Introduction: Navigating the Global Market for what is microfiber fabric made of

In the ever-evolving textile industry, understanding what microfiber fabric is made of is essential for international B2B buyers seeking high-quality, cost-effective solutions. Sourcing durable and versatile materials can pose a significant challenge, especially for companies operating in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia. This guide delves deep into the intricate world of microfiber, exploring its composition, types, and applications, while also addressing critical factors such as supplier vetting and pricing.

Microfiber fabric, known for its ultra-fine synthetic fibers, offers remarkable properties including breathability, moisture-wicking abilities, and durability, making it suitable for a wide range of applications—from cleaning products to apparel. With the increasing demand for sustainable textiles, it’s vital for buyers to be informed about the environmental implications and production processes associated with microfiber.

This comprehensive guide empowers B2B buyers by providing actionable insights into the sourcing process, enabling them to make informed purchasing decisions. By understanding the diverse applications and characteristics of microfiber fabric, companies can enhance their product offerings while navigating the complexities of the global market. Equip your business with the knowledge needed to leverage microfiber’s unique benefits, ensuring a competitive edge in your industry.

Table Of Contents

- Top 4 What Is Microfiber Fabric Made Of Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is microfiber fabric made of

- Understanding what is microfiber fabric made of Types and Variations

- Key Industrial Applications of what is microfiber fabric made of

- 3 Common User Pain Points for ‘what is microfiber fabric made of’ & Their Solutions

- Strategic Material Selection Guide for what is microfiber fabric made of

- In-depth Look: Manufacturing Processes and Quality Assurance for what is microfiber fabric made of

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is microfiber fabric made of’

- Comprehensive Cost and Pricing Analysis for what is microfiber fabric made of Sourcing

- Alternatives Analysis: Comparing what is microfiber fabric made of With Other Solutions

- Essential Technical Properties and Trade Terminology for what is microfiber fabric made of

- Navigating Market Dynamics and Sourcing Trends in the what is microfiber fabric made of Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is microfiber fabric made of

- Strategic Sourcing Conclusion and Outlook for what is microfiber fabric made of

- Important Disclaimer & Terms of Use

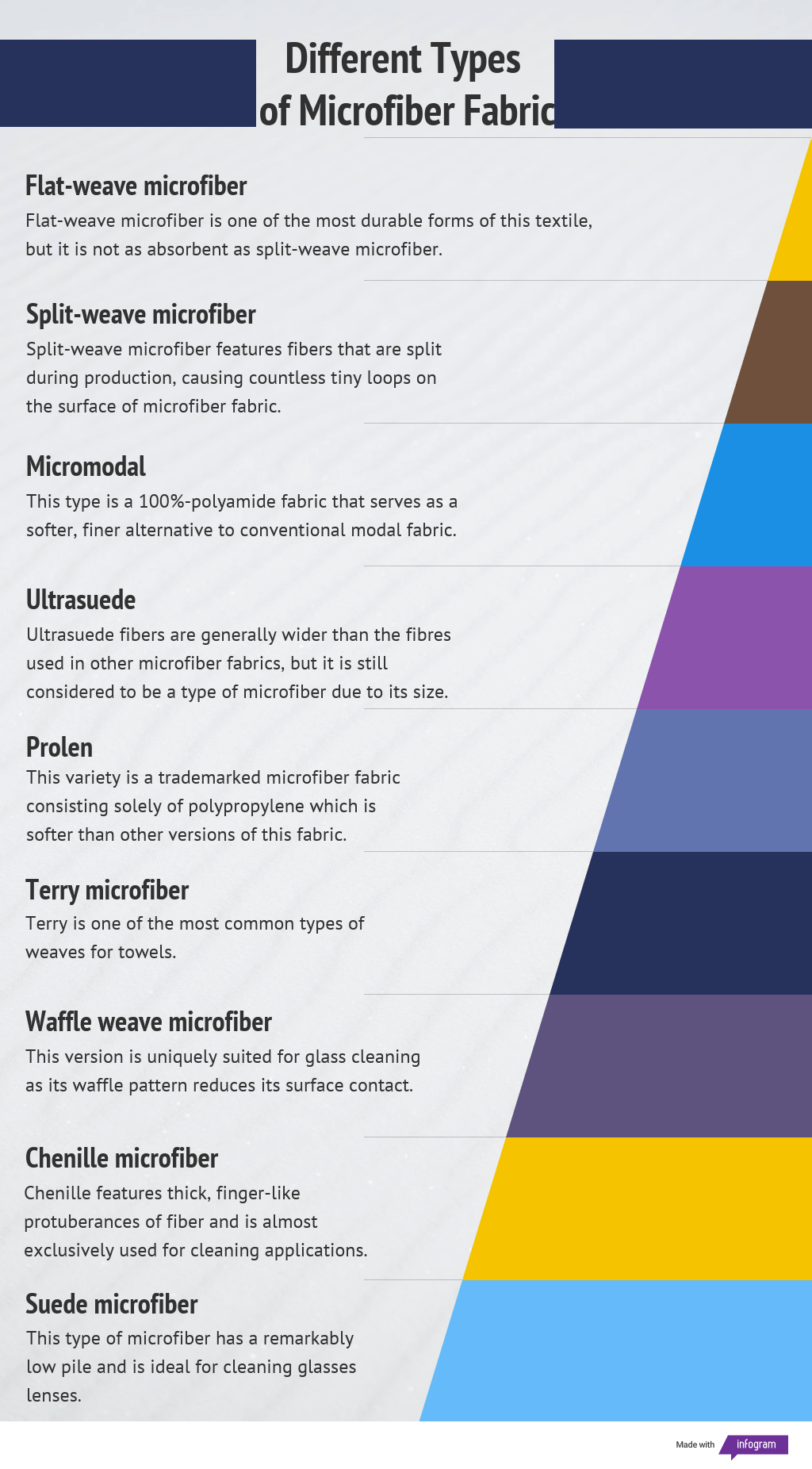

Understanding what is microfiber fabric made of Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flat-Weave Microfiber | Durable, low absorbency | Upholstery, outdoor gear | Pros: Highly durable, easy to clean. Cons: Less absorbent than other types. |

