Introduction: Navigating the Global Market for synthetic leather

In an increasingly competitive landscape, sourcing high-quality synthetic leather can be a daunting task for B2B buyers across diverse markets. This versatile material, known for its affordability and aesthetic appeal, serves as a crucial component in various industries, from fashion to automotive and furniture. However, the challenge lies in navigating a complex global supply chain, understanding material specifications, and ensuring ethical sourcing practices.

This comprehensive guide is designed to empower international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, by providing valuable insights into the synthetic leather market. We will delve into the various types of synthetic leather available, explore their applications, and offer strategies for vetting suppliers effectively. Additionally, we will address cost considerations and emerging trends, including sustainable alternatives that align with growing consumer preferences for environmentally friendly products.

By equipping buyers with the knowledge to make informed purchasing decisions, this guide aims to streamline the sourcing process, mitigate risks, and enhance product offerings. Whether you are looking to expand your product line or optimize your supply chain, understanding the nuances of synthetic leather will be essential for staying ahead in today’s global market.

Table Of Contents

- Top 9 Synthetic Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for synthetic leather

- Understanding synthetic leather Types and Variations

- Key Industrial Applications of synthetic leather

- 3 Common User Pain Points for ‘synthetic leather’ & Their Solutions

- Strategic Material Selection Guide for synthetic leather

- In-depth Look: Manufacturing Processes and Quality Assurance for synthetic leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic leather’

- Comprehensive Cost and Pricing Analysis for synthetic leather Sourcing

- Alternatives Analysis: Comparing synthetic leather With Other Solutions

- Essential Technical Properties and Trade Terminology for synthetic leather

- Navigating Market Dynamics and Sourcing Trends in the synthetic leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of synthetic leather

- Strategic Sourcing Conclusion and Outlook for synthetic leather

- Important Disclaimer & Terms of Use

Understanding synthetic leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyurethane (PU) | Soft, flexible, and breathable; mimics genuine leather closely | Apparel, upholstery, automotive interiors | Pros: Durable, versatile, eco-friendlier than PVC. Cons: Generally higher cost than PVC. |

| Polyvinyl Chloride (PVC) | Stiff, water-resistant, and cost-effective; less breathable | Bags, shoes, furniture, outdoor gear | Pros: Affordable, easy to clean. Cons: Less durable, can be less environmentally friendly. |

| Microfiber Leather | Made from ultra-fine synthetic fibers; highly durable and stain-resistant | High-end fashion, upholstery, automotive interiors | Pros: Soft, strong, and easy to maintain. Cons: Higher price point, potential for limited color options. |

| Vegan Leather | Derived from plant-based materials; eco-conscious alternative | Fashion, accessories, furniture | Pros: Sustainable, cruelty-free. Cons: May have durability issues compared to traditional options. |

| Recycled Synthetic Leather | Made from post-consumer waste; promotes sustainability | Fashion, upholstery, eco-friendly products | Pros: Environmentally friendly, unique textures. Cons: Availability and consistency can vary. |

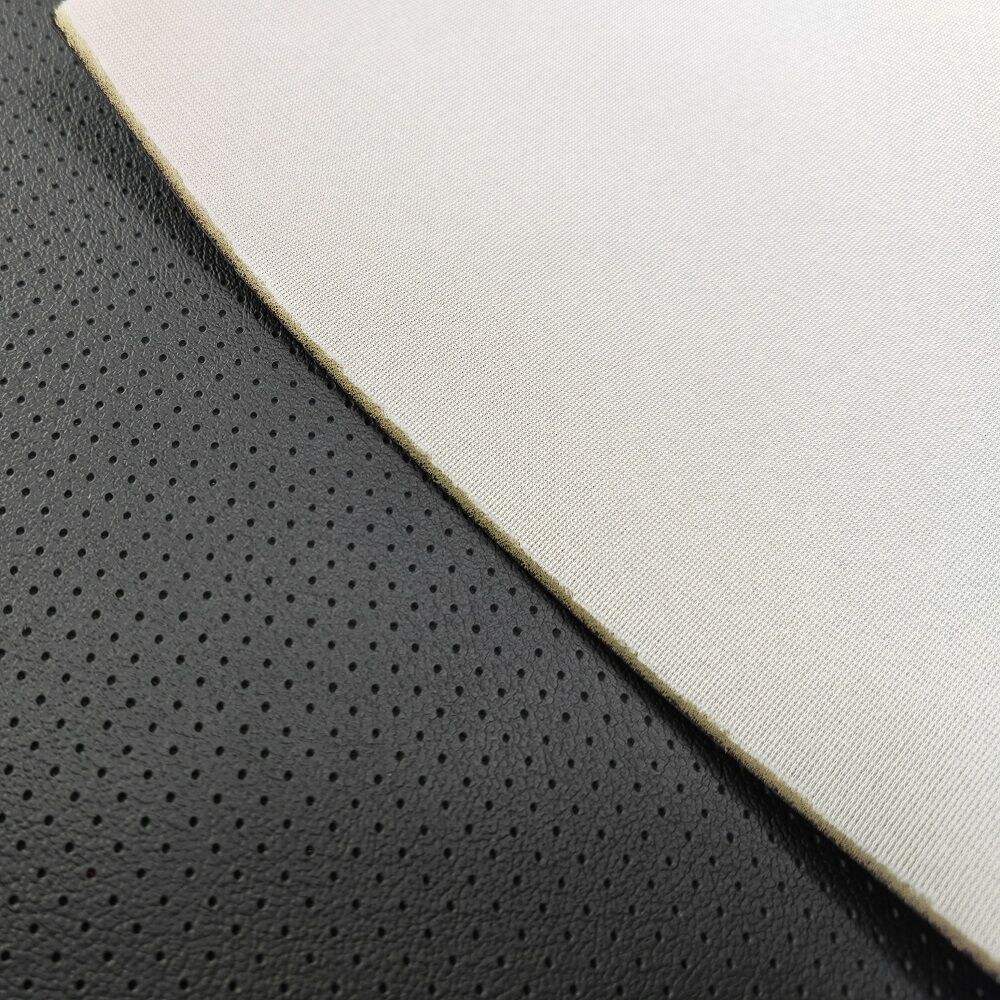

What Are the Characteristics and Suitability of Polyurethane (PU) Synthetic Leather?

Polyurethane synthetic leather is known for its soft texture and flexibility, making it a popular choice in various industries. Its ability to closely mimic genuine leather allows it to be used in high-quality apparel and upholstery, particularly in the automotive sector. B2B buyers should consider the durability and versatility of PU, especially for products that require a premium look and feel. While it is generally more expensive than PVC, its enhanced breathability and lower environmental impact can justify the investment for brands aiming for sustainability.

