Introduction: Navigating the Global Market for alcantara roll

In today’s competitive landscape, sourcing high-quality Alcantara rolls presents a significant challenge for international B2B buyers. With diverse applications ranging from automotive interiors to fashion and furniture, the demand for this versatile, synthetic suede is on the rise. However, navigating the complexities of supplier selection, material specifications, and pricing can be overwhelming, especially for businesses in regions such as Africa, South America, the Middle East, and Europe. This guide serves as your comprehensive resource for understanding the Alcantara roll market, equipping you with the insights needed to make informed purchasing decisions.

Throughout this guide, we will delve into various types of Alcantara rolls, including foam-backed and unbacked options, and their specific applications in different industries. We will discuss strategies for vetting suppliers to ensure quality and reliability, alongside a breakdown of pricing structures and cost-saving tips. By addressing these critical areas, our goal is to empower B2B buyers, such as those in Nigeria and Vietnam, to confidently navigate the global market for Alcantara rolls. With the right knowledge and resources, you can enhance your procurement strategy, ensuring that your business benefits from the aesthetic appeal and functional advantages that Alcantara offers.

Table Of Contents

- Top 8 Alcantara Roll Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara roll

- Understanding alcantara roll Types and Variations

- Key Industrial Applications of alcantara roll

- 3 Common User Pain Points for ‘alcantara roll’ & Their Solutions

- Strategic Material Selection Guide for alcantara roll

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara roll

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara roll’

- Comprehensive Cost and Pricing Analysis for alcantara roll Sourcing

- Alternatives Analysis: Comparing alcantara roll With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara roll

- Navigating Market Dynamics and Sourcing Trends in the alcantara roll Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara roll

