, upholstery | Pros: Luxurious feel, durable; Cons: Prone to stains, requires maintenance |

| Waterproof Nubuck | Treated for water resistance and stain protection | Outdoor gear, high-end upholstery | Pros: Stain-resistant, durable; Cons: Higher cost due to treatment |

| Vegetable-Tanned Nubuck | Eco-friendly tanning process, maintains natural characteristics | Fashion items, eco-conscious brands | Pros: Sustainable, soft texture; Cons: Less water-resistant, may age differently |

| Nubuck Calfskin | Made from premium calf hides, finer texture | Luxury goods, high-end fashion | Pros: Exceptional softness, premium quality; Cons: Higher price point, limited availability |

| Nubuck Bullhide | Thicker and more robust, retains natural markings | Heavy-duty applications, furniture | Pros: Very durable, ideal for high-traffic use; Cons: Heavier, may be less supple |

What Are the Characteristics of Traditional Nubuck Leather?

Traditional nubuck is characterized by its soft, velvety surface that showcases the natural grain of the hide. Often sourced from cowhide, it is lightly sanded to reveal a plush texture while retaining unique markings that add character. This type of nubuck is ideal for products like footwear and handbags, where aesthetics and durability are essential. B2B buyers should consider the maintenance requirements, as traditional nubuck is prone to staining and needs regular care to maintain its appearance.

How Does Waterproof Nubuck Differ from Other Variants?

Waterproof nubuck undergoes specialized treatment to enhance its resistance to moisture and stains. This makes it particularly suitable for outdoor gear and high-end upholstery that may face environmental challenges. Buyers in sectors like outdoor apparel and luxury furniture should prioritize waterproof nubuck for its ability to withstand spills and weather exposure. However, the added treatment often results in a higher price point, which should be factored into budget considerations.

Illustrative image related to nubuck leather material

Why Choose Vegetable-Tanned Nubuck for Eco-Conscious Brands?

Vegetable-tanned nubuck is processed using natural tannins derived from plant sources, making it a sustainable choice for environmentally conscious brands. This type maintains the hide’s natural characteristics, offering a unique texture and appearance. Its applications are best suited for fashion items that emphasize eco-friendliness. Buyers should be aware that vegetable-tanned nubuck may have lower water resistance and can exhibit different aging patterns, which could affect long-term product appearance.

What Are the Advantages of Nubuck Calfskin?

Nubuck calfskin is sourced from premium calf hides, resulting in a finer texture and a more luxurious feel. This variant is often used in high-end fashion and luxury goods, where the quality of materials significantly impacts brand perception. B2B buyers should consider the exceptional softness and premium quality of nubuck calfskin, although it comes with a higher price point and may have limited availability compared to other types.

When Should You Consider Nubuck Bullhide for Heavy-Duty Applications?

Nubuck bullhide is thicker and more robust than traditional nubuck, making it an excellent choice for heavy-duty applications such as furniture and high-traffic areas. Its durability is unmatched, allowing it to withstand wear and tear while maintaining its aesthetic appeal. Buyers should note that while nubuck bullhide is very durable, it may be heavier and less supple than other variants, which can influence design choices and application suitability.

Key Industrial Applications of nubuck leather material

| Industry/Sector | Specific Application of nubuck leather material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear | High-end shoes and boots | Offers durability and a luxurious appearance, appealing to premium markets | Ensure waterproofing treatments and color consistency |

| Upholstery | Furniture and automotive interiors | Provides a sophisticated look while maintaining breathability and comfort | Look for stain-resistant options and high-quality hides |

| Fashion Accessories | Handbags and belts | Enhances brand image with a touch of elegance and luxury | Source from reputable tanneries to guarantee quality |

| Sporting Goods | Sportswear and outdoor gear | Combines style with functionality, suitable for high-performance products | Verify durability and resistance to wear and tear |

| Leather Goods Manufacturing | Custom leather goods | Allows for unique, high-quality products that stand out in the market | Focus on sourcing hides with minimal imperfections |

