Introduction: Navigating the Global Market for sneaker lining

When sourcing sneaker lining, international B2B buyers face the challenge of balancing quality, comfort, and cost-effectiveness. The right lining not only enhances the overall comfort of the sneaker but also plays a crucial role in durability and breathability. This guide serves as a comprehensive resource, delving into various types of sneaker linings—from luxurious leather to synthetic options like Cambrelle—each with distinct characteristics tailored to meet specific market needs.

We will explore the applications of different linings in various sneaker designs, providing insights into how these materials can enhance performance and consumer satisfaction. Additionally, the guide will outline essential criteria for vetting suppliers, ensuring that buyers can identify reliable partners who meet their quality and ethical standards. Cost considerations, including sourcing strategies and negotiation tips, will also be addressed to empower buyers to make informed purchasing decisions.

Designed specifically for B2B buyers in Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—this guide equips you with the knowledge needed to navigate the global sneaker lining market effectively. By understanding the nuances of material selection and supplier evaluation, you can enhance your product offerings and ultimately drive your business success.

Table Of Contents

- Top 5 Sneaker Lining Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for sneaker lining

- Understanding sneaker lining Types and Variations

- Key Industrial Applications of sneaker lining

- 3 Common User Pain Points for ‘sneaker lining’ & Their Solutions

- Strategic Material Selection Guide for sneaker lining

- In-depth Look: Manufacturing Processes and Quality Assurance for sneaker lining

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘sneaker lining’

- Comprehensive Cost and Pricing Analysis for sneaker lining Sourcing

- Alternatives Analysis: Comparing sneaker lining With Other Solutions

- Essential Technical Properties and Trade Terminology for sneaker lining

- Navigating Market Dynamics and Sourcing Trends in the sneaker lining Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sneaker lining

- Strategic Sourcing Conclusion and Outlook for sneaker lining

- Important Disclaimer & Terms of Use

Understanding sneaker lining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Lining | Breathable, moisture-wicking, odor-controlling properties | High-end sneakers, luxury footwear | Pros: Durable, comfortable, premium feel. Cons: Higher cost, may require more care. |

| Fleece Lining | Soft, warm, and cozy; mimics natural fibers | Casual wear, winter footwear | Pros: Comfort, insulation. Cons: Bulkiness, not ideal for refined designs. |

| Polyester Lining | Cost-effective, but lacks breathability | Budget sneakers, mass-market shoes | Pros: Affordable, widely available. Cons: Poor moisture management, can cause odors. |

| Cotton Lining | Naturally breathable and hypoallergenic | Casual shoes, slippers | Pros: Soft, comfortable, hypoallergenic. Cons: Absorbs moisture, can lead to odor if not dried. |

| Cambrelle Lining | Synthetic, antifungal, and antibacterial properties | Sports shoes, heavy-duty footwear | Pros: Moisture-wicking, durable. Cons: Limited aesthetic appeal, primarily functional. |

What Are the Characteristics of Leather Lining in Sneakers?

Leather lining is often favored for high-end sneakers due to its inherent properties such as breathability, moisture-wicking, and odor control. Full-grain leather, in particular, offers a luxurious feel and durability, making it suitable for premium footwear brands targeting discerning consumers. B2B buyers should consider sourcing 100% full-grain leather to ensure quality, as blended materials may compromise performance and comfort. While the initial investment may be higher, the long-term benefits of leather lining can enhance customer satisfaction and brand reputation.

How Does Fleece Lining Enhance Comfort in Sneakers?

Fleece lining provides a soft and cozy interior, making it a popular choice for casual and winter sneakers. Its plush texture offers warmth, ideal for colder climates. However, its bulkiness may not be suitable for more refined sneaker designs. B2B buyers should weigh the comfort benefits against potential design limitations, especially if targeting a fashion-forward market. Sourcing eco-friendly fleece options can also appeal to environmentally conscious consumers, adding value to the product line.

Why Is Polyester Lining Commonly Used in Budget Sneakers?

Polyester lining is a widely used material in budget sneakers due to its cost-effectiveness and availability. However, it lacks breathability, often leading to moisture retention and unpleasant odors. This makes it less suitable for high-performance or luxury sneakers. B2B buyers should consider the target market when opting for polyester linings, as the trade-off between price and quality can significantly impact customer satisfaction. Offering alternatives or upgrades in moisture management can differentiate products in a competitive market.

What Are the Benefits and Drawbacks of Cotton Lining?

Cotton lining is appreciated for its natural breathability and hypoallergenic properties, making it a good choice for casual shoes and slippers. However, it absorbs moisture, which can lead to discomfort and odor if not properly managed. B2B buyers should consider the intended use of the footwear when selecting cotton lining, as it may be best suited for open-back designs that allow for air circulation. Offering cotton-lined options can cater to consumers seeking comfort and natural materials, enhancing product appeal.

How Does Cambrelle Lining Perform in Sports Footwear?

Cambrelle lining is a synthetic material known for its antifungal and antibacterial properties, making it ideal for sports and heavy-duty footwear. It excels in moisture management, helping to keep feet dry during rigorous activities. B2B buyers should consider Cambrelle for performance-oriented sneaker lines, especially in markets focused on athletic and outdoor footwear. Its durability and functional benefits can justify a higher price point, appealing to consumers seeking reliable performance in their footwear.

