Introduction: Navigating the Global Market for hot leather stamp

As global markets expand, sourcing high-quality hot leather stamps has become a pivotal challenge for businesses in various sectors, from fashion to manufacturing. The demand for personalized branding on leather goods is rising, making it essential for B2B buyers to understand the nuances of selecting the right tools for their needs. This guide will delve into the diverse types of hot leather stamps available, their specific applications, and the critical factors to consider when vetting suppliers.

Additionally, it will provide insights on cost considerations and the best practices for ensuring a successful purchasing process. Whether you’re operating in Africa, South America, the Middle East, or Europe—including countries like Vietnam and Saudi Arabia—this comprehensive resource is designed to equip you with the knowledge needed to make informed decisions.

By navigating the complexities of the hot leather stamp market, you can enhance your product offerings and ensure that your branding stands out in a competitive landscape. With this guide in hand, you will be empowered to select high-quality equipment that aligns with your operational goals and resonates with your target audience.

Table Of Contents

- Top 2 Hot Leather Stamp Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hot leather stamp

- Understanding hot leather stamp Types and Variations

- Key Industrial Applications of hot leather stamp

- 3 Common User Pain Points for ‘hot leather stamp’ & Their Solutions

- Strategic Material Selection Guide for hot leather stamp

- In-depth Look: Manufacturing Processes and Quality Assurance for hot leather stamp

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot leather stamp’

- Comprehensive Cost and Pricing Analysis for hot leather stamp Sourcing

- Alternatives Analysis: Comparing hot leather stamp With Other Solutions

- Essential Technical Properties and Trade Terminology for hot leather stamp

- Navigating Market Dynamics and Sourcing Trends in the hot leather stamp Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hot leather stamp

- Strategic Sourcing Conclusion and Outlook for hot leather stamp

- Important Disclaimer & Terms of Use

Understanding hot leather stamp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Heat Embosser | Adjustable temperature, custom brass stamps | Branding leather goods, logos, designs | Pros: Precision, quick setup; Cons: Initial cost |

| Electric Branding Iron | High wattage, variable temperature control | High-volume production, consistent results | Pros: Versatile, suitable for various leather types; Cons: Requires electricity |

| Handheld Steel Stamp | Manual operation, simple design | Small batches, artisanal products | Pros: Cost-effective, easy to use; Cons: Labor-intensive, less consistent results |

| Hot Stamping Machine | Automated process, compatibility with foils | Mass production of leather items | Pros: Efficient, high output; Cons: Higher investment |

| Cold Stamping Tool | Traditional method, uses mallet for impact | Custom designs, smaller projects | Pros: Authentic look, low cost; Cons: Limited to smaller designs |

What Are the Key Features of a Custom Heat Embosser?

The Custom Heat Embosser is designed for precision branding on leather products. It features adjustable temperature settings, allowing users to tailor the heat according to the type of leather being stamped. This tool is particularly beneficial for businesses looking to create high-quality, custom designs, logos, or brand names on their leather goods. B2B buyers should consider the initial investment but can appreciate the long-term benefits of durability and quick turnaround times.

How Does an Electric Branding Iron Enhance Production Efficiency?

An Electric Branding Iron is ideal for companies engaged in high-volume leather production. With its high wattage and variable temperature control, it can effectively stamp various leather types, including chrome-tanned and vegetable-tanned leather. This tool is perfect for businesses that require consistent branding across large quantities of products. While the upfront cost may be higher, the efficiency and quality it offers make it a worthwhile investment for bulk operations.

Why Choose a Handheld Steel Stamp for Small Batch Production?

The Handheld Steel Stamp is a manual stamping option suitable for businesses focusing on small batches or artisanal leather goods. This tool is straightforward to use and cost-effective, making it an attractive choice for startups or niche brands. However, buyers should note that it requires more labor and may yield less consistent results compared to automated options, making it less ideal for larger-scale operations.

What Advantages Does a Hot Stamping Machine Offer for Mass Production?

Hot Stamping Machines automate the stamping process, making them highly efficient for mass production of leather items. These machines can work with or without foils, providing versatility in branding options. B2B buyers in the leather manufacturing sector will find this equipment beneficial for achieving high output with consistent quality. However, the initial investment can be significant, which should be considered when evaluating long-term production needs.

When Is a Cold Stamping Tool the Right Choice?

Cold Stamping Tools are ideal for businesses that prioritize traditional craftsmanship and the authentic look of leather products. This method involves manually pressing a stamp into the leather, creating a deep impression without heat. While this technique is cost-effective and simple, it is limited to smaller designs and requires more physical effort. Companies focused on unique, custom designs may find this method appealing, especially for artisanal or high-end products.

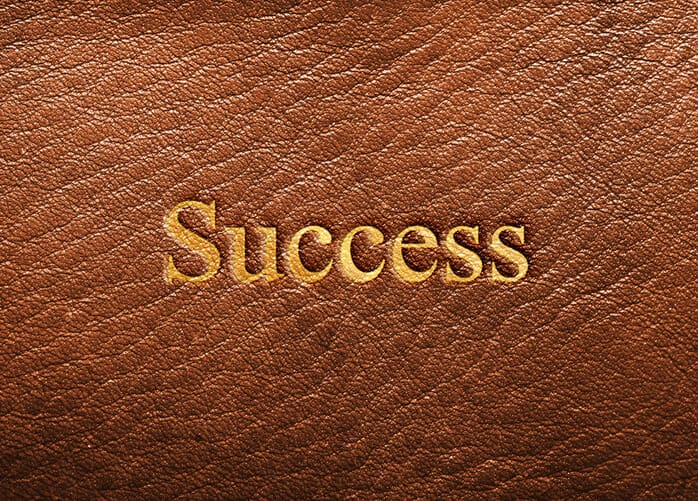

Illustrative image related to hot leather stamp

Key Industrial Applications of hot leather stamp

| Industry/Sector | Specific Application of hot leather stamp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Accessories | Branding leather goods like bags and wallets | Enhances brand identity, creating a premium feel for products | Quality of materials used in stamps, customization options, and turnaround time for orders |

