Introduction: Navigating the Global Market for motorcycle seat cover material

The global market for motorcycle seat cover material presents a unique set of challenges for international B2B buyers, particularly those seeking high-quality, durable, and aesthetically pleasing options. As the demand for motorcycle customization grows, sourcing the right materials to enhance comfort and style becomes increasingly crucial. Buyers from regions like Africa, South America, the Middle East, and Europe—such as Nigeria and Brazil—are tasked with navigating a complex landscape of materials, suppliers, and pricing strategies to meet diverse consumer needs.

This comprehensive guide aims to empower B2B buyers by dissecting the intricacies of motorcycle seat cover materials. We will explore various types of materials—including vinyl, leather, and advanced foam technologies—while detailing their applications in different motorcycle segments, from cruisers to sport bikes. Additionally, we will provide insights into effective supplier vetting processes, ensuring that buyers can select partners who meet their quality and reliability standards. Cost considerations will also be examined, helping buyers make informed purchasing decisions that align with their budget constraints and market expectations.

By equipping B2B buyers with actionable insights and a clear understanding of the motorcycle seat cover material market, this guide seeks to facilitate successful sourcing strategies and foster long-term business relationships in an increasingly competitive industry.

Table Of Contents

- Top 7 Motorcycle Seat Cover Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for motorcycle seat cover material

- Understanding motorcycle seat cover material Types and Variations

- Key Industrial Applications of motorcycle seat cover material

- 3 Common User Pain Points for ‘motorcycle seat cover material’ & Their Solutions

- Strategic Material Selection Guide for motorcycle seat cover material

- In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat cover material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat cover material’

- Comprehensive Cost and Pricing Analysis for motorcycle seat cover material Sourcing

- Alternatives Analysis: Comparing motorcycle seat cover material With Other Solutions

- Essential Technical Properties and Trade Terminology for motorcycle seat cover material

- Navigating Market Dynamics and Sourcing Trends in the motorcycle seat cover material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat cover material

- Strategic Sourcing Conclusion and Outlook for motorcycle seat cover material

- Important Disclaimer & Terms of Use

Understanding motorcycle seat cover material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| الفينيل | Durable, affordable, water-resistant, easy to clean | Mass production, aftermarket customization | Pros: Cost-effective, low maintenance. Cons: Can crack over time if low quality. |

| Leather | Premium feel, develops patina, requires maintenance | High-end custom builds, luxury motorcycles | Pros: Comfort, aesthetic appeal. Cons: Higher cost, sensitive to weather. |

| جلد صناعي | Mimics leather appearance, less maintenance required | Mid-range custom builds, fashion-forward designs | Pros: Durable, easier to maintain than real leather. Cons: May not offer the same comfort level as genuine leather. |

| Memory Foam | Conforms to body shape, offers superior comfort | Long-distance touring, premium aftermarket seats | Pros: Enhanced comfort, pressure relief. Cons: Can compress over time, may require replacement. |

| Gel Inserts | Provides additional cushioning, pressure distribution | Custom upgrades, aftermarket enhancements | Pros: Increases comfort without full seat replacement. Cons: May require modification to existing seats. |

What are the characteristics of vinyl motorcycle seat covers?

Vinyl is a popular choice for motorcycle seat covers due to its affordability and durability. It is water-resistant, making it suitable for various weather conditions, and is easy to clean. This material is commonly used in mass production and aftermarket customization, allowing manufacturers to offer cost-effective solutions to a wide range of customers. When sourcing vinyl seat covers, buyers should ensure they select high-quality options to avoid premature cracking and wear.

Why choose leather for motorcycle seat covers?

Leather seat covers provide a premium look and feel, often preferred for high-end custom builds and luxury motorcycles. They develop a unique patina over time, adding character to the bike. However, leather requires regular maintenance to protect against moisture and sun damage. B2B buyers should consider the long-term care requirements and the higher upfront costs associated with leather products when making purchasing decisions.

What advantages does synthetic leather offer?

Synthetic leather offers the aesthetic appeal of real leather while being more affordable and requiring less maintenance. This material is suitable for mid-range custom builds and designs that prioritize style without the high costs of genuine leather. Buyers should evaluate the quality of synthetic leather options, as lower-grade materials may not provide the same durability or comfort as higher-end alternatives.

How does memory foam enhance motorcycle seat comfort?

Memory foam is ideal for long-distance touring and premium aftermarket seats, as it conforms to the rider’s body, providing superior comfort and pressure relief. While it offers a more luxurious experience, memory foam can compress over time, necessitating eventual replacement. B2B buyers should consider the longevity and comfort needs of their target market when incorporating memory foam into their product offerings.

What role do gel inserts play in motorcycle seat comfort?

Gel inserts are an effective solution for enhancing comfort without the need for a complete seat replacement. They distribute pressure more evenly and can be added to existing seats, making them a popular choice for custom upgrades. However, buyers should be aware that installing gel inserts may require modifications to the existing seat structure. This factor can influence purchasing decisions, particularly for businesses focused on aftermarket enhancements.

Key Industrial Applications of motorcycle seat cover material

| Industry/Sector | Specific Application of motorcycle seat cover material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom motorcycle seat production | Tailored comfort and durability for end-users | Quality of materials, customization options, lead times |

| Motorcycle Retail | Replacement seat covers for aftermarket sales | Increased customer satisfaction and retention | Variety of styles, pricing competitiveness, warranty options |

| Motorcycle Rentals | Durable and weather-resistant seat covers | Enhanced rider comfort and protection against elements | Material longevity, ease of cleaning, bulk order discounts |

| Tourism & Leisure | Custom-branded seat covers for tour operators | Brand visibility and improved rider experience | Customization capabilities, branding options, delivery timelines |

| Sports & Racing | Performance-oriented seat covers | Improved rider control and comfort during races | Material performance under stress, weight considerations |

How is motorcycle seat cover material utilized in automotive manufacturing?

