Introduction: Navigating the Global Market for polyurethane material

In today’s competitive landscape, sourcing high-quality polyurethane materials can be a daunting challenge for B2B buyers. Whether you are looking for durable insulation solutions for construction projects or comfortable cushioning for consumer products, understanding the diverse applications and types of polyurethane is crucial. This guide serves as a comprehensive resource, addressing the various forms of polyurethane—from flexible foams to rigid composites—and their respective applications across industries such as automotive, construction, and consumer goods.

As an international buyer, navigating the complexities of supplier vetting, pricing structures, and material specifications can significantly impact your purchasing decisions. This guide empowers you with actionable insights, including best practices for evaluating suppliers, understanding market trends, and assessing the cost-effectiveness of polyurethane materials. By focusing on regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—you will gain a deeper understanding of local regulations, sourcing strategies, and potential partnerships.

With this knowledge at your fingertips, you can make informed choices that enhance your product offerings while ensuring compliance and sustainability in your operations. Dive into this essential guide to unlock the full potential of polyurethane materials and elevate your business in the global marketplace.

Table Of Contents

- Top 4 Polyurethane Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for polyurethane material

- Understanding polyurethane material Types and Variations

- Key Industrial Applications of polyurethane material

- 3 Common User Pain Points for ‘polyurethane material’ & Their Solutions

- Strategic Material Selection Guide for polyurethane material

- In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane material’

- Comprehensive Cost and Pricing Analysis for polyurethane material Sourcing

- Alternatives Analysis: Comparing polyurethane material With Other Solutions

- Essential Technical Properties and Trade Terminology for polyurethane material

- Navigating Market Dynamics and Sourcing Trends in the polyurethane material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane material

- Strategic Sourcing Conclusion and Outlook for polyurethane material

- Important Disclaimer & Terms of Use

Understanding polyurethane material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Polyurethane Foam | Soft, lightweight, and compressible; excellent cushioning properties | Furniture cushioning, mattresses, automotive interiors | Pros: Comfortable, versatile, cost-effective; Cons: Limited durability under extreme conditions |

| Rigid Polyurethane Foam | High insulation value; solid structure; low thermal conductivity | Building insulation, refrigeration, pipeline insulation | Pros: Excellent energy efficiency, long-lasting; Cons: Heavier and less flexible than flexible foams |

| Polyurethane Elastomers | Durable, abrasion-resistant; can be formulated for varying hardness | Wheels, seals, gaskets, industrial parts | Pros: High resilience, customizable; Cons: Can be more expensive than other materials |

| Thermoplastic Polyurethane (TPU) | Flexible, elastic, and resistant to oils and chemicals; can be processed like thermoplastics | Footwear, medical devices, automotive parts | Pros: High performance, recyclable; Cons: May require specialized processing equipment |

| Polyurethane Coatings | Versatile surface protection; excellent adhesion and durability | Wood finishes, automotive coatings, industrial applications | Pros: Enhances durability, aesthetic appeal; Cons: Can be sensitive to UV exposure without additives |

What are the Characteristics of Flexible Polyurethane Foam?

Flexible polyurethane foam is known for its soft and compressible nature, making it ideal for applications that require cushioning and comfort. Commonly used in furniture and mattresses, this type of foam is lightweight and can be easily shaped to fit various designs. For B2B buyers, the cost-effectiveness of flexible foam is a significant advantage; however, its durability may be limited in extreme conditions, necessitating careful consideration of end-use environments.

How Does Rigid Polyurethane Foam Stand Out?

Rigid polyurethane foam is characterized by its exceptional thermal insulation properties and solid structure. This type is commonly used in construction for insulation purposes, refrigeration units, and even pipeline insulation. Its high energy efficiency can lead to substantial cost savings over time. However, buyers should note that while it provides excellent insulation, its weight and rigidity may limit its applicability in certain scenarios where flexibility is required.

What Are the Advantages of Polyurethane Elastomers?

Polyurethane elastomers are distinguished by their high durability and abrasion resistance, making them suitable for demanding applications such as wheels, seals, and gaskets. These materials can be tailored for varying hardness levels, offering versatility in design and functionality. While the resilience and customization options are significant benefits for buyers, the higher cost compared to other materials may be a consideration for budget-sensitive projects.

Why Choose Thermoplastic Polyurethane (TPU)?

Thermoplastic polyurethane (TPU) is recognized for its flexibility, elasticity, and resistance to oils and chemicals. It is widely used in applications such as footwear, medical devices, and automotive components. One of the key advantages of TPU is its recyclability, appealing to businesses focused on sustainability. However, buyers should consider that TPU may require specialized processing equipment, which could impact overall project costs.

What Are the Key Benefits of Polyurethane Coatings?

Polyurethane coatings provide versatile surface protection, enhancing the durability and aesthetic appeal of various materials. Commonly used in wood finishes, automotive coatings, and industrial applications, these coatings offer excellent adhesion and resistance to wear. For B2B buyers, the ability to improve product longevity is a strong selling point; however, the potential sensitivity to UV exposure means that additional additives may be necessary for outdoor applications.

Key Industrial Applications of polyurethane material

| Industry/Sector | Specific Application of polyurethane material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Rigid foam for sound insulation in vehicles | Reduces noise, enhancing passenger comfort | Quality of insulation, compliance with safety regulations |

| Construction | Spray foam insulation for buildings | Improves energy efficiency, reduces utility costs | Thermal performance, environmental impact, fire resistance |

| Furniture | Flexible foam for seating and mattresses | Increases comfort and durability of products | Density, resilience, and compliance with health standards |

| Footwear | Polyurethane soles for shoes | Provides cushioning and durability, enhancing wear | Abrasion resistance, flexibility, and eco-friendliness |

| Coatings and Adhesives | Protective coatings for various surfaces | Enhances durability and resistance to wear | Chemical resistance, application method, and drying time |

How is Polyurethane Used in the Automotive Industry?