| Automotive | Custom leather interiors and accessories | Adds unique branding to vehicles, improving customer loyalty | Compatibility with various leather types and durability of stamps for high-use environments |

| Furniture | Embossing leather upholstery | Provides a distinctive look, elevating product appeal | Temperature control features for different leather types, precision in stamp design |

| Sports Equipment | Marking leather sports gear (e.g., gloves, balls) | Differentiates products in a competitive market | Ability to handle intricate designs and ensure consistency across large batches |

| Gift and Promotional Items | Personalizing leather gifts and corporate giveaways | Increases perceived value and personal touch in gifting | Customization capabilities, quick production for promotional events, and material durability |

How is hot leather stamping used in the fashion and accessories industry?

In the fashion and accessories sector, hot leather stamping is utilized to imprint logos and designs on various leather goods such as handbags and wallets. This technique not only enhances the aesthetic appeal of the products but also reinforces brand identity. Buyers in this sector often seek high-quality brass stamps that can create deep, lasting impressions, ensuring that the branding remains visible even after prolonged use. Additionally, sourcing options must include customization capabilities to accommodate unique designs and quick turnaround times for seasonal collections.

What are the applications of hot leather stamping in the automotive sector?

The automotive industry employs hot leather stamping for branding custom leather interiors and accessories, such as seat covers and steering wheel wraps. This application adds a touch of sophistication and personalization to vehicles, thereby enhancing customer loyalty and satisfaction. Buyers need to consider the compatibility of stamping equipment with various leather types, including chrome-tanned and vegetable-tanned leathers, as well as the durability of stamps to withstand the wear and tear of automotive environments. Additionally, adjustable temperature settings for different leather types are crucial for achieving optimal results.

How does hot leather stamping benefit the furniture industry?

In the furniture sector, hot leather stamping is commonly used to emboss leather upholstery, adding a unique touch to sofas, chairs, and other furnishings. This not only elevates the product’s visual appeal but also communicates quality craftsmanship to consumers. For international buyers, sourcing considerations include the precision of the stamp design, which must accommodate intricate patterns and logos. Furthermore, temperature control features are essential to ensure that the stamping process is suitable for various leather types used in furniture production.

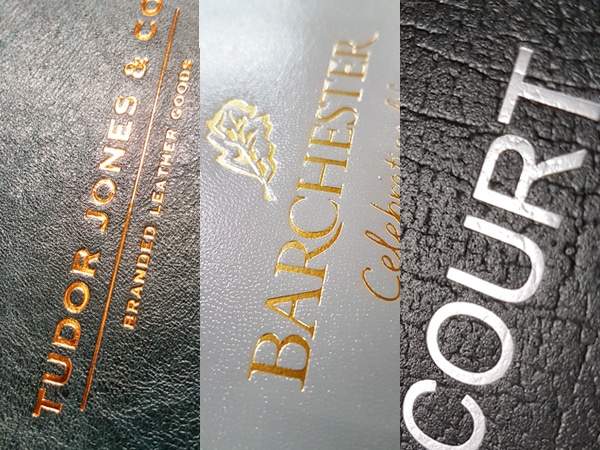

Illustrative image related to hot leather stamp

What role does hot leather stamping play in sports equipment?

Hot leather stamping finds significant application in the sports equipment industry, particularly for marking leather sports gear like gloves and balls. This technique helps differentiate products in a highly competitive market, allowing brands to establish a unique identity. Buyers should focus on sourcing stamps that can handle intricate designs while ensuring consistency across large batches. Additionally, the durability of the stamps is crucial, as sports equipment is subject to rigorous use, requiring high-quality materials that withstand repeated impressions.

How is hot leather stamping used for gifts and promotional items?

In the realm of gifts and promotional items, hot leather stamping is an effective way to personalize leather gifts and corporate giveaways, enhancing their perceived value. This application enables businesses to create unique and memorable products that resonate with recipients. Buyers in this sector should prioritize customization capabilities, ensuring that stamps can be tailored to specific designs and logos. Quick production times are also essential, especially for promotional events, making the ability to handle rush orders a key consideration when sourcing hot leather stamping solutions.

3 Common User Pain Points for ‘hot leather stamp’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Results Across Different Leather Types

The Problem: Many B2B buyers encounter challenges when attempting to hot stamp on various leather types, such as chrome-tanned, vegetable-tanned, or suede. Each type of leather responds differently to heat, and without a thorough understanding of these nuances, achieving a consistent and high-quality result can be frustrating. Buyers often find that while their branding looks perfect on one type of leather, it may burn or underperform on another, leading to wasted materials and increased costs.

The Solution: To overcome this issue, buyers should invest in a variable-temperature electric branding iron. This tool allows users to adjust the heat settings according to the specific type of leather being used. For example, vegetable-tanned leather requires lower temperatures, while chrome-tanned leather may need more heat for optimal results. Buyers should also conduct a small test on scrap pieces of leather to determine the best temperature before proceeding with full production. Additionally, sourcing stamps that are specifically designed for different leather types can improve outcomes. Collaborating with suppliers who provide detailed guidance on temperature settings and leather compatibility will further enhance the stamping process.

Scenario 2: Limited Customization Options Leading to Brand Identity Issues

The Problem: Many companies struggle to find hot leather stamps that can accurately replicate their logos or designs in a way that reflects their brand identity. A lack of customization options or poor-quality stamps can result in branding that looks unprofessional, diluting the brand’s image and failing to resonate with customers. This is particularly problematic for businesses aiming to create a unique presence in competitive markets.

