Introduction: Navigating the Global Market for green leather fabric

In an era where sustainability is paramount, navigating the global market for green leather fabric presents both opportunities and challenges for international B2B buyers. Sourcing eco-friendly materials, such as green leather, can significantly enhance product offerings while addressing the growing consumer demand for environmentally responsible options. However, with a plethora of suppliers and varying standards of sustainability, the process can be daunting. This guide aims to demystify the complexities surrounding green leather fabric by providing a comprehensive overview of its types, applications, and supplier vetting processes.

From upholstery in high-end furniture to durable automotive interiors, green leather serves diverse industries and meets varying aesthetic and functional needs. Buyers will gain insights into evaluating suppliers based on sustainability certifications, quality control measures, and pricing strategies, enabling them to make informed purchasing decisions. Furthermore, this guide addresses specific regional considerations, particularly for buyers in Africa, South America, the Middle East, and Europe, including Saudi Arabia and Vietnam, ensuring that their sourcing strategies align with local market demands and regulations. By empowering B2B buyers with knowledge and actionable insights, this resource will facilitate a more sustainable and profitable approach to incorporating green leather into their product lines.

Table Of Contents

- Top 5 Green Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for green leather fabric

- Understanding green leather fabric Types and Variations

- Key Industrial Applications of green leather fabric

- 3 Common User Pain Points for ‘green leather fabric’ & Their Solutions

- Strategic Material Selection Guide for green leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for green leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘green leather fabric’

- Comprehensive Cost and Pricing Analysis for green leather fabric Sourcing

- Alternatives Analysis: Comparing green leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for green leather fabric

- Navigating Market Dynamics and Sourcing Trends in the green leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of green leather fabric

- Strategic Sourcing Conclusion and Outlook for green leather fabric

- Important Disclaimer & Terms of Use

Understanding green leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| المفروشات الجلدية | Durable, available in various textures and finishes | Furniture, automotive, interior design | Pros: High durability, aesthetic appeal; Cons: Higher cost compared to synthetic options. |

| Embossed Leather | Unique patterns and textures created through embossing | Fashion accessories, upholstery | Pros: Distinctive look, customizable; Cons: May be less durable than full-grain leather. |

| Pearlized Leather | Shimmering, iridescent finish that catches light | Luxury goods, high-end furniture | Pros: Eye-catching, luxurious feel; Cons: Can be more expensive and requires careful maintenance. |

| جلد نابا | Soft and supple texture, often dyed in vibrant colors | Apparel, luxury goods, accessories | Pros: Softness and comfort; Cons: Less resistant to wear and tear compared to other types. |

| Vegetable-Tanned Leather | Eco-friendly tanning process, natural look and feel | Sustainable products, artisan goods | Pros: Environmentally friendly, develops a patina; Cons: Can be more expensive and less uniform in color. |

What Are the Characteristics of Upholstery Leather?

Upholstery leather is a primary choice for B2B buyers in sectors such as furniture manufacturing and automotive design. Its durability is a key feature, allowing it to withstand wear and tear in high-traffic areas. Available in a variety of textures and finishes, upholstery leather can meet diverse aesthetic requirements. Buyers should consider factors such as the leather’s thickness and treatment to ensure it suits specific applications, balancing cost with quality.

How Does Embossed Leather Stand Out?

Embossed leather is distinguished by its unique patterns and textures, created through a pressing technique. This type of leather is popular in fashion accessories and upholstery where a distinctive look is desired. B2B buyers should note that while embossed leather offers customization options, it may not match the durability of full-grain leather. Understanding the intended use and potential wear is crucial when selecting this type for projects.

What Makes Pearlized Leather a Luxury Option?

Pearlized leather features a shimmering finish that adds a luxurious touch to products. It is often used in high-end furniture and luxury goods, appealing to markets that prioritize aesthetics. While it provides a visually striking appearance, B2B buyers should be mindful of its maintenance requirements and higher price point. Assessing the target market’s preferences can guide purchasing decisions for pearlized leather.

Why Choose Nappa Leather for Premium Products?

Nappa leather is known for its soft and supple texture, making it ideal for apparel and luxury goods. Its vibrant colors enhance its appeal in fashion markets. However, B2B buyers should be aware that Nappa leather may not withstand heavy wear as effectively as other leathers. It is essential to evaluate the specific use case and longevity expectations when considering Nappa leather for products.

What Are the Benefits of Vegetable-Tanned Leather?

Vegetable-tanned leather is produced using eco-friendly methods, making it a popular choice for sustainable products and artisan goods. Its natural look and ability to develop a unique patina over time add character to items. However, B2B buyers should anticipate a higher cost and potential color variations. Understanding the market demand for sustainable options can influence purchasing decisions for vegetable-tanned leather.

Key Industrial Applications of green leather fabric

| Industry/Sector | Specific Application of green leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for eco-friendly furniture | Enhances brand image through sustainability | Ensure compliance with international eco-certifications |

| Automotive | Interior trims and seating | Meets consumer demand for sustainable options | Assess durability and ease of maintenance |

| Fashion and Accessories | Handbags, wallets, and apparel | Appeals to environmentally conscious consumers | Verify sourcing transparency and ethical production |

| Interior Design | Wall coverings and decorative accents | Adds luxury and eco-credibility to designs | Consider color variety and customizability options |

| Hospitality | Upholstery for hotel furniture and decor | Improves guest experience with sustainable choices | Evaluate fire safety standards and maintenance needs |

How is green leather fabric used in furniture manufacturing, and what benefits does it provide?

In the furniture manufacturing sector, green leather fabric is increasingly utilized for upholstery in eco-friendly furniture designs. This material not only enhances the aesthetic appeal of furniture but also aligns with growing consumer preferences for sustainable products. By opting for green leather, manufacturers can strengthen their brand image and attract environmentally conscious buyers. International B2B buyers should prioritize suppliers who comply with eco-certifications and provide transparent sourcing information to ensure the sustainability of their purchases.