Key Industrial Applications of sneaker lining

| Industry/Sector | Specific Application of sneaker lining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | High-performance athletic shoes | Enhanced comfort and durability, leading to customer satisfaction | Material quality, breathability, moisture-wicking properties |

| Fashion Retail | Casual sneakers for lifestyle brands | Trendy designs with comfort, appealing to a broader customer base | Aesthetic appeal, variety of materials, and customization options |

| Sports & Recreation | Outdoor and hiking footwear | Improved performance and foot health in rugged conditions | Abrasion resistance, moisture control, and temperature regulation |

| Medical & Orthopedic Footwear | Therapeutic sneakers for foot health | Supports foot health, reduces injury risk, and enhances patient comfort | Antimicrobial properties, cushioning, and flexibility |

| DIY Shoemaking | Custom sneaker lining for personalized footwear | Unique product offerings, catering to niche markets | Versatility of materials, ease of use, and compatibility with various shoe designs |

How is sneaker lining used in footwear manufacturing?

In the footwear manufacturing sector, sneaker lining plays a crucial role in the production of high-performance athletic shoes. The right lining materials enhance comfort and durability, addressing common issues such as foot fatigue and moisture retention. Buyers from regions with diverse climates, like Africa and the Middle East, must prioritize breathable and moisture-wicking linings to ensure foot health in hot environments. Additionally, sourcing durable materials that withstand rigorous use is essential for maintaining product quality.

What applications exist for sneaker lining in fashion retail?

In the fashion retail industry, sneaker lining is integral to the production of casual sneakers, which combine style with comfort. Brands targeting younger demographics require linings that not only provide comfort but also align with current fashion trends. Buyers should look for customizable options in linings to create unique designs that stand out in competitive markets like Europe and South America. The aesthetic appeal, alongside the comfort provided by quality linings, can significantly influence customer purchasing decisions.

How does sneaker lining benefit outdoor and hiking footwear?

For outdoor and hiking footwear, sneaker lining is essential for enhancing performance and ensuring foot health in challenging environments. Linings that offer abrasion resistance, moisture control, and temperature regulation are crucial for maintaining comfort during long treks. B2B buyers in regions with rugged terrains, such as parts of Africa and South America, should focus on sourcing linings that can withstand extreme conditions while providing adequate support and breathability.

What role does sneaker lining play in medical and orthopedic footwear?

In the medical and orthopedic footwear sector, sneaker lining is vital for creating therapeutic sneakers that support foot health. These linings often feature antimicrobial properties and cushioning to reduce the risk of injury and enhance patient comfort. Buyers in the healthcare sector must ensure that the linings sourced are not only effective in promoting foot health but also comply with medical standards. This is particularly important for international buyers who must navigate varying regulatory environments.

Why is sneaker lining significant for DIY shoemaking?

In the DIY shoemaking industry, sneaker lining materials are essential for creating personalized footwear. Customization allows consumers to express their individuality and cater to niche markets. Buyers should consider the versatility and ease of use of lining materials, as well as their compatibility with various shoe designs. Sourcing quality linings can facilitate a smoother production process and lead to unique product offerings that resonate with customers seeking bespoke solutions.

3 Common User Pain Points for ‘sneaker lining’ & Their Solutions

Scenario 1: Sourcing Quality Materials for Durable Sneaker Lining

The Problem: B2B buyers often face the challenge of sourcing high-quality sneaker linings that meet both durability and comfort standards. In regions such as Africa and South America, where local supply chains may be underdeveloped, it can be difficult to find materials that are both cost-effective and reliable. Buyers may encounter low-quality polyester linings that lack breathability, leading to discomfort for end-users and increased returns.

The Solution: To overcome this issue, buyers should prioritize sourcing from reputable manufacturers who specialize in high-performance materials. When considering sneaker lining options, look for suppliers who offer a variety of materials such as full-grain leather, Cambrelle, or high-quality synthetic blends. These materials not only provide the necessary durability and comfort but also enhance the overall sneaker experience. Establishing partnerships with local distributors who can guarantee quality checks and offer samples can further ensure that the materials meet the required specifications. It’s also advisable to perform on-site inspections or audits of production facilities to validate the sourcing claims and ensure consistent quality.

Scenario 2: Addressing Moisture Management in Sneaker Linings

The Problem: Another significant pain point for B2B buyers is managing moisture within sneakers. In humid climates, such as those found in parts of the Middle East or Southeast Asia, moisture retention can lead to unpleasant odors and bacterial growth, negatively affecting product longevity and customer satisfaction. Buyers often struggle to find lining materials that effectively wick away moisture without compromising comfort.

The Solution: Buyers should focus on sourcing linings with superior moisture-wicking properties. Materials like Cambrelle or specialized polyester blends designed for breathability can be excellent choices. Additionally, incorporating a moisture management system within the sneaker design can further enhance performance. This could involve integrating breathable mesh panels or perforated linings that allow air circulation. Providing education and guidelines to manufacturers on moisture management technologies will also empower them to produce more effective sneaker linings. Consider collaborating with material scientists or industry experts who can offer insights into advanced moisture-wicking technologies.

Scenario 3: Ensuring Eco-Friendliness in Sneaker Linings

The Problem: With increasing consumer demand for sustainable products, B2B buyers are under pressure to source eco-friendly sneaker linings. Many traditional materials, such as synthetic polyesters, contribute to environmental degradation, and buyers are often uncertain about how to transition to more sustainable options without inflating costs.

