Introduction: Navigating the Global Market for leather backing

In an increasingly competitive global market, sourcing high-quality leather backing can pose significant challenges for B2B buyers. Whether you’re in Nigeria or Saudi Arabia, the quest for reliable suppliers and consistent product quality often leads to complexities that can disrupt your operations. This guide addresses these challenges head-on by offering a comprehensive overview of leather backing, including various types, applications across industries, and essential tips for supplier vetting.

From understanding the distinctions between thin and thick leather backings to exploring eco-friendly options such as recycled materials, this guide equips international buyers with the knowledge needed to make informed purchasing decisions. You’ll also find insights into pricing structures and cost-effective strategies, ensuring that your investment yields maximum returns.

Moreover, we delve into critical factors like durability, flexibility, and environmental impact, all of which are vital in selecting the right leather backing for your specific needs. By the end of this guide, you will be empowered to navigate the complexities of the leather backing market with confidence, fostering long-term partnerships that enhance your product offerings and satisfy your customers across Africa, South America, the Middle East, and Europe.

Table Of Contents

- Top 6 Leather Backing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather backing

- Understanding leather backing Types and Variations

- Key Industrial Applications of leather backing

- 3 Common User Pain Points for ‘leather backing’ & Their Solutions

- Strategic Material Selection Guide for leather backing

- In-depth Look: Manufacturing Processes and Quality Assurance for leather backing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather backing’

- Comprehensive Cost and Pricing Analysis for leather backing Sourcing

- Alternatives Analysis: Comparing leather backing With Other Solutions

- Essential Technical Properties and Trade Terminology for leather backing

- Navigating Market Dynamics and Sourcing Trends in the leather backing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather backing

- Strategic Sourcing Conclusion and Outlook for leather backing

- Important Disclaimer & Terms of Use

Understanding leather backing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather Backing | Made from the top layer of the hide, retains natural grain. | High-end leather goods, upholstery | Pros: Durable, luxurious appearance. Cons: Higher cost. |

| Thin Backing Leather | Lightweight, flexible, often used for sub-patching. | Repair work, smaller leather goods | Pros: Cost-effective, easy to work with. Cons: Limited durability. |

| Recycled Leather Bonded Backing | Eco-friendly, made from leather waste, offers stiffness. | Bags, wallets, crafts | Pros: Sustainable, versatile. Cons: May vary in quality. |

| Puncture & Tear Resistant Backing | Enhanced durability, designed for high-traffic areas. | Commercial upholstery, flooring | Pros: Long-lasting, cost-effective in the long run. Cons: Heavier material. |

| Fleece Backing | Self-adhesive, prevents indentations, enhances softness. | Automotive leather, furniture | Pros: Easy application, maintains aesthetics. Cons: May require specialized tools. |

What Are the Key Characteristics of Full Grain Leather Backing?

Full grain leather backing is derived from the uppermost layer of the hide, preserving the natural grain and texture. This type is often favored for its durability and luxurious appearance, making it suitable for high-end leather goods and upholstery. When purchasing, B2B buyers should consider the cost implications, as full grain leather tends to be more expensive than other types. However, its longevity and quality can justify the investment, especially for premium products.

How Does Thin Backing Leather Serve B2B Needs?

Thin backing leather is a lightweight and flexible option, commonly used for sub-patching and repairs. It is particularly beneficial for crafting smaller leather goods, where flexibility and ease of use are paramount. Buyers should note that while this option is cost-effective, it may not provide the same level of durability as thicker alternatives. This makes it ideal for projects where weight and cost are more critical than long-term wear.

Why Choose Recycled Leather Bonded Backing?

Recycled leather bonded backing is an eco-friendly choice made from leather waste, offering a sustainable solution for manufacturers. This type provides a degree of stiffness, making it suitable for bags, wallets, and various leather crafts. Buyers interested in sustainability will find this option appealing, but they should also be aware that the quality can vary based on the sourcing of the recycled materials. Ensuring consistent quality is essential for maintaining brand integrity.

What Advantages Does Puncture & Tear Resistant Backing Offer?

Puncture and tear resistant backing is engineered for high durability, making it ideal for commercial upholstery and flooring applications. This type is particularly valuable in environments with high foot traffic, such as restaurants or hotels, where wear and tear are significant concerns. While it offers a longer lifespan and potential cost savings over time, buyers should consider the heavier weight and potential higher initial costs associated with this robust material.

How Does Fleece Backing Enhance Leather Products?

Fleece backing is a self-adhesive option designed to prevent seat indentations and improve the tactile quality of leather products. Commonly used in automotive applications and furniture, it enhances the longevity and aesthetics of leather. B2B buyers should evaluate the ease of application, as this backing can eliminate the need for additional gluing methods. However, it may require specialized tools for optimal application, which could impact overall project costs.

Key Industrial Applications of leather backing

| Industry/Sector | Specific Application of leather backing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery and seat manufacturing | Enhances durability and comfort, reduces wear and tear | Compliance with safety regulations, material weight, and thickness |

| Fashion and Accessories | Handbags and small leather goods | Provides stiffness and structure while maintaining aesthetic appeal | Sourcing eco-friendly options, color matching, and texture consistency |

| Furniture | Upholstery for commercial and residential use | Increases lifespan of furniture, cost-effective in high-traffic areas | Fire resistance, ease of cleaning, and compatibility with adhesives |

| Leather Repair and Restoration | Backing for repair patches and restoration kits | Facilitates seamless repairs, extends the life of leather products | Thickness and flexibility, bonding capabilities, and weight |

| Craft and DIY | Leathercraft projects and artisanal goods | Versatile application for various crafts, supports customization | Sourcing in bulk, availability of different textures, and eco-friendliness |

How is Leather Backing Used in the Automotive Industry?

In the automotive sector, leather backing is primarily utilized for upholstery and seat manufacturing. It provides a robust foundation that enhances the durability and comfort of car interiors. By reducing wear and tear, leather backing helps maintain the aesthetic appeal of vehicles over time. International buyers, particularly from regions like the Middle East and Europe, should consider compliance with safety regulations, as well as specific requirements regarding the material’s weight and thickness to meet OEM standards.

