Catalog

Material Insight: Leatherette Material

B2B Product Guide: Leatherette Material

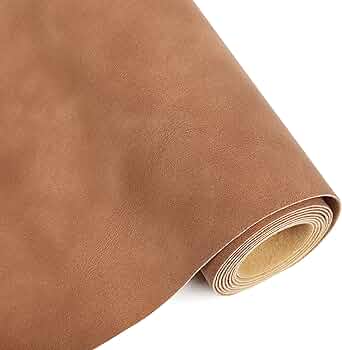

Leatherette material, commonly known as faux or synthetic leather, is a high-performance alternative to genuine leather engineered for durability, consistency, and sustainability. Made primarily from polyurethane (PU) or polyvinyl chloride (PVC) layered over a textile backing, leatherette replicates the aesthetic and tactile qualities of natural leather while offering enhanced control over physical properties such as abrasion resistance, color fastness, and environmental impact. Its versatility makes it ideal for industries including automotive interiors, furniture manufacturing, consumer electronics, footwear, and medical equipment.

Faux leather stands out as the best choice for modern industrial applications due to its ethical production, cost efficiency, and customizable performance. Unlike genuine leather, which varies in quality and is subject to natural imperfections, leatherette delivers uniform thickness, consistent appearance, and scalable production. Additionally, it supports eco-conscious manufacturing—especially PU-based leatherette—through reduced carbon footprint, absence of harmful tanning chemicals, and compatibility with recycling initiatives.

With over 20 years of specialized expertise, WINIW is a trusted global leader in synthetic leather innovation. We combine advanced material science with sustainable manufacturing practices to deliver premium leatherette solutions tailored to the exact needs of B2B clients. Our R&D-driven approach ensures products that meet rigorous international standards for durability, safety, and environmental responsibility. From concept to large-scale production, WINIW empowers industries with smarter, cleaner, and more reliable alternatives to traditional leather.

Technical Performance & Standards

WINIW Premium Leatherette: Technical Product Guide for Industrial Applications

WINIW Premium Leatherette delivers a scientifically engineered synthetic alternative to genuine leather, designed explicitly for B2B manufacturers seeking performance, sustainability, and operational efficiency. Our material undergoes rigorous quality control under ISO 9001-certified processes and adheres strictly to REACH (EC 1907/2006) chemical safety regulations, ensuring global market compliance and end-user safety. Below are the core technical advantages driving cost savings and design flexibility for industrial clients.

Key Technical Advantages

-

Cost-Effective Production

WINIW Leatherette reduces total landed costs by 25–40% compared to premium genuine leather, factoring in material yield efficiency (95%+ vs. 60–70% for leather), zero waste from hide defects, and simplified cutting processes. Lower storage requirements (consistent roll widths) and reduced labor for finishing further optimize operational expenditure. -

Engineered Durability

Formulated with high-density polyurethane (PU) and reinforced polyester backing, our material achieves: - 50,000+ double-rub cycles (Martindale ASTM D4966) without coating failure

- Tensile strength of 25–35 N/mm² (ISO 1798)

- Tear resistance >45 N (ISO 3377-1)

-

UV stability (500+ hours QUV exposure, ASTM G154) for outdoor applications

-

Unmatched Color Customization

WINIW offers Pantone®-matched color consistency across batches (ΔE <1.0), with capabilities for: - Matte, satin, or high-gloss finishes

- Metallic, pearlescent, and textured embossing

-

Custom color formulation within 15 business days (min. order: 500 linear meters)

-

REACH & Chemical Compliance

Full substance screening confirms zero SVHCs (Substances of Very High Concern), phthalates, azo dyes, or heavy metals (Cd, Pb, Hg, Cr⁶⁺). All formulations are pre-verified for EU, U.S., and APAC market准入 requirements. -

ISO 9001 Quality Assurance

Every production lot undergoes real-time statistical process control (SPC), with traceable batch documentation ensuring dimensional stability (±0.3mm thickness tolerance) and colorfastness (Grade 4–5, ISO 105-B02).

