Introduction: Navigating the Global Market for red fake leather fabric

Navigating the complexities of sourcing red fake leather fabric can be a daunting task for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. As businesses strive to balance quality with cost-effectiveness, understanding the nuances of this vibrant material becomes essential. Red faux leather not only offers a luxurious aesthetic but also serves as a versatile solution across various applications, from upholstery to fashion accessories.

This comprehensive guide delves into the diverse types of red fake leather fabric available in the market, their specific applications, and the critical factors for supplier vetting. Buyers will gain insights into pricing structures, material durability, and environmental considerations, enabling them to make informed purchasing decisions. Whether you’re a buyer in Nigeria seeking high-quality upholstery materials or a distributor in Vietnam looking to expand your product line, this guide is tailored to meet your needs.

By equipping you with the knowledge to navigate the global market for red fake leather fabric, we aim to empower your business to thrive in a competitive landscape. Understanding these dynamics not only streamlines your sourcing process but also enhances your ability to deliver exceptional value to your customers. Embrace the opportunities that lie within this vibrant material and elevate your offerings in the marketplace.

Table Of Contents

- Top 5 Red Fake Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for red fake leather fabric

- Understanding red fake leather fabric Types and Variations

- Key Industrial Applications of red fake leather fabric

- 3 Common User Pain Points for ‘red fake leather fabric’ & Their Solutions

- Strategic Material Selection Guide for red fake leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for red fake leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘red fake leather fabric’

- Comprehensive Cost and Pricing Analysis for red fake leather fabric Sourcing

- Alternatives Analysis: Comparing red fake leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for red fake leather fabric

- Navigating Market Dynamics and Sourcing Trends in the red fake leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of red fake leather fabric

- Strategic Sourcing Conclusion and Outlook for red fake leather fabric

- Important Disclaimer & Terms of Use

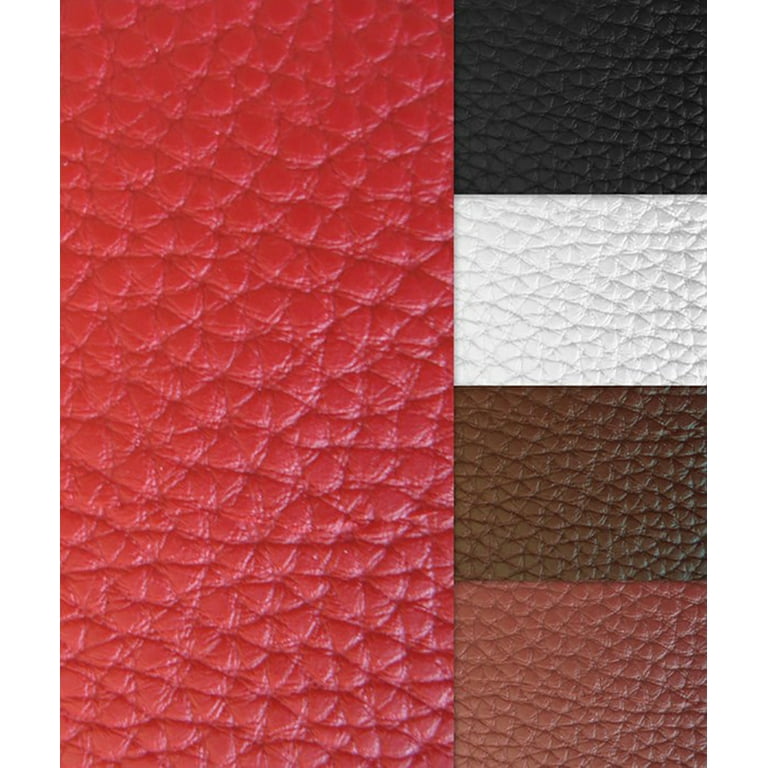

Understanding red fake leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Faux Leather Vinyl | Waterproof, flexible, and durable | Upholstery, automotive, fashion | Pros: Cost-effective, easy to clean. Cons: Can be less breathable than genuine leather. |

| جلد البولي يوريثان | Soft, pliable, and available in various textures | Apparel, bags, furniture | Pros: Vegan-friendly, wide range of textures. Cons: May not be as durable as PVC options. |

| Naugahyde | High-performance, resistant to wear and tear | Commercial furniture, marine use | Pros: Excellent durability, water-resistant. Cons: Higher cost compared to other faux leathers. |

| Embossed Faux Leather | Textured surface mimicking animal skins | Fashion accessories, upholstery | Pros: Aesthetic appeal, variety of designs. Cons: Texture may wear over time. |

| Lightweight Faux Leather | Ultra-thin, flexible, and easy to handle | Crafting, small goods, apparel | Pros: Lightweight, cost-effective. Cons: Less suitable for heavy-duty applications. |

What are the Key Characteristics of Faux Leather Vinyl?

Faux leather vinyl is a versatile material known for its waterproof and flexible properties, making it an ideal choice for various applications, including upholstery and automotive interiors. Its easy-to-clean surface and resistance to tearing and wrinkling enhance its appeal, especially for businesses that require durable materials. Buyers should consider the specific use case, as while it offers significant cost savings over genuine leather, it may not provide the same breathability.

How Does PU Leather Compare to Other Variants?

Polyurethane (PU) leather is celebrated for its soft and pliable nature, coming in a range of textures from smooth to pebbled. This vegan alternative is commonly used in apparel and fashion accessories, as well as furniture. Its diverse texture options allow for creative designs. However, businesses should weigh its durability against PVC alternatives, as PU may wear out faster under heavy use.

Why Choose Naugahyde for Commercial Applications?