In the automotive sector, polyurethane is widely utilized for sound insulation, particularly in the form of rigid foam. This application addresses the need for quieter cabins, significantly enhancing passenger comfort. Buyers in this industry should prioritize sourcing high-quality materials that comply with stringent safety regulations and performance standards, particularly in regions like Europe and the Middle East where regulations are stringent.

What Role Does Polyurethane Play in Construction?

Polyurethane serves a crucial role in the construction industry as a spray foam insulation material. This application not only improves energy efficiency by creating a thermal barrier but also helps reduce utility costs for building owners. International buyers must consider thermal performance ratings and environmental impact, especially in regions with extreme climates, such as Africa and South America, where energy efficiency is paramount.

How is Polyurethane Enhancing Furniture Comfort?

In the furniture industry, polyurethane is predominantly used in flexible foam applications for seating and mattresses. This material provides exceptional comfort and durability, meeting consumer demands for high-quality products. When sourcing polyurethane for furniture, buyers should focus on the density and resilience of the foam, alongside compliance with health and safety standards, which can vary significantly across markets in Europe and the Middle East.

What Advantages Does Polyurethane Offer in Footwear?

Polyurethane is increasingly popular in the footwear sector, particularly for creating soles that offer both cushioning and durability. This application addresses the need for comfortable yet long-lasting footwear, appealing to consumers seeking quality. Buyers should assess the abrasion resistance and flexibility of the polyurethane used, as well as its eco-friendliness, to meet the growing demand for sustainable products in global markets.

How are Coatings and Adhesives Enhanced by Polyurethane?

Polyurethane is also extensively used in coatings and adhesives, providing protective layers for various surfaces. This application enhances the durability and resistance to wear of products across multiple industries. When sourcing polyurethane for coatings, businesses should evaluate the chemical resistance, application methods, and drying times, ensuring compatibility with the specific requirements of their operations, especially in regions with diverse climatic conditions.

3 Common User Pain Points for ‘polyurethane material’ & Their Solutions

Scenario 1: Sourcing Quality Polyurethane Materials for Diverse Applications

The Problem: B2B buyers often face challenges in sourcing high-quality polyurethane materials that meet specific performance requirements for various applications, such as insulation, coatings, or cushioning. This difficulty can stem from a lack of reliable suppliers, inconsistent product specifications, or variations in material quality that compromise the final product’s integrity. For instance, a construction firm may need polyurethane for insulation that complies with local energy efficiency standards but finds that suppliers cannot consistently deliver the desired thermal performance. This inconsistency can lead to project delays and increased costs.

The Solution: To mitigate these sourcing challenges, B2B buyers should establish a rigorous supplier evaluation process that includes assessing certifications, conducting sample tests, and verifying production capabilities. Engage with suppliers who provide transparent product specifications and can demonstrate compliance with international standards, such as ISO 9001 for quality management. Additionally, consider forming partnerships with suppliers who specialize in polyurethane materials for your specific industry, as they are more likely to understand your unique requirements. Regularly review supplier performance and maintain open lines of communication to address any quality issues before they impact your production processes.

Scenario 2: Navigating Polyurethane’s Environmental Impact and Sustainability Concerns

The Problem: With increasing pressure to adopt sustainable practices, many companies are concerned about the environmental impact of the polyurethane materials they use. B2B buyers may struggle to find eco-friendly alternatives that still deliver the necessary performance characteristics. For example, a furniture manufacturer looking to replace traditional foam with a more sustainable option might find that many available polyurethane products are not environmentally friendly, leading to potential backlash from consumers who prioritize sustainability.

The Solution: To address sustainability concerns, B2B buyers should actively seek out polyurethane materials that are produced using renewable resources or have lower environmental footprints. Look for products that are certified by recognized environmental standards, such as GreenGuard or Cradle to Cradle. Engage with manufacturers who are committed to sustainability, as they may offer innovative solutions like bio-based polyurethanes or those designed for recycling. Additionally, consider conducting life cycle assessments to understand the environmental impact of your material choices fully and to communicate these efforts effectively to your customers, enhancing your brand’s reputation.

