Catalog

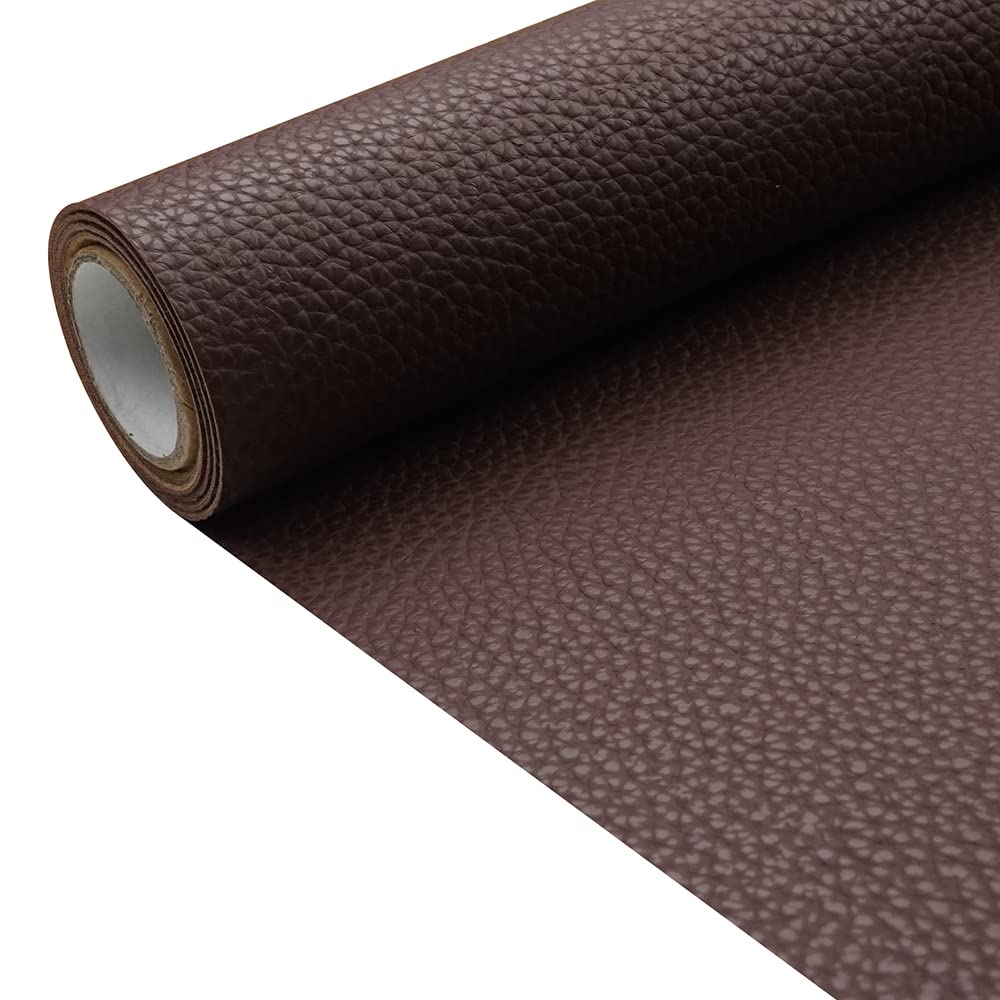

Material Insight: Roll Of Leather Material

B2B Product Guide: Roll of Faux Leather Material

Faux leather rolls have become a preferred material solution across a wide range of industries, including automotive interiors, furniture manufacturing, fashion accessories, and footwear production. Designed to deliver consistent quality, durability, and aesthetic versatility, roll-form faux leather provides manufacturers with a scalable and sustainable alternative to genuine leather. Supplied in continuous lengths, these rolls enable efficient cutting, minimal waste, and seamless integration into high-volume production lines.

- Offers uniform texture and thickness across the entire roll for reliable processing

- Available in customizable widths, thicknesses, and finishes to meet specific product requirements

- Resistant to abrasion, UV exposure, and environmental wear—ideal for long-term performance

- Easily compatible with automated cutting and lamination systems

Why Faux Leather Is the Best Choice for This Application

Faux leather outperforms traditional materials in both functionality and sustainability, making it the optimal choice for modern manufacturing demands.

- Consistency & Scalability: Unlike natural leather, which varies in grain and thickness, faux leather ensures batch-to-batch uniformity, critical for mass production.

