Introduction: Navigating the Global Market for how to make a hole in a leather belt

In the competitive landscape of leather goods, understanding how to make a hole in a leather belt can significantly impact product functionality and customer satisfaction. As businesses worldwide strive to meet the diverse needs of their clients—from accommodating fluctuating waist sizes to adapting to various pant styles—this guide offers essential insights for B2B buyers. Whether you’re sourcing high-quality leather belts for resale or seeking to enhance your manufacturing processes, knowing the methods and tools for creating belt holes is vital.

This comprehensive guide delves into multiple techniques for making holes in leather belts, catering to different production environments and skill levels. It covers traditional methods, innovative tools, and even DIY solutions, ensuring that you can choose the best approach based on your operational capabilities. Additionally, it addresses critical considerations such as supplier vetting, cost analysis, and the importance of material quality to empower informed purchasing decisions.

By equipping international B2B buyers from regions like Africa, South America, the Middle East, and Europe with this knowledge, we aim to enhance your understanding of leather belt production. This not only streamlines your supply chain but also helps you deliver exceptional products that meet the unique demands of your market. Embrace the opportunity to elevate your business strategy and enhance customer satisfaction through effective leather belt management.

Table Of Contents

- Top 5 How To Make A Hole In A Leather Belt Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a hole in a leather belt

- Understanding how to make a hole in a leather belt Types and Variations

- Key Industrial Applications of how to make a hole in a leather belt

- 3 Common User Pain Points for ‘how to make a hole in a leather belt’ & Their Solutions

- Strategic Material Selection Guide for how to make a hole in a leather belt

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a hole in a leather belt

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a hole in a leather belt’

- Comprehensive Cost and Pricing Analysis for how to make a hole in a leather belt Sourcing

- Alternatives Analysis: Comparing how to make a hole in a leather belt With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a hole in a leather belt

- Navigating Market Dynamics and Sourcing Trends in the how to make a hole in a leather belt Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a hole in a leather belt

- Strategic Sourcing Conclusion and Outlook for how to make a hole in a leather belt

- Important Disclaimer & Terms of Use

Understanding how to make a hole in a leather belt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Hole Punch | Uses a specialized tool for precise, clean holes | Leather goods manufacturing, repairs | Pros: High precision, durable holes. Cons: Requires investment in tools. |

| Power Drill Method | Employs a power drill with a bit for quick hole creation | Workshops, production lines | Pros: Fast, effective on various materials. Cons: Risk of uneven holes if not handled properly. |

| Heated Nail Technique | Utilizes a heated nail to melt through the leather | Small-scale repairs, emergency fixes | Pros: Low-cost, easy to implement. Cons: May not provide clean edges, risk of damage. |

| Awl or Sharp Tool Method | Employs a sharp tool to pierce the leather by rotation | DIY repairs, customizations | Pros: Versatile, requires minimal investment. Cons: Skill-dependent, may produce rough holes. |

| Professional Services | Involves outsourcing to leather specialists for hole punching | Retail, custom leather goods production | Pros: Expertise ensures quality. Cons: Additional costs, longer turnaround time. |

What Are the Key Characteristics of Using a Leather Hole Punch?

The leather hole punch is a specialized tool designed for creating precise holes in leather belts. It features various sizes, allowing for customization based on the specific needs of the belt. This method is widely used in leather goods manufacturing and repair, ensuring a clean and durable hole. For B2B buyers, investing in a leather hole punch is ideal for businesses that frequently work with leather products, as it enhances efficiency and maintains quality.

How Does the Power Drill Method Enhance Efficiency?

Using a power drill equipped with an appropriate bit is a fast and effective way to create holes in leather belts. This technique is suitable for workshops and production lines where speed is crucial. B2B buyers should consider this method if they have access to power tools, as it allows for quick modifications without the need for specialized equipment. However, users must exercise caution to avoid uneven holes, which can compromise the product’s integrity.

Why is the Heated Nail Technique a Viable Option?

The heated nail technique involves using a heated nail to melt through the leather, making it a low-cost option for small-scale repairs or emergency fixes. This method is particularly useful for businesses that may not have access to specialized tools. While it is easy to implement, buyers should be aware that the holes may not be as clean as those made with a punch, potentially affecting the overall aesthetics of the product.

What Makes the Awl or Sharp Tool Method Versatile?

Employing a sharp tool, such as an awl, to pierce leather requires minimal investment and can be done with commonly available tools. This method is particularly suitable for DIY repairs and customizations, allowing for flexibility in hole placement. However, it is skill-dependent, meaning that inexperienced users may produce rough holes. B2B buyers should consider the skill level of their workforce when opting for this method.

How Can Professional Services Benefit B2B Buyers?

Outsourcing to professional leather specialists for hole punching ensures high-quality results and expert craftsmanship. This option is ideal for retailers and custom leather goods producers who prioritize quality over speed. While it incurs additional costs and may involve longer turnaround times, the assurance of expertise can significantly enhance the final product’s value, making it a worthwhile investment for businesses focused on premium offerings.

