Catalog

Material Insight: Leather Factory Florence Italy

B2B Product Guide: Premium Faux Leather Solutions from a Leather Factory in Florence, Italy

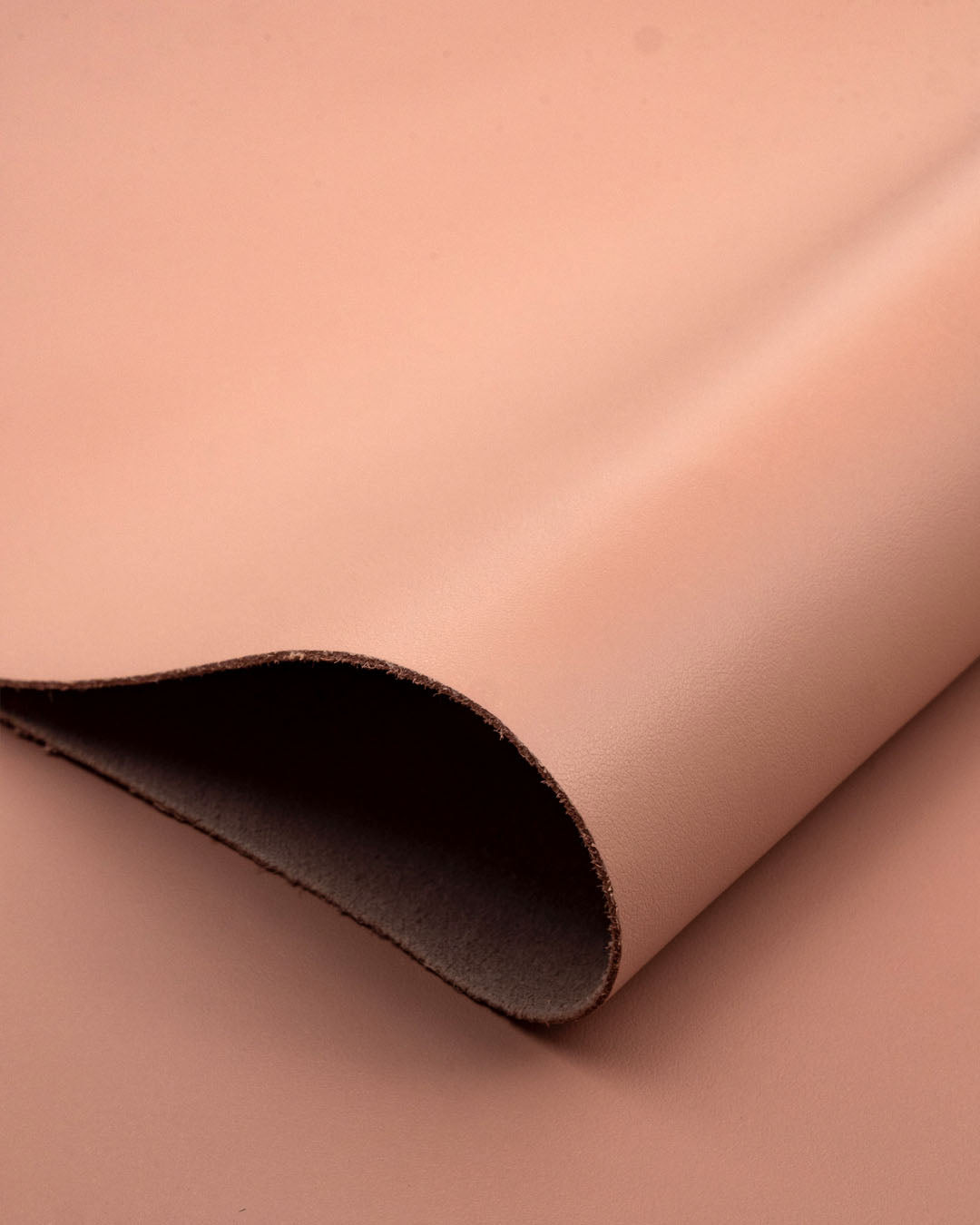

Florence, Italy has long been synonymous with craftsmanship, elegance, and innovation in the world of luxury materials. As a global hub for high-end fashion and design, the region’s leather factories have set the benchmark for quality and artistry. Today, as sustainability and ethical sourcing become paramount in the manufacturing landscape, forward-thinking producers are turning to advanced faux leather alternatives without compromising on aesthetics or performance. At the intersection of Italian design heritage and modern material science, faux leather emerges as the optimal solution for luxury goods, furniture, automotive interiors, and architectural applications.