Illustrative image related to green leather fabric

In what ways is green leather fabric applied in the automotive industry?

The automotive industry employs green leather fabric primarily for interior trims and seating, catering to a rising demand for sustainable materials. This application not only meets regulatory requirements but also aligns with consumer expectations for eco-friendly vehicles. Buyers in this sector should consider the durability and maintenance aspects of green leather, ensuring that the fabric can withstand the rigors of everyday use while maintaining its appearance over time. Additionally, sourcing from suppliers with a proven track record of sustainability practices is crucial.

What role does green leather fabric play in fashion and accessories?

In the fashion industry, green leather fabric is a popular choice for creating handbags, wallets, and apparel, appealing to a demographic that values sustainability. This material allows designers to offer stylish products without compromising on environmental responsibility. For B2B buyers, it is essential to verify the sourcing transparency of the green leather, ensuring that it comes from ethical production processes. This not only boosts the brand’s reputation but also attracts a loyal customer base that prioritizes eco-friendly choices.

How can interior designers leverage green leather fabric in their projects?

Interior designers are increasingly incorporating green leather fabric into their projects for wall coverings and decorative accents. This application provides a luxurious feel while contributing to sustainable design practices. By using green leather, designers can enhance the eco-credibility of their projects, making them more appealing to environmentally conscious clients. Buyers should consider the variety of colors and textures available, as well as the customizability options that can elevate their design concepts.

Illustrative image related to green leather fabric

What advantages does green leather fabric offer to the hospitality industry?

In the hospitality sector, green leather fabric is used for upholstery in hotel furniture and decor, significantly enhancing the guest experience through its luxurious and sustainable qualities. This material not only contributes to a sophisticated ambiance but also aligns with the growing trend of sustainability in hospitality. B2B buyers in this industry should evaluate the fire safety standards of the green leather and consider maintenance requirements to ensure longevity and compliance with health regulations.

3 Common User Pain Points for ‘green leather fabric’ & Their Solutions

Scenario 1: Navigating Sourcing Challenges for Green Leather Fabric

The Problem: B2B buyers often face difficulties in sourcing green leather fabric that meets both sustainability standards and quality expectations. In regions like Africa and the Middle East, where local suppliers may not have established sustainable practices, buyers struggle to find reliable sources that can provide eco-friendly options without compromising on quality. This can lead to delays in production schedules and increased costs, as buyers may have to settle for less desirable alternatives or spend time sourcing from international suppliers.

The Solution: To effectively navigate these sourcing challenges, buyers should establish strong relationships with reputable suppliers who specialize in sustainable leather. This can be achieved by researching suppliers who prioritize environmental stewardship and have transparent supply chains. Participating in trade shows and industry conferences focused on sustainable materials can also provide valuable networking opportunities. Additionally, consider utilizing online platforms that aggregate verified sustainable leather suppliers, allowing for easier comparison of options. When engaging with suppliers, request certifications that prove sustainability claims, such as ISO 14001 or the Leather Working Group certification. By ensuring that your supply chain aligns with sustainability goals, you not only enhance your brand’s reputation but also mitigate risks associated with sourcing.

Scenario 2: Understanding the Varied Quality of Green Leather Fabrics

The Problem: Another common pain point is the inconsistency in the quality of green leather fabrics. Buyers may receive samples that look and feel different from what is delivered, leading to dissatisfaction and potential financial loss. This inconsistency can be particularly problematic for manufacturers in sectors like automotive and furniture, where quality and durability are paramount.

The Solution: To address this issue, buyers should implement a rigorous quality control process when evaluating green leather fabrics. Start by ordering samples from multiple suppliers and conducting a thorough assessment of each sample’s texture, durability, and colorfastness. Additionally, set clear specifications for what you require in terms of thickness, finish, and environmental impact. Engaging a third-party quality assurance service can also provide an unbiased assessment of the materials before large orders are placed. Maintaining an open line of communication with suppliers regarding any discrepancies can foster a collaborative relationship that encourages improvements in product consistency. Establishing a clear return policy for unsatisfactory goods can further safeguard your investment.

Scenario 3: Addressing Limited Color and Style Options in Green Leather Fabrics

The Problem: Many B2B buyers find that the selection of green leather fabrics is often limited in terms of color and style. This can be particularly challenging for businesses aiming to create distinctive products that stand out in the market. In regions such as South America and Europe, where design trends can vary significantly, the lack of variety can hinder creativity and brand differentiation.

The Solution: To overcome this limitation, buyers should actively seek suppliers who offer custom dyeing and finishing services. By collaborating with manufacturers who can create bespoke colors and finishes, you can ensure that your products align with market trends and customer preferences. Additionally, consider investing in smaller runs of custom fabrics, which can be more financially viable and allow for experimentation with unique styles. Engaging with design professionals to forecast upcoming trends can also inform your sourcing strategy, ensuring you are ahead of the curve. Utilizing digital design tools can help visualize potential color combinations and styles, making it easier to communicate your needs to suppliers. This proactive approach not only enhances your product line but also positions your brand as a leader in innovation within your industry.

Strategic Material Selection Guide for green leather fabric

What Are the Key Materials Used in Green Leather Fabric?

When selecting green leather fabric for various applications, international B2B buyers should consider a range of materials that contribute to sustainability while meeting performance standards. Here are four common materials used in green leather fabric, along with their properties, advantages, disadvantages, and specific considerations for international markets.

What Are the Key Properties of Vegetable-Tanned Leather?

Vegetable-tanned leather is made using natural tannins derived from plant sources. This method is eco-friendly, as it avoids harmful chemicals found in traditional tanning processes.

- Key Properties: It offers excellent breathability and moisture-wicking capabilities, making it suitable for upholstery and fashion items. It has a moderate temperature resistance, typically up to 70°C (158°F).