- Strategic Sourcing Conclusion and Outlook for alcantara roll

- Important Disclaimer & Terms of Use

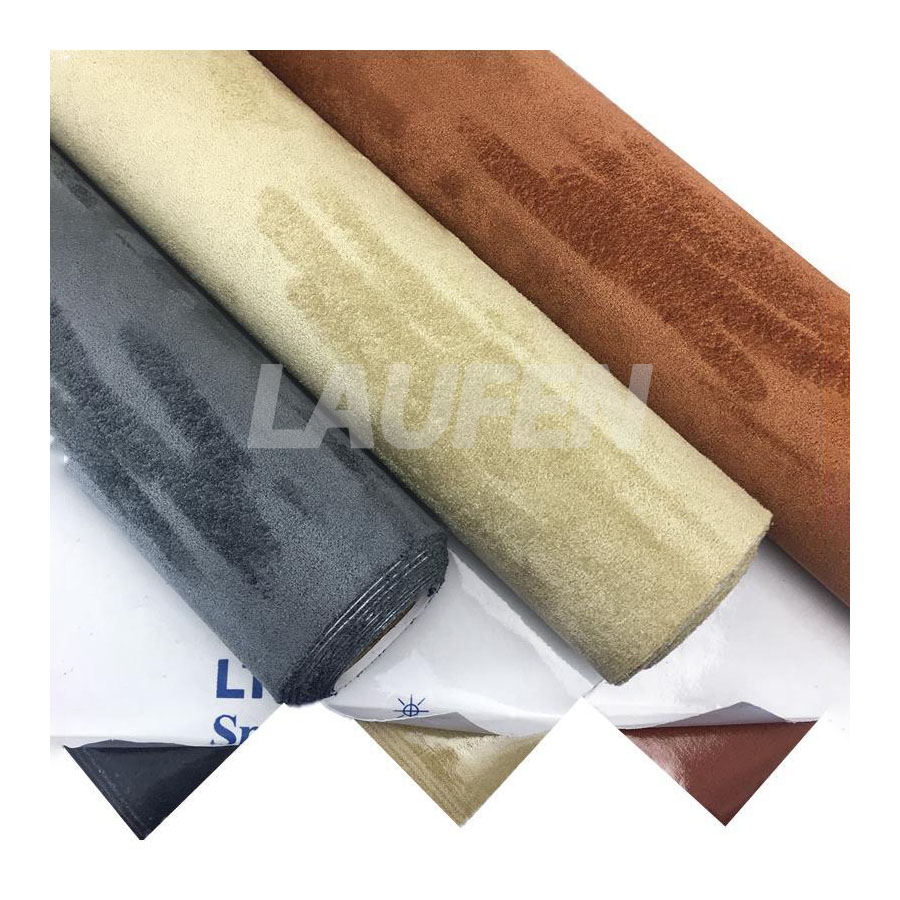

Understanding alcantara roll Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Soft | Foam-backed, enhanced grip, easy to clean | Automotive interiors, luxury furniture | Pros: Durable, cool to touch, reduces glare. Cons: Higher cost compared to standard fabrics. |

| Alcantara Unbacked | Single-layer, increased stretch, lightweight | Door panels, headliners, trim surfaces | Pros: Excellent for tight fits, versatile. Cons: Less cushioning, may require additional backing for some applications. |

| Alcantara Cover | Backed material, added durability | Upholstery, seating covers | Pros: Enhanced durability, suitable for high-traffic areas. Cons: Heavier, potentially less breathable. |

| Alcantara Perforated | Ventilation holes for breathability | Automotive seating, sports equipment | Pros: Improves airflow, stylish appearance. Cons: May be less durable in high-wear applications. |

| Alcantara EXO Outdoor | Weather-resistant, UV stabilized | Outdoor furniture, marine applications | Pros: Resistant to fading, easy maintenance. Cons: Limited color options compared to indoor variants. |

What are the Characteristics and Suitability of Alcantara Soft?

Alcantara Soft is a premium foam-backed textile that offers superior grip and comfort, making it ideal for automotive interiors and luxury furniture applications. Composed of 68% polyester and 32% polyurethane, it is easy to clean and maintains a cool temperature, enhancing user experience in warm climates. B2B buyers should consider its durability and aesthetic appeal, although the cost may be higher compared to standard upholstery materials.

How Does Alcantara Unbacked Differ from Other Types?

Alcantara Unbacked is a single-layer textile designed for applications requiring increased stretch and lightweight properties. Its flexibility makes it suitable for intricate designs in automotive interiors, such as door panels and headliners. While it offers excellent workability, B2B buyers must evaluate the need for additional backing in certain applications to ensure durability and performance.

What Advantages Does Alcantara Cover Offer for Upholstery?

Alcantara Cover features a backing that enhances its durability, making it an excellent choice for upholstery and seating covers in high-traffic areas. This type is particularly well-suited for environments where wear and tear are a concern, such as commercial spaces or luxury vehicles. Buyers will appreciate its longevity and ease of maintenance, but should be aware of its heavier weight compared to unbacked options.

Why Choose Alcantara Perforated for Ventilated Applications?

Alcantara Perforated is designed with ventilation holes, enhancing breathability, which is particularly beneficial for automotive seating and sports equipment. This feature not only improves comfort but also adds a stylish element to the design. However, while it provides increased airflow, B2B buyers should consider the potential for reduced durability in high-wear applications, necessitating careful selection based on usage.

What Makes Alcantara EXO Outdoor Suitable for External Use?

Alcantara EXO Outdoor is engineered to withstand outdoor conditions, featuring UV stabilization and weather resistance. This makes it an ideal choice for outdoor furniture and marine applications where exposure to the elements is a concern. Buyers should appreciate its low-maintenance properties and resistance to fading, although the selection of color options may be more limited than indoor variants.

Key Industrial Applications of alcantara roll

| Industry/Sector | Specific Application of alcantara roll | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery for luxury vehicles | Enhances aesthetic appeal and perceived value of vehicles | Ensure compliance with automotive standards and certifications. |

| Furniture | Upholstery for high-end furniture pieces | Provides durability and easy maintenance for premium products | Consider color matching and material specifications for durability. |

| Fashion & Apparel | Clothing and accessories | Offers a stylish, lightweight alternative to traditional materials | Source from reputable manufacturers to guarantee quality and ethical production. |

| Aviation | Cabin interiors and seating | Combines luxury with weight-saving properties for aircraft | Verify fire-retardant properties and compliance with aviation regulations. |

| Marine | Upholstery for luxury yachts and boats | Resists moisture while providing a luxurious feel | Assess UV resistance and water repellency for longevity in marine environments. |

How is Alcantara Roll Used in the Automotive Sector?