Key Industrial Applications of how to make a hole in a leather belt

| Industry/Sector | Specific Application of how to make a hole in a leather belt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Customization of leather belts for fashion brands | Enhances product appeal and customer satisfaction | Quality of leather, tooling options, and production capacity |

| Leather Goods Manufacturing | Production of bespoke leather accessories | Increases market competitiveness and margins | Sourcing of high-quality materials and precision tools |

| Automotive & Transportation | Custom leather seat belts and accessories | Ensures comfort and safety for end-users | Compliance with safety standards and material durability |

| Craftsmanship & DIY | Small-scale crafting and repairs for leather goods | Enables artisans to offer personalized services | Availability of various tools and training resources |

| Retail | Offering belt hole punching services in stores | Adds value to customer service and retention | Location, tool availability, and skilled labor resources |

How is ‘How to Make a Hole in a Leather Belt’ Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, the ability to make holes in leather belts is crucial for customization. Brands often seek to provide tailored solutions to their customers, allowing for adjustments based on individual preferences or body changes. This not only enhances customer satisfaction but also fosters brand loyalty. International buyers from regions like Africa or Europe should consider the quality of leather and the tools used for precision, as these factors directly impact the final product’s appeal.

Illustrative image related to how to make a hole in a leather belt

What is the Role of Hole Making in Leather Goods Manufacturing?

In leather goods manufacturing, the process of making holes in belts is essential for creating bespoke accessories. Manufacturers can offer tailored products, catering to niche markets that demand uniqueness. This capability can significantly increase a company’s market competitiveness and profit margins. Buyers should prioritize sourcing high-quality materials and precision tools to ensure that the finished products meet the highest standards of craftsmanship.

How Do Automotive and Transportation Industries Benefit from Leather Hole Making?

The automotive and transportation sectors utilize leather in various applications, including custom seat belts and interior accessories. Ensuring that these leather products fit perfectly is vital for user comfort and safety. The ability to create additional holes allows manufacturers to tailor products to specific vehicle models or customer preferences. Buyers must ensure compliance with safety standards and focus on the durability of the materials used in production.

Why is Hole Making Important for Craftsmanship & DIY?

For artisans and DIY enthusiasts, the ability to make holes in leather belts is essential for creating and repairing leather goods. This skill enables them to offer personalized services, enhancing their product offerings. Access to various tools and training resources is critical for these small-scale craftsmen, particularly in regions with limited access to specialized equipment. Buyers should focus on sourcing versatile tools that can handle various leather types and thicknesses.

How Can Retailers Leverage Hole Punching Services?

Retailers can enhance their customer service by offering belt hole punching services in-store. This added value can significantly improve customer retention and satisfaction as shoppers appreciate the convenience of customizing their purchases on-site. Retailers should consider location, tool availability, and the skill level of staff when implementing such services, ensuring they can meet customer demands effectively.

Illustrative image related to how to make a hole in a leather belt

3 Common User Pain Points for ‘how to make a hole in a leather belt’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Tools for Making Belt Holes

The Problem: B2B buyers, particularly in regions with limited access to specialized tools, often struggle to find reliable methods for making holes in leather belts without investing in expensive equipment. This can be especially frustrating for businesses in the leather goods industry that require flexibility in product offerings but lack the necessary tools or equipment. Many buyers may also be concerned about the quality of the holes made, as poorly executed holes can lead to product returns and customer dissatisfaction.

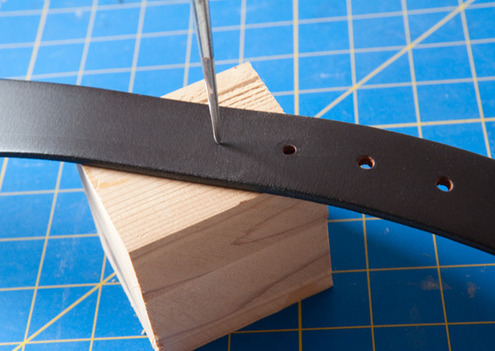

The Solution: To address this challenge, businesses can source versatile and cost-effective alternatives to traditional leather hole punches. One practical solution is to utilize a power drill with a small drill bit, which can be found in most local hardware stores. For best results, it’s important to place a piece of scrap wood underneath the belt to support it while drilling. This method not only creates clean holes but also minimizes the risk of damaging the leather. Additionally, businesses can consider purchasing multi-tool kits that include awls or screwdrivers, which can be used to create holes without requiring significant investment. By training staff on these techniques, companies can ensure they are prepared to meet customer needs quickly and effectively.

Scenario 2: Ensuring Consistency in Hole Sizes Across Multiple Belts

The Problem: When producing belts in bulk, maintaining consistency in hole sizes is crucial for ensuring a professional look and proper functionality. Buyers often find that variations in hole size can lead to mismatched products, increasing the likelihood of returns or customer complaints. This is particularly pertinent in regions where the demand for customized leather goods is growing, as consumers expect a high level of craftsmanship.