- Cost-Effectiveness: Eliminates the high cost and scarcity associated with premium animal hides while maintaining a high-end appearance.

- Sustainability: Reduces reliance on animal agriculture and supports eco-conscious production with options in PU and recycled content formulations.

- Design Flexibility: Can be engineered to mimic exotic grains or deliver unique textures, colors, and performance properties such as water resistance or breathability.

نبذة عن WINIW

WINIW is a leading innovator in high-performance synthetic leather solutions, with over 20 years of industry expertise. Specializing in microfiber and PU-based materials, WINIW serves global B2B clients across automotive, furniture, apparel, and sports industries. Our commitment to quality, environmental responsibility, and technical excellence has positioned us as a trusted partner for brands seeking durable, ethical, and customizable leather alternatives.

- ISO-certified manufacturing with stringent quality control

- R&D-driven innovation focused on eco-friendly materials and advanced textures

- Global supply chain with reliable delivery and technical support

By combining decades of experience with forward-thinking material science, WINIW delivers faux leather rolls that meet the highest standards of performance, aesthetics, and sustainability.

Technical Performance & Standards

WINIW Premium Synthetic Leather Roll: Technical Product Guide for Industrial Applications

WINIW’s engineered synthetic leather rolls deliver a superior balance of performance, sustainability, and economic efficiency for B2B manufacturing partners. Designed for high-volume production in furniture, automotive, luggage, and apparel sectors, our material eliminates compromises between quality, compliance, and cost. Below are the core technical advantages driving ROI for forward-thinking manufacturers.

Key Technical Advantages

-

Cost-Effective Production

Optimized roll format (max. 50m/roll) minimizes material waste during cutting by 12–18% versus sheet formats. High tensile strength (≥25 MPa) reduces seam failures, lowering rework rates. Consistent thickness tolerance (±0.05mm) ensures precise automated cutting, accelerating throughput by up to 22%. -

Engineered Durability

Achieves 50,000+ double-rub cycles (Martindale, ISO 12947) without coating degradation. Resists hydrolysis (tested per ISO 1419:2018), maintaining integrity in 85% humidity environments for 5+ years. Tear strength (≥35 N) exceeds standard PU leathers by 40%, critical for high-stress applications like automotive seating. -

Precision Color Customization

Proprietary pigment dispersion system supports 1:1 Pantone® matching (ΔE <1.5) across 1,200+ standard colors. Custom formulations delivered in 15–20 days without MOQ penalties. UV-stable dyes prevent fading (tested per AATCC 16), retaining color integrity after 1,000 hours of xenon-arc exposure. -

Full REACH Compliance

Rigorously screened for all 223 REACH SVHCs (Substances of Very High Concern); 0% detectable phthalates, AZO dyes, or heavy metals (Cd, Pb, Hg). Certified via SGS batch testing, ensuring seamless market access in EU, UK, and regulated global regions. -

ISO 9001-Certified Quality Control

Integrated production monitoring (from polymer extrusion to finishing) guarantees ≤0.5% defect rate per ISO 9001:2015 standards. Real-time thickness/width sensors and 100% roll inspection prevent batch inconsistencies.

Technical Specifications Overview

| المعلمة | المواصفات | Test Standard |

|---|---|---|

| Thickness Range | 0.6mm – 1.8mm (custom up to 2.5mm) | ISO 2424:2017 |

| Roll Width | 137cm ± 0.5cm (standard) | ISO 2286-1:2016 |

| Weight | 450 – 850 g/m² | ISO 9073-3:1989 |

| Abrasion Resistance | ≥50,000 cycles (no coating failure) | ISO 12947-2:2016 |

| Tensile Strength | ≥25 MPa (warp & weft) | ISO 1766:2019 |

| Tear Strength | ≥35 N | ISO 13937-1:2019 |

| Color Fastness (Light) | Grade 7–8 (AATCC Scale) | AATCC 16-2014 |

| Backing Fabric | Recycled PET knit (≥30% post-consumer) | GRS 4.0 Certified |

| Certifications | REACH, ISO 9001, OEKO-TEX® Standard 100 | Full documentation |

Why WINIW Rolls Outperform Alternatives

WINIW’s closed-loop manufacturing reduces water usage by 70% versus conventional processes while delivering materials with 32% lower carbon footprint (verified by third-party LCA). The roll format’s consistent caliper and edge stability prevent feeding errors in CNC cutters, directly lowering scrap rates. Combined with rapid color-matching agility and uncompromised regulatory adherence, WINIW rolls provide manufacturers with a scalable, future-proof material solution that enhances brand reputation and operational margins. Partner with WINIW to transform sustainability targets into competitive advantage—without sacrificing performance or profitability.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather – A Comparative Overview

In the evolving landscape of material sourcing for industries such as furniture, automotive, fashion, and accessories, businesses are increasingly evaluating the balance between performance, sustainability, and cost. Two prominent materials in this discussion are synthetic leather rolls and real (animal-derived) leather. This guide provides a professional comparison to support informed procurement decisions.