- Pros & Cons: The durability is high, with a lifespan that can exceed decades if properly maintained. However, it can be costlier due to the lengthy tanning process and is less resistant to water and stains compared to synthetic alternatives.

- Impact on Application: Ideal for high-end furniture and accessories, vegetable-tanned leather ages beautifully, developing a unique patina over time.

- Considerations for International Buyers: Compliance with environmental regulations such as REACH in Europe is crucial. Buyers from regions like Africa and South America may need to consider local climate conditions that can affect leather maintenance.

How Does Recycled Leather Compare?

Recycled leather is produced from scraps and offcuts from the leather industry, making it a sustainable choice.

Illustrative image related to green leather fabric

- Key Properties: It retains much of the original leather’s durability and aesthetic appeal. However, its performance can vary based on the quality of the recycled materials used.

- Pros & Cons: Cost-effective and environmentally friendly, it reduces waste significantly. However, the manufacturing process can be complex, leading to variability in quality and texture.

- Impact on Application: Suitable for a range of products from bags to upholstery, recycled leather can appeal to eco-conscious consumers.

- Considerations for International Buyers: Buyers should ensure that recycled leather meets local standards for durability and safety, such as ASTM or JIS certifications.

What Are the Benefits of Synthetic Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is increasingly being produced with eco-friendly processes.

- Key Properties: It is highly resistant to water, stains, and UV light, making it suitable for outdoor applications. Its temperature resistance can vary, but typically it performs well in moderate climates.

- Pros & Cons: Synthetic leather is generally less expensive and easier to maintain than natural leather. However, it may lack the breathability and tactile qualities of genuine leather.

- Impact on Application: Commonly used in automotive interiors and furniture, synthetic leather can be tailored to meet specific design needs.

- Considerations for International Buyers: It’s essential to verify compliance with international standards for VOC emissions and material safety, especially in regions with strict environmental regulations.

Why Choose Eco-Friendly Coated Leather?

Eco-friendly coated leather involves applying a sustainable coating to natural leather, enhancing its durability while maintaining its natural properties.

- Key Properties: This material combines the luxurious feel of leather with added resistance to scratches and stains. It can withstand temperatures up to 60°C (140°F).

- Pros & Cons: Offers a balance of durability and aesthetic appeal, making it suitable for high-end applications. However, the coating can sometimes reduce the leather’s breathability.

- Impact on Application: Ideal for luxury goods and high-traffic furniture, eco-friendly coated leather provides a sustainable option without compromising on quality.

- Considerations for International Buyers: Buyers should look for certifications like OEKO-TEX to ensure that the coatings used are free from harmful substances.

Summary Table of Material Selection for Green Leather Fabric

| المواد | Typical Use Case for green leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end furniture and accessories | Eco-friendly and durable | Higher cost and less water-resistant | عالية |

| Recycled Leather | Bags and upholstery | Cost-effective and sustainable | Variable quality | Medium |

| جلد صناعي | Automotive interiors and furniture | Water and UV resistant | Less breathable | منخفضة |

| Eco-Friendly Coated Leather | Luxury goods and high-traffic furniture | Durable and aesthetically pleasing | Reduced breathability | Medium |

This guide provides a foundational understanding of materials for green leather fabric, facilitating informed purchasing decisions for international B2B buyers.

Illustrative image related to green leather fabric

In-depth Look: Manufacturing Processes and Quality Assurance for green leather fabric

What Are the Key Stages in the Manufacturing Process of Green Leather Fabric?

The manufacturing of green leather fabric involves several critical stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages is essential for B2B buyers seeking high-quality leather products.

Material Preparation: Sourcing and Treatment

The first step in the manufacturing process is the careful sourcing of raw materials, typically cowhide. Ethical sourcing is a cornerstone of green leather production, ensuring that the hides come from sustainable farms where animal welfare is prioritized. Once sourced, the hides undergo a cleaning process to remove impurities and prepare them for tanning.

Tanning is a crucial process that transforms raw hides into durable leather. In green leather production, environmentally friendly tanning methods, such as vegetable tanning, are often employed. This method uses natural tannins from plant sources, reducing the ecological impact compared to traditional chromium tanning methods.

Forming: Shaping the Leather

After tanning, the leather is dried and conditioned. During this phase, the hides are cut into various shapes and sizes, depending on the intended use—be it upholstery, fashion, or accessories. Advanced cutting techniques such as laser cutting may be utilized to ensure precision and minimize waste.

Once cut, the leather pieces may undergo embossing or printing to enhance their visual appeal. This step can include adding textures or patterns that align with current market trends, making the leather more attractive to consumers.

Illustrative image related to green leather fabric

Assembly: Crafting the Final Product

In the assembly phase, the prepared leather pieces are stitched together to create the final product. This could involve sewing leather for upholstery, crafting bags, or producing garments. Skilled artisans often oversee this stage, ensuring that the craftsmanship meets high-quality standards.

Quality control checkpoints are integrated into the assembly process to catch any defects early. Regular inspections are conducted to ensure that stitching is even, and that the leather pieces fit together seamlessly.

Finishing: Enhancing Durability and Aesthetics

Finishing treatments are applied to enhance the leather’s durability and aesthetic qualities. This may include applying protective coatings, dyes, or conditioners that improve the leather’s resistance to wear and tear. Sustainable practices are increasingly being adopted, utilizing non-toxic and biodegradable materials to ensure that the finishing processes align with green manufacturing principles.

How Is Quality Assurance Implemented in Green Leather Fabric Production?

Quality assurance (QA) is vital in maintaining the integrity of green leather fabric. It ensures that the product not only meets international standards but also fulfills customer expectations.

What Are the Relevant International Standards for Quality Assurance?

