Introduction: Navigating the Global Market for how to make a leather gun holster

In the dynamic landscape of international trade, sourcing high-quality leather gun holsters presents a significant challenge for B2B buyers. Whether you are looking to meet the specific demands of law enforcement agencies, military units, or civilian markets across Africa, South America, the Middle East, and Europe, understanding the nuances of making a leather gun holster is essential. This comprehensive guide will take you through the entire process—from selecting the right type of leather and understanding various holster designs to exploring production methods and supplier vetting practices.

By delving into the intricacies of leather holster manufacturing, you will gain insights into the cost implications and quality benchmarks necessary for making informed purchasing decisions. This guide not only outlines the practical steps involved in crafting holsters but also highlights the importance of supplier relationships and the standards expected in different markets.

Empowering international buyers with knowledge about materials, design applications, and production techniques, this resource will enhance your capability to navigate the global market confidently. Whether you are based in Nigeria, Vietnam, or elsewhere, you will find actionable strategies to optimize your sourcing process and ensure that you offer your customers durable, well-crafted leather gun holsters that meet their needs.

Table Of Contents

- Top 3 How To Make A Leather Gun Holster Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to make a leather gun holster

- Understanding how to make a leather gun holster Types and Variations

- Key Industrial Applications of how to make a leather gun holster

- 3 Common User Pain Points for ‘how to make a leather gun holster’ & Their Solutions

- Strategic Material Selection Guide for how to make a leather gun holster

- In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather gun holster

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather gun holster’

- Comprehensive Cost and Pricing Analysis for how to make a leather gun holster Sourcing

- Alternatives Analysis: Comparing how to make a leather gun holster With Other Solutions

- Essential Technical Properties and Trade Terminology for how to make a leather gun holster

- Navigating Market Dynamics and Sourcing Trends in the how to make a leather gun holster Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather gun holster

- Strategic Sourcing Conclusion and Outlook for how to make a leather gun holster

- Important Disclaimer & Terms of Use

Understanding how to make a leather gun holster Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fitted Leather Holster | Molded to specific firearm shape, often vacuum-formed | Custom holster manufacturing, firearms retail | Pros: Excellent fit and retention; Cons: Time-consuming to produce. |

| Western Leather Holster | Characteristic open-top design, often decorative | Cowboy-themed events, reenactments | Pros: Aesthetic appeal; Cons: Less secure than fitted styles. |

| Tactical Holster | Designed for quick access, often with additional features | Military, law enforcement, self-defense | Pros: Functional and versatile; Cons: Bulkier than traditional styles. |

| OWB (Outside Waistband) | Sits on the outside of the belt, easy to draw | Concealed carry, everyday wear | Pros: Comfortable for extended wear; Cons: Less concealed than IWB. |

| IWB (Inside Waistband) | Designed to be worn inside the waistband | Concealed carry, personal defense | Pros: Highly concealable; Cons: Can be uncomfortable for some users. |

What Are the Characteristics and Suitability of Fitted Leather Holsters?

Fitted leather holsters are specifically molded to the shape of a firearm, providing a snug fit that enhances retention and accessibility. This type often employs techniques such as vacuum-forming to achieve precise contours. For B2B buyers, particularly manufacturers and retailers, the demand for fitted holsters is high due to their tailored nature, making them ideal for custom orders. However, the production process can be labor-intensive and time-consuming, which may impact pricing and delivery timelines.

How Do Western Leather Holsters Differ from Other Types?

Western leather holsters are characterized by their open-top design and often elaborate decorative elements, making them popular in cowboy-themed events and historical reenactments. These holsters prioritize aesthetic appeal over functionality, often lacking the retention features found in fitted styles. B2B buyers in the entertainment and costume industries may find these holsters valuable for their unique designs. However, the trade-off is a less secure fit, which may not be suitable for everyday carry or tactical applications.

What Makes Tactical Holsters Essential for Certain Markets?

Tactical holsters are built for functionality, allowing for quick access to the firearm while often including additional features such as magazine pouches and adjustable retention. These holsters are primarily used in military, law enforcement, and self-defense markets, where efficiency is paramount. B2B buyers in these sectors should consider the balance between bulkiness and versatility, as tactical holsters tend to be larger than traditional designs. Their practicality makes them a preferred choice for those requiring immediate firearm access.

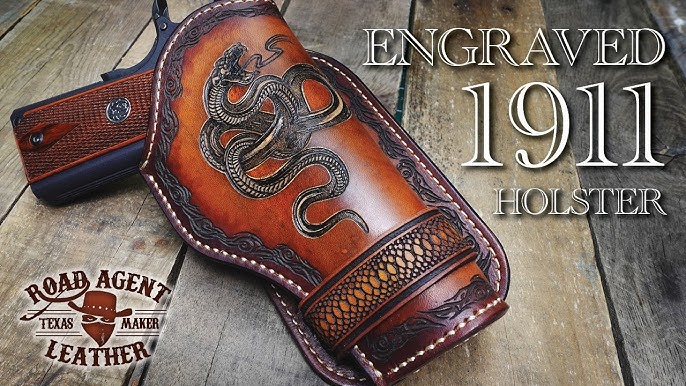

Illustrative image related to how to make a leather gun holster

Why Choose OWB Holsters for Everyday Carry?

Outside Waistband (OWB) holsters are designed to be worn on the outside of the belt, providing easy access to the firearm. This type is favored for everyday carry and offers comfort during extended wear. B2B buyers focusing on personal defense and concealed carry markets should note that while OWB holsters are comfortable, they offer less concealment compared to Inside Waistband (IWB) options. Buyers may want to consider customer preferences for comfort versus concealability when selecting OWB holsters.

What Are the Benefits and Drawbacks of IWB Holsters?

Inside Waistband (IWB) holsters are designed to be worn inside the waistband, making them highly concealable and ideal for personal defense. They are particularly suited for B2B buyers targeting the concealed carry market, as many customers prioritize discreet firearm access. However, IWB holsters can sometimes be uncomfortable, especially for prolonged use. B2B buyers should assess consumer comfort levels and the importance of concealment when deciding on IWB holster offerings.