| Split-Weave Microfiber | High absorbency, soft texture | Cleaning cloths, towels, bathrobes | Pros: Excellent for cleaning, very soft. Cons: Can wear out faster if not maintained. |

| Brushed Microfiber | Soft, fuzzy surface, enhanced comfort | Apparel, bedding, blankets | Pros: Soft feel, good thermal insulation. Cons: Prone to pilling over time. |

| Microfiber Suede | Imitates leather, luxurious feel | Fashion accessories, upholstery | Pros: Aesthetic appeal, versatile use. Cons: Can be sensitive to heat and moisture. |

| Microfiber Mesh | Breathable, lightweight, structured weave | Athletic wear, protective gear | Pros: Excellent breathability, moisture-wicking. Cons: Less durable under heavy use. |

What Are the Key Characteristics of Flat-Weave Microfiber?

Flat-weave microfiber is characterized by its durability and low absorbency, making it ideal for applications requiring robustness. This type of microfiber is often used in upholstery and outdoor gear, where exposure to wear and tear is common. Buyers should consider the fabric’s resistance to stains and ease of cleaning, making it a practical choice for high-traffic areas. However, its lower absorbency may limit its use in applications where moisture retention is crucial.

How Does Split-Weave Microfiber Stand Out?

Split-weave microfiber is known for its high absorbency and soft texture, making it an excellent choice for cleaning cloths, towels, and bathrobes. This type of microfiber captures dirt and grime effectively, making it a preferred option in cleaning applications. B2B buyers should consider the balance between absorbency and durability, as split-weave fabrics can wear out faster if not properly maintained. Its softness also enhances user comfort, making it suitable for personal care products.

What Are the Advantages of Brushed Microfiber?

Brushed microfiber features a soft, fuzzy surface that enhances comfort, making it popular for apparel, bedding, and blankets. This type of microfiber provides good thermal insulation, which is beneficial in colder climates. B2B buyers should be aware that while brushed microfiber is soft and comfortable, it can be prone to pilling over time. Therefore, selecting high-quality brushed microfiber can mitigate this issue and extend the product’s lifespan.

Why Choose Microfiber Suede for Fashion and Upholstery?

Microfiber suede mimics the luxurious feel of leather, making it an attractive option for fashion accessories and upholstery. Its aesthetic appeal is a significant draw for B2B buyers looking to create high-end products without the cost of genuine leather. However, it is important to note that microfiber suede can be sensitive to heat and moisture, which may affect its longevity. Buyers should consider the environmental conditions in which the product will be used to ensure durability.

What Makes Microfiber Mesh Ideal for Athletic Wear?

Microfiber mesh is distinguished by its breathability and lightweight nature, making it suitable for athletic wear and protective gear. This type of microfiber excels at moisture-wicking, keeping users dry during physical activities. B2B buyers should evaluate the fabric’s durability, as it may be less resilient under heavy use compared to other microfiber types. Nonetheless, its breathability and comfort make it a popular choice in the sports and fitness industry.

Key Industrial Applications of what is microfiber fabric made of

| Industry/Sector | Specific Application of what is microfiber fabric made of | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cleaning & Janitorial | Microfiber cleaning cloths and mops | Enhanced cleaning efficiency and reduced chemical usage | Ensure high thread count for durability; consider eco-friendly options |

| Apparel & Fashion | Microfiber jackets and activewear | Lightweight, moisture-wicking, and durable clothing | Focus on fabric softness and stretchability; verify supplier standards |

| Automotive | Microfiber upholstery and detailing products | Superior aesthetics and easy maintenance | Source from reputable manufacturers to ensure quality and consistency |

| Industrial Filtration | Microfiber filter media for air and liquid filtration | Improved filtration efficiency and reduced energy costs | Assess compatibility with existing systems; consider regulatory compliance |

| Home Goods | Microfiber bedding and upholstery | Soft, breathable, and hypoallergenic products | Prioritize certifications for safety and quality; evaluate supply chain reliability |

How is Microfiber Fabric Used in Cleaning and Janitorial Applications?

Microfiber fabric is extensively used in cleaning cloths and mops due to its unique ability to trap dirt and grime more effectively than traditional materials. The electrostatic properties of microfiber allow it to attract and hold onto dust and allergens, minimizing the need for chemical cleaners. For international buyers, sourcing high-thread-count microfiber ensures durability and effectiveness, making it a preferred choice for both commercial and residential cleaning services, particularly in regions where hygiene standards are paramount.

What Role Does Microfiber Play in Apparel and Fashion?

In the apparel industry, microfiber fabric is favored for its lightweight, moisture-wicking, and durable properties, making it ideal for jackets and activewear. Its softness provides comfort, while its strength ensures longevity, appealing to both consumers and manufacturers. For B2B buyers in diverse markets, including Africa and Europe, it is crucial to verify the stretchability and softness of the fabric, as these characteristics significantly influence customer satisfaction and brand loyalty.

How is Microfiber Fabric Beneficial in Automotive Applications?