Illustrative image related to synthetic leather

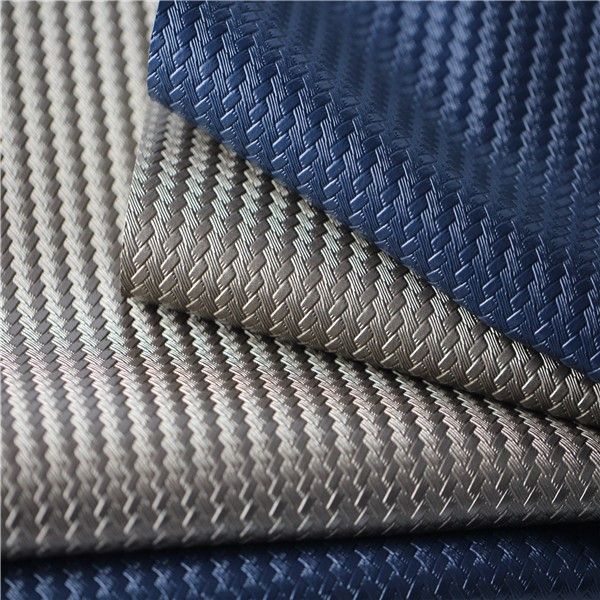

How Does Polyvinyl Chloride (PVC) Compare to Other Synthetic Leathers?

Polyvinyl chloride (PVC) is the most commonly used synthetic leather due to its cost-effectiveness and water resistance. It is widely applied in products like bags, shoes, and outdoor gear. However, buyers should be cautious of its lower breathability and potential environmental concerns associated with its production. PVC’s affordability makes it attractive for high-volume applications, but businesses aiming for a premium offering may want to consider alternatives like PU or microfiber leather.

Why Choose Microfiber Leather for High-End Applications?

Microfiber leather stands out due to its ultra-fine synthetic fibers, offering exceptional durability and stain resistance. This type is often used in high-end fashion items and automotive interiors, where a luxurious appearance is essential. B2B buyers should weigh the benefits of its softness and strength against its typically higher price point. Additionally, the limited color options may be a consideration for brands looking for specific aesthetics.

What Advantages Do Vegan Leather Options Provide?

Vegan leather, made from plant-based materials, has gained traction as a sustainable alternative to traditional leather. It appeals to environmentally conscious consumers and businesses, making it suitable for fashion, accessories, and furniture applications. B2B buyers should assess the durability and performance of vegan leather, as it can vary significantly between manufacturers. While it addresses ethical concerns, some products may not match the longevity of synthetic leathers made from petroleum-based materials.

How Does Recycled Synthetic Leather Support Sustainability Efforts?

Recycled synthetic leather is produced from post-consumer waste, making it an eco-friendly option for brands seeking to enhance their sustainability credentials. This material can be utilized in a range of products, from fashion to upholstery. Buyers should consider the unique textures and styles that recycled leather can offer, though they may face challenges regarding availability and consistency. Investing in recycled options can not only meet consumer demand for sustainable products but also differentiate a brand in a competitive market.

Key Industrial Applications of synthetic leather

| Industry/Sector | Specific Application of synthetic leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Car interiors (seats, dashboards, door panels) | Cost-effective, durable, and easy to clean; enhances aesthetics and comfort | Quality certifications, weather resistance, color options |

| Fashion & Apparel | Handbags, shoes, jackets, and accessories | Versatile design options, cruelty-free, and lower production costs | Compliance with ethical standards, customization capabilities |

| Furniture | Upholstery for sofas, chairs, and cushions | Durable and stain-resistant; offers a range of textures and colors | Supplier reliability, long-term durability, maintenance requirements |

| Sports Equipment | Protective gear, bags, and sports apparel | Lightweight, water-resistant, and easy to maintain; enhances performance | Breathability, flexibility, and adherence to safety standards |

| Home Decor | Wall coverings, decorative accessories | Aesthetic appeal, easy maintenance; sustainable options available | Environmental impact, sourcing of eco-friendly materials |

How is Synthetic Leather Used in the Automotive Industry?

In the automotive sector, synthetic leather is primarily utilized for car interiors, including seats, dashboards, and door panels. This material offers a cost-effective alternative to genuine leather, providing durability and ease of maintenance, which is crucial for high-traffic areas within vehicles. For international B2B buyers, especially in regions like Africa and the Middle East, sourcing synthetic leather that meets quality certifications and is resistant to wear and weather conditions is vital. Buyers should also consider customization options to match brand aesthetics.

Illustrative image related to synthetic leather

What Role Does Synthetic Leather Play in Fashion and Apparel?

Synthetic leather is widely used in the fashion industry for products such as handbags, shoes, jackets, and various accessories. Its versatility allows designers to create a wide range of styles without the ethical concerns associated with animal leather. For B2B buyers in South America and Europe, ensuring compliance with ethical standards and the ability to customize colors and textures is essential. Furthermore, the lower production costs associated with synthetic leather can enhance profit margins, making it an attractive option for fashion brands.

Why is Synthetic Leather Important in Furniture Manufacturing?

In the furniture industry, synthetic leather is commonly used for upholstery on sofas, chairs, and cushions. Its stain-resistant and durable qualities make it an ideal choice for households with children or pets, where longevity is a key concern. B2B buyers should prioritize sourcing from reliable suppliers who can provide long-term durability and a variety of textures and colors to meet consumer preferences. Additionally, understanding maintenance requirements is crucial for maintaining the quality of the furniture over time.

How is Synthetic Leather Utilized in Sports Equipment?

Synthetic leather is increasingly used in the production of sports equipment, including protective gear, bags, and apparel. Its lightweight and water-resistant properties enhance athlete performance while ensuring comfort during use. For international buyers, especially in regions with varying climates, sourcing synthetic leather that offers breathability and flexibility is essential. Adherence to safety standards is also a critical consideration, as it ensures that the equipment is suitable for competitive use.

What Are the Benefits of Using Synthetic Leather in Home Decor?

In home decor, synthetic leather is employed for wall coverings and decorative accessories, providing an aesthetic appeal that is both modern and functional. The material is easy to clean and maintain, making it an attractive choice for homeowners and designers alike. For B2B buyers, particularly those focused on sustainability, sourcing eco-friendly options is increasingly important. Evaluating the environmental impact of materials and ensuring that suppliers provide sustainable sourcing practices can enhance brand reputation and consumer trust.

Illustrative image related to synthetic leather

3 Common User Pain Points for ‘synthetic leather’ & Their Solutions

Scenario 1: Quality Assurance in Bulk Orders of Synthetic Leather

The Problem: B2B buyers often face challenges in ensuring the quality and consistency of synthetic leather when placing large orders. Variability in thickness, texture, and color can lead to discrepancies in finished products, affecting branding and customer satisfaction. Buyers may receive materials that do not meet their specifications, which can result in increased costs due to rework or returns. This is particularly concerning for businesses in fashion or upholstery where aesthetics and durability are paramount.