Key Industrial Applications of how to make a leather gun holster

| Industry/Sector | Specific Application of how to make a leather gun holster | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom holsters for duty weapons | Enhanced officer safety and weapon accessibility | Quality leather sourcing, durability, and compliance with regulations |

| Military | Tactical holsters for firearms | Improved soldier performance and readiness | Lightweight materials, adaptability to various firearm types |

| Outdoor Retail | Holsters for hunting and recreational shooting | Increased customer satisfaction and product offerings | Sourcing environmentally sustainable leather and custom designs |

| Sporting Goods | Holsters for competitive shooting sports | Attracts niche markets and enhances brand reputation | Precision in fit and finish, competitive pricing |

| Craftsmanship | Artisanal leather holster production | Unique product offerings that command higher prices | Sourcing high-quality leather and skilled artisans |

How is ‘how to make a leather gun holster’ utilized in Law Enforcement?

In law enforcement, the making of custom leather gun holsters is critical for ensuring that officers can access their weapons quickly and securely. The design must accommodate various duty weapons while ensuring comfort and functionality. International buyers, particularly from regions like Africa and the Middle East, may face challenges regarding compliance with local regulations and standards, making it essential to source high-quality, durable leather that meets these requirements. The right holster not only enhances safety but also boosts officer confidence in the field.

What role does ‘how to make a leather gun holster’ play in the Military?

The military sector utilizes leather gun holsters for tactical operations, where quick access to firearms is essential. Holsters must be designed for various firearm types while remaining lightweight and adaptable to different combat situations. For international military buyers, especially in regions like South America, sourcing materials that can withstand harsh environments is vital. Additionally, ensuring that holsters comply with military specifications can enhance soldier performance and readiness in the field.

Illustrative image related to how to make a leather gun holster

How can Outdoor Retailers benefit from ‘how to make a leather gun holster’?

Outdoor retailers can capitalize on the demand for holsters designed for hunting and recreational shooting by offering custom-made leather holsters. These holsters improve customer satisfaction by providing options that fit specific firearms and user preferences. Buyers from regions such as Europe may prioritize environmentally sustainable leather options to align with consumer values. Additionally, retailers need to consider the durability and weather resistance of the holsters to ensure they meet the demands of outdoor activities.

Why is ‘how to make a leather gun holster’ significant in Sporting Goods?

In the sporting goods sector, leather gun holsters are essential for competitive shooting sports, where precision and performance matter. Custom holsters can enhance the shooting experience, attracting niche markets and improving brand reputation. International buyers, particularly from Asia, should focus on sourcing holsters that offer a perfect fit and finish for various firearms. Competitive pricing and quality craftsmanship are critical to stand out in this highly specialized market.

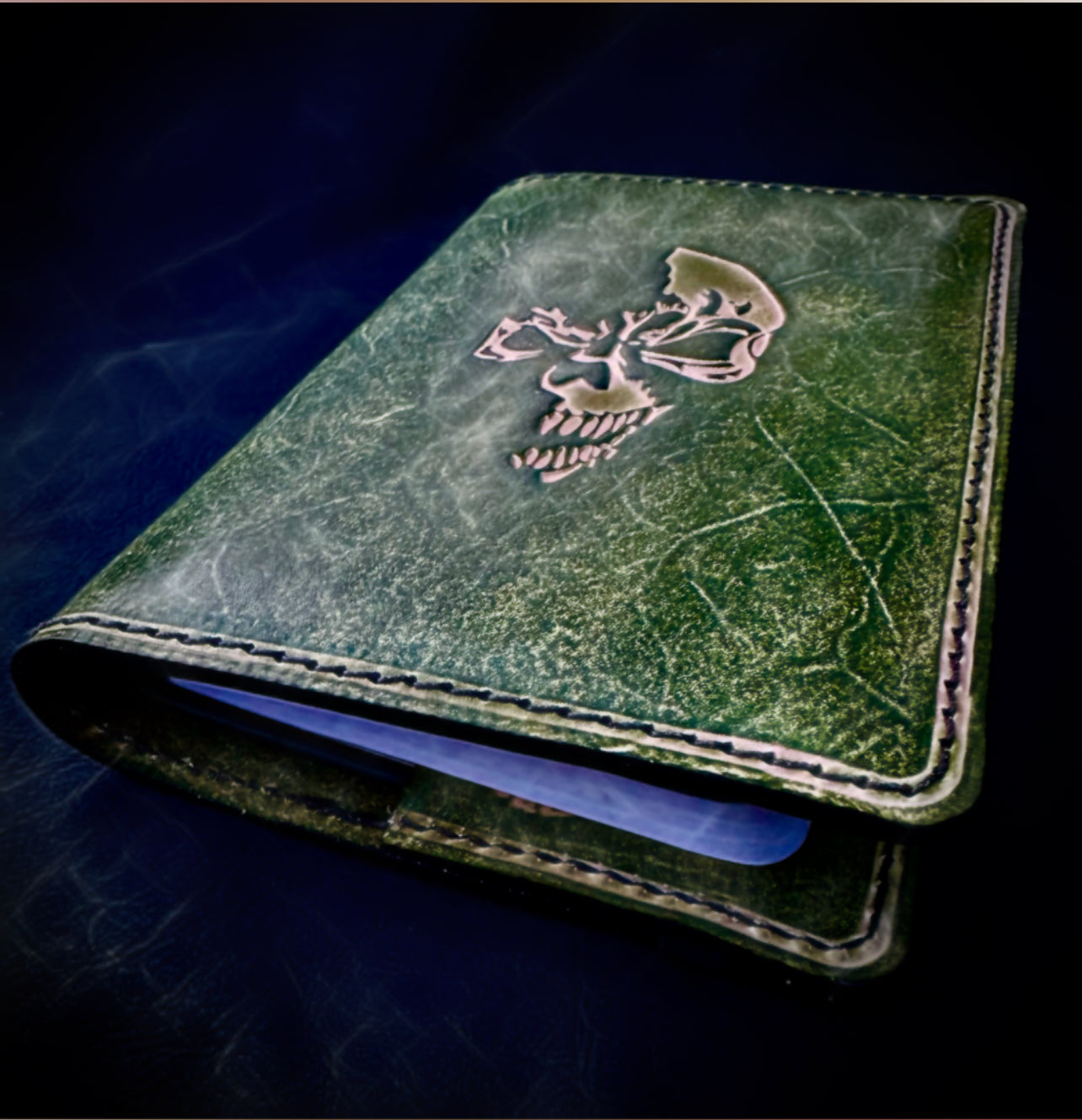

How does ‘how to make a leather gun holster’ contribute to Craftsmanship?