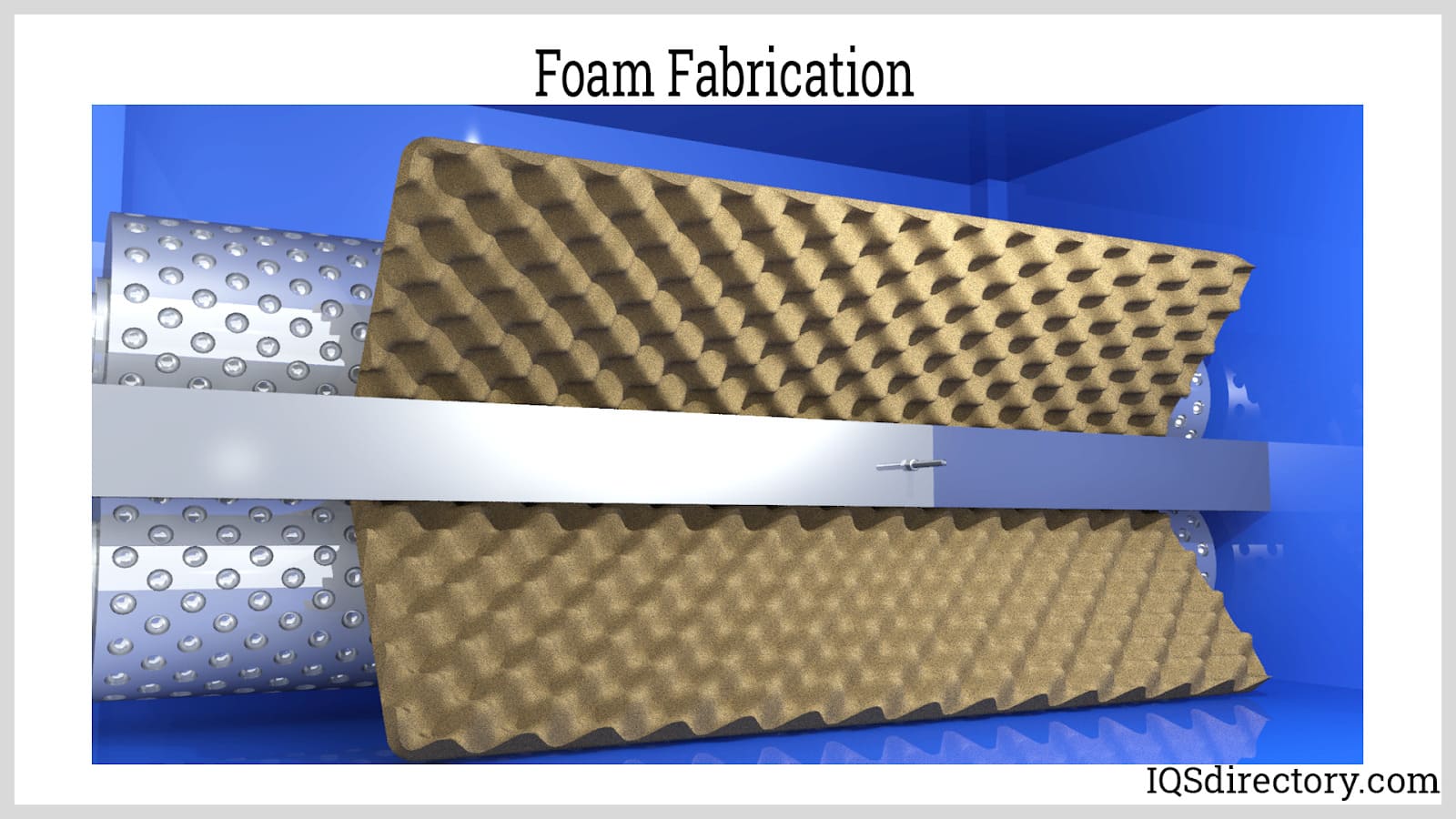

Illustrative image related to polyurethane material

Scenario 3: Ensuring Compatibility and Performance in Diverse Manufacturing Processes

The Problem: Another common challenge faced by B2B buyers is ensuring that polyurethane materials are compatible with existing manufacturing processes and that they perform reliably under specific conditions. This is particularly critical in sectors like automotive or aerospace, where safety and performance are paramount. Buyers may encounter situations where the selected polyurethane does not adhere properly to other materials or fails to perform under extreme temperatures, leading to costly production errors and product failures.

The Solution: To ensure compatibility and performance, B2B buyers should engage in thorough testing and validation of polyurethane materials within their specific production environments. Before committing to large orders, conduct small-scale trials to evaluate how the polyurethane interacts with other materials and assess its performance under anticipated operational conditions. Collaborate with suppliers who can provide technical support and guidance in selecting the right formulation for your application. Consider investing in training for your production team to understand the nuances of working with different polyurethane types, ensuring that they can troubleshoot potential issues before they escalate into larger problems.

Strategic Material Selection Guide for polyurethane material

When selecting polyurethane materials for various applications, B2B buyers must consider several factors, including material properties, advantages and disadvantages, and specific regional compliance requirements. Below, we analyze four common polyurethane materials that are widely used in different industries.

What Are the Key Properties of Rigid Polyurethane Foam?

Rigid polyurethane foam is known for its excellent thermal insulation properties, making it a preferred choice for building insulation and refrigeration applications. It typically has a temperature rating of -60°C to 100°C, allowing it to perform well in extreme conditions. Additionally, its low density contributes to reduced weight in construction materials, enhancing energy efficiency.

Pros: Rigid foam is durable, lightweight, and provides superior insulation, which can lead to significant energy savings in heating and cooling applications.

Illustrative image related to polyurethane material

Cons: However, its manufacturing process can be complex and may involve higher initial costs compared to other insulation materials. It may also have limited flexibility, making it unsuitable for applications requiring material movement.

How Does Flexible Polyurethane Foam Perform in Different Applications?

Flexible polyurethane foam is widely used in furniture, bedding, and automotive applications due to its comfort and cushioning properties. It has a temperature rating of -30°C to 60°C and can withstand various pressures, making it suitable for seating and mattresses.

Pros: This material is highly versatile, offering excellent comfort and durability while being relatively cost-effective to produce.

Cons: Its susceptibility to degradation from UV exposure and moisture can limit its lifespan unless treated with protective coatings.

Illustrative image related to polyurethane material

What Are the Unique Properties of Thermoplastic Polyurethane (TPU)?

Thermoplastic polyurethane (TPU) is a highly elastic and durable material that combines the benefits of rubber and plastic. It is resistant to abrasion, oil, and grease, making it ideal for applications in automotive parts, footwear, and industrial components. TPUs can operate effectively within a temperature range of -40°C to 80°C.

Pros: TPUs are known for their flexibility and strength, which allows them to maintain performance under various conditions. They can be easily molded and processed, making them suitable for complex shapes.

Cons: The cost of TPU can be higher than traditional polyurethane materials, which may deter some buyers. Additionally, its production may require specialized equipment, increasing manufacturing complexity.

What Should Buyers Consider When Choosing Coatings and Adhesives Based on Polyurethane?

Polyurethane coatings and adhesives provide excellent adhesion, flexibility, and resistance to chemicals and weathering. They are commonly used in construction, automotive, and consumer goods industries. These products typically have a temperature tolerance of -20°C to 120°C.

Pros: They offer long-lasting protection and can enhance the durability of the underlying materials, making them suitable for outdoor applications.

Illustrative image related to polyurethane material

Cons: The curing time can be longer than other types of adhesives, and the application process may require specific environmental conditions to achieve optimal performance.