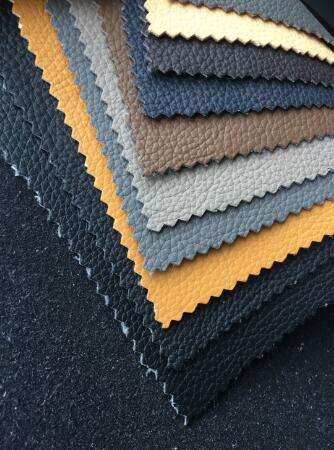

Illustrative image related to leather backing

What Role Does Leather Backing Play in Fashion and Accessories?

Leather backing is crucial in the production of handbags and small leather goods, where it adds stiffness and structure while retaining the desired aesthetic appeal. This backing allows designers to create products that are both functional and visually appealing. For B2B buyers in Africa and South America, sourcing eco-friendly leather options is becoming increasingly important, along with ensuring color matching and texture consistency to meet consumer demands.

How is Leather Backing Beneficial for Furniture Upholstery?

In the furniture industry, leather backing is extensively used for upholstery in both commercial and residential applications. It significantly increases the lifespan of furniture, making it a cost-effective choice for high-traffic areas. Buyers should focus on sourcing materials that offer fire resistance, ease of cleaning, and compatibility with various adhesives, especially in regions where safety and maintenance are top priorities.

How Does Leather Backing Enhance Repair and Restoration Efforts?

Leather backing serves as an essential component in repair patches and restoration kits for damaged leather products. Its flexibility and ability to bond seamlessly with existing leather allow for effective repairs that extend the life of items like jackets, furniture, and accessories. Buyers should prioritize the thickness and bonding capabilities of the leather backing to ensure optimal performance in restoration applications.

What is the Importance of Leather Backing in Craft and DIY Projects?

In the craft and DIY sector, leather backing is versatile and supports a wide range of projects, from artisanal goods to custom leather items. It enables crafters to achieve unique designs while maintaining structural integrity. For international buyers, sourcing leather backing in bulk, along with diverse textures and eco-friendly options, can significantly enhance their product offerings and appeal to environmentally conscious consumers.

3 Common User Pain Points for ‘leather backing’ & Their Solutions

Scenario 1: Quality Variability in Leather Backing Materials

The Problem: B2B buyers often face challenges in ensuring consistent quality when sourcing leather backing materials. Variations in thickness, texture, and durability can lead to complications in production, affecting the final product’s quality and reliability. For businesses in regions like Nigeria or Saudi Arabia, where sourcing local materials can be limited, the risk of receiving subpar leather backing can disrupt supply chains and lead to costly reworks or returns.

The Solution: To mitigate quality variability, buyers should establish strong relationships with reputable suppliers known for their consistent product standards. Before placing bulk orders, request samples to evaluate the leather backing’s quality firsthand. It’s also beneficial to inquire about the supplier’s quality control processes, such as third-party inspections or certification standards. Furthermore, leveraging technology for communication, such as video calls to inspect materials, can enhance transparency. Establishing a clear specification document outlining desired qualities—like thickness, finish, and durability—can also help suppliers meet expectations.

Scenario 2: Environmental Concerns and Sustainability in Leather Production

The Problem: With increasing global awareness around sustainability, B2B buyers are often challenged to find leather backing that aligns with eco-friendly practices. Buyers from South America and Europe, in particular, are under pressure to source materials that not only meet their production needs but also adhere to environmental regulations and ethical standards. Sourcing leather that is not sustainably produced can damage a company’s reputation and alienate environmentally conscious consumers.

Illustrative image related to leather backing

The Solution: Buyers should prioritize suppliers that offer sustainably sourced leather backing, such as those using vegetable tanning methods or recycled leather materials. Engaging with suppliers that provide transparency about their sourcing practices and environmental impact can help mitigate these concerns. Additionally, consider using leather backing made from composted waste, as this can significantly reduce the ecological footprint. Request certifications or reports that confirm the sustainability claims of suppliers to ensure that the materials meet environmental standards. Building a portfolio of eco-friendly suppliers will not only enhance product offerings but also position the business as a leader in sustainable practices.

Scenario 3: Difficulties in Customization and Compatibility

The Problem: Many B2B buyers encounter issues when attempting to customize leather backing for specific applications, such as upholstery or accessories. In regions with diverse market demands, like the Middle East and Africa, the need for tailored solutions can complicate sourcing, as not all suppliers offer flexible options. Buyers may find that the leather backing they receive does not adhere well to the intended materials, leading to challenges in production and customer dissatisfaction.

The Solution: To address customization challenges, buyers should engage with suppliers that specialize in bespoke solutions. This involves clearly communicating specific requirements, such as size, thickness, and intended use, during the initial discussions. Requesting samples of customized leather backing can help assess compatibility with other materials before finalizing orders. Additionally, consider collaborating with manufacturers that offer technical support or consultation services to identify the best backing options for particular applications. Using advanced adhesives or bonding techniques can also enhance the compatibility of leather backing with various substrates, ensuring a seamless integration into the final product. By fostering a collaborative relationship with suppliers, buyers can achieve the level of customization necessary to meet market demands effectively.

Strategic Material Selection Guide for leather backing

What Are the Key Properties of Common Leather Backing Materials?

When selecting leather backing materials, it is essential to consider their properties, advantages, disadvantages, and suitability for various applications. Below are analyses of four common materials used in leather backing.

Illustrative image related to leather backing

1. Thin Leather Backing

Key Properties: Thin leather backing typically ranges from 2.5 to 3 oz in weight, offering flexibility and a natural aesthetic. It is breathable and can withstand moderate temperature variations, making it suitable for various applications.

Pros & Cons: The primary advantage of thin leather backing is its lightweight nature, which helps in maintaining the overall weight of the final product. However, it may not provide sufficient durability for high-wear applications. Its cost is generally moderate, but sourcing high-quality leather can increase expenses.