The Solution: Transitioning to eco-friendly sneaker linings can be achieved by exploring materials made from recycled fibers or natural options like organic cotton or hemp. Buyers should seek out suppliers who adhere to sustainability certifications, such as GOTS (Global Organic Textile Standard) or OEKO-TEX, which ensure that materials are environmentally friendly. Additionally, engaging with suppliers who are innovating in the space of biodegradable linings can present new opportunities. To offset costs, consider bulk purchasing agreements or long-term contracts with suppliers, which can yield discounts while supporting sustainable practices. Educating end consumers about the benefits of eco-friendly materials can also enhance brand value and customer loyalty, making the investment worthwhile.

Strategic Material Selection Guide for sneaker lining

What Are the Key Properties of Common Sneaker Lining Materials?

When selecting materials for sneaker linings, it is crucial to understand their properties, pros and cons, and how they align with the specific needs of different markets. Here, we analyze four common materials used in sneaker linings: leather, polyester, cotton, and Cambrelle.

How Does Leather Perform as a Sneaker Lining Material?

Leather is a premium choice for sneaker linings due to its natural properties. It offers excellent breathability, moisture-wicking capabilities, and temperature regulation, making it ideal for comfort during wear. Leather linings are typically durable and resistant to wear, which is essential for high-quality sneakers.

Pros: Leather provides a luxurious feel and is naturally odor-controlling. It is also flexible, allowing for a comfortable fit.

Cons: The primary drawback is the higher cost compared to synthetic alternatives. Additionally, leather requires more complex manufacturing processes, which may not be suitable for all production scales.

Impact on Application: Leather is well-suited for premium sneaker lines targeting consumers who prioritize comfort and quality.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for leather quality. Preferences may vary by region, with European markets often favoring full-grain leather.

What Are the Characteristics of Polyester as a Sneaker Lining?

Polyester is a widely used synthetic material in sneaker linings, known for its cost-effectiveness and availability. It is lightweight and can be manufactured in various textures, making it versatile for different sneaker designs.

Pros: The primary advantage of polyester is its affordability and ease of production. It can also be treated for additional properties such as moisture resistance.

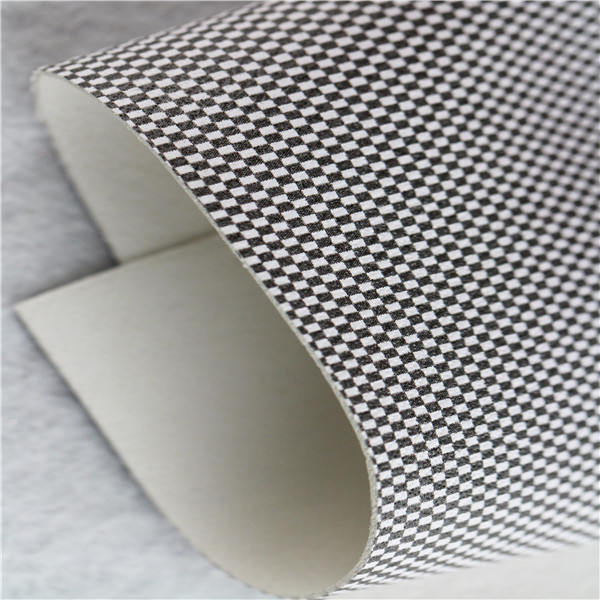

Illustrative image related to sneaker lining

Cons: However, polyester does not breathe well, which can lead to moisture buildup and discomfort. Its durability is also inferior to natural materials like leather.

Impact on Application: Polyester linings are commonly found in budget-friendly sneakers aimed at mass markets.

Considerations for International Buyers: Buyers should be aware of potential environmental regulations concerning synthetic materials, especially in regions like Europe, where sustainability is a growing concern.

How Does Cotton Compare as a Sneaker Lining Material?

Cotton linings are valued for their hypoallergenic properties and natural breathability. They are a good insulator, making them suitable for cooler climates.

Pros: Cotton is soft, comfortable, and less likely to irritate the skin, appealing to consumers with sensitivities.

Cons: The main limitation is that cotton absorbs moisture without releasing it, which can lead to dampness and odor if not properly managed.

Impact on Application: Cotton is best suited for casual sneakers or slippers rather than performance footwear.

Considerations for International Buyers: Compliance with textile standards is essential, and buyers should consider regional preferences for natural fibers, particularly in markets that prioritize sustainability.

What Advantages Does Cambrelle Offer as a Sneaker Lining Material?

Cambrelle is a synthetic lining made from nylon, known for its moisture-wicking and antibacterial properties. It is often used in athletic and work footwear due to its durability and comfort.

Pros: Cambrelle is highly breathable and dries quickly, making it ideal for active use. Its resistance to bacteria also enhances foot health.

Cons: The main downside is that Cambrelle can be more expensive than traditional polyester, which may deter budget-conscious buyers.

Illustrative image related to sneaker lining

Impact on Application: Cambrelle is ideal for performance-oriented sneakers, particularly in markets focused on sports and outdoor activities.

Considerations for International Buyers: Buyers should look for compliance with performance standards, especially in regions like Europe and North America, where stringent testing is common.

Summary Table of Sneaker Lining Materials

| المواد | Typical Use Case for sneaker lining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Premium sneakers | Breathable and moisture-wicking | Higher cost and complex manufacturing | عالية |

| Polyester | Budget-friendly sneakers | Cost-effective and versatile | Poor breathability and durability | منخفضة |

| Cotton | Casual sneakers and slippers | Hypoallergenic and comfortable | Absorbs moisture, leading to dampness | Med |

| Cambrelle | Athletic and performance footwear | Moisture-wicking and antibacterial | Higher cost compared to polyester | Med-High |

This guide aims to equip international B2B buyers with the insights needed to make informed decisions regarding sneaker lining materials, considering both product performance and regional market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for sneaker lining

What Are the Key Stages in the Manufacturing Process of Sneaker Linings?