The Solution: B2B buyers should prioritize suppliers that offer custom brass stamps made through CNC machining. This method ensures precision and quality, allowing for intricate designs and logos to be reproduced accurately. When placing an order, buyers should provide high-resolution vector files (AI or PDF formats) of their designs to ensure clarity and detail in the final product. It is also advisable to request samples or prototypes before finalizing larger orders, enabling buyers to assess the quality and make adjustments if necessary. Establishing a strong relationship with the supplier can facilitate ongoing support for future design needs, ensuring that branding remains consistent and impactful.

Scenario 3: Inefficiencies in Production Time and Workflow

The Problem: For businesses that rely on hot stamping as part of their production process, inefficiencies can arise when using outdated or low-quality equipment. Slow heating times, inconsistent stamping pressure, and frequent equipment failures can significantly disrupt workflow, leading to missed deadlines and lost revenue. This is particularly critical for businesses that operate in fast-paced industries or have high-volume production needs.

The Solution: To enhance production efficiency, businesses should invest in high-quality hot stamping machines with features such as rapid heating capabilities and adjustable pressure settings. Investing in equipment that can accommodate multiple stamp sizes and designs will also streamline the process. Additionally, implementing a maintenance schedule for the stamping equipment can prevent unexpected breakdowns and ensure consistent performance. Training staff on the best practices for operating the stamping equipment can further optimize workflow. Engaging with suppliers who offer comprehensive support and training resources can also improve operational efficiency and reduce production delays.

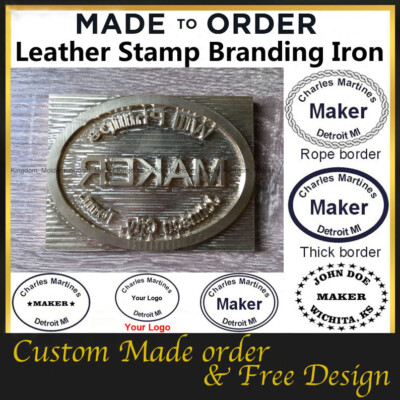

Illustrative image related to hot leather stamp

Strategic Material Selection Guide for hot leather stamp

What Materials Are Commonly Used for Hot Leather Stamps?

When selecting materials for hot leather stamps, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance and suitability of the stamping process for various leather types. Below is an analysis of four common materials used in hot leather stamping.

How Does Brass Perform as a Material for Hot Leather Stamps?

Brass is a popular choice for hot leather stamps due to its excellent thermal conductivity and durability. It can withstand high temperatures, making it suitable for hot stamping applications. Brass also exhibits good corrosion resistance, which is beneficial for maintaining the integrity of the stamp over time.

Pros: Brass is highly durable and can produce crisp, clear impressions on leather. Its ability to resist corrosion makes it a long-lasting option, reducing the need for frequent replacements.

Cons: The initial cost of brass stamps can be higher compared to other materials like aluminum. Additionally, brass can be heavier, which may affect the ease of handling during the stamping process.