The Solution: To ensure uniformity, businesses should implement a standardized template or guide for hole placement. This can be achieved by creating a jig that aligns the belt correctly, ensuring that each hole is punched at the same distance from the end of the belt. Additionally, investing in adjustable hole punch tools can provide flexibility while maintaining consistent sizes. For those who opt for drilling, using a drill press can ensure that each hole is made with precision. Regular training sessions for employees on the importance of consistency and techniques for achieving it can also enhance product quality and customer satisfaction.

Scenario 3: Managing Customer Expectations for Quick Adjustments

The Problem: In the fashion and accessories market, customer preferences can change rapidly. B2B buyers often find themselves needing to accommodate last-minute requests for extra holes in leather belts, which can be challenging if they do not have the right tools or processes in place. This can lead to delays in fulfilling orders, which not only frustrates customers but can also harm business relationships and reputation.

The Solution: To manage customer expectations effectively, businesses should establish a streamlined process for adding holes to leather belts. This includes training staff to perform quick adjustments using efficient methods, such as the heated nail technique or using a sharp-pointed awl. It’s also beneficial to maintain a small inventory of commonly needed tools and materials, ensuring that adjustments can be made on the spot. Communicating clearly with customers about the services offered and the expected turnaround times can help set realistic expectations. By adopting a proactive approach to potential customer requests, businesses can enhance their reputation for reliability and customer service in a competitive market.

Strategic Material Selection Guide for how to make a hole in a leather belt

What Materials Are Suitable for Making Holes in Leather Belts?

When it comes to making holes in leather belts, the choice of tools and materials is crucial for achieving the desired results. Below, we analyze several common materials used for this purpose, highlighting their key properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Steel Hole Punches

Key Properties:

Steel hole punches are renowned for their hardness and durability. They can withstand significant pressure without deforming, making them ideal for creating clean holes in leather. Their corrosion resistance is generally good, especially when treated with protective coatings.

Pros & Cons:

The primary advantage of steel hole punches is their longevity and ability to produce precise holes consistently. However, they can be relatively costly, particularly high-quality brands. Manufacturing complexity is low, as they are straightforward to produce, but they require proper maintenance to prevent rust.

Impact on Application:

Steel punches are compatible with various leather types, including full-grain and top-grain leather. They provide a clean cut, which is essential for maintaining the aesthetic of the belt.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure that the steel used complies with international standards such as ASTM or ISO. Additionally, local market preferences for durability may influence purchasing decisions.

2. Leather Hole Punch Sets

Key Properties:

Leather hole punch sets typically include multiple punch sizes and are made from hardened steel or stainless steel. They are designed specifically for leather, ensuring that the punches can handle the material’s density without causing damage.

Illustrative image related to how to make a hole in a leather belt

Pros & Cons:

These sets offer versatility, allowing users to create various hole sizes. They are generally more affordable than single high-quality punches but may not last as long if used frequently. The complexity of manufacturing is moderate, as they often require precise engineering to ensure sharpness.

Impact on Application:

Leather hole punch sets are ideal for crafting and repair applications, providing flexibility for different belt styles and sizes.

Considerations for International Buyers:

Buyers should look for sets that meet local regulations regarding tool safety and quality. In regions like the Middle East, where craftsmanship is valued, sets that allow for customization may be preferred.

3. Electric Hole Punch Machines

Key Properties:

Electric hole punch machines offer high efficiency and precision, capable of producing multiple holes in a short time. They are designed for heavy-duty use and can handle various materials, including thicker leather.

Pros & Cons:

The main advantage is speed and consistency, making them suitable for large-scale production. However, the initial investment cost is high, and they may require maintenance and technical knowledge to operate effectively.

Illustrative image related to how to make a hole in a leather belt

Impact on Application:

These machines are ideal for manufacturers producing leather goods in bulk, ensuring uniformity in hole sizes and placement.

Considerations for International Buyers:

Buyers should consider the availability of technical support and spare parts in their region. Compliance with electrical standards is also crucial, especially in markets like Europe where safety regulations are stringent.

4. Heated Tools (e.g., Heated Nails)

Key Properties:

Heated tools, such as nails or metal rods, rely on thermal conductivity to create holes in leather. They are simple to use but require a heat source.

Pros & Cons:

The primary advantage is low cost and easy accessibility, as many users can create holes without specialized tools. However, the precision may not match that of dedicated punches, and there is a risk of damaging the leather if not used carefully.

Impact on Application:

This method is suitable for quick fixes or DIY projects but may not be ideal for professional applications where quality is paramount.

Considerations for International Buyers:

Buyers should be aware of local safety standards regarding the use of heated tools. In regions with less access to advanced tools, this method may be more popular due to its low cost.