The manufacturing process for sneaker linings involves several critical stages, ensuring that the final product meets both functional and aesthetic requirements. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Sneaker Linings?

Material preparation is the first step in the manufacturing process. It involves selecting the appropriate lining materials, which can range from natural fibers like leather to synthetic options such as polyester or Cambrelle. Each material has distinct properties—leather offers breathability and moisture-wicking capabilities, while polyester is cost-effective but may lack breathability.

Illustrative image related to sneaker lining

Once the materials are chosen, they undergo pre-treatment processes, such as cutting to size and applying any necessary coatings for durability. Quality control begins at this stage, where inspections ensure that the materials meet specific standards for strength, flexibility, and breathability.

What Techniques Are Used in Forming Sneaker Linings?

The forming stage involves shaping the lining materials to fit the design specifications of the sneaker. Key techniques include die-cutting, where precise shapes are cut from sheets of material, and molding, which is often used for synthetic linings that require specific shapes or contours.

Advanced technologies, such as laser cutting, may also be employed for intricate designs, ensuring precision and reducing waste. This stage is crucial for achieving a snug fit, which enhances comfort and performance for the end-user.

How Are Sneaker Linings Assembled?

Assembly is the next crucial phase, where the formed linings are integrated into the sneaker structure. This process often involves sewing or bonding the linings to the upper part of the sneaker. Depending on the material, manufacturers may use adhesives or stitching techniques to secure the lining effectively.

Illustrative image related to sneaker lining

Attention to detail is paramount during assembly, as any imperfections can lead to discomfort or reduced durability. Manufacturers may implement automated systems to streamline this process, ensuring consistency and efficiency while maintaining high-quality standards.

What Are the Finishing Steps in Sneaker Lining Production?

Finishing touches are applied after assembly to enhance the overall quality of the sneaker lining. This may include additional treatments such as waterproofing, UV protection, or odor control, depending on the intended use of the sneaker.

Quality checks during this phase involve inspecting the final product for any defects, ensuring that the linings are free from wrinkles, tears, or other flaws that could affect performance. Once the finishing touches are complete, the sneakers are ready for packaging and distribution.

How Is Quality Assurance Implemented in Sneaker Lining Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the sneaker linings meet both international standards and customer expectations.

What International Standards Are Relevant for Sneaker Lining Quality Control?

International standards such as ISO 9001 play a significant role in establishing quality management systems within manufacturing processes. Compliance with ISO 9001 ensures that manufacturers maintain consistent quality in their products and services, fostering trust among B2B buyers.

In addition to ISO standards, industry-specific certifications such as CE (for products sold in Europe) and API (for certain performance criteria) may also apply, depending on the target market for the sneakers. These certifications ensure that the products adhere to safety and performance regulations, which are particularly crucial for international B2B buyers.

What Are the Key Quality Control Checkpoints During Production?

Quality control checkpoints are strategically placed throughout the manufacturing process to monitor and verify the quality of the sneaker linings. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During production, random samples are tested to detect any deviations from quality standards. This stage helps identify issues early, allowing for timely corrective actions.

- Final Quality Control (FQC): After finishing, a thorough inspection of the final product is conducted to ensure all specifications are met before the product is shipped.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers employ various testing methods to assess the quality and performance of sneaker linings. Common tests include:

- Breathability Tests: Measuring the material’s ability to allow air and moisture to pass through.

- Durability Tests: Assessing the lining’s resistance to wear and tear under simulated conditions.

- Comfort Tests: Evaluating how the lining feels against the skin, which is crucial for customer satisfaction.

These tests help manufacturers identify potential weaknesses in the lining materials and make necessary adjustments to improve overall quality.

Illustrative image related to sneaker lining

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are some effective methods:

What Role Do Audits Play in Supplier Quality Verification?

Conducting regular audits of suppliers is an essential practice for B2B buyers. These audits can be either announced or unannounced, providing insights into the supplier’s manufacturing processes, quality control measures, and compliance with international standards. Buyers should request copies of audit reports and certifications to assess the supplier’s commitment to quality.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These inspections typically occur at various stages of production and can help identify any non-conformities that may not be evident during internal audits.

Buyers should consider building relationships with reputable inspection agencies that specialize in the footwear industry, ensuring that the inspections are thorough and reliable.

Illustrative image related to sneaker lining

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial. Different regions may have varying standards and expectations regarding materials and manufacturing practices. For instance, buyers from Europe may prioritize compliance with CE standards, while those from Africa or South America might focus on cost-effectiveness and sustainability.

Buyers should also consider the logistical challenges of sourcing materials globally, including shipping times and customs regulations. Establishing clear communication with suppliers about quality expectations and requirements is vital for successful partnerships.

In conclusion, the manufacturing and quality assurance processes for sneaker linings are intricate and multifaceted. By understanding these processes and implementing effective quality verification methods, B2B buyers can ensure they source high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sneaker lining’

The following guide serves as a comprehensive checklist for B2B buyers seeking to procure sneaker lining materials. This structured approach will help ensure that you make informed decisions that align with your business needs and consumer expectations.