Artisanal craftsmanship in leather holster production allows businesses to offer unique and high-quality products that can command higher prices. Craftsmanship emphasizes the importance of skilled artisans who can create bespoke designs tailored to individual customer needs. For international buyers, particularly in emerging markets, sourcing high-quality leather and skilled labor is essential to maintain product integrity and customer satisfaction. This approach not only enhances product offerings but also fosters a connection with customers seeking authenticity and craftsmanship in their purchases.

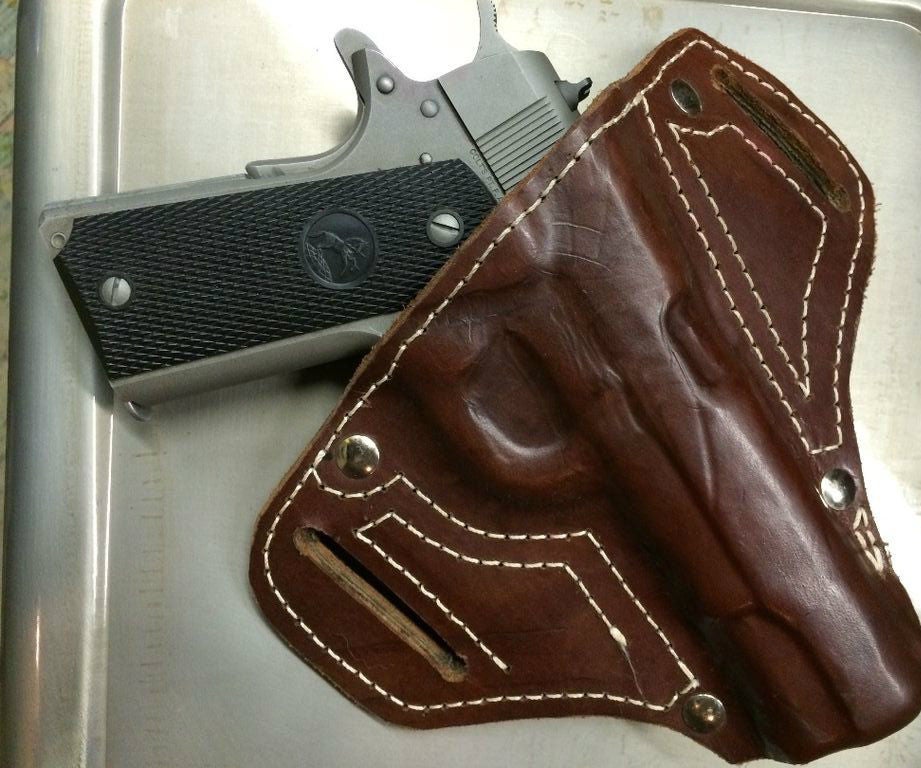

Illustrative image related to how to make a leather gun holster

3 Common User Pain Points for ‘how to make a leather gun holster’ & Their Solutions

Scenario 1: Difficulty Sourcing Quality Leather for Holster Making

The Problem: Many B2B buyers face the challenge of sourcing high-quality leather suitable for gun holster manufacturing. Leather quality directly affects durability, comfort, and safety. In regions such as Africa and South America, where access to premium leather may be limited, buyers often struggle with inconsistent supply chains, leading to delays and unsatisfactory product outcomes. In addition, without proper knowledge about leather grades, buyers may inadvertently purchase inferior materials that compromise their final product.

The Solution: To overcome these sourcing challenges, buyers should establish partnerships with reputable leather suppliers who specialize in gun holster materials. This can be achieved by attending industry trade shows or leveraging online platforms that connect manufacturers with verified suppliers. It’s essential to inquire about the leather’s provenance, processing methods, and thickness. Buyers should also request samples to evaluate the leather’s feel and durability before making bulk purchases. Implementing a rigorous quality assessment process can help ensure that the leather meets the necessary specifications for gun holsters, ultimately leading to better customer satisfaction and reduced returns.

Scenario 2: Inefficient Holster Design and Prototyping Process

The Problem: Many manufacturers encounter bottlenecks during the design and prototyping phase of leather gun holster production. Inefficient workflows can lead to excessive lead times, increased costs, and frustration among design teams. Common issues include the lack of clear templates, inadequate tools for cutting and stitching, and insufficient feedback loops for design iterations, resulting in a final product that does not meet market needs.

The Solution: Implementing a structured design process can significantly enhance efficiency. First, investing in high-quality design software tailored for leatherwork can facilitate the creation of precise templates and patterns. Using digital tools allows for easy modifications and rapid prototyping. Furthermore, establishing a cross-functional team that includes designers, engineers, and marketing professionals can foster collaboration and ensure that designs align with customer expectations. Regular feedback sessions should be scheduled throughout the prototyping phase to identify issues early and make necessary adjustments, thereby streamlining the overall process and reducing time to market.

Illustrative image related to how to make a leather gun holster

Scenario 3: Lack of Skilled Labor for Leather Holster Crafting

The Problem: The skill gap in leather crafting poses a significant challenge for B2B buyers looking to produce high-quality leather gun holsters. Many manufacturers struggle to find workers who possess the necessary expertise in leatherworking techniques, such as stitching, edge finishing, and molding. This shortage can lead to inconsistent product quality, increased production costs, and an inability to meet customer demand.