Technical Specifications Comparison

| Property | WINIW Premium Leatherette | Standard PVC Leatherette | Genuine Leather (Top Grain) |

|---|---|---|---|

| Thickness Range | 0.6–1.2 mm | 0.8–1.5 mm | 1.0–2.0 mm (variable) |

| Weight (g/m²) | 350–550 | 400–650 | 800–1,200 |

| Abrasion Resistance | 50,000+ cycles | 15,000–25,000 cycles | 30,000–40,000 cycles |

| Color Fastness (Light) | Grade 6 (ISO 105-B02) | Grade 3–4 | Grade 4–5 |

| Tensile Strength | 25–35 N/mm² | 15–25 N/mm² | 20–30 N/mm² |

| REACH SVHC Compliance | Certified Negative | Often Requires Testing | Variable (tannery-dependent) |

| Production Lead Time | 15–20 days | 10–15 days | 60+ days |

Sustainability Integration

WINIW Leatherette uses water-based PU coatings (VOC <50 g/L), reducing carbon footprint by 30% versus solvent-based alternatives. The material is fully recyclable through industrial streams, supporting circular economy initiatives without compromising on the durability or aesthetic requirements of automotive interiors, furniture, and technical upholstery sectors.

WINIW Leatherette eliminates the supply chain volatility of animal hides while delivering superior batch-to-batch consistency, accelerated time-to-market, and compliance certainty. For technical datasheets or custom formulation consultations, contact WINIW’s engineering team to optimize material specifications for your production line.

Why Choose Synthetic over Real Leather

B2B Product Guide: Leatherette Material vs Real Leather

When selecting materials for upholstery, accessories, or industrial applications, businesses must weigh performance, cost, and sustainability. Two of the most commonly compared materials are leatherette (synthetic leather) and real leather. Each has distinct characteristics that influence their suitability across industries such as automotive, furniture, fashion, and consumer goods.

Leatherette is a man-made material engineered to mimic the appearance and texture of real leather. Typically composed of a polyurethane (PU) or polyvinyl chloride (PVC) coating over a fabric backing, it offers a cruelty-free and often more affordable alternative. Real leather, derived from animal hides—primarily bovine—is valued for its natural grain, longevity, and premium tactile qualities.

Below is a comparative analysis of leatherette and real leather based on key business considerations:

| Factor | خامة جلدية | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher initial investment |

| المتانة | Moderate; prone to cracking over time, especially with UV exposure | High; develops patina and improves with age if maintained |

| Eco-friendliness | Varies: PU-based options are more eco-friendly than PVC; recyclable options available | Mixed: biodegradable but tanning process can be resource-intensive and polluting |

Key Considerations:

- Cost Efficiency:

- Leatherette provides significant cost savings in production, especially for high-volume manufacturing.

-

Real leather carries higher material and processing costs due to sourcing, tanning, and grading requirements.

-

Durability and Performance:

- Leatherette performs well in controlled environments but may degrade faster under prolonged sunlight, heat, or abrasion.

-

Real leather offers superior resilience, breathability, and aging characteristics, making it ideal for premium, long-life products.

-

Sustainability:

- Modern leatherette, particularly PU-based, supports eco-conscious manufacturing with reduced carbon footprint and animal-free sourcing.

-

While real leather utilizes a byproduct of the meat industry, traditional tanning (especially chrome tanning) raises environmental concerns. However, vegetable-tanned and chrome-free options are improving its sustainability profile.

-

Customization and Consistency:

- Leatherette offers uniform texture, color, and width, enabling greater design control and reduced waste during cutting.

- Real leather features natural variations, which may be desirable for luxury aesthetics but can complicate mass production.

Businesses choosing between leatherette and real leather should align their selection with brand values, product lifecycle expectations, and environmental goals. For applications requiring scalability, affordability, and ethical sourcing, high-quality leatherette—such as WINIW’s eco-enhanced PU leather—is a competitive, sustainable solution. For premium, long-wearing goods where authenticity and tactile experience are paramount, real leather remains the benchmark.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global B2B Partners

WINIW delivers premium, eco-conscious synthetic leather solutions through an integrated manufacturing ecosystem designed for scale, innovation, and uncompromising quality. Our vertically aligned operations ensure end-to-end control from R&D to export, meeting the rigorous demands of international markets while prioritizing environmental stewardship.