Illustrative image related to sneaker lining

Step 1: Define Your Technical Specifications

Understanding your specific requirements for sneaker lining is crucial. Consider factors such as breathability, moisture-wicking properties, durability, and comfort. Each type of lining material offers different characteristics, so outline what is essential for your target market, whether it’s athletic performance or luxury comfort.

- Breathability: Essential for active footwear to prevent moisture build-up.

- Durability: Choose materials that withstand wear and tear, especially for high-use sneakers.

Step 2: Research Available Lining Materials

Familiarize yourself with the various types of lining materials available in the market. Common options include leather, fleece, polyester, cotton, and specialized synthetic materials like Cambrelle. Each material has distinct advantages and disadvantages that can impact the performance and comfort of the final product.

- Leather: Offers natural breathability and moisture control, ideal for premium sneakers.

- Polyester: Often found in budget models but lacks breathability, which can lead to discomfort.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, client references, and case studies. Ensure they have a proven track record in providing high-quality materials that meet your specifications.

- Certifications: Verify if the supplier holds industry certifications that ensure material quality and safety standards.

- Samples: Request samples of the lining material to assess quality firsthand.

Step 4: Assess Cost vs. Quality

Balancing cost with quality is a critical aspect of sourcing sneaker lining. While cheaper options may be tempting, they can lead to higher long-term costs due to poor performance or customer dissatisfaction. Calculate the total cost of ownership, including potential returns or replacements.

- Long-Term Value: Invest in materials that enhance product longevity and customer satisfaction.

- Bulk Discounts: Inquire about bulk purchasing options to reduce per-unit costs without compromising quality.

Step 5: Understand Minimum Order Quantities (MOQs)

Different suppliers have varying MOQs, which can affect your production planning. Ensure you understand these requirements and how they align with your production capacity and sales forecasts.

Illustrative image related to sneaker lining

- Flexibility: Look for suppliers willing to negotiate MOQs, especially for new or smaller businesses.

- Inventory Management: Consider how MOQs will impact your inventory and cash flow.

Step 6: Verify Delivery Timelines and Logistics

Understanding the supplier’s delivery timelines is essential for maintaining your production schedule. Confirm their logistics capabilities and reliability in meeting deadlines, particularly if you are sourcing internationally.

- Shipping Options: Explore different shipping methods to balance cost and speed.

- Customs and Duties: Be aware of any potential customs implications when sourcing from overseas suppliers.

Step 7: Review Quality Control Processes

Inquire about the supplier’s quality control measures. A robust quality assurance process can mitigate risks associated with material defects, ensuring that your final product meets both safety and performance standards.

- Testing Procedures: Ask for details on how they test their materials for durability and safety.

- Feedback Mechanisms: Understand how they handle quality issues and customer feedback.

By following this checklist, B2B buyers can strategically approach the sourcing of sneaker lining, ensuring a successful partnership with suppliers that align with their business goals.

Comprehensive Cost and Pricing Analysis for sneaker lining Sourcing

What Are the Key Cost Components for Sneaker Lining Sourcing?

When sourcing sneaker linings, understanding the cost structure is essential. The primary cost components include:

-

Materials: The choice of lining material significantly influences cost. Leather linings, especially full-grain varieties, tend to be more expensive than synthetic options like polyester or cotton. High-quality materials enhance durability and comfort, which can justify higher costs.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. Regions with lower labor costs can offer competitive pricing; however, the quality of workmanship is crucial for product longevity and performance.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can lower these costs, impacting the final price.

-

Tooling: Initial tooling costs for custom designs can be substantial. For buyers requiring unique specifications, these costs should be factored into the total pricing.

-

Quality Control (QC): Rigorous QC processes ensure the linings meet specified standards. Investing in QC can prevent costly returns and enhance brand reputation.

-

Logistics: Shipping and handling costs can vary based on the origin of the materials, destination, and chosen transport method. International buyers should be aware of potential delays and additional charges.

-

Margin: Suppliers typically include a profit margin that reflects their business model and market conditions. This margin can vary based on competition and the supplier’s operational efficiency.

How Do Price Influencers Affect Sneaker Lining Costs?

Several factors influence the pricing of sneaker linings:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Negotiating minimum order quantities (MOQs) can yield better pricing for larger purchases.

-

Specifications and Customization: Customized linings or specific material requests can increase costs. Buyers should balance the need for customization with budget constraints.

-

Material Quality and Certifications: Higher quality materials, such as certified organic or sustainably sourced options, can elevate costs. Certifications may also add to the price but can enhance marketability.

-

Supplier Factors: Supplier reputation, reliability, and production capacity can influence pricing. Established suppliers may command higher prices due to perceived quality and service levels.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for cost management. Different terms can affect shipping costs and responsibilities, impacting the overall price.

What Buyer Tips Can Help Optimize Sneaker Lining Sourcing Costs?

International B2B buyers should consider the following strategies to enhance cost efficiency:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Building long-term relationships can lead to better terms and conditions.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial costs to consider the long-term implications of sourcing decisions. Higher quality linings may incur higher upfront costs but can lead to reduced returns and improved customer satisfaction.

-

Understand Pricing Nuances: Different regions have varying pricing structures due to local economic conditions, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should research local market dynamics to make informed decisions.

-

Stay Informed on Market Trends: Keeping abreast of material innovations and pricing trends can provide leverage in negotiations and sourcing strategies.

Disclaimer on Indicative Prices

Pricing for sneaker linings can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is advisable for buyers to request detailed quotes and conduct thorough market research to obtain accurate pricing information.