Microfiber is increasingly popular in the automotive sector, particularly for upholstery and detailing products. Its soft texture prevents scratching on surfaces while providing an aesthetically pleasing finish. Additionally, microfiber materials are easy to clean and maintain, which is a significant advantage for car manufacturers and detailing businesses. Buyers should ensure they source from reputable suppliers to guarantee product consistency and performance, especially in regions with varying climate conditions.

What are the Industrial Applications of Microfiber in Filtration?

In industrial settings, microfiber fabric serves as an effective filter media for air and liquid filtration systems. Its fine fibers can capture smaller particles, improving overall filtration efficiency while reducing energy costs. For B2B buyers in sectors such as manufacturing and construction, it is essential to assess the compatibility of microfiber filters with existing systems and ensure compliance with industry regulations to avoid operational disruptions.

How is Microfiber Used in Home Goods?

Microfiber is a popular choice for home goods, particularly in bedding and upholstery, due to its softness, breathability, and hypoallergenic properties. These features make microfiber products appealing to consumers looking for comfort and safety in their homes. For international buyers, prioritizing suppliers that offer certifications for safety and quality is crucial, as it ensures that the products meet local market standards and consumer expectations.

3 Common User Pain Points for ‘what is microfiber fabric made of’ & Their Solutions

Scenario 1: Understanding Microfiber Composition for Specific Applications

The Problem: B2B buyers often struggle to understand the exact composition of microfiber fabric, which can lead to inappropriate sourcing decisions. For instance, a company in the cleaning industry may require microfiber cloths that are specifically designed to trap dust and debris effectively. However, if they source generic microfiber that lacks the optimal blend of polyester and polyamide, they may find that their products perform poorly, resulting in customer dissatisfaction and increased returns. This lack of clarity can also lead to miscommunication with suppliers, exacerbating the issue.

Illustrative image related to what is microfiber fabric made of

The Solution: To mitigate this problem, B2B buyers should prioritize sourcing microfiber fabrics that explicitly state their fiber composition and properties. It’s crucial to engage with suppliers who provide detailed technical specifications, including the percentage of polyester and polyamide used. Buyers can request samples to test the fabric’s effectiveness in real-world applications, ensuring that it meets their performance requirements. Additionally, investing in supplier education can be beneficial; understanding the implications of different fiber blends can empower buyers to make more informed purchasing decisions.

Scenario 2: Navigating Environmental Concerns Related to Microfiber

The Problem: With increasing awareness around environmental sustainability, B2B buyers face pressure to select materials that align with eco-friendly practices. However, the widespread concern about microfiber pollution, particularly from washing synthetic fabrics, presents a dilemma. Buyers in industries like hospitality or apparel may find it challenging to reconcile the performance benefits of microfiber with their commitment to sustainability. This can lead to hesitance in adopting microfiber products, potentially stalling innovation and product development.

The Solution: To address environmental concerns, B2B buyers should seek out suppliers who are committed to sustainable practices in the production of microfiber. This includes looking for certifications that validate the eco-friendliness of the materials used. Suppliers may offer microfiber products that incorporate recycled fibers or have undergone treatments to minimize microfiber shedding during laundering. Additionally, buyers can collaborate with suppliers to implement sustainable washing and care instructions for microfiber products, thereby reducing their environmental impact while still reaping the benefits of this versatile fabric.

Scenario 3: Ensuring Quality and Consistency in Microfiber Fabric Sourcing

The Problem: Quality inconsistency is a significant challenge faced by B2B buyers when sourcing microfiber fabric. Variations in manufacturing processes across different suppliers can result in inconsistent thread counts, absorbency levels, and durability. For companies reliant on microfiber for high-quality end products, such as athletic wear or cleaning supplies, this inconsistency can negatively impact brand reputation and customer loyalty.

The Solution: To combat quality inconsistencies, B2B buyers should establish stringent quality assurance protocols when selecting suppliers. This includes conducting thorough audits of potential suppliers to evaluate their production methods and quality control measures. Buyers can also develop long-term relationships with a select few suppliers known for their reliability and consistency, rather than frequently switching vendors. Implementing a standardized testing process for incoming materials can further ensure that all batches meet the required specifications, allowing companies to maintain high standards for their products. Additionally, collaborating with suppliers on product development can lead to tailored solutions that meet specific quality benchmarks, thereby enhancing the overall value proposition.

In conclusion, addressing these common pain points through proactive sourcing strategies, environmental responsibility, and strict quality controls can empower B2B buyers to make informed decisions about microfiber fabric. By doing so, they can enhance their product offerings while mitigating risks associated with performance, sustainability, and quality.

Strategic Material Selection Guide for what is microfiber fabric made of

What Are the Key Materials Used in Microfiber Fabric?

Microfiber fabric is primarily composed of ultra-fine synthetic fibers, most commonly polyester and polyamide. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers looking to source microfiber for various applications. Below, we analyze the key materials used in microfiber fabric, focusing on their performance and suitability for different markets.

What Are the Key Properties of Polyester in Microfiber Fabric?

Polyester is one of the primary components of microfiber fabric, known for its high tensile strength and durability. It typically exhibits excellent moisture-wicking properties, making it suitable for applications that require quick drying. Polyester can withstand a range of temperatures, generally rated from -40°C to 150°C, but its performance can be affected by prolonged exposure to high heat.

Illustrative image related to what is microfiber fabric made of

Pros: Polyester is cost-effective, widely available, and offers good resistance to UV light and abrasion. Its durability makes it suitable for a variety of end products, including cleaning cloths, upholstery, and apparel.

Cons: However, polyester can be prone to pilling and may not be as breathable as natural fibers. Its environmental impact is also a concern, as it contributes to microplastic pollution.

How Does Polyamide Enhance Microfiber Fabric Performance?