Why Faux Leather is the Best Choice for This Application

- Faux leather offers consistent texture and color uniformity, ensuring high yield and minimal waste in precision manufacturing environments.

- It is produced under controlled conditions, enabling scalability and batch-to-batch reliability—critical for B2B supply chains.

- Modern microfiber and PU-based faux leathers match the softness, drape, and durability of premium genuine leather while eliminating variability inherent in animal hides.

- It supports eco-conscious production with reduced water usage, no heavy metals, and lower carbon footprint compared to traditional tanning processes.

- Faux leather is animal-free, aligning with global regulations and brand commitments to cruelty-free and sustainable sourcing.

- Customization is seamless—from texture and thickness to color and performance finishes—making it ideal for bespoke design requirements in luxury markets.

Introducing WINIW: Two Decades of Innovation in Synthetic Leather

WINIW is a leading developer and manufacturer of high-performance synthetic leather, with over 20 years of experience serving global B2B clients in fashion, automotive, furniture, and interior design. Rooted in material innovation and sustainable practices, WINIW partners with European design studios and manufacturers—including those in Florence—to deliver premium faux leather that meets the rigorous standards of Italian craftsmanship.

By combining advanced polymer technology with eco-friendly production methods, WINIW provides materials that are not only visually and tactilely indistinguishable from fine leather but also engineered for enhanced durability, breathability, and environmental responsibility. As the industry shifts toward a more sustainable future, WINIW stands at the forefront, empowering leather factories in Italy and beyond to innovate with confidence, quality, and conscience.

Technical Performance & Standards

WINIW Microfiber Leather: Technical Product Guide for B2B Applications

WINIW delivers premium synthetic leather solutions engineered for global manufacturing excellence. While WINIW operates advanced production facilities in China (not Italy), our materials are rigorously designed to meet the exacting standards associated with European craftsmanship—offering superior performance, sustainability, and cost efficiency for automotive, furniture, and luxury goods industries. Below are the core technical advantages of WINIW’s flagship microfiber leather series, optimized for high-volume production without compromising quality.

Key Technical Advantages

- Cost-Effective Production: Achieve up to 15% material savings through optimized cutting yield and reduced waste vs. traditional leather. Our consistent roll goods (50–60m per roll) minimize downtime and streamline automated cutting processes.

- Industrial-Grade Durability: Engineered with high-density polyurethane (PU) and ultra-fine polyester fibers for 100,000+ double-rub cycles (Martindale test), 20N tensile strength, and resistance to hydrolysis (70°C/95% RH for 14 days). Ideal for high-traffic applications like automotive seating and commercial furniture.

- Precision Color Customization: Access 10,000+ standardized color options (Pantone®/RAL matched) with batch-to-batch consistency (ΔE ≤ 0.5). Low MOQs (500 linear meters) enable agile response to design trends without inventory risk.

- REACH Compliance: Fully compliant with EU REACH Annex XVII, including zero detectable levels of banned substances (e.g., AZO dyes, phthalates, PCP). Certified via SGS/TÜV third-party testing.

- ISO 9001:2015 Quality Assurance: End-to-end process control from raw material sourcing to finishing, ensuring dimensional stability (±0.5% after 24h conditioning) and defect rates <0.3%.