For B2B buyers, understanding applicable international standards is crucial. ISO 9001 is a widely recognized quality management standard that ensures organizations consistently meet customer and regulatory requirements. Compliance with ISO standards indicates that a manufacturer has implemented effective QA processes.

Illustrative image related to green leather fabric

Additionally, industry-specific certifications such as CE marking (for products sold within the European Economic Area) and API standards (for products used in the oil and gas industry) may apply depending on the intended use of the leather. Buyers should verify that their suppliers hold relevant certifications to ensure compliance with local regulations and market expectations.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is embedded in the manufacturing process through various checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival. Suppliers must provide documentation proving the sustainability and quality of the hides, including traceability to ensure ethical sourcing.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to monitor the quality of the leather. This includes checking for defects during tanning, cutting, and assembly.

-

Final Quality Control (FQC): Before the finished products are shipped, a thorough inspection is conducted to ensure they meet all specifications and quality standards. This includes checking the final appearance, durability, and functionality of the leather goods.

What Testing Methods Are Commonly Used in the Quality Assurance Process?

Various testing methods are employed to assess the quality of green leather fabric, including:

-

Physical Testing: This includes tensile strength tests, abrasion resistance tests, and colorfastness tests to ensure the leather can withstand everyday use.

-

Chemical Testing: This ensures that the leather is free from harmful chemicals and adheres to environmental regulations. Tests for pH levels, heavy metals, and other toxic substances are conducted.

-

Visual Inspections: Trained quality inspectors perform visual checks for consistency in color, texture, and finish.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are actionable steps to consider:

Conduct Audits and Assessments

Request regular audits of the manufacturing facility, focusing on their quality management systems and compliance with international standards. Engaging third-party auditing firms can provide an unbiased assessment of the supplier’s processes.

Illustrative image related to green leather fabric

Review Quality Control Reports

Ask for detailed quality control reports that outline inspection results and any corrective actions taken. This transparency will give insight into the supplier’s commitment to maintaining high standards.

Engage in Third-Party Inspections

Consider utilizing third-party inspection services to evaluate the quality of goods before shipment. This can help mitigate risks associated with receiving substandard products.

What Are the Quality Control and Certification Nuances for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific quality control and certification nuances:

-

Regional Standards: Different regions may have varying standards and regulations regarding leather production. Understanding local market requirements is essential for compliance.

-

Cultural Considerations: Buyers should also consider cultural perceptions of sustainability and quality. Engaging with local experts can provide valuable insights into market expectations.

-

Supply Chain Transparency: Establishing a transparent supply chain is increasingly important. Buyers should seek suppliers who are willing to share information about their sourcing and manufacturing processes.

By paying close attention to these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing green leather fabric, ensuring they partner with reliable suppliers committed to sustainability and quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘green leather fabric’

مقدمة

Sourcing green leather fabric requires careful consideration to ensure quality, sustainability, and compliance with industry standards. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process efficiently, making informed decisions that align with both business objectives and environmental responsibilities.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital before initiating the sourcing process. Identify the type of green leather fabric needed, including its intended use, thickness, grain, and finish. This clarity will not only streamline communication with suppliers but also ensure that the final product meets your quality and functional requirements.

- Consider the application: Will the leather be used for upholstery, automotive interiors, or fashion?

- Specify environmental standards: Determine if you require certifications such as OEKO-TEX or GOTS for organic materials.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify suppliers who specialize in green leather fabric. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors.

- Focus on sustainability: Look for suppliers who highlight their eco-friendly practices and sustainable sourcing methods.

- Evaluate their product range: Ensure they offer a variety of colors and textures that align with your specifications.

Step 3: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of the green leather fabric to assess quality. This step is crucial to ensure that the material meets your expectations in terms of texture, color, and durability.

- Inspect the samples: Check for consistency in color and texture across different pieces.

- Test for performance: Consider how the leather reacts to wear, tear, and environmental factors relevant to your product.

Step 4: Verify Supplier Certifications and Compliance

Before finalizing your supplier choice, verify their certifications and compliance with international standards. This ensures that the leather is produced ethically and sustainably.

- Check for relevant certifications: Ensure the supplier holds certifications like LWG (Leather Working Group) or ISO 14001 for environmental management.

- Review compliance records: Look into their track record for adhering to labor and environmental regulations.

Step 5: Discuss Terms and Conditions Clearly

Engage in detailed discussions regarding terms and conditions with your chosen supplier. This includes pricing, payment terms, delivery schedules, and return policies.

- Negotiate pricing: Ensure that the pricing aligns with your budget while considering the quality.

- Clarify delivery expectations: Confirm lead times to align with your production schedules.

Step 6: Establish Communication Protocols

Effective communication is essential for a successful sourcing process. Establish clear communication protocols to ensure both parties are aligned throughout the transaction.

- Set points of contact: Designate key personnel from both sides for smooth communication.

- Schedule regular updates: Agree on a timeline for updates on production status and any potential issues.

Step 7: Evaluate and Monitor Supplier Performance

After sourcing, continuously evaluate and monitor the supplier’s performance to ensure ongoing quality and compliance. Establish metrics for assessing product quality, delivery times, and customer service.

Illustrative image related to green leather fabric

- Gather feedback: Regularly solicit feedback from your team on the quality of the leather and the reliability of the supplier.

- Revisit contracts as needed: Be prepared to adjust terms based on performance evaluations and market conditions.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing green leather fabric with confidence, ensuring they make sustainable and quality-driven procurement decisions.

Comprehensive Cost and Pricing Analysis for green leather fabric Sourcing

What Are the Key Cost Components in Sourcing Green Leather Fabric?

When sourcing green leather fabric, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw materials, including hides and finishing agents, can vary significantly based on quality and source. Green leather, often sourced from environmentally sustainable processes, may carry a premium price. Buyers should evaluate suppliers that offer transparency in their sourcing practices to ensure they are receiving high-quality materials.

