Introduction: Navigating the Global Market for how to make a leather pistol holster

In today’s global market, the demand for high-quality leather pistol holsters is on the rise, presenting both opportunities and challenges for international B2B buyers. Sourcing the right materials and ensuring craftsmanship that meets diverse regulatory standards can be daunting. This comprehensive guide addresses these challenges by providing a thorough overview of how to make a leather pistol holster, focusing on various styles, applications, and the essential steps involved in the crafting process.

From selecting the appropriate leather type to understanding the nuances of design and assembly, this guide empowers buyers with actionable insights. It delves into critical considerations such as supplier vetting, pricing strategies, and market trends across key regions, including Africa, South America, the Middle East, and Europe. By equipping decision-makers with the knowledge needed to navigate the complexities of sourcing and production, this resource ensures that businesses can make informed purchasing decisions that align with their operational needs and market demands.

Whether you are a retailer looking to enhance your product offerings or a manufacturer seeking to improve your production techniques, this guide serves as a valuable tool for mastering the art of leather holster creation. Get ready to elevate your understanding and capabilities in the leather goods market.

Table Of Contents

- Top 4 How To Make A Leather Pistol Holster Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather pistol holster

- Understanding how to make a leather pistol holster Types and Variations

- Key Industrial Applications of how to make a leather pistol holster

- 3 Common User Pain Points for ‘how to make a leather pistol holster’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather pistol holster

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather pistol holster

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather pistol holster’

- Comprehensive Cost and Pricing Analysis for how to make a leather pistol holster Sourcing

- Alternatives Analysis: Comparing how to make a leather pistol holster With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather pistol holster

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather pistol holster Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather pistol holster

- Strategic Sourcing Conclusion and Outlook for how to make a leather pistol holster

- Important Disclaimer & Terms of Use

Understanding how to make a leather pistol holster Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fitted Leather Holster | Custom-molded to specific pistol shapes | Law enforcement, military, custom shops | Pros: Excellent fit and retention; Cons: Time-consuming to make. |

| Western Leather Holster | Open-top design with decorative elements | Sporting events, cowboy reenactments | Pros: Stylish and traditional; Cons: Less secure retention. |

| Tactical Holster | Retention systems and modular attachments | Military, tactical training, security | Pros: Versatile and secure; Cons: Can be bulkier than other types. |

| Shoulder Holster | Worn under the arm, conceals well | Concealed carry, personal defense | Pros: Discreet and comfortable; Cons: Slower draw time. |

| Cross-Draw Holster | Positioned for draw from the opposite side | Hunters, outdoor enthusiasts | Pros: Allows for easy access when seated; Cons: Less common design. |

What are the Key Characteristics of Fitted Leather Holsters?

Fitted leather holsters are specifically molded to the shape of individual firearms, providing a snug fit that enhances retention and accessibility. This type of holster is primarily used by law enforcement and military personnel, as well as by custom leather shops that cater to specific client needs. When purchasing fitted holsters, businesses should consider the time and craftsmanship involved, as these holsters require precise molding and assembly, which can affect lead times and pricing.

How Do Western Leather Holsters Stand Out?

Western leather holsters are characterized by their open-top design and often feature decorative elements such as tooling or embossing. These holsters are popular in sporting events and cowboy reenactments, appealing to buyers looking for both functionality and aesthetic appeal. While they provide a stylish option, businesses should weigh the pros and cons, as the lack of a secure closure can lead to a risk of firearm displacement during active use.

What Makes Tactical Holsters a Preferred Choice?

Tactical holsters are designed with advanced retention systems and may include modular attachments for additional gear. They are widely used in military and tactical training environments, where quick access and security are paramount. For B2B buyers, the versatility and functionality of tactical holsters are attractive, but it is essential to consider the added bulk that may come with enhanced features when assessing usability for specific applications.

Why Choose Shoulder Holsters for Concealed Carry?

Shoulder holsters offer a discreet carrying option, worn under the arm to conceal the firearm effectively. This type of holster is ideal for concealed carry and personal defense, appealing to businesses that cater to civilian markets. While they provide comfort and concealment, buyers must consider the slower draw time compared to other holster types, which can be a critical factor for users requiring immediate access.

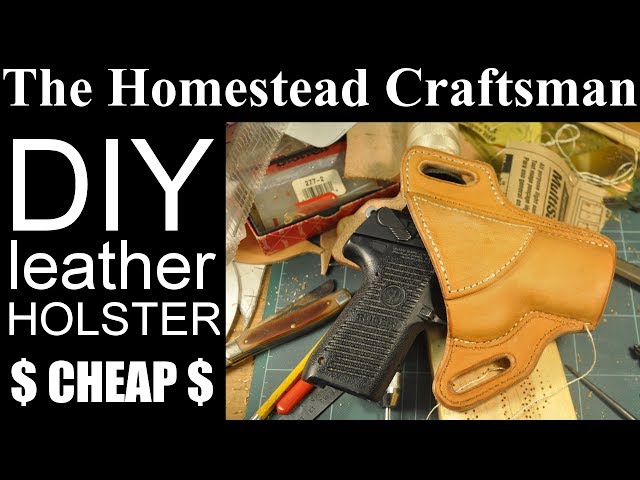

Illustrative image related to how to make a leather pistol holster

What Are the Benefits of Cross-Draw Holsters?