Overview of Materials

-

Synthetic Leather (e.g., WINIW PU/TPU Leather): Engineered from high-performance polymers such as polyurethane (PU) or thermoplastic polyurethane (TPU), synthetic leather is designed to replicate the aesthetic and functional qualities of real leather. It is produced in continuous rolls, enabling efficient cutting and reduced waste in manufacturing.

-

Real Leather: Sourced from animal hides (primarily bovine), real leather undergoes tanning and finishing processes to preserve and enhance its natural properties. While valued for its authenticity and aging characteristics, it presents challenges in consistency, environmental footprint, and ethical considerations.

Key Comparative Metrics

| Metric | Synthetic Leather (Roll Form) | Real Leather |

|---|---|---|

| Cost | Lower initial cost per square meter; consistent pricing due to controlled production. | Higher cost due to raw material scarcity, labor-intensive processing, and variable hide quality. |

| المتانة | High resistance to cracking, fading, and abrasion; performance can be tailored (e.g., UV resistance, cold crack resistance). Uniform thickness enhances product consistency. | Naturally durable but prone to drying, cracking over time; quality varies by hide grade and tanning method. |

| Eco-Friendliness | Lower carbon footprint; no animal sourcing. Modern versions (e.g., water-based PU, recycled TPU) are recyclable and reduce VOC emissions. WINIW’s eco-series supports circular economy goals. | High environmental impact: land use, methane emissions, water-intensive tanning (especially chrome tanning), and chemical runoff. Limited biodegradability due to treatment chemicals. |

Advantages of Synthetic Leather Rolls for B2B Applications

- Consistent Quality: Uniform texture, thickness, and color across production batches ensure reliability in large-scale manufacturing.

- Design Flexibility: Available in a wide range of colors, textures, and finishes—customizable to brand specifications.

- Sustainability Compliance: Aligns with corporate ESG goals; supports cruelty-free and low-impact production standards.

- Efficiency: Roll format minimizes material waste during cutting and optimizes logistics and storage.

Considerations for Real Leather

- Market Perception: Preferred in luxury segments for its natural origin and aging characteristics.

- Traceability Challenges: Ethical sourcing requires rigorous supply chain oversight to avoid deforestation or unethical farming practices.

- Longer Lead Times: Dependent on hide availability and tanning capacity.

الخاتمة

For B2B manufacturers prioritizing cost-efficiency, sustainability, and production scalability, synthetic leather rolls—particularly advanced eco-friendly variants—offer a compelling alternative to real leather. While real leather maintains niche appeal in premium markets, synthetic solutions from innovators like WINIW deliver performance parity with significantly reduced environmental impact.

WINIW Factory Capabilities

WINIW Synthetic Leather: Advanced Manufacturing Capabilities for Global Partners

WINIW operates one of the industry’s most advanced synthetic leather manufacturing ecosystems, engineered to deliver consistent quality, innovation, and scalability for B2B partners worldwide. Our vertically integrated facility spans 100,000 square meters, enabling end-to-end control from raw material processing to finished product dispatch. This scale supports high-volume production without compromising agility, ensuring reliable fulfillment for global supply chains.

Core Manufacturing Strengths

- Integrated Production Capacity: 100,000 sqm facility housing extrusion, coating, finishing, and testing lines under one roof, eliminating third-party dependencies.

- Dedicated R&D Innovation Hub: 50+ multidisciplinary engineers and material scientists focused on eco-performance breakthroughs, including water-based PU formulations, recycled content integration, and bio-based alternatives.

- Patent-Protected Processes: 128+ proprietary technologies optimizing durability, texture fidelity, and low-impact manufacturing.

- Sustainable Infrastructure: On-site wastewater recycling (95% reuse rate), solar energy integration, and closed-loop solvent recovery systems.