In the automotive manufacturing sector, motorcycle seat cover material is crucial for producing custom seats that meet specific ergonomic and aesthetic requirements. Manufacturers often utilize high-quality vinyl or leather options that offer durability and comfort, addressing the wear and tear typical of motorcycle use. For international buyers, especially in regions like Africa and South America, sourcing materials that withstand diverse weather conditions is vital. The ability to customize seat covers enhances brand identity and caters to niche markets, making sourcing decisions critical for maintaining competitive advantage.

What role does motorcycle seat cover material play in motorcycle retail?

In motorcycle retail, replacement seat covers are a significant aftermarket product. Retailers benefit from offering a variety of materials and styles, ensuring that customers can find a suitable option that enhances both comfort and aesthetics. This not only boosts customer satisfaction but also fosters brand loyalty. Buyers from the Middle East and Europe may prioritize quality and design, necessitating a focus on premium materials and unique customizations to meet diverse consumer preferences. Retailers should consider competitive pricing and warranty options when sourcing these materials.

How do motorcycle rentals leverage seat cover materials?

Motorcycle rental businesses utilize durable and weather-resistant seat covers to enhance rider comfort and protect the underlying seat from environmental damage. This is particularly important in regions with varying climates, where seat covers must withstand sun, rain, and humidity without degrading. For B2B buyers in Africa and Brazil, sourcing materials that are easy to clean and maintain is essential to minimize operational costs. Bulk order discounts and reliable supply chains are key considerations for ensuring a consistent rental experience.

What benefits do tourism and leisure sectors gain from custom motorcycle seat covers?

In the tourism and leisure sectors, custom-branded motorcycle seat covers serve as an effective marketing tool while enhancing the rider experience. These covers can be tailored to feature company logos and designs, increasing brand visibility during tours. For international buyers, especially in Europe, the ability to provide a unique riding experience is crucial for attracting tourists. Sourcing materials that offer both comfort and durability, along with customization capabilities, will be vital for businesses looking to stand out in a competitive market.

How does performance-oriented seat cover material impact sports and racing?

For the sports and racing industry, performance-oriented motorcycle seat covers are designed to provide superior grip and comfort, which is essential for optimal control during high-speed maneuvers. Materials must be lightweight yet robust enough to withstand the stresses of racing conditions. Buyers in this sector should prioritize sourcing options that offer high performance under stress, as well as weight considerations that can affect bike handling. Custom features may also be required to meet specific racing regulations or team branding needs.

3 Common User Pain Points for ‘motorcycle seat cover material’ & Their Solutions

Scenario 1: The Challenge of Material Durability in Harsh Environments

The Problem: B2B buyers in regions with extreme weather conditions—such as heavy rain in parts of Africa or intense sunlight in South America—often struggle with the durability of motorcycle seat cover materials. These materials must withstand not only the daily wear and tear from riding but also the harsh effects of UV rays and moisture. Buyers may find that lower-quality materials fade, crack, or deteriorate quickly, leading to increased replacement costs and dissatisfied customers.

Illustrative image related to motorcycle seat cover material

The Solution: To mitigate these issues, B2B buyers should focus on sourcing high-quality, UV-resistant synthetic materials such as marine-grade vinyl or specially treated fabrics designed for outdoor use. When selecting materials, look for those with a warranty that covers fading and cracking. Moreover, consider integrating a protective coating that adds an extra layer of defense against the elements. Collaborating with manufacturers that offer custom solutions can also ensure that the materials meet specific regional demands, enhancing longevity and performance in challenging environments.

Scenario 2: The Need for Comfort and Ergonomics

The Problem: Buyers in the motorcycle aftermarket are increasingly aware of the importance of rider comfort, especially for long-distance travel. Many standard seat covers do not provide adequate cushioning, leading to discomfort and fatigue during rides. This can result in negative feedback from customers, ultimately affecting sales and brand reputation.

The Solution: To address comfort issues, B2B buyers should consider seat covers that incorporate multi-layer foam systems or gel inserts. Sourcing materials that combine open-cell and closed-cell foams can provide a balance of comfort and support, making the seat more ergonomic. Additionally, it’s essential to engage with manufacturers that specialize in custom seat designs. This allows for tailored solutions that can meet specific customer needs, such as varying thicknesses of padding or unique shapes that accommodate different riding styles.

Scenario 3: The Challenge of Aesthetic Appeal and Customization

The Problem: In a competitive marketplace, the aesthetic appeal of motorcycle seat covers is crucial for attracting customers. Buyers often face the challenge of sourcing materials that not only perform well but also offer customization options that reflect individual brand identities or customer preferences. Standard options may not suffice, leaving buyers frustrated with limited choices.

The Solution: To enhance aesthetic appeal, B2B buyers should seek out suppliers who offer a wide range of customization options, such as varied colors, textures, and stitching patterns. Fabrics that can be easily embroidered or printed on can also provide additional branding opportunities. Collaborating with manufacturers that specialize in bespoke solutions can enable buyers to create unique designs that stand out in the market. Furthermore, requesting fabric samples before committing to a bulk order can help ensure that the chosen materials meet both performance and visual standards, leading to greater customer satisfaction.