Naugahyde is a high-performance faux leather known for its exceptional resistance to wear and tear, making it particularly suitable for commercial furniture and marine applications. Its water-resistant properties ensure longevity, which is a significant advantage for businesses in demanding environments. While it may come at a higher price point, its durability and maintenance ease can lead to long-term savings for B2B buyers.

What Are the Benefits of Embossed Faux Leather?

Embossed faux leather features a textured surface that mimics the look of animal skins, making it a popular choice for fashion accessories and upholstery. Its aesthetic appeal is complemented by a variety of designs and colors, allowing businesses to cater to different market segments. However, buyers should be aware that the texture may wear over time, potentially impacting its visual appeal.

When Should Businesses Consider Lightweight Faux Leather?

Lightweight faux leather is an ultra-thin material that is flexible and easy to handle, making it ideal for crafting and small goods. Its cost-effective nature makes it attractive for businesses looking to produce items at scale without compromising on style. However, it may not be suitable for heavy-duty applications, so buyers should assess their specific needs before opting for this variant.

Key Industrial Applications of red fake leather fabric

| Industry/Sector | Specific Application of red fake leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture & Upholstery | Upholstery for sofas, chairs, and decorative items | Cost-effective luxury appearance | Durability, ease of cleaning, and compliance with fire safety standards |

| Automotive | Interior trim and seating covers | Enhanced aesthetic appeal and comfort | Resistance to wear and tear, UV stability, and colorfastness |

| Fashion & Accessories | Production of bags, wallets, and garments | Trendy designs at lower costs | Material flexibility, variety of textures, and ethical sourcing |

| Hospitality | Decorative elements in hotels and restaurants | Creates a luxurious ambiance | Stain resistance, easy maintenance, and compliance with health regulations |

| Sports & Fitness | Equipment covers and athletic wear | Lightweight and durable for performance | Breathability, moisture-wicking properties, and color retention |

How is Red Fake Leather Fabric Used in Furniture & Upholstery?

In the furniture and upholstery sector, red fake leather fabric is widely utilized for sofas, chairs, and decorative items. This material provides a cost-effective alternative to genuine leather, offering a luxurious appearance without the associated high costs. It is particularly appealing to international buyers looking for stylish yet affordable solutions. Key considerations for sourcing include ensuring the fabric’s durability and ease of cleaning, as well as compliance with fire safety standards, which can vary by region.

What Role Does Red Fake Leather Fabric Play in the Automotive Industry?

In the automotive industry, red fake leather fabric is frequently used for interior trim and seating covers. This application enhances the aesthetic appeal of vehicles while providing comfort to passengers. International buyers must prioritize sourcing materials that resist wear and tear, have UV stability to prevent fading, and maintain colorfastness. Meeting these requirements ensures that the products not only look good but also stand the test of time in various climates.

How is Red Fake Leather Fabric Transforming Fashion & Accessories?

The fashion and accessories industry leverages red fake leather fabric to create trendy bags, wallets, and garments. This material allows designers to produce high-quality items at a fraction of the cost of traditional leather. For B2B buyers, it is crucial to consider the material’s flexibility and the variety of available textures to meet diverse consumer preferences. Additionally, ethical sourcing is increasingly important for brands looking to appeal to environmentally conscious consumers.

Why is Red Fake Leather Fabric Ideal for the Hospitality Sector?

In the hospitality sector, red fake leather fabric is employed for decorative elements in hotels and restaurants, contributing to a luxurious ambiance. This application is particularly valuable for establishments seeking to create an inviting atmosphere without incurring high costs. Sourcing considerations include ensuring the fabric is stain-resistant and easy to maintain, as well as compliant with health regulations, which can differ significantly across regions.

How is Red Fake Leather Fabric Beneficial in Sports & Fitness Applications?

Red fake leather fabric finds applications in sports and fitness equipment, such as covers for gym machines and athletic wear. Its lightweight and durable properties make it suitable for performance-oriented products. Buyers in this sector should focus on the fabric’s breathability and moisture-wicking capabilities, along with its ability to retain color over time. These attributes are essential for ensuring that the products not only perform well but also maintain their aesthetic appeal in active environments.

3 Common User Pain Points for ‘red fake leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Red Fake Leather Fabric

The Problem: One of the most significant challenges B2B buyers face when sourcing red fake leather fabric is ensuring the quality and durability of the material. With numerous suppliers offering various grades and finishes, buyers often struggle to identify fabrics that meet their specific requirements for projects, such as upholstery or fashion. Inconsistent quality can lead to production delays, increased costs, and ultimately dissatisfied customers if the fabric does not perform as expected.

The Solution: To effectively source high-quality red fake leather fabric, buyers should establish clear specifications before reaching out to suppliers. This includes detailing the intended use (e.g., upholstery, apparel, accessories), required durability standards (e.g., tear resistance, water resistance), and desired aesthetic (e.g., texture and finish). Engaging in samples testing is critical—request swatches from potential suppliers to assess the look and feel of the material firsthand. Additionally, consider partnering with reputable manufacturers known for their quality control processes, such as Naugahyde or Boltaflex. Using platforms that aggregate supplier reviews can also help identify reliable sources, ensuring that the chosen fabric aligns with the intended application.

Scenario 2: Managing Inventory and Waste of Red Faux Leather

The Problem: Another common issue for B2B buyers is managing inventory effectively, particularly when dealing with red fake leather fabric. Overestimating demand can lead to excess stock that may become obsolete, while underestimating can result in missed opportunities and production bottlenecks. This is especially crucial for businesses operating in regions with fluctuating trends, like fashion or automotive upholstery.