Summary of Key Considerations for International B2B Buyers

For buyers from Africa, South America, the Middle East, and Europe, compliance with local standards such as ASTM, DIN, and JIS is crucial. Understanding the specific needs of each market, including climate conditions and regulatory requirements, can significantly influence material selection. Additionally, buyers should consider the availability of local suppliers and manufacturers to reduce lead times and shipping costs.

| المواد | Typical Use Case for polyurethane material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rigid Polyurethane Foam | Building insulation | Excellent thermal insulation | Higher initial costs | Medium |

| Flexible Polyurethane Foam | Furniture and bedding | High comfort and versatility | Susceptible to UV degradation | منخفضة |

| Thermoplastic Polyurethane (TPU) | Automotive parts and footwear | High elasticity and durability | Higher production costs | عالية |

| Polyurethane Coatings and Adhesives | Construction and consumer goods | Long-lasting protection | Longer curing time | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane material

What Are the Key Stages in the Manufacturing Process of Polyurethane Materials?

The manufacturing process of polyurethane (PU) materials involves several critical stages that ensure the final product meets both performance and quality standards. Understanding these stages is essential for B2B buyers looking to procure high-quality polyurethane materials.

How Is Material Prepared for Polyurethane Production?

The first step in the manufacturing process is material preparation, which includes sourcing and selecting the right chemical components. Polyurethane is produced by reacting diisocyanates (such as TDI or MDI) with polyols. The quality of these raw materials significantly impacts the final product’s properties, such as flexibility, hardness, and durability.

After selecting the appropriate chemicals, they are weighed and mixed in precise proportions. This stage may also involve the addition of various additives, such as catalysts, colorants, and fillers, to enhance specific characteristics of the PU material. A thorough understanding of chemical interactions is crucial here, as it influences the physical and mechanical properties of the final product.

What Techniques Are Used for Forming Polyurethane?

Once the materials are prepared, the next stage is forming. This can be accomplished through various techniques, including:

-

Casting: In this method, the mixed polyurethane is poured into molds to create specific shapes and sizes. This technique is widely used for producing items like foam cushions, automotive parts, and industrial products.

-

Foaming: This involves introducing a blowing agent to create a cellular structure. For example, carbon dioxide can be used to produce soft, flexible foams, while pentane is employed for rigid foam applications.

-

Injection Molding: This technique is ideal for creating complex shapes and is commonly used for producing components like automotive parts, where precision and consistency are critical.

These forming techniques allow manufacturers to customize the properties of polyurethane products based on their intended applications, catering to diverse industries from automotive to construction.

How Is the Assembly Process Conducted in Polyurethane Manufacturing?

The assembly process is crucial for creating multi-component polyurethane products, such as composite parts or systems. This stage involves the integration of different polyurethane components or the combination of polyurethane with other materials, like metals or plastics.

For instance, in the automotive sector, PU foams might be assembled with rigid plastic shells to create comfortable seating solutions. Quality control during assembly is vital, as misalignment or improper bonding can lead to product failures.

What Finishing Techniques Are Commonly Used for Polyurethane Products?

Finishing processes are essential for enhancing the aesthetics and performance characteristics of polyurethane materials. Common finishing techniques include:

-

Surface Treatments: These can involve coatings that improve chemical resistance, UV stability, or aesthetic appeal. For example, adding a protective layer can prevent wear and tear in high-use applications.

-

Trimming and Cutting: After curing, excess material is removed to achieve precise dimensions and finishes. This ensures that the final product meets the specifications required by clients.

-

Quality Checks: Final inspection and testing occur at this stage to ensure that the product adheres to the necessary standards.

What Are the Key Quality Assurance Practices in Polyurethane Manufacturing?

Quality assurance (QA) is a cornerstone of polyurethane manufacturing, ensuring that products meet international standards and client specifications. Understanding these practices is vital for B2B buyers to make informed procurement decisions.

Which International Standards Should Buyers Be Aware Of?

International standards play a significant role in ensuring product quality and safety. One of the primary standards applicable to polyurethane manufacturing is ISO 9001, which focuses on quality management systems. Compliance with this standard indicates that the manufacturer has established processes to consistently meet customer and regulatory requirements.

Additionally, industry-specific certifications such as CE marking in Europe and API standards in the oil and gas sector can further validate product quality. B2B buyers should ensure that their suppliers hold relevant certifications to guarantee product reliability and safety.

What Are the QC Checkpoints in Polyurethane Manufacturing?

Quality control checkpoints are integral to the manufacturing process and typically include:

-

Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials for conformity to specifications before they enter the production process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, continuous monitoring ensures that processes remain within defined parameters. This includes checking temperature, mixing ratios, and curing times.

-

Final Quality Control (FQC): Once the product is finished, FQC involves rigorous testing for physical and mechanical properties, such as tensile strength, hardness, and density.

These checkpoints help identify issues early in the production process, reducing the risk of defects in the final product.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to assess the quality of polyurethane materials, including:

-

Mechanical Testing: This assesses properties such as tensile strength, elongation, and tear resistance, ensuring the material can withstand expected operational stresses.

-

Thermal Testing: Evaluating thermal conductivity and resistance helps determine the insulation capabilities of polyurethane products, which is crucial for applications in construction and refrigeration.

-

Chemical Resistance Testing: This tests how well the polyurethane can withstand exposure to various chemicals, which is especially important in industrial applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for maintaining product integrity.

What Auditing Practices Should Buyers Consider?

Conducting supplier audits is an effective way to assess quality control processes firsthand. Buyers should look for comprehensive audits that evaluate compliance with international standards and internal QA procedures.

Additionally, requesting quality reports and documentation from suppliers can provide insights into their manufacturing practices and any corrective actions taken in response to past issues.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can further validate supplier claims and ensure that products meet specified standards. These independent inspections can provide an objective assessment of manufacturing practices and product quality.