The Solution: To address this labor issue, manufacturers should consider investing in training programs for existing employees or establishing apprenticeship schemes to cultivate new talent. Collaborating with local vocational schools or leatherworking guilds can also provide access to a pool of skilled labor. Additionally, incorporating standardized operating procedures (SOPs) and quality control measures can help streamline training and ensure that even novice workers can produce quality holsters. By fostering a culture of continuous learning and skill development, manufacturers can enhance their workforce’s capabilities and ensure consistent product quality in the long term.

Strategic Material Selection Guide for how to make a leather gun holster

What Are the Key Materials for Making Leather Gun Holsters?

When selecting materials for leather gun holster production, it is crucial to consider various properties that affect performance, durability, and overall suitability for the end product. Below is an analysis of four common materials used in leather gun holster manufacturing, focusing on their characteristics, pros and cons, and considerations for international B2B buyers.

1. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is known for its natural tanning process, which makes it environmentally friendly. It has excellent breathability and can withstand moderate temperatures without losing its shape.

Illustrative image related to how to make a leather gun holster

Pros & Cons: This type of leather is highly durable and develops a rich patina over time, making it aesthetically appealing. However, it can be more expensive than other types of leather and may require additional finishing processes to enhance water resistance.

Impact on Application: Vegetable-tanned leather is suitable for holsters that require a snug fit and flexibility, as it molds well to the shape of the firearm. However, it may not be ideal for environments with high humidity unless treated properly.

Specific Considerations for International Buyers: Buyers should verify compliance with environmental regulations in their regions, as some countries have strict standards regarding tanning processes. Additionally, understanding local preferences for leather finishes can influence purchasing decisions.

2. Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is processed using chromium salts, which provide excellent resistance to water and heat. It is typically softer and more pliable than vegetable-tanned leather.

Illustrative image related to how to make a leather gun holster

Pros & Cons: The primary advantage of chrome-tanned leather is its durability and resistance to wear and tear, making it a popular choice for holsters. However, it may not develop the same aesthetic appeal over time and can be less environmentally friendly due to the chemicals used in the tanning process.

Impact on Application: This material is suitable for holsters that require quick draw capabilities, as its softness allows for easier access. However, it may not provide the same level of rigidity as vegetable-tanned leather.

Specific Considerations for International Buyers: Buyers should be aware of compliance with safety and environmental standards, such as REACH in Europe, which regulates chemicals used in leather production. Understanding local market preferences for leather types can also guide purchasing decisions.

3. Suede Leather

Key Properties: Suede leather is made from the underside of animal hides, giving it a soft texture and a unique appearance. It is less durable than full-grain leather but offers a distinct aesthetic.

Pros & Cons: The softness of suede makes it comfortable against the skin, which is advantageous for holsters worn directly against the body. However, it is more susceptible to staining and damage from moisture, requiring careful maintenance.

Illustrative image related to how to make a leather gun holster

Impact on Application: Suede is ideal for holsters designed for casual or fashion-oriented use rather than rugged environments. Its texture can enhance grip, but it may not be suitable for tactical applications.

Specific Considerations for International Buyers: Buyers should consider the availability of suede leather in their regions and the potential need for additional treatments to enhance water resistance. Understanding local fashion trends can also influence the demand for suede holsters.

4. Synthetic Leather (Microfiber)

Key Properties: Synthetic leather, often made from polyester or polyurethane, mimics the look and feel of real leather while being more resistant to water and wear.

Pros & Cons: The primary advantage of synthetic leather is its cost-effectiveness and ease of maintenance. It is also available in a variety of colors and textures. However, it may lack the durability and aesthetic appeal of genuine leather over time.

Impact on Application: Synthetic leather is suitable for budget-conscious buyers looking for a functional holster without the premium price of real leather. However, it may not provide the same level of comfort or breathability.

Specific Considerations for International Buyers: Buyers should evaluate the environmental impact of synthetic materials and ensure compliance with local regulations regarding plastics. Awareness of local market trends toward sustainable materials can also guide purchasing decisions.

Illustrative image related to how to make a leather gun holster

Summary Table

| Material | Typical Use Case for how to make a leather gun holster | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Custom-fit holsters requiring durability and aesthetics | Develops a rich patina, environmentally friendly | More expensive, requires finishing | High |

| Chrome-Tanned Leather | Quick-draw holsters needing flexibility and durability | Excellent water and heat resistance | Less environmentally friendly, aesthetic appeal may diminish | Medium |

| Suede Leather | Fashion-oriented or casual holsters | Soft, comfortable against the skin | Susceptible to stains and moisture damage | Medium |

| Synthetic Leather | Budget-friendly holsters for functional use | Cost-effective, easy maintenance | Lacks durability and aesthetic appeal of real leather | Low |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to make informed decisions in the leather gun holster market. Understanding the properties and implications of each material can help businesses align their offerings with market demands and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for how to make a leather gun holster

What Are the Key Manufacturing Processes for Leather Gun Holsters?

The manufacturing process for leather gun holsters involves several stages, each critical to producing a high-quality final product. Understanding these stages can help international B2B buyers ensure they are sourcing from reputable suppliers who adhere to industry best practices.

How Is Material Prepared for Leather Gun Holsters?

The initial step in the manufacturing process is material preparation. High-quality leather, typically around 8 ounces thick, is selected for its durability and ability to hold shape. Suppliers often opt for vegetable-tanned leather, which is not only environmentally friendly but also offers excellent molding capabilities.

- Cutting: The leather is cut into pieces that will form the holster. Precision in cutting is essential to ensure that all parts fit together seamlessly.

- Soaking: The leather is soaked to make it pliable. While some manufacturers use water, others might experiment with different agents. This step is crucial for ensuring the leather can be molded accurately around the firearm.

- Molding: After soaking, the leather is placed around a model of the firearm, often secured in a vacuum bag to create a tight fit. This process can involve additional tools, like clamps, to maintain the shape during drying.

What Techniques Are Used During the Forming Stage?

The forming stage is where the leather begins to take on its final shape. Key techniques include:

- Vacuum Forming: By removing air from around the leather and the firearm, this method ensures the leather tightly conforms to the contours of the gun.