Summary Table of Material Selection for Making Holes in Leather Belts

| Material | Typical Use Case for how to make a hole in a leather belt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Hole Punches | Professional leather crafting and repairs | High durability and precision | Higher cost and maintenance required | High |

| Leather Hole Punch Sets | Crafting and occasional repairs | Versatile with multiple sizes | May wear out faster with heavy use | Medium |

| Electric Hole Punch Machines | Mass production of leather goods | Fast and consistent output | High initial investment | High |

| Heated Tools (e.g., Heated Nails) | Quick fixes and DIY projects | Low cost and easy access | Less precision and potential damage | Low |

This strategic material selection guide provides insights into the various tools and methods available for making holes in leather belts, catering to the specific needs of international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a hole in a leather belt

What Are the Key Stages in the Manufacturing Process of Leather Belts?

Manufacturing leather belts involves several critical stages that ensure the final product meets the desired quality and functionality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

– Leather Selection: The process begins with selecting high-quality leather, which is often sourced from tanneries that follow sustainable practices. Buyers should look for suppliers that provide information on leather origin and quality grading.

– Cutting: The leather is cut into strips of the required width and length using precision cutting tools. This step is crucial as it determines the final dimensions of the belt and any holes that will be punched later. -

Forming

– Hole Punching: The next step involves creating holes in the leather. This can be done using various methods, including manual hole punches or automated machines. For B2B buyers, understanding the method used is essential, as different techniques may yield varying hole quality and durability.

– Edge Treatment: Edges are then treated to prevent fraying and enhance aesthetics. This might include sanding, burnishing, or applying edge paints. -

Assembly

– Buckle Attachment: Once the leather is prepared, the buckle is attached. This is typically done using rivets or stitching, depending on the design. The fastening method impacts the belt’s strength and longevity.

– Quality Checks: During assembly, checkpoints for quality control are critical. These may include ensuring that holes are evenly spaced and properly aligned with the buckle. -

Finishing

– Final Inspection: After assembly, a final inspection is conducted to ensure that the belt meets quality standards, including checking for proper hole sizes and alignment.

– Packaging: The last stage involves packaging, where belts are carefully wrapped and labeled. This is important for branding and helps in maintaining product quality during shipping.

What Quality Control Measures Are Essential for Leather Belt Manufacturing?

Quality assurance is crucial in the leather belt manufacturing process to ensure that the final product meets international standards and customer expectations. Here are the relevant quality control measures:

Illustrative image related to how to make a hole in a leather belt

-

International Standards Compliance

– ISO 9001: This standard outlines the criteria for a quality management system. Manufacturers should demonstrate adherence to ISO 9001, which emphasizes customer satisfaction and continual improvement.

– CE Marking: For products sold in Europe, compliance with CE marking regulations ensures that the belt meets safety and environmental requirements. -

Industry-Specific Certifications

– API Standards: While primarily associated with the oil and gas industry, API standards can also apply to certain leather products, particularly in high-performance applications.

– Other Certifications: Depending on the market, additional certifications may be required. B2B buyers should inquire about specific certifications relevant to their region. -

Quality Control Checkpoints

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. This ensures that only high-quality leather is used in production.

– In-Process Quality Control (IPQC): During manufacturing, IPQC checks are performed to monitor the production process. This helps identify defects early, reducing waste and rework.

– Final Quality Control (FQC): Before shipping, a final inspection is conducted. This includes checking for the accuracy of hole sizes and overall finish quality.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability. Here are some effective strategies:

-

Supplier Audits

– Conducting on-site audits allows buyers to assess the manufacturing process directly. This includes evaluating equipment, personnel training, and adherence to quality control measures. -

Requesting Quality Control Reports

– Buyers should request detailed reports on quality control processes, including IQC, IPQC, and FQC results. This transparency builds trust and allows buyers to make informed decisions. -

Third-Party Inspections

– Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. This is particularly beneficial for international transactions where buyers may not be able to conduct audits themselves. -

Understanding QC Nuances for International Trade

– B2B buyers must be aware of different quality standards and expectations across regions. For instance, European standards may differ significantly from those in African markets. Understanding these nuances can help buyers set clear expectations with suppliers.

What Common Testing Methods Are Used in Quality Control for Leather Belts?

Various testing methods are employed to ensure that leather belts meet quality standards. Here are some common methods:

-

Durability Testing

– This involves subjecting the leather to stress tests to evaluate its resistance to wear and tear. Buyers should look for suppliers that conduct such tests and provide results. -

Hole Integrity Testing

– Ensuring that the holes can withstand repeated use is critical. Tests may include pulling force tests to check the strength of the holes. -

Aesthetic Quality Checks

– Visual inspections are conducted to assess the finish, color consistency, and overall appearance of the belts. This step ensures that products meet aesthetic expectations.

Conclusion

Understanding the manufacturing processes and quality assurance measures for leather belts is essential for B2B buyers, particularly in international markets. By focusing on these aspects, buyers can ensure they select reliable suppliers who adhere to high-quality standards, thus safeguarding their investment and enhancing customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a hole in a leather belt’

Introduction

This guide serves as a practical checklist for B2B buyers interested in sourcing solutions for creating holes in leather belts. Whether for manufacturing, retail, or personal use, understanding the steps involved in making precise holes can enhance product offerings and customer satisfaction. The following checklist provides actionable insights to streamline the process.