Polyamide, or nylon, is another critical material in microfiber production. It is known for its exceptional elasticity and abrasion resistance, making it ideal for applications where flexibility and durability are essential. Polyamide fibers can withstand temperatures up to 180°C, making them suitable for a range of industrial applications.

Pros: The inclusion of polyamide enhances the absorbency of microfiber fabrics, making them effective for cleaning and filtration purposes. Its lightweight nature also contributes to the overall softness of the fabric.

Cons: On the downside, polyamide can be more expensive than polyester, which may affect the overall cost of the final product. Additionally, it can be less resistant to UV degradation compared to polyester.

What Are the Implications of Using Polypropylene in Microfiber Fabric?

Polypropylene is less commonly used in microfiber fabrics but is notable for its chemical resistance and low moisture absorption. This makes it suitable for applications requiring high durability and resistance to various chemicals, such as industrial cleaning.

Pros: Polypropylene is lightweight, cost-effective, and provides excellent thermal insulation properties. It is also resistant to mildew and mold, making it a good choice for outdoor applications.

Cons: However, polypropylene is less durable than polyester and polyamide, which may limit its use in high-wear applications. Its lower tensile strength can lead to quicker degradation under stress.

What Should International B2B Buyers Consider When Sourcing Microfiber Fabric?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, compliance with local standards is crucial. Many countries have specific regulations regarding the environmental impact of synthetic textiles, including microfibers. Buyers should also consider the availability of materials in their region, as sourcing from major producers like China may incur additional shipping costs and lead times. Understanding common standards such as ASTM, DIN, and JIS can also aid in ensuring product quality and compatibility.

Illustrative image related to what is microfiber fabric made of

Summary Table of Microfiber Fabric Materials

| Material | Typical Use Case for what is microfiber fabric made of | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Cleaning cloths, upholstery, apparel | High durability and moisture-wicking | Prone to pilling, environmental concerns | Low |

| Polyamide | Athletic wear, cleaning products | Excellent elasticity and absorbency | Higher cost, less UV resistance | Medium |

| Polypropylene | Industrial cleaning, outdoor applications | Chemical resistance and lightweight | Lower durability, less tensile strength | Low |

This comprehensive analysis of the materials used in microfiber fabric provides valuable insights for B2B buyers, helping them make informed decisions that align with their specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for what is microfiber fabric made of

What Are the Key Stages in the Manufacturing Process of Microfiber Fabric?

Microfiber fabric is produced through a multi-stage process that emphasizes precision and quality. Understanding the manufacturing process is crucial for B2B buyers, as it directly affects the quality and performance of the final product.

Material Preparation: What Raw Materials Are Used in Microfiber Fabric?

The primary raw materials for microfiber production are polyester and polyamide. Polyester serves as the core of the fibers due to its durability, while polyamide acts as a filler, enhancing the fabric’s absorbency and softness. Initially, these materials are produced as separate entities. The preparation phase includes selecting high-quality polymers, which are then processed into small chips that are ready for melting and extrusion.

Illustrative image related to what is microfiber fabric made of

How Are Microfiber Fibers Formed?

The formation of microfiber fibers involves advanced extrusion techniques. Unlike conventional textiles, microfiber requires specialized equipment to produce fibers with diameters less than 10 micrometers. Manufacturers typically use long, metallic spinnerets to extrude the polyester and polyamide in a controlled manner. This process often utilizes a melt-blown method, where the molten polymer is forced through tiny holes, cooling to form ultra-fine filaments. The resulting fibers can be shaped into various configurations, such as star-shaped cores that maximize surface area.

What Steps Are Involved in the Assembly of Microfiber Fabrics?

Once the fibers are formed, they undergo an assembly process that includes weaving or knitting to create fabric sheets. The assembly stage is critical, as the method of construction influences the fabric’s final characteristics, including breathability and stretchability. Manufacturers may employ techniques like split-weave or flat-weave to achieve different qualities. After weaving, the fabric is typically treated for color and additional properties, such as water repellency or UV resistance.

What Finishing Techniques Enhance Microfiber Fabric Quality?

The finishing stage involves several treatments that enhance the fabric’s performance. This can include dyeing, chemical treatments, and finishing processes that improve softness, durability, and resistance to wear. Additionally, finishing may involve applying anti-static agents or moisture-wicking treatments to maximize the fabric’s usability in various applications. The quality of these finishing processes can significantly impact the product’s marketability and functionality.

How Is Quality Assurance Implemented in Microfiber Fabric Production?

Quality assurance is paramount in the production of microfiber fabric, ensuring that the final product meets international standards and customer expectations. For B2B buyers, understanding the quality control measures in place can help in selecting reliable suppliers.

What International Standards Guide Microfiber Fabric Quality?

Microfiber fabric manufacturers often adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) or API (American Petroleum Institute) may be relevant, depending on the fabric’s intended use.

What Are the Key Quality Control Checkpoints in Microfiber Production?

Quality control is typically segmented into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting the raw materials for consistency, quality, and adherence to specifications. Testing methods may include physical inspections and material testing for tensile strength and chemical composition.

-

In-Process Quality Control (IPQC): During the production phase, ongoing monitoring is essential. This involves regular sampling and testing of fibers and fabrics for defects, ensuring that any issues are identified and corrected promptly.

-

Final Quality Control (FQC): Once the fabric is finished, a comprehensive evaluation is conducted. This includes assessing the fabric for color fastness, dimensional stability, and physical properties such as strength and absorbency.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of suppliers:

-

Audits: Conducting regular audits of suppliers’ facilities can provide insight into their production processes and quality assurance measures.