Core Manufacturing Capabilities

- 100,000 sqm Integrated Campus: A single-site manufacturing facility in China enabling seamless production flow, reduced lead times, and strict environmental management. Our campus houses extrusion, coating, finishing, and testing under one roof, minimizing logistical waste.

- Dedicated R&D Team: 40+ material scientists and engineers focused on sustainable innovation, including bio-based polymers, waterless dyeing technologies, and ultra-low-VOC formulations. Annual R&D investment exceeds 5% of revenue.

- Strict Quality Control Protocol: Multi-stage QC checkpoints (raw material intake, in-process, final inspection) with ISO 9001-certified procedures. Every batch undergoes 12+ physical performance tests (abrasion, colorfastness, peel strength) and chemical compliance screening. Full traceability via digital batch tracking.

Global Compliance & Export Readiness

WINIW products consistently meet the highest regulatory standards for eco-sensitive markets. Our materials are routinely certified for:

| Certification | Scope | Relevance for EU/USA Clients |

|---|---|---|

| REACH SVHC | Phthalates, heavy metals | Mandatory for EU chemical compliance |

| OEKO-TEX® Standard 100 | Harmful substance screening | Consumer safety assurance |

| CPSIA | Lead, phthalates (children’s goods) | Required for US toy/furniture sectors |

| ISO 14001 | Environmental management system | Validates sustainable operations |

We maintain direct export channels to 30+ countries, with 65% of annual volume shipped to Europe and North America. Our logistics network ensures FCL/LCL shipments with full documentation (including IMDS for automotive clients) and adherence to INCOTERMS 2020. Partner with WINIW for synthetics that balance performance, sustainability, and global market access—engineered for the future of responsible manufacturing.

Contact Us for Samples

B2B Product Guide: Premium Leatherette Material by WINIW

WINIW specializes in high-performance, eco-friendly leatherette materials engineered for durability, aesthetics, and sustainability. Our advanced microfiber leather solutions are trusted by manufacturers and designers across furniture, automotive, fashion, and interior design industries. With a focus on innovation and environmental responsibility, WINIW delivers leather alternatives that meet rigorous commercial standards without compromising on quality or ethics.

Our leatherette material is crafted using state-of-the-art technology to replicate the texture, feel, and performance of genuine leather—while offering superior resistance to wear, UV exposure, and staining. As a sustainable alternative, WINIW’s leatherette reduces reliance on animal products and lowers environmental impact through low-emission production processes.

Key Benefits of WINIW Leatherette:

- High abrasion resistance for long-term durability in high-use environments

- Eco-conscious manufacturing with REACH and RoHS compliance

- Available in a wide range of textures, colors, and finishes (suede, glossy, matte, embossed)

- Excellent breathability and soft hand feel for enhanced comfort

- Lightweight and easy to process—ideal for cutting, sewing, and laminating

- Resistant to fading, cracking, and microbial growth

- Customizable thickness (0.6mm to 2.0mm) and backing options (knit, non-woven, PU-coated)

Applications Across Industries:

- Automotive interiors (seats, dashboards, door panels)

- Furniture upholstery (sofas, chairs, office seating)

- Fashion accessories (bags, wallets, belts)

- Footwear and sportswear

- Hospitality and contract interiors

Technical Specifications Overview:

| Property | Standard Value |

|---|---|

| Thickness Range | 0.6 mm – 2.0 mm |

| Weight | 200 – 450 g/m² |

| Tensile Strength | ≥ 25 N/cm |

| Elongation at Break | ≥ 80% |

| Martindale Abrasion | ≥ 30,000 cycles |

| Light Fastness | Grade 4–5 (ISO 105-B02) |

| Environmental Standards | REACH, RoHS, Oeko-Tex® compliant |

WINIW is committed to supporting B2B partners with scalable production, consistent quality control, and rapid turnaround times. We offer OEM and ODM services tailored to your design and performance requirements.

Request Free Samples Today

Experience the quality and versatility of WINIW leatherette firsthand. Free samples are available for qualified business partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.