Cross-draw holsters are positioned to allow access from the opposite side of the body, making them particularly useful for seated users, such as those in vehicles. This design is favored by hunters and outdoor enthusiasts who require quick access while in a sitting position. B2B buyers should evaluate the unique access benefits against the relative rarity of this design, which may impact inventory decisions and customer preferences.

Key Industrial Applications of how to make a leather pistol holster

| Industry/Sector | Specific Application of how to make a leather pistol holster | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom holsters for officers to carry firearms securely | Enhances officer safety and accessibility to their service weapon | Quality leather, durability, and local laws compliance |

| Military | Tactical holsters for soldiers in the field | Provides quick access to weapons while ensuring protection | Lightweight materials, weather resistance, and ease of use |

| Outdoor Recreation | Holsters for hunting and sports shooting | Facilitates safe transport and quick access to firearms | Comfort, fit for specific firearm models, and style options |

| Security Services | Holsters for security personnel | Improves professional appearance and firearm accessibility | Branding options, custom designs, and material quality |

| Custom Leather Goods | Bespoke holster creation for collectors and enthusiasts | Meets specific customer preferences and enhances product offering | Artisanal craftsmanship, unique designs, and material sourcing |

How is ‘how to make a leather pistol holster’ Applied in Law Enforcement?

In the law enforcement sector, the ability to create custom leather pistol holsters is crucial for ensuring that officers can carry their firearms securely and comfortably. A well-fitted holster not only enhances safety but also allows for quick access during emergencies. International buyers, particularly from regions with specific law enforcement standards, must consider local regulations regarding holster design and material durability to ensure compliance and functionality.

What is the Importance of Tactical Holsters in the Military?

Military applications of leather pistol holsters focus on tactical designs that cater to the unique demands of soldiers in various environments. These holsters must provide rapid access to firearms while ensuring protection from the elements. Buyers from military sectors need to prioritize lightweight materials and weather-resistant features, as well as the holster’s compatibility with military gear, to enhance operational effectiveness.

Illustrative image related to how to make a leather pistol holster

How Do Outdoor Recreation Enthusiasts Benefit from Custom Holsters?

In the outdoor recreation industry, particularly among hunters and sport shooters, custom leather holsters are essential for safe firearm transport and quick access. These holsters not only provide functionality but also reflect personal style and preferences. Buyers from regions with diverse outdoor activities should focus on comfort and fit for specific firearm models, as well as options that allow for easy integration with outdoor gear.

Why are Holsters Important for Security Services?

Security personnel require holsters that enhance their professional appearance while ensuring easy access to their firearms. The right holster can significantly improve the effectiveness of security operations. B2B buyers in this sector should consider options that allow for branding, custom designs, and high-quality materials to maintain a professional image while fulfilling their operational needs.

How Can Custom Leather Goods Manufacturers Leverage Holster Creation?

For businesses specializing in custom leather goods, the ability to create bespoke holsters for firearm collectors and enthusiasts presents a unique market opportunity. This application allows manufacturers to cater to specific customer preferences, enhancing their product offerings. Buyers in this segment should prioritize artisanal craftsmanship, unique designs, and reliable material sourcing to meet the diverse demands of their clientele.

3 Common User Pain Points for ‘how to make a leather pistol holster’ & Their Solutions

Scenario 1: Insufficient Knowledge of Leather Types for Holster Making

The Problem: Many B2B buyers entering the leather holster manufacturing space often struggle with selecting the right type of leather for their projects. With numerous options such as vegetable-tanned, chrome-tanned, or exotic leathers, the decision can be overwhelming. Poor choices can lead to holsters that lack durability or functionality, ultimately affecting customer satisfaction and brand reputation. Buyers from regions like Africa or South America may face additional challenges due to limited access to high-quality leather suppliers and a lack of resources to educate themselves on leather properties.

The Solution: To overcome this hurdle, buyers should focus on developing a solid understanding of leather types and their applications. Conducting market research and reaching out to established leather suppliers can provide valuable insights. For instance, vegetable-tanned leather is ideal for holsters due to its stiffness and ability to mold to the gun’s shape, while chrome-tanned leather offers greater flexibility. Buyers should also consider investing in educational workshops or partnering with experienced craftsmen to gain hands-on experience with different leather types. Utilizing local resources or online platforms can help bridge the knowledge gap, ensuring that the right materials are used for optimal product quality.

Scenario 2: Difficulty in Achieving the Perfect Fit for Firearms

The Problem: A significant pain point for B2B buyers is the challenge of crafting holsters that fit firearms precisely. Inaccurate measurements or poorly designed templates can lead to holsters that are either too loose, compromising safety, or too tight, making them difficult to draw. This issue is particularly acute for businesses aiming to cater to a diverse clientele with varying firearm models, especially in regions with a mix of local and international firearm brands.

The Solution: To address fitting issues, buyers should adopt a systematic approach to measurement and design. Utilizing a 3D scanning technology or CAD software can help create precise templates based on specific firearm models. Additionally, establishing partnerships with firearm manufacturers can provide access to detailed specifications and prototypes. Implementing a feedback loop with customers who test the holsters can also refine the fit over time. Ensuring that the design phase includes multiple iterations and testing with real firearms will enhance the final product’s functionality and user satisfaction.

Scenario 3: Inefficient Production Processes Leading to Increased Costs

The Problem: Many B2B buyers face inefficiencies in their production processes, leading to increased operational costs and longer lead times. This is especially true for businesses that rely on manual techniques without leveraging modern tools or methods. Inefficient workflows can result in wasted materials, higher labor costs, and ultimately, reduced profit margins. Buyers in emerging markets may struggle further due to limited access to advanced manufacturing technologies.