-

Labor: Labor costs can fluctuate based on geographic location and the complexity of the manufacturing process. Skilled labor is often required for leather processing, which can increase costs, especially in regions with higher wage standards.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, equipment maintenance, and factory management. A well-optimized production facility can help minimize these overhead costs, thus impacting the final price.

-

Tooling: Initial setup costs for manufacturing can be significant, particularly for custom or specialized leather products. Tooling costs can be amortized over larger production runs, making bulk purchases more economically viable.

-

Quality Control (QC): Implementing robust QC processes is essential for ensuring the durability and appearance of green leather. Costs associated with QC can vary depending on the complexity of the products and the standards required.

-

Logistics: Shipping and handling costs play a vital role in the overall pricing of green leather fabric. Factors such as distance, shipping mode, and Incoterms can significantly affect logistics expenses. It is advisable to negotiate terms that minimize risks and costs.

-

Margin: Finally, suppliers will include a profit margin in their pricing. Understanding the typical margins in the green leather market can help buyers gauge whether they are receiving competitive pricing.

How Do Price Influencers Affect Green Leather Fabric Pricing?

Several factors influence the pricing of green leather fabric, which B2B buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for larger orders. Understanding the MOQ can help buyers plan their purchases more effectively and negotiate better terms.

-

Specifications and Customization: Custom requirements can drive up costs. Buyers should be clear about their needs and explore whether standardized options can meet their specifications without incurring additional costs.

-

Materials and Quality Certifications: The type of leather and any certifications related to sustainability or quality can impact pricing. Buyers should consider the long-term benefits of higher-quality materials, which can lead to reduced maintenance costs and improved product lifespan.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers may charge a premium for their products due to their proven track record and customer service.

-

Incoterms: Understanding the shipping terms (Incoterms) can influence total costs. Buyers should negotiate terms that minimize their exposure to unforeseen costs, such as customs duties or insurance.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies for cost-effective sourcing of green leather fabric:

-

Negotiation: Always approach suppliers with a clear understanding of your requirements and budget. Leverage your purchasing power and establish long-term relationships for better pricing.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront cost. Consider factors such as durability, maintenance, and potential resale value when assessing overall expenses.

-

Pricing Nuances: Be aware of regional pricing differences and how local economic conditions can impact costs. Understanding these nuances can help in negotiating better deals.

-

Sample Evaluation: Request samples before committing to larger orders. This ensures that the quality meets your expectations and helps avoid costly mistakes down the line.

-

Market Research: Stay informed about market trends and pricing fluctuations. This knowledge can empower buyers to make informed decisions and capitalize on favorable purchasing conditions.

Disclaimer

The prices and cost structures mentioned herein are indicative and can vary based on multiple factors including supplier, location, and market conditions. Always conduct thorough due diligence and market analysis before making purchasing decisions.

Alternatives Analysis: Comparing green leather fabric With Other Solutions

Exploring Alternatives to Green Leather Fabric for B2B Buyers

In the quest for sustainable and aesthetically appealing materials, green leather fabric has emerged as a popular choice among manufacturers and designers. However, it’s crucial for B2B buyers to evaluate alternative solutions that may suit their specific needs or preferences. The following analysis compares green leather fabric with two viable alternatives: synthetic leather and recycled textile composites.

| Comparison Aspect | Green Leather Fabric | جلد صناعي | Recycled Textile Composites |

|---|---|---|---|

| Performance | Durable and breathable; offers luxurious texture | Versatile but may lack breathability; durability varies | Good durability; texture can vary based on materials used |

| Cost | Generally higher due to sourcing and processing | Typically lower; economies of scale can reduce costs | Mid-range; dependent on material sourcing and processing |

| Ease of Implementation | Requires skilled labor for crafting and finishing | Easier to work with; often available in rolls and sheets | Moderate; may require specialized machinery for processing |

| Maintenance | Requires regular conditioning to maintain appearance | Easy to clean and maintain; resistant to stains | Maintenance depends on the material; generally easy to clean |

| Best Use Case | Luxury furniture, high-end automotive interiors | Mass-produced consumer goods, fashion accessories | Sustainable fashion, eco-friendly upholstery |

What Are the Pros and Cons of Synthetic Leather Compared to Green Leather Fabric?

Synthetic leather, often made from polyurethane or PVC, is a popular alternative due to its cost-effectiveness and ease of use. Its performance can vary significantly, with some high-quality synthetics mimicking the look and feel of genuine leather quite well. However, it generally lacks the breathability and natural feel of green leather, making it less desirable for luxury applications. While synthetic leather is more affordable and easier to maintain, it raises environmental concerns related to its production and disposal, particularly regarding plastic waste.

How Do Recycled Textile Composites Stack Up Against Green Leather Fabric?

Recycled textile composites are crafted from repurposed materials, making them an environmentally friendly alternative. They can provide good durability and a unique aesthetic, appealing to brands focused on sustainability. However, the texture and quality can vary significantly depending on the source materials. In terms of cost, recycled composites often fall in the mid-range, making them an attractive option for brands looking to balance sustainability with budget. While maintenance is generally easy, the initial investment in specialized equipment for processing recycled materials can be a barrier for some manufacturers.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between green leather fabric and its alternatives, B2B buyers should consider several factors, including the intended application, budget constraints, and sustainability goals. Green leather fabric excels in luxury markets where quality and aesthetics are paramount, while synthetic leather and recycled textile composites may be better suited for mass-market products or eco-conscious brands. Ultimately, the right choice will depend on aligning the material’s characteristics with the specific demands of the project at hand, ensuring both functionality and brand integrity.

Essential Technical Properties and Trade Terminology for green leather fabric

What Are the Key Technical Properties of Green Leather Fabric?