Impact on Application: This material is ideal for products like wallets and small leather goods where weight and aesthetics are crucial. However, it may not be suitable for heavy-duty applications, such as upholstery in high-traffic areas.

Illustrative image related to leather backing

Considerations for International Buyers: Buyers should ensure compliance with local leather processing regulations. In regions like Europe, adherence to REACH regulations is critical, while in Africa and South America, buyers should verify the sourcing of leather to avoid ethical concerns.

2. Recycled Leather Backing

Key Properties: Recycled leather backing is made from leather waste, typically offering a thickness of around 0.3 mm. It is eco-friendly and provides a good balance of stiffness and flexibility.

Pros & Cons: The key advantage is its sustainability, appealing to environmentally conscious buyers. However, its availability may be limited, and it can sometimes lack the uniformity found in virgin leather. The cost is usually lower than that of new leather, making it an attractive option for budget-conscious projects.

Impact on Application: This material is excellent for crafting bags and small goods that require a touch of stiffness without compromising on eco-friendliness. Its compatibility with various adhesives makes it versatile for different crafting techniques.

Considerations for International Buyers: Buyers should check for certifications that confirm the recycled content and environmental impact. In regions like the Middle East, where sustainability is becoming increasingly important, this material can enhance brand reputation.

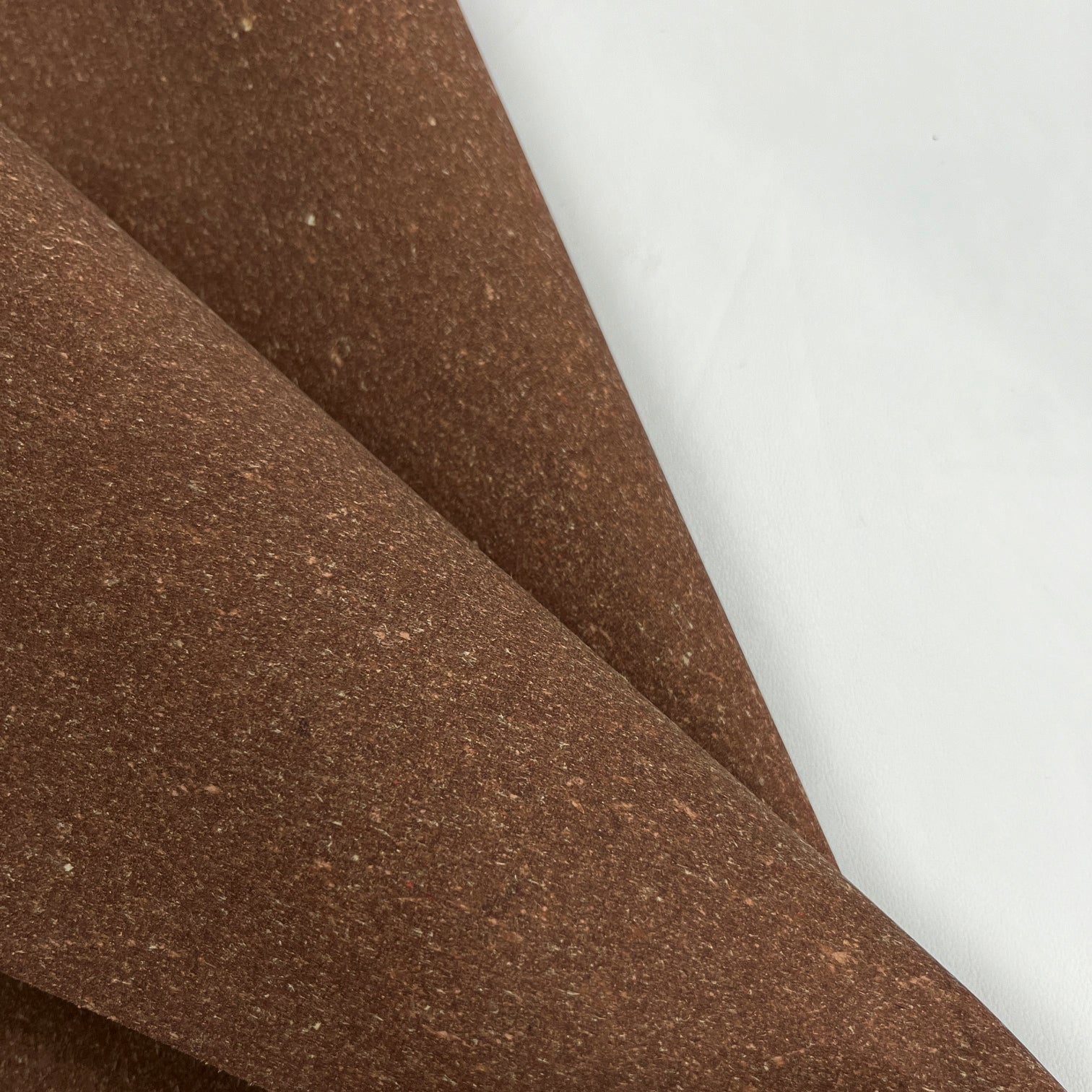

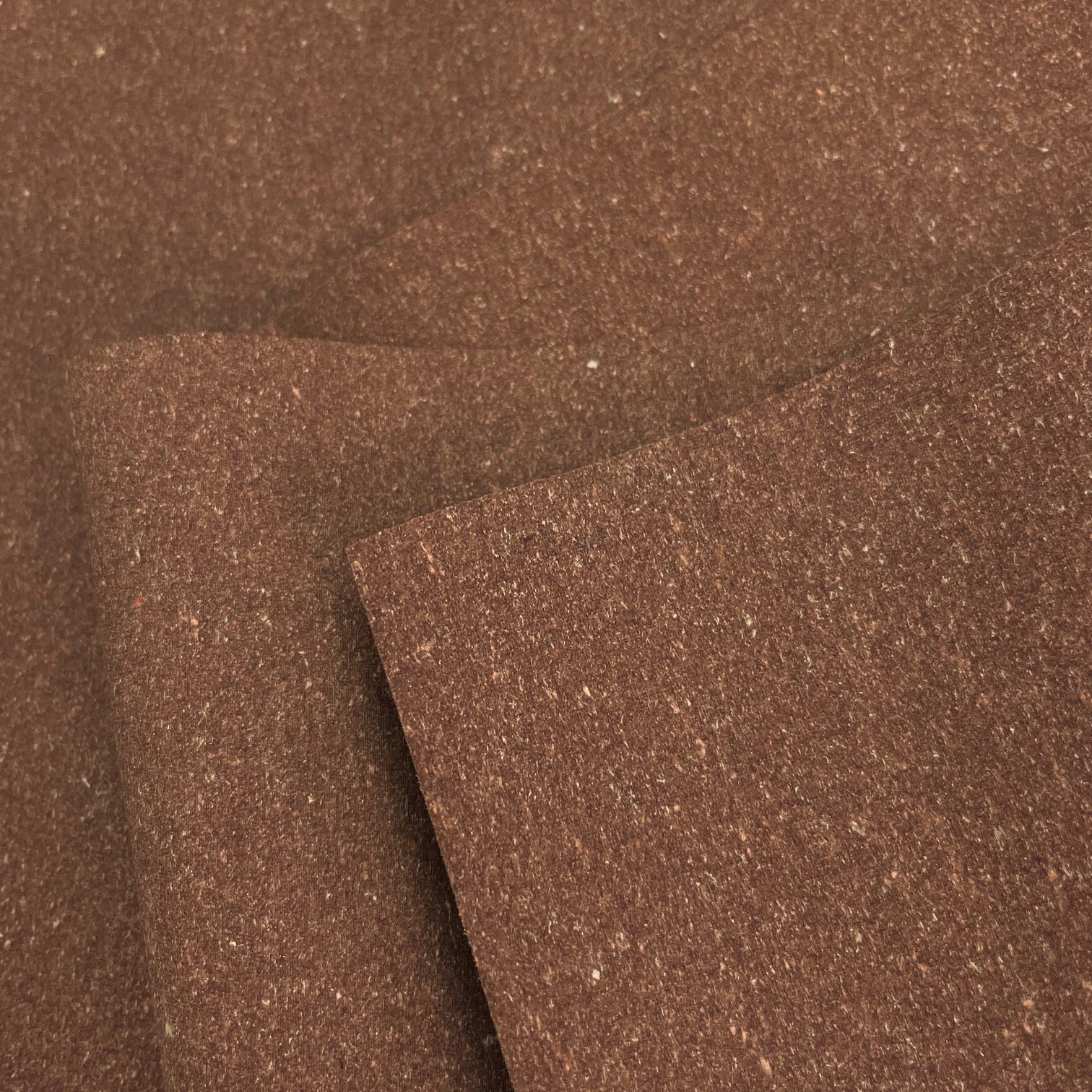

3. Puncture and Tear Resistant Backing

Key Properties: This backing is designed to withstand high pressure and punctures, making it ideal for commercial applications. It is often bonded to leather, enhancing the durability and lifespan of the final product.

Pros & Cons: The primary advantage is its exceptional durability, making it suitable for high-traffic environments such as restaurants and hotels. However, the manufacturing process can be complex and may increase costs.

Impact on Application: This material is particularly effective in upholstery and flooring applications, where resistance to wear and tear is paramount. It is not recommended for applications requiring a soft touch, as it can feel stiffer.

Illustrative image related to leather backing

Considerations for International Buyers: Compliance with industry standards such as ASTM for safety and durability is crucial. Buyers in regions like Europe and North America may prioritize these standards, while those in developing regions should consider local regulations.

4. Fleece Backing

Key Properties: Fleece backing offers a soft touch and is self-adhesive, making it easy to apply. It helps retain the shape of leather products and is resistant to indentations.

Pros & Cons: The key advantage is its ability to enhance the aesthetic and tactile qualities of leather goods. However, it may not be suitable for all types of leather, particularly those exposed to extreme conditions. The cost is generally moderate, providing good value for its benefits.