- Detailing: After molding, artisans may use tools to enhance details, ensuring that the holster not only fits well but also looks aesthetically pleasing.

How Is the Assembly of Leather Gun Holsters Conducted?

Once the leather is formed, the assembly stage begins. This involves:

- Gluing: The two halves of the holster are glued together using industrial-grade adhesives like Barge Cement. Proper alignment is critical to maintain the holster’s functionality.

- Cutting and Shaping: The outline of the holster is carefully cut, and belt loops are added for attachment to a belt. This stage may involve the use of specialized cutting tools to ensure clean edges.

- Stitching: A robust stitching method is employed, often using waxed threads. Artisans typically use two needles to create a durable seam that can withstand wear and tear.

What Finishing Techniques Enhance the Quality of Leather Gun Holsters?

The finishing stage is vital for both aesthetics and durability. Common practices include:

- Edge Treatment: Edges are smoothed and rounded using tools like edge bevelers or sanders to prevent fraying and enhance the look of the holster.

- Conditioning: Oils, such as Neatsfoot oil, are applied to moisturize the leather, enhancing its color and longevity.

- Final Inspection: A thorough check for defects and quality issues ensures that only holsters meeting high standards are sent to market.

How Is Quality Assurance Implemented in Leather Gun Holster Manufacturing?

Quality assurance (QA) is essential to guarantee that leather gun holsters meet international standards and customer expectations. For B2B buyers, understanding these QA processes can prevent costly mistakes and ensure product reliability.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should look for manufacturers that comply with international quality standards such as ISO 9001, which focuses on quality management systems. Additionally, industry-specific certifications, such as CE marking in Europe, can indicate compliance with safety and environmental regulations.

Illustrative image related to how to make a leather gun holster

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, random checks are performed to catch defects early. This may include testing the strength of adhesives and stitching techniques.

- Final Quality Control (FQC): Once the holsters are completed, a final inspection occurs to assess the overall quality, fit, and finish.

What Testing Methods Are Commonly Used for Leather Gun Holsters?

Manufacturers may employ various testing methods to ensure the durability and performance of leather gun holsters:

- Tensile Strength Testing: Measures the strength of the stitching and the leather itself.

- Flexural Testing: Evaluates how well the leather withstands repeated bending, simulating real-world use.

- Water Resistance Testing: Assesses the leather’s ability to repel water, which is crucial for longevity.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is crucial.

What Should B2B Buyers Look for in Supplier Audits and Reports?

Buyers should request access to quality assurance reports and audit results. This information provides insights into the supplier’s QC processes and adherence to standards. Buyers can also consider:

Illustrative image related to how to make a leather gun holster

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s production processes and final products.

- Certification Verification: Confirming that suppliers hold relevant certifications can assure buyers of their commitment to quality.

What Are the Nuances of Quality Control for International Buyers?

Different regions may have specific regulatory requirements or cultural expectations regarding quality. For instance, European buyers may prioritize certifications like CE, while buyers from Africa or South America may focus more on cost-effectiveness and local compliance standards. Understanding these nuances can help buyers make informed decisions.

By comprehensively understanding the manufacturing processes and quality assurance measures in leather gun holster production, B2B buyers can ensure they select reliable suppliers who deliver high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to make a leather gun holster’

Introduction

Creating a leather gun holster requires careful planning and precise execution, especially when sourcing materials and tools. This guide provides a structured checklist designed for B2B buyers looking to procure the necessary items for making leather gun holsters. By following these steps, you can ensure that you select the right suppliers and materials, leading to high-quality finished products.

Step 1: Identify Required Materials

Before starting your project, outline the materials needed for crafting a leather gun holster. Key materials include:

– Leather: Choose high-quality vegetable-tanned leather, typically 6-8 oz thick, for durability and shape retention.

– Stitching Supplies: Secure waxed thread and appropriate needles designed for leatherwork.

– Adhesives: Select strong leather adhesives such as Barge Cement for assembly.

Understanding the materials will guide your sourcing decisions and ensure the final product meets quality standards.

Step 2: Define Your Technical Specifications

Establish clear specifications for your holster, including dimensions, style (e.g., fitted or western), and functionality (e.g., retention features).

– Design Considerations: Consider user preferences, such as comfort and accessibility.

– Compliance Requirements: Ensure the design adheres to local regulations regarding firearms.

Defining these specifications early on will streamline your supplier search and minimize the risk of errors during production.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making commitments. Request detailed company profiles, product samples, and references from businesses in similar industries.

– Quality Assurance: Inquire about their quality control processes and certifications.

– Experience: Look for suppliers with a proven track record in leather goods manufacturing.

A rigorous evaluation process will help you select reliable partners who can deliver consistent quality.

Step 4: Assess Tool Requirements

Determine the tools necessary for leather holster making and ensure your suppliers can provide them. Essential tools include:

– Cutting Tools: Invest in sharp knives or rotary cutters for precise cuts.

– Stitching Equipment: Consider purchasing a stitching pony or clamps to hold leather while sewing.

Illustrative image related to how to make a leather gun holster

Having the right tools is essential for achieving professional results and improving efficiency.

Step 5: Conduct Cost Analysis

Analyze the total cost of materials, tools, and shipping from potential suppliers.

– Price Comparison: Gather quotes from multiple suppliers to identify competitive pricing.

– Budgeting: Factor in additional costs such as duties and taxes for international shipments.

Conducting a thorough cost analysis will aid in making informed purchasing decisions that align with your budget constraints.

Step 6: Plan for Post-Production Finishing

Identify finishing products that enhance the durability and appearance of the holster. Key items include:

– Conditioners: Use Neatsfoot oil or similar products to moisturize and protect the leather.

– Dyes and Finishes: Consider eco-friendly dyes and finishes to provide a professional look.

Planning for finishing processes ensures that the final product is visually appealing and long-lasting.

Illustrative image related to how to make a leather gun holster

Step 7: Establish a Quality Control Protocol

Implement a quality control system for inspecting the finished holsters.