The Solution: Implementing a robust inventory management system is essential to balance supply with demand. Utilize data analytics tools to track sales trends and customer preferences, which can inform ordering decisions. Establishing a flexible ordering process with suppliers can allow for smaller, more frequent orders, reducing the risk of overstocking. Additionally, consider creating a plan for remnant fabric use—these smaller pieces can be utilized for smaller projects or sold off to minimize waste. Collaborating with suppliers who offer just-in-time delivery can also enhance inventory efficiency, ensuring that businesses receive materials as needed without the burden of excess stock.

Scenario 3: Difficulty in Achieving Desired Aesthetic with Red Faux Leather

The Problem: B2B buyers often struggle to achieve the desired aesthetic in their projects when working with red fake leather fabric. The wide variety of textures, finishes, and colors can lead to confusion, especially when trying to match specific design requirements. In some cases, the fabric may not hold dye well or may not be as vibrant as anticipated, impacting the overall visual appeal of the final product.

The Solution: To overcome aesthetic challenges, buyers should invest time in understanding the different types of finishes available for red faux leather. For instance, options such as embossed, matte, or glossy finishes can significantly alter the look of the fabric. It is advisable to consult with suppliers about their offerings and request samples of various textures to see how they perform under different lighting conditions. Collaborating with a design consultant can also provide insights into color matching and fabric pairing strategies. Finally, leveraging technology, such as virtual design tools, can help visualize how the red fake leather will fit within the overall design, reducing the likelihood of aesthetic mismatches before production begins.

Strategic Material Selection Guide for red fake leather fabric

What Are the Key Materials Used in Red Fake Leather Fabric?

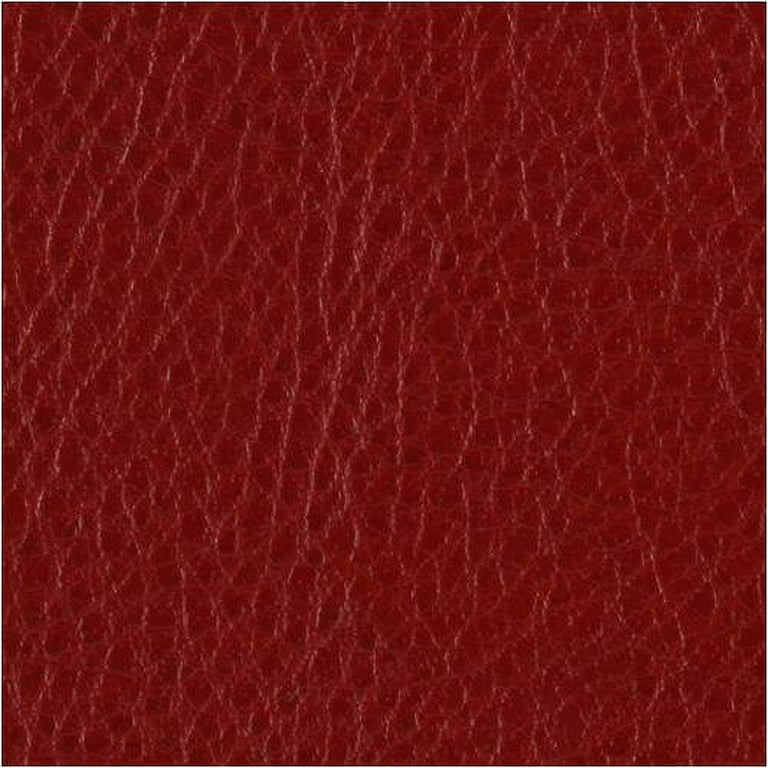

When selecting red fake leather fabric, B2B buyers must consider various materials that influence performance, cost, and suitability for specific applications. Below, we analyze four common materials used in red faux leather production: PVC (Polyvinyl Chloride), PU (Polyurethane), Naugahyde, and Microfiber. Each material presents unique properties and considerations for international buyers.

How Does PVC Contribute to the Performance of Red Fake Leather Fabric?

PVC is a widely used material in faux leather production due to its durability and versatility. It typically offers excellent waterproofing and resistance to abrasion, making it suitable for both indoor and outdoor applications. However, PVC can be less flexible than other materials, which may limit its use in applications requiring high elasticity.

Pros: PVC is cost-effective and widely available, making it a popular choice for upholstery and fashion items. Its easy maintenance and resistance to stains enhance its appeal.

Cons: The environmental impact of PVC production is a significant concern, as it can release harmful chemicals during manufacturing and disposal. Additionally, its rigidity may not be suitable for all applications.

Impact on Application: PVC’s waterproof nature makes it ideal for outdoor furniture and marine applications, while its durability suits automotive interiors.

Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations and standards, such as ASTM D-2000 for rubber materials. Preferences for eco-friendly options are increasing, particularly in Europe.

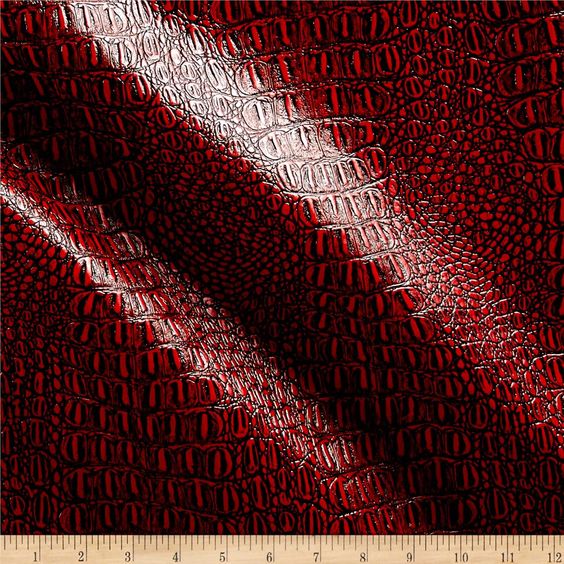

Illustrative image related to red fake leather fabric

What Advantages Does PU Offer for Red Faux Leather Applications?