The Solution: To streamline production, buyers should consider adopting lean manufacturing principles and investing in tools that enhance efficiency. Implementing techniques such as just-in-time inventory management can reduce waste and improve cash flow. Additionally, buyers can explore automation tools for cutting and stitching, which not only speed up production but also ensure consistency in quality. Training staff in best practices for leatherworking, combined with regular process audits, will identify bottlenecks and areas for improvement. Collaborating with local artisans or investing in technology transfer from more advanced markets can also help modernize production capabilities and enhance competitiveness in the global market.

Strategic Material Selection Guide for how to make a leather pistol holster

When selecting materials for crafting leather pistol holsters, it is essential to consider various factors that affect performance, durability, and manufacturing complexity. Below is a detailed analysis of four common materials used in the production of leather holsters, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Vegetable-Tanned Leather for Holsters?

Vegetable-tanned leather is a popular choice for holster making due to its natural tanning process that enhances durability and flexibility. This type of leather is resistant to moisture and can withstand various temperatures, making it suitable for outdoor use. Its ability to mold to the shape of a firearm ensures a snug fit, which is crucial for safety and accessibility.

Illustrative image related to how to make a leather pistol holster

Pros:

– High durability and resistance to wear.

– Excellent moldability for a custom fit.

– Environmentally friendly due to natural tanning methods.

Cons:

– Higher cost compared to synthetic alternatives.

– Requires more time for the tanning process, affecting production timelines.

Impact on Application:

Vegetable-tanned leather is compatible with various climates, but it may require additional conditioning in extremely dry or humid environments to maintain its integrity.

Illustrative image related to how to make a leather pistol holster

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local environmental regulations regarding leather sourcing. Understanding ASTM standards for leather quality can also be beneficial.

How Does Top Grain Leather Compare for Holster Applications?

Top grain leather is known for its smooth finish and high-quality appearance. It is made from the uppermost layer of the hide, offering a good balance of durability and aesthetic appeal. This material is less prone to stretching and maintains its shape well, which is essential for holster functionality.

Pros:

– Attractive finish suitable for premium products.

– Good resistance to wear and tear.

– Easier to clean and maintain than other types of leather.

Cons:

– Generally more expensive than full-grain leather.

– May not be as durable as vegetable-tanned leather in high-stress applications.

Impact on Application:

Top grain leather is ideal for holsters that require a refined look while still providing adequate protection for the firearm.

Illustrative image related to how to make a leather pistol holster

Considerations for International Buyers:

Buyers in Europe may prefer top grain leather for its aesthetic qualities, but they should also consider the sourcing practices to ensure they meet EU regulations on animal welfare.

What are the Benefits of Synthetic Leather for Holster Production?

Synthetic leather, such as polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to traditional leather. It is lightweight, water-resistant, and can be produced in various colors and textures, making it highly versatile for holster designs.

Pros:

– Lower manufacturing costs and reduced waste during production.

– Consistent quality and availability.

– Easier to clean and maintain.

Cons:

– Less durable than natural leather, particularly under extreme conditions.

– May not provide the same level of breathability as genuine leather.

Impact on Application:

Synthetic leather is suitable for casual holsters and can be used in humid environments without the risk of mold or rot.

Illustrative image related to how to make a leather pistol holster

Considerations for International Buyers:

In regions like the Middle East, where humidity is high, synthetic leather may be preferred. However, buyers should verify compliance with local standards for synthetic materials.

Why Choose Suede Leather for Holster Design?

Suede leather, known for its soft texture and flexibility, is often used for holsters that prioritize comfort and ease of wear. While it may not be as durable as other leather types, its lightweight nature makes it appealing for specific applications.

Pros:

– Soft and comfortable against the skin.

– Lightweight and easy to work with.

– Offers a unique aesthetic appeal.

Illustrative image related to how to make a leather pistol holster

Cons:

– Less durable and more prone to staining.

– Requires careful maintenance to prevent damage.

Impact on Application:

Suede is best suited for holsters intended for light-duty use or for users who prioritize comfort over durability.

Considerations for International Buyers:

Buyers should be aware of the maintenance requirements of suede, especially in regions with heavy rainfall or dust, which could affect the material’s longevity.

Summary Table of Material Selection for Leather Pistol Holsters

| Material | Typical Use Case for how to make a leather pistol holster | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Custom-fit holsters for outdoor use | High durability and moldability | Longer tanning process | High |

| Top Grain Leather | Premium holsters with aesthetic appeal | Attractive finish | Less durable under stress | High |

| Synthetic Leather | Casual holsters and lightweight designs | Cost-effective and versatile | Less durability compared to natural | Low |

| Suede Leather | Comfortable holsters for light-duty use | Soft texture and comfort | Prone to staining and less durable | Medium |

This analysis provides valuable insights for B2B buyers in various regions, enabling informed decisions when selecting materials for leather pistol holsters.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather pistol holster

What Are the Key Stages in the Manufacturing Process of Leather Pistol Holsters?

Manufacturing leather pistol holsters involves several distinct stages, each critical to ensuring the final product meets quality and functional standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Leather Holster Production?

The journey begins with selecting the right leather. Typically, vegetable-tanned leather is preferred for its durability and aesthetic appeal. Once the leather is sourced, it is cut to size, usually in 8 oz (approximately 3-4 mm thick) pieces, ensuring that the dimensions are precise to accommodate the specific pistol model.