Illustrative image related to sneaker lining

Alternatives Analysis: Comparing sneaker lining With Other Solutions

Exploring Alternatives to Sneaker Lining Solutions

When evaluating sneaker lining options, it is essential to consider alternative solutions that can serve similar functions while varying in performance, cost, and application. This comparative analysis will provide B2B buyers with insights into the strengths and weaknesses of sneaker linings against alternative materials and technologies.

| Comparison Aspect | Sneaker Lining | Leather Lining | Synthetic Mesh Lining |

|---|---|---|---|

| Performance | Breathable, moisture-wicking, odor-resistant | Excellent breathability, moisture control, premium feel | Lightweight, good breathability, quick-drying |

| Cost | Mid-range, varies by material | Generally higher cost | Lower cost, widely available |

| Ease of Implementation | Requires skilled labor for installation | Complex, requires craftsmanship | Easy to implement, suitable for mass production |

| Maintenance | Moderate; requires regular care | High; needs conditioning | Low; easy to clean and maintain |

| Best Use Case | Sports, casual wear, performance footwear | Dress shoes, high-end casual wear | Athletic shoes, budget-friendly designs |

In-Depth Analysis of Alternative Solutions

Leather Lining

Leather linings are renowned for their superior breathability and moisture control, making them ideal for high-quality footwear. They offer a premium feel and can help regulate temperature and moisture, enhancing comfort for the wearer. However, the cost is significantly higher, which may not be feasible for all manufacturers. The complexity of implementing leather linings requires skilled labor and craftsmanship, often leading to longer production times. Additionally, they demand more maintenance to preserve their quality, which can be a drawback for brands looking to minimize after-sales service.

Synthetic Mesh Lining

Synthetic mesh linings present a budget-friendly alternative that excels in lightweight applications. They are often designed to be quick-drying and provide good breathability, making them suitable for athletic shoes or casual wear. The ease of implementation allows for mass production, catering to high-volume needs. While synthetic mesh is low-maintenance, it may not offer the same durability or moisture-wicking properties as sneaker lining or leather options. Furthermore, synthetic materials can sometimes lead to unpleasant odors due to moisture retention, which can affect the user experience over time.

Illustrative image related to sneaker lining

Making the Right Choice for Your Footwear Needs

When selecting the appropriate lining solution for sneakers, B2B buyers must consider their target market, production capabilities, and budget constraints. Sneaker linings offer a balanced approach with moderate costs and performance, making them suitable for a variety of applications. However, if the focus is on luxury and performance, leather linings may be the ideal choice despite their higher costs and maintenance requirements. Conversely, for high-volume production with budget constraints, synthetic mesh lining could be the most practical option.

Ultimately, understanding the specific needs of your footwear line will guide you in making an informed decision that aligns with your business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for sneaker lining

What Are the Key Technical Properties of Sneaker Lining?

When evaluating sneaker linings, several critical properties significantly impact both product performance and buyer satisfaction. Understanding these properties helps B2B buyers make informed decisions.

1. Material Grade

Material grade refers to the quality and composition of the lining material used in sneakers. Common materials include leather, polyester, cotton, and synthetic blends. High-grade materials like full-grain leather offer superior breathability and moisture-wicking properties, which are essential for comfort and foot health. For B2B buyers, selecting the right material grade can enhance the overall quality of the footwear and meet customer expectations regarding comfort and durability.

2. Abrasion Resistance

Abrasion resistance measures how well a material can withstand wear and tear from friction. For sneaker linings, high abrasion resistance is crucial, especially in athletic or work-related footwear. This property helps maintain the lining’s integrity over time, reducing the need for replacements and ensuring customer satisfaction. B2B buyers should prioritize abrasion-resistant materials to ensure longevity and minimize returns.

3. Moisture Management

Moisture management encompasses the lining’s ability to wick away sweat and maintain a dry environment for the foot. Materials with high moisture-wicking capabilities, such as Cambrelle or high-quality leather, help prevent odor and bacterial growth. For B2B buyers, selecting linings with excellent moisture management properties can improve the user experience and appeal to health-conscious consumers.

4. Flexibility and Comfort

Flexibility refers to how easily the lining conforms to foot movements without compromising support. Comfortable linings are typically soft and pliable, allowing for a natural range of motion. B2B buyers must consider flexibility as a key specification since it directly impacts the wearer’s comfort and overall satisfaction with the sneaker.

5. Breathability

Breathability is the ability of a material to allow air circulation, helping to regulate temperature and reduce moisture buildup. Linings that offer breathability are essential for comfort, particularly in warmer climates or for athletic use. B2B buyers should assess breathability ratings to ensure that their products meet customer demands for comfort and performance.

What Are Common Trade Terms Related to Sneaker Lining?

Understanding industry terminology is vital for effective communication and negotiation in the sneaker lining market. Here are several essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are later marketed under another company’s brand. In the sneaker industry, OEM suppliers may provide linings that footwear brands incorporate into their designs. B2B buyers often engage with OEMs to ensure they receive high-quality materials tailored to their specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and initial costs. Understanding MOQ can help businesses plan their purchases and ensure they meet production demands without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to solicit pricing and terms for specific products. In the context of sneaker linings, an RFQ can help buyers compare different suppliers, negotiate prices, and finalize deals. Crafting a well-defined RFQ can streamline the procurement process and lead to more favorable terms.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping and delivery. Understanding these terms is essential for B2B buyers engaging in international trade, as they clarify who bears the costs and risks associated with transporting sneaker linings. Familiarity with Incoterms can help avoid misunderstandings and ensure smoother transactions.