Understanding the technical specifications of green leather fabric is crucial for B2B buyers to ensure that they select the right materials for their projects. Below are some essential properties to consider:

1. Material Grade

Material grade refers to the quality classification of the leather based on its surface finish, thickness, and durability. Common grades include full-grain, top-grain, and corrected grain. For green leather, full-grain is often preferred for upholstery and high-end products due to its natural appearance and durability. Selecting the appropriate material grade impacts the product’s longevity and aesthetic appeal, which are vital for maintaining brand reputation.

2. Thickness

The thickness of leather is measured in millimeters or ounces. Typical leather thickness ranges from 0.8 mm to 2.0 mm for upholstery applications. Thicker leather generally offers greater durability and resistance to wear and tear, making it suitable for high-traffic areas. However, it can also be heavier and less flexible. Understanding the thickness required for specific applications helps buyers match their needs with product capabilities.

3. Finish Type

The finish type indicates how the leather is treated after tanning. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather is prized for its natural look but is less resistant to stains, while pigmented leather offers more protection but may lack the same aesthetic qualities. Buyers should consider the intended use and maintenance requirements when selecting a finish type to ensure that it aligns with their product’s performance expectations.

4. Tensile Strength

Tensile strength measures the leather’s resistance to being pulled apart. It is critical for applications that require durability, such as automotive and commercial upholstery. High tensile strength indicates that the leather can withstand significant stress without tearing. For B2B buyers, understanding tensile strength is essential for ensuring that the leather will perform well in its intended application, especially in high-use environments.

5. Color Fastness

Color fastness refers to the leather’s ability to retain its color when exposed to light, water, and other environmental factors. This property is particularly important for green leather, as vibrant colors may fade over time if not treated properly. Buyers should inquire about the color fastness ratings to ensure the leather will maintain its visual appeal throughout its lifecycle, especially for products exposed to sunlight or moisture.

What Are Common Trade Terms Used in the Green Leather Fabric Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation processes for B2B buyers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then sold under another brand’s name. In the leather industry, OEMs might manufacture leather goods for other brands, ensuring that the leather meets specific quality and design standards. Understanding this term is vital for buyers looking to source customized leather products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand, as it influences inventory management and cost calculations. Knowing the MOQ helps businesses plan their purchases effectively and avoid overstocking or understocking.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specified products or services. This term is essential for B2B buyers seeking competitive pricing and is often used in the procurement process. Crafting a clear RFQ can help buyers receive accurate and comparable quotes from multiple suppliers.

Illustrative image related to green leather fabric

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, as it clarifies who is responsible for costs and risks during transportation.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. In the leather industry, this can vary based on factors such as production capacity and shipping logistics. Understanding lead times is essential for effective project management and ensuring timely delivery of products to meet market demands.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when sourcing green leather fabric, ultimately contributing to the success of their projects.

Navigating Market Dynamics and Sourcing Trends in the green leather fabric Sector

What Are the Current Market Dynamics and Key Trends in Green Leather Fabric?

The global market for green leather fabric is experiencing significant growth, driven by increasing consumer awareness of sustainability and eco-friendly practices. Key trends influencing this sector include the rising demand for ethically sourced materials, particularly among international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. Notably, markets in Saudi Arabia and Vietnam are becoming increasingly receptive to sustainable products, reflecting a broader shift toward responsible consumption.

Emerging B2B technologies are also reshaping sourcing practices. Digital platforms facilitate direct connections between manufacturers and buyers, streamlining the procurement process. Innovations such as blockchain technology are enhancing transparency in the supply chain, allowing buyers to verify the ethical sourcing of green leather. Additionally, the adoption of AI-driven analytics is enabling companies to forecast trends more accurately, helping them align their inventory with market demands.

Moreover, the green leather fabric market is witnessing a diversification of product offerings. Manufacturers are experimenting with alternative tanning methods, such as vegetable tanning, which not only reduces environmental impact but also caters to a growing consumer preference for natural materials. This trend is particularly relevant for buyers looking to differentiate their offerings in competitive markets.

How Is Sustainability Shaping the B2B Landscape for Green Leather Fabric?

Sustainability is at the forefront of the green leather fabric sector, influencing both consumer preferences and procurement strategies. The environmental impact of traditional leather production has prompted a shift toward sustainable practices, making it essential for B2B buyers to prioritize ethical sourcing. Buyers are increasingly seeking suppliers who can demonstrate compliance with environmental standards and certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification.

These certifications not only ensure that the leather is produced with minimal environmental impact but also promote fair labor practices throughout the supply chain. By choosing certified green leather, businesses can enhance their brand image and appeal to environmentally conscious consumers. Furthermore, suppliers that prioritize ethical sourcing often foster stronger relationships with their clients, as they share similar values regarding sustainability.

In addition, the emphasis on circular economy principles is gaining traction in the industry. This involves not only sourcing sustainable materials but also considering the entire lifecycle of the product, from production to disposal. B2B buyers are increasingly interested in suppliers who offer take-back programs or recycling options for end-of-life products, which can significantly reduce waste and enhance their sustainability profile.

What Is the Historical Context of Green Leather Fabric in B2B Sourcing?

The evolution of green leather fabric can be traced back to the growing awareness of environmental issues in the late 20th century. As concerns about pollution and animal welfare became more pronounced, the leather industry began exploring alternative tanning methods and sustainable practices. This shift was initially driven by consumer demand but has since been bolstered by regulatory pressures and the need for businesses to adopt more responsible sourcing strategies.

Over the years, advancements in technology have further facilitated the growth of the green leather sector. The introduction of synthetic alternatives and innovative production techniques has allowed for a broader range of eco-friendly leather options, catering to diverse market needs. Today, green leather fabric is not just a niche market but a vital component of the broader movement towards sustainability in the textile industry, providing international B2B buyers with opportunities to align their procurement strategies with evolving consumer expectations.

In summary, the green leather fabric sector is poised for continued growth, driven by sustainability trends, technological advancements, and an increasing focus on ethical sourcing. B2B buyers must stay informed of these dynamics to effectively navigate the evolving market landscape.