الخاتمة

The manufacturing processes and quality assurance practices for polyurethane materials are complex but essential for ensuring high-quality end products. By understanding these processes, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet international standards and deliver products suited to their specific needs. As the market for polyurethane continues to grow, being well-informed about manufacturing and quality control will be key to successful procurement strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane material’

In the realm of B2B procurement, sourcing polyurethane materials effectively requires a strategic approach. This guide outlines essential steps to streamline your sourcing process, ensuring you select the right materials and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining your requirements for polyurethane materials. This includes the type (rigid, flexible, foam, etc.), intended application (insulation, coatings, automotive parts), and any specific performance criteria such as durability, flexibility, or thermal resistance. Having precise specifications helps suppliers understand your needs and reduces the risk of receiving unsuitable materials.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of polyurethane materials. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers and distributors. Focus on suppliers with a strong reputation and experience in your specific application area, as they are more likely to meet your quality and performance expectations.

Illustrative image related to polyurethane material

Step 3: Evaluate Supplier Certifications

Verify the certifications and compliance of potential suppliers. Look for industry-standard certifications such as ISO 9001 for quality management and REACH compliance for safety and environmental regulations. These certifications not only indicate reliability but also ensure that the materials meet the necessary regulatory standards in your region, particularly important in international trade.

Step 4: Request Samples and Technical Data Sheets

Before making a large order, request samples of the polyurethane materials along with technical data sheets. This allows you to assess the material’s properties, such as tensile strength, flexibility, and thermal insulation capabilities. Evaluating samples helps you ensure that the materials align with your project requirements and quality standards.

Step 5: Assess Pricing and Terms of Service

Once you have shortlisted suppliers, compare pricing structures and terms of service. Look for transparency in pricing, including any additional costs for shipping or handling. It’s also crucial to understand the payment terms and conditions, as well as the supplier’s return policy in case the materials do not meet your expectations.

Step 6: Negotiate and Finalize Contracts

Engage in negotiations with your chosen supplier to finalize the contract terms. Ensure that all specifications, pricing, delivery timelines, and warranty conditions are clearly documented. A well-defined contract protects both parties and sets clear expectations, reducing the likelihood of disputes in the future.

Step 7: Establish a Long-term Relationship

After successfully sourcing your polyurethane materials, focus on building a long-term relationship with your supplier. Regular communication and feedback can lead to better service, potential discounts on future orders, and access to new products. A strong partnership can be invaluable, especially if you require continuous supply for ongoing projects.

By following this checklist, B2B buyers can navigate the complexities of sourcing polyurethane materials more effectively, ensuring they make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for polyurethane material Sourcing

What Are the Key Cost Components for Sourcing Polyurethane Material?

When sourcing polyurethane materials, understanding the cost structure is crucial for effective budgeting and negotiation. The primary components include:

-

Materials: The base ingredients for polyurethane, mainly diisocyanates and polyols, significantly influence the overall cost. Variations in material prices can arise due to market demand, geopolitical factors, and supplier availability.

-

Labor: Labor costs encompass the workforce required for manufacturing, processing, and quality control. In regions with higher labor costs, such as parts of Europe, this can notably affect pricing.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility expenses. Efficient manufacturing processes can help minimize overhead, which is a vital consideration for suppliers.

-

Tooling: Custom molds and machinery for specific polyurethane applications add to the initial investment. This cost can be amortized over larger production runs, making it essential to consider the volume of orders.

-

Quality Control (QC): Ensuring that polyurethane meets industry standards requires investment in quality assurance processes. This not only affects immediate costs but also the long-term reliability of the material.

-

Logistics: Transportation, warehousing, and handling costs can fluctuate based on the distance from suppliers and the mode of transport. International buyers must account for these additional expenses when sourcing from different regions.

-

Margin: Suppliers will add a profit margin to cover their risks and operational costs. Understanding typical margins in the polyurethane industry can provide leverage during negotiations.

What Influences Pricing for Polyurethane Materials?

Several factors can influence the pricing of polyurethane materials, which international B2B buyers should be aware of:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs. Negotiating favorable MOQs can yield significant savings, especially for ongoing projects.

-

Specifications and Customization: Tailored solutions that meet specific application needs can increase costs. Buyers should clearly define requirements to avoid unexpected price hikes due to last-minute changes.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, REACH) generally come at a premium. Buyers should assess whether the additional investment aligns with their quality needs.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The agreed terms of delivery (e.g., FOB, CIF) impact total costs. Understanding the implications of these terms can help buyers optimize their logistics and avoid hidden fees.

What Are the Best Negotiation Tips for B2B Buyers of Polyurethane Materials?

To effectively negotiate prices and achieve cost-efficiency in sourcing polyurethane, consider the following tips:

-

Research Market Prices: Familiarize yourself with prevailing market rates for polyurethane to strengthen your negotiation position. This knowledge can help you identify fair pricing and avoid overpaying.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the entire lifecycle cost of the material, including maintenance, disposal, and energy efficiency. This holistic view can justify higher upfront costs if long-term savings are evident.

-

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication and reliability can foster trust, resulting in more favorable terms over time.

-

Be Prepared for Counteroffers: Suppliers may respond with counteroffers. Be ready to articulate the value you provide as a buyer, including order volume and payment reliability, to negotiate effectively.

-

Consider Regional Differences: Be mindful of regional pricing variations, especially when sourcing from Africa, South America, the Middle East, or Europe. Local economic conditions can significantly affect material costs and supplier pricing strategies.

Disclaimer on Indicative Prices

Prices for polyurethane materials can fluctuate based on market conditions, currency exchange rates, and other external factors. The figures provided in sourcing discussions should be viewed as indicative rather than fixed, and buyers are encouraged to obtain formal quotes for accurate budgeting.

Alternatives Analysis: Comparing polyurethane material With Other Solutions

Understanding Alternatives to Polyurethane Material

When considering materials for various applications, it’s essential to evaluate the available alternatives to polyurethane, a versatile and widely used plastic. This analysis focuses on comparing polyurethane against two viable alternatives: expanded polystyrene (EPS) and thermoplastic elastomers (TPE). Each material presents unique characteristics that can cater to different needs in industrial and commercial applications.