Polyurethane (PU) is another popular material for faux leather, known for its soft texture and flexibility. PU faux leather mimics the look and feel of genuine leather more closely than PVC, making it a preferred choice for high-end applications.

Pros: PU is lightweight, breathable, and offers excellent resistance to wear and tear. It is also easier to dye, allowing for vibrant colors like red.

Cons: PU can be more expensive than PVC and may not be as waterproof, which could limit its use in certain environments.

Impact on Application: PU is often used in fashion accessories, furniture upholstery, and automotive interiors where aesthetics and comfort are paramount.

Illustrative image related to red fake leather fabric

Considerations for International Buyers: Buyers should check for compliance with standards such as ISO 14001 for environmental management, particularly in regions with stringent regulations like Europe.

Why Is Naugahyde a Preferred Material for Red Faux Leather?

Naugahyde is a brand name often associated with high-quality synthetic leather. It combines a PVC base with a soft, fabric-like finish, providing durability and a luxurious feel.

Pros: Naugahyde is resistant to stains, easy to clean, and offers a high-end appearance. It is also available in various textures and colors, including vibrant reds.

Cons: The cost of Naugahyde can be higher than standard PVC, which may deter budget-conscious buyers.

Impact on Application: Naugahyde is commonly used in commercial upholstery, automotive interiors, and high-end furniture, where durability and aesthetics are crucial.

Considerations for International Buyers: Buyers should verify the product’s compliance with industry standards like ASTM D-751 for strength and durability, especially when sourcing from different regions.

How Does Microfiber Compare as a Material for Red Fake Leather?

Microfiber is a synthetic material made from polyester and polyamide fibers. It is known for its softness and durability, making it a popular choice for faux leather applications.

Pros: Microfiber is lightweight, breathable, and has excellent stain resistance. It offers a luxurious feel similar to genuine leather at a lower cost.

Cons: While microfiber is durable, it may not be as resistant to water and chemicals as PVC or PU, which could limit its applications.

Impact on Application: Microfiber is ideal for fashion items, upholstery, and accessories where comfort and aesthetics are essential.

Illustrative image related to red fake leather fabric

Considerations for International Buyers: Buyers should ensure that microfiber products meet relevant standards, such as Oeko-Tex certification for safety and environmental impact, especially in regions with strict regulations.

Summary Table of Material Comparisons

| المواد | Typical Use Case for red fake leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, outdoor furniture | Cost-effective and durable | Less flexible, environmental concerns | منخفضة |

| البولي يوريثان | Fashion accessories, automotive interiors | Soft, breathable, high-end look | More expensive, less waterproof | Medium |

| Naugahyde | Commercial upholstery, high-end furniture | Luxurious feel, stain-resistant | Higher cost | عالية |

| ألياف دقيقة | Fashion items, upholstery | Soft, lightweight, stain-resistant | Limited water resistance | Medium |

This guide provides a comprehensive overview of the materials used in red fake leather fabric, allowing B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for red fake leather fabric

What Are the Key Stages in the Manufacturing Process of Red Fake Leather Fabric?

The manufacturing process of red fake leather fabric involves several critical stages, each designed to ensure that the final product meets quality, durability, and aesthetic standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with selecting high-quality synthetic materials, typically polyvinyl chloride (PVC) or polyurethane (PU). These materials are chosen for their durability, flexibility, and ease of maintenance. In this stage, raw materials undergo chemical treatments to enhance their properties, such as UV resistance and water repellency. This preparation may also include dyeing the base material to achieve the desired red hue, ensuring uniform color distribution throughout the fabric. -

Forming

Once the materials are prepared, they are processed into sheets or rolls. This is done through techniques like extrusion or calendering. In extrusion, the melted polymer is forced through a die to form sheets, while calendering involves passing the material through rollers to achieve the desired thickness and texture. For red fake leather, various textures can be created, including smooth, embossed, or patterned finishes, enhancing the aesthetic appeal and mimicking the look of genuine leather. -

Assembly

After forming, the fabric is cut into specified dimensions for various applications, such as upholstery, fashion, or automotive uses. During this stage, manufacturers may also apply additional coatings or treatments to enhance the fabric’s performance characteristics. For example, a protective layer can be added to improve scratch resistance or ease of cleaning. This stage is crucial for ensuring that the fabric meets the specific requirements of the intended application. -

Finishing

The final stage in manufacturing involves applying finishing touches to the fabric. This may include heat setting, where the fabric is subjected to controlled heat to stabilize its dimensions and enhance durability. Other treatments might involve applying a topcoat for gloss or matte finishes, depending on the product requirements. Quality checks are performed at this stage to ensure that the fabric meets all specifications and standards before it is shipped to buyers.

How Is Quality Assurance Implemented in Red Fake Leather Fabric Production?

Quality assurance in the production of red fake leather fabric is a multi-faceted process designed to ensure that the final product meets both international standards and specific customer requirements. Key components of this process include adherence to international standards, quality checkpoints, and common testing methods.

-

Relevant International Standards

Manufacturers must comply with several international quality standards, such as ISO 9001, which outlines the criteria for a quality management system. Additionally, industry-specific certifications like CE marking (indicating conformity with health, safety, and environmental protection standards) and API standards (for products used in the oil and gas industry) may also apply, depending on the intended use of the fabric. Compliance with these standards not only enhances product credibility but also facilitates smoother trade across international borders. -

Quality Control Checkpoints

Quality control (QC) checkpoints are integral to the manufacturing process. These checkpoints typically include:

– Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Conducts regular checks during the manufacturing stages to identify any deviations from quality standards.