– Inspection Criteria: Define standards for stitching quality, leather defects, and overall design integrity.

– Feedback Loop: Create a process for gathering customer feedback to continuously improve product quality.

A robust quality control protocol will help maintain high standards and build customer trust in your products.

Comprehensive Cost and Pricing Analysis for how to make a leather gun holster Sourcing

What Are the Key Cost Components for Making Leather Gun Holsters?

When analyzing the cost structure for producing leather gun holsters, several key components must be considered. Materials form the foundation of the cost structure, with high-quality leather being the most significant expense. Expect to pay between $5 to $15 per square foot for premium leather, depending on thickness and finish. Additional materials like stitching, adhesives, and hardware (such as Chicago screws) can add another $2 to $5 to the total cost per unit.

Labor costs will vary based on the complexity of the design and the skill level of the craftsmen. In regions with lower labor costs, such as parts of Africa and South America, you might see hourly wages as low as $5-$10, while skilled artisans in Europe might command rates of $20-$40 per hour. Manufacturing overhead includes expenses related to facility maintenance, utilities, and administrative costs, typically estimated at 15-25% of direct labor costs.

Illustrative image related to how to make a leather gun holster

Tooling is another essential cost, particularly for custom or specialized designs. Initial investments in tools can range from $200 to $1,000, depending on the scale of production and the precision required. Quality Control (QC) processes should also be factored in, as ensuring each holster meets specific standards can add an additional 10-15% to overall production costs.

Finally, logistics expenses, including shipping and handling, can vary significantly based on the destination and Incoterms. International shipping can add $2 to $10 per unit, depending on the volume and shipping method chosen.

How Do Price Influencers Affect Leather Gun Holster Costs?

Several price influencers can impact the overall cost of leather gun holster production. Volume and Minimum Order Quantity (MOQ) are crucial; larger orders typically reduce per-unit costs due to economies of scale. Customization options—like unique designs or specialized materials—can also increase costs, as they often require additional labor and specialized tools.

Illustrative image related to how to make a leather gun holster

The choice of materials and their quality directly influences pricing. Premium leather with certifications (such as eco-friendliness or sustainability) may cost more but can attract higher-end customers. Supplier factors such as reliability, reputation, and geographical location also play a role; sourcing from local suppliers may reduce shipping costs and lead times, while overseas suppliers might offer lower raw material prices.

What Buyer Tips Should International B2B Buyers Consider?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of pricing is essential. Negotiation can be a powerful tool; many suppliers are willing to offer discounts for bulk purchases or long-term contracts.

When considering cost-efficiency, evaluate the Total Cost of Ownership (TCO) rather than just the upfront cost. This includes maintenance, durability, and potential resale value of the holsters, which can significantly impact the overall investment.

Be mindful of pricing nuances related to international trade. Currency fluctuations, tariffs, and local regulations can affect the final price. Understanding Incoterms is vital for clarifying responsibilities for shipping, handling, and insurance costs, which can vary significantly based on the agreement.

Illustrative image related to how to make a leather gun holster

Conclusion and Disclaimer

The above insights provide a framework for understanding the costs and pricing associated with leather gun holster production. However, prices may vary based on specific supplier agreements, market conditions, and customization needs. Always consult with potential suppliers for the most accurate and up-to-date pricing to ensure a successful B2B procurement process.

Alternatives Analysis: Comparing how to make a leather gun holster With Other Solutions

Introduction

In the realm of crafting gun holsters, particularly leather holsters, various methods and technologies exist that can cater to diverse needs and preferences. Understanding the strengths and weaknesses of each approach is vital for B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. This analysis compares the traditional leather gun holster-making process against alternative solutions, providing insights that can guide procurement decisions.

Comparison Table

| Comparison Aspect | How To Make A Leather Gun Holster | Alternative 1: Kydex Holster Production | Alternative 2: Nylon Holster Manufacturing |

|---|---|---|---|

| Performance | High durability and customization options; retains shape well. | Excellent retention and quick-draw capability; lightweight. | Moderate durability; less shape retention than leather or Kydex. |

| Cost | Moderate to high, depending on leather quality and tools. | Generally lower than leather; bulk production reduces costs. | Low; materials are inexpensive and readily available. |

| Ease of Implementation | Requires skill in leatherworking and access to specialized tools. | Easier and faster to mold with minimal tooling required. | Very easy to produce; often involves simple sewing techniques. |

| Maintenance | Requires regular conditioning to maintain leather quality. | Low maintenance; easy to clean and resistant to moisture. | Low maintenance; may require occasional checks for wear and tear. |

| Best Use Case | Ideal for custom, high-end applications or specific fit requirements. | Best for tactical or competitive environments where speed is crucial. | Suitable for budget-conscious buyers or casual users needing basic protection. |

Detailed Breakdown

Kydex Holster Production

Kydex holsters are molded from a thermoplastic material that offers a lightweight and durable alternative to leather. The performance aspect is notably strong; Kydex holsters provide excellent retention and allow for a smooth draw, making them a favorite among law enforcement and competitive shooters. The cost is generally lower than leather holsters, especially in bulk production scenarios. Implementation is straightforward, requiring less skill than leather crafting, which can be a significant advantage for manufacturers looking to scale production quickly. Maintenance is minimal, as Kydex is resistant to moisture and easy to clean. However, Kydex lacks the aesthetic appeal and comfort of leather, making it less suitable for those seeking a traditional look or feel.

Nylon Holster Manufacturing

Nylon holsters represent a cost-effective solution for users who prioritize affordability and ease of use. The performance is decent, but nylon does not offer the same shape retention as leather or Kydex, which may be a drawback for some users. The production cost is among the lowest, making it an attractive option for budget-conscious consumers or retailers. The implementation process is simple, often requiring basic sewing skills, which opens the market to a wider range of manufacturers. Maintenance is also minimal, though users should regularly inspect for wear. Nylon holsters are best suited for casual users or as temporary solutions, as they may not provide the same level of durability or fit as leather or Kydex options.