Technical Specifications Table

| Property | Value | Test Standard |

|---|---|---|

| Thickness | 0.6–1.8 mm (customizable) | ISO 2418 |

| Weight | 300–800 g/m² | ISO 2418 |

| Abrasion Resistance | ≥100,000 cycles (Martindale) | ISO 12947-2 |

| Tensile Strength | ≥20 N | ISO 1767 |

| Color Fastness (Light) | Grade 6–7 (ISO scale) | ISO 105-B02 |

| Hydrolysis Resistance | Pass (14 days @ 70°C/95% RH) | ISO 14145-2 |

| Eco-Credentials | REACH, OEKO-TEX® Standard 100 | EC 1907/2006 |

| Roll Length | 50–60 meters | Internal Quality |

Why WINIW for Sustainable B2B Procurement

WINIW’s closed-loop manufacturing reduces water usage by 90% versus bovine leather tanning, while our solvent-free PU coating technology eliminates VOC emissions. All materials are recyclable via industrial streams, supporting client ESG goals without sacrificing performance. With ISO 9001-certified traceability and 48-hour technical support for color/formulation adjustments, we ensure seamless integration into your supply chain—delivering European-quality standards at globally competitive pricing.

WINIW: Precision-engineered synthetic leather for brands that demand responsibility without compromise.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather from WINIW vs. Traditional Real Leather – A Comparative Analysis

In the evolving landscape of luxury and performance materials, manufacturers and designers are increasingly evaluating alternatives to traditional real leather. One prominent option gaining traction is high-performance synthetic leather, particularly from advanced producers such as WINIW, inspired by the craftsmanship associated with leather manufacturing regions like Florence, Italy. While Florence symbolizes heritage and artisanal excellence in leatherworking, modern synthetic leathers offer a compelling alternative that aligns with sustainability, consistency, and cost-efficiency demands in B2B applications.

This guide compares synthetic leather—produced using state-of-the-art technology and design principles akin to those of a premium leather factory in Florence, Italy—with traditionally tanned real leather. The evaluation focuses on three critical factors for commercial buyers: cost, durability, and eco-friendliness.

- Synthetic leather, such as WINIW’s eco-friendly microfiber and PU leather solutions, replicates the look, feel, and performance of real leather while offering enhanced control over texture, thickness, and color consistency.