In the automotive industry, Alcantara rolls are predominantly used for the interior upholstery of luxury vehicles. This premium synthetic suede material is favored by manufacturers for its aesthetic appeal and superior tactile experience. It enhances the perceived value of the vehicle, making it a popular choice among high-end brands like Audi, Tesla, and Lamborghini. B2B buyers in this sector should ensure that the sourced materials meet stringent automotive standards and certifications, which are critical for safety and performance.

What Role Does Alcantara Play in Furniture Design?

Alcantara rolls are increasingly popular in the furniture industry, especially for high-end upholstery applications. The material’s durability, ease of cleaning, and luxurious appearance make it an ideal choice for premium furniture pieces. It allows manufacturers to create stylish and functional products that stand out in the marketplace. For international buyers, it’s essential to consider color matching and specific durability requirements to align with customer expectations and regional trends.

Why is Alcantara Important in Fashion and Apparel?

In the fashion and apparel sector, Alcantara is utilized in clothing and accessories, offering a stylish and lightweight alternative to traditional fabrics. Its versatility allows designers to create unique products that appeal to environmentally conscious consumers, as it is produced with sustainable practices. Buyers should prioritize sourcing from reputable manufacturers to ensure quality and ethical production, especially when targeting markets in Africa, South America, and Europe, where sustainable fashion is gaining traction.

How is Alcantara Used in Aviation Interiors?

Alcantara rolls are also extensively used in aviation for cabin interiors and seating. The material provides a luxurious feel while being lightweight, which is crucial for aircraft efficiency. Additionally, Alcantara’s fire-retardant properties make it a safe choice for aviation applications. Buyers in this sector must verify compliance with aviation regulations and standards to ensure safety and comfort for passengers.

What Benefits Does Alcantara Offer in Marine Upholstery?

In the marine industry, Alcantara is used for upholstery in luxury yachts and boats due to its resistance to moisture and UV rays. This characteristic ensures longevity and maintains the aesthetic appeal of the marine interiors. B2B buyers should assess the material’s water repellency and UV resistance to ensure it meets the harsh conditions of marine environments, thereby enhancing customer satisfaction and product durability.

3 Common User Pain Points for ‘alcantara roll’ & Their Solutions

Scenario 1: Sourcing Genuine Alcantara Rolls for Quality Assurance

The Problem: B2B buyers, especially in the automotive and luxury goods sectors, often face challenges in sourcing genuine Alcantara rolls. With numerous suppliers in the market, it can be difficult to ascertain the authenticity of the material. This issue is compounded by the risk of receiving inferior products that do not meet quality standards, leading to potential damage to brand reputation and customer dissatisfaction. Buyers may also encounter discrepancies in color and texture, making it hard to match with existing designs.

The Solution: To ensure the authenticity of Alcantara rolls, buyers should prioritize sourcing from certified distributors who have established relationships with the manufacturers, such as Alcantara S.p.A. Requesting samples before placing bulk orders is crucial; this allows for tactile assessment of texture, color, and durability. Additionally, utilizing resources like the EZMatch Swatch Scanner offered by certain suppliers can help buyers achieve precise color matching. Establishing clear communication with suppliers about product specifications and requesting detailed documentation, such as certificates of authenticity, can further safeguard against counterfeit materials.

Scenario 2: Navigating Alcantara’s Care and Maintenance Requirements

The Problem: Alcantara is renowned for its luxurious feel and aesthetic appeal, but many B2B buyers are often unprepared for the specific care and maintenance requirements associated with this material. Improper cleaning methods can lead to permanent damage, such as discoloration or texture loss, which can affect the overall quality of the end product. Buyers may be unaware of the necessary cleaning solutions or techniques to maintain Alcantara’s integrity, leading to increased costs and decreased customer satisfaction.