– Final Quality Control (FQC): A thorough inspection of the finished product before it is packaged and shipped. This may involve testing for durability, colorfastness, and resistance to wear and tear. -

Common Testing Methods

Various testing methods are employed to assess the quality of red fake leather fabric. These may include:

– Physical Testing: Assessing tensile strength, tear resistance, and abrasion resistance.

– Chemical Testing: Evaluating the fabric’s response to various chemicals, ensuring it meets safety standards.

– Environmental Testing: Checking for UV resistance and water repellency, crucial for outdoor applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, must take proactive steps to verify the quality control measures of their suppliers. Here are several actionable strategies:

-

Supplier Audits

Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems in place. This firsthand observation can reveal a lot about the supplier’s commitment to quality and adherence to international standards. -

Requesting Quality Reports

Suppliers should provide quality assurance documentation, including test reports and compliance certifications. Buyers should request these documents regularly to ensure ongoing adherence to quality standards. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an objective evaluation of the supplier’s quality control processes. These services can conduct random inspections and testing to verify that products meet the specified standards before shipment.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is essential for navigating the complexities of global trade. Key considerations include:

-

Regional Standards and Compliance: Different regions may have specific regulations and standards that must be adhered to. For instance, products exported to the European Union must comply with REACH regulations, which govern the use of chemical substances.

-

Cultural and Communication Barriers: Buyers should be aware of potential cultural differences that may impact communication with suppliers. Clear communication regarding quality expectations and standards is crucial to avoid misunderstandings.

-

Logistics and Supply Chain Management: Quality control does not end with manufacturing. Buyers should also consider the logistics of transporting the fabric, ensuring that it remains in optimal condition throughout the supply chain. This may involve additional inspections during transit.

By implementing these strategies and understanding the nuances of quality assurance, B2B buyers can ensure they source high-quality red fake leather fabric that meets their specific needs while fostering strong supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘red fake leather fabric’

مقدمة

Sourcing red fake leather fabric can be a complex process, especially for B2B buyers navigating international markets. This step-by-step checklist is designed to guide you through the essential stages of procurement, ensuring you make informed decisions while securing high-quality materials that meet your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for successful sourcing. Consider the intended use of the red fake leather—whether for upholstery, fashion, or accessories. Key specifications to define include:

– Thickness and Weight: Determine the appropriate thickness for your application, as this impacts durability and drape.

– Texture and Finish: Decide on the desired finish, such as matte or glossy, and textures like pebble or crocodile.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is vital to ensure quality and reliability. Research potential suppliers by checking industry directories, online marketplaces, and trade shows. Important factors to consider include:

– Reputation and Experience: Look for suppliers with a proven track record in faux leather production.

– Product Range: Ensure they offer a variety of red faux leather options that meet your specifications.

Illustrative image related to red fake leather fabric

Step 3: Request Samples for Quality Assessment

Before placing a bulk order, always request samples. This allows you to evaluate the quality and suitability of the fabric firsthand. When assessing samples, pay attention to:

– Color Consistency: Ensure the red shade matches your expectations across different pieces.

– المتانة: Test for resistance to tearing, wrinkling, and water exposure, depending on your application.

Step 4: Verify Supplier Certifications and Compliance

Confirm that your chosen suppliers comply with relevant industry standards and regulations. This step is crucial for maintaining product quality and ethical sourcing practices. Key certifications to look for include:

– ISO Certifications: Indicate adherence to international quality management standards.

– Environmental Compliance: Check for certifications like Oeko-Tex, which ensure the fabric is free from harmful substances.

Step 5: Evaluate Pricing and Payment Terms

Understanding the pricing structure and payment terms is essential for budgeting and financial planning. When comparing prices, consider:

– Volume Discounts: Inquire about bulk purchase discounts that could lower your overall cost.

– Payment Flexibility: Assess payment options, such as deposits or credit terms, to ensure they align with your cash flow needs.

Step 6: Understand Shipping and Logistics

Logistics can significantly impact your procurement process. Clarify shipping options, timelines, and costs with your supplier. Important considerations include:

– Shipping Methods: Determine whether air or sea freight is more suitable based on urgency and budget.

– Customs Regulations: Familiarize yourself with import duties and regulations in your country to avoid unexpected delays or costs.

Illustrative image related to red fake leather fabric

Step 7: Establish a Long-Term Relationship

Building a long-term partnership with your supplier can lead to better pricing, priority service, and enhanced product quality over time. To foster a solid relationship:

– Regular Communication: Keep in touch to discuss future needs and potential issues.

– Feedback Loop: Provide constructive feedback on product quality and service to help them improve.

By following this checklist, B2B buyers can navigate the complexities of sourcing red fake leather fabric more effectively, ensuring they meet their operational requirements while fostering beneficial supplier relationships.

Comprehensive Cost and Pricing Analysis for red fake leather fabric Sourcing

What Are the Key Cost Components for Sourcing Red Fake Leather Fabric?

When sourcing red fake leather fabric, a comprehensive understanding of the cost structure is essential. Key components include:

-

Materials: The primary cost driver is the type of faux leather used. High-quality materials such as PVC or PU can vary significantly in price. For example, Naugahyde and Boltaflex brands may command higher costs due to their durability and aesthetic appeal.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. Skilled labor may be required for intricate designs or customizations, thus increasing costs.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment depreciation. Efficient manufacturing practices can help reduce these overheads, translating into competitive pricing.