Conclusion

Choosing the right holster manufacturing method involves a careful consideration of performance, cost, ease of implementation, maintenance, and the intended use case. For B2B buyers, the decision may hinge on factors such as target market preferences, production capabilities, and budget constraints. Leather holsters offer unmatched customization and durability but require more investment and skill. In contrast, Kydex and nylon options provide quick and economical solutions that may appeal to different customer segments. By evaluating these alternatives, businesses can align their offerings with market demands and optimize their production strategies.

Illustrative image related to how to make a leather gun holster

Essential Technical Properties and Trade Terminology for how to make a leather gun holster

What Are the Critical Technical Properties for Leather Gun Holsters?

When manufacturing leather gun holsters, understanding the technical properties of materials and construction methods is crucial for ensuring quality and performance. Here are some essential specifications:

-

Material Grade

Leather is categorized into various grades, such as full-grain, top-grain, and genuine leather. Full-grain leather is the highest quality, retaining the natural texture and durability, which is crucial for a holster that needs to withstand wear and tear. B2B buyers should prioritize sourcing full-grain leather for its longevity and ability to form-fit around the firearm. -

Thickness

The thickness of the leather, typically measured in ounces (oz), directly affects the holster’s strength and rigidity. A thickness of 8 oz is common for gun holsters, providing a balance between flexibility and protection. Buyers must ensure that the thickness chosen aligns with the intended use of the holster, as it impacts comfort and retention. -

Stitching Specifications

The stitching type and thread quality are vital for durability. Using waxed thread and employing techniques like saddle stitching can enhance the longevity of the seams. B2B partners should specify stitch density (number of stitches per inch) and thread thickness to ensure the product meets their durability standards. -

Moisture Resistance

Leather’s natural properties can absorb moisture, leading to degradation over time. Treatments with oils, such as Neatsfoot oil, can enhance moisture resistance. Buyers should inquire about treatments applied during manufacturing to ensure the holsters can withstand diverse environmental conditions, particularly in regions with high humidity. -

Finish Type

The finish applied to leather affects both aesthetics and functionality. Common finishes include aniline, semi-aniline, and pigmented. Each type offers different levels of protection and appearance. For B2B buyers, understanding the finish type is essential for aligning the product with their branding and functional requirements. -

Fit and Form

Precision in forming the leather around the firearm is critical for user safety and comfort. Techniques such as vacuum forming ensure a snug fit. Buyers should emphasize the importance of accurate molding processes, as this directly influences user experience and retention.

What Are Common Trade Terms in Leather Holster Manufacturing?

Familiarity with industry jargon can streamline communication and negotiations in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or products that are used in another company’s final product. In the context of holster manufacturing, buyers may work with OEMs to produce custom designs or specifications that fit their branding. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest order quantity a supplier is willing to accept. Understanding MOQ is critical for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate terms that align with their sales forecasts. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to request pricing and availability from suppliers. It’s essential for establishing clear expectations and comparisons among manufacturers. B2B buyers should prepare detailed RFQs to ensure they receive accurate and competitive bids. -

Incoterms

International Commercial Terms (Incoterms) are standard trade terms that define the responsibilities of buyers and sellers in international transactions. They are crucial for understanding shipping responsibilities and costs, particularly in cross-border trade, which is common in regions such as Africa and South America. -

Lead Time

Lead time is the period between placing an order and receiving the product. It’s vital for planning inventory and sales strategies. Buyers should always clarify lead times with suppliers to ensure they can meet market demands. -

Customization Options

This term refers to the ability to alter standard products to meet specific buyer needs. In leather holster manufacturing, this could include unique designs, colors, or features. Buyers should explore customization options to enhance their product offerings and cater to niche markets.

Understanding these technical properties and trade terms can significantly enhance the decision-making process for B2B buyers in the leather gun holster market, ensuring they select high-quality products that meet their specific needs.

Illustrative image related to how to make a leather gun holster

Navigating Market Dynamics and Sourcing Trends in the how to make a leather gun holster Sector

What Are the Key Drivers and Trends in the Leather Gun Holster Market?

The leather gun holster market is influenced by several global drivers, including the increasing demand for personal safety and self-defense products, particularly in regions with rising crime rates. This trend is particularly noticeable in Africa and South America, where consumers prioritize reliable and durable holsters. Additionally, the growing popularity of shooting sports and recreational hunting is fueling the market, prompting manufacturers to innovate and offer a wider variety of holsters tailored to different firearms.

Emerging B2B tech trends, such as digital design and 3D printing, are transforming the way holsters are produced. These technologies enable manufacturers to create customized designs that cater to specific firearm models, enhancing user satisfaction. Furthermore, e-commerce platforms are becoming crucial for international buyers, providing access to a broader range of suppliers and products. In regions like the Middle East and Europe, there is also a noticeable shift towards online procurement, enabling businesses to streamline their sourcing processes and reduce costs.

Market dynamics are also shaped by regulatory factors, as different countries impose varying restrictions on firearm ownership and usage. Understanding these regulations is essential for international buyers, as compliance can significantly affect sourcing decisions. The competitive landscape is also evolving, with both established brands and new entrants vying for market share, making it vital for B2B buyers to stay informed about their options and negotiate favorable terms.

How Does Sustainability Impact the Leather Gun Holster Supply Chain?

Sustainability and ethical sourcing have become increasingly important in the leather gun holster sector. The environmental impact of leather production, including deforestation, water usage, and chemical waste, necessitates a shift towards more sustainable practices. B2B buyers are now seeking suppliers who prioritize eco-friendly materials and processes, such as vegetable-tanned leather, which reduces the use of harmful chemicals during production.

Illustrative image related to how to make a leather gun holster

Moreover, the importance of ethical supply chains cannot be overstated. International buyers are increasingly aware of labor practices and are inclined to partner with manufacturers that uphold fair working conditions and humane treatment of workers. Certifications such as the Leather Working Group (LWG) or Global Organic Textile Standard (GOTS) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

In addition, there is a growing trend towards circular economy principles, where manufacturers are encouraged to implement recycling and waste reduction strategies. This approach not only minimizes environmental impact but also appeals to a consumer base that is more environmentally conscious. As a result, B2B buyers must prioritize sourcing from suppliers that demonstrate a commitment to sustainability, as this will likely enhance brand reputation and customer loyalty in the long term.