The Solution: To mitigate these risks, B2B buyers should establish clear quality assurance protocols with suppliers. This includes requesting samples before bulk purchases and defining specifications in detail, such as thickness, tensile strength, and color matching. Implementing a standardized testing procedure for the synthetic leather—such as abrasion resistance tests or colorfastness assessments—can help ensure that the material meets the required standards. Additionally, consider sourcing from suppliers who offer certifications for their products, which can serve as a guarantee of quality. Regular audits and maintaining open lines of communication with suppliers can further enhance product consistency.

Scenario 2: Environmental Concerns with Synthetic Leather Production

The Problem: Increasingly, businesses are under pressure to adopt sustainable practices, and synthetic leather, primarily made from PVC or other petroleum-based materials, can present environmental challenges. B2B buyers must navigate the growing demand for eco-friendly options while balancing cost and performance. This complexity can lead to difficulties in sourcing materials that align with both environmental goals and market expectations.

Illustrative image related to synthetic leather

The Solution: To address these concerns, buyers should actively seek out suppliers who specialize in sustainable synthetic leather alternatives, such as plant-based or recycled materials. When evaluating options, it is crucial to inquire about the manufacturing processes and the environmental impact of the materials used. Collaborating with suppliers who have transparent supply chains and eco-certifications can enhance credibility and appeal to environmentally conscious consumers. Additionally, adopting a lifecycle assessment approach when selecting synthetic leather can help businesses understand the long-term impacts of their sourcing decisions, allowing for more informed choices that align with sustainability goals.

Scenario 3: Performance Limitations of Synthetic Leather in Extreme Conditions

The Problem: B2B buyers in sectors such as automotive or outdoor equipment often encounter challenges with synthetic leather’s performance in extreme weather conditions. Issues such as cracking, fading, or loss of structural integrity can arise when synthetic leather is exposed to high heat, humidity, or UV light. These performance limitations can lead to increased warranty claims and damage to brand reputation.

The Solution: To overcome these performance challenges, buyers should focus on sourcing high-quality synthetic leather specifically designed for extreme conditions. This involves looking for materials that incorporate UV-resistant additives or enhanced durability features. Engaging in thorough product testing under various environmental conditions prior to mass production can provide insights into how the material will perform. Buyers can also collaborate with manufacturers to develop custom formulations that meet specific performance criteria, ensuring that the synthetic leather will withstand the demands of their application. By prioritizing performance specifications alongside aesthetic considerations, businesses can enhance the longevity and reliability of their products, ultimately leading to higher customer satisfaction.

Strategic Material Selection Guide for synthetic leather

What Are the Key Materials Used in Synthetic Leather Production?

When selecting synthetic leather for various applications, understanding the materials involved is crucial for international B2B buyers. The most common materials used in synthetic leather production include Polyvinyl Chloride (PVC), Polyurethane (PU), and vegetable-based alternatives. Each material has unique properties, advantages, and limitations that can significantly impact the final product’s performance.

How Does Polyvinyl Chloride (PVC) Perform in Synthetic Leather Applications?

PVC is one of the most widely used materials for synthetic leather due to its cost-effectiveness and versatility. It exhibits low breathability and moisture-wicking abilities but offers high heat retention, making it suitable for various applications, including upholstery and fashion items.

Illustrative image related to synthetic leather

Pros: PVC is generally more affordable than other materials and can be produced in a wide range of colors and textures. It also provides good resistance to abrasions and cuts, making it a durable option for products like bags and shoes.

Cons: However, PVC is less environmentally friendly, as it is derived from petroleum and does not biodegrade. Additionally, it can feel less luxurious compared to genuine leather, which may affect its marketability in high-end applications.

Impact on Application: PVC’s low moisture-wicking capabilities may limit its use in environments where breathability is essential, such as in athletic wear or items requiring prolonged contact with skin.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local regulations regarding PVC usage, as some countries are moving towards stricter environmental standards. Compliance with ASTM or DIN standards may also be necessary.

What Are the Advantages of Using Polyurethane (PU) in Synthetic Leather?

PU is another popular choice for synthetic leather, known for its flexibility and comfort. It is often preferred for clothing and upholstery due to its softer texture and more natural feel compared to PVC.

Pros: PU offers better breathability and moisture management, making it suitable for clothing and accessories. It is also more environmentally friendly than PVC, as it can be produced without harmful chemicals.

Cons: On the downside, PU can be more expensive than PVC and may have lower durability in high-wear applications. It can also be prone to wear and tear over time, especially in environments with high friction.

Impact on Application: PU’s superior breathability makes it ideal for items like jackets and footwear, where comfort is a priority. However, its lower durability may limit its use in heavy-duty applications.

Illustrative image related to synthetic leather

Considerations for International Buyers: Buyers in Europe and the Middle East should look for PU products that comply with environmental regulations, such as REACH, to ensure sustainability.

What Role Do Vegetable-Based Alternatives Play in Synthetic Leather?

Vegetable-based synthetic leathers are emerging as a sustainable alternative to traditional PVC and PU options. Made from natural materials, these alternatives aim to address environmental concerns associated with petroleum-based products.

Pros: These materials are biodegradable and often free from harmful chemicals, appealing to eco-conscious consumers and businesses. They can also offer unique textures and finishes that differentiate products in the market.

Illustrative image related to synthetic leather

Cons: The production of vegetable-based synthetic leather can be more complex and costly, which may limit its accessibility for some manufacturers. Additionally, performance characteristics may vary widely depending on the specific formulation used.

Impact on Application: Vegetable-based synthetic leathers can be utilized in a variety of applications, from fashion to upholstery, but may not yet provide the same level of durability as traditional materials.

Considerations for International Buyers: Buyers should ensure that vegetable-based products meet local compliance standards and consider the market demand for sustainable options, particularly in regions with strong environmental regulations.

Summary Table of Material Selection for Synthetic Leather

| Material | Typical Use Case for synthetic leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Upholstery, bags, shoes | Cost-effective and versatile | Less environmentally friendly | Low |

| Polyurethane (PU) | Clothing, accessories | Better breathability and comfort | Higher cost and lower durability | Med |

| Vegetable-based alternatives | Fashion, upholstery | Biodegradable and eco-friendly | More complex and costly production | High |

This guide aims to provide actionable insights for B2B buyers in diverse international markets, helping them make informed decisions regarding synthetic leather material selection.

In-depth Look: Manufacturing Processes and Quality Assurance for synthetic leather

What Are the Key Stages in the Manufacturing Process of Synthetic Leather?

The manufacturing of synthetic leather involves several distinct stages, each critical to ensuring the final product meets quality standards and market demands. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Synthetic Leather Production?

The first step in synthetic leather production involves sourcing the base materials, typically cotton or polyester. These materials must be carefully selected for their porosity and durability. Manufacturers often collaborate with third-party suppliers to obtain the required fabrics, ensuring they meet industry specifications.