Illustrative image related to motorcycle seat cover material

Strategic Material Selection Guide for motorcycle seat cover material

What Are the Key Properties of Common Motorcycle Seat Cover Materials?

When selecting materials for motorcycle seat covers, understanding the unique properties of each option is crucial for ensuring performance and durability. Below, we analyze four common materials used in motorcycle seat covers: vinyl, leather, polyurethane foam, and gel inserts.

How Does Vinyl Perform as a Motorcycle Seat Cover Material?

Vinyl is a synthetic material known for its affordability and durability. It typically has a temperature rating that can withstand a range of environmental conditions, making it suitable for various climates. Vinyl is resistant to cracking and fading, which is essential for maintaining the aesthetic of motorcycle seats over time.

Pros: Vinyl is cost-effective and easy to clean, making it an attractive option for budget-conscious buyers. It is also available in various textures and colors, allowing for customization.

Cons: While vinyl is durable, lower-quality options may crack or wear out faster. It can also lack the premium feel of leather, which may be a consideration for high-end motorcycle brands.

Impact on Application: Vinyl is compatible with most motorcycle seat designs and is often used in both standard and custom applications.

Considerations for International Buyers: Compliance with international standards such as ASTM for material safety and durability is essential. Buyers in regions like Africa and South America may prefer vinyl for its cost-effectiveness, while European buyers may lean towards higher-quality options.

Illustrative image related to motorcycle seat cover material

What Are the Advantages and Disadvantages of Leather for Motorcycle Seats?

Leather is a natural material that offers a premium look and feel. It provides excellent durability and can develop a unique patina over time, enhancing its aesthetic appeal. However, leather has a lower temperature tolerance compared to synthetic materials and can degrade if not properly treated.

Pros: The comfort and luxury of leather are unmatched, making it a preferred choice for high-end motorcycles. With proper care, leather can last for many years.

Cons: Leather requires regular maintenance, including conditioning and cleaning, to prevent cracking and water damage. It is also more expensive than vinyl and other synthetic options.

Impact on Application: Leather is often used in premium motorcycle models and custom builds, where aesthetics and rider comfort are prioritized.

Considerations for International Buyers: Buyers should consider the availability of leather treatment products and the potential for compliance with environmental regulations regarding animal products, especially in Europe.

Illustrative image related to motorcycle seat cover material

How Does Polyurethane Foam Enhance Motorcycle Seat Comfort?

Polyurethane foam is commonly used as the comfort layer in motorcycle seats. It comes in various densities, which can affect its pressure rating and comfort level. Open-cell foam is generally preferred for comfort, while closed-cell foam is used in racing applications for support.

Pros: Polyurethane foam is versatile and cost-effective, making it suitable for various motorcycle types. It provides good shock absorption and can be molded to fit specific seat designs.

Cons: Over time, foam can compress and lose its supportive qualities, leading to discomfort. It also may not offer the same aesthetic appeal as other materials.

Illustrative image related to motorcycle seat cover material

Impact on Application: This material is essential for enhancing rider comfort, particularly in long-distance touring motorcycles.

Considerations for International Buyers: Compliance with manufacturing standards such as JIS for foam density and performance is crucial. Buyers should also consider local preferences for comfort versus performance.

What Role Do Gel Inserts Play in Motorcycle Seat Design?

Gel inserts are often added to motorcycle seats to enhance comfort by distributing pressure more evenly. They can be used in conjunction with foam layers to provide a customized seating experience.

Pros: Gel inserts significantly improve comfort, especially for long rides, making them popular among touring and adventure motorcycle riders.

Cons: They can add to the overall cost of the seat and may require modifications to the existing seat structure for proper installation.

Impact on Application: Gel inserts are compatible with most seat designs but may require professional installation for optimal results.

Considerations for International Buyers: Buyers should ensure that gel inserts meet local safety and performance standards. Market preferences in regions like the Middle East may favor high-comfort solutions for long rides.

Summary Table of Motorcycle Seat Cover Materials

| المواد | Typical Use Case for motorcycle seat cover material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| الفينيل | Standard motorcycle seats, budget-friendly options | Affordable and durable | Can crack if low quality | منخفضة |

| Leather | Premium motorcycles, custom builds | Luxurious feel and durability | Requires maintenance, more expensive | عالية |

| Polyurethane Foam | Comfort layer in various motorcycle types | Versatile and cost-effective | Can compress over time | Medium |

| Gel Inserts | Long-distance touring and adventure bikes | Enhances comfort significantly | Adds to overall cost, installation needed | Medium |

This strategic material selection guide provides essential insights for B2B buyers in the motorcycle industry, helping them make informed decisions based on performance, cost, and regional preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for motorcycle seat cover material

What Are the Main Stages of Manufacturing Motorcycle Seat Cover Materials?

Manufacturing motorcycle seat cover materials involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets the durability and aesthetic expectations of consumers.

How Is Material Prepared for Motorcycle Seat Covers?

The process begins with material selection, where manufacturers typically choose between vinyl, leather, or synthetic options. These materials must undergo rigorous quality checks to ensure they meet industry standards for durability and weather resistance. After selection, the materials are prepped, which includes cutting them into the required shapes and sizes, and treating them with coatings that enhance their resistance to UV rays and moisture.

What Techniques Are Used in Forming Motorcycle Seat Covers?

Forming involves shaping the prepared materials into the desired design. Techniques can vary based on the complexity of the seat cover. Common methods include:

- Die Cutting: This technique is employed to create precise shapes and patterns from the material.