Impact on Application: This material is commonly used in automotive applications, where comfort and appearance are critical. It can also be used in high-end leather goods requiring a premium finish.

Illustrative image related to leather backing

Considerations for International Buyers: Buyers should ensure that the fleece backing meets regional standards for automotive materials, especially in markets like the Middle East, where luxury automotive products are prevalent.

Summary Table

| المواد | Typical Use Case for leather backing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thin Leather Backing | Wallets and small leather goods | Lightweight and aesthetically pleasing | Limited durability for high-wear use | Medium |

| Recycled Leather Backing | Bags and small goods | Eco-friendly and sustainable | Limited availability and uniformity | منخفضة |

| Puncture and Tear Resistant Backing | Upholstery and commercial flooring | Exceptional durability | Complex manufacturing process | عالية |

| Fleece Backing | Automotive and high-end leather goods | Enhances comfort and appearance | Not suitable for extreme conditions | Medium |

This guide provides a strategic overview of leather backing materials, enabling B2B buyers to make informed decisions tailored to their specific market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather backing

What Are the Key Stages in the Manufacturing Process of Leather Backing?

The production of leather backing involves several critical stages that ensure the final product meets the required specifications for durability, flexibility, and quality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality leather from tanneries. The leather is inspected for quality and consistency in thickness, texture, and color. For sustainable options, recycled leather may also be used, which is derived from leather scraps and waste. The material is then cut to specific dimensions based on the intended application, whether for upholstery, bags, or other goods.

-

Forming: During this phase, the leather is processed to achieve the desired thickness and flexibility. Techniques such as splitting, where thicker hides are cut into thinner layers, are common. Additionally, bonding agents may be applied to enhance strength and durability. For instance, fleece backing is often used in automotive applications to prevent indentations and improve comfort.

-

Assembly: In this stage, the prepared leather is combined with other materials, if necessary, to create composite products. This might involve laminating the leather with fabric or synthetic materials to enhance properties like water resistance or puncture resistance. The assembly process can include stitching, gluing, or heat bonding, depending on the product requirements.

-

Finishing: The final stage involves applying protective coatings or treatments to the leather backing. This can include dyeing, waterproofing, or applying UV protection. Finishing not only enhances the appearance of the leather but also increases its longevity and usability in various applications.