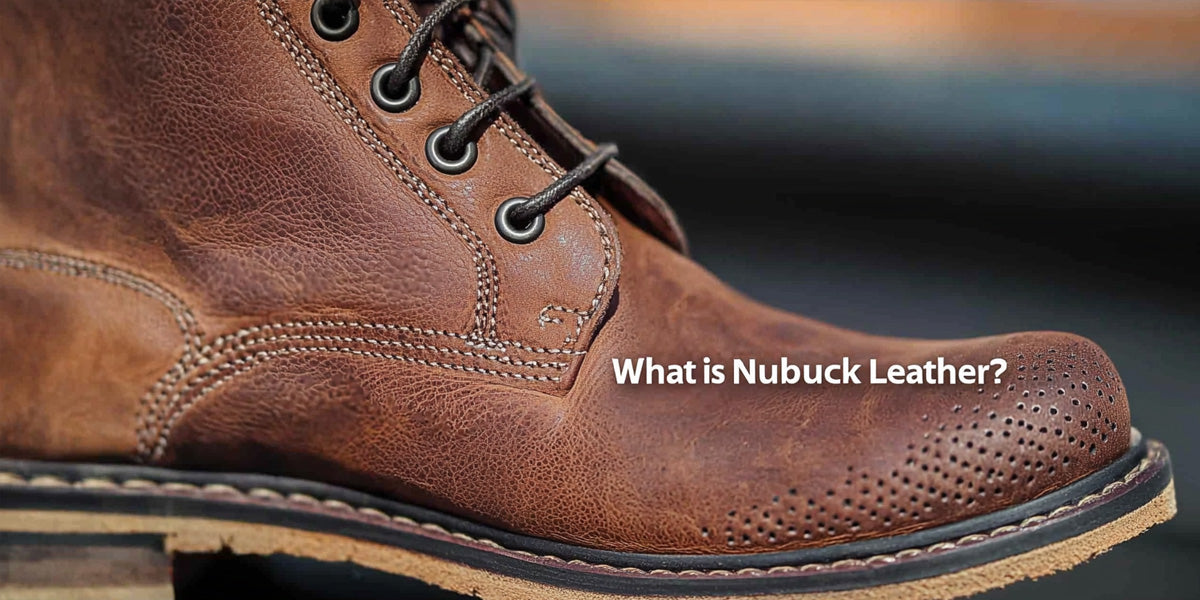

How is Nubuck Leather Used in the Footwear Industry?

Nubuck leather is extensively utilized in the production of high-end footwear, including shoes and boots. Its unique velvety texture not only provides a luxurious appearance but also ensures durability, making it ideal for everyday wear. International buyers, especially from regions like Africa and the Middle East, should prioritize sourcing nubuck that has been treated for water resistance, as this enhances the leather’s longevity and performance in diverse climates. Additionally, consistency in color and texture is crucial for maintaining brand standards in premium markets.

Illustrative image related to nubuck leather material

What Role Does Nubuck Leather Play in Upholstery?

In the upholstery sector, nubuck leather is favored for its sophisticated look and comfort. It is commonly used in luxury furniture and automotive interiors, where aesthetics and durability are paramount. Buyers should consider sourcing stain-resistant varieties to address the challenges of maintenance, particularly in high-traffic areas. For businesses in South America and Europe, ensuring that the leather meets strict quality standards will help in creating long-lasting and visually appealing products that resonate with consumers seeking elegance.

How is Nubuck Leather Incorporated into Fashion Accessories?

Nubuck leather is a popular choice for fashion accessories, such as handbags and belts, where its luxurious feel enhances the overall appeal of the product. This material allows brands to position themselves in the premium segment, attracting consumers who appreciate quality and craftsmanship. When sourcing nubuck for these applications, businesses should focus on partnering with reputable tanneries that provide consistent quality and minimal imperfections, which are essential for maintaining a high-end image in competitive markets, particularly in Europe and Africa.

What are the Applications of Nubuck Leather in Sporting Goods?

In the sporting goods industry, nubuck leather is incorporated into sportswear and outdoor gear, where it combines style with functionality. Its durability makes it suitable for high-performance products, appealing to athletes and outdoor enthusiasts. Buyers should ensure that the nubuck sourced is capable of withstanding wear and tear, particularly in active environments. Additionally, considering the climate conditions in regions like the Middle East, sourcing water-resistant and breathable options will enhance product performance and user satisfaction.

Illustrative image related to nubuck leather material

How Does Nubuck Leather Benefit Leather Goods Manufacturing?

Nubuck leather is a key material in the custom leather goods manufacturing sector, allowing artisans to create unique, high-quality products that stand out in the market. Its natural texture and luxurious appearance enable manufacturers to cater to niche markets that prioritize craftsmanship and exclusivity. When sourcing nubuck for custom applications, businesses should focus on acquiring hides with minimal imperfections to ensure the final product meets the high standards expected by discerning customers in global markets, including Africa and South America.

3 Common User Pain Points for ‘nubuck leather material’ & Their Solutions

Scenario 1: Difficulty in Maintaining Nubuck Leather’s Appearance

The Problem: B2B buyers often find that nubuck leather, while luxurious and aesthetically pleasing, is notoriously difficult to maintain. The soft, velvety surface can quickly become stained or damaged by water, dirt, and oils. This poses a significant challenge, especially for businesses in high-traffic sectors like hospitality or retail, where the appearance of leather goods must remain pristine to maintain brand reputation and customer satisfaction. Moreover, many buyers are unsure of the proper cleaning techniques, which can lead to further damage if not handled correctly.

The Solution: To effectively maintain nubuck leather, businesses should invest in high-quality protective sprays designed specifically for nubuck. These sprays create a barrier against water and stains while preserving the leather’s natural texture. Additionally, implementing a regular cleaning schedule can prevent the accumulation of dirt and oils. This includes using a soft brush to gently remove surface dirt and a specialized nubuck eraser for tougher stains. Training staff on proper maintenance techniques ensures that the leather remains in excellent condition, thereby prolonging its lifespan and preserving its luxury appeal.