-

Tooling: Custom tooling for unique designs or specifications adds to initial costs but can yield long-term benefits through economies of scale when large orders are placed.

-

Quality Control (QC): Implementing strict QC measures ensures product consistency and quality, which may add to the costs but is essential for maintaining brand integrity.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. The choice of Incoterms (e.g., FOB, CIF) can significantly affect logistics expenses.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the standard margin in the industry can aid buyers in evaluating price competitiveness.

How Do Pricing Influencers Affect the Cost of Red Faux Leather Fabric?

Several factors influence the pricing of red fake leather fabric:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding the minimum order quantities (MOQ) can help in negotiating more favorable terms.

-

Specifications and Customization: Custom designs or specific textures (e.g., embossed, smooth) can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Fabrics with certifications (e.g., fire-retardant, eco-friendly) may come at a premium. However, these certifications can enhance marketability and compliance with regulations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and quality assurance.

-

Incoterms: Understanding shipping terms can help buyers manage costs better. Terms like CIF (Cost, Insurance, Freight) include shipping costs in the price, while FOB (Free on Board) means the buyer takes on shipping costs from the port.

What Tips Can Help Buyers Optimize Costs in Red Fake Leather Fabric Sourcing?

To navigate the complexities of sourcing red fake leather fabric effectively, consider the following tips:

Illustrative image related to red fake leather fabric

-

Negotiation: Always negotiate pricing, especially when placing larger orders. Suppliers may have flexibility in pricing, especially for bulk purchases.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the upfront price. Factors like durability, maintenance, and potential waste should be considered to assess long-term value.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import tariffs that can affect overall costs. Building relationships with local suppliers can also help mitigate these risks.

-

Research and Compare: Investigate multiple suppliers to understand market pricing and establish benchmarks. This not only aids in negotiations but also enhances the likelihood of finding the best deal.

الخاتمة

Sourcing red fake leather fabric requires a thorough understanding of cost components, pricing influencers, and strategic negotiation tactics. By leveraging these insights, international B2B buyers can optimize their sourcing strategy and achieve better pricing while ensuring quality and compliance with industry standards. Always remember that prices can fluctuate based on market conditions, so continuous monitoring is advisable.

Alternatives Analysis: Comparing red fake leather fabric With Other Solutions

Understanding Alternatives to Red Fake Leather Fabric

In the quest for versatile and cost-effective materials, red fake leather fabric is a popular choice among B2B buyers. However, it’s essential to evaluate other alternatives that may meet specific needs more effectively. This analysis will compare red fake leather fabric with two viable alternatives: traditional leather and cork fabric. Each option presents unique advantages and disadvantages, making it crucial for buyers to understand their options before making a procurement decision.

Comparison Table

| Comparison Aspect | Red Fake Leather Fabric | Traditional Leather | Cork Fabric |

|---|---|---|---|

| Performance | Durable, waterproof, and flexible | Extremely durable, high-end aesthetic | Eco-friendly, water-resistant |

| Cost | Generally lower cost per yard | Higher initial investment | Mid-range cost |

| Ease of Implementation | Easy to cut and sew; widely available | Requires specialized tools for working | Simple to handle, but limited suppliers |

| Maintenance | Easy to clean, resistant to stains | Requires conditioning, more upkeep | Low maintenance, but can be damaged by water |

| Best Use Case | Upholstery, fashion accessories, and automotive interiors | High-end furniture, luxury goods, and apparel | Eco-conscious products, home decor, and accessories |

Detailed Breakdown of Alternatives

Traditional Leather

Traditional leather is a time-tested material known for its durability and luxurious appearance. It provides excellent wear resistance and can last for decades when cared for properly. However, the cost of traditional leather can be significantly higher than that of red fake leather fabric, making it less accessible for budget-conscious buyers. Furthermore, its maintenance requires regular conditioning to prevent drying and cracking, which can add to the long-term costs. Traditional leather is best suited for high-end products such as luxury furniture or premium fashion items where aesthetic appeal is paramount.

Illustrative image related to red fake leather fabric

Cork Fabric

Cork fabric, derived from the bark of cork oak trees, is a sustainable alternative that has gained popularity in recent years. It is eco-friendly, lightweight, and provides a unique texture that stands out in various applications. While cork fabric is relatively easy to work with and offers water resistance, it may not be as durable as red fake leather or traditional leather. The cost of cork fabric generally falls in the mid-range, making it a feasible option for environmentally conscious buyers. However, its availability may be limited compared to more established materials, which can pose challenges for consistent supply.

Conclusion: How to Choose the Right Solution

When selecting the right material for your business needs, consider the specific application, budget constraints, and desired aesthetic. Red fake leather fabric is an excellent choice for those looking for affordability and versatility in various uses. In contrast, traditional leather may be better suited for high-end products where durability and luxury are prioritized. Cork fabric presents a sustainable option for eco-conscious brands but may require careful consideration regarding its durability and availability. Ultimately, a thorough understanding of each material’s strengths and weaknesses will empower B2B buyers to make informed purchasing decisions that align with their business goals.

Essential Technical Properties and Trade Terminology for red fake leather fabric

What Are the Key Technical Properties of Red Fake Leather Fabric?

