Catalog

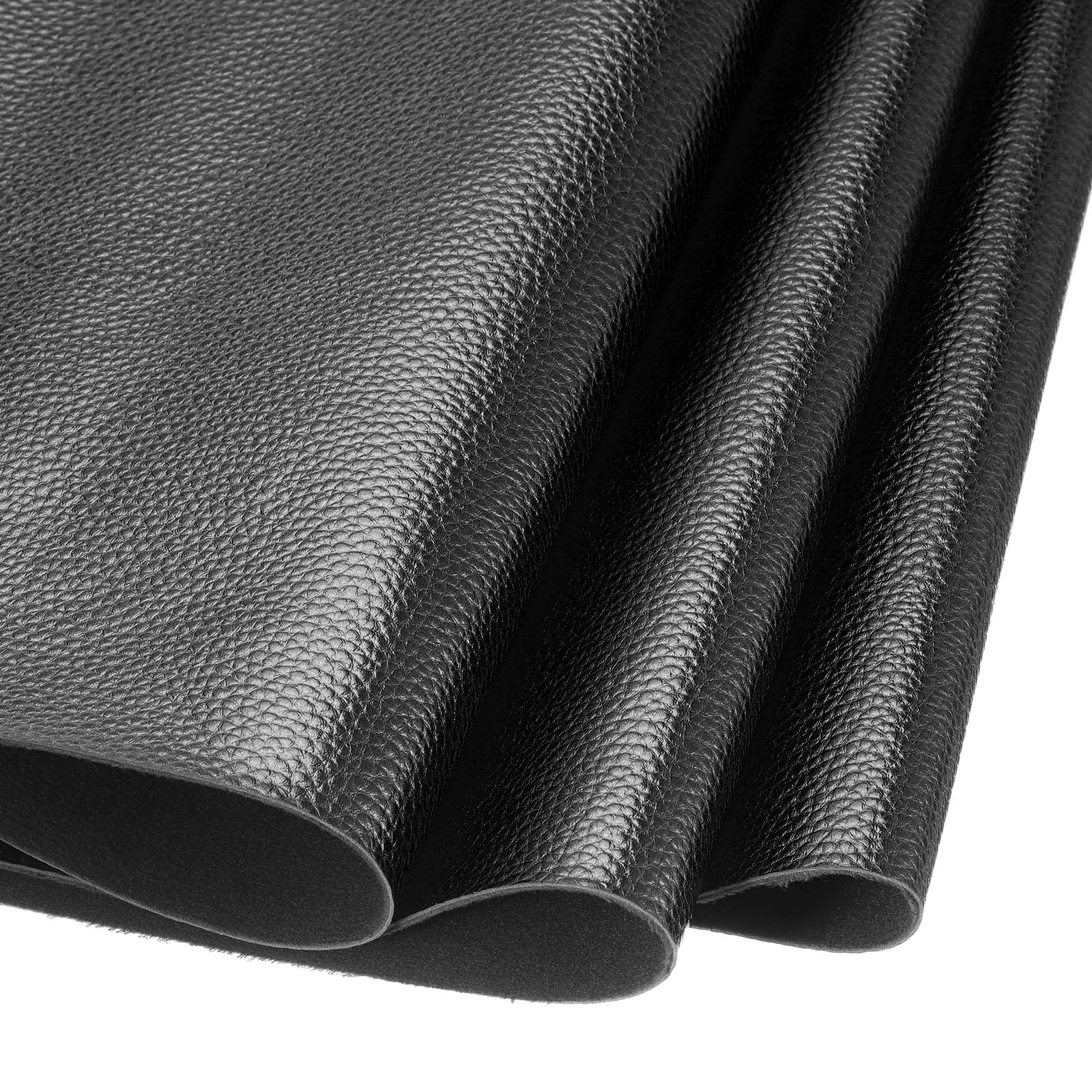

Material Insight: Fake Leather Fabric

B2B Product Guide: Synthetic Leather Fabric Solutions

Introduction to Synthetic Leather Fabric

Synthetic leather fabric, often referred to as faux leather, PU leather, or microfiber leather, is an engineered material designed to replicate the aesthetic, texture, and performance characteristics of genuine leather without utilizing animal hides. Composed primarily of polyurethane (PU) or polyvinyl chloride (PVC) coatings applied to textile backings (such as polyester or recycled fibers), modern synthetic leather delivers exceptional consistency, durability, and design versatility. Unlike traditional leather, it eliminates variables like natural scars or grain inconsistencies, providing manufacturers with a uniform, reliable substrate for high-volume production. Crucially, advanced eco-engineered variants now prioritize reduced environmental impact through waterless dyeing, recycled content, and non-toxic formulations—aligning with global sustainability mandates.