Illustrative image related to green leather fabric

Frequently Asked Questions (FAQs) for B2B Buyers of green leather fabric

-

1. How do I ensure the quality of green leather fabric from suppliers?

To ensure the quality of green leather fabric, start by requesting samples from potential suppliers. Evaluate the texture, color consistency, and durability of the material. It’s also essential to check if the leather complies with international quality standards, such as ISO certifications. Conducting factory visits or audits can provide deeper insights into their manufacturing processes and quality control measures. Additionally, seek references from other businesses that have sourced from these suppliers to gauge their reliability and product quality. -

2. What is the best type of green leather for upholstery?

The best type of green leather for upholstery typically depends on the intended use and aesthetic preferences. Full-grain leather is renowned for its durability and natural look, making it ideal for high-traffic areas. Aniline leather offers a soft feel and rich color but may require more maintenance. For a more eco-friendly option, consider vegetable-tanned leather, which uses natural tannins and is free from harmful chemicals. Ultimately, the choice should align with your project requirements and design vision. -

3. How can I verify the sustainability of green leather products?

To verify the sustainability of green leather products, inquire about the sourcing and tanning processes used by suppliers. Look for certifications like the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, which indicate environmentally responsible practices. Additionally, ask suppliers about their waste management and water usage during production. Transparency in their supply chain and adherence to eco-friendly practices are key indicators of sustainability. -

4. What are the typical minimum order quantities (MOQs) for green leather fabric?

Minimum order quantities (MOQs) for green leather fabric can vary significantly between suppliers, typically ranging from 10 to 100 hides, depending on the type and customization level. For bespoke projects or specialized colors, MOQs may be higher. It’s advisable to discuss your specific needs with the supplier to understand their limitations and negotiate terms that suit your business requirements. Some suppliers may offer flexibility for first-time orders or long-term partnerships. -

5. What payment terms should I expect when sourcing green leather?

Payment terms for sourcing green leather typically vary by supplier and region. Common arrangements include a deposit (often 30-50%) upfront with the balance due upon delivery or before shipment. Some suppliers may offer net payment terms, allowing a set period (e.g., 30-90 days) for payment after receipt of goods. Always clarify payment methods accepted (bank transfer, credit terms, etc.) and ensure that contracts specify terms to avoid misunderstandings. -

6. How can I manage logistics for importing green leather fabric?

Managing logistics for importing green leather fabric involves coordinating with freight forwarders who understand the specific requirements for shipping leather products. Ensure compliance with customs regulations in your country, including necessary documentation like import permits and certificates of origin. To minimize delays, work with suppliers who can provide timely shipping information and track shipments. Consider insurance for high-value orders to protect against loss or damage during transit. -

7. What customization options are available for green leather fabric?

Customization options for green leather fabric include color variations, embossing patterns, and finishes such as matte or glossy. Many suppliers offer bespoke solutions to meet specific design needs. Discuss your project requirements with potential suppliers to understand their capabilities, lead times, and any additional costs associated with customization. It’s also beneficial to request prototypes or samples before finalizing large orders to ensure the final product meets your expectations. -

8. How do I vet suppliers of green leather fabric for reliability?

Vetting suppliers of green leather fabric involves researching their market reputation and checking for reviews or testimonials from previous clients. Request information about their production capacity, lead times, and adherence to quality standards. Consider arranging visits to their facilities or utilizing third-party inspection services to verify their operations. Additionally, establishing clear communication and asking detailed questions can provide insights into their reliability and customer service approach.

Top 5 Green Leather Fabric Manufacturers & Suppliers List

1. Barbarossa Leather – Green Leather Options

Domain: barbarossaleather.com

Registered: 2005 (20 years)

مقدمة: Green Leather options available include various designs and shades such as: Abyss, Amazon, Anaconda, Arabesque, Aspen, Aviator, Aztec, Baby Hornback, Bolero, Brands, Cambridge, Capri, Cascavel, Celine, Chateau, Cheyenne, Dakota, Diamond, Divine, Driftwood, Dundee Croc, Florence, Gateway, Gator Hornback, Giant Croc, Heraldic, Hornback Italia, Imperial, Indiano, Jumbo Croc, Kingston, Kyalami, La Boh…

2. Green Hides – Luxurious Sustainable Leathers

Domain: greenhides.com

Registered: 2003 (22 years)

مقدمة: Green Hides offers a variety of luxurious leathers suitable for various interiors. Key product categories include: 1. Sustainability Leathers: Carbon Neutral, Chrome Free, Bleach Cleanable. 2. Applications: Aviation, Contract, Hospitality, Marine, Outdoor, Residential. 3. Collections: DiGiorgi Collection, Hair on Hides, Sheepskin, Embossing & Perforation, Quilted Leather. 4. Specific Products: Mil…

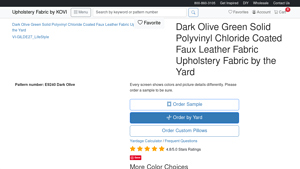

3. Kovi Fabrics – E9240 Dark Olive Upholstery Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

مقدمة: {“Pattern number”: “E9240 Dark Olive”, “Recommended use”: [“Automotive Seating”, “Bags”, “Decorative Accessories”, “Healthcare Seating”, “Hospitality Seating”, “Marine Seating”, “Office Seating”, “Residential Seating”, “Rv Seating”, “Upholstery”, “Hockey Equipment”, “Indoor Seating”], “Warranty”: “Limited lifetime warranty”, “Minimum order”: “1 yard”, “Color”: “Green”, “Type”: “Polyvinyl Chloride …