Step 1: Assess Your Needs and Specifications

Identify the specific requirements for the hole-making process. Consider factors such as the type of leather, the desired hole size, and the quantity of belts needing adjustments. Understanding these specifications helps in selecting the right tools and methods, ensuring that the final product meets your quality standards.

Illustrative image related to how to make a hole in a leather belt

Step 2: Research Available Tools and Methods

Explore various tools and techniques for making holes in leather belts. Common methods include using leather punches, drills, or even heated nails. Each method has its pros and cons regarding precision, cost, and ease of use, so it’s essential to evaluate which aligns best with your production capabilities.

- Leather Punches: Ideal for precision, but may require an upfront investment.

- Drills: Versatile and can be adapted for different hole sizes, but may require additional equipment like clamps to stabilize the belt.

Step 3: Evaluate Supplier Options for Tools

When sourcing tools, assess potential suppliers thoroughly. Request catalogs, product samples, and information on the durability and efficacy of their tools. It’s crucial to ensure that the tools meet your technical specifications and can withstand the demands of your production environment.

- Supplier Reliability: Check for reviews and testimonials from other businesses in your industry.

- Product Guarantees: Look for suppliers that offer warranties or return policies on their tools.

Step 4: Consider Training and Support Services

Evaluate whether the suppliers offer training for the use of their tools. Proper training can significantly reduce errors and improve efficiency in your production line. Additionally, consider ongoing support services for troubleshooting and maintenance.

Illustrative image related to how to make a hole in a leather belt

- Training Sessions: Some suppliers may provide on-site or virtual training for staff.

- Technical Support: Ensure that the supplier has a responsive customer service team to assist with any issues.

Step 5: Verify Compliance and Safety Standards

Ensure that the tools and methods you plan to use comply with local regulations and safety standards. This is particularly important when dealing with machinery or chemicals that may be involved in the leather working process. Non-compliance can lead to legal issues and safety hazards.

- Certifications: Request documentation proving that tools meet international safety standards.

- Risk Assessments: Conduct risk assessments to identify potential hazards associated with the tools and methods you choose.

Step 6: Establish a Quality Control Process

Implement a quality control system to monitor the hole-making process. This ensures that each hole meets the required specifications and that the leather belts maintain their integrity. Regular checks can help identify issues early, minimizing waste and rework.

- Quality Checkpoints: Set specific checkpoints in the production process to verify hole size and placement.

- Feedback Loop: Establish a system for collecting feedback from workers to continually refine the process.

Step 7: Plan for Future Needs

Consider your long-term needs for leather hole-making tools. As your business grows, you may require more advanced tools or larger quantities of belts. Establish relationships with suppliers that can scale with your business and adapt to changing demands.

- Scalability: Look for suppliers that can provide tools for both small and large production runs.

- Innovative Solutions: Stay informed about new technologies or methods that could enhance your production capabilities in the future.

By following this checklist, B2B buyers can streamline the process of making holes in leather belts, ensuring efficiency, compliance, and high-quality results.

Comprehensive Cost and Pricing Analysis for how to make a hole in a leather belt Sourcing

What Are the Key Cost Components in Making a Hole in a Leather Belt?

When sourcing solutions for adding holes to leather belts, several cost components must be considered. These include:

-

Materials: The primary material is leather, which varies in quality and price. High-quality leather will naturally cost more. Additionally, tools such as leather punches, drills, or heated implements may have associated costs if not already owned.

-

Labor: Labor costs depend on the complexity of the method chosen for making the hole. Simple methods such as using a heated nail or a screwdriver may require minimal labor, while specialized techniques involving professional services will incur higher costs.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and other operational expenses. If outsourcing the work, overhead costs are typically factored into the service fee charged by the professional or shop.

-

Tooling: Investment in quality tools can lead to better results and efficiency. For businesses, the initial expense of acquiring tools like leather punches or drills should be amortized over their usage.

-

Quality Control (QC): Ensuring that the hole is made correctly involves quality checks, especially if the belts are part of a larger product line. This may add to labor costs but is crucial for maintaining brand reputation.

-

Logistics: If materials or services are sourced from different regions, shipping costs must be considered, especially for international transactions. Import duties and taxes may also apply, impacting the final cost.

-

Margin: Suppliers will include a margin to cover their costs and profit. This can vary widely based on market conditions, supplier relationships, and the perceived value of the service offered.

How Do Price Influencers Impact the Cost of Making a Hole in a Leather Belt?

Several factors influence the pricing structure for making holes in leather belts, particularly in a B2B context:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, which is advantageous for businesses needing to produce belts in large quantities.

-

Specifications and Customization: Custom designs or specifications may increase costs. For example, unique hole sizes or placements might require more skilled labor or specialized tools.

-

Material Quality and Certifications: High-quality leather with certifications (e.g., eco-friendly or ethically sourced) typically commands higher prices. Buyers should assess whether the added cost aligns with their brand values and target market.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers with a track record of quality may charge more, but the assurance of quality and timely delivery can justify the cost.

-

Incoterms: Understanding the international commercial terms (Incoterms) is crucial, especially for international buyers. These terms define who is responsible for shipping, insurance, and tariffs, influencing overall costs.