Once the base fabric is secured, the next step is the formulation of the synthetic polymer that will be bonded to it. The two most common types of plastics used are polyurethane (PU) and polyvinyl chloride (PVC). The production of these plastics involves complex chemical processes. For PVC, salt and petroleum derivatives are combined to create ethylene dichloride, which is then polymerized to form the final resin. In contrast, PU requires the reaction of isocyanates and polyols, resulting in a flexible, durable material.

What Techniques Are Used in Forming Synthetic Leather?

Once the materials are prepared, the forming stage begins. This typically involves binding the formulated plastic to the base textile. Manufacturers employ techniques such as coating, where the plastic is melted and spread over the fabric, or lamination, which involves layering the plastic onto the fabric using heat and pressure.

In recent years, advancements in technology have introduced more efficient methods such as digital printing and embossing, allowing for greater customization and aesthetic appeal. These techniques enable manufacturers to create a wide range of colors and textures that can closely mimic genuine leather, catering to diverse consumer preferences.

How Is Assembly Conducted in Synthetic Leather Manufacturing?

The assembly stage involves cutting the bonded material into specific shapes and sizes, preparing it for final products. This stage requires precision to minimize waste and ensure that the dimensions meet the required specifications for various applications, such as upholstery, apparel, and accessories.

Automation plays a significant role in this phase, with computerized cutting machines increasing efficiency and accuracy. Skilled labor is still essential, particularly for detailed work that requires manual intervention, ensuring that the final product meets quality expectations.

What Finishing Processes Are Applied to Synthetic Leather?

Finishing processes enhance the durability and aesthetic appeal of synthetic leather. These processes may include applying protective coatings, treatments for water resistance, and adding textures or patterns. Quality control during this stage is critical, as it directly affects the performance characteristics of the final product.

Finishing also involves extensive quality checks to ensure that the synthetic leather meets desired standards for softness, flexibility, and resistance to wear and tear. Additionally, manufacturers may conduct tests for color fastness and abrasion resistance to ensure longevity.

Illustrative image related to synthetic leather

How Is Quality Assurance Implemented in Synthetic Leather Production?

Quality assurance (QA) is integral to the synthetic leather manufacturing process, ensuring that products meet international standards and client specifications.

What Are the Relevant International Quality Standards for Synthetic Leather?

Manufacturers typically adhere to several international quality standards, such as ISO 9001, which focuses on quality management systems, and CE marking for products sold in Europe. These standards provide a framework for consistent quality and safety in manufacturing processes.

In addition, industry-specific certifications, such as those from the American Petroleum Institute (API), can be relevant for synthetic leathers used in automotive applications. Adherence to these standards not only enhances product reliability but also builds trust with B2B buyers.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control in synthetic leather manufacturing is structured around several critical checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint assesses raw materials upon arrival, ensuring they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring occurs throughout the manufacturing process. This includes inspections during material preparation, forming, and assembly stages to detect any issues early.

- Final Quality Control (FQC): At the end of the production line, a thorough inspection of finished products is conducted. This includes testing for physical properties such as thickness, tensile strength, and color consistency.

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods include tensile strength tests, abrasion resistance tests, and hydrostatic pressure tests for water resistance. Chemical testing may also be conducted to ensure compliance with safety regulations, particularly regarding harmful substances.

B2B buyers should ensure that suppliers provide documentation of testing results, which can be invaluable for verifying quality and compliance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should conduct thorough due diligence, including:

- Supplier Audits: Regular audits help assess compliance with quality standards and identify areas for improvement. Buyers can schedule on-site audits or request documentation of previous audits conducted by third parties.

- Quality Assurance Reports: Buyers should request detailed reports that outline the quality control processes, testing results, and adherence to international standards. These documents should be readily available from reputable suppliers.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing practices and product quality. This step is particularly important when sourcing from international suppliers in regions such as Africa, South America, and the Middle East, where regulatory standards may vary.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, understanding the nuances of quality control in synthetic leather production is crucial. Different regions may have varying standards and practices, which can impact product quality. For example, while European buyers may prioritize compliance with CE standards, buyers in the Middle East might focus on durability and weather resistance due to climatic conditions.

Moreover, cultural differences in business practices can affect how quality assurance is perceived and implemented. Buyers should foster open communication with suppliers, clearly outlining their quality expectations and ensuring that these are understood and integrated into the manufacturing process.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for synthetic leather is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring that they procure high-quality synthetic leather that meets their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘synthetic leather’

To assist B2B buyers in effectively sourcing synthetic leather, this guide outlines essential steps to ensure a successful procurement process. By following this checklist, buyers can navigate the complexities of the synthetic leather market, focusing on quality, sustainability, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the synthetic leather meets your product requirements. Consider factors such as thickness, texture, color, and intended use (e.g., upholstery, fashion accessories, or automotive applications). This clarity will help you communicate your needs effectively to potential suppliers.

Step 2: Research Market Trends and Innovations

Understanding current market trends and innovations in synthetic leather is essential for making informed purchasing decisions. Look for advancements in eco-friendly materials, such as vegetable-based alternatives, and emerging applications in various industries. Staying updated on these trends will not only enhance your product offerings but also align your sourcing strategy with consumer preferences.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is a critical step in the sourcing process. Request company profiles, production capabilities, and references from other businesses in your industry. Additionally, assess their experience with international shipping and compliance with local regulations to ensure a smooth procurement process.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers hold relevant certifications that demonstrate their commitment to quality and sustainability. Look for certifications such as ISO 9001 for quality management and OEKO-TEX for environmental safety. Compliance with international standards will mitigate risks associated with product safety and environmental impact.

Step 5: Request Samples for Quality Assessment

Before finalizing any orders, request samples of the synthetic leather to evaluate its quality and performance. Pay attention to aspects such as texture, durability, and colorfastness under different conditions. Testing samples allows you to ensure that the product meets your expectations and specifications.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to establish favorable terms and pricing. Discuss minimum order quantities, payment terms, and delivery timelines. A transparent negotiation process can lead to a mutually beneficial partnership and help in managing costs effectively.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the synthetic leather during production and upon delivery. Define quality benchmarks and establish communication channels with the supplier for addressing any issues that may arise. A robust quality control system will help maintain the integrity of your products and build trust with your supplier.

By following this checklist, B2B buyers can streamline their sourcing of synthetic leather, ensuring they find high-quality materials that align with their business needs and market demands.

Comprehensive Cost and Pricing Analysis for synthetic leather Sourcing

What Are the Key Cost Components in Synthetic Leather Sourcing?

When sourcing synthetic leather, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

- Materials: The choice between PVC and PU significantly influences costs. PVC is generally cheaper, but PU offers better durability and environmental benefits, which may justify a higher price for some buyers.

- Labor: Labor costs vary by region. Countries with lower labor costs, such as China, can offer competitive pricing. However, labor costs in regions like Europe may be higher, affecting the overall pricing structure.