Illustrative image related to nubuck leather material

Scenario 2: Sourcing High-Quality Nubuck Leather

The Problem: B2B buyers often struggle with sourcing high-quality nubuck leather that meets their specifications for durability and aesthetics. With numerous suppliers in the market, differentiating between quality grades can be challenging. Buyers may face issues such as receiving inferior products that do not meet industry standards, leading to dissatisfaction among customers and potential financial loss.

The Solution: To mitigate sourcing challenges, buyers should prioritize suppliers who provide comprehensive product information, including details on the tanning process, hide origin, and quality assurance certifications. Establishing relationships with reputable suppliers who specialize in nubuck leather, particularly those that offer samples, can help buyers evaluate quality firsthand. Additionally, seeking out suppliers who provide transparency in their production methods and sustainability practices can ensure that the leather aligns with the buyer’s brand values. Engaging in trade shows or industry expos can also provide opportunities to connect with quality manufacturers and examine their products directly.

Scenario 3: Understanding the Differences Between Nubuck and Suede

The Problem: Many B2B buyers are often confused about the differences between nubuck and suede leather, which can lead to misinformed purchasing decisions. This confusion can result in selecting the wrong type of leather for specific applications, negatively impacting product quality and customer satisfaction. For example, a buyer may opt for suede for high-wear items like footwear, unaware of nubuck’s superior durability and performance in such contexts.

The Solution: To address this confusion, buyers should invest time in understanding the distinct characteristics of nubuck and suede. Educational resources, such as webinars, workshops, or detailed guides from suppliers, can clarify the differences in texture, durability, and maintenance requirements. Additionally, creating a decision matrix that outlines the specific applications and benefits of each leather type can help buyers make informed choices. For businesses, providing training for sales staff on the nuances of leather types will enhance customer interactions and ensure that clients receive products that best fit their needs. By emphasizing the unique qualities of nubuck, businesses can position themselves as knowledgeable experts in the leather market, fostering trust and long-term relationships with clients.

Strategic Material Selection Guide for nubuck leather material

What Are the Key Properties of Nubuck Leather Materials?

Nubuck leather is derived from the outer grain side of animal hides, most commonly cowhide, calfskin, or sheepskin. The tanning process, which can be either chrome or vegetable-based, involves lightly sanding the surface to achieve its characteristic velvety texture. This unique process retains the natural grain and imperfections of the hide, making it a favored choice for high-end products.

جلد نوبوك

Key Properties: Nubuck leather exhibits excellent breathability and a soft, luxurious feel. It is generally more durable than suede due to its grain-side origin, which contributes to its resistance to wear and tear. However, it is susceptible to staining and requires careful maintenance to preserve its appearance.

Pros & Cons: The primary advantages of nubuck leather include its aesthetic appeal and durability, making it suitable for a variety of applications, including footwear, upholstery, and accessories. On the downside, its vulnerability to moisture and stains can limit its usability in certain environments, requiring additional care and protective treatments.

Impact on Application: Nubuck’s compatibility with high-end fashion and luxury goods is significant. However, its maintenance requirements can be a barrier for mass-market applications, particularly in regions with high humidity or exposure to dirt and grime.

Considerations for International Buyers: For B2B buyers in regions like Africa and the Middle East, understanding local climate conditions is crucial. Compliance with international standards such as ASTM or DIN for leather products is essential, as is awareness of regional preferences for durability and maintenance.

Illustrative image related to nubuck leather material

Waterproof Nubuck Leather

Key Properties: New advancements in nubuck technology have led to the development of waterproof nubuck leather, which retains the luxurious feel while offering enhanced resistance to moisture. This material is treated during the tanning process to create a barrier against water and stains.

Pros & Cons: The key advantage of waterproof nubuck is its versatility, allowing it to be used in a wider range of applications, including outdoor gear and footwear. However, the manufacturing process can be more complex and costly, which may affect pricing and availability.

Impact on Application: Waterproof nubuck is particularly suitable for products that require exposure to the elements, such as outdoor apparel and accessories. Its enhanced properties make it a viable option for buyers in regions with wet climates.

Considerations for International Buyers: Buyers should ensure that waterproof nubuck meets local standards for water resistance and durability. Understanding the treatment processes used can also help in assessing the long-term performance of the material.

Illustrative image related to nubuck leather material

Nubuck vs. Suede Leather

Key Properties: While both nubuck and suede are known for their soft textures, nubuck is derived from the grain side, offering superior durability. Suede, on the other hand, comes from the inner split layer and is generally less durable.

Pros & Cons: Nubuck’s durability makes it ideal for high-contact applications, while suede is often chosen for fashion items due to its softer feel. However, suede is more prone to damage and stains, making it less suitable for everyday use.