What Buyer Tips Should Be Considered for Cost-Efficiency?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Effectively: Buyers should not hesitate to negotiate prices, especially when placing large orders. Building strong relationships with suppliers can lead to better terms and lower costs.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with quality, durability, and maintenance of the leather belts. A lower initial cost may lead to higher replacement rates, negating savings.

-

Understand Pricing Nuances: Different regions may have varying price structures due to local market conditions, labor costs, and material availability. Buyers should conduct market research to understand these dynamics.

-

Consider Local Sourcing: Whenever possible, sourcing locally can reduce shipping costs and lead times, providing a more efficient supply chain.

Disclaimer on Pricing

Prices mentioned in this analysis are indicative and can fluctuate based on market conditions, currency exchange rates, and specific supplier agreements. Buyers are encouraged to conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing how to make a hole in a leather belt With Other Solutions

Introduction to Alternative Solutions for Making Holes in Leather Belts

When it comes to adjusting the size of a leather belt, businesses often seek effective methods that balance performance, cost, and ease of use. While traditional techniques such as using a leather punch are common, there are several alternatives available that can achieve similar results. This analysis will compare the conventional method of making a hole in a leather belt against two viable alternatives: using a power drill and utilizing a heated nail. Understanding these options can help B2B buyers make informed decisions based on their specific operational needs.

Comparison Table

| Comparison Aspect | How To Make A Hole In A Leather Belt | Power Drill Method | Heated Nail Method |

|---|---|---|---|

| Performance | High precision and durability | Moderate precision; risk of tearing | Moderate precision; easy to control |

| Cost | Low (requires a punch tool) | Moderate (cost of drill bits) | Very low (common household item) |

| Ease of Implementation | Requires specific tools and skills | Requires power tools; setup needed | Simple and quick; minimal setup |

| Maintenance | Low (punch tool requires little upkeep) | Moderate (drill maintenance needed) | Very low (nail is single-use) |

| Best Use Case | For consistent, professional results | For quick fixes in bulk settings | Ideal for one-off adjustments |

Detailed Breakdown of Alternatives

Power Drill Method

Using a power drill is a popular alternative for creating holes in leather belts, especially in settings where speed is essential. This method allows for quick adjustments, making it suitable for businesses that need to modify multiple belts in a short time. However, it requires a drill and appropriate drill bits, which can increase costs and maintenance efforts. Additionally, there is a risk of tearing the leather if not executed carefully, making it less suitable for high-end leather products.

Heated Nail Method

The heated nail method is an effective and low-cost solution for adding holes to leather belts without specialized tools. By heating a nail and pushing it through the leather, users can create a hole in a straightforward manner. This method is particularly advantageous in environments where tools are limited, making it accessible for small businesses or individual craftsmen. However, while it is easy to execute, the precision may not match that of a professional punch or drill, and it may not be ideal for thicker leather.

Conclusion: Choosing the Right Solution for Your Needs

When deciding how to make a hole in a leather belt, B2B buyers should consider their specific operational requirements, including the volume of belts needing adjustments, the quality of the leather, and available resources. For high-volume production, investing in a power drill may offer efficiency despite the higher upfront costs. Conversely, for occasional adjustments or smaller operations, the heated nail method provides a cost-effective and straightforward alternative. By carefully evaluating these factors, businesses can select the method that best aligns with their operational goals and customer expectations.

Illustrative image related to how to make a hole in a leather belt

Essential Technical Properties and Trade Terminology for how to make a hole in a leather belt

What are the Critical Technical Properties for Making a Hole in a Leather Belt?

When considering the process of making a hole in a leather belt, several technical properties play a crucial role in ensuring quality and durability. Understanding these specifications can help B2B buyers make informed decisions regarding materials and methods.

-

Material Grade

The grade of leather used in a belt significantly influences its strength and longevity. Full-grain leather, for instance, is the highest quality and retains the natural texture and durability. Buyers should prioritize this grade for products that require longevity, especially in industries like fashion and accessories. -

Thickness (Gauge)

Leather thickness is measured in ounces or millimeters and can affect how easily a hole can be made. Typically, belts range from 1.5 mm to 5 mm in thickness. Thicker belts may require specialized tools to create holes, impacting the production process. Understanding the gauge helps in selecting appropriate tools and methods. -

Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the hole. For instance, a tolerance of ±0.5 mm is standard for precision work. Inconsistent hole sizes can lead to poor fit and functionality, making tolerance a critical property for manufacturers aiming for high-quality products. -

Finish Type

The finish of leather affects its appearance and performance. Common finishes include aniline, semi-aniline, and pigmented. Each finish has different properties regarding scratch resistance and color retention. Buyers should choose finishes that align with their branding and product requirements. -

Flexibility and Durability

Flexibility refers to the leather’s ability to bend without cracking, while durability indicates how well it withstands wear and tear. These properties are vital for belts that experience regular use. Testing flexibility and durability can help ensure that the leather can endure the rigors of everyday wear.