- Thermoforming: In cases where the seat cover needs to be molded to fit specific contours, thermoforming is used, where heat is applied to make the material pliable.

- Sewing: Once formed, the pieces are stitched together using industrial sewing machines, often reinforced with double stitching to enhance durability.

How Does the Assembly Process Work for Motorcycle Seat Covers?

The assembly stage is where all components come together. This typically involves:

- Layering: If the design incorporates multiple layers, such as a foam padding layer for comfort, these are added during this stage.

- Attachment: Components like zippers, buckles, or straps are attached, ensuring that they are securely fastened and functional.

- Final Adjustments: Any necessary adjustments are made to ensure that the seat cover fits snugly and meets design specifications.

What Are the Finishing Touches Applied to Motorcycle Seat Covers?

Finishing touches include quality checks and aesthetic enhancements. This may involve:

- Quality Control: A thorough inspection of stitching, material integrity, and overall appearance to ensure the product is free of defects.

- Customizations: Adding elements such as embroidery or branding, which can enhance the product’s market appeal.

What Quality Assurance Standards Are Relevant for Motorcycle Seat Covers?

Quality assurance is vital in the manufacturing process, particularly for international B2B buyers. Compliance with recognized standards ensures that the products are safe, reliable, and consistent. Key standards include:

Illustrative image related to motorcycle seat cover material

- ISO 9001: This international standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Particularly important in Europe, this mark indicates that the product meets EU safety, health, and environmental protection standards.

- API Standards: In specific markets, especially those related to motor vehicles, adherence to American Petroleum Institute (API) standards can indicate the quality of materials used.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure compliance with standards. Common checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are performed to monitor the production process and identify any deviations from quality standards.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted to verify the overall quality of the finished product before shipment.

What Common Testing Methods Are Used for Motorcycle Seat Covers?

Testing methods for motorcycle seat covers vary based on the material used and the expected conditions of use. Common methods include:

- Abrasion Resistance Testing: Measures the durability of the material against wear and tear.

- Water Resistance Testing: Ensures that materials can withstand exposure to moisture without degrading.

- UV Resistance Testing: Assesses how well materials resist fading and degradation from sunlight.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control measures is crucial for ensuring product reliability. Buyers can take several steps:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality control processes and compliance with international standards.

- Request Quality Reports: Suppliers should be able to provide documentation detailing their quality control procedures, test results, and certifications.

- Engage Third-Party Inspectors: Hiring independent inspection agencies to evaluate the manufacturing process and products can offer an unbiased assessment of quality.

What Are the QC and Certification Nuances for International Buyers?

International buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of several nuances:

- Regional Standards: Different regions may have specific standards and regulations; understanding these can help ensure compliance and prevent delays.

- Cultural Considerations: Communication styles and business practices may vary, so establishing clear expectations and maintaining open lines of communication can aid in smoother transactions.

- Documentation and Certification: Buyers should ensure that all necessary documentation, including certificates of compliance and test reports, is in order before finalizing orders.

الخاتمة

Understanding the manufacturing processes and quality assurance measures for motorcycle seat cover materials is essential for B2B buyers. By familiarizing themselves with the various stages of production, quality control standards, and verification methods, buyers can make informed decisions that ensure they receive high-quality products that meet their specific needs. With the right approach, international buyers can navigate the complexities of sourcing effectively and confidently.

Illustrative image related to motorcycle seat cover material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motorcycle seat cover material’

مقدمة

Sourcing motorcycle seat cover material requires careful consideration to ensure quality, durability, and suitability for your specific needs. This guide provides a structured checklist for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Following these steps will help streamline your procurement process and enhance the quality of your products.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the materials you source meet your quality and performance requirements. Consider factors such as material type (e.g., vinyl, leather, synthetic), thickness, and weather resistance. This foundational step will guide your sourcing decisions and help you communicate effectively with suppliers.

Step 2: Research Material Options

Take the time to explore various material options available in the market. Look for materials that offer durability, comfort, and aesthetic appeal. For instance, vinyl is often favored for its affordability and resistance to wear, while leather provides a premium look and feel. Understanding the properties of different materials will allow you to make informed choices that align with your brand’s positioning.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product samples, and references from other businesses in your industry. Assess their production capabilities, lead times, and quality control processes to ensure they can meet your demands consistently. This diligence will minimize risks and foster long-term partnerships.

Step 4: Verify Supplier Certifications and Compliance

It’s crucial to verify that your suppliers comply with relevant industry standards and certifications. Check for certifications related to material safety, environmental sustainability, and manufacturing quality. Suppliers who adhere to these standards are more likely to provide reliable products that meet international regulations.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the materials you are considering. Conduct tests to evaluate the materials’ performance under various conditions, such as exposure to sunlight, moisture, and abrasion. This step helps ensure that the selected materials will withstand the rigors of motorcycle use and maintain their appearance over time.

Step 6: Assess Pricing and Payment Terms

Obtain detailed pricing from potential suppliers, including costs for bulk orders and any additional fees for customization or shipping. Compare these prices against the quality and specifications you require. Additionally, clarify payment terms to avoid any misunderstandings later in the transaction process. Transparent pricing will help you manage your budget effectively.

Step 7: Establish a Communication Plan

Finally, create a communication plan with your chosen supplier. Regular updates and open lines of communication will facilitate smoother transactions and allow for quick resolutions to any issues that may arise. Establishing clear expectations regarding timelines, order changes, and delivery will enhance your partnership’s effectiveness.

Illustrative image related to motorcycle seat cover material

By following these steps, B2B buyers can effectively source high-quality motorcycle seat cover materials that meet their specific needs and enhance their product offerings.