Impact on Application: The choice between nubuck and suede can significantly affect product longevity and maintenance. Nubuck is often preferred for items that require durability, while suede is better suited for less demanding applications.

Considerations for International Buyers: B2B buyers should be aware of the differences in maintenance and care requirements between these two materials. Additionally, understanding local market trends can guide the selection of the appropriate leather type for specific applications.

Summary Table of Nubuck Leather Materials

| المواد | Typical Use Case for nubuck leather material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| جلد نوبوك | Footwear, upholstery, high-end accessories | Luxurious look and durability | Prone to staining and water damage | عالية |

| Waterproof Nubuck Leather | Outdoor gear, waterproof footwear | Enhanced water resistance | Higher manufacturing complexity | عالية |

| Nubuck vs. Suede | Fashion items, high-contact goods | Greater durability than suede | Higher cost compared to suede | Med to High |

This guide provides a comprehensive overview of nubuck leather materials, highlighting their properties, advantages, limitations, and considerations for international B2B buyers. Understanding these factors can aid in making informed purchasing decisions tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leather material

What Are the Main Stages of Nubuck Leather Manufacturing?

The manufacturing process of nubuck leather is intricate and demands meticulous attention to detail, ensuring that the final product meets high standards of quality and aesthetics. The process can be broken down into four primary stages: material preparation, forming, assembly, and finishing.

How is Material Prepared for Nubuck Leather Production?

The first step in manufacturing nubuck leather begins with the selection of high-quality hides, predominantly from cowhide, calfskin, or sheepskin. This selection is crucial, as the quality of the hide directly affects the final product. Once selected, the hides undergo a tanning process, which can be either chrome or vegetable tanning.

- Chrome Tanning: This is a faster process using chromium salts, yielding a more supple and pliable leather. It is favored for its efficiency and consistency.

- Vegetable Tanning: A slower, more traditional method that uses natural tannins found in plants. This process results in a firmer leather with a more rustic finish.

After tanning, the hides are washed, dried, and conditioned to prepare them for the next stage. This initial preparation ensures that the leather maintains its natural grain characteristics, which are essential for nubuck’s soft and luxurious feel.

What Techniques Are Used in the Forming and Assembly of Nubuck Leather?

Following material preparation, the next stage involves the sanding or buffing of the grain surface. This technique is pivotal in creating the velvety texture associated with nubuck leather.

- Sanding/Buffing: This process removes the top layer of the hide, exposing fine fibers that contribute to the soft surface of nubuck. Precision is critical here; excessive sanding can damage the hide, while insufficient sanding can lead to a less desirable texture.

Once the hides are treated and sanded, they are cut into the desired shapes for various products such as footwear, handbags, and upholstery. The cutting must be performed with precision to minimize waste and ensure that each piece meets quality standards.

The assembly phase typically involves stitching and bonding, where pieces are meticulously joined together. Quality control begins at this stage, as proper alignment and secure stitching are crucial for the durability and appearance of the finished product.

What Finishing Processes Are Applied to Nubuck Leather?

Finishing is the final stage in the nubuck leather manufacturing process. This stage involves applying treatments that enhance the leather’s properties and appearance.

Illustrative image related to nubuck leather material

- Dyeing: Nubuck can be dyed in various colors to meet market demands. Quality dyes are used to ensure that colors are vibrant and long-lasting.

- Waterproofing and Stain Resistance: Given nubuck’s susceptibility to staining, many manufacturers apply treatments that make the leather more resistant to water and stains. These treatments are essential for enhancing the leather’s longevity and maintaining its luxurious appearance.

What Quality Assurance Measures Are Essential for Nubuck Leather?

Quality assurance (QA) is critical in the nubuck leather manufacturing process to ensure that the final product meets both international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

For manufacturers of nubuck leather, adherence to international standards such as ISO 9001 is essential. This standard outlines the criteria for a quality management system, helping organizations ensure they meet customer and regulatory requirements consistently.

In addition to ISO 9001, specific industry certifications may apply, such as CE marking for products sold in Europe, ensuring compliance with health, safety, and environmental protection standards. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with these standards to ensure that suppliers adhere to the necessary regulations.

What Are the Key Quality Control Checkpoints in Nubuck Leather Production?

Quality control in nubuck leather production typically involves several checkpoints throughout the manufacturing process:

Illustrative image related to nubuck leather material

- Incoming Quality Control (IQC): At this stage, raw hides are inspected for defects such as scars, blemishes, or imperfections. Only hides that meet quality criteria proceed to the tanning process.

- In-Process Quality Control (IPQC): During the sanding and assembly stages, regular inspections ensure that the leather maintains its desired texture and that stitching is secure.