What Common Trade Terms Should B2B Buyers Know?

Understanding industry jargon can enhance communication between buyers and suppliers. Here are several key terms relevant to the process of making a hole in a leather belt:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of leather belts, an OEM might manufacture the leather or components that other brands use to create their belts. Understanding OEM relationships can help buyers ensure quality sourcing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs based on their sales forecasts to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products or services. When making a hole in a leather belt, buyers might issue an RFQ to gather competitive pricing and terms from multiple suppliers, helping them make cost-effective decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B transactions involving leather belts, as they outline shipping costs, risks, and responsibilities. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving it. For manufacturers, understanding lead times is essential for planning production schedules and inventory levels. Buyers should inquire about lead times to ensure timely delivery of materials needed for making leather belts.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies and ensure they are making informed decisions in the leather goods market.

Navigating Market Dynamics and Sourcing Trends in the how to make a hole in a leather belt Sector

What Are the Current Market Dynamics and Key Trends in the Leather Belt Sector?

The leather belt market is experiencing dynamic shifts driven by global consumer preferences, fashion trends, and technological advancements in manufacturing. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe engage with this market, understanding these trends becomes crucial. One key driver is the growing demand for personalized and customizable products, which allows consumers to adapt their leather belts to their specific needs, such as adjusting sizes through additional holes. This trend is particularly pronounced in developing markets where consumers are increasingly seeking quality and durability in their purchases.

Moreover, the rise of e-commerce has transformed sourcing strategies, enabling buyers to access a broader range of suppliers and manufacturers. Digital platforms facilitate direct communication and negotiations, allowing B2B buyers to source materials and tools for belt modifications, such as hole punches or alternative DIY methods. Additionally, advancements in manufacturing technology, such as laser cutting and automated leather processing, are making it easier for producers to create bespoke products quickly and efficiently, thereby meeting the demand for rapid customization.

How Is Sustainability and Ethical Sourcing Influencing the Leather Belt Industry?

Sustainability is becoming a cornerstone of sourcing strategies within the leather belt sector. International B2B buyers are increasingly prioritizing suppliers who adopt environmentally friendly practices and materials. The environmental impact of leather production, including deforestation and water usage, has prompted a shift towards sustainable sourcing. This includes the use of vegetable-tanned leather and other eco-friendly materials, which not only reduce the ecological footprint but also appeal to a growing base of environmentally conscious consumers.

Moreover, ethical sourcing practices are gaining traction, with buyers seeking transparency in the supply chain. This includes ensuring that leather is sourced from suppliers that adhere to fair labor practices and animal welfare standards. Certifications such as the Leather Working Group (LWG) or Global Organic Textile Standard (GOTS) are becoming essential for suppliers to showcase their commitment to sustainability and ethical practices. By prioritizing these certifications, B2B buyers can align their purchasing decisions with the values of their target markets, enhancing brand loyalty and market competitiveness.

What Is the Evolution of Techniques for Making Holes in Leather Belts?

The techniques for making holes in leather belts have evolved significantly over time. Historically, artisans relied on rudimentary methods such as heated nails or simple hand tools to create holes. These techniques were often time-consuming and required a level of craftsmanship that limited accessibility for average consumers.

As the leather goods industry grew, so did the need for efficiency and precision. The introduction of specialized tools such as leather hole punches revolutionized the process, allowing for clean and uniform holes, which are essential for both functionality and aesthetics. In recent years, the advent of power tools, including drills and electric screwdrivers, has further streamlined the process, enabling users to create holes quickly and with minimal effort.

Today, the focus is not only on the practicality of these methods but also on their environmental impact. Innovations in tool design are increasingly incorporating sustainable materials and practices, reflecting the broader trends in the leather industry towards sustainability and ethical sourcing. As a result, international B2B buyers are presented with a variety of options that cater to both their operational needs and their commitment to responsible sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a hole in a leather belt

-

1. How do I choose the right tool for making a hole in a leather belt?

Selecting the appropriate tool depends on the thickness and quality of the leather. A leather punch is ideal for precision, while a power drill can be effective for thicker materials. For those not wanting to invest in specialized tools, alternatives like a heated nail or a sharp knife can work in a pinch. However, using a quality leather punch ensures a clean hole and minimizes damage to the belt, making it a worthwhile investment for businesses focused on quality craftsmanship. -

2. What are the best practices for making a hole in a leather belt?

To achieve the best results, start by marking the desired hole location with a pen or chalk. Use a sturdy surface and support the belt with a piece of wood to prevent it from moving. When using a punch or drill, apply even pressure and avoid rushing the process, as this can lead to uneven holes. Always ensure safety precautions are in place, such as wearing protective eyewear and securing the belt properly during the operation. -

3. What are the common mistakes to avoid when adding a hole to a leather belt?

Common mistakes include not measuring correctly, which can lead to misalignment, and using improper tools that can damage the leather. Additionally, failing to support the belt properly while working can result in jagged holes or injury. Ensure to avoid using excessive force, which can cause tearing or fraying of the leather edges. Taking time to prepare and double-check measurements can prevent costly errors. -