Comprehensive Cost and Pricing Analysis for motorcycle seat cover material Sourcing

What Are the Key Cost Components in Motorcycle Seat Cover Material Sourcing?

When sourcing motorcycle seat cover materials, understanding the cost structure is crucial for B2B buyers. The primary cost components typically include:

-

Materials: The choice of fabric—such as vinyl, leather, or synthetic options—greatly influences the price. High-quality materials, such as marine-grade vinyl or treated leather, are more expensive but offer better durability and comfort. For instance, vinyl can range from $30 to $60 per linear yard, while premium leather can exceed $100 per yard.

-

Labor: Labor costs vary by region and the complexity of the design. Custom seat covers requiring intricate stitching or unique designs will incur higher labor costs. In regions with lower wage rates, such as parts of Africa and South America, labor expenses may be reduced, potentially offsetting some material costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower overhead costs, making it essential for suppliers to optimize operations.

-

Tooling: For custom or specialized designs, tooling costs can be significant. This includes the creation of molds or patterns specifically for unique seat shapes. Buyers should inquire about these costs upfront to avoid surprises.

-

Quality Control (QC): Ensuring that materials meet specific standards requires investment in QC processes. Suppliers with robust QC protocols may charge higher prices but can provide better assurance of product quality.

-

Logistics: Shipping costs, especially for international buyers, can vary greatly based on distance, weight, and shipping method. Incoterms will dictate who bears these costs, so understanding these terms is critical for budgeting.

-

Margin: Suppliers will add a profit margin to their costs. This can vary widely depending on the supplier’s market positioning and the level of competition in the region.

How Do Price Influencers Affect Sourcing Costs?

Several factors can influence the pricing of motorcycle seat cover materials, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield discounts. Buyers should negotiate MOQs to optimize costs while ensuring they can manage inventory.

-

Specifications and Customization: Custom designs or specific material requirements will increase costs. Being clear about specifications from the outset can help suppliers provide accurate quotes.

-

Material Quality and Certifications: Materials with certifications for durability or environmental standards may come at a premium. Buyers should weigh the long-term benefits against the initial costs.

-

Supplier Factors: Established suppliers with a reputation for quality may charge higher prices. However, they often provide better reliability and customer service, which can justify the expense.

-

Incoterms: Understanding shipping terms can significantly impact total costs. Buyers should familiarize themselves with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to manage expenses effectively.

What Negotiation Tips Can Help Buyers Optimize Costs?

To achieve cost-efficiency in sourcing motorcycle seat cover materials, buyers should consider the following strategies:

-

Leverage Volume Discounts: If planning to make bulk purchases, negotiate for lower prices based on volume. Suppliers are often willing to accommodate larger orders.

-

Conduct a Total Cost of Ownership (TCO) Analysis: Look beyond the initial purchase price. Consider factors like durability, maintenance, and potential replacement costs over time.

-

Research Market Prices: Understanding the market can give buyers leverage in negotiations. Comparing prices from multiple suppliers helps in identifying reasonable pricing.

-

Be Clear About Specifications: Providing detailed specifications can prevent misunderstandings that may lead to additional costs or delays.

-

Stay Informed About International Pricing Nuances: Different regions may have varying pricing structures due to local economic conditions, tariffs, and import duties. Buyers from Africa and South America should be particularly vigilant about these factors.

الخاتمة

Navigating the cost and pricing landscape for motorcycle seat cover material sourcing requires a comprehensive understanding of various cost components and price influencers. By applying strategic negotiation techniques and conducting thorough market research, B2B buyers can optimize their sourcing strategies, ensuring both quality and cost-effectiveness in their purchases. As prices may fluctuate, it’s advisable to treat the pricing information as indicative and seek direct quotes for the most accurate figures.

Alternatives Analysis: Comparing motorcycle seat cover material With Other Solutions

Introduction: Exploring Alternatives to Motorcycle Seat Cover Materials

When considering the best solutions for motorcycle seating, it is essential to evaluate various options beyond traditional seat cover materials. Motorcycle seat cover materials, such as vinyl and leather, provide a range of benefits including comfort, durability, and aesthetic appeal. However, alternative solutions can offer unique advantages depending on specific needs, such as enhanced performance, cost-effectiveness, or ease of maintenance. This analysis will compare motorcycle seat cover materials against gel inserts and custom seat replacements, allowing buyers to make informed decisions based on their requirements.

Comparison Table

| Comparison Aspect | Motorcycle Seat Cover Material | Gel Inserts | Custom Seat Replacements |

|---|---|---|---|

| Performance | Good durability and comfort | Excellent pressure relief | Superior comfort and fit |

| Cost | Moderate (varies by material) | Low to moderate | High (customized solutions) |

| Ease of Implementation | Relatively easy to install | Simple installation | Requires professional fitting |

| Maintenance | Moderate (depends on material) | Low (minimal upkeep needed) | High (requires care and upkeep) |

| Best Use Case | General use, aesthetic appeal | Long-distance rides, comfort | Custom or specialized needs |

Detailed Breakdown of Alternatives

Gel Inserts: Are They Worth the Investment?

Gel inserts are an excellent option for those seeking additional comfort without the need for a complete seat replacement. They provide superior pressure relief, making them ideal for long-distance rides where comfort is paramount. Installation is straightforward, typically requiring minimal adjustments to the existing seat. Cost-wise, gel inserts are relatively low, making them accessible for budget-conscious buyers. However, they may not offer the same aesthetic appeal as traditional cover materials and could require eventual replacement if wear occurs.