- Final Quality Control (FQC): This final inspection occurs after the finishing process. The finished products are checked for color consistency, texture quality, and adherence to specifications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures implemented by their suppliers. This can be achieved through:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control practices directly. This firsthand observation can provide valuable insights into the supplier’s operations.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance with international standards. These reports should detail the methods used and the outcomes achieved.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These services can conduct random inspections during production and offer reports on compliance with specified standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate various nuances when sourcing nubuck leather, particularly in regions like Africa, South America, the Middle East, and Europe.

- Cultural Differences: Understanding cultural practices related to quality assurance can enhance communication with suppliers. Different regions may have varying standards and expectations, so clear dialogue is essential.

- Logistical Considerations: International shipping can impact the quality of leather products. Buyers should ensure that suppliers employ suitable packaging and transport methods to prevent damage during transit.

- Regulatory Compliance: Buyers must be aware of the specific regulations that apply to their region, which may differ significantly from those in the supplier’s country. This includes import regulations and local standards for leather goods.

In conclusion, the manufacturing processes and quality assurance for nubuck leather are complex and critical for ensuring high-quality products. By understanding the nuances of production and implementing thorough quality control measures, B2B buyers can confidently source nubuck leather that meets their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leather material’

In this guide, we provide a practical checklist for B2B buyers seeking to procure nubuck leather material. Nubuck leather, known for its luxurious feel and durability, requires careful consideration during the sourcing process to ensure quality and suitability for your needs.

Illustrative image related to nubuck leather material

Step 1: Define Your Technical Specifications

Begin by identifying the specific requirements for your nubuck leather. Consider factors such as thickness, color, finish, and intended application (e.g., footwear, upholstery). These specifications will guide your supplier discussions and help you avoid mismatches later in the sourcing process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of nubuck leather. Look for companies with a strong track record in the leather industry, particularly those who specialize in nubuck. Verify their location, production capabilities, and customer reviews to ensure they can meet your quality and quantity needs.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, check for relevant certifications that demonstrate compliance with industry standards. Important certifications may include ISO 9001 for quality management and environmental certifications like the Leather Working Group (LWG) certification. These indicators can provide assurance regarding the quality and sustainability of the materials.

Step 4: Request Samples

Always request samples before finalizing your order. This step is crucial for assessing the texture, color, and overall quality of the nubuck leather. Evaluate the samples under various lighting conditions and consider how they fit with your intended use. Pay attention to the durability and feel to ensure they meet your expectations.

Step 5: Understand Pricing Structures

Discuss pricing with your suppliers to understand their pricing structures clearly. Consider factors such as minimum order quantities, bulk discounts, and payment terms. Be mindful that higher-quality nubuck may come at a premium, but this investment can lead to better product performance and customer satisfaction.

Illustrative image related to nubuck leather material

Step 6: Clarify Lead Times and Delivery Options

Inquire about lead times for production and delivery. Understanding the timeline is essential for planning your production schedules and meeting market demands. Additionally, discuss shipping options and costs, particularly if you are sourcing internationally, to avoid unexpected expenses.

Step 7: Establish a Quality Control Process

Once you have selected a supplier, establish a quality control process to ensure that all received materials meet your specifications. This could involve setting up regular inspections, testing samples, and maintaining open communication with your supplier regarding any quality issues. A proactive approach can help mitigate risks and ensure consistent product quality.

By following these steps, B2B buyers can streamline the sourcing process for nubuck leather, ensuring they select high-quality materials that align with their business needs.

Comprehensive Cost and Pricing Analysis for nubuck leather material Sourcing

What Are the Key Cost Components in Nubuck Leather Material Sourcing?

Understanding the cost structure of nubuck leather sourcing is essential for B2B buyers aiming to make informed purchasing decisions. The primary cost components include:

-

Materials: The quality of the raw hides significantly impacts pricing. Nubuck leather is derived from the grain side of the hide, typically cowhide, calfskin, or sheepskin, which is more expensive than suede. Prices can vary based on the source of the hide and the specific tanning process used, whether chrome or vegetable.

-

Labor: Skilled labor is required to process nubuck leather, including tanning, sanding, and finishing. Labor costs can fluctuate based on geographical location and the expertise of the workforce, which is particularly relevant when sourcing from different regions.

-

Manufacturing Overhead: This encompasses operational costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs and improve overall pricing competitiveness.

-

Tooling: Investment in specialized machinery for processing nubuck leather can add to initial costs. However, high-quality tooling can enhance efficiency and product quality, ultimately leading to better pricing strategies.

-

Quality Control (QC): Ensuring that the leather meets specific standards requires investment in quality control measures. This can include inspections during production, which may increase costs but is crucial for maintaining product integrity.

-

Logistics: Transportation costs can vary widely based on the distance from the supplier to the buyer, as well as the chosen shipping method. For international buyers, understanding Incoterms is critical to determining who bears these costs.

-

Margin: Suppliers will add a margin to cover their costs and profit, which can vary based on market conditions and competition.

How Do Pricing Influencers Affect Nubuck Leather Costs?

Several factors can influence the pricing of nubuck leather:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should consider their needs carefully to negotiate favorable terms.