Illustrative image related to how to make a leather pistol holster

Before moving forward, the leather must undergo a conditioning process, which can involve soaking in water or a moisture-retaining solution. This step is crucial as it allows the leather to become pliable, making it easier to mold and shape. Proper conditioning ensures that the leather retains its structural integrity during the forming stage.

What Techniques Are Used in the Forming Stage of Holster Production?

The forming stage is vital for creating a holster that fits the firearm snugly. This typically involves soaking the leather, either in water or a suitable solution, followed by placing the firearm between two leather pieces. A vacuum bag is then used to remove air, allowing the leather to conform closely to the gun’s shape.

Additional techniques may involve using molds or forms to achieve specific designs, especially for more complex holster styles. The leather is left to dry in this position, which sets its shape permanently. This stage is critical as any misalignment can lead to a poorly fitting holster, impacting both usability and safety.

How Is the Assembly of Leather Holsters Conducted?

Once the leather is properly formed, it moves to the assembly stage. This involves adhering the two halves of the holster together using strong leather cement, such as Barge Cement. Precision is key; the outlines must align perfectly to avoid functionality issues.

Illustrative image related to how to make a leather pistol holster

After the glue sets, the outline of the holster is traced out, including belt loops and other essential features. Cutting is performed with a sharp blade or band saw, followed by drilling holes for stitching. This meticulous approach ensures that all components fit together seamlessly.

What Finishing Techniques Enhance the Quality of Leather Holsters?

The finishing stage is where the holster’s aesthetic and protective qualities are enhanced. This involves sanding the edges for a smooth finish, applying conditioners like Neatsfoot oil to darken and moisturize the leather, and sealing it for durability. Finishing touches can also include adding decorative elements or additional functional features such as snaps or Chicago screws for enhanced strength.

What Quality Assurance Measures Should Be in Place for Leather Holster Manufacturing?

Quality assurance (QA) is paramount in leather holster manufacturing, ensuring that each product meets industry standards and customer expectations. Implementing a robust QA process not only protects the buyer’s investment but also enhances brand reputation.

Which International Standards Are Relevant for Leather Holster Production?

For manufacturers looking to operate internationally, adhering to standards such as ISO 9001 is essential. This standard focuses on quality management systems and ensures that the production process is consistent and meets customer requirements. Other industry-specific standards, such as CE marking for products sold within Europe or API for certain applications, may also apply depending on the intended use of the holsters.

What Quality Control Checkpoints Should Be Implemented During Production?

Quality control (QC) checkpoints are critical throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducting inspections at various stages of production to catch defects early.

- Final Quality Control (FQC): A thorough inspection of the completed holster, checking for fit, finish, and functionality.

How Can B2B Buyers Verify a Supplier’s Quality Control Practices?

B2B buyers should conduct due diligence when selecting suppliers. This can include requesting documentation of quality assurance practices, such as QC reports and audit results. Furthermore, third-party inspections can provide an unbiased assessment of the supplier’s processes and products.

Buyers should also consider conducting on-site audits. This allows them to observe the manufacturing environment, review quality control measures, and assess compliance with international standards. Such proactive measures can mitigate risks associated with quality issues in the supply chain.

Illustrative image related to how to make a leather pistol holster

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must be aware of the varying standards and regulations across countries. Understanding local compliance requirements and the supplier’s ability to meet these can significantly impact product quality.

Additionally, cultural differences in manufacturing practices may influence quality. Buyers should foster clear communication with suppliers to ensure expectations align and that any potential discrepancies are addressed promptly.

Conclusion

The manufacturing processes and quality assurance measures for leather pistol holsters are intricate and multifaceted. By understanding each stage—from material preparation to finishing—and implementing rigorous quality control measures, B2B buyers can ensure they receive products that not only meet but exceed industry standards. This diligence is particularly crucial in an international context, where standards and practices may vary widely. Engaging in thorough supplier assessments and maintaining open lines of communication will ultimately foster stronger partnerships and enhance product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather pistol holster’

Introduction

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing the necessary components and knowledge for crafting leather pistol holsters. Whether you are a manufacturer, retailer, or artisan, understanding the steps involved in creating high-quality leather holsters will help you streamline your procurement process and ensure that you meet your customers’ demands effectively.

Illustrative image related to how to make a leather pistol holster

Step 1: Identify Your Target Market

Understanding your target market is crucial for tailoring your holster designs. Research the specific needs and preferences of customers in regions such as Africa, South America, the Middle East, and Europe. Consider factors such as local regulations, cultural preferences, and popular firearm models to create a product that resonates with your audience.

Step 2: Define Your Technical Specifications

Before sourcing materials, establish clear specifications for the holsters you intend to produce. This includes determining the size, type of leather (e.g., vegetable-tanned, chrome-tanned), and any additional features like retention systems or lining materials. These specifications will guide your sourcing decisions and help ensure product consistency.

Step 3: Source Quality Leather and Materials

Select high-quality leather that meets your technical specifications. Look for reputable suppliers who can provide samples and certifications for their materials. Pay attention to the following:

– Leather Weight: Choose heavy-weight leather (around 8 oz) for durability.

– Finishing Products: Ensure you have access to conditioners and finishes, such as Neatsfoot oil, to enhance the leather’s longevity and appearance.

Illustrative image related to how to make a leather pistol holster

Step 4: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your quality and production standards. Request company profiles, case studies, and references from buyers in similar industries. Look for suppliers who have experience in leather goods and can provide insights into their production processes and capabilities.