4. How can I ensure the quality of leather when sourcing belts for customization?

When sourcing leather belts for customization, prioritize suppliers who provide detailed information about their leather quality, such as sourcing methods and tanning processes. Request samples to assess the material’s texture, durability, and finish. Additionally, check for certifications and compliance with international standards, especially for eco-friendly practices, which can enhance your brand’s reputation in the market. -

5. What are the minimum order quantities (MOQ) for custom leather belts?

MOQs can vary significantly between suppliers, influenced by factors like material costs and production capabilities. Typically, you may encounter MOQs ranging from 50 to 500 units for custom leather belts. It’s essential to communicate your needs clearly and negotiate terms that suit your business model, especially if you’re a smaller enterprise or startup looking to test the market. -

6. How do I vet suppliers for leather belt production?

To vet suppliers, start by researching their reputation through customer reviews and industry feedback. Request information on their production processes, quality control measures, and compliance with international standards. Consider visiting their facilities if possible or conducting virtual audits. Establish clear communication and request references from previous clients to ensure reliability and quality in their service. -

7. What payment terms should I negotiate with leather belt suppliers?

Payment terms can greatly affect cash flow, so it’s crucial to negotiate favorable conditions. Common terms include a 30% deposit upfront, with the remaining balance due upon delivery or after inspection. Always clarify the payment methods accepted, such as wire transfers or letters of credit, and ensure that all terms are documented in the contract to prevent misunderstandings. -

8. What logistics considerations should I keep in mind when importing leather belts?

When importing leather belts, consider shipping methods, customs duties, and lead times. Choose a reliable freight forwarder familiar with international regulations to navigate customs clearance smoothly. Ensure that all necessary documentation, such as invoices and certificates of origin, is prepared to avoid delays. Additionally, factor in potential tariffs and local regulations that may impact your costs and delivery schedules.

Top 5 How To Make A Hole In A Leather Belt Manufacturers & Suppliers List

1. Art of Manliness – Rotary Punch & Round Drive Punch

Domain: artofmanliness.com

Registered: 2007 (18 years)

Introduction: 1. Rotary Punch: A tool specifically for leather, typically using #5 sized punch. Simple to use by centering over the marking and squeezing the handle. Recommended for frequent use. Available at Tandy Leather or hardware stores.

2. Round Drive Punch: Sharp steel tubes available in various sizes, typically 3/16″ for standard belt buckles. Requires a mallet for use. Can be purchased at Tandy or har…

2. Life Hacks – Belt Hole Solutions

Domain: lifehacks.stackexchange.com

Registered: 2009 (16 years)

Introduction: Substitute tools for adding a belt hole without a leather punch include: 1. Power drill with a small drill bit – Use a piece of scrap wood underneath the belt. 2. Heated nail – Heat a nail and use pliers to push it into the belt. 3. Sharp pointed knife – Rotate gently at the marked spot to create a hole. 4. Screwdriver bit in an electric screwdriver – Works effectively for making holes. 5. Awl poi…

3. Kangaroo Belt Co – Hand Braided Leather Belts

Domain: kangaroobeltco.com.au

Introduction: Hand braided Kangaroo leather belts designed and crafted in Australia. Built to last a lifetime – guaranteed.

4. WikiHow – Leather Belt Hole Punching Guide

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: The article provides instructions on how to punch holes in a leather belt using various tools, including a rotary leather hole punch, a sharp tool (like an awl or rod punch), or an electric drill. It emphasizes the importance of measuring the distance between existing holes and marking the new hole’s position accurately. The rotary punch is highlighted as the ideal tool due to its multiple size op…

5. Leatherworker – Belt Cutting Jigs and Tools

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Belt cutting jigs, 30mm and 45mm belt styles, removable buckle retainer, clicker press, steel rule die (19mm or 3/4″), knife cost approximately $150 AU or $100 US, Masonite board (3mm or 1/8″), skirting pine (30-40mm by 12mm or 1 1/4″ to 1 1/2″ by 3/8″), aluminum support strip.

Strategic Sourcing Conclusion and Outlook for how to make a hole in a leather belt

In conclusion, understanding how to make a hole in a leather belt is not just a practical skill; it represents an opportunity for strategic sourcing in the leather goods industry. Whether you are sourcing leather belts for resale or seeking to improve customer satisfaction with customizable options, the techniques outlined—from using a leather punch to innovative DIY methods—empower your business to address customer needs effectively.

By investing in quality tools and training your team on these methods, you can enhance your product offerings, reduce waste, and foster customer loyalty through tailored solutions. Additionally, the demand for versatile leather goods is growing across international markets, particularly in regions such as Africa, South America, the Middle East, and Europe.

As you look to the future, consider integrating these practices into your sourcing strategy to stay competitive. Embrace innovation and customer-centric approaches, and position your business to meet the evolving needs of your clientele. Now is the time to act—explore new partnerships, invest in quality materials, and elevate your brand in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how to make a hole in a leather belt

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.