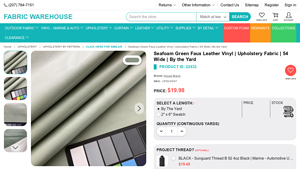

4. Fabric Warehouse – Seafoam Green Faux Leather Vinyl

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

مقدمة: {‘product_name’: ‘Seafoam Green Faux Leather Vinyl’, ‘category’: ‘Upholstery Fabric’, ‘width’: ’54 inches’, ‘sold_by’: ‘By the Yard’, ‘price_range’: ‘$3.00 – $19.98’, ‘fiber_content’: ‘PVC / Vinyl’, ‘upholstery_weight’: ‘Medium Weight’, ‘drapery_weight’: ‘Too Heavy For Drapery’, ‘pattern’: ‘Solid/Plain’, ‘color_theme’: ‘Green’, ‘description’: ‘A beautiful seafoam green faux leather vinyl fabric th…

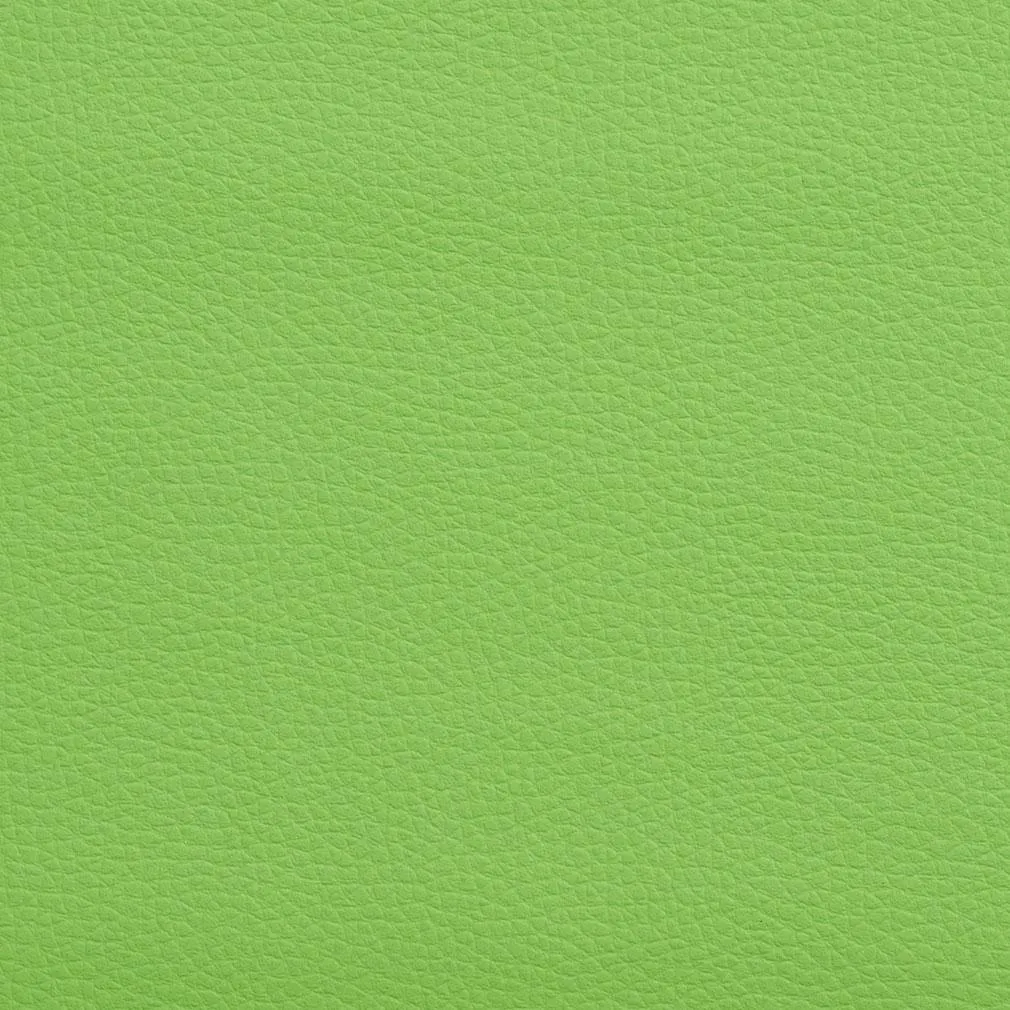

5. Stitches Seattle – Stretch Faux Leather Fabric

Domain: stitchesseattle.com

Registered: 2004 (21 years)

مقدمة: {“name”:”Stretch Faux Leather Fabric – Dark Army Green”,”regular_price”:”$11.95″,”sale_price”:”$15.95″,”unit_price”:”per yard”,”width”:”56 inches”,”shipping”:”calculated at checkout”}

Strategic Sourcing Conclusion and Outlook for green leather fabric

What Are the Key Benefits of Strategic Sourcing for Green Leather Fabric?

In conclusion, strategic sourcing of green leather fabric is not only a sustainable choice but also a smart business move for international B2B buyers. By prioritizing eco-friendly materials, companies can enhance their brand reputation and meet the growing consumer demand for sustainable products. The diverse range of green leather options—from upholstery to automotive applications—provides buyers with the flexibility to choose materials that align with their specific project needs while promoting environmental stewardship.

How Can International Buyers Leverage Sustainable Sourcing?

For buyers in Africa, South America, the Middle East, and Europe, establishing relationships with reputable suppliers of green leather can result in cost savings and high-quality materials tailored to regional preferences. Engaging in closeout sales and sampling options allows businesses to test materials before committing to larger orders, ensuring they meet both aesthetic and functional requirements.

What Does the Future Hold for Green Leather Fabric in Global Markets?

Looking ahead, the demand for sustainable materials is poised to grow, driven by increased environmental awareness and regulatory pressures. B2B buyers are encouraged to act now by integrating green leather into their supply chains, positioning themselves as leaders in sustainability. By fostering partnerships with innovative suppliers, companies can not only fulfill market demands but also contribute positively to the planet.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.