Custom Seat Replacements: What Are the Benefits and Drawbacks?

Custom seat replacements present the ultimate solution for motorcycle enthusiasts seeking a tailored fit and enhanced comfort. These seats can be designed to meet specific ergonomic needs, offering superior support compared to standard seat covers. However, the cost can be significantly higher due to the bespoke nature of the product, often requiring a substantial investment. Moreover, the installation process typically involves professional fitting, which can add to the overall expense. Maintenance is also a consideration, as custom materials may require specialized care to preserve their appearance and function over time.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers in the motorcycle industry, selecting the right seating solution is crucial for ensuring rider comfort and satisfaction. Motorcycle seat cover materials are a solid choice for general use, offering a balance of durability and aesthetics. However, alternatives like gel inserts can provide targeted comfort for long-distance riders at a lower cost, while custom seat replacements offer unparalleled personalization and support for specialized applications. Ultimately, the decision should be based on specific needs, budget considerations, and the desired balance between comfort, performance, and maintenance.

Essential Technical Properties and Trade Terminology for motorcycle seat cover material

What Are the Key Technical Properties of Motorcycle Seat Cover Materials?

When selecting motorcycle seat cover materials, several technical properties are critical to ensure durability, comfort, and performance. Understanding these properties helps B2B buyers make informed decisions.

Illustrative image related to motorcycle seat cover material

1. Material Grade

Material grade refers to the quality and type of material used in the seat cover, such as vinyl, leather, or synthetic options. Higher-grade materials offer better durability and resistance to wear and tear, critical for products exposed to outdoor elements. For B2B buyers, selecting a higher-grade material can result in lower replacement costs and greater customer satisfaction.

2. UV Resistance

UV resistance measures a material’s ability to withstand degradation from ultraviolet light. Motorcycle seats are often exposed to sunlight, which can lead to fading and cracking over time. For B2B buyers, choosing UV-resistant materials ensures longer-lasting products, reducing warranty claims and enhancing brand reputation in markets where sun exposure is significant.

3. Water Resistance

Water resistance is essential for motorcycle seat covers, particularly in regions with varied climates. Materials that resist water penetration help prevent mold and mildew, extending the lifespan of the seat cover. B2B buyers should prioritize water-resistant materials to appeal to customers who use motorcycles in diverse weather conditions.

4. Grip and Texture

The grip and texture of the seat cover material significantly impact rider comfort and safety. Textured surfaces help riders maintain control during rides, especially in wet conditions. B2B buyers should consider materials that provide optimal grip while ensuring comfort, as this can influence customer loyalty and repeat purchases.

5. Weight Capacity

Weight capacity refers to the maximum load the seat can support without compromising its structure. This property is particularly important for heavier riders or those carrying additional gear. Understanding weight capacity helps B2B buyers recommend products that meet safety standards and customer needs.

What Are Common Trade Terms in the Motorcycle Seat Cover Industry?

In the motorcycle seat cover industry, several trade terms are commonly used. Familiarity with these terms is crucial for effective communication and negotiation.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. In the motorcycle seat cover market, OEM suppliers produce seat covers specifically designed for particular motorcycle models. B2B buyers often partner with OEMs for custom projects or replacement parts, ensuring compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and negotiate pricing. Suppliers with a low MOQ can be more appealing to smaller businesses looking to test new products without committing to large quantities.

3. RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to suppliers requesting pricing information for specific products or services. In the context of motorcycle seat covers, an RFQ helps buyers gather competitive quotes, facilitating better budgeting and decision-making. Buyers should provide clear specifications in the RFQ to receive accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers involved in international transactions, as they clarify delivery obligations and risk management, ensuring smooth logistics.

Illustrative image related to motorcycle seat cover material

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the motorcycle seat cover industry, lead time can vary based on the complexity of the order and supplier capabilities. B2B buyers should consider lead time when planning inventory and fulfilling customer demands, as longer lead times can impact customer satisfaction.

By grasping these essential technical properties and trade terminology, B2B buyers can enhance their purchasing strategies and build stronger relationships with suppliers in the motorcycle seat cover market.

Navigating Market Dynamics and Sourcing Trends in the motorcycle seat cover material Sector

What Are the Key Trends Influencing the Motorcycle Seat Cover Material Market?

The global motorcycle seat cover material market is experiencing significant growth driven by increasing motorcycle ownership, particularly in emerging markets such as Nigeria and Brazil. The rise in disposable income and a growing interest in recreational biking are contributing to this trend. As a result, international B2B buyers are increasingly seeking high-quality materials that not only enhance comfort but also withstand various environmental conditions.

Illustrative image related to motorcycle seat cover material

Current sourcing trends are leaning towards innovative materials that integrate comfort and durability. For instance, there is a growing preference for synthetic fabrics like advanced vinyl and polyurethane, which offer advantages such as resistance to wear and tear and ease of maintenance. Additionally, customization options, such as embroidery and unique stitching, are gaining traction as buyers look to differentiate their products in a competitive marketplace.

Emerging B2B technologies are also shaping the sourcing landscape. Online platforms for direct procurement and customization have simplified the buying process, allowing international buyers to access a broader range of suppliers. Furthermore, data analytics tools are enabling companies to better forecast demand and manage inventory, ensuring a more streamlined supply chain. The integration of e-commerce solutions is particularly vital for buyers in regions with varying levels of access to traditional retail channels.

How Does Sustainability and Ethical Sourcing Impact the Motorcycle Seat Cover Material Sector?