Comparison Table

| Comparison Aspect | Polyurethane Material | Expanded Polystyrene (EPS) | Thermoplastic Elastomers (TPE) |

|---|---|---|---|

| Performance | High durability, excellent insulation properties, flexible or rigid forms | Good insulation, lightweight but less durable under pressure | Excellent flexibility, good abrasion resistance, weather-resistant |

| Cost | Moderate to high, depending on formulation | Low cost, economical for bulk applications | Moderate, often higher than EPS but offers better performance |

| Ease of Implementation | Requires specialized equipment for processing | Easily molded and cut, straightforward installation | Can be processed using standard plastic processing methods |

| Maintenance | Low maintenance, but can degrade under UV exposure | Low maintenance, can be recycled but not biodegradable | Low maintenance, good longevity but can be subject to wear over time |

| Best Use Case | Insulation, automotive parts, cushioning | Packaging, insulation panels, disposable containers | Automotive parts, consumer goods, medical applications |

Expanded Polystyrene (EPS)

Expanded polystyrene is a lightweight material primarily used for insulation and packaging. Its cost-effectiveness makes it an attractive option for bulk applications. However, EPS lacks the durability and flexibility of polyurethane. While it provides good insulation, it may not perform well under extreme pressure or in applications requiring high durability. Additionally, EPS is not biodegradable, which can be a concern for environmentally conscious buyers.

Thermoplastic Elastomers (TPE)

Thermoplastic elastomers are a class of materials that combine the properties of rubber and plastic, offering excellent flexibility and resilience. TPEs are commonly used in automotive and consumer goods applications where durability and weather resistance are essential. While they can be more expensive than EPS, they provide superior performance in demanding environments. One drawback is that TPEs can wear over time, which may necessitate replacement sooner than polyurethane in certain applications.

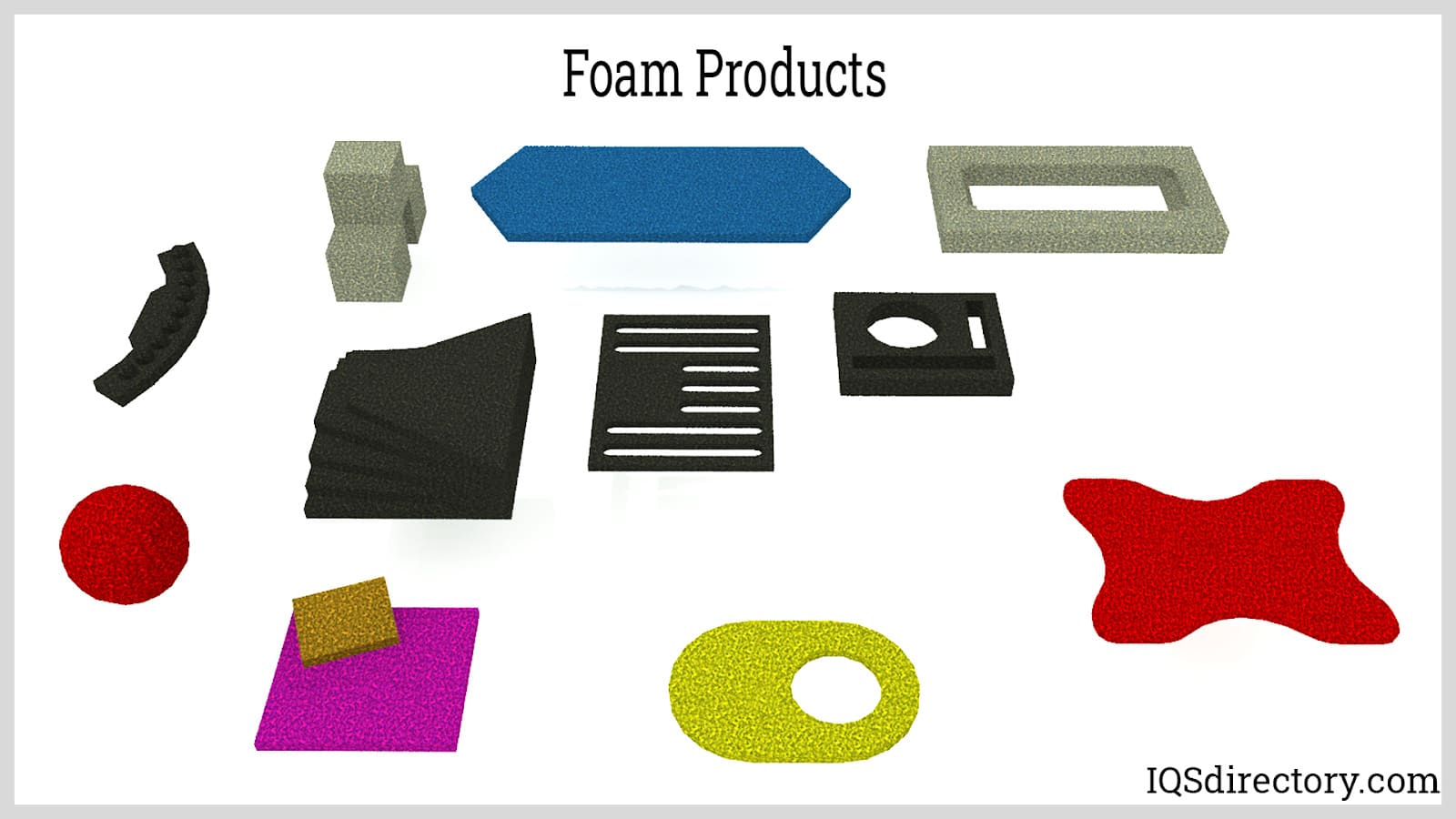

Illustrative image related to polyurethane material

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate material for your project, consider the specific requirements of your application, including performance, cost, and ease of implementation. Polyurethane may be the best option for applications demanding high durability and insulation, whereas EPS could be ideal for cost-sensitive projects requiring lightweight solutions. TPEs offer a middle ground, providing flexibility and durability for diverse applications. By analyzing these factors, B2B buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for polyurethane material

What Are the Key Technical Properties of Polyurethane Material for B2B Buyers?