Step 5: Assess Production Techniques

Evaluate the production techniques employed by your suppliers to ensure they align with your quality standards. Investigate their methods for cutting, stitching, and finishing leather. Consider the following:

– Machinery Used: Ensure that suppliers use modern equipment for precision and efficiency.

– Craftsmanship: Look for artisanship in stitching and edge finishing, which affects both durability and aesthetics.

Step 6: Verify Compliance with Regulations

Ensure that your suppliers comply with local and international regulations regarding firearm accessories. This is particularly important in markets like Europe and the Middle East, where regulations can be stringent. Request documentation proving compliance to avoid potential legal issues.

Step 7: Establish Logistics and Distribution Plans

Plan how you will receive and distribute the finished holsters. Consider logistics partners who specialize in handling leather goods and have experience in your target markets. Efficient logistics will ensure timely delivery, which is crucial for maintaining customer satisfaction and growing your business.

By following this checklist, B2B buyers can effectively navigate the sourcing process for leather pistol holsters, ensuring they procure quality products that meet market demands and regulatory requirements.

Illustrative image related to how to make a leather pistol holster

Comprehensive Cost and Pricing Analysis for how to make a leather pistol holster Sourcing

What Are the Key Cost Components for Making a Leather Pistol Holster?

When analyzing the cost structure for producing leather pistol holsters, several components must be taken into account. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary material is high-quality leather, typically ranging from 8 oz to 10 oz thickness, which can cost between $5 to $15 per square foot depending on the type and quality. Additional materials include adhesives, stitching threads, and finishing oils, which can add another $2 to $5 per holster.

-

Labor: Labor costs will vary by region and skill level. In regions like Africa or South America, skilled labor can range from $5 to $15 per hour. A skilled craftsman might take approximately 2-4 hours to produce a holster, resulting in labor costs between $10 and $60.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Overhead can be estimated at around 10-20% of total production costs.

-

Tooling: Initial setup costs for tools such as stitching machines and cutting dies can be significant but are often amortized over a larger production volume. Expect to allocate $500 to $2,000 for initial tooling, which will decrease the unit cost as production increases.

-

Quality Control (QC): Ensuring the quality of each holster is essential, especially for B2B buyers who require consistency. QC processes can add an estimated $1 to $3 per unit.

-

Logistics: Shipping costs can vary widely based on destination, weight, and shipping method. For international shipments, costs can range from $10 to $50 per holster, significantly affecting the total price for buyers in Africa or South America.

-

Margin: Businesses typically mark up costs by 30-50% to ensure profitability, which will influence the final pricing.

How Do Price Influencers Impact Leather Pistol Holster Costs?

Several factors influence the pricing of leather holsters, particularly for B2B transactions:

-

Volume/MOQ: Larger orders often lead to discounts due to economies of scale. Minimum order quantities (MOQ) can also affect pricing, with larger batches resulting in lower per-unit costs.

-

Specifications/Customization: Custom designs or specific requirements will increase costs due to additional labor and material usage. Customization can add anywhere from 10% to 30% to the base price.

-

Materials: The choice of leather type (e.g., vegetable-tanned, chrome-tanned) and additional features like embossed patterns or reinforced stitching can significantly influence costs.

-

Quality/Certifications: Buyers seeking certified or higher-quality products may pay a premium. Certifications ensuring ethical sourcing or environmental compliance can also add to the cost.

-

Supplier Factors: The reliability, reputation, and location of suppliers can affect pricing. Suppliers based in regions with higher labor costs or stringent regulations may have higher prices.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Different Incoterms (e.g., FOB, CIF) will dictate who bears the costs and risks during shipping, impacting the overall cost structure.

What Buyer Tips Can Enhance Cost Efficiency in Leather Holster Procurement?

For international B2B buyers, particularly from Africa, South America, and the Middle East, navigating the complexities of sourcing leather holsters can be simplified through strategic approaches:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for larger orders. Many suppliers are willing to negotiate terms and discounts based on volume.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider durability, maintenance, and potential resale value when evaluating costs.

-

Pricing Nuances: Be aware of currency fluctuations and import duties that may affect the final cost. Understanding local market conditions can provide leverage during negotiations.

-

Research and Compare: Investigate multiple suppliers and compare their offerings. This can lead to better pricing and quality assurance while allowing for informed decision-making.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive products or deals.

Disclaimer

The prices and costs mentioned in this analysis are indicative and may vary based on specific circumstances, regional economic conditions, and market fluctuations. Always conduct thorough research and consult with multiple suppliers to obtain accurate and tailored pricing information.

Illustrative image related to how to make a leather pistol holster

Alternatives Analysis: Comparing how to make a leather pistol holster With Other Solutions

Exploring Alternatives to Making a Leather Pistol Holster

When considering the creation of a leather pistol holster, it’s essential to evaluate various alternatives that can meet similar needs. Each approach comes with its own set of advantages and challenges, depending on the specific requirements of the end-user. This analysis will compare the traditional method of making a leather pistol holster with alternative solutions, including using synthetic materials and purchasing pre-made holsters.

| Comparison Aspect | How To Make A Leather Pistol Holster | Synthetic Holsters | Pre-Made Holsters |

|---|---|---|---|

| Performance | High durability; custom fit | Good durability; less custom fit | Variable quality; generally reliable |

| Cost | Moderate (materials & tools) | Low to moderate (mass-produced) | Variable (brand & quality dependent) |

| Ease of Implementation | Requires skill and tools | Easy; no specialized skills needed | Very easy; ready to use |

| Maintenance | Requires regular conditioning | Low maintenance | Varies; generally low maintenance |

| Best Use Case | Custom designs for specific firearms | Budget-conscious users | Buyers needing immediate solutions |

In-Depth Examination of Alternatives

1. Synthetic Holsters

Synthetic holsters, made from materials like nylon or polymer, offer a lightweight and cost-effective alternative to leather. They are typically less expensive and easier to produce, making them ideal for budget-conscious buyers or those needing bulk orders. However, they may not provide the same level of durability or aesthetic appeal as leather. Synthetic materials can also be less comfortable against the skin, particularly in hot climates, which may be a consideration for users in regions like Africa or the Middle East.