-

Specifications and Customization: Custom orders or specific finishes can lead to increased costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher quality hides and certifications (like environmental sustainability) can increase prices but may also enhance the product’s marketability.

-

Supplier Factors: The reliability and reputation of suppliers play a significant role in pricing. Established suppliers may charge more due to their proven quality and service levels.

What Buyer Tips Can Help Optimize Nubuck Leather Sourcing Costs?

To navigate the complexities of sourcing nubuck leather, consider the following tips:

-

Negotiate Effectively: Build strong relationships with suppliers and be open about your budget constraints. Leveraging volume purchases can also provide negotiating power.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term factors such as durability, maintenance, and potential resale value. Nubuck leather, while more expensive upfront, may offer better longevity compared to cheaper alternatives.

-

Understand Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, consider local market conditions, currency fluctuations, and import tariffs. Understanding these factors will aid in making more informed purchasing decisions.

Disclaimer on Indicative Prices

It is essential to note that prices for nubuck leather can vary significantly based on the aforementioned factors. Always consult with suppliers for current pricing and availability to ensure you are making the best-informed decisions for your business needs.

Alternatives Analysis: Comparing nubuck leather material With Other Solutions

Exploring Alternatives to Nubuck Leather Material

When evaluating materials for upholstery, footwear, or high-end fashion accessories, it is crucial for international B2B buyers to consider various alternatives to nubuck leather. Each alternative presents unique characteristics, benefits, and drawbacks, which can significantly impact the overall quality, aesthetics, and cost-effectiveness of the final product. Below, we compare nubuck leather with suede leather and synthetic leather—two popular alternatives in the leather market.

| Comparison Aspect | Nubuck Leather Material | Suede Leather | جلد صناعي |

|---|---|---|---|

| Performance | Durable, luxurious feel; suitable for high-end applications | Softer, less durable; more suitable for low-contact items | Varies widely; can mimic leather appearance but may lack breathability |

| Cost | Generally higher due to quality and processing | More affordable; budget-friendly option | Typically lower cost; varies based on quality and brand |

| Ease of Implementation | Requires skilled craftsmanship for optimal use | Easier to work with for less complex designs | Easy to manufacture; can be mass-produced |

| Maintenance | Requires careful cleaning and protection; prone to staining | Needs regular brushing and protection; less durable | Low maintenance; easy to clean but may wear over time |

| Best Use Case | High-end shoes, handbags, upholstery | Fashion accessories, clothing, casual footwear | Affordable fashion items, bags, upholstery in budget-conscious markets |

In-Depth Analysis of Alternatives

Suede Leather

Suede leather is derived from the inner layer of the hide, resulting in a soft and fuzzy texture. It is generally more affordable than nubuck, making it a popular choice for fashion accessories and garments. However, its lower durability and higher susceptibility to stains and water damage limit its use in high-wear applications. Suede is ideal for products that require a softer touch but may not withstand the rigors of daily use as effectively as nubuck.

جلد صناعي

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to natural leathers, including nubuck. It can be designed to mimic the appearance of leather, making it a popular choice for budget-conscious consumers. While synthetic leather is generally easier to maintain and resistant to staining, it often lacks the breathability and luxurious feel of nubuck. Additionally, its long-term durability can vary significantly depending on the manufacturing quality, making it essential for buyers to evaluate specific products carefully.

Choosing the Right Solution for Your Needs

When determining the best material for your specific application, it is vital to consider the intended use, budget constraints, and desired aesthetic. Nubuck leather stands out for its luxurious feel and durability, making it suitable for high-end products. Conversely, suede provides a more economical option for fashion items that do not require high durability, while synthetic leather offers versatility and affordability for mass-market products. By carefully weighing these factors, B2B buyers can make informed decisions that align with their product goals and target market preferences.

Essential Technical Properties and Trade Terminology for nubuck leather material

What Are the Key Technical Properties of Nubuck Leather Material?

When sourcing nubuck leather, understanding its critical technical properties is essential for B2B buyers to ensure they select the right material for their applications. Here are some vital specifications:

1. Material Grade

Nubuck leather is categorized primarily by the quality of the hide used, which can range from standard to premium grades. Premium nubuck is derived from high-quality cowhide or calfskin, which is more durable and aesthetically pleasing. For buyers, selecting a higher material grade often translates into superior durability and a better overall product, essential for high-end applications such as luxury handbags and upholstery.

2. Tolerance Levels

Tolerance levels refer to the acceptable variations in the thickness and texture of the leather. Nubuck typically has a thickness ranging from 1.0 mm to 1.5 mm. Maintaining tight tolerances is crucial in manufacturing processes, as inconsistencies can affect the final product’s fit and finish. Buyers should confirm tolerance levels with suppliers to ensure compatibility with their production requirements.

3. Water Resistance Rating

While nubuck leather is not inherently waterproof, many manufacturers offer treatments that enhance its water resistance. Buyers should inquire about the specific water resistance rating of the nubuck being sourced. This rating is significant for applications in environments where moisture exposure is likely, such as footwear or outdoor furniture.