How Is Quality Assurance Implemented in Leather Backing Manufacturing?

Quality assurance (QA) in leather backing production is paramount to ensure that the final products meet international standards and customer expectations. This process typically involves several key components.

-

International Standards Compliance: Manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with such standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe may also be relevant.

-

Quality Control Checkpoints: Quality control (QC) is integrated throughout the manufacturing process with specific checkpoints:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival. This ensures that only high-quality leather and other components are used in production.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor adherence to specifications. This includes checking dimensions, thickness, and adhesion of bonded layers.

– Final Quality Control (FQC): After production, a comprehensive inspection assesses the finished leather backing for any defects, ensuring it meets the required standards before shipping. -

Testing Methods for Leather Backing: Various testing methods are employed to verify the quality of leather backing. These may include:

– Tensile Strength Testing: Measures the strength of the leather and its ability to withstand stress.

– Flexibility Testing: Assesses how well the leather backing can bend and flex without damage.

– Water Resistance Testing: Determines the effectiveness of any waterproofing treatments applied during the finishing stage.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. This may include visiting their facilities to observe production practices and QC checkpoints.

-

Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the quality measures a supplier implements. These reports should outline the results of IQC, IPQC, and FQC processes, along with any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of confidence. These independent organizations can conduct thorough inspections and provide objective assessments of the quality of leather backing before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers need to be aware of specific nuances in quality control that may affect their procurement decisions:

-

Regulatory Compliance: Different regions may have varying regulations regarding leather products. Understanding these regulations is vital for ensuring compliance and avoiding potential legal issues.

-

Cultural and Market Differences: Preferences for leather quality, finish, and durability can vary significantly between markets. Buyers should communicate their specific requirements clearly to suppliers to ensure that the products meet local market expectations.

-

Sustainability Considerations: With growing awareness of environmental issues, many buyers are now prioritizing suppliers who use sustainable practices in their manufacturing processes. This includes sourcing leather from eco-friendly tanneries or using recycled materials in production.

الخاتمة

The manufacturing processes and quality assurance practices for leather backing are integral to delivering a high-quality product that meets the diverse needs of international B2B buyers. Understanding these processes enables buyers to make informed decisions when selecting suppliers, ensuring they receive products that not only meet their specifications but also comply with necessary quality standards. As the leather industry continues to evolve, staying abreast of manufacturing innovations and quality control measures will be essential for successful procurement and long-term partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather backing’

مقدمة

This guide serves as a practical checklist for international B2B buyers looking to procure leather backing. Sourcing high-quality leather backing is essential for various applications, from fashion to upholstery. Following these steps will help ensure that you make informed decisions, align with your project requirements, and establish successful supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating your sourcing journey, it’s vital to clearly outline your technical specifications. This includes determining the type of leather backing required, such as thickness, size, and weight. Knowing these details will streamline your search and ensure that suppliers can meet your exact needs.

Illustrative image related to leather backing

- Consider the application: Different applications may require different types of leather backing, like thin backing for small leather goods or thicker options for upholstery.

- Quality standards: Specify any quality requirements, including durability, flexibility, and eco-friendliness.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the leather backing market. Utilize online platforms, industry directories, and trade shows to compile a list of reputable manufacturers.

- Check reviews and ratings: Look for feedback from other B2B buyers to gauge reliability and product quality.

- Geographical considerations: Pay attention to suppliers in regions that are known for high-quality leather production, such as Italy or Brazil.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with industry standards. Certifications such as ISO 9001 for quality management or environmental certifications can indicate a supplier’s commitment to quality and sustainability.

- Request documentation: Ask for copies of certifications to ensure they are up-to-date.

- Consider ethical sourcing: Look for suppliers that adhere to ethical practices, especially if you are targeting markets sensitive to sustainability.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of their leather backing products. This is a critical step to assess the quality and suitability of the material for your specific applications.

Illustrative image related to leather backing

- Evaluate texture and durability: Inspect the samples for flexibility, thickness, and overall quality.

- Test compatibility: Ensure the leather backing works well with the other materials you intend to use.

Step 5: Negotiate Terms and Pricing

After selecting a supplier based on samples, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear communication during this phase can prevent misunderstandings later.

- Discuss minimum order quantities: Some suppliers may have minimum order requirements, which can affect your budget.

- Explore bulk discounts: If you plan to order large quantities, inquire about bulk pricing to optimize your costs.

Step 6: Finalize the Agreement

Once all terms are agreed upon, finalize the procurement agreement. This should include all negotiated terms, quality expectations, and delivery timelines.

- Include a penalty clause: Consider adding a clause for late deliveries or quality issues to protect your interests.

- Establish a communication plan: Set up a clear line of communication for updates and potential issues during the production and delivery phases.

Step 7: Monitor Delivery and Quality Control

Upon receiving the leather backing, conduct a thorough inspection to ensure it meets the agreed specifications. Establish a quality control process to identify any discrepancies early.

- Document any issues: Keep records of any defects or quality concerns for future reference.

- Provide feedback to the supplier: Constructive feedback can help improve future transactions and strengthen your supplier relationship.

By following these steps, B2B buyers can effectively navigate the sourcing process for leather backing, ensuring that they procure high-quality materials that meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for leather backing Sourcing

What Are the Key Cost Components in Leather Backing Sourcing?

When sourcing leather backing, understanding the cost structure is vital for B2B buyers. The primary components include:

-

Materials: The type of leather used significantly influences cost. For example, genuine leather generally commands a higher price compared to synthetic alternatives. Leather sourced from specific regions (like Italy or South America) may also carry a premium due to its quality and craftsmanship.

-

Labor: Labor costs vary based on the region of production. Countries with higher wages may present increased labor costs, impacting overall pricing. However, regions with skilled artisans may justify higher prices through superior craftsmanship.

-

Manufacturing Overhead: This includes utilities, rent, and other operational costs. A well-managed facility can optimize these costs, leading to more competitive pricing.

-

Tooling: The initial investment in machinery and tools can affect pricing. Custom tooling for specific designs or specifications may lead to higher upfront costs that are reflected in the product price.