- Manufacturing Overhead: This includes utilities, equipment maintenance, and administrative expenses. It’s essential to consider these costs, as they contribute to the final price.

- Tooling: Custom tooling for specific designs can be a substantial upfront cost. However, the investment can lead to lower per-unit costs for larger orders.

- Quality Control (QC): Rigorous QC processes ensure product consistency and compliance with international standards. Investing in QC can increase initial costs but reduce returns and complaints in the long run.

- Logistics: Shipping costs are influenced by the size of the order, the destination, and chosen Incoterms. International logistics can significantly add to costs, particularly for buyers in Africa and South America.

- Margin: Supplier margins vary based on market positioning, brand reputation, and product uniqueness. Understanding supplier pricing strategies can help buyers negotiate better deals.

How Do Price Influencers Affect Synthetic Leather Costs?

Several factors can influence the pricing of synthetic leather:

- Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts. Buyers should negotiate MOQ to optimize costs.

- Specifications and Customization: Customized products typically come at a premium. Clearly defining specifications upfront can help suppliers provide accurate quotes and minimize unexpected costs.

- Materials and Quality Certifications: Higher-quality materials and certifications (e.g., OEKO-TEX, REACH) can increase costs but may be necessary for specific markets, especially in Europe where regulations are stricter.

- Supplier Factors: Established suppliers may have more stable pricing, while newer suppliers might offer lower prices to gain market share. Assessing supplier reputation and reliability is vital.

- Incoterms: The choice of Incoterms affects who bears the shipping costs and risks. Understanding these terms can help buyers calculate total landed costs accurately.

What Tips Can Help Buyers Optimize Their Synthetic Leather Sourcing Costs?

To navigate the complexities of synthetic leather sourcing effectively, consider the following strategies:

- Negotiate Strategically: Leverage volume and long-term relationships to negotiate better pricing. Establishing a rapport with suppliers can lead to favorable terms.

- Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, shipping, and potential returns. A lower upfront cost may not always result in the best value if quality issues arise later.

- Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and local market conditions that can affect pricing. Establishing contracts in stable currencies can mitigate some risks.

- Conduct Market Research: Regularly analyze market trends and supplier pricing to ensure competitive sourcing. This can help identify opportunities for cost savings or better-quality products.

- Consider Regional Differences: Buyers from Africa, South America, the Middle East, and Europe should account for regional preferences and requirements, as these can impact both sourcing strategies and pricing.

Disclaimer on Pricing

The prices for synthetic leather can vary widely based on numerous factors. The insights provided here are indicative and should be verified with suppliers for accurate, up-to-date pricing information tailored to specific sourcing needs.

Alternatives Analysis: Comparing synthetic leather With Other Solutions

Exploring Alternatives to Synthetic Leather: A Comparative Analysis

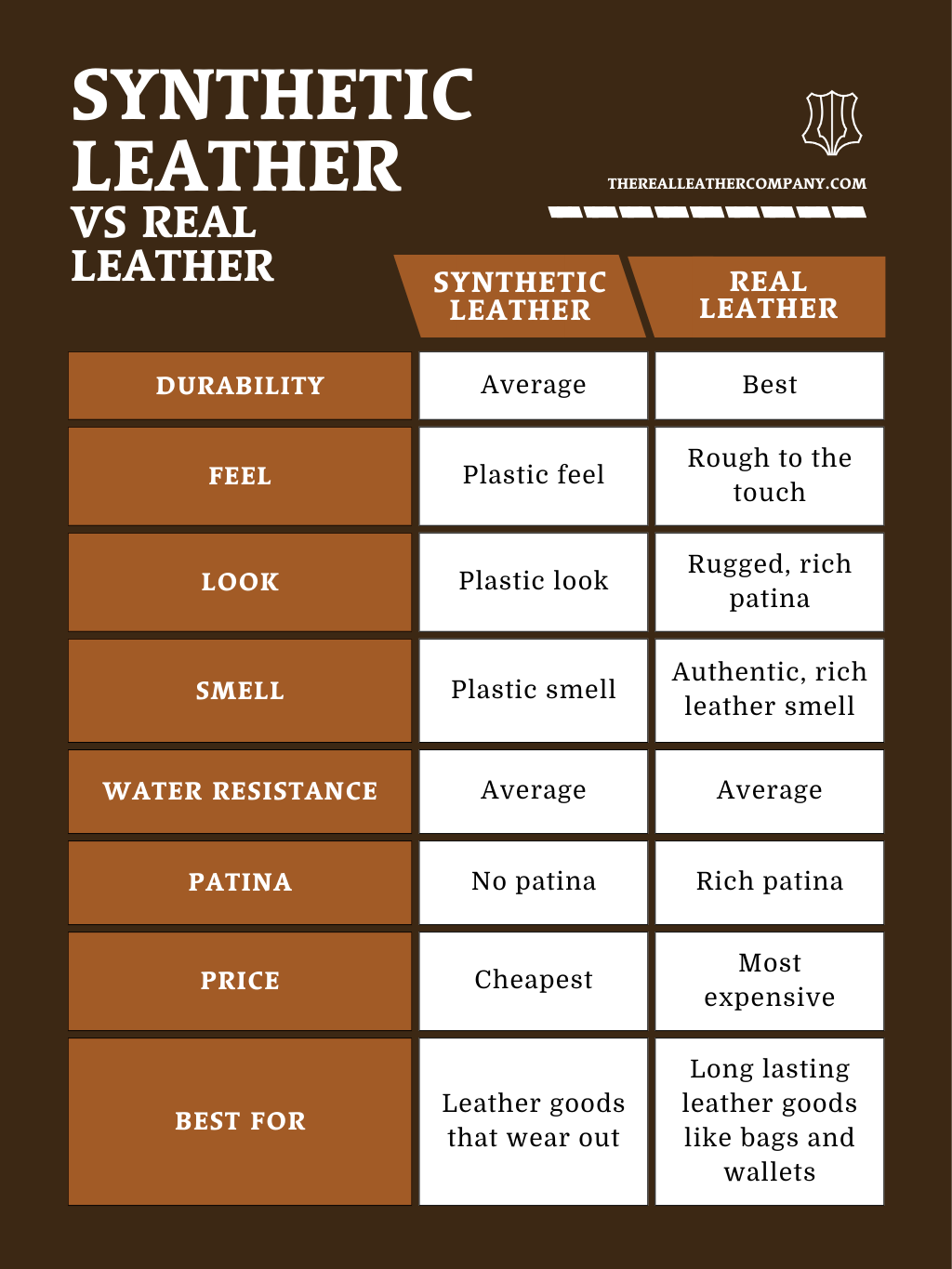

As the demand for sustainable and ethical materials grows, businesses are increasingly exploring alternatives to synthetic leather. This section presents a detailed comparison of synthetic leather against two viable alternatives: natural leather and plant-based leather. Each alternative has its own unique attributes, making it essential for B2B buyers to evaluate their options based on performance, cost, and specific use cases.

| Comparison Aspect | Synthetic Leather | Natural Leather | Plant-Based Leather |

|---|---|---|---|

| Performance | Moderate durability, water-resistant but less breathable | High durability, excellent breathability | Varies by type, often less durable than both |

| Cost | Generally lower cost | Higher cost due to sourcing and processing | Competitive but can be premium depending on sourcing |

| Ease of Implementation | Widely available, easy to process | Requires specialized handling | Varies; may require new processes for manufacturers |

| Maintenance | Low maintenance, easy to clean | Requires conditioning and care | Varies; often similar to natural leather |

| Best Use Case | Fashion items, upholstery, and accessories | High-end products, luxury items | Eco-friendly products, sustainable brands |

What Are the Pros and Cons of Natural Leather as an Alternative?