Polyurethane (PU) is a versatile polymer with various applications across industries, making it essential for international B2B buyers to understand its critical properties. Here are some key specifications that are vital for informed decision-making:

-

Material Grade

Polyurethane is categorized into different grades, including flexible, rigid, and thermoplastic variants. Each grade has unique characteristics tailored for specific applications, such as cushioning, insulation, or coatings. Understanding the material grade is crucial for selecting the right PU for products like automotive components or furniture, ensuring performance and durability. -

Tensile Strength

This property measures how much force a material can withstand while being stretched or pulled before breaking. High tensile strength is essential for applications requiring durability and resistance to deformation, such as in automotive parts or industrial seals. For B2B buyers, knowing the tensile strength helps in evaluating whether a polyurethane product can meet the demands of its intended use. -

Density

The density of polyurethane affects its weight, insulation capabilities, and overall performance. Lower density foams are typically used for comfort applications, like mattresses, while higher density options are better suited for structural components. B2B purchasers should consider density in relation to transportation costs and product performance. -

Thermal Conductivity

This property indicates how well a material can conduct heat. Polyurethanes with low thermal conductivity are preferred for insulation applications, such as in refrigerators and buildings. Understanding thermal conductivity helps B2B buyers assess energy efficiency and potential cost savings in their applications. -

Elongation at Break

This measure indicates how much a material can stretch before breaking. A high elongation at break is beneficial for applications requiring flexibility and resilience, such as in footwear and sportswear. For B2B buyers, knowing this property aids in selecting materials that can withstand physical stress without failure. -

Chemical Resistance

Polyurethane’s ability to resist degradation from chemicals is crucial in industrial applications. Buyers should evaluate chemical resistance to ensure longevity and reliability in environments where exposure to oils, solvents, or other harsh substances is a concern.

What Are Common Trade Terms Related to Polyurethane Materials?

Understanding industry jargon can facilitate smoother transactions and communication between B2B buyers and suppliers. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For polyurethane products, knowing the OEM is crucial for ensuring compatibility and quality in end-use applications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to assess whether they can meet purchasing requirements without overcommitting to excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. This process is vital for B2B buyers to gather competitive quotes and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities. -

Lead Time

This term refers to the time taken from placing an order until the product is delivered. Knowing the lead time is critical for B2B buyers to manage their supply chains effectively and align their production schedules. -

Technical Data Sheet (TDS)

A TDS provides detailed information about a product’s properties, applications, and handling instructions. B2B buyers should review TDS to ensure they select the right polyurethane for their specific needs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing polyurethane materials, ultimately enhancing their product offerings and competitive advantage in the market.

Navigating Market Dynamics and Sourcing Trends in the polyurethane material Sector

What Are the Current Market Trends Influencing Polyurethane Material Sourcing?

The polyurethane material sector is experiencing significant growth, driven by the increasing demand for lightweight, durable, and versatile materials across various industries. Global drivers such as urbanization, rising disposable incomes, and a surge in the automotive and construction sectors are propelling this demand. In regions like Africa and South America, infrastructure development and economic growth are particularly influencing the market. Meanwhile, in Europe and the Middle East, stringent regulations regarding energy efficiency and sustainability are pushing manufacturers to adopt advanced polyurethane solutions.

Emerging B2B technology trends, including digital supply chain management and automation, are reshaping sourcing practices. Buyers are increasingly relying on data analytics to optimize their procurement processes, ensuring they can quickly adapt to market changes. The shift towards online platforms for sourcing and procurement is also gaining traction, providing international buyers with enhanced access to suppliers and a wider range of products. As a result, B2B buyers must remain vigilant about market dynamics, including fluctuating raw material prices and evolving consumer preferences, to make informed purchasing decisions.

How Can Sustainability and Ethical Sourcing Impact Your Polyurethane Material Procurement?

The environmental impact of polyurethane materials is a pressing concern for many businesses today. As polyurethane production can generate significant carbon emissions, the industry is increasingly focusing on sustainability initiatives. Ethical sourcing practices are becoming critical for B2B buyers who aim to minimize their environmental footprint and align with global sustainability goals. This includes seeking suppliers who utilize renewable resources or implement eco-friendly manufacturing processes.

Additionally, green certifications such as ISO 14001 (Environmental Management) and certifications related to low-VOC (Volatile Organic Compounds) emissions can guide buyers in identifying environmentally responsible products. By prioritizing suppliers with these certifications, businesses can enhance their brand reputation and meet the growing consumer demand for sustainable products. Furthermore, adopting circular economy principles by sourcing recycled polyurethane materials can significantly reduce waste and resource consumption, making it a win-win for both businesses and the environment.

What Historical Developments Have Shaped the Polyurethane Material Industry?

The journey of polyurethane materials began in the 1930s with the groundbreaking work of Professor Dr. Otto Bayer, who first synthesized these versatile polymers. Initially used as a substitute for rubber during World War II, polyurethanes rapidly expanded into various applications, including adhesives, coatings, and flexible foams in the 1950s. As technology advanced, so did the range of polyurethane products, with significant developments in the late 20th century focusing on energy efficiency and environmental impact.

Today, polyurethanes are ubiquitous in everyday products, from automotive components to thermal insulation materials. This evolution reflects the industry’s adaptability and responsiveness to market demands, making it essential for international B2B buyers to understand the historical context of the materials they source. By appreciating this evolution, buyers can better navigate current market dynamics and anticipate future trends that will influence their procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane material

-

How do I solve quality issues with polyurethane materials?

To address quality concerns with polyurethane materials, start by conducting a thorough supplier audit. This involves reviewing their manufacturing processes, certifications, and previous client feedback. Request sample products for testing to evaluate their performance in your specific application. Establish clear quality standards in your purchase agreements, including specifications for durability, flexibility, and chemical resistance. Regular quality assurance checks and open communication with your supplier can help maintain consistent product quality. -

What is the best polyurethane type for insulation applications?