-

Quality Reports: Requesting detailed quality reports can help assess compliance with international standards and internal benchmarks.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the supplier’s products can provide an unbiased assessment of quality. This is particularly important for buyers from regions like Africa, South America, and the Middle East, where local quality standards may differ from international expectations.

What Are the Unique Quality Control Considerations for International B2B Buyers?

For B2B buyers operating in diverse markets, understanding the nuances of quality control is vital. Buyers from regions such as Africa and South America may face different regulatory standards compared to European or Middle Eastern markets. Therefore, it is crucial to ensure that suppliers not only comply with international standards but also understand and meet local regulatory requirements.

Additionally, buyers should be aware of potential environmental concerns related to microfiber production, such as pollution and sustainability. Engaging suppliers who prioritize eco-friendly practices and certifications can enhance the credibility and marketability of their products.

Illustrative image related to what is microfiber fabric made of

Conclusion: Ensuring Quality in Microfiber Fabric Supply Chains

The manufacturing processes and quality assurance practices in microfiber fabric production are complex but essential for delivering high-quality products. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to better product quality and customer satisfaction. Emphasizing rigorous quality control and adherence to international standards will not only mitigate risks but also foster trust in supply chain relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is microfiber fabric made of’

Introduction

This practical sourcing guide is designed to assist B2B buyers in understanding the composition of microfiber fabric and effectively procuring it for their business needs. Microfiber, known for its unique properties and applications, requires careful consideration during the sourcing process. This checklist will help you navigate the essential steps to ensure you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establish clear specifications for the microfiber fabric you intend to procure. Consider factors such as fiber composition (e.g., polyester and polyamide ratios), thread count (ranging from 200 to 1,800), and desired properties like breathability and moisture-wicking abilities. Defining these parameters will help you communicate effectively with suppliers and ensure that the material meets your quality standards.

Illustrative image related to what is microfiber fabric made of

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in microfiber fabric. Utilize industry directories, trade shows, and online platforms to compile a list of candidates. Look for suppliers with a strong reputation and positive reviews, focusing on their experience in producing microfiber for your specific application, whether it be apparel, cleaning products, or home textiles.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier, verify their certifications and compliance with industry standards. This may include ISO certifications, environmental regulations, and labor practices. Ensuring that your supplier adheres to these standards not only protects your brand’s reputation but also contributes to sustainable sourcing practices.

Step 4: Request Samples for Testing

Always request fabric samples from potential suppliers before making a bulk order. Testing samples for properties such as softness, durability, absorbency, and colorfastness is crucial. This hands-on evaluation allows you to assess the quality of the microfiber and ensure it aligns with your project requirements.

Step 5: Inquire About Production Capabilities

Assess the production capabilities of your shortlisted suppliers. This includes understanding their manufacturing processes, lead times, and minimum order quantities. Suppliers with advanced production techniques and flexible capabilities can better accommodate your specific needs, ensuring timely delivery and consistent quality.

Illustrative image related to what is microfiber fabric made of

Step 6: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing and payment terms. Consider factors such as bulk order discounts, shipping costs, and payment schedules. Establishing clear terms upfront can lead to a more favorable purchasing experience and help maintain a strong supplier relationship.

Step 7: Plan for Long-Term Collaboration

Consider the potential for a long-term partnership with your chosen supplier. Building a collaborative relationship can lead to improved pricing, priority service, and shared insights on trends and innovations in microfiber fabric. Regular communication and feedback will enhance the partnership and support your ongoing sourcing needs.

By following these steps, B2B buyers can confidently navigate the sourcing process for microfiber fabric, ensuring they procure high-quality materials that meet their specific business requirements.

Comprehensive Cost and Pricing Analysis for what is microfiber fabric made of Sourcing

What Are the Key Cost Components in Microfiber Fabric Sourcing?

When sourcing microfiber fabric, understanding the cost structure is essential for B2B buyers. The cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The primary materials for microfiber fabric are ultra-fine synthetic fibers like polyester and polyamide. The cost of these raw materials can fluctuate based on market demand and availability. Generally, microfiber is less expensive than natural fibers like silk or cotton, making it an attractive option for cost-conscious buyers.

-

Labor: Labor costs vary significantly by region. In countries like China, where most microfiber production occurs, labor costs are lower compared to Europe or North America. However, as manufacturers in these regions adopt automation, the labor component may decrease over time.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. In regions with high energy costs, manufacturing overhead can significantly affect overall pricing.

-

Tooling: Depending on the complexity of the microfiber fabric (e.g., different weaves or finishes), tooling costs can vary. Custom designs or specialized machinery might necessitate higher initial investments, affecting the final price.

-

Quality Control (QC): Ensuring product quality is crucial, particularly for industries requiring specific certifications. QC processes can add to costs but are vital for maintaining the fabric’s integrity and performance.

-

Logistics: Shipping costs depend on the distance from the manufacturing site and the mode of transport. International buyers need to consider customs duties and tariffs, which can impact the total cost.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. This margin varies based on the supplier’s market positioning and the demand for microfiber products.

What Influences Pricing for Microfiber Fabric?

Several factors influence pricing beyond the basic cost components:

-

Volume/MOQ: Minimum order quantities (MOQ) and volume purchases can significantly impact pricing. Larger orders often qualify for bulk discounts, providing cost efficiencies for buyers.

-

Specifications and Customization: Customized microfiber fabric can incur additional costs. Buyers seeking specific colors, weaves, or treatments should be prepared for potential price increases.

-

Materials Quality and Certifications: Higher-quality fibers or eco-friendly certifications can raise costs. Buyers should assess the trade-off between price and quality to meet their specific application needs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more for their experience and quality assurance, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define responsibilities regarding shipping costs, insurance, and customs duties, which can significantly affect the total landed cost.