Why Synthetic Leather is the Optimal Choice for Commercial Applications

For B2B partners in furniture, automotive, fashion, and accessories, synthetic leather outperforms alternatives by addressing critical operational and ethical demands:

- Supply Chain Resilience: Eliminates dependency on volatile leather tanning markets and ethical concerns tied to animal agriculture, ensuring stable pricing and uninterrupted production.

- Precision Performance: Engineered for specific requirements (e.g., abrasion resistance >50,000 double rubs, lightfastness >6 on Blue Wool Scale), enabling compliance with rigorous industry standards (ISO, ASTM).

- Eco-Compliance: Reduces water consumption by up to 90% versus chrome-tanned leather and avoids hazardous chemicals (REACH/CA Prop 65 compliant), supporting ESG reporting and circular economy goals.

- Design Flexibility: Offers infinite color, texture, and thickness customization (0.6mm–1.8mm) without MOQ constraints, accelerating time-to-market for trend-driven collections.

- Total Cost Efficiency: Lowers waste through consistent roll goods (95%+ utilization vs. 70–80% for leather) and eliminates costly grading/sorting processes.

WINIW: Your Trusted Partner in Sustainable Material Innovation

With over 20 years of specialized expertise in synthetic leather engineering, WINIW has pioneered eco-conscious material solutions for global B2B leaders. We merge deep technical knowledge with a commitment to planetary stewardship, delivering:

- Proven Technical Mastery: In-house R&D focused on high-performance polymers, resulting in proprietary technologies like EcoSoft™ (100% solvent-free PU) and Recyclex™ (30–50% recycled content fabrics).

- End-to-End Sustainability: Certified by OEKO-TEX® STANDARD 100, GRS, and Bluesign®, with full traceability from raw material to finished roll.

- Application-Specific Engineering: Dedicated technical teams collaborate with clients to solve material challenges—from automotive seating requiring extreme UV resistance to luxury handbags demanding supple drape.

- Global Scale, Local Support: 5 manufacturing facilities across Asia and Europe ensure rapid prototyping, regional compliance adherence, and agile supply chain integration.

WINIW’s synthetic leather fabrics transform sustainability from a constraint into a competitive advantage—delivering uncompromised quality, ethical integrity, and measurable operational value for forward-thinking brands. Partner with us to future-proof your material strategy.

Technical Performance & Standards

WINIW Synthetic Leather Fabric – B2B Product Technical Guide

WINIW specializes in high-performance synthetic leather fabrics engineered for commercial and industrial applications. Our PU and microfiber-based solutions deliver a sustainable, cost-effective alternative to genuine leather without compromising on quality, durability, or aesthetics. Designed for sectors including automotive interiors, furniture, footwear, and accessories, WINIW’s fake leather fabric combines advanced material science with environmental responsibility.

Key Technical Advantages

-

Cost-Effective Manufacturing

WINIW’s synthetic leather reduces raw material and processing costs compared to genuine leather. With consistent roll yields and minimal waste during cutting, manufacturers benefit from lower production overhead and improved scalability. -

Superior Durability

Engineered with reinforced backings and high-tenacity fibers, WINIW’s fabric offers excellent abrasion resistance (≥50,000 cycles Wyzenbeek), tensile strength, and dimensional stability. It maintains integrity under prolonged mechanical stress and environmental exposure. -

Customizable Colors & Finishes

Our advanced dyeing and coating technologies support full color customization across Pantone, RAL, or customer-provided samples. Matte, glossy, embossed, and soft-touch finishes are available to meet brand-specific design requirements. -

REACH Compliant

WINIW’s synthetic leather is fully compliant with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted hazardous substances. This supports safe handling and global market access. -

ISO 9001-Certified Production

Our manufacturing processes are certified under ISO 9001:2015, guaranteeing consistent product quality, traceability, and continuous improvement in production standards.