Rigorous Quality Assurance Framework

Every meter of WINIW synthetic leather undergoes 11-stage validation, exceeding international safety and performance benchmarks. Our QC protocol ensures compliance with stringent regional regulations while prioritizing environmental stewardship.

| QC Stage | Process Details | Certifications Validated |

|---|---|---|

| Raw Material | Spectral analysis of polymers & additives | REACH, OEKO-TEX® STANDARD 100 |

| In-Process | Real-time thickness/tensile monitoring (AI sensors) | ISO 9001, ISO 14001 |

| Final Inspection | Colorfastness, abrasion, chemical resistance tests | CPSIA, ASTM D412 |

| Eco-Compliance | Heavy metal screening, VOC emissions validation | bluesign®, GRS |

Global Market Readiness

WINIW materials are engineered for seamless integration into international supply chains, with 87% of exports serving Europe and North America. Our compliance framework meets evolving regulatory landscapes:

– Full alignment with EU REACH Annex XVII restricted substances

– CPSIA-compliant children’s product formulations (USA)

– Traceable documentation for LCA (Life Cycle Assessment) reporting

– Dedicated logistics partners for carbon-neutral shipping options

This operational excellence positions WINIW as a strategic manufacturing ally for brands committed to premium performance, ethical sourcing, and circular economy principles. Our facility’s scale, scientific rigor, and eco-conscious infrastructure deliver the reliability global partners require in today’s demanding market.

Contact Us for Samples

WINIW Microfiber Leather – B2B Product Guide

WINIW is a leading manufacturer of premium synthetic leather, specializing in eco-friendly, high-performance microfiber materials for global B2B clients. Our advanced production technology ensures consistent quality, durability, and sustainability across industries including automotive, furniture, footwear, and fashion accessories.

Engineered to replicate the look and feel of genuine leather, WINIW microfiber leather offers superior strength, breathability, and resistance to abrasion and UV exposure. With a strong commitment to environmental responsibility, our materials are REACH-compliant, free from hazardous substances, and produced using low-impact processes.

Key Advantages of WINIW Microfiber Leather

- Exceptional durability and wear resistance for long-term performance

- Soft hand feel and high aesthetic versatility with customizable textures and finishes

- Eco-conscious manufacturing: 30% lower carbon footprint compared to traditional leather

- Water-resistant, anti-mildew, and easy to clean—ideal for high-use applications

- Available in wide widths (up to 1.5 meters), reducing material waste and seam lines

- Cost-effective alternative to genuine leather with consistent batch-to-batch quality

Customization Options

WINIW supports large-scale OEM and ODM projects with full customization capabilities:

- Thickness: 0.6 mm to 2.0 mm

- Weight: 200 g/m² to 600 g/m²

- Finish: Matte, glossy, textured, embossed (e.g., grain, nubuck, exotic patterns)

- Color: Pantone-matched or custom color development

- Backing: Knit fabric, woven, or non-woven scrim for enhanced stability

Applications by Industry

- Automotive Interiors: Seat covers, dashboards, door panels, steering wheels

- Furniture & Upholstery: Sofas, office chairs, headboards, decorative panels

- Footwear: Sneakers, boots, sandals with flexible, breathable performance

- Accessories: Handbags, wallets, watch straps, luggage

- Electronics & Sports: Protective cases, wearable gear, gym equipment

Technical Performance Overview

| Property | Test Standard | Typical Value |

|---|---|---|

| Tensile Strength | ISO 1421 | ≥ 90 N/50mm (warp & weft) |

| Tear Strength | ISO 4674 | ≥ 15 N |

| Color Fastness (Rubbing) | ISO 105-X12 | Dry: 4–5, Wet: 3–4 |

| Light Fastness | ISO 105-B02 | ≥ 4 (grade 1–8) |

| Water Resistance | Spray Test, ISO 4920 | > 90% hydrophobic |

| Environmental Compliance | REACH, RoHS, Oeko-Tex | Free of AZO, PCP, formaldehyde |

Sustainability Commitment

WINIW microfiber leather is part of our vision for a greener future. Our production facilities utilize closed-loop water systems and energy-efficient processes. The material is fully recyclable at end-of-life and contains no animal-derived components, making it ideal for brands pursuing cruelty-free and circular economy goals.

Call to Action

Request a roll of leather material for your next production cycle. WINIW offers free samples to qualified B2B partners to support prototyping and quality evaluation.

Contact us today at MKT88@MicrofiberLeather.com to discuss your project requirements, request technical datasheets, or place a sample order.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.