What Are Some Negotiation Tips for Buyers Sourcing Microfiber Fabric?

To ensure cost-efficiency when sourcing microfiber fabric, buyers should consider the following tips:

Illustrative image related to what is microfiber fabric made of

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not only the purchase price but also shipping, tariffs, and potential returns. This holistic view can reveal the most cost-effective options.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Regular communication and trust can yield favorable negotiation outcomes.

-

Market Research: Understanding market trends and competitor pricing can empower buyers during negotiations. Being informed about alternative suppliers can also provide leverage.

-

Flexibility in Orders: Being flexible with order sizes or delivery schedules can open opportunities for discounts. Suppliers may be willing to negotiate better terms for larger or more frequent orders.

-

Quality Over Cost: While it’s tempting to prioritize the lowest price, consider the quality implications. Investing in higher-quality microfiber can lead to better performance and lower replacement costs over time.

Disclaimer on Pricing

It is essential to note that prices for microfiber fabric can vary widely based on the aforementioned factors. The information provided is indicative and subject to change based on market conditions, supplier negotiations, and other variables. Buyers are encouraged to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing what is microfiber fabric made of With Other Solutions

Exploring Alternatives to Microfiber Fabric: A Comparative Analysis

In the quest for effective textiles, particularly in cleaning, apparel, and industrial applications, understanding the composition and performance of microfiber fabric is essential. Microfiber, primarily made from polyester and polyamide, offers unique properties such as softness, durability, and moisture-wicking capabilities. However, other materials and technologies also exist, each with its own set of advantages and disadvantages. This analysis will compare microfiber fabric with two viable alternatives: cotton fabric and bamboo fabric.

Comparison Table

| Comparison Aspect | What Is Microfiber Fabric Made Of | Cotton Fabric | Bamboo Fabric |

|---|---|---|---|

| Performance | High absorbency and durability | Moderate absorbency, soft | High absorbency, soft |

| Cost | Low to moderate | Moderate to high | Moderate to high |

| Ease of Implementation | Easy to produce and dye | Requires significant processing | Requires processing but eco-friendly |

| Maintenance | Machine washable, quick drying | Machine washable, prone to wrinkling | Machine washable, antimicrobial properties |

| Best Use Case | Cleaning cloths, apparel, upholstery | Apparel, bedding | Eco-friendly apparel, home textiles |

In-Depth Analysis of Alternatives

Cotton Fabric

Cotton is a natural fiber known for its breathability and comfort. It has been a staple in textiles for centuries, making it highly recognizable and widely accepted in various markets. While cotton is soft and absorbent, it typically does not match the moisture-wicking and quick-drying capabilities of microfiber. Additionally, cotton fabrics can be more expensive due to the farming and harvesting processes involved. On the maintenance front, cotton is prone to wrinkling and may require ironing, which could be a drawback for industries looking for low-maintenance solutions.

Illustrative image related to what is microfiber fabric made of

Bamboo Fabric

Bamboo fabric is increasingly gaining popularity for its eco-friendly properties. Made from the pulp of bamboo plants, this material is naturally antibacterial and highly absorbent. It offers a soft texture similar to silk and has excellent moisture-wicking abilities. However, the production of bamboo fabric can be more complex and costly than that of microfiber or cotton, which may deter some businesses. Bamboo is also machine washable, making it a practical option, but its higher price point may not align with budget-conscious buyers.

Conclusion: How to Choose the Right Fabric Solution

When selecting the ideal fabric solution, B2B buyers must consider their specific needs, including performance requirements, cost constraints, and maintenance expectations. Microfiber is an excellent choice for applications requiring high durability and moisture-wicking properties, particularly in cleaning and industrial settings. Conversely, cotton may be preferable for traditional apparel and bedding, while bamboo fabric is an attractive option for eco-conscious brands aiming for sustainability without compromising on quality. Ultimately, understanding the unique characteristics of each material will empower buyers to make informed decisions that best fit their operational requirements and market demands.

Essential Technical Properties and Trade Terminology for what is microfiber fabric made of

What Are the Key Technical Properties of Microfiber Fabric?

Understanding the technical properties of microfiber fabric is essential for B2B buyers, especially when sourcing materials that meet specific industry needs. Here are several critical specifications that define microfiber fabric:

1. Fabric Composition

Microfiber is typically made from ultra-fine synthetic fibers, primarily polyester and polyamide (nylon). The combination of these materials contributes to the fabric’s high durability, softness, and absorbent qualities. For B2B buyers, knowing the composition is vital for assessing performance in various applications, from cleaning products to apparel.

Illustrative image related to what is microfiber fabric made of

2. Thread Count

Microfiber fabrics can have a thread count ranging from 200 to 1,800. This metric indicates the density of the fabric, affecting its softness, durability, and overall quality. A higher thread count generally means a softer and more durable fabric. For manufacturers and suppliers, understanding thread count can guide decisions related to product positioning and pricing strategies.

3. Moisture-Wicking Ability

Microfiber is known for its excellent moisture-wicking properties, making it suitable for applications where moisture management is crucial, such as athletic wear and cleaning products. This property is especially important for B2B buyers in the textile and sports industries, as it directly impacts product performance and consumer satisfaction.

4. Heat Retention and Breathability

Microfiber has medium heat retention capabilities while offering high breathability. These properties make it versatile for various uses, from clothing to home textiles. For B2B buyers, understanding these characteristics is essential for selecting the right fabric for specific climates or usage scenarios.