Product Specifications

| Property | المواصفات |

|---|---|

| Base Material | High-density polyurethane (PU) or microfiber |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight Range | 180 g/m² – 450 g/m² |

| Abrasion Resistance | ≥50,000 cycles (Wyzenbeek, ASTM D4157) |

| Color Fastness to Rubbing | Grade 4–5 (dry/wet, ISO 105-X12) |

| Light Fastness | ≥4–6 (ISO 105-B02, 40+ hours Xenon) |

| Tensile Strength | ≥80 N/5cm (warp and weft) |

| Tear Strength | ≥15 N |

| Cold Crack Resistance | ≤ -20°C (no cracking) |

| Environmental Compliance | REACH, RoHS,不含偶氮染料 (Azo-free) |

| Certifications | ISO 9001:2015, OEKO-TEX® STANDARD 100 (upon request) |

| Customization Options | Color, thickness, texture, backing fabric |

WINIW’s synthetic leather is ideal for B2B partners seeking reliable, scalable, and eco-conscious materials. With in-house R&D and flexible production lines, we support low minimum order quantities (MOQs) and rapid prototyping for global clients.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Genuine Leather for Commercial Applications

As WINIW’s Synthetic Leather Expert, we provide objective insights to support sustainable material selection for furniture, automotive, fashion, and accessories manufacturing. This guide compares synthetic leather (often termed “vegan leather” or “PU leather” in B2B contexts) and genuine leather across critical commercial metrics. Note: “Fake leather” is a non-industry colloquialism; we use precise terminology to ensure clarity in procurement and design.

Comparative Analysis: Key Metrics

| Metric | Synthetic Leather (WINIW Grade) | Genuine Leather |

|---|---|---|

| Cost | 30-50% lower initial material cost. Consistent pricing unaffected by hide defects. Reduced waste in cutting (up to 20% higher yield). | Higher base cost (premium hides 2-3x synthetic). Price volatility due to livestock market, hide quality variations, and tanning costs. Significant waste (15-25% unusable due to scars/inconsistencies). |

| المتانة | High resistance to stains, UV fading, and abrasion (tested to 50,000+ Martindale rubs). Uniform structure ensures predictable performance. No risk of drying/cracking with proper care. | Develops patina over time but susceptible to scratches, moisture damage, and fading. Requires conditioning to prevent cracking. Natural grain variations create weak points. Premium full-grain lasts decades; lower grades degrade faster. |

| Eco-Friendliness | WINIW uses 85%+ recycled content (PET bottles, PU) and water-based coatings. Zero animal sourcing. Lower CO2e (up to 60% less than bovine leather) and water use (90% less). OEKO-TEX® certified, non-toxic. Note: Microplastic shedding requires end-of-life recycling solutions. | High environmental burden: 17,000L water per kg hide, methane emissions from livestock, toxic tanning chemicals (chromium). Biodegradable but slow (decades). Certifications (e.g., Leather Working Group) mitigate impacts but cannot eliminate core resource demands. |

Key Considerations for B2B Decision-Making

- Supply Chain Stability: Synthetic leather offers consistent color/texture batches and shorter lead times. Genuine leather faces hide scarcity and tannery capacity constraints.

- Design Flexibility: Synthetic allows unlimited color, texture, and thickness customization. Genuine leather limited by natural hide characteristics.

- End-of-Life: WINIW’s recyclable synthetics align with EU Ecodesign directives. Genuine leather landfills contribute to methane; recycling infrastructure is underdeveloped.

- Brand Alignment: Synthetic supports ESG goals (cruelty-free, circular economy). Genuine leather appeals to heritage/luxury segments but faces growing ethical scrutiny.

Strategic Recommendation

Prioritize WINIW synthetic leather لـ

– High-volume production requiring cost control and design uniformity (e.g., contract furniture, mass-market automotive interiors).

– Brands committed to traceable, low-impact materials with certifications (GRS, OEKO-TEX®).

– Applications needing stain/water resistance (healthcare, public transport).

Choose genuine leather only for:

– Ultra-premium, low-volume products where natural aging is a value driver.

– Markets with strong cultural preference for animal-derived materials (validate with LCA).

WINIW’s closed-loop manufacturing and 92% renewable energy usage ensure synthetic leather delivers uncompromised performance while advancing your sustainability KPIs. Request our full LCA report and sample kit to validate material fit for your application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our large-scale production capabilities, technical expertise, and rigorous quality standards position us as a trusted partner across industries including automotive, furniture, fashion, and technical textiles.