2. Pre-Made Holsters

Purchasing pre-made holsters presents a convenient solution for buyers who require immediate access to a holster without the time investment of crafting one. These holsters come in various styles, materials, and sizes, allowing for flexibility depending on the firearm. However, the trade-off often includes limited customization options and variability in quality. Buyers may find themselves compromising on fit or design, especially if their firearm has unique dimensions. For businesses seeking a quick turnaround, pre-made holsters can be advantageous, but they may not always align with specific user needs.

Conclusion: How to Choose the Right Holster Solution

When selecting the appropriate method for obtaining a pistol holster, B2B buyers should consider their specific requirements, such as durability, budget constraints, and the urgency of the need. If a custom fit and high performance are paramount, making a leather pistol holster may be the best choice despite the investment in time and resources. For those prioritizing cost and convenience, synthetic or pre-made holsters can provide satisfactory alternatives. Ultimately, the decision should align with the operational demands of the buyer’s industry and the intended use of the holster.

Illustrative image related to how to make a leather pistol holster

Essential Technical Properties and Trade Terminology for how to make a leather pistol holster

What Are the Key Technical Properties to Consider When Making a Leather Pistol Holster?

When producing leather pistol holsters, understanding the essential technical properties is crucial for ensuring quality, durability, and customer satisfaction. Here are some critical specifications to consider:

-

Material Grade

– Definition: The material grade refers to the quality and thickness of the leather used. Common grades include top-grain, full-grain, and corrected grain leather, with thickness typically measured in ounces (oz).

– Importance: High-quality leather (e.g., full-grain, 8-10 oz thickness) offers superior durability and a better aesthetic, which appeals to high-end markets. This can influence pricing and customer perception significantly. -

Tolerance

– Definition: Tolerance in holster manufacturing indicates the permissible limit of variation in dimensions, such as the size of the gun pocket or belt loops.

– Importance: Precise tolerances are critical for ensuring that the holster fits the firearm correctly. Inaccuracies can lead to safety issues or customer dissatisfaction, impacting brand reputation. -

Stitching Strength

– Definition: This property refers to the tensile strength of the stitching material and the stitch pattern used in assembly.

– Importance: Strong stitching is essential for the holster’s durability, particularly under stress. A well-stitched holster can withstand regular use without fraying or breaking, which is vital for customer trust and repeat business. -

Finish and Treatment

– Definition: The finish refers to the final treatment applied to the leather, such as oils, dyes, or protective coatings.

– Importance: Proper finishing enhances the leather’s water resistance, color retention, and overall aesthetic appeal. A well-finished product can differentiate a brand in a competitive market. -

Weight Capacity

– Definition: This specification indicates the maximum weight the holster can safely carry without compromising its structure.

– Importance: Understanding weight capacity is vital for compliance with safety standards and for meeting customer needs, especially for law enforcement or military applications where heavier firearms may be used.

What Are Common Trade Terms in Leather Holster Manufacturing?

Familiarizing yourself with industry jargon can facilitate smoother communication and negotiation processes in the B2B environment. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help in sourcing high-quality materials or components for holster production, ensuring consistency and reliability. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for inventory management and cost efficiency, especially for small businesses looking to enter the market without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a price quote for specific products or services.

– Importance: Utilizing RFQs can streamline procurement processes, helping businesses compare prices and terms from different suppliers, ultimately leading to better cost control. -

Incoterms (International Commercial Terms)

– Definition: These are pre-defined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, cost allocations, and risk management, especially for international trade in leather products. -

Lead Time

– Definition: Lead time is the amount of time it takes from placing an order until the product is delivered.

– Importance: Knowing lead times can help businesses plan their inventory and production schedules effectively, ensuring timely fulfillment of customer orders.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding leather pistol holster manufacturing, ultimately enhancing their product offerings and market competitiveness.

Illustrative image related to how to make a leather pistol holster

Navigating Market Dynamics and Sourcing Trends in the how to make a leather pistol holster Sector

What are the Current Trends Shaping the Leather Pistol Holster Market?

The global leather pistol holster market is experiencing a significant evolution driven by various factors. One major trend is the rising demand for custom and fitted holsters, reflecting a growing consumer preference for personalized products. This trend is particularly evident in regions such as Europe and North America, where consumers are increasingly seeking unique designs that cater to individual specifications. In emerging markets like Africa and South America, there is a notable interest in functional yet stylish leather holsters, influenced by a blend of traditional craftsmanship and modern design aesthetics.

Moreover, technological advancements in manufacturing processes are reshaping the sourcing landscape. The introduction of digital tools for design and production, including 3D modeling and automated cutting machines, is enhancing efficiency and precision. This allows manufacturers to reduce lead times and cater to the specific needs of international buyers more effectively. Additionally, as the online marketplace expands, B2B buyers are increasingly leveraging e-commerce platforms to source materials and finished products, facilitating a more streamlined procurement process.