Natural leather is renowned for its durability and unique aesthetic qualities. It offers superior breathability and comfort, making it suitable for high-end products like luxury handbags and automotive interiors. However, the sourcing and processing of natural leather can be costly and time-consuming. Additionally, ethical concerns regarding animal welfare and environmental impact during production can deter some consumers.

How Does Plant-Based Leather Compare to Synthetic Leather?

Plant-based leather, often derived from materials like pineapple leaves, apple peels, or other agricultural by-products, presents a compelling eco-friendly alternative. It is biodegradable and often produced with a lower carbon footprint compared to synthetic options. However, the durability of plant-based leather can vary significantly based on the source material, and it may not withstand wear and tear as effectively as synthetic or natural leather. This option is ideal for brands emphasizing sustainability but may require a shift in manufacturing processes.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate leather alternative, B2B buyers should consider several factors, including their target market, product application, and brand values. For instance, if cost and ease of implementation are primary concerns, synthetic leather may be the best fit. Conversely, brands focusing on luxury and sustainability may gravitate towards natural or plant-based leather. Ultimately, understanding the specific requirements and expectations of their customer base will guide buyers in making informed decisions that align with their business goals.

Illustrative image related to synthetic leather

Essential Technical Properties and Trade Terminology for synthetic leather

What Are the Key Technical Properties of Synthetic Leather for B2B Buyers?

When sourcing synthetic leather, understanding its technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that B2B buyers should consider:

1. Material Composition

Synthetic leather is primarily made from polyurethane (PU) or polyvinyl chloride (PVC). Each material offers different characteristics; for instance, PU is generally softer and more breathable, while PVC tends to be more durable and resistant to moisture. Buyers should evaluate the material based on the intended application, as different end products will demand varying levels of durability and comfort.

2. Thickness

The thickness of synthetic leather is usually measured in millimeters and can significantly impact its usability. Thicker materials may offer enhanced durability and resistance to wear, making them suitable for upholstery and heavy-use applications. Conversely, thinner materials are often preferred for apparel and accessories, where flexibility and a lightweight feel are essential. Understanding the thickness helps buyers gauge the suitability of the fabric for their specific needs.

3. Abrasion Resistance

Abrasion resistance indicates how well the synthetic leather can withstand wear and tear from friction. This property is crucial for applications like furniture, automotive interiors, and fashion items, where the material is subject to frequent contact and movement. A high abrasion resistance rating ensures that the product will maintain its appearance and structural integrity over time, which is vital for customer satisfaction and return on investment.

4. Water Resistance

Water resistance refers to the material’s ability to repel moisture. While synthetic leather is generally more water-resistant than natural leather, the level of water resistance can vary between different products. This property is particularly important for items exposed to the elements, such as outdoor furniture or automotive upholstery. Buyers should confirm the water resistance rating to ensure it meets their specific requirements.

5. Color Fastness

Color fastness measures the resistance of synthetic leather to fading or running when exposed to light or washing. This property is crucial for maintaining the aesthetic appeal of products over time, especially in fashion and interior design. B2B buyers should seek materials with high color fastness ratings to ensure that their products will remain vibrant and attractive, reducing the risk of returns or customer complaints.

Which Trade Terminology Should B2B Buyers Understand When Sourcing Synthetic Leather?

Familiarity with industry jargon can streamline the procurement process and enhance communication with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then marketed by another company under its brand. Understanding OEM relationships can help buyers identify quality suppliers and manage branding strategies effectively.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to assess whether a supplier can meet their needs without incurring excess inventory costs or operational inefficiencies.

3. RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to solicit price quotes from suppliers for specific products. B2B buyers should understand how to create effective RFQs to ensure they receive accurate and competitive pricing information.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers navigate shipping costs, risks, and responsibilities, ultimately leading to smoother transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory management and planning, especially in industries where timing is critical.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing synthetic leather, ensuring they meet both their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the synthetic leather Sector

What are the Current Market Dynamics and Key Trends in the Synthetic Leather Sector?

The synthetic leather market is experiencing robust growth, driven by increasing consumer demand for sustainable and cruelty-free alternatives to genuine leather. Key global markets, particularly in Africa, South America, the Middle East, and Europe, are witnessing a surge in the adoption of synthetic leather in various applications, including fashion, automotive, and upholstery. As of now, China remains the largest producer and exporter, but emerging markets are rapidly catching up due to their growing industrial capabilities and demand for affordable, high-quality materials.

Technological advancements are reshaping sourcing trends, with innovations such as digital textile printing and automated manufacturing processes enhancing efficiency and customization. International B2B buyers are increasingly leveraging digital platforms for sourcing, enabling them to connect with manufacturers and suppliers worldwide. This shift is particularly significant for buyers in regions like Brazil and Saudi Arabia, where traditional sourcing methods may have limited options. Additionally, a focus on supply chain transparency is gaining momentum, as buyers seek to ensure product authenticity and quality.

The rise of plant-based synthetic leathers is another noteworthy trend. These materials offer an eco-friendly alternative to petroleum-based products, appealing to environmentally conscious consumers and businesses. As demand for these alternatives grows, suppliers are encouraged to diversify their product lines and invest in sustainable practices, further influencing market dynamics.

How is Sustainability and Ethical Sourcing Changing the Synthetic Leather Landscape?

Sustainability and ethical sourcing have become paramount in the synthetic leather sector. The environmental impact of traditional synthetic leather production, primarily through the use of PVC and other non-biodegradable materials, has prompted a shift towards more sustainable practices. International B2B buyers are increasingly prioritizing suppliers who adopt eco-friendly production methods and use renewable resources, such as plant-based polymers, in their offerings.

Illustrative image related to synthetic leather

The importance of ethical supply chains cannot be overstated, as consumers and businesses alike demand transparency regarding the sourcing of materials. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can provide assurance to buyers that the products they source are not only environmentally friendly but also produced under fair labor conditions. Buyers from regions like Europe, where regulatory frameworks are stricter, must be particularly vigilant in their sourcing decisions to align with local sustainability standards.