When sourcing red fake leather fabric, understanding its technical properties is essential for making informed purchasing decisions. Below are critical specifications that B2B buyers should consider:

-

Material Composition

Red fake leather is typically made from synthetic materials such as polyurethane (PU) or polyvinyl chloride (PVC). PU leather is known for its durability and breathability, making it suitable for upholstery and fashion. PVC, while more cost-effective, is often less flexible and may not offer the same aesthetic appeal. Understanding the composition helps buyers select the right type for their intended use. -

Thickness

The thickness of faux leather can vary widely, usually measured in millimeters or ounces. Common thickness ranges from 0.8 mm to 1.5 mm. Thicker materials tend to be more durable and are often used for heavy-duty applications like upholstery, while thinner options are preferred for garments. Knowing the thickness is crucial for ensuring the fabric meets performance requirements. -

Weight

Weight is an important specification, typically expressed in grams per square meter (GSM). Heavier fabrics provide better durability and are less prone to wear and tear. For example, upholstery-grade faux leather may weigh between 300-600 GSM, while fashion-grade options might be lighter. Buyers should consider the end use to determine the appropriate weight. -

Colorfastness

Colorfastness refers to the fabric’s ability to retain its color when exposed to light, washing, or rubbing. This property is especially vital for products that will be in direct sunlight or are frequently cleaned. It is often tested using standardized methods, with ratings ranging from 1 (poor) to 5 (excellent). High colorfastness ratings ensure that the vibrant red remains consistent over time, reducing the need for replacements. -

Water Resistance

Many faux leather fabrics are treated to be water-resistant, making them suitable for both indoor and outdoor applications. This property is measured by the fabric’s ability to repel water and resist stains. For B2B buyers in regions with high humidity or rainfall, sourcing water-resistant options can significantly enhance product longevity and customer satisfaction.

What Are Common Trade Terminology and Jargon in the Faux Leather Industry?

Familiarity with industry jargon can streamline the procurement process and enhance communication with suppliers. Here are some key terms relevant to red fake leather fabric:

Illustrative image related to red fake leather fabric

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are sold under another brand’s name. In the faux leather industry, this could mean that a manufacturer produces red fake leather fabric that is then branded and marketed by another company. Understanding OEM relationships can help buyers identify potential partners and negotiate effectively. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of fabric that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts budget and inventory management. Knowing the MOQ helps in planning purchases and avoids excess stock that can tie up capital. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests pricing and terms from suppliers for specific products. In the context of red fake leather fabric, an RFQ allows buyers to compare costs, quality, and lead times across multiple vendors, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. For instance, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly affect the total cost of purchasing red fake leather fabric from overseas suppliers. Understanding these terms ensures smooth logistics and cost management. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. In the faux leather industry, lead times can vary based on factors such as production schedules and shipping methods. Knowing the expected lead time helps buyers plan their inventory and avoid delays in their supply chain.

By understanding these technical properties and industry terms, B2B buyers can make more strategic decisions when sourcing red fake leather fabric, ultimately leading to better outcomes for their businesses.

Navigating Market Dynamics and Sourcing Trends in the red fake leather fabric Sector

What Are the Key Trends Influencing the Red Fake Leather Fabric Market?

The global red fake leather fabric market is experiencing significant growth driven by a variety of factors. The increasing demand for cost-effective and durable materials across multiple industries, including upholstery, fashion, and automotive, is a primary driver. In regions like Africa and South America, where traditional leather can be prohibitively expensive, faux leather presents an attractive alternative. Additionally, the rise of e-commerce platforms has streamlined sourcing processes, allowing international buyers from Europe and the Middle East to easily access a wide range of products, including niche variations like red faux leather.

Emerging technologies are also reshaping the market. Innovations in manufacturing processes are leading to higher quality and more versatile products. For instance, advancements in the production of textured and embossed faux leather are making these materials more appealing to buyers looking for unique aesthetics. Furthermore, the trend towards customization is gaining traction, with suppliers offering bespoke options that cater to specific design requirements. This adaptability is particularly beneficial for businesses in dynamic markets such as Nigeria and Vietnam, where consumer preferences can shift rapidly.

How Does Sustainability Impact Sourcing Trends for Red Fake Leather Fabric?

Sustainability and ethical sourcing are increasingly critical considerations for international B2B buyers in the red fake leather fabric sector. The environmental impact of traditional leather production, which involves significant water usage and chemical treatments, has prompted a shift towards more sustainable alternatives. Faux leather, particularly vegan options, is being embraced for its lower environmental footprint. Buyers are now more inclined to seek suppliers who prioritize eco-friendly practices and materials.

Illustrative image related to red fake leather fabric

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential benchmarks for ethical sourcing. These certifications assure buyers of the materials’ safety and sustainability, fostering trust in supply chains. Additionally, suppliers are beginning to highlight their commitment to sustainable practices, such as using recycled materials or implementing waste-reduction initiatives, further appealing to environmentally conscious businesses. As the demand for sustainable products grows, international buyers must prioritize partnerships with suppliers who align with their ethical values and sustainability goals.

What Is the Historical Context of Red Fake Leather Fabric in B2B Markets?

The evolution of red fake leather fabric can be traced back to the mid-20th century when synthetic materials began to gain popularity as a cost-effective alternative to traditional leather. Initially used primarily for affordable consumer goods, the quality and variety of faux leather have improved dramatically over the decades. By the 1980s and 1990s, advancements in technology allowed for the creation of faux leather that closely mimicked the look and feel of genuine leather, leading to its broader acceptance in fashion and upholstery.

In recent years, the rise of the ethical consumer has further propelled the market, as buyers increasingly seek cruelty-free and sustainable options. This historical context underscores the transition from a purely aesthetic choice to a more thoughtful consideration of environmental and ethical implications, shaping the current landscape of red fake leather fabric sourcing in the B2B sector. As a result, international buyers are now positioned to leverage the rich heritage of faux leather while meeting modern demands for sustainability and ethical production.

Frequently Asked Questions (FAQs) for B2B Buyers of red fake leather fabric

-

How do I ensure the quality of red fake leather fabric before purchasing?