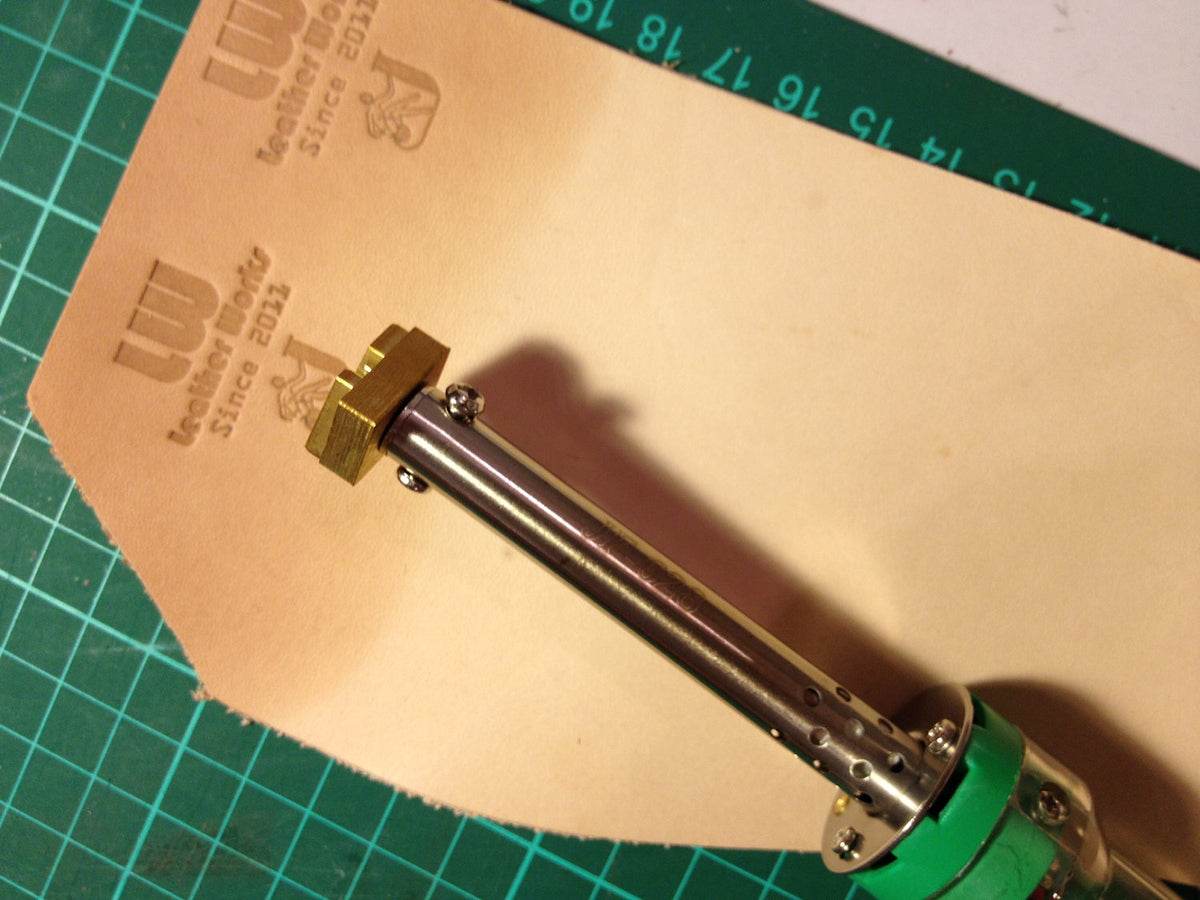

Illustrative image related to hot leather stamp

Impact on Application: Brass stamps work exceptionally well with vegetable-tanned and chrome-tanned leather, providing a clean and professional finish. However, users must ensure that the temperature is adequately controlled to avoid damaging the leather.

What Are the Benefits of Aluminum in Hot Leather Stamping?

Aluminum is another material often used for hot leather stamps. It is lighter than brass and generally less expensive, making it an attractive option for businesses looking to minimize costs.

Pros: The affordability of aluminum makes it a cost-effective choice for small-scale operations or startups. Its lightweight nature allows for easier handling during the stamping process.

Cons: Aluminum is less durable than brass and can be prone to wear and deformation over time, especially under high heat. This can lead to a decrease in the quality of impressions.

Impact on Application: Aluminum stamps are suitable for less demanding applications or for stamping softer leathers. However, they may not perform as well on tougher leather types, where a more robust material would be preferable.

Illustrative image related to hot leather stamp

Why Consider Steel for Hot Leather Stamps?

Steel, particularly stainless steel, is a robust option for hot leather stamps. It offers excellent strength and durability, making it suitable for high-volume stamping operations.

Pros: Steel stamps can withstand significant wear and tear, ensuring longevity and consistent performance. They are also resistant to corrosion, which is critical for maintaining the quality of the stamp.

Cons: The cost of steel can be higher than both brass and aluminum, and the manufacturing process may be more complex, potentially leading to longer lead times.

Illustrative image related to hot leather stamp

Impact on Application: Steel stamps are ideal for heavy-duty applications, particularly when stamping thicker leather or when high precision is required. They can produce clear impressions even on challenging materials.

What About Composite Materials for Hot Leather Stamps?

Composite materials, which may include a mix of metals and polymers, are increasingly being used in hot leather stamping. These materials can be engineered to offer specific properties tailored to the stamping process.

Pros: Composite materials can be designed to provide a balance of durability, weight, and cost-effectiveness. They can also be engineered to have specific thermal properties, enhancing their performance in various applications.

Illustrative image related to hot leather stamp

Cons: The complexity of manufacturing composite materials can lead to higher costs and longer production times. Additionally, the long-term durability of composites compared to metals may still be a concern.

Impact on Application: Composites can be effective for specialized applications where unique properties are required, such as flexibility or lightweight designs. However, buyers should ensure that these materials meet industry standards for durability and performance.

Summary Table of Material Selection for Hot Leather Stamps

| Material | Typical Use Case for hot leather stamp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General hot stamping on various leathers | Durable and corrosion-resistant | Higher initial cost | High |

| Aluminum | Budget-friendly options for soft leathers | Lightweight and cost-effective | Less durable, prone to wear | Low |

| Steel | High-volume stamping on thick leathers | Excellent strength and longevity | Higher cost and complex manufacturing | High |

| Composite | Specialized applications requiring unique properties | Customizable for specific needs | Potential durability concerns | Medium |

This strategic material selection guide provides B2B buyers with the insights needed to make informed decisions when investing in hot leather stamps, ensuring compatibility with their specific applications and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hot leather stamp

What Are the Key Stages in the Manufacturing Process of Hot Leather Stamps?

The manufacturing process of hot leather stamps involves several critical stages, each contributing to the quality and performance of the final product. Understanding these stages is essential for B2B buyers looking to ensure they receive high-quality stamping tools.

Illustrative image related to hot leather stamp

Material Preparation: What Materials Are Used in Hot Leather Stamps?

The first step in manufacturing hot leather stamps is the selection and preparation of materials. Commonly, brass is used due to its durability and resistance to wear. The material is often sourced from reputable suppliers to ensure consistency in quality. Once received, the brass is cut into appropriate sizes for the stamps, and any necessary treatments, such as surface cleaning or polishing, are performed to remove impurities.

How Are Hot Leather Stamps Formed?

Formation of hot leather stamps typically involves advanced machining techniques. Computer Numerical Control (CNC) machining is a widely adopted method due to its precision and efficiency. This technique allows manufacturers to create intricate designs and logos with high fidelity. The CNC machine carves the design into the brass or steel plate, ensuring that the engraving is deep enough for effective stamping.

What Assembly Steps Are Involved in Creating Hot Leather Stamps?

After forming, the next stage involves assembling the components of the hot leather stamp. For electric branding irons, this includes integrating heating elements and temperature control systems. Each component must be carefully fitted to ensure proper functionality. The assembly process is often done in a clean environment to prevent contamination, which can affect the performance of the stamps.

How Is the Finishing Process Conducted for Hot Leather Stamps?