-

Quality Control (QC): Rigorous QC processes ensure the leather backing meets industry standards. While this may add to the cost, it is essential for maintaining product integrity and reducing returns.

-

Logistics: Transportation costs, particularly for international shipping, can significantly impact pricing. Buyers should consider shipping methods and associated fees, which may vary by region.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding typical margins in the leather backing industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Leather Backing Costs?

Several factors influence the pricing of leather backing, which buyers should consider:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can impact pricing. Larger orders often lead to discounts, while smaller orders may incur higher per-unit costs due to economies of scale.

-

Specifications and Customization: Customized leather backing, such as specific thicknesses or finishes, typically incurs additional charges. Buyers should clarify their requirements upfront to receive accurate quotes.

-

Materials and Quality Certifications: Leather with specific quality certifications (like eco-friendly or sustainably sourced) may have higher costs. Buyers should weigh the benefits of these certifications against the price.

-

Supplier Factors: Reputation, reliability, and location of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but provide greater assurance of product consistency.

-

Incoterms: The agreed Incoterms can significantly influence total costs. For instance, terms like FOB (Free on Board) mean that the buyer assumes responsibility for shipping costs after the goods are loaded onto the vessel, which can lead to variable pricing.

What Are Some Effective Buyer Tips for Leather Backing Sourcing?

To navigate the complexities of leather backing sourcing, international buyers should consider the following tips:

-

Negotiate Wisely: Always negotiate prices and terms. Understanding the supplier’s cost structure can provide leverage in discussions.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, storage, and potential wastage. A slightly higher upfront cost may lead to savings in the long run.

-

Understand Pricing Nuances: Prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors, especially for buyers in Africa, South America, the Middle East, and Europe. Staying informed about these factors can aid in better purchasing decisions.

-

Seek Multiple Quotes: Request quotes from several suppliers to compare pricing and terms. This not only provides a benchmark but also opens opportunities for negotiation.

-

Consider Long-Term Relationships: Building long-term partnerships with suppliers can lead to better pricing and service, as trust and reliability often translate into favorable terms.

Disclaimer on Pricing Information

The prices mentioned in this analysis are indicative and may vary based on current market conditions, supplier negotiations, and specific order requirements. Buyers are encouraged to conduct thorough research and obtain quotes tailored to their unique needs.

Alternatives Analysis: Comparing leather backing With Other Solutions

Exploring Alternatives to Leather Backing: A Comprehensive Analysis

In the realm of materials for backing solutions, leather backing stands out due to its durability and aesthetic appeal. However, various alternatives exist that may suit specific needs better, depending on the application and target market. This section provides a detailed comparison of leather backing against several viable alternative solutions, offering insights into their respective advantages and disadvantages.

Illustrative image related to leather backing

| Comparison Aspect | Leather Backing | Thin Recycled Leather Bonded Backing | Puncture and Tear Resistant Backing |

|---|---|---|---|

| Performance | High durability and aesthetic appeal; excellent for crafting and upholstery. | Good stiffness and eco-friendly; suitable for small leather goods. | Superior durability; ideal for high-traffic commercial applications. |

| Cost | Moderate to high; typically $90 for half hides. | Affordable; around $24.99 per yard. | Higher initial cost due to advanced technology; varies based on application. |

| Ease of Implementation | Requires experience in leatherworking; may need specialized tools for best results. | Easy to use with standard leather adhesives; suitable for various crafts. | More complex installation; may require professional assistance for optimal results. |

| Maintenance | Requires regular care and conditioning to maintain appearance and longevity. | Low maintenance; cleaning typically involves standard leather care. | Very low maintenance; designed to withstand heavy wear without significant upkeep. |

| Best Use Case | Ideal for high-end leather products, upholstery, and custom crafting. | Best for eco-conscious projects, small goods, and light-duty applications. | Perfect for commercial settings needing durable, long-lasting materials. |

In-Depth Analysis of Alternatives

Thin Recycled Leather Bonded Backing

Thin recycled leather bonded backing is an innovative solution that merges environmental sustainability with functionality. This material is made from composted leather waste, making it an eco-friendly choice. Its lightweight nature allows for easy application, especially in crafting small leather goods like wallets and bags. However, while it offers decent stiffness, it may not provide the same level of durability and aesthetic quality as traditional leather backing, making it less suitable for high-end applications.

Puncture and Tear Resistant Backing

This type of backing is engineered for exceptional durability, making it an ideal choice for commercial upholstery in high-traffic environments. The composite material bonded to leather ensures that it can withstand punctures and tears, which is crucial in settings like restaurants or theaters where durability is paramount. However, the complexity of installation and higher initial costs may deter some buyers. It is best suited for businesses looking to minimize replacement costs over time.

Making the Right Choice for Your Needs

When selecting the appropriate backing material, B2B buyers should consider their specific application requirements, budget constraints, and desired performance attributes. Leather backing remains a premium choice for high-end products, while alternatives like thin recycled leather and puncture-resistant backing offer unique benefits for different use cases. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their business goals and customer expectations.

Illustrative image related to leather backing

Essential Technical Properties and Trade Terminology for leather backing

What are the Key Technical Properties of Leather Backing?