Furthermore, the growing trend of circular economy initiatives is influencing the synthetic leather market. Companies are exploring recycling programs and closed-loop systems to minimize waste and reduce their carbon footprint. For B2B buyers, partnering with suppliers who share these values can enhance brand reputation and appeal to a wider consumer base.

What is the Historical Context of Synthetic Leather Development?

The evolution of synthetic leather dates back to the early 20th century, with significant milestones influencing its current market presence. Initially developed in Germany during World War I as Presstoff, synthetic leather gained popularity with the introduction of Naugahyde in the 1920s by the U.S. Rubber Company. This innovation marked the beginning of a viable alternative to genuine leather, leading to widespread adoption in various industries.

Over the decades, synthetic leather has been shaped by changing consumer preferences and environmental awareness. The 1970s saw a decline in public perception due to concerns over the environmental impact of petroleum-based materials. However, recent advancements in technology and a renewed focus on sustainability have revitalized interest in synthetic leather, paving the way for innovative, eco-friendly alternatives.

Illustrative image related to synthetic leather

Understanding this historical context is crucial for B2B buyers, as it highlights the ongoing evolution of the market and the increasing importance of sustainability in sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of synthetic leather

1. How do I select a reliable supplier for synthetic leather?

Selecting a reliable supplier for synthetic leather involves several key steps. First, conduct thorough research to identify potential manufacturers, focusing on their production capabilities and product range. Look for certifications such as ISO or compliance with international standards, which indicate quality assurance. Additionally, request samples to assess material quality, durability, and color accuracy. It’s also advisable to check customer reviews and testimonials. Establish clear communication regarding your specifications, lead times, and after-sales support to ensure alignment with your business needs.

2. What are the key factors to consider when sourcing synthetic leather?

When sourcing synthetic leather, consider factors such as material composition (PU vs. PVC), breathability, and environmental impact. Evaluate the supplier’s production processes, including whether they offer biodegradable options or utilize sustainable materials. Additionally, assess customization capabilities for colors, textures, and finishes to meet your product requirements. Minimum Order Quantity (MOQ) is also critical; ensure it aligns with your purchasing capacity. Lastly, factor in pricing, payment terms, and shipping logistics to determine the overall cost-effectiveness of your sourcing decision.

3. What is the typical MOQ for synthetic leather orders?

Minimum Order Quantities (MOQ) for synthetic leather can vary significantly among suppliers, often ranging from 100 to 500 meters. Factors influencing MOQ include the type of synthetic leather, customization requirements, and the supplier’s production capacity. For large-scale manufacturers, higher MOQs might be necessary to justify production costs. However, some suppliers may offer flexibility for smaller orders, especially if you’re willing to pay a premium. Always confirm MOQs before finalizing agreements to ensure they align with your purchasing strategy.

4. What payment terms should I negotiate with synthetic leather suppliers?

When negotiating payment terms with synthetic leather suppliers, consider options like partial upfront payments, net 30 or 60 days, and letters of credit. Partial payments can secure your order while allowing time for production and shipping. Ensure that the payment terms are clearly outlined in the contract to avoid misunderstandings. Be wary of suppliers asking for full payment upfront, especially if they are unfamiliar or unverified. Establishing a mutually beneficial payment plan can foster a strong business relationship.

Illustrative image related to synthetic leather

5. How can I ensure quality assurance for synthetic leather products?

To ensure quality assurance for synthetic leather products, implement a robust quality control process that includes pre-production and post-production inspections. Request samples before bulk orders to evaluate texture, durability, and color fidelity. Consider third-party quality audits, especially if importing from overseas suppliers, to validate compliance with your specifications. Establish clear quality benchmarks in your contract, and maintain open communication with the supplier throughout the production process to address any concerns promptly.

6. What are the logistics considerations when importing synthetic leather?

When importing synthetic leather, logistics considerations include shipping methods, customs clearance, and lead times. Determine whether air or sea freight is more cost-effective based on your timeline and budget. Work with a freight forwarder who is familiar with regulations and tariffs related to synthetic leather in your target market. Ensure all documentation, such as bills of lading and customs declarations, is accurate to avoid delays. Additionally, factor in warehousing and distribution logistics to optimize your supply chain efficiency.

7. Can synthetic leather be customized for specific applications?

Yes, synthetic leather can be customized for various applications such as upholstery, fashion, or automotive uses. Manufacturers often offer options for different textures, colors, finishes, and even performance characteristics like water resistance or fire retardance. Discuss your specific requirements with potential suppliers to explore their customization capabilities. Providing detailed specifications and examples of desired outcomes can help ensure that the final product meets your expectations.

8. How does the environmental impact of synthetic leather compare to genuine leather?

The environmental impact of synthetic leather differs significantly from that of genuine leather. While synthetic leather avoids animal cruelty, traditional production methods often rely on non-biodegradable plastics like PVC, leading to pollution and waste issues. However, advancements in the industry have led to the development of more eco-friendly alternatives, such as plant-based synthetic leathers. Buyers should inquire about the materials and production processes used by suppliers to select options that align with their sustainability goals.

Illustrative image related to synthetic leather

Top 9 Synthetic Leather Manufacturers & Suppliers List

1. Sewport – Faux Leather Solutions

Domain: sewport.com

Registered: 2015 (10 years)