To ensure quality, request samples from suppliers before placing a bulk order. Look for certifications that indicate compliance with international standards, such as ISO or REACH. Additionally, inquire about the production processes and materials used. A reliable supplier should provide transparency about their quality control measures, including testing for durability, colorfastness, and resistance to wear and tear. -

What is the best type of red fake leather fabric for upholstery projects?

For upholstery, choose high-quality vinyl faux leather that is both durable and easy to clean. Options like Naugahyde or Boltaflex are popular due to their resistance to tearing and fading. These materials often come with various textures, such as pebble or crocodile, adding both aesthetic appeal and functionality. Ensure the fabric has a suitable weight and thickness for your specific application. -

What customization options are available for red fake leather fabric?

Many suppliers offer customization options, including color matching, texture variations, and even embossed patterns. You can also request specific widths and lengths to fit your project requirements. When discussing customization, clarify the minimum order quantities (MOQs) and any additional costs involved. Customization can enhance your product’s uniqueness and align it with your brand identity. -

What are the minimum order quantities (MOQ) for red fake leather fabric?

MOQs can vary significantly between suppliers, often ranging from 10 to 100 yards, depending on the material and the supplier’s production capabilities. It’s essential to confirm the MOQ before initiating the order process, as this can impact your budgeting and inventory management. If your needs are smaller, consider finding suppliers who specialize in low MOQ orders or are willing to negotiate. -

What payment terms should I expect when sourcing red fake leather fabric internationally?

Payment terms can vary widely among suppliers. Common options include full payment upfront, 30% deposit with the balance upon delivery, or net 30/60 days after receipt of goods. Always discuss and agree on payment terms before finalizing your order to avoid misunderstandings. It’s also advisable to use secure payment methods, such as letters of credit or escrow services, to protect your investment. -

How can I vet suppliers of red fake leather fabric for international trade?

To vet suppliers, start by checking their business credentials, including registration, certifications, and reviews from previous clients. Utilize platforms like Alibaba or Global Sources, which often provide supplier ratings and transaction histories. You can also request references and conduct background checks. Finally, consider visiting their facilities if feasible, or using third-party inspection services to evaluate their production capabilities. -

What logistics considerations should I keep in mind when importing red fake leather fabric?

When importing, consider shipping methods, lead times, and customs regulations. Choose between air freight for speed or sea freight for cost-effectiveness based on your timeline and budget. Ensure your supplier provides all necessary documentation, such as bills of lading and certificates of origin, to facilitate smooth customs clearance. Additionally, account for potential tariffs and taxes that may apply to your imports. -

How can I handle potential quality issues with red fake leather fabric after delivery?

If you encounter quality issues, promptly contact your supplier with detailed documentation, including photographs and descriptions of the problem. Most reputable suppliers will have return and replacement policies in place. Establish clear communication regarding quality standards upfront to minimize disputes. Additionally, consider implementing a quality assurance process upon receipt of goods to catch issues early and ensure compliance with your specifications.

Top 5 Red Fake Leather Fabric Manufacturers & Suppliers List

1. Naugahyde – AM39 American Beauty

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

مقدمة: Red Faux Leather Upholstery Vinyl available from industry leading brands including Naugahyde and Boltaflex. Order by the yard or roll at wholesale prices. Key products include: 1. AM39 Naugahyde ALL-AMERICAN AM 39 AMERICAN BEAUTY – $27.95 per yard, 51 yards in stock. 2. LDR18 LANDERS RED – $14.95 per yard, 59 yards in stock. 3. 6077123 SIMON RED – $24.95 per yard, 19 yards in stock. 4. CP458690 Om…

2. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

مقدمة: Faux Leather collection by Sallie Tomato includes 66 products available in various colors and textures. Colors include Beige, Black, Blue, Brown, Green, Grey, Navy, Orange, Pink, Purple, Red, Teal, White, and Yellow. Textures available are Alligator, Basket Weave, Crocodile, Legacy, Limited Edition, Lite, Ostrich, Pebble, Rugged, and Shimmer. The fabric is sold by quarter yard, with a price point …

3. Etsy – Red Matte Pleather Fabric

Domain: etsy.com

Registered: 2004 (21 years)

مقدمة: This company, Etsy – Red Matte Pleather Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Online Fabric Store – Vinyl & Faux Leather Fabrics

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

مقدمة: This company, Online Fabric Store – Vinyl & Faux Leather Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Mood Fabrics – Faux Leather by the Yard

Domain: moodfabrics.com

Registered: 2001 (24 years)

مقدمة: Faux Leather Fabric by the Yard | Ethical Alternative

Strategic Sourcing Conclusion and Outlook for red fake leather fabric

As international B2B buyers explore the red fake leather fabric market, several key takeaways emerge that can guide strategic sourcing decisions. The variety of textures, from sleek finishes to embossed patterns, enhances the appeal of red faux leather across multiple applications, including upholstery and fashion. Sourcing from reputable suppliers ensures not only quality but also competitive pricing, which is crucial for maintaining profit margins in diverse markets such as Africa, South America, the Middle East, and Europe.

The versatility and sustainability of faux leather present a valuable opportunity for businesses aiming to meet growing consumer demand for eco-friendly alternatives. With advancements in manufacturing technologies, these materials are now more durable and easier to maintain, making them suitable for both indoor and outdoor applications.

Illustrative image related to red fake leather fabric

Looking ahead, B2B buyers are encouraged to engage with suppliers that offer comprehensive product lines and customization options. By leveraging strategic sourcing practices, companies can stay ahead of trends and enhance their product offerings. Embrace the potential of red fake leather fabric today and position your business for success in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to red fake leather fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.