5. Pilling Resistance

Microfiber exhibits a medium tendency to pill, which can affect the aesthetic and functional longevity of the fabric. Buyers should consider this property, particularly for high-wear items like upholstery or clothing, where appearance and durability are key concerns.

6. Environmental Impact

While microfiber is a versatile fabric, it is important to note its environmental implications, particularly regarding microfiber pollution. B2B buyers are increasingly focused on sustainability, making it crucial to consider the lifecycle and ecological footprint of the materials they source.

What Are Common Trade Terms in the Microfiber Fabric Industry?

Familiarizing yourself with industry jargon can enhance communication with suppliers and improve negotiation processes. Here are several common trade terms relevant to microfiber fabric:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that are marketed under another brand’s name. In the microfiber industry, understanding OEM relationships can be beneficial for buyers looking to source custom products or private label options.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of product that a supplier is willing to sell. This term is crucial for B2B buyers as it influences inventory management and budgeting. Negotiating MOQs can lead to better pricing and reduced waste.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For microfiber fabric buyers, issuing an RFQ helps in obtaining competitive pricing and understanding the market landscape.

4. Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings related to shipping costs, risks, and delivery responsibilities.

5. Denier

Denier is a unit of measurement that indicates the thickness of the fibers used in the fabric. Understanding denier can help B2B buyers select the appropriate fabric based on durability and intended use.

6. Bicomponent Polymers

This term refers to materials made from two different types of polymers, which are fused together to create stronger fibers. Recognizing the significance of bicomponent polymers is important for buyers interested in the latest advancements in microfiber technology.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when sourcing microfiber fabric, ensuring they meet their specific requirements while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the what is microfiber fabric made of Sector

What Are the Key Market Dynamics and Trends Affecting Microfiber Fabric Sourcing?

Market Overview & Key Trends

The global microfiber fabric market is witnessing significant growth, driven by increased demand across multiple sectors including cleaning, apparel, and industrial applications. This surge is largely attributed to microfiber’s unique properties, such as high absorbency, durability, and softness, making it an ideal choice for a variety of uses. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking to source microfiber fabric as a cost-effective alternative to traditional textiles.

Emerging trends in the microfiber market include the rise of smart textiles, where microfiber is integrated with technology for enhanced functionality, such as moisture management and odor control. Additionally, advancements in production techniques are leading to the development of specialized microfiber variants that cater to niche markets, such as medical textiles and high-performance apparel. As competition intensifies, suppliers are focusing on differentiation through product innovation and customization, thus presenting new sourcing opportunities for buyers.

Furthermore, the geopolitical landscape is influencing sourcing strategies. For instance, the ongoing trade tensions and tariffs between major economies have led buyers to diversify their supply chains, considering emerging markets such as Vietnam and Bangladesh as potential sourcing hubs for microfiber fabric. This shift not only aims to mitigate risks but also to capitalize on lower production costs in these regions.

How Is Sustainability and Ethical Sourcing Addressed in the Microfiber Fabric Industry?

As sustainability becomes a focal point for international buyers, the microfiber industry faces scrutiny regarding its environmental impact. Microfiber, predominantly made from synthetic materials like polyester and polyamide, poses challenges in terms of microplastic pollution. Therefore, an emphasis on ethical sourcing and sustainable practices is crucial for B2B buyers looking to enhance their brand reputation.

Illustrative image related to what is microfiber fabric made of

To address these concerns, many manufacturers are investing in eco-friendly production processes that minimize waste and reduce energy consumption. Buyers are encouraged to seek suppliers who adhere to stringent environmental standards and possess certifications such as Global Recycled Standard (GRS) or OEKO-TEX, which ensure that the materials used are sourced responsibly and sustainably.

Additionally, the adoption of recycled microfiber is gaining traction, providing a viable solution to reduce the carbon footprint associated with virgin materials. Buyers can leverage these innovations not only to meet regulatory requirements but also to align their sourcing strategies with the growing consumer demand for sustainable products. Emphasizing partnerships with suppliers committed to sustainability can enhance corporate social responsibility efforts, making ethical sourcing a key consideration in procurement strategies.

What Is the Brief Evolution of Microfiber Fabric?

The history of microfiber fabric dates back to the early 1950s when textile manufacturers first experimented with ultra-fine fibers. However, it was not until the 1960s that significant advancements were made, notably by the Japanese textile company Toray, which pioneered mass production techniques for microfiber. By the 1990s, microfiber gained widespread popularity in Europe, particularly for cleaning applications, due to its superior performance and versatility.

Illustrative image related to what is microfiber fabric made of

As the market evolved, manufacturers began exploring various applications of microfiber beyond cleaning products, leading to its adoption in apparel and home textiles. The fabric’s unique properties, such as high moisture-wicking capabilities and durability, have paved the way for innovative uses in diverse industries, including automotive and healthcare. Today, microfiber stands as a testament to technological advancements in textiles, with ongoing research and development focused on enhancing its functionality and sustainability.