Finishing is a crucial step that enhances both aesthetics and functionality. After assembly, stamps undergo surface treatments like anodizing or coating to improve resistance against corrosion and wear. The final product is also tested for smoothness and quality of the engraved design. This step ensures that each stamp will produce a clear and lasting impression on leather.

Illustrative image related to hot leather stamp

What Quality Assurance Measures Are Essential for Hot Leather Stamps?

Quality assurance (QA) is vital in the manufacturing of hot leather stamps, particularly for B2B buyers who require consistent performance and reliability.

Which International Standards Should Be Considered?

International standards such as ISO 9001 play a crucial role in ensuring quality across manufacturing processes. ISO 9001 focuses on quality management systems and helps manufacturers maintain consistent quality in their products. Additionally, industry-specific certifications such as CE (for compliance with European health, safety, and environmental protection standards) may also be relevant, depending on the market.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in hot leather stamp manufacturing typically includes several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection occurs upon receiving raw materials. Suppliers must provide certificates of compliance to ensure that the materials meet specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor the quality of machining and assembly. This includes checking dimensions, tolerances, and the quality of engravings.

-

Final Quality Control (FQC): Before shipment, each stamp undergoes a final inspection to ensure it meets all specifications. This may include testing the heating elements of branding irons to verify temperature accuracy.

How Can B2B Buyers Verify the Quality Control Processes of Suppliers?

For international buyers, verifying the quality control processes of suppliers can be challenging but essential. Here are several strategies to ensure compliance and quality:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality control reports that outline the supplier’s adherence to international standards. Audits conducted by third-party organizations can provide an unbiased assessment of the manufacturer’s quality management systems. Look for evidence of ISO certifications and any relevant industry-specific certifications.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide additional assurance of quality. These services can conduct random checks on production batches and verify compliance with specifications before shipment. This is particularly useful for buyers in regions like Africa and South America, where local regulations may differ from international standards.

What Quality Control Nuances Should International Buyers Consider?

When dealing with suppliers from various regions, it’s important to understand potential nuances in quality control practices:

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and practices. For instance, manufacturers in Europe may adhere to stricter environmental and safety regulations compared to those in other regions. Buyers should familiarize themselves with local regulations and ensure that suppliers comply with both local and international standards.

What Role Does Communication Play in Quality Control?

Clear communication is essential for ensuring quality expectations are met. B2B buyers should establish open channels with suppliers to discuss quality standards, production timelines, and any potential issues that may arise. This proactive approach can help mitigate risks and ensure that the final products meet expectations.

Illustrative image related to hot leather stamp

Conclusion

Understanding the manufacturing processes and quality assurance measures associated with hot leather stamps is crucial for international B2B buyers. By focusing on material preparation, formation, assembly, and finishing, buyers can gain insights into the quality of the products they are purchasing. Additionally, emphasizing quality control measures, international standards, and effective communication with suppliers will further enhance the likelihood of receiving high-quality stamping tools that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot leather stamp’

Introduction

This sourcing guide provides a practical checklist for B2B buyers looking to procure hot leather stamps. By following these steps, you can ensure that you select the right equipment and supplier for your leather branding needs, ultimately enhancing the quality of your products and the effectiveness of your branding efforts.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. Consider factors such as the type of leather you will be working with, the size of the stamps you need, and any specific features like adjustable temperature settings. These specifications will guide your search and help you communicate effectively with potential suppliers.

Step 2: Research Supplier Credentials

Thoroughly investigate potential suppliers to verify their credibility. Look for certifications such as ISO or similar quality assurance standards that indicate reliability and adherence to industry norms. Request references and customer testimonials, particularly from businesses in your region or industry, to gauge their experience and customer satisfaction.

Illustrative image related to hot leather stamp

Step 3: Evaluate Product Range and Customization Options

Assess the variety of hot leather stamps offered by suppliers. A diverse product range indicates a supplier’s capability to meet your specific needs. Additionally, inquire about customization options for stamps to ensure that you can create unique branding that resonates with your target market. Look for suppliers who can provide CNC machined stamps for higher precision.

Step 4: Check Material Quality

The material used in the construction of hot leather stamps significantly impacts their durability and performance. Brass is often preferred due to its robustness, while aluminum may be more cost-effective but less durable. Ensure that the materials used can withstand repeated use without compromising the quality of the branding.

Step 5: Inquire About After-Sales Support and Warranty

Evaluate the after-sales service offered by potential suppliers. A strong warranty policy and customer support can save you time and money in the long run. Check whether they offer replacements or repairs for defective products and how responsive they are to customer inquiries.

Step 6: Request Samples for Testing

Once you have shortlisted suppliers, request samples of their hot leather stamps. Testing these samples will provide insight into the quality of the imprint, ease of use, and compatibility with the types of leather you plan to work with. This step is crucial to ensure that the final product meets your expectations.

Step 7: Compare Pricing and Delivery Terms

Finally, compare the pricing structures and delivery terms of the suppliers you are considering. While cost is an important factor, also consider the overall value, including product quality and supplier reliability. Ensure that the delivery timelines align with your production schedule to avoid any disruptions.

By following this checklist, you can confidently navigate the procurement process for hot leather stamps, ensuring you choose the best supplier to meet your business needs.

Comprehensive Cost and Pricing Analysis for hot leather stamp Sourcing

What Are the Key Cost Components in Hot Leather Stamp Production?

When sourcing hot leather stamps, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly influences costs. Brass is commonly used for its durability, while aluminum is a more economical alternative but may wear out faster. The thickness and size of the stamp also affect material costs, as larger or thicker stamps require more raw material.

-

Labor: Labor costs encompass the wages paid to skilled workers who operate machinery and perform quality checks. In regions with lower labor costs, such as parts of South America or Africa, the overall production cost may be reduced.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs associated with production. Efficient manufacturing processes can help minimize overhead and improve profit margins.