Market dynamics are also influenced by the global economic environment, with fluctuating leather prices and raw material availability posing challenges. Buyers must remain vigilant in their sourcing strategies, considering factors such as local regulations and trade agreements that can impact pricing and availability of quality leather. Understanding these dynamics will empower international B2B buyers to make informed decisions and capitalize on emerging opportunities within the leather pistol holster sector.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in Leather Production?

Sustainability is becoming a crucial consideration in the leather pistol holster market, with increasing awareness of environmental impacts associated with traditional leather production methods. B2B buyers are urged to prioritize ethical sourcing practices that minimize harm to the environment and promote animal welfare. This includes seeking suppliers that utilize vegetable-tanned leather or other eco-friendly tanning processes, which reduce the use of harmful chemicals and promote biodegradability.

In addition to material sourcing, the importance of ethical supply chains cannot be overstated. Buyers should engage with manufacturers who uphold fair labor practices and provide transparency in their sourcing processes. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are indicators of a commitment to sustainable practices and can serve as benchmarks when evaluating potential suppliers.

Moreover, as consumer demand shifts towards sustainable products, offering eco-friendly leather holsters can provide a competitive edge in the market. B2B buyers should consider collaborating with manufacturers who are invested in sustainability initiatives, as this alignment can resonate well with end customers and enhance brand reputation.

What is the Historical Context of Leather Holster Craftsmanship?

The craftsmanship of leather holsters has evolved significantly over centuries, influenced by historical, cultural, and technological changes. Initially, leather holsters were designed for functional purposes, primarily to securely hold firearms while allowing for quick access. As the popularity of firearms grew, so did the demand for holsters, leading to the emergence of various styles, including Western, tactical, and concealment holsters.

In the early 20th century, the art of leatherworking became more refined, with techniques such as tooling and embossing gaining popularity. This not only enhanced the aesthetic appeal of holsters but also contributed to their durability. The introduction of synthetic materials in the late 20th century posed a challenge to traditional leather craftsmanship, but it also spurred innovation within the industry, leading to the development of hybrid holsters that combine leather with modern materials for enhanced functionality.

Today, the leather holster market is characterized by a blend of traditional craftsmanship and contemporary design, catering to diverse consumer preferences across the globe. This rich history serves as a foundation for current and future innovations in the leather pistol holster sector, offering B2B buyers valuable insights into the craftsmanship that defines quality leather products.

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather pistol holster

-

How do I choose the right leather for making a pistol holster?

Selecting the appropriate leather is crucial for durability and functionality. For pistol holsters, look for vegetable-tanned leather with a thickness of around 8-10 oz. This type provides the rigidity needed to maintain the shape and protect the firearm. Ensure that the leather is free from imperfections and has a smooth finish. Additionally, consider the leather’s suppleness and ability to mold around the firearm, as this will enhance comfort and usability. Sourcing from reputable suppliers with consistent quality assurance is vital, especially for international buyers. -

What is the best method for forming leather around a pistol?

The most effective method for forming leather is to soak it in water or a mild solution, then wrap it around the firearm, securing it in a vacuum bag. This technique allows the leather to conform perfectly to the gun’s shape. After forming, let it dry completely before removing the firearm. This method not only ensures a snug fit but also maintains the structural integrity of the holster. For mass production, consider investing in molds that replicate this process efficiently, accommodating various firearm models. -

What are the key considerations for customizing leather holsters?

Customization of leather holsters can involve alterations in size, shape, color, and additional features like retention straps or belt attachments. When customizing for clients, gather specific measurements and preferences to ensure the final product meets their needs. Consider the intended use of the holster—whether for daily carry or tactical applications—as this will influence design choices. Collaborating with skilled artisans who specialize in custom leatherwork can enhance the quality and uniqueness of each holster, appealing to diverse market segments. -

How do I vet suppliers for leather holster production?

To effectively vet suppliers, start by reviewing their portfolio and customer testimonials to assess quality. Request samples of their leather and finished products to evaluate craftsmanship. It’s also important to inquire about their production processes, sourcing methods, and compliance with international quality standards. Establish clear communication to discuss lead times, minimum order quantities (MOQs), and payment terms. Engaging in initial small orders can help build trust and gauge reliability before committing to larger contracts. -

What are typical minimum order quantities (MOQs) for leather holster production?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 500 units for custom leather holsters. Factors influencing MOQs include the complexity of the design, the type of leather used, and the supplier’s production capacity. For international buyers, it’s advisable to negotiate MOQs based on your market demand and inventory capabilities. Establishing a strong relationship with your supplier can also lead to more flexible terms, allowing for smaller test orders to gauge market response. -

What payment terms are commonly accepted in international B2B leather trade?

Payment terms in international B2B transactions often include options like advance payment, letter of credit, or payment upon delivery. Many suppliers may request a deposit (typically 30-50%) before production begins, with the balance due upon completion. It’s essential to clarify these terms upfront and consider using secure payment methods to protect both parties. Additionally, understanding the currency exchange rates and potential fees can help in budgeting and financial planning for your purchases. -

How can I ensure quality assurance in leather holster production?