In conclusion, understanding the dynamics of the microfiber fabric market, along with the importance of sustainability and the historical context, can empower international B2B buyers to make informed sourcing decisions that align with their business objectives and ethical commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of what is microfiber fabric made of

-

1. What is microfiber fabric made of?

Microfiber fabric is primarily composed of ultra-fine synthetic fibers, predominantly polyester and polyamide (nylon). These fibers are engineered to have diameters smaller than 10 micrometers, making them highly effective for various applications due to their exceptional softness, durability, and moisture-wicking properties. The unique structure of microfiber allows it to excel in both absorbency and cleaning capabilities, which has led to its widespread use in textiles, cleaning products, and apparel. -

2. How do I choose a reliable supplier for microfiber fabric?

When selecting a supplier for microfiber fabric, consider their production capabilities, quality certifications, and experience in the industry. Verify their manufacturing processes and inquire about their sourcing of raw materials. Request samples to assess the fabric’s quality and performance. Additionally, reviewing customer testimonials and references can provide insights into their reliability and service. Finally, ensure that they can meet your specific requirements for customization and minimum order quantities. -

3. What are the typical minimum order quantities (MOQs) for microfiber fabric?

MOQs for microfiber fabric can vary significantly depending on the supplier and the specific type of fabric required. Generally, MOQs can range from 500 to 1,000 meters for standard fabrics. However, for custom colors or designs, suppliers might set higher MOQs. It is essential to discuss your needs upfront and negotiate terms that work for both parties, especially if you are a smaller business or just starting your sourcing journey. -

4. How can I ensure quality assurance (QA) for my microfiber fabric orders?

To ensure quality assurance for microfiber fabric, establish clear quality standards and specifications before placing an order. Request samples for initial testing and establish a comprehensive QA process that includes inspections at various production stages. Collaborate with the supplier to define acceptable quality levels and consider third-party inspection services to validate product quality before shipment. Additionally, maintain open communication with your supplier to address any potential issues promptly. -

5. What customization options are available for microfiber fabric?

Customization options for microfiber fabric include variations in color, pattern, texture, and fabric weight. Suppliers often offer services such as dyeing, printing, and blending different fiber types to achieve desired properties. It’s essential to communicate your specific requirements clearly and inquire about their capabilities for custom production. Keep in mind that customizations may affect lead times and pricing, so plan accordingly. -

6. What are common payment terms for international orders of microfiber fabric?

Payment terms for international orders typically vary based on the supplier’s policies and the buyer’s negotiation. Common terms include a deposit (usually 30% to 50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer letters of credit or payment through escrow services for added security. It is crucial to discuss and agree on payment terms upfront to avoid misunderstandings later in the transaction process. -

7. How does logistics impact the sourcing of microfiber fabric?

Logistics plays a critical role in sourcing microfiber fabric, influencing delivery times, costs, and overall supply chain efficiency. Consider factors such as shipping methods (air or sea), customs regulations, and potential tariffs when planning your orders. Working with a supplier experienced in international shipping can help streamline the process. Additionally, understanding the lead times and transit times will aid in better inventory management and timely product availability. -

8. What environmental considerations should I be aware of when sourcing microfiber fabric?

While microfiber fabric is popular for its performance, it is essential to consider its environmental impact. Microfibers can contribute to pollution when they shed during washing, entering water systems. When sourcing, inquire about the supplier’s practices regarding sustainability and eco-friendly production methods. Some manufacturers offer recycled microfiber options or treatments to minimize shedding. Understanding these factors can help align your sourcing practices with environmental responsibility and consumer expectations.

Top 4 What Is Microfiber Fabric Made Of Manufacturers & Suppliers List

1. Reddit – Microfiber Fabric Identification

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: To determine if a fabric is made of microfibers, look for labels that specifically state ‘microfibers.’ If the label does not mention microfibers, it is likely not made from them. Synthetic fabrics like polyester can shed microfibers, contributing to plastic pollution, especially pile fleeces and faux furs.

2. The Spruce – Microfiber Cleaning Solutions

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Microfiber is an ultra-thin synthetic fiber, no more than one denier thick, used in various applications including cleaning cloths, athletic gear, upholstery, and bed sheets. It is produced by mixing polyester with nylon for strength and water repellency. Microfiber cleaning cloths are lint-free, antibacterial, and effective at removing dirt. They should be washed after every use. Microfiber uphol…

3. ScienceDirect – Microfiber Overview

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Microfiber is defined as a staple fiber or filaments with a linear density of approximately 1 dtex or less, and above 0.3 dtex. The main materials used for microfibers are polyester and polyamide, although acrylic, viscose, and polypropylene are also available. Microfibers are significantly finer than traditional fibers, being half the diameter of fine silk, one-third that of cotton, one-quarter t…

4. Calderon Textiles – Microfiber Excellence

Domain: calderontextiles.com

Registered: 1999 (26 years)

Introduction: Microfiber is a synthetic fiber weighing less than one denier, thirty times finer than cotton, ten times finer than silk, and 1/16th the thickness of human hair. Conventional microfiber is composed of polyester and polyamide in an 80:20 ratio. It has enhanced absorbency and dirt-trapping capabilities due to a splitting process that creates over 200 million openings per square inch. Microfiber can …

Strategic Sourcing Conclusion and Outlook for what is microfiber fabric made of

As the demand for high-performance textiles continues to rise globally, understanding the composition and applications of microfiber fabric is crucial for international B2B buyers. Microfiber, primarily made from polyester and polyamide, offers a unique blend of softness, durability, and absorbency, making it suitable for various industries, from cleaning and home textiles to apparel and industrial applications. Its competitive pricing, coupled with the ability to produce intricate designs, positions microfiber as a valuable asset in sourcing strategies.

Strategic sourcing of microfiber fabric presents opportunities for businesses to enhance their product offerings while maintaining cost-effectiveness. As environmental concerns regarding textile pollution grow, buyers should prioritize suppliers that adopt sustainable practices in microfiber production.

Illustrative image related to what is microfiber fabric made of

Looking ahead, the evolving market landscape indicates a potential for innovative applications of microfiber, particularly in eco-friendly products. By leveraging strategic sourcing initiatives and fostering partnerships with reputable manufacturers, international buyers from Africa, South America, the Middle East, and Europe can capitalize on the benefits of microfiber fabric. Engage with suppliers now to explore the vast possibilities this versatile textile offers and stay ahead in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.