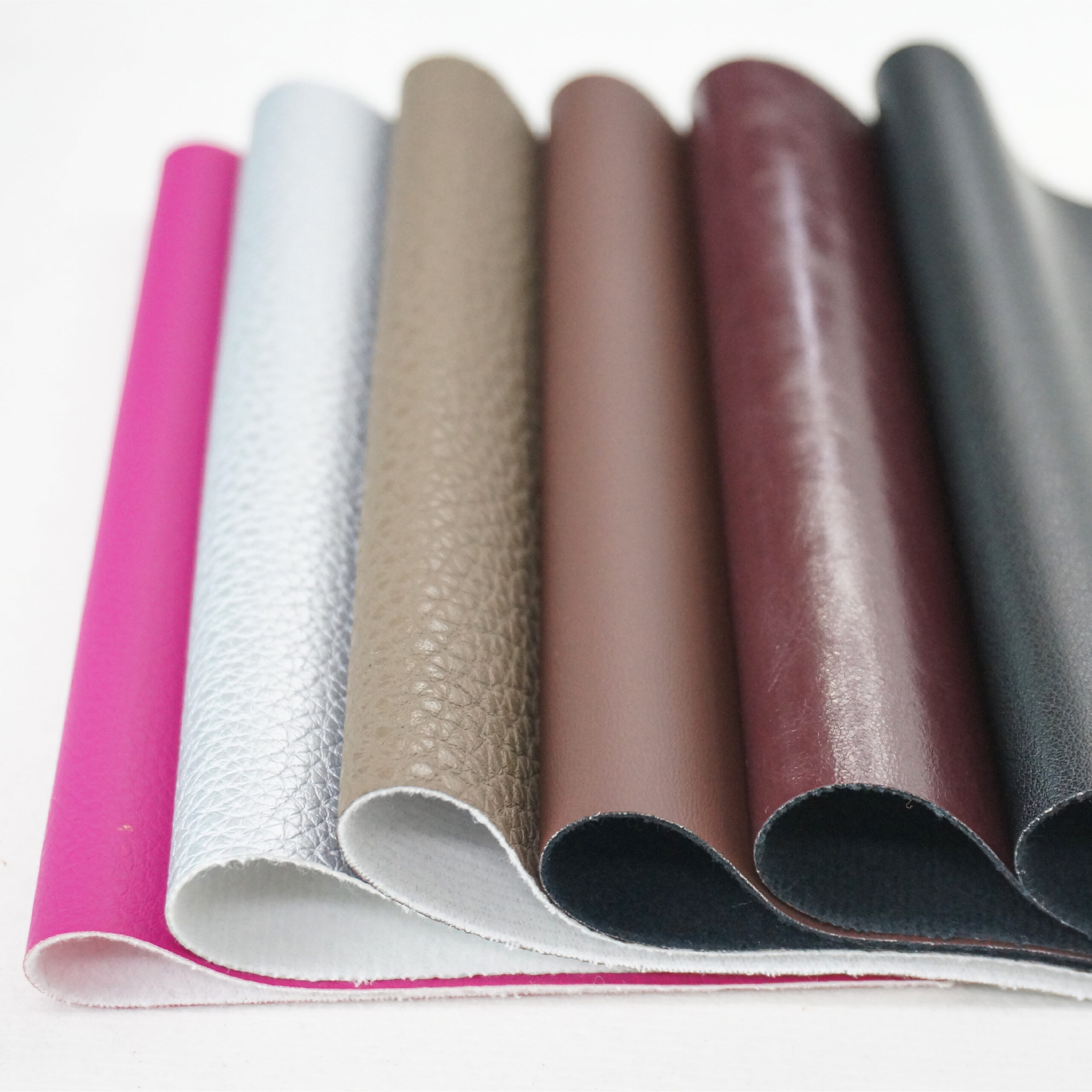

Introduction: Faux leather, also known as pleather, vegan leather, Naugahyde, synthetic leather, artificial leather, fake leather, ersatz leather. Fabric composition: PVC or vegetable oils. Properties: Low breathability, low moisture-wicking abilities, high heat retention, high stretchability, low prone to pilling/bubbling. First produced in the United States, currently produced/exported by China. Recommended w…

2. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes a variety of vegan materials that serve as an alternative to leather or cork fabric. The fabrics are soft, pliable, and available in eight different textures: Weave, Pebble, Legacy, Shimmer, Crocodile, Alligator, Ostrich, and Rugged. Select Faux Leathers are also available in Lite Legacy, an ultra-thin material. The fabrics are sold by the quarter …

3. Buffalo Jackson – Faux Leather Goods

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Faux leather, also known as synthetic leather, is made from a fabric base such as polyester, which is then treated with wax, dye, polyvinyl chloride (PVC), or polyurethane to create an imitation leather finish and texture. It is designed to look like real leather but has a uniform surface and feels cold and unnaturally even. Faux leather does not last as long as real leather and does not wear out …

4. The Real Leather Company – Synthetic Leather

Domain: therealleathercompany.com

Registered: 2019 (6 years)

Introduction: Synthetic leather, also known as faux leather or vegan leather, is a man-made material designed to mimic the look and feel of real leather. It is typically composed of plastic-based materials such as polyurethane (PU) or polyvinyl chloride (PVC). Synthetic leather offers a cruelty-free alternative to traditional leather products but has its own sustainability concerns. It is produced through a pro…

5. Decorative Fabrics Direct – PU Leather & Faux Leather

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric

– Terms: Free Shipping Coupon Code: SHIPFREE for Most $199 Orders

– Product Types: Faux Leather, Vinyl Upholstery Fabric

– Features: Durable, easy to clean, available in rich colors, lower cost than genuine leather

– Uses: Furniture, Automotive, Marine, RV, Commercial projects

– Brands: Naugahyde, Omnova Boltaflex, Nassimi, Spradling

– Fabric Typ…

6. Yorkshire Fabric Shop – PU Leather

Domain: yorkshirefabricshop.com

Registered: 2014 (11 years)

Introduction: PU leather is synthetic leather made from polyurethane, a plastic that mimics the feel of real leather without harming animals. Faux leather, derived from upholstery fabric like polyester, offers a premium quality with a luxury look and feel, often incorporating materials like wax, dye, PVC, or polyurethane to achieve an imitation leather finish. Both types are water-resistant, easy to clean, and …

7. Genuine Leather – Premium Quality

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Genuine leather is more expensive and of higher quality compared to synthetic leather, which is cheaper and of lower value. Genuine leather tends to age better and lasts longer, while synthetic leather can look worse over time and cannot be reconditioned. Some people may judge the use of synthetic leather in outfits, although there are no strict dress codes requiring genuine leather. High-quality …

8. Sailrite – Real vs. Faux Leather

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Real Leather vs. Faux Leather: Key Factors to Consider

1. Look & Feel:

– Real Leather: Unique, natural texture with imperfections; softens and develops a patina over time.

– Faux Leather: More uniform appearance; mimics real leather but lacks natural variations.

2. Durability & Longevity:

– Real Leather: Extremely durable, especially full grain; resists punctures and tears; can last d…

9. LeatherCult – Faux Leather Solutions

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: Faux leather, also known as synthetic leather or vegan leather, is a material designed to mimic the appearance and texture of genuine leather. It is made from various materials, including polyurethane (PU) and polyvinyl chloride (PVC). Faux leather is often more affordable than real leather and is considered a more ethical choice for consumers who prefer not to use animal products. It is available…

Strategic Sourcing Conclusion and Outlook for synthetic leather

As the global demand for synthetic leather continues to rise, strategic sourcing emerges as a pivotal strategy for B2B buyers. Key takeaways highlight the versatility and cost-effectiveness of synthetic leather, making it an attractive alternative to genuine leather across various sectors including apparel, upholstery, and accessories. With the largest production base in China and increasing interest in sustainable options, buyers should focus on sourcing materials that align with ethical standards while meeting quality requirements.

Understanding the nuances of faux leather—including its composition, manufacturing processes, and application potentials—enables businesses to make informed decisions that can enhance their product offerings. In regions like Africa, South America, the Middle East, and Europe, where market dynamics are shifting, embracing synthetic leather can provide a competitive edge.

Looking ahead, international B2B buyers are encouraged to leverage strategic sourcing partnerships that prioritize innovation and sustainability. By doing so, businesses can not only meet consumer demand but also contribute positively to environmental initiatives. Engaging with reliable suppliers and exploring new synthetic leather technologies will be essential in navigating this evolving market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.