-

Tooling: The initial investment in tooling, which includes the creation of dies and molds, is a critical factor. Custom stamps require more intricate tooling, which can increase upfront costs but may lead to better long-term value for unique designs.

-

Quality Control (QC): Ensuring that stamps meet specified standards adds to the cost but is essential for maintaining product quality. Investing in robust QC processes can prevent costly errors in production.

-

Logistics: Shipping costs and transportation logistics can vary based on the supplier’s location and the destination country. International buyers must consider potential tariffs and customs duties.

-

Margin: Suppliers typically add a profit margin to cover their expenses and achieve profitability. This margin can vary widely depending on the supplier’s reputation, product quality, and market demand.

How Do Price Influencers Affect Hot Leather Stamp Costs?

Several factors influence the pricing of hot leather stamps, and understanding these can help buyers make informed decisions:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often result in lower per-unit costs. Suppliers may offer discounts for larger quantities, making it crucial for buyers to assess their needs and order accordingly.

-

Specifications and Customization: Custom designs, sizes, and features can significantly impact pricing. Highly detailed or unique specifications may require more sophisticated manufacturing processes, leading to increased costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications can add to the cost but may be necessary for certain markets. Buyers should weigh the benefits of higher-quality products against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge more, but they often provide better service and quality assurance.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is crucial for managing costs. These terms dictate who is responsible for shipping costs and risks, impacting the overall price.

What Are Effective Buyer Tips for Sourcing Hot Leather Stamps Internationally?

International buyers, particularly from regions like Africa, South America, and the Middle East, should consider the following tips to enhance cost efficiency:

-

Negotiate Pricing and Terms: Don’t hesitate to negotiate with suppliers. Discuss volume discounts, payment terms, and potential reductions in shipping costs.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, replacement, and shipping. A cheaper option may not always be the most cost-effective in the long run.

-

Understand Pricing Nuances for International Transactions: Currency fluctuations and international tariffs can impact costs. Buyers should stay informed about these factors to avoid unexpected expenses.

-

Research and Verify Suppliers: Conduct thorough research on potential suppliers. Check reviews, request samples, and verify their production capabilities to ensure they can meet your requirements.

-

Leverage Local Partnerships: Building relationships with local distributors or agents can help navigate regional market dynamics and reduce logistics costs.

Disclaimer on Indicative Prices

While indicative prices for hot leather stamps can be provided, they are subject to fluctuations based on market conditions, supplier pricing strategies, and changes in material costs. Always consult with suppliers for the most accurate and up-to-date pricing tailored to your specific requirements.

Alternatives Analysis: Comparing hot leather stamp With Other Solutions

When evaluating the best method for branding leather products, businesses often seek alternatives to the popular hot leather stamp. Understanding the various options available can help B2B buyers make informed decisions that align with their production needs and branding strategies. This analysis compares hot leather stamping with two viable alternatives: traditional leather stamping and laser engraving.

Comparison Table

| Comparison Aspect | Hot Leather Stamp | Traditional Leather Stamping | Laser Engraving |

|---|---|---|---|

| Performance | Produces deep, lasting impressions on various leather types; ideal for larger logos. | Creates raised impressions; limited by stamp size and requires manual force. | Offers high precision with detailed designs; can engrave complex patterns. |

| Cost | Moderate initial investment; costs can rise with custom designs. | Generally lower initial costs; more economical for small runs but labor-intensive. | Higher upfront costs for equipment; cost-effective for large volumes due to speed. |

| Ease of Implementation | User-friendly; requires minimal training. | Requires manual skill; can be labor-intensive and time-consuming. | Requires technical expertise to operate equipment; setup can be complex. |

| Maintenance | Low maintenance; occasional replacement of stamps needed. | Low maintenance; tools can last long with proper care. | Higher maintenance; laser machines may require regular servicing and software updates. |

| Best Use Case | Ideal for branding large quantities with consistent results; suitable for various leather types. | Best for small batches or artisanal products where traditional aesthetics are desired. | Excellent for intricate designs and personalization; suitable for diverse materials beyond leather. |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Traditional Leather Stamping?

Traditional leather stamping utilizes a mallet and a metal stamp to create impressions in the leather. This method is favored for its ability to produce a classic, handcrafted look, appealing to artisans and small-scale producers. However, the limitations of traditional stamping include difficulty in achieving uniform impressions, especially on larger designs, and the physical labor required, which can slow down production rates. Additionally, the method is less versatile, primarily suited for vegetable-tanned leather and simple designs.

How Does Laser Engraving Compare to Hot Leather Stamping?

Laser engraving is a modern technique that uses focused laser beams to etch designs into leather. Its advantages lie in the precision and detail it offers, making it possible to create intricate patterns that would be difficult or impossible to achieve with traditional methods. Furthermore, laser engraving can be applied to a wider range of materials beyond leather, including plastics and metals, providing versatility for businesses that work with multiple substrates. However, the initial investment in laser equipment is typically higher, and the operation requires more technical knowledge, which may pose a barrier for some businesses.

Conclusion: Which Leather Branding Solution Is Right for Your Business?

Choosing the right branding solution depends on various factors, including production volume, design complexity, and budget. Hot leather stamping is an excellent choice for businesses focused on branding large quantities with consistent results, particularly for straightforward logos. Traditional leather stamping suits smaller operations that value artisanal craftsmanship but may limit production efficiency. Conversely, laser engraving provides unparalleled design detail and versatility, making it ideal for businesses looking to expand their product offerings. By carefully assessing these alternatives, B2B buyers can select the best method that aligns with their operational goals and customer expectations.