For insulation purposes, rigid polyurethane foam is often the best choice due to its excellent thermal resistance and energy efficiency. This type of polyurethane can significantly reduce energy costs when used in building insulation, as it requires less material thickness compared to traditional insulation materials. When sourcing, consider the foam’s density and thermal conductivity ratings to ensure it meets your specific insulation requirements. -

What customization options are available when sourcing polyurethane materials?

Many suppliers offer customization options for polyurethane materials, including variations in hardness, color, and formulation. You can request specific additives for enhanced properties such as fire resistance, UV stability, or antimicrobial features. Collaborating closely with your supplier during the design phase can help create a product that meets your unique application needs. Be sure to discuss minimum order quantities (MOQs) for custom formulations, as these may vary by supplier. -

What are the typical minimum order quantities (MOQs) for polyurethane materials?

Minimum order quantities for polyurethane materials can vary significantly based on the type of product and supplier. Generally, MOQs can range from 100 kg for standard products to several tons for custom formulations. It’s advisable to discuss MOQs upfront to avoid any misunderstandings. Smaller businesses may benefit from pooling orders with other buyers to meet MOQ requirements or negotiating with suppliers for flexibility. -

What payment terms should I expect when purchasing polyurethane materials?

Payment terms for polyurethane materials typically range from 30% upfront and 70% upon delivery, to net 30 or net 60 days after receipt of goods. Some suppliers may offer discounts for early payments or flexible financing options for larger orders. Be sure to clarify payment terms during negotiations and consider using letters of credit for international transactions to safeguard your investment. -

How can I ensure reliable logistics for international shipments of polyurethane materials?

To ensure reliable logistics, partner with experienced freight forwarders who specialize in international shipping of industrial materials. Discuss shipping options, including air freight for urgent deliveries or sea freight for cost-effective bulk shipments. Confirm that your supplier has experience with export documentation and customs clearance procedures in your destination country. Establish clear timelines for delivery and stay in communication throughout the shipping process to mitigate potential delays. -

What certifications should I look for in polyurethane suppliers?

When sourcing polyurethane materials, look for suppliers with certifications that demonstrate adherence to international quality standards, such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Additionally, check for compliance with specific industry standards relevant to your application, such as REACH for chemical safety in Europe or UL certifications for fire safety. These certifications can provide assurance of the supplier’s commitment to quality and sustainability. -

How do I evaluate the environmental impact of polyurethane materials?

To assess the environmental impact of polyurethane materials, inquire about the supplier’s production processes and raw material sourcing. Look for products that are CFC-free, HCFC-free, and use renewable resources. Suppliers committed to sustainability often provide documentation on lifecycle assessments (LCA) and eco-labels. Engaging with suppliers who focus on reducing waste and energy consumption during production can help align your sourcing decisions with your company’s sustainability goals.

Top 4 Polyurethane Material Manufacturers & Suppliers List

1. Mitchell Faux Leathers – Polyurethane Imitation Leather

Domain: mitchellfauxleathers.com

Registered: 2011 (14 years)

مقدمة: Polyurethane (PU) is a composite material made of polymer resins and a textile backing, providing a realistic imitation of leather. It is water resistant, lightweight, and flexible, with a soft hand that mimics real leather. PU does not require plasticizers, preventing cracking and peeling, and remains supple over time. It is considered greener than vinyl and is less expensive than real leather bu…

2. Neckog – Polyurethanes Solutions

Domain: neckog.com

Registered: 2019 (6 years)

مقدمة: Polyurethanes (PUR or PU) are synthetic polymers created through a chemical reaction between polyols and diisocyanates. They are known for their versatility, durability, and adaptability, making them suitable for various applications across multiple industries. Key characteristics include:

– Versatility: Can mimic properties of rubber, plastic, or foam.

– Durability: Excellent resistance to abrasi…

3. Xometry – Polypropylene Insights

Domain: xometry.com

Registered: 2015 (10 years)

مقدمة: Polypropylene vs. Polyurethane: Material Differences and Comparisons

Polypropylene:

– Type: Thermoplastic

– Manufacturing Process: Polymerization of propylene monomers

– Applications: Belt covers, living hinges, textiles, container lids, buffers, bottles, toys, wire insulation

– Chemical Resistance: High

– Tensile Strength: 4,800 psi

– Density: 0.90-0.92 g/cm3

– Impact Tolerance: Good

– Water Abs…

4. Got Urethane – Polyurethane Solutions

Domain: goturethane.com

Registered: 2000 (25 years)

مقدمة: Polyurethane is a versatile material used across various industries, including automotive, packaging, apparel, flooring, aquatics, medical, composite wood, and electronics. It comes in two main types: polyester and polyether, each with unique properties. Key types of polyurethane include: 1. Flexible Polyurethane Foam: Used for cushioning in furniture, mattresses, and vehicle interiors. 2. Rigid P…

Strategic Sourcing Conclusion and Outlook for polyurethane material

In the evolving landscape of polyurethane materials, strategic sourcing remains a pivotal factor for businesses aiming to enhance product quality and sustainability. The versatility of polyurethane, from insulation in building materials to cushioning in furniture and automotive applications, underscores its importance across various industries. Buyers should prioritize suppliers who not only offer a diverse range of polyurethane products but also demonstrate a commitment to eco-friendly manufacturing processes, as sustainability is increasingly becoming a key purchasing criterion.

Furthermore, as global supply chains continue to adapt to market fluctuations, establishing strong relationships with reliable polyurethane manufacturers can lead to improved cost efficiency and product innovation. Buyers in Africa, South America, the Middle East, and Europe, particularly in regions such as Saudi Arabia and Germany, are encouraged to leverage this opportunity to optimize their sourcing strategies.

Looking ahead, the polyurethane industry is poised for further advancements in energy-efficient production and innovative applications. By actively engaging with suppliers who prioritize sustainability and technological innovation, international B2B buyers can not only meet current market demands but also position themselves as leaders in their respective sectors. Take the next step in your sourcing journey today—explore the myriad opportunities within the polyurethane market and secure a competitive advantage for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.