Illustrative image related to nubuck leather material

4. Grain Character

The natural grain character of nubuck, including its pores and scars, contributes to its unique appearance. This property is essential for buyers who prioritize aesthetics in their products. Understanding the grain character can help in marketing the leather goods as premium or artisanal, appealing to consumers who appreciate natural textures.

5. Finish Type

The finish applied to nubuck can vary widely, affecting both its look and functionality. Common finishes include aniline, which preserves the natural look, and pigment finishes, which offer enhanced protection. Buyers should consider the intended use of the leather when discussing finish types with suppliers, as this can influence durability and maintenance requirements.

What Are Common Trade Terms Used in Nubuck Leather Transactions?

Navigating the trade terminology associated with nubuck leather can significantly enhance communication between buyers and suppliers. Here are some essential terms:

Illustrative image related to nubuck leather material

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces goods for another company under that company’s brand name. For nubuck leather buyers, working with an OEM can facilitate the creation of customized leather products tailored to specific market needs.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of product a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory costs effectively and ensure that their purchasing aligns with production needs. High MOQs might necessitate bulk purchasing, impacting cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific quantities of nubuck leather. It is an essential tool for buyers to compare costs and negotiate terms before making purchasing decisions. Providing detailed specifications in an RFQ can lead to more accurate and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms is crucial for B2B transactions involving nubuck leather, as they clarify obligations such as shipping, insurance, and import duties.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the goods. Understanding lead times is vital for buyers to plan their production schedules and meet market demands. Long lead times can impact inventory levels, necessitating careful forecasting and planning.

6. Certification Standards

Certification standards indicate compliance with specific quality and safety regulations. For nubuck leather, certifications may include environmental or sustainability standards, which can influence consumer preferences. Buyers should inquire about certification status when sourcing to align with market trends and regulatory requirements.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing nubuck leather, ensuring they select high-quality materials that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the nubuck leather material Sector

What are the Key Trends Influencing the Nubuck Leather Market?

The global nubuck leather market is experiencing significant shifts driven by evolving consumer preferences and technological advancements. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality materials that align with luxury and durability. The rise of e-commerce platforms has facilitated easier access to suppliers, enabling buyers to source nubuck leather from diverse regions, including Italy, known for its premium quality hides.

One notable trend is the growing preference for waterproof and stain-resistant nubuck options, such as the Italia Nubuck Collection. This innovation caters to consumers’ desire for both aesthetics and practicality, making nubuck leather suitable for various applications, from high-end footwear to luxury upholstery. Additionally, the increasing adoption of digital tools for inventory management and order tracking has streamlined the sourcing process, allowing for more efficient transactions and better supply chain management.

Moreover, sustainability is becoming a crucial factor influencing purchasing decisions. Buyers are more inclined to partner with suppliers who prioritize eco-friendly practices and materials, which has prompted manufacturers to explore sustainable tanning processes and certifications.

How is Sustainability Impacting the Nubuck Leather Sector?

Sustainability is reshaping the nubuck leather industry, with a focus on reducing environmental impact and promoting ethical sourcing practices. The tanning process of nubuck leather, which traditionally involves chemical treatments, has faced scrutiny due to its potential environmental hazards. As a result, many suppliers are transitioning to vegetable tanning methods, which utilize natural materials and significantly lower ecological footprints.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Sourcing from suppliers that adhere to fair labor practices and environmental standards not only enhances brand reputation but also meets the growing consumer demand for responsible products. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification are becoming increasingly relevant, providing assurance that the materials sourced are environmentally friendly and ethically produced.

Furthermore, the shift towards sustainability is prompting innovation in product offerings. Suppliers are now developing nubuck leather options that incorporate recycled materials or biodegradable treatments, appealing to eco-conscious buyers looking to enhance their sustainability credentials.

Illustrative image related to nubuck leather material

What is the Historical Context of Nubuck Leather in B2B Markets?

Nubuck leather has a rich history that dates back to the early 20th century when it emerged as a luxury material, valued for its soft texture and durability. Originally, nubuck was made from high-quality cowhide and was primarily used for upscale footwear and accessories. Over the decades, its applications have expanded to include furniture upholstery, automotive interiors, and fashion items, driven by its aesthetic appeal and robust nature.

The production techniques have also evolved, with advancements in tanning methods leading to improved durability and resistance to stains and water. This evolution has made nubuck leather increasingly attractive to international B2B buyers, as it aligns well with the demands for quality and longevity in high-end markets. Today, as consumer preferences lean towards both luxury and sustainability, nubuck leather continues to hold a prominent place in the global leather industry, adapting to new trends and challenges while maintaining its status as a premium product.

Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leather material

-

How do I choose the right supplier for nubuck leather?