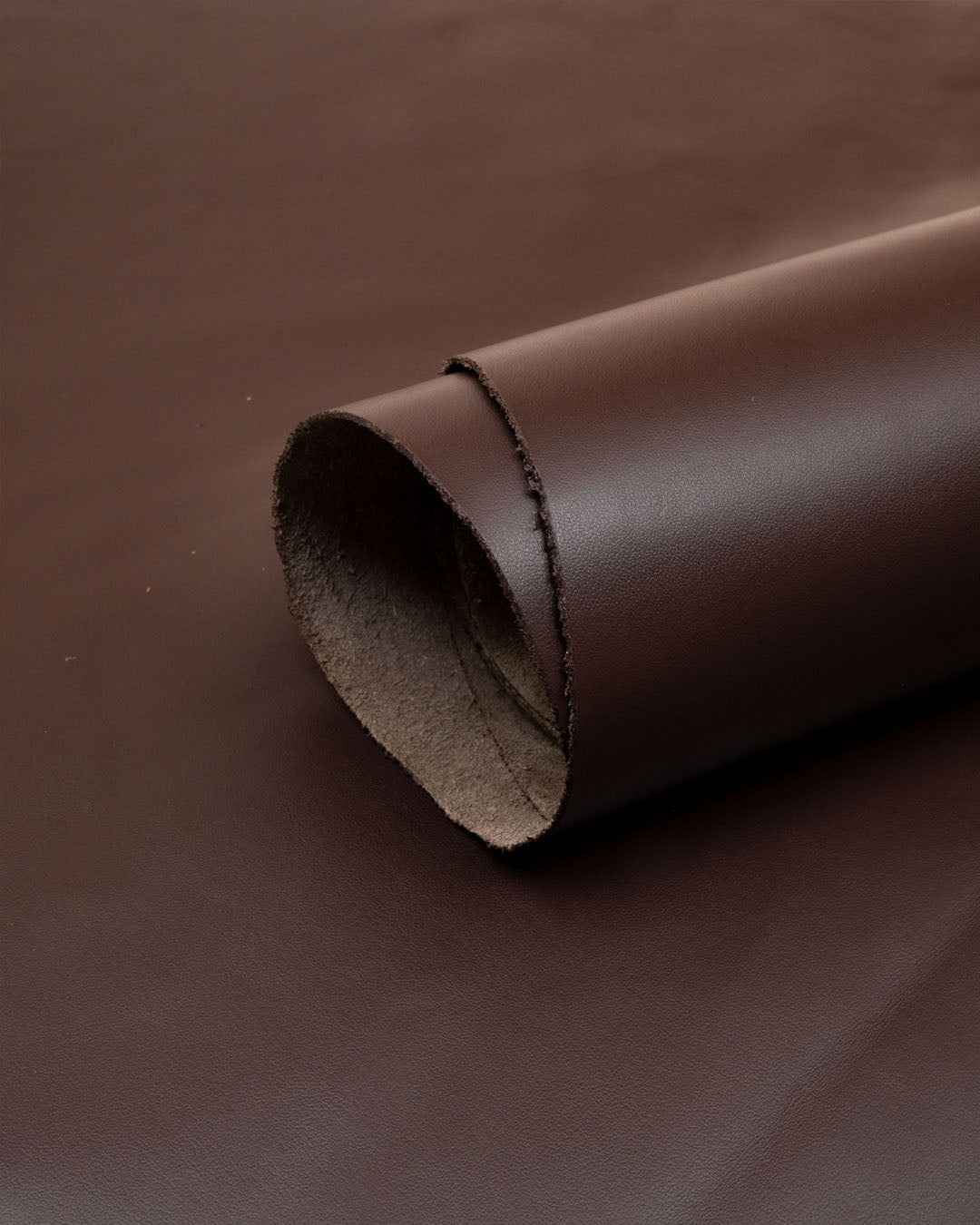

- Real leather, traditionally sourced from Italian tanneries in regions like Florence, is prized for its natural grain and aging characteristics but comes with variability in quality and environmental footprint.

- WINIW’s production process emphasizes repeatability and scalability, making it ideal for global supply chains requiring uniform material performance across high-volume orders.

The following table provides a comparative overview based on key business and sustainability metrics:

| Criteria | Leather Factory (Florence, Italy) – Real Leather | WINIW Synthetic Leather (Florence-Inspired Performance) |

|---|---|---|

| Cost | High – Due to raw material scarcity, labor-intensive tanning, and import logistics | Moderate to Low – Economies of scale, reduced material waste, and efficient production |

| المتانة | High – Natural hide offers strength and develops a patina over time; however, sensitive to moisture and UV degradation | High – Engineered for abrasion resistance, UV stability, and consistent performance under stress; less prone to cracking or fading |

| Eco-Friendliness | Moderate to Low – Involves high water usage, toxic tanning agents (e.g., chromium), and significant carbon footprint | High – Uses water-based PU, recycled fibers, and low-VOC emissions; compliant with REACH, OEKO-TEX®, and RoHS standards |

- WINIW’s synthetic leather solutions are designed for industries including automotive interiors, luxury goods, furniture, and footwear, where both aesthetic excellence and environmental responsibility are critical.

- Unlike real leather, which depends on livestock farming and resource-heavy processing, WINIW’s materials reduce dependency on animal agriculture and eliminate associated methane emissions.

- The traceability and compliance of synthetic leather batches support corporate ESG (Environmental, Social, and Governance) reporting, a growing requirement for B2B procurement in Europe and North America.

For forward-thinking brands seeking to balance heritage-inspired quality with modern sustainability standards, synthetic leather from innovators like WINIW offers a strategic advantage over traditional real leather—without compromising on performance or premium appeal.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW operates one of the industry’s most advanced synthetic leather manufacturing ecosystems, designed to deliver consistent quality, innovation, and supply chain resilience for global partners. Our vertically integrated 100,000 sqm facility in China serves as the cornerstone of this capability, enabling end-to-end control from raw material formulation to finished roll goods. This scale ensures agile production capacity while maintaining rigorous environmental stewardship across all operations.

Core Factory Strengths Driving Client Success:

– Integrated Manufacturing Scale: 100,000 sqm facility with automated production lines for PU, PVC, and microfiber substrates, supporting annual capacities exceeding 50 million meters to meet high-volume global demand.