The Solution: To effectively maintain Alcantara, buyers should familiarize themselves with the care instructions provided by manufacturers. This includes using a soft brush or cloth to remove dirt and dust, followed by specialized cleaning solutions that are safe for synthetic suede. Suppliers often provide detailed care guides; leveraging these resources can ensure the longevity of the material. Buyers can also invest in training for their staff on proper maintenance techniques, which will minimize damage and extend the lifespan of Alcantara products. Creating a maintenance schedule for regular cleaning can help prevent long-term wear and keep the material looking pristine.

Scenario 3: Understanding the Versatility of Alcantara for Different Applications

The Problem: Many B2B buyers struggle to understand the diverse applications of Alcantara, leading to miscalculations in purchasing and project planning. For instance, Alcantara can be utilized in various settings—from automotive interiors to high-end fashion and home decor—but buyers may not be aware of the specific types or finishes that are most suitable for their intended use. This lack of knowledge can result in overspending on unnecessary materials or purchasing unsuitable options that do not fulfill project requirements.

The Solution: To maximize the potential of Alcantara, buyers should conduct thorough research into the various product lines available, such as unbacked, backed, or perforated options, and their respective applications. Engaging with suppliers to discuss project needs can provide valuable insights into the most suitable types of Alcantara for specific uses. Additionally, attending industry trade shows or workshops can enhance understanding of the material’s versatility and showcase innovative applications. By leveraging supplier expertise and networking opportunities, buyers can make informed decisions that align with their project goals, ultimately leading to cost savings and enhanced product offerings.

Strategic Material Selection Guide for alcantara roll

What Are the Key Materials for Alcantara Rolls in B2B Applications?

When selecting materials for Alcantara rolls, several options are available, each with distinct properties and implications for performance, durability, and cost. Understanding these materials is essential for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Alcantara Soft (Foam-Backed)?

Alcantara Soft is a popular choice among manufacturers due to its unique composition of 68% polyester and 32% polyurethane. This foam-backed variant offers excellent grip and durability, making it ideal for automotive interiors and high-traffic applications. Its ability to reduce glare enhances driver visibility, while its cool-to-the-touch surface provides comfort. However, while it is easy to clean, its foam backing may limit its use in applications requiring a more rigid structure.

What Are the Advantages and Disadvantages of Alcantara Unbacked?

Alcantara Unbacked is a single-layer textile that excels in applications where flexibility and stretch are paramount. This material is often used for automotive paneling, headliners, and other interior trim surfaces. Its lightweight nature and superior craftsmanship make it suitable for luxury applications. However, it may not be as durable as foam-backed options, and its price point can be higher, making it a less economical choice for budget-sensitive projects.

How Does Alcantara Perforated Compare in Terms of Media Compatibility?

Alcantara Perforated is specifically designed for applications requiring ventilation, such as automotive seating. The perforations allow for air circulation, enhancing comfort during warmer climates. This material maintains the luxurious aesthetic of Alcantara while offering practical benefits. However, the added complexity in manufacturing perforated materials can lead to increased costs and longer lead times, which may be a consideration for B2B buyers in regions with tight project timelines.

What Should International Buyers Consider When Selecting Alcantara Materials?

For international B2B buyers, compliance with local standards such as ASTM, DIN, or JIS is crucial. Buyers from Africa and South America may need to consider the availability of local suppliers and shipping logistics, while those in Europe might prioritize sustainability and ethical sourcing. Additionally, understanding regional preferences for color and texture can influence purchasing decisions. Ensuring that the selected Alcantara material aligns with these considerations can facilitate smoother transactions and enhance customer satisfaction.

Summary Table of Alcantara Materials

| المواد | Typical Use Case for alcantara roll | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Soft (Foam-Backed) | Automotive interiors, upholstery | Excellent grip and durability | Foam backing limits rigidity | Medium |

| Alcantara Unbacked | Automotive paneling, headliners | Lightweight and flexible | Less durable than foam-backed options | عالية |

| Alcantara Perforated | Ventilated seating applications | Enhanced air circulation | Increased manufacturing complexity | Medium to High |

| Alcantara