Illustrative image related to sneaker lining

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For sneaker linings, lead time can vary based on material availability and production schedules. B2B buyers should consider lead time when planning inventory and production schedules to avoid delays in product launches.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their sourcing strategies for sneaker linings, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the sneaker lining Sector

What Are the Current Market Dynamics and Key Trends in the Sneaker Lining Sector?

The global sneaker lining market is experiencing robust growth, driven by rising consumer awareness regarding comfort, performance, and aesthetics. Buyers from Africa, South America, the Middle East, and Europe are increasingly seeking high-quality materials that enhance sneaker durability and wearer comfort. Key trends include the integration of advanced materials, such as moisture-wicking textiles and breathable synthetics, which cater to the diverse climatic conditions across these regions. Moreover, the rise of e-commerce platforms is revolutionizing sourcing dynamics, allowing international buyers to access a broader range of suppliers and materials, often at competitive prices.

Emerging technologies, including 3D printing and smart textiles, are reshaping sneaker lining production. These innovations enable manufacturers to create customized linings that improve fit and performance while minimizing waste. Additionally, the demand for sustainable products is influencing sourcing decisions, with buyers increasingly favoring suppliers that employ eco-friendly practices. This shift is particularly notable in European markets, where regulatory frameworks are pushing for greater transparency and sustainability in supply chains.

How Is Sustainability Influencing Sourcing Decisions in the Sneaker Lining Sector?

Sustainability has become a critical factor in sourcing decisions for sneaker lining materials, as businesses recognize their environmental impact and the importance of ethical supply chains. The sneaker industry is notorious for its resource-intensive processes, leading to significant waste and pollution. As a result, international B2B buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as using recycled materials, reducing water consumption, and minimizing carbon footprints.

Illustrative image related to sneaker lining

The adoption of ‘green’ certifications, such as Global Organic Textile Standard (GOTS) and OEKO-TEX, is gaining traction among suppliers, providing buyers with assurance regarding the ecological integrity of their products. Additionally, innovative materials like bio-based synthetics and eco-friendly leathers are becoming popular choices for lining. These materials not only reduce environmental impact but also meet consumer demand for products that align with their values. By embracing sustainable sourcing, businesses can enhance their brand reputation and appeal to a growing segment of environmentally conscious consumers.

What Is the Brief Evolution of Sneaker Lining Materials?

The evolution of sneaker lining materials reflects broader trends in technology, consumer preferences, and sustainability. Historically, linings were predominantly made from basic textiles like cotton or polyester, which offered limited comfort and breathability. However, as footwear technology advanced, manufacturers began to explore more specialized materials, such as leather and synthetic blends, which provided enhanced performance attributes.

In recent years, the focus has shifted towards integrating advanced fabrics that improve moisture management, breathability, and comfort. This shift is accompanied by a growing emphasis on sustainability, prompting manufacturers to innovate with eco-friendly materials. The evolution of sneaker lining materials not only enhances the wearer’s experience but also aligns with the increasing demand for responsible and ethical sourcing practices in the global market.

Illustrative image related to sneaker lining

By understanding these dynamics, B2B buyers can make informed decisions that align with their business strategies and consumer expectations, positioning themselves for success in the competitive sneaker market.

Frequently Asked Questions (FAQs) for B2B Buyers of sneaker lining

-

How do I choose the right material for sneaker lining?

Selecting the right material for sneaker lining depends on several factors, including comfort, breathability, and durability. Leather linings are excellent for their moisture-wicking and temperature-regulating properties, making them ideal for high-end sneakers. For budget-friendly options, polyester linings may suffice but can lead to moisture retention. Consider the intended use of the sneakers; for sports, materials like Cambrelle offer moisture absorption and quick drying, while fleece provides warmth for casual wear. Always assess the specific needs of your target market to make an informed decision. -

What is the best type of lining for athletic sneakers?

For athletic sneakers, Cambrelle or mesh linings are often the best choices. Cambrelle is a synthetic material known for its exceptional moisture-wicking capabilities and breathability, making it ideal for high-performance footwear. Mesh linings provide lightweight comfort and ventilation, crucial for athletic use. Ensure that the lining material you select can withstand rigorous activity while maintaining comfort to cater to athletes’ needs effectively. -

How do I verify the quality of sneaker lining materials from suppliers?

To verify the quality of sneaker lining materials, request samples from potential suppliers. Assess the material for breathability, durability, and moisture-wicking properties. Additionally, inquire about certifications, such as ISO or ASTM standards, which indicate compliance with international quality benchmarks. Conducting factory audits or third-party inspections can further ensure that the supplier adheres to quality control practices. Finally, check references or reviews from other businesses to gauge the supplier’s reliability and product quality. -

What are the typical minimum order quantities (MOQs) for sneaker linings?

Minimum order quantities (MOQs) for sneaker linings can vary significantly depending on the supplier and material. Generally, MOQs can range from 100 to 1000 meters for fabric linings. For customized linings, MOQs may be higher due to the additional manufacturing processes involved. It’s advisable to negotiate MOQs based on your specific needs and discuss potential flexibility with the supplier, especially if you are a small to medium-sized business. -

What payment terms should I expect when sourcing sneaker lining materials?