Illustrative image related to hot leather stamp

Essential Technical Properties and Trade Terminology for hot leather stamp

What Are the Key Technical Properties of Hot Leather Stamps?

When considering a hot leather stamp for branding or marking leather goods, several essential technical properties play a crucial role in ensuring quality and efficiency. Understanding these specifications can help international B2B buyers make informed decisions.

1. Material Composition

The most common materials used for hot leather stamps are brass and steel. Brass is favored for its durability and ability to produce crisp impressions, while steel is often used for heavy-duty applications. For B2B buyers, selecting the right material is vital as it affects the longevity of the stamp and the quality of the imprint. A solid brass stamp can endure repeated use without losing detail, making it a cost-effective choice over time.

2. Power Rating

Hot leather stamps come with varying power ratings, typically measured in watts (W). For instance, a 60W heat embosser is suitable for smaller or less intricate designs, while a 500W branding iron can handle larger stamps and more demanding applications. Understanding power ratings is important for B2B buyers as it directly influences the efficiency and speed of the stamping process, especially for high-volume production.

3. Temperature Control

Adjustable temperature settings (commonly ranging from 200°C to 450°C) allow users to tailor the heat level to different types of leather, such as vegetable-tanned or chrome-tanned leather. This flexibility is crucial for achieving optimal results without damaging the material. For B2B companies, investing in equipment with precise temperature control can enhance product consistency and reduce waste.

4. Stamp Size and Thickness

The size and thickness of the stamp impact both the design’s visibility and the ease of use. A stamp’s design area can range significantly, with custom options available up to 10 cm². The thickness also affects durability; for instance, a thicker stamp generally offers more stability during use. Buyers should consider their specific branding requirements and the types of products they manufacture to choose the right size and thickness.

5. Interchangeability

Many modern hot leather stamping systems feature interchangeable stamps, allowing businesses to switch designs quickly without needing multiple tools. This versatility can lead to increased productivity and cost savings, especially for companies that offer personalized products. Understanding this property can help B2B buyers plan their production processes more effectively.

What Are Common Trade Terms in the Hot Leather Stamp Industry?

Familiarity with industry-specific terminology is essential for navigating purchases and contracts effectively. Here are some common terms relevant to hot leather stamps:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hot leather stamps, buyers can work with OEMs to create custom solutions tailored to their branding needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory and budget effectively while ensuring they can meet production demands.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. For businesses looking to procure hot leather stamps, issuing an RFQ helps gather competitive offers and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Knowing these terms is essential for B2B buyers to clarify shipping costs, risks, and responsibilities associated with their hot leather stamp purchases.

5. CNC (Computer Numerical Control)

CNC technology is used to automate the control of machining tools via computers. In the context of hot leather stamps, CNC machining ensures high precision and quality in the manufacturing process, which is essential for producing detailed designs.

By understanding these technical properties and trade terms, B2B buyers can make better-informed decisions when sourcing hot leather stamps, ultimately enhancing their branding capabilities and product offerings.

Navigating Market Dynamics and Sourcing Trends in the hot leather stamp Sector

What Are the Current Market Dynamics and Key Trends in the Hot Leather Stamp Sector?

The hot leather stamp sector is experiencing significant growth, driven by rising demand for customized leather products across various industries, including fashion, accessories, and upholstery. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, customizable branding solutions. Key trends include the adoption of advanced technologies like CNC machining for precision and customization, as well as the integration of electric branding irons that allow for efficient and consistent stamping across diverse leather types.

Moreover, the shift towards e-commerce has facilitated easier access to suppliers and manufacturers, enabling buyers to source products from around the globe. As companies look to differentiate their offerings, there is a growing focus on the aesthetic appeal of stamped designs, prompting manufacturers to innovate with materials and techniques. For instance, the use of gold foils and the production of stamps capable of handling various leather types are becoming more prevalent.

Furthermore, the demand for sustainable practices in manufacturing is gaining momentum, as businesses seek to align with global sustainability goals. Buyers are more inclined to partner with suppliers who can demonstrate eco-friendly production methods and materials, ensuring their branding efforts resonate with environmentally-conscious consumers.

How Is Sustainability Influencing Sourcing Trends in the Hot Leather Stamp Sector?

Sustainability is becoming a critical factor in the sourcing of hot leather stamps, as companies increasingly recognize the environmental impact of their supply chains. The leather industry traditionally faces scrutiny over issues such as deforestation, water usage, and chemical pollution from tanning processes. Therefore, B2B buyers are now prioritizing suppliers that adhere to ethical sourcing practices and offer environmentally friendly materials.

One of the notable trends is the use of vegetable-tanned leather, which is less harmful to the environment compared to chrome-tanned alternatives. This type of leather is biodegradable and produced using natural tannins, making it a preferred choice for eco-conscious brands. Additionally, certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential benchmarks for ethical sourcing. Suppliers who hold these certifications can provide buyers with assurance that their materials are sourced responsibly.

Moreover, brands are increasingly investing in technologies that reduce waste during production. For example, CNC machining not only enhances the precision of stamps but also minimizes material waste, aligning with sustainable manufacturing practices. By choosing suppliers who prioritize sustainability, international buyers can enhance their brand reputation and appeal to a growing segment of environmentally aware consumers.

What Is the Historical Context of the Hot Leather Stamp Industry?

The art of leather stamping dates back centuries, with origins rooted in ancient civilizations that used simple tools to imprint designs onto leather goods. Initially, these techniques were labor-intensive and required skilled artisans to create unique pieces. Over time, as demand for leather products grew, particularly during the industrial revolution, methods evolved to incorporate more efficient tools and machinery.