Our manufacturing strength is anchored in a state-of-the-art facility spanning 100,000 square meters. This extensive production base enables us to maintain high output volumes while ensuring operational efficiency and flexibility to meet diverse client demands. The facility integrates advanced production lines with automated processes, supporting consistent product quality and scalability for both standard and custom orders.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 50 technical experts focused on material innovation, sustainability, and performance enhancement. The team regularly develops new formulations that align with evolving environmental regulations and market needs, including water-based, solvent-free, and recycled-content leather solutions.

- Comprehensive in-house testing laboratories equipped to perform durability, colorfastness, abrasion resistance, and eco-compliance testing, ensuring every product meets international standards.

- Strict quality control protocols implemented at every stage—from raw material selection to final inspection. Our QC system complies with ISO 9001 standards and is audited regularly to maintain consistency for global markets.

- Strong environmental stewardship through low-emission processes, waste reduction systems, and sustainable sourcing, supporting clients’ ESG goals.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products consistently meet stringent regional requirements, including REACH, RoHS, and California Proposition 65, enabling seamless integration into high-end supply chains. Long-term partnerships with global brands reflect our reputation for reliability, innovation, and compliance.

By combining scale, technology, and sustainability, WINIW delivers synthetic leather solutions that meet the highest commercial and environmental standards.

Contact Us for Samples

WINIW Premium Microfiber Leather: Sustainable Performance Fabric for B2B Applications

WINIW delivers next-generation synthetic leather solutions engineered for durability, aesthetics, and environmental responsibility. Our microfiber leather fabrics replace traditional leather and inferior synthetics across automotive, furniture, footwear, and luxury goods manufacturing. Designed for high-volume production, WINIW materials offer consistent quality, reduced waste, and full traceability—aligning with global sustainability mandates without compromising performance.

Key Advantages for Industrial Partners

- Eco-Intelligent Production: Water-based PU resins, 100% solvent-free manufacturing, and OEKO-TEX® STANDARD 100 certification ensure zero toxic residues and compliance with EU REACH regulations.

- Performance Parity: Matches genuine leather in tear strength (≥45 N), abrasion resistance (≥50,000 cycles Martindale), and flexibility, while offering superior color consistency and batch-to-batch reliability.

- Waste Reduction: Precision-engineered thickness tolerance (±0.05mm) minimizes cutting waste by up to 18% versus conventional synthetics.

- Customization Agility: Rapid formulation adjustments for texture (Nappa, Suede, Grain), color (Pantone® matched), and functional properties (flame retardancy, antimicrobial).

- Supply Chain Resilience: Dedicated production lines for MOQs from 5,000 meters, with 30-day lead times for standard grades.

Technical Specifications Comparison

| Property | WINIW EcoPro™ (Standard) | WINIW Luxe™ (Premium) | WINIW EcoCycle™ (Recycled) |

|---|---|---|---|

| Base Material | Microfiber polyester | Microfiber polyester | 40% recycled PET + PU |

| Thickness Range | 0.8–1.8 mm | 0.6–2.2 mm | 1.0–1.5 mm |

| Tensile Strength | ≥ 25 MPa | ≥ 32 MPa | ≥ 22 MPa |

| Elongation at Break | ≥ 25% | ≥ 30% | ≥ 20% |

| Color Fastness | Grade 4–5 (ISO 105) | Grade 5 | Grade 4 |

| Eco-Certifications | OEKO-TEX®, ISO 14001 | OEKO-TEX®, GRS | GRS, Global Recycled Standard |

| Primary Applications | Contract furniture, bags | Automotive interiors, luxury goods | Sustainable footwear, accessories |

Why Global Manufacturers Partner with WINIW

- Carbon-Neutral Pathway: 35% lower carbon footprint vs. bovine leather (verified LCA), with carbon-neutral shipping options.

- Regulatory Assurance: Full compliance documentation (including SVHC screening) for EU, US, and APAC markets.

- Scalable Sustainability: Recycled content options without performance trade-offs—EcoCycle™ maintains 95% of Luxe™’s durability.

- Technical Partnership: WINIW engineering teams co-develop solutions for extreme conditions (e.g., UV resistance for marine upholstery, cold-crack resistance to -30°C).

Request Free Production Samples & Technical Dossiers

Accelerate your sustainable material transition with WINIW. Contact our B2B solutions team for:

– Grade-specific physical samples (cut to your application requirements)

– Full technical data sheets and compliance reports

– Custom formulation consultation

Email: MKT88@MicrofiberLeather.com

Samples dispatched within 48 hours for qualified industrial buyers. No minimum order for sample validation.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.