Sustainability is becoming an increasingly crucial factor in the motorcycle seat cover material sector. International buyers are becoming more environmentally conscious and are actively seeking suppliers who prioritize sustainable practices. This includes the use of eco-friendly materials and processes that minimize environmental impact, such as low-VOC (volatile organic compounds) adhesives and dyes.

Illustrative image related to motorcycle seat cover material

The importance of ethical supply chains cannot be overstated. Buyers are encouraged to partner with manufacturers that adhere to ethical labor practices and sustainability certifications. Green certifications, such as OEKO-TEX® and Global Organic Textile Standard (GOTS), are becoming valuable indicators of material quality and environmental responsibility. As the demand for sustainable products rises, suppliers that can offer certified eco-friendly materials may find themselves at a competitive advantage.

Moreover, the shift towards sustainability is not merely a trend but a necessity, as consumers increasingly favor brands that demonstrate a commitment to environmental stewardship. This shift is particularly relevant in markets like Europe, where regulations around sustainability are becoming more stringent.

What Is the Historical Context of Motorcycle Seat Cover Materials?

The evolution of motorcycle seat cover materials reflects broader changes in consumer preferences and manufacturing technologies. Initially, leather was the predominant choice for seat covers, prized for its aesthetic appeal and comfort. However, over the years, advancements in synthetic materials have transformed the landscape, offering alternatives that are not only more affordable but also more resilient to the elements.

In the late 20th century, the introduction of vinyl and polyurethane revolutionized the market. These materials provided significant advantages in terms of durability, ease of cleaning, and resistance to fading. As consumer demand for customization grew, manufacturers began to explore a range of textures, colors, and finishes, allowing for a more personalized riding experience.

Today, the market continues to innovate, with a notable shift towards multifunctional materials that combine comfort, durability, and sustainability. This ongoing evolution highlights the necessity for B2B buyers to stay informed about emerging materials and technologies that can enhance their product offerings while meeting the demands of an increasingly discerning customer base.

Illustrative image related to motorcycle seat cover material

Frequently Asked Questions (FAQs) for B2B Buyers of motorcycle seat cover material

-

How do I select the right material for motorcycle seat covers?

Choosing the right material for motorcycle seat covers involves understanding the specific needs of your target market. Key factors include durability, weather resistance, comfort, and aesthetics. Vinyl is a popular choice for its affordability and resistance to cracking, while leather offers a premium look but requires more maintenance. Consider the intended use—racing, touring, or casual riding—as this will influence material selection. Conduct market research to identify preferences in your region, such as Africa or South America, to ensure your offerings align with local demand. -

What is the best material for motorcycle seat covers?

The best material for motorcycle seat covers typically depends on the intended use and the preferences of the end user. Vinyl is favored for its durability and low maintenance, making it suitable for everyday riders. Leather provides a luxurious feel and aesthetic but demands regular care. For enhanced comfort, consider multi-layer options combining polyurethane foam and gel inserts, especially for long-distance touring. Evaluate regional preferences and climatic conditions, as these can greatly influence material effectiveness and buyer satisfaction. -

What are the minimum order quantities (MOQs) for motorcycle seat cover materials?

Minimum order quantities (MOQs) for motorcycle seat cover materials can vary significantly among suppliers. Typically, MOQs may range from 100 to 500 units, depending on the type of material and the manufacturer’s capabilities. When negotiating with suppliers, discuss your anticipated sales volume and potential for future orders to secure favorable terms. Be sure to consider shipping costs and timelines, especially for international orders, as these factors can impact your overall pricing and inventory management. -

How do I vet suppliers for motorcycle seat cover materials?

Vetting suppliers is crucial for ensuring quality and reliability in your motorcycle seat cover material sourcing. Start by researching potential suppliers online, checking their industry reputation through reviews and testimonials. Request samples to evaluate material quality firsthand. It’s also beneficial to verify their production capabilities, lead times, and compliance with international trade regulations. Establishing direct communication will help assess their responsiveness and willingness to accommodate your specific needs, fostering a strong business relationship. -

What customization options are available for motorcycle seat covers?

Customization options for motorcycle seat covers are extensive and can greatly enhance the appeal of your offerings. Many suppliers provide choices in material type, color, stitching patterns, and even personalized embroidery. Consider customer preferences in your target market, as customized products can command a premium price. Engage with suppliers to understand their capabilities and turnaround times for custom orders, ensuring they can meet your clients’ expectations without significant delays. -

What payment terms should I expect when sourcing motorcycle seat cover materials?

Payment terms can vary widely among suppliers in the motorcycle seat cover material industry. Common terms include a 30% deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer credit terms or discounts for early payments. It’s essential to discuss these terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods, such as letters of credit or escrow services, especially for larger international transactions, to protect your investment. -

How can I ensure quality assurance (QA) for my motorcycle seat cover materials?

Ensuring quality assurance (QA) for motorcycle seat cover materials requires a systematic approach. Start by establishing clear quality standards and specifications with your supplier. Conduct regular inspections during production and request samples from each batch before full shipment. Implement a feedback loop with your customers to gather insights on product performance and satisfaction. Consider third-party inspection services to validate quality, especially for international shipments, providing an added layer of assurance for your business. -

What logistics considerations should I keep in mind for international shipping of motorcycle seat cover materials?

When planning logistics for international shipping of motorcycle seat cover materials, consider factors such as shipping methods, customs regulations, and delivery timelines. Choose reliable freight forwarders with experience in your target regions, like Africa or South America, to navigate potential challenges. Be aware of import duties and taxes that may affect your total cost. Ensure that your supplier provides proper documentation for customs clearance, and maintain clear communication with all parties involved to avoid delays and ensure smooth delivery.