– Dedicated R&D Innovation Hub: 40+ material scientists and engineers focused on eco-performance breakthroughs, including water-based PU systems, recycled content integration (up to 30% PCR), and bio-based polymer development.

– Zero-Compromise Quality Control: Multi-stage QC protocols validated by international certifications, ensuring every meter meets stringent brand specifications before shipment.

– Global Compliance Infrastructure: Full alignment with EU REACH, U.S. CPSIA, and California Proposition 65 standards, enabling seamless export to Tier-1 automotive, furniture, and fashion brands across Europe and North America.

Quality Assurance Certification Framework

| Certification | Scope | Direct Client Benefit |

|——————–|—————————————-|——————————————-|

| ISO 9001:2015 | End-to-end quality management | Consistent batch-to-batch reliability |

| OEKO-TEX® STANDARD 100 | Restricted substance screening | Guaranteed consumer safety compliance |

| ISO 14001 | Environmental management | Reduced supply chain sustainability risk |

| SCS Recycled Content | Verified PCR material traceability | Credible eco-claims for marketing |

Our export infrastructure processes 85% of output for direct shipment to Europe and the USA, with dedicated logistics partners ensuring customs-ready documentation and carbon-neutral transport options. This combination of scale, scientific rigor, and regulatory foresight positions WINIW as a strategic manufacturing ally for brands demanding performance, sustainability, and compliance certainty in competitive international markets.

Contact Us for Samples

WINIW Microfiber Leather – Premium Synthetic Leather for Luxury Applications

WINIW is a global leader in high-performance synthetic leather, delivering sustainable, durable, and luxurious alternatives to genuine leather. Engineered for discerning B2B clients in fashion, automotive, and upholstery industries, our microfiber leather combines advanced material science with eco-conscious production processes. Trusted by premium manufacturers across Europe and beyond, WINIW offers a responsible choice without compromising on aesthetics or performance.

Our products are ideal for partners seeking consistent quality, scalability, and compliance with environmental standards. With production facilities optimized for international supply chains, we support long-term collaborations with brands committed to innovation and sustainability.

Why Choose WINIW Microfiber Leather?

- Superior softness and hand feel comparable to top-grain genuine leather

- High abrasion resistance and tensile strength for long-lasting performance

- Eco-friendly manufacturing with low-VOC emissions and REACH-compliant chemistry

- Available in a wide range of textures, colors, and finishes—including custom development

- Water-resistant, breathable, and easy to clean—ideal for high-use applications

- Consistent roll-to-roll quality with minimal waste during cutting and processing

- Cruelty-free and 100% animal-free—certified by international vegan standards

Technical Specifications (Typical Values)

| Property | Test Method | Value |

|---|---|---|

| Thickness | ISO 2417 | 0.8 – 2.0 mm (customizable) |

| Tensile Strength | ISO 1766 | |

| Elongation at Break | ISO 1766 | ≥ 20% |

| Martindale Abrasion | ISO 12947 | 50,000+ cycles |

| Color Fastness to Rubbing | ISO 105-X12 | Class 4–5 (dry/wet) |

| Light Fastness | ISO 105-B02 | ≥ 6 (on Blue Scale) |

التطبيقات

- Luxury handbags, wallets, and accessories

- Upholstered furniture and high-end interior design

- Automotive and RV seating and trim

- Footwear and apparel requiring premium drape

- Wall panels and acoustic coverings

Partner with a Leather Factory in Florence, Italy

For European brands and designers seeking local craftsmanship with global standards, WINIW collaborates with a state-of-the-art leather finishing facility in Florence, Italy. This strategic partnership enables:

- EU-based quality control and rapid turnaround

- Artisan-level finishing techniques with modern performance

- Compliance with Italian and EU environmental regulations

- Seamless integration with local design houses and manufacturers

This facility specializes in premium microfiber leather applications, combining Tuscan tradition with sustainable innovation.

Request Free Samples Today

Evaluate WINIW microfiber leather firsthand with complimentary sample swatches. We offer standard and custom options to match your design and technical requirements.

Contact our B2B team:

MKT88@MicrofiberLeather.com

WINIW – Redefining Leather for a Sustainable Future.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.