Choosing the right supplier involves assessing several key factors. First, verify the supplier’s reputation through reviews and references from other B2B buyers. Evaluate their quality assurance processes, including certifications for the leather they provide. Additionally, inquire about their sourcing practices to ensure ethical and sustainable procurement. Lastly, consider their ability to meet your specific customization needs and delivery timelines, as this will greatly affect your supply chain efficiency. -

What is the best application for nubuck leather in my business?

Nubuck leather is ideal for high-end products requiring durability and a luxurious feel, such as footwear, handbags, and upholstery. Its fine texture and natural grain make it suitable for items that benefit from a sophisticated appearance while ensuring strength. If your business focuses on luxury goods or requires materials that can withstand regular use, nubuck leather is an excellent choice due to its balance of aesthetics and durability. -

What are the minimum order quantities (MOQ) for nubuck leather?

Minimum order quantities for nubuck leather can vary significantly by supplier and region. Typically, MOQs range from 50 to 200 square meters, depending on the manufacturer’s production capabilities and the specific leather type. It’s advisable to discuss MOQs upfront with potential suppliers to ensure they align with your business needs and budget. Some suppliers may offer flexibility on MOQs for long-term partnerships or bulk orders. -

How do I ensure quality assurance for nubuck leather materials?

To ensure quality assurance, request samples before finalizing your order. Examine the samples for texture, durability, and any defects. Additionally, ask suppliers about their quality control processes, including any testing they perform on their hides for durability and stain resistance. Consider establishing a quality assurance agreement that outlines your expectations regarding material standards and compliance with international regulations. -

What payment terms should I expect when sourcing nubuck leather?

Payment terms can vary widely, but common practices include a 30% deposit upon order confirmation with the balance due before shipment. Some suppliers may offer net 30 or net 60 terms for established customers. Always clarify payment methods accepted, whether via bank transfer, credit card, or letters of credit. Negotiating favorable terms can enhance your cash flow and reduce financial risk when purchasing nubuck leather. -

How can I customize nubuck leather for my products?

Customization options for nubuck leather typically include color, texture, and finishing treatments. Many suppliers offer dyeing services to achieve your desired color, while specific treatments can enhance water resistance or add unique textures. Discuss your customization requirements early in the procurement process to ensure the supplier can accommodate your needs and provide samples for approval before mass production. -

What logistics considerations should I keep in mind when importing nubuck leather?

When importing nubuck leather, consider shipping methods, lead times, and customs regulations specific to your country. Opt for reliable freight forwarders experienced in handling leather goods to navigate potential complications. Additionally, ensure that all necessary documentation, such as import permits and certificates of origin, is in order to avoid delays at customs. Understanding logistics can help streamline your supply chain and prevent unexpected costs. -

What are the environmental considerations when sourcing nubuck leather?

Sourcing nubuck leather requires awareness of environmental impacts, particularly related to tanning processes and animal welfare. Inquire about suppliers’ tanning methods, preferring those that utilize eco-friendly techniques, such as vegetable tanning. Moreover, consider suppliers who source hides from sustainable farms or implement recycling programs. Aligning with environmentally responsible suppliers not only enhances your brand image but also meets the increasing consumer demand for sustainable products.

Top 2 Nubuck Leather Material Manufacturers & Suppliers List

1. The Real Leather Company – Nubuck Leather

Domain: therealleathercompany.com

Registered: 2019 (6 years)

مقدمة: Nubuck leather is a smooth leather made from the top grain of an animal hide, known for its velvety texture and stylish appearance. It is more resilient and strong than suede or faux/vegan leathers. Nubuck leather is created from the outer side of calfskin or cowhide, sanded to expose fibrous layers, resulting in a soft and smooth texture. Advantages include longevity, natural look, and comfort, w…

2. Avetco Inc – Premium Suede & Nubuck Leather

Domain: avetcoinc.com

Registered: 2005 (20 years)

مقدمة: This company, Avetco Inc – Premium Suede & Nubuck Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for nubuck leather material

In the evolving landscape of leather sourcing, nubuck leather stands out as a premium choice for various applications, from high-end footwear to luxury upholstery. Its unique texture, durability, and aesthetic appeal make it an attractive option for manufacturers seeking to elevate their product offerings. However, the inherent challenges, such as susceptibility to staining and water damage, highlight the importance of strategic sourcing. Buyers must prioritize suppliers who offer treated or high-quality nubuck, ensuring that products meet both performance and aesthetic standards.

Understanding the distinctions between nubuck and other leather types, such as suede, further empowers international buyers to make informed decisions that align with their market needs. By leveraging insights into production processes, maintenance requirements, and end-use applications, businesses can enhance their competitive edge.

As the demand for high-quality materials continues to grow in regions like Africa, South America, the Middle East, and Europe, the time is ripe for strategic partnerships with reliable suppliers. Embrace the opportunity to source premium nubuck leather that not only meets consumer expectations but also drives innovation in your product lines. Engage with trusted suppliers today to secure your position in the market and ensure future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.