Top 7 Motorcycle Seat Cover Material Manufacturers & Suppliers List

1. Luimoto – Premium Motorcycle Seat Covers

Domain: luimoto.com

Registered: 2004 (21 years)

مقدمة: Motorcycle Seat Covers, Tank Grips & More – Luimoto offers premium aftermarket Rider Seat Covers made from marine-grade materials for comfort and style. Passenger Seat Covers enhance grip and styling, outperforming OEM covers. Custom Seat Covers allow for personalized designs with special stitching and embroidery. Premium Gold Gel inserts reduce rider fatigue and absorb road shock. Products are ta…

2. Marine-Grade Vinyl – Motorcycle Seat Re-Covering

Domain: reddit.com

Registered: 2005 (20 years)

مقدمة: Marine-grade vinyl and polyester are recommended materials for re-covering motorcycle seats, particularly for ADV bikes. Marine-grade vinyl is noted for its durability and water resistance, while polyester is lightweight. Adding foam padding is suggested for extra comfort.

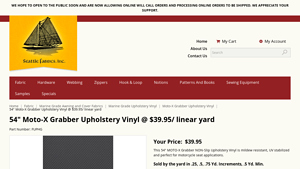

3. Seattle Fabrics – 54 Moto-X Grabber Upholstery Vinyl

Domain: seattlefabrics.com

Registered: 1998 (27 years)

مقدمة: {“Product Name”: “54” Moto-X Grabber Upholstery Vinyl”, “Price”: “$39.95/linear yard”, “Part Number”: “FUPHG”, “Width”: “54 inches”, “Material Type”: “NON-Slip Upholstery Vinyl”, “Features”: [“Mildew resistant”, “UV stabilized”], “Applications”: “Perfect for motorcycle seat applications”, “Availability”: “Sold by the yard in .25, .5, .75 yard increments, .5 yard minimum”, “Color”: “Black”, “Weight…

4. MotoDeal – Motorcycle Seats

Domain: motodeal.com.ph

مقدمة: Motorcycle seats typically consist of three layers: 1) Backing plate (plastic molding or fiberglass/carbon fiber for super sportbikes), 2) Foam layer (open-cell polyurethane for comfort, closed-cell polyurethane for racing, memory foam for molded fit), 3) Seat cover (vinyl for durability and affordability, leather for premium comfort but requires care, synthetic options mimic leather). Gel inserts…

5. Sunbrella – Outdoor Fabric Solutions

Domain: advrider.com

Registered: 2001 (24 years)

مقدمة: 1. Sunbrella outdoor fabric: Fade and stain resistant, waterproof, wear resistant, available in various colors, textures, and weights. Recommended for traction due to rough texture. 2. High-grade leather-look grain black vinyl: Durable but may not be breathable. 3. 4-way stretch vinyl: Easier to work with, helps avoid creases and folds, durable. 4. Hospital/industrial grade vinyl: Recommended with…

6. DIY Upholstery Supply – Motorcycle Vinyl

Domain: diyupholsterysupply.com

Registered: 2004 (21 years)

مقدمة: Motorcycle Vinyl is a stretchable, pliable upholstery vinyl suitable for various applications including gaming rails, marine use, ATVs, snow machines, and motorcycles. It features a -60°F cold crack resistance, 360° stretch, and is flame retardant. Available colors include: Black, High-Tac Black, Chalk, Nu Bright Yellow, Bright Red, Silver Met, Royal Blue, Electric Blue, Marine Green, and Bright V…

7. Sailrite – Morbern™ Allsport Stretch Vinyl & Accessories

Domain: sailrite.com

Registered: 1996 (29 years)

مقدمة: Materials List: Morbern™ Allsport 360º Stretch Electric Blue 54″ Vinyl Fabric (#104175), Morbern™ Allsport 360º Stretch Black 54″ Vinyl Fabric (#104182), PremoBond® Tex 90 (V-92) White UV Bonded Polyester Thread 4 oz. (1,350 yds.) (#123337), Cushion Wrap Silk Film 54″ (#103933), 5-Ply Waxed Polyester Twine Bobbin (81 ft.) (#29206), 21 Gauge 3/8″ (10mm) Staples 10,000/Box (Stainless Steel) (#8010SS…

Strategic Sourcing Conclusion and Outlook for motorcycle seat cover material

The motorcycle seat cover material market presents a wealth of opportunities for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. As the demand for durable and stylish motorcycle seat covers continues to rise, strategic sourcing becomes essential for identifying high-quality materials that meet diverse consumer preferences. Buyers should prioritize understanding the balance between cost and quality, ensuring that materials like vinyl, leather, and advanced foams align with their target markets’ needs.

Investing in premium materials can enhance customer satisfaction and brand loyalty, particularly as motorcycle enthusiasts seek comfort, durability, and aesthetics. Moreover, customization options, such as personalized designs and gel inserts, can differentiate your offerings in a competitive landscape.

Looking ahead, the focus on sustainability and innovative materials will likely shape the future of the motorcycle seat cover industry. B2B buyers should remain agile, adapting to market trends and consumer demands to leverage these opportunities. By fostering strong partnerships with reliable suppliers, businesses can not only meet current demands but also position themselves for future growth in the evolving motorcycle accessories market. Engage with suppliers today to ensure your offerings are at the forefront of this dynamic industry.

Illustrative image related to motorcycle seat cover material

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.