When sourcing leather backing, understanding its technical properties is essential for making informed purchasing decisions. Here are critical specifications that buyers should consider:

-

Material Grade

Material grade refers to the quality of the leather used for backing. High-grade leather typically offers better durability, appearance, and performance. In B2B contexts, selecting the appropriate material grade can influence product longevity and customer satisfaction, especially in applications such as upholstery or leather goods manufacturing. -

Thickness

The thickness of leather backing is measured in ounces (oz) or millimeters (mm). Common thickness ranges from 0.5 oz (approximately 0.3 mm) to 3 oz (around 2.4 mm). Thicker leather provides increased durability and support, making it suitable for high-traffic applications. Buyers should assess the thickness based on the intended use, as thicker materials may be more suitable for items requiring structural integrity. -

Weight

Weight is an important consideration that can affect handling, shipping costs, and application performance. Leather backing typically weighs between 1.5 oz to 3 oz per square foot. Understanding weight specifications helps businesses calculate shipping logistics and ensures compatibility with existing manufacturing processes. -

Width

The width of leather backing can vary significantly, commonly available in widths ranging from 36 to 60 inches. Wider backing allows for greater design flexibility and reduces material waste during production. B2B buyers should consider the width that best aligns with their production requirements, especially for large-scale manufacturing. -

Tannages

Tannage refers to the process used to treat the leather, impacting its durability, appearance, and flexibility. Common tanning methods include chrome, vegetable, and synthetic tanning. Each method imparts different characteristics to the leather, affecting its suitability for specific applications. Understanding tannages is crucial for buyers to select the right backing for their products. -

Eco-Friendliness

With increasing awareness of environmental sustainability, the eco-friendliness of leather backing is becoming an essential property. Buyers should inquire whether the leather is sourced from sustainable practices or if it involves recycled materials. Eco-friendly options can enhance brand reputation and appeal to environmentally conscious consumers.

What are Common Trade Terms in the Leather Backing Industry?

Understanding industry jargon can facilitate smoother transactions and negotiations. Here are several key terms relevant to leather backing:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. In the leather industry, this often involves manufacturers producing leather backing for larger brands. Understanding OEM relationships can help buyers secure reliable sources for their leather needs. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity a supplier is willing to sell. It is a crucial consideration for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases effectively, ensuring they meet supplier requirements while optimizing inventory levels. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. In the leather backing industry, sending an RFQ can help buyers compare prices and terms from multiple suppliers, enabling informed decisions based on cost and quality. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international trade. They specify who pays for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers, especially when importing leather backing from international suppliers, to avoid misunderstandings and ensure compliance. -

Lead Time

Lead time refers to the duration between placing an order and receiving the goods. Understanding lead times is critical for B2B buyers to manage production schedules effectively and meet customer demands without delays. -

Sub-Patching

Sub-patching refers to the process of reinforcing or repairing leather goods using backing material. This term is particularly relevant for manufacturers involved in leather restoration or repair services. Knowing about sub-patching techniques can guide buyers in selecting appropriate backing materials for their specific applications.

By grasping these technical properties and trade terms, B2B buyers can navigate the leather backing market more effectively, ensuring they make well-informed purchasing decisions that align with their business objectives.

Navigating Market Dynamics and Sourcing Trends in the leather backing Sector

What Are the Current Market Dynamics and Sourcing Trends in the Leather Backing Sector?

The global leather backing market is witnessing transformative shifts driven by evolving consumer preferences, technological advancements, and sustainability imperatives. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly seek quality and versatility, several key trends are emerging.

One significant driver is the demand for lightweight yet durable backing materials that enhance the performance of leather goods. Buyers are gravitating towards thinner, stronger backing options that can provide structural integrity without adding excessive weight. This trend is particularly relevant for sectors like fashion, automotive, and upholstery, where both aesthetics and functionality are paramount.

Additionally, digital transformation is reshaping sourcing strategies in the leather backing sector. B2B platforms are streamlining procurement processes, enabling buyers to compare products, prices, and suppliers with greater ease. The integration of AI and data analytics in supply chain management is also helping businesses anticipate market fluctuations, optimize inventory, and improve supplier relationships.

Illustrative image related to leather backing

Emerging markets, especially in Africa and South America, are becoming crucial players in the leather backing supply chain. Countries like Nigeria and Brazil are investing in local production capabilities, reducing dependency on imports, and fostering a more resilient supply chain. This shift not only enhances cost efficiency but also promotes regional economic development.

How Is Sustainability Shaping the Leather Backing Supply Chain?

The leather backing industry is increasingly prioritizing sustainability and ethical sourcing, driven by both regulatory pressures and consumer expectations. The environmental impact of leather production, particularly in terms of water usage and chemical runoff, has led buyers to seek out materials that are produced in a more eco-friendly manner.

Sustainable sourcing practices are gaining traction, with many suppliers now offering eco-friendly options such as recycled leather backing. This not only reduces waste but also appeals to environmentally conscious consumers. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification are becoming essential for buyers aiming to ensure their supply chains adhere to ethical and sustainable practices.

Incorporating ‘green’ materials into leather backing products can significantly enhance a brand’s reputation and marketability. Buyers are encouraged to engage with suppliers who provide transparency regarding their sourcing processes and the environmental impact of their products. This not only supports a responsible supply chain but also aligns with the growing consumer demand for ethically produced goods.

What Is the Historical Context of Leather Backing in B2B Markets?

Historically, leather backing has evolved from being a simple support material to a critical component that enhances the durability and aesthetics of leather products. The use of leather as backing dates back centuries, initially serving practical purposes in various applications, from clothing to upholstery.

Illustrative image related to leather backing

In recent decades, advancements in tanning and manufacturing processes have led to the development of specialized backing materials that cater to the diverse needs of various industries. The introduction of synthetic and composite materials has also expanded the options available to manufacturers, allowing for greater customization and performance enhancements.

As the market continues to innovate, the evolution of leather backing reflects broader trends in sustainability and technology, positioning it as a vital area for B2B buyers to explore as they seek to improve their product offerings and meet changing consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of leather backing

-

How do I choose the right leather backing for my project?

Selecting the appropriate leather backing depends on the specific application and desired properties. Consider factors such as thickness, flexibility, and durability. For instance, if you’re crafting bags or wallets, a thinner, more flexible backing may be suitable, while upholstery projects might require thicker, more robust options. Additionally, assess the environmental impact by opting for recycled or eco-friendly leather backings, especially if sustainability is a priority for your brand. -

What are the key qualities to look for in leather backing?

The essential qualities of leather backing include strength, weight, and resistance to wear and tear. Look for materials that offer good tensile strength, which ensures longevity and durability. Weight is also crucial; heavier backings are typically more robust, making them ideal for high-use applications. Additionally, ensure that the backing is compatible with your primary leather to prevent issues such as warping or peeling during use. -

What is the minimum order quantity (MOQ) for leather backing?