Payment terms can vary by supplier and region. Common arrangements include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer net 30 or net 60 terms for established business relationships. It’s crucial to clarify payment methods accepted, such as bank transfers or letters of credit, and ensure that all terms are documented in the contract to avoid misunderstandings. -

How do I handle logistics and shipping for international sneaker lining orders?

When handling logistics for international sneaker lining orders, work closely with your supplier to determine the best shipping method, whether by air or sea, based on budget and urgency. Ensure that all customs documentation is prepared to avoid delays at the border. Consider partnering with a freight forwarder who specializes in international shipments to streamline the process and navigate any regulatory challenges. Always factor in shipping costs and delivery times in your overall sourcing strategy. -

What customization options are available for sneaker linings?

Many suppliers offer customization options for sneaker linings, including fabric type, colors, patterns, and thickness. Some manufacturers may provide additional features such as antimicrobial treatments or specific moisture-wicking capabilities. Discuss your design requirements with suppliers to understand the extent of customization they can accommodate. Be prepared to share detailed specifications and possibly pay higher costs for bespoke solutions, especially for small production runs. -

How can I ensure compliance with international trade regulations when sourcing sneaker linings?

To ensure compliance with international trade regulations, familiarize yourself with import/export laws in your country and those of your suppliers. Check for any tariffs or duties that may apply to the materials you are sourcing. It is also essential to verify that the materials meet safety and environmental standards in your target market, such as REACH or CPSIA compliance. Engaging a legal expert in international trade can help you navigate these regulations and avoid costly penalties.

Top 5 Sneaker Lining Manufacturers & Suppliers List

1. Beckett Simonon – Shoe Lining Guide

Domain: beckettsimonon.com

Registered: 2012 (13 years)

مقدمة: 5 Types of Shoe Lining: 1. Leather Shoe Lining: Breathable, odor-controlling, moisture-wicking, and temperature-regulating; ideal for sweaty feet and wearing without socks. Look for 100% full-grain leather. 2. Fleece Shoe Lining: Soft, warm, and cozy; made from recycled plastic or blended with natural fibers; not suitable for refined footwear. 3. Polyester Shoe Lining: Common in cheaply made shoes…

2. Shoemakers Academy – Black Polyester Shoe Lining Mesh

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

مقدمة: Product Name: Black Polyester Shoe Lining Mesh 5mm Foam Backed

Rating: 5.00 out of 5 based on 2 customer ratings

Price: $12 – $60

Material Composition: Black 5mm Lining Fabric + 5mm KFF Foam + Tricot Mesh

Size: 28″ x 14″ (120% larger than previous size)

Features: 3-layer sandwich construction (Polyester knit mesh, 5mm foam, smooth tricot backing), peel and stick backing for easy use, breathable

Av…

3. A&A – Sneaker Lining

Domain: aleatherstore.com

Registered: 2021 (4 years)

مقدمة: {“product_name”: “Sneaker Lining – A&A CRACK”, “price”: {“2 SQFT”: “$25.68”, “1/4 – 5 SQFT”: “$56.18”, “1/2 – 10 SQFT”: “$112.36”, “FULL – 20 SQFT”: “$208.68”}, “sizes_available”: [“2 SQFT”, “1/4 – 5 SQFT”, “1/2 – 10 SQFT”, “FULL – 20 SQFT”], “stock_status”: “Only 3 items in stock!”}

4. Bridges L – Faux Leather Shoe Lining Fabrics

Domain: bridgesl.com

Registered: 2015 (10 years)

مقدمة: Faux leather shoe lining fabrics suitable for different footwear; high-quality synthetic leather from selected manufacturers; optimum air permeability, moisture wicking property, temperature regulation, and physical comfort; manufactured with mixed materials for comfort and heat dissipation; includes distressed faux calfskin synthetic leather, water absorbent shoe lining without base PU fake leath…

5. Etsy – Interlock Jersey Lining Fabric

Domain: reddit.com

Registered: 2005 (20 years)

مقدمة: Lining fabric: Interlock jersey lining fabric, thin polyester with stretch, sourced from Etsy (link: https://www.etsy.com/uk/listing/995315403/interlock-jersey-lining-fabric). Collar/Tongue padding: 1/4 inch thick low density upholstery foam, sourced from eBay (link: https://www.ebay.co.uk/itm/154390453126?hash=item23f2635b86:g:OB4AAOSwh5Zcy~Gy).

Strategic Sourcing Conclusion and Outlook for sneaker lining

In today’s competitive footwear market, the choice of sneaker lining plays a pivotal role in product quality and customer satisfaction. B2B buyers must prioritize materials that not only enhance comfort but also offer durability, breathability, and moisture management. Understanding the various types of linings—such as leather, fleece, polyester, cotton, and Cambrelle—can significantly impact sourcing decisions. Each material presents unique advantages that cater to different consumer needs and preferences, making it essential to align your product offerings with market demands.

Strategic sourcing is vital for establishing reliable supply chains that ensure consistent quality and responsiveness to market trends. By engaging with reputable suppliers and manufacturers, businesses can optimize production costs while enhancing product performance. This approach not only supports sustainability initiatives but also fosters innovation in sneaker design.

As you look ahead, consider diversifying your sourcing strategies to include emerging markets in Africa, South America, the Middle East, and Europe. By tapping into these regions, you can access unique materials and manufacturing techniques that differentiate your products. Embrace the opportunity to innovate and expand your offerings, ensuring you remain competitive in the global sneaker industry.

Illustrative image related to sneaker lining

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.