To ensure quality assurance, establish clear specifications and standards with your supplier before production begins. Request regular updates and samples during the manufacturing process to assess quality control. It may also be beneficial to conduct third-party inspections, especially for larger orders, to verify that the products meet your requirements. Implementing a feedback loop with your supplier can help address any issues promptly and maintain a high standard of quality in your leather holsters. -

What logistics considerations should I keep in mind when importing leather holsters?

When importing leather holsters, consider shipping methods, costs, and customs regulations in your destination country. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure compliance with all import/export regulations, including any tariffs or taxes applicable to leather goods. Building relationships with reliable logistics partners can streamline the process and help navigate potential challenges, ensuring timely delivery and minimizing disruptions in your supply chain.

Top 4 How To Make A Leather Pistol Holster Manufacturers & Suppliers List

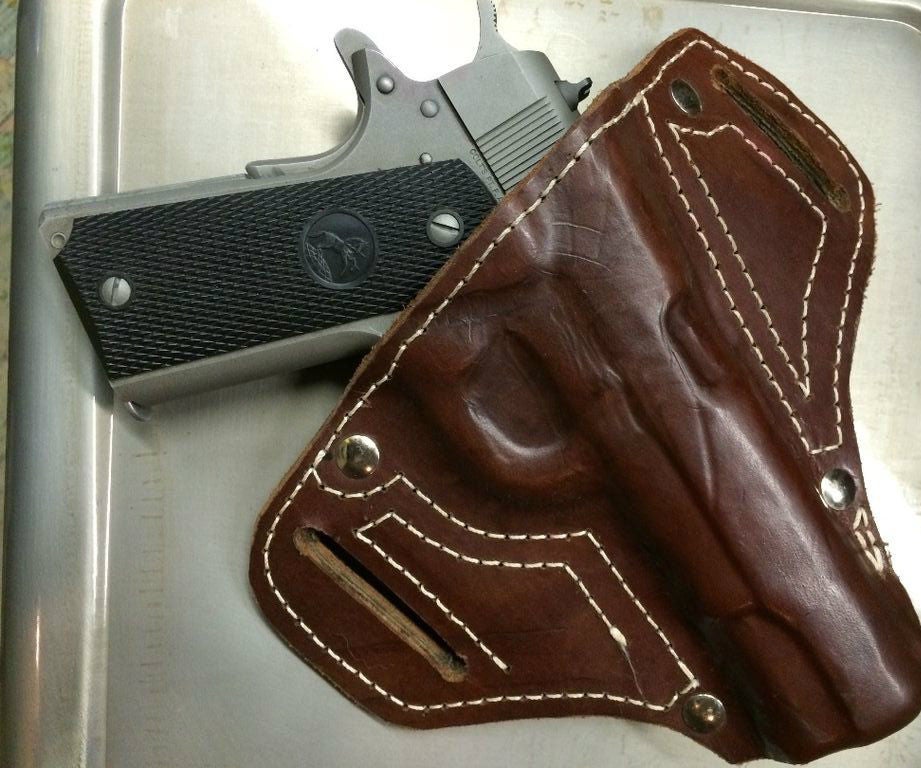

1. Instructables – Fitted Leather Holster for Colt 1911

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Fitted Leather Holster for Colt Model 1911 .45 Caliber pistol; made from heavy weight leather (approximately 8 oz thickness); formed using isopropyl alcohol (recommended to use water instead); assembly involves gluing two halves with Barge Cement or E6000; features belt loops for proper angle when worn; stitching technique includes two passes over each set of holes; finished with Neatsfoot oil to …

2. Tandy Leather – Holster Design Tutorial

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Holster Design Tutorial, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Holster Making Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Holster making techniques for fitting a gun, specifically a 1911. Suggestions include tracing the gun’s silhouette on leather, leaving extra room for stitching, and ensuring the trigger is covered. Recommended leather thickness is 8-10 oz for durability. Advice on using paper stencils for testing fit and considering belt loop design. Mention of resources like YouTube channels for tutorials and tip…

4. Leatherworker – Sewing Machines

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1. Hand Stitching: Relatively inexpensive method for leather holster making.

2. Machine Sewing: Relatively expensive method with costs starting from $1000 USD for hand-operated machines and $2800 USD for motorized machines.

3. Recommended Sewing Machines: Juki DNU – 1541S, Juki DU – 1181N, Singer 29K – 71 (1949), Chinese Patcher (Tinkers Delight), Warlock TSC-441, Techsew 2750 Pro, Consew DCS-S4 S…

Strategic Sourcing Conclusion and Outlook for how to make a leather pistol holster

The process of creating leather pistol holsters offers significant opportunities for international B2B buyers seeking to enhance their product offerings. By strategically sourcing high-quality leather and employing efficient production techniques, manufacturers can ensure that their holsters meet the diverse needs of customers across various markets, including Africa, South America, the Middle East, and Europe. Key takeaways include the importance of selecting the right leather type, understanding the precise fitting techniques, and utilizing effective assembly methods to create durable and aesthetically appealing products.

Investing in quality materials and skilled craftsmanship not only improves product performance but also strengthens brand reputation in competitive markets. As global demand for customized and functional leather goods continues to rise, businesses that prioritize strategic sourcing will be better positioned to capitalize on emerging trends and consumer preferences.

Looking ahead, we encourage international buyers to explore partnerships with skilled artisans and reliable suppliers to enhance their product lines. By embracing innovation and quality, your business can thrive in the dynamic leather market, paving the way for growth and expanded market reach. The time to act is now—invest in strategic sourcing to secure your place in the future of leather craftsmanship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to how to make a leather pistol holster

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.