What Is the Historical Context of Leather Gun Holster Production?

The production of leather gun holsters has a rich history dating back to the early days of firearms. Initially, holsters were crafted by hand from locally sourced materials, with artisans employing traditional techniques to ensure durability and functionality. Over time, as firearms became more prevalent in society, the demand for specialized holsters grew, leading to the establishment of dedicated workshops and manufacturers.

The evolution of leatherworking techniques and the introduction of new materials have significantly influenced the design and production of holsters. In the 20th century, advancements in synthetic materials provided alternatives to traditional leather, but the demand for high-quality leather holsters has persisted due to their aesthetic appeal and superior performance. Today, the market continues to evolve, driven by consumer preferences for customization, comfort, and style, while still honoring the craftsmanship and heritage of leather holster making.

This historical context is vital for B2B buyers, as understanding the evolution of the industry can inform sourcing decisions and highlight the importance of quality craftsmanship in the current market.

Illustrative image related to how to make a leather gun holster

Frequently Asked Questions (FAQs) for B2B Buyers of how to make a leather gun holster

-

How do I select the right leather for making a gun holster?

When sourcing leather for gun holsters, consider factors such as thickness, durability, and finish. Full-grain leather is often preferred for its strength and natural look, while vegetable-tanned leather is ideal for molding. Aim for a weight of at least 8 oz for robust designs. Additionally, test samples from suppliers to ensure the leather meets your specifications in terms of flexibility and resistance to wear. -

What techniques can I use to ensure a precise fit when making a leather gun holster?

To achieve a precise fit, start by creating a template based on the firearm’s dimensions. Use wet-forming techniques by soaking the leather, which allows it to mold around the gun. Employ vacuum sealing to enhance the forming process, ensuring the leather captures all contours. Always measure multiple times and consider adjustments based on the specific firearm to avoid fit issues. -

What are the common methods for stitching leather gun holsters?

Popular stitching methods include saddle stitching and machine stitching. Saddle stitching is favored for its strength and durability, requiring two needles and waxed thread. For a more efficient production process, consider using industrial sewing machines equipped for leatherwork. Ensure that the stitching is spaced evenly and reinforced at stress points to enhance the holster’s longevity. -

How can I customize leather gun holsters for my clients?

Customization can be achieved through various means such as leather type, color, and stitching patterns. Additionally, consider offering personalization options like embossing initials or logos. Engage with clients to understand their specific needs and preferences. Keep in mind that customization may affect production timelines and minimum order quantities (MOQs), so communicate clearly about these aspects. -

What are the minimum order quantities (MOQs) for leather gun holsters?

MOQs can vary significantly based on the supplier and the complexity of the holster design. Typically, MOQs may range from 50 to 100 units for standard designs. For customized or unique designs, the MOQ might be higher due to increased production costs. It’s essential to discuss your needs with suppliers upfront to ensure they can meet your order requirements. -

What payment terms should I expect when sourcing leather gun holsters internationally?

Payment terms can vary widely among suppliers. Common practices include upfront payments, deposits followed by balance payments upon delivery, or net 30/60 terms. Ensure to clarify the payment method accepted, whether it be bank transfers, letters of credit, or online payment systems. Additionally, consider negotiating terms that align with your cash flow needs and the supplier’s policies. -

How do I ensure quality assurance (QA) in leather gun holster production?

Implementing a robust quality assurance process is crucial. Establish clear specifications and standards with your supplier regarding materials, stitching, and finishing. Consider conducting periodic inspections during production and request samples before full-scale production. Additionally, having a return policy in place can help address any quality issues that may arise post-delivery. -

What logistics considerations should I keep in mind when importing leather gun holsters?

When importing, factor in shipping methods, customs regulations, and duties that may apply to leather products. Choose reliable logistics partners experienced in handling international shipments to ensure timely delivery. Be aware of any import restrictions or certifications required in your target market. Planning for potential delays and understanding the total landed cost will help in managing your supply chain effectively.

Top 3 How To Make A Leather Gun Holster Manufacturers & Suppliers List

1. Instructables – Fitted Leather Holster for Colt 1911

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Fitted Leather Holster for Colt Model 1911 .45 Caliber pistol; made from heavy weight leather (approximately 8 oz); formed using isopropyl alcohol (recommended to use water instead); assembly involves gluing two halves with Barge Cement or E6000; features belt loops for proper angle when worn; stitched with a technique of over and under passes; finished with Chicago screws for added strength; edge…

2. Leatherworker – Sewing Machines

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 1) Hand stitching – relatively inexpensive method for leather holster making. 2) Machine sewing – relatively expensive method. Basic new hand-operated sewing machine from $1000 USD and motorized sewing machine from $2800 USD. Recommended sewing machines include: Juki DNU – 1541S, Juki DU – 1181N, Singer 29K – 71 (1949), Chinese Patcher (Tinkers Delight), Warlock TSC-441, Techsew 2750 Pro, Consew D…

3. Tandy Leather – Holster Design Guide

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Holster Design Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how to make a leather gun holster

In the competitive landscape of leather gun holster production, strategic sourcing is paramount for success. By selecting high-quality materials, such as heavy-weight leather and reliable adhesives, manufacturers can ensure durability and functionality in their products. Leveraging local suppliers can also reduce shipping costs and lead times, while fostering relationships that enhance trust and collaboration.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of leather holster making can unlock opportunities for tailored solutions that meet diverse market needs. By investing in skilled labor and advanced tools, businesses can improve their production quality and expand their product offerings, catering to a growing customer base.

Looking ahead, the demand for custom leather goods, including holsters, is likely to rise. Engaging with innovative suppliers and exploring sustainable sourcing options will not only enhance product quality but also align with global trends towards responsible manufacturing. We encourage international buyers to take proactive steps in sourcing materials and forming partnerships that will drive their business forward in this evolving market.

Illustrative image related to how to make a leather gun holster

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.