MOQs can vary significantly based on the supplier and the type of leather backing. Generally, suppliers may set a MOQ of 50 to 100 square feet for bulk orders. However, some manufacturers offer flexibility for smaller projects, particularly for custom orders. It’s advisable to discuss your specific needs with suppliers to negotiate terms that suit your business requirements. -

How can I vet suppliers for leather backing?

To effectively vet suppliers, conduct thorough research and request samples of their products. Check for certifications that indicate quality standards, such as ISO or environmental certifications. Additionally, assess their production capacity and lead times to ensure they can meet your demands. Engaging with references or previous clients can also provide insight into their reliability and quality of service. -

What are common payment terms for international B2B leather backing transactions?

Payment terms in international trade can vary, but common practices include advance payments, letters of credit, or net 30/60 terms. It’s essential to establish clear payment terms with your supplier upfront to avoid misunderstandings. Consider using escrow services for added security, especially for larger transactions, to protect both parties until the goods are delivered and meet quality expectations. -

How do I handle shipping and logistics for leather backing orders?

When sourcing leather backing internationally, consider logistics options such as air freight for faster delivery or sea freight for cost-effectiveness. Ensure your supplier provides clear shipping terms, including estimated delivery times and costs. Additionally, familiarize yourself with import regulations and tariffs in your country to avoid unexpected charges upon arrival. Working with a freight forwarder can simplify the shipping process and help navigate customs. -

What quality assurance measures should I implement when sourcing leather backing?

Implementing quality assurance (QA) measures is critical when sourcing leather backing. Request product specifications and compliance documentation from suppliers to ensure they meet industry standards. Conduct regular inspections of samples and final products to assess quality and consistency. Establish a clear return policy for defective items and maintain open communication with your suppliers to address any quality issues promptly. -

Can I customize leather backing for specific applications?

Yes, many suppliers offer customization options for leather backing. You can specify dimensions, thickness, and even the type of finish to suit your particular application. Discuss your requirements with potential suppliers to explore available customization services. Keep in mind that customized orders may have longer lead times and potentially higher costs, so it’s essential to factor these into your project planning.

Top 6 Leather Backing Manufacturers & Suppliers List

1. Amblard Leather Atelier – Leather Backing

Domain: amblardleatheratelier.com

Registered: 2011 (14 years)

مقدمة: Leather Backing – Regular price: $90.00. Sold as half hides. Size range: 18 – 20 sq ft. Weight: approximately 2.5 – 3 oz. Pictures are close representation of hide color.

2. Refinish Coatings – Thin Backing Leather

Domain: refinishcoatings.com

Registered: 2014 (11 years)

مقدمة: {“product_name”: “Thin Backing Leather”, “price”: “$7.00”, “description”: “Very thin but strong piece of leather used for sub-patching material.”, “size”: “5\” x 6\””, “weight”: “1.6 oz”, “dimensions”: “5 × 6 × 0.25 in”, “intended_use”: “professional use only”}

3. District Leathers – Thin Recycled Leather Bonded Backing

Domain: districtleathers.com

Registered: 2016 (9 years)

مقدمة: {‘name’: ‘Thin Recycled Leather Bonded Backing’, ‘price’: ‘$24.99’, ‘width’: ’55 inches’, ‘thickness’: ‘0.3 mm / 0.75 oz’, ‘description’: “Our recycled leather backing is the perfect material to use for making bags, small leather goods, wallets, and other leather crafts that would require a touch of stiffness. Both sides of the interfacing are not backed and can be glued to either leather or suede…

4. Leather Touch – 9 x 10 Leather Repair Cloth

Domain: leathertouchupdye.com

Registered: 2012 (13 years)

مقدمة: {“name”: “9 x 10″ Leather Repair Cloth”, “price”: “USD $3.95”, “sku”: “LTUD-LRC”, “category”: “Accessories”, “description”: “An excellent backing for all your leather repairs will bend and flex at the same rate as the leather. The leather filler bonds into the fibers of the cloth making an excellent quality backing for all thickness of leather. Does not produce backing indentations.”, “weight”: “0…

5. FabTuff® – Puncture and Tear Resistant Backing

Domain: fabricback.com

Registered: 2009 (16 years)

مقدمة: Puncture and Tear Resistant Backing for Fabric and Leather, branded as FabTuff ®, provides added durability to fabrics and flooring. It is designed for commercial upholstery and flooring applications, particularly in high traffic areas such as restaurant booths, chairs, nightclub dance floors, and other environments that require resistance to punctures from objects like stiletto heels. FabTuff ® b…

6. Hydes Leather – Fleece Backing for Automotive Leather

Domain: hydesleather.com

Registered: 2006 (19 years)

مقدمة: Fleece Backing for Automotive Leather is a self-adhesive fleece designed to prevent seat indentations and maintain the appearance of leather under strenuous conditions. It is used by OEM manufacturers to enhance the soft feel and increase tensile strength, reducing bagging. The product eliminates the need for gluing foam or wool backing. Key benefits include shape retention, enhanced durability, a…

Strategic Sourcing Conclusion and Outlook for leather backing

In the dynamic landscape of leather backing, strategic sourcing emerges as a critical factor for businesses aiming to enhance their product offerings and operational efficiencies. By understanding the diverse types of leather backing available—from thin recycled options to robust puncture-resistant materials—international buyers can make informed decisions that align with their specific needs, whether for upholstery, fashion, or automotive applications.

Illustrative image related to leather backing

The value of strategic sourcing is underscored by the potential for cost savings and quality improvements. Establishing strong relationships with reliable suppliers across regions like Africa, South America, the Middle East, and Europe can lead to better pricing, enhanced material quality, and more sustainable practices. As the demand for eco-friendly materials grows, investing in sustainable leather backing solutions not only meets consumer preferences but also strengthens brand reputation.

Looking ahead, B2B buyers should prioritize adaptability and innovation in their sourcing strategies. Engaging with suppliers who offer customizable options and scalable solutions will be crucial in staying competitive. Now is the time to explore partnerships that will not only fulfill immediate requirements but also pave the way for future growth in the leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to leather backing

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.