The introduction of heat-based stamping techniques in the 20th century marked a significant evolution in the industry. This allowed for more intricate designs and faster production times, catering to the needs of mass production while still retaining a degree of customization. Today, the hot leather stamp sector stands at the intersection of tradition and innovation, combining artisanal craftsmanship with modern technology. This evolution reflects the ongoing balance between maintaining the heritage of leatherworking and meeting the demands of a globalized market.

In summary, the hot leather stamp industry is not only a reflection of historical craftsmanship but also a dynamic sector responding to contemporary market demands, sustainability concerns, and technological advancements. International B2B buyers can leverage these insights to make informed sourcing decisions that enhance their product offerings while aligning with modern consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of hot leather stamp

-

How do I choose the right hot leather stamp for my business needs?

Choosing the right hot leather stamp involves evaluating the type of leather you work with, the design complexity, and the production volume. For instance, vegetable-tanned leather requires different temperature settings compared to chrome-tanned leather. If your designs are intricate, opt for a branding iron that allows for variable temperature control to ensure clear impressions. Additionally, consider the size of the stamp and whether you need a custom design. Consulting with suppliers about your specific requirements can lead to the best choice for your production needs. -

What are the common materials used in hot leather stamps, and which is best for durability?

Hot leather stamps are typically made from brass or aluminum. Brass is favored for its durability and ability to withstand high temperatures without warping, making it ideal for long-term use. Aluminum, while more affordable, can be prone to damage under heavy use. For businesses prioritizing longevity and consistent quality in branding, investing in brass stamps is recommended. Always inquire about the material specifications from suppliers to ensure you make an informed decision. -

What customization options are available for hot leather stamps?

Customization options for hot leather stamps are extensive. Most suppliers allow you to submit your design for a bespoke stamp, which can include logos, text, or intricate patterns. You can also specify the size and thickness of the stamp. Some manufacturers even offer interchangeable stamps, allowing for greater versatility. It’s advisable to communicate your design specifications clearly and provide vector files if possible to ensure the best outcome. -

What is the minimum order quantity (MOQ) for hot leather stamps from suppliers?

The MOQ for hot leather stamps varies by supplier and can range from a single unit for custom orders to larger quantities for mass-produced items. Many manufacturers are flexible, especially for custom designs, but larger orders often result in lower per-unit costs. When sourcing, be sure to clarify the MOQ with potential suppliers and consider your production needs to optimize your budget. -

How do I ensure quality when sourcing hot leather stamps internationally?

To ensure quality when sourcing hot leather stamps internationally, conduct thorough supplier vetting. Look for manufacturers with good reputations, verified customer reviews, and quality certifications. Request samples to evaluate craftsmanship before placing large orders. Additionally, consider suppliers that offer warranties or guarantees for their products, as this can provide further assurance of their commitment to quality. -

What payment terms should I expect when buying hot leather stamps?

Payment terms for purchasing hot leather stamps can vary widely among suppliers. Common arrangements include full payment upfront, deposits with the balance upon delivery, or payment on delivery. It’s crucial to discuss and negotiate these terms clearly before finalizing your order to avoid any misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with international suppliers. -

How do logistics and shipping work for international orders of hot leather stamps?

Logistics and shipping for international orders of hot leather stamps typically involve selecting a reliable freight forwarder or logistics provider. Suppliers may offer shipping options that vary in cost and delivery time, depending on your urgency. Be sure to discuss shipping terms upfront, including who bears the cost and responsibility for customs clearance. Understanding import regulations in your country is also essential to avoid any delays upon arrival. -

What are the best practices for maintaining hot leather stamps?

Maintaining hot leather stamps is essential for ensuring longevity and consistent performance. After use, clean the stamps to remove any residue or debris, using a soft cloth and appropriate cleaning solutions. Store them in a cool, dry place to prevent corrosion or warping. Regularly check for any signs of wear and tear, and consider having backup stamps for high-volume production. By following these practices, you can extend the life of your hot leather stamps and maintain high-quality branding.

Top 2 Hot Leather Stamp Manufacturers & Suppliers List

1. Infinity Stamps Inc. – Leather Stamping Solutions

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Hot Stamps for Leather – Infinity Stamps Inc. offers a variety of stamping products specifically designed for leather. The company has been family-owned for over 25 years and is based in the USA. They provide different types of stamps including handheld stamps, plate stamps, and pin marking devices. The collection includes hot stamps, steel type stamps, and holders for leather applications. Custom…

2. Reddit – Stamping Tools for Leather

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Stamps: Two stamps tapped at 8 mm; Gold foil for hot stamping; Electric handle (350 watts); Butcher paper for protection; Trying threaded rod with map gas torch or heat gun; Leather types: Chrome, Veg-tan; Sizes of stamps: Big stamp 4 in x 5 in, small stamp 2 in x 2.5 in; Leather type for final product: White leather; Vegan leather scrap purchased (20 bucks for 3 pounds).

Strategic Sourcing Conclusion and Outlook for hot leather stamp

In navigating the evolving landscape of hot leather stamping, strategic sourcing emerges as a cornerstone for B2B buyers aiming to enhance product branding and quality. By investing in high-quality custom stamps and heat embossers, companies can achieve consistent and durable branding across various leather types, from vegetable-tanned to chrome-tanned leathers. The choice between traditional leather stamping and modern hot stamping methods should align with your brand’s aesthetic and production needs, allowing for flexibility in design and application.

Moreover, understanding the technical specifications—such as temperature control and material durability—will empower buyers to make informed decisions that yield better results and longer-lasting impressions. As international markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for custom leather products is likely to rise.

Now is the time to leverage these insights for your sourcing strategy. By prioritizing quality and innovation in your leather stamping tools, you can position your brand for success in a competitive marketplace. Embrace this opportunity to elevate your product offerings and drive customer loyalty through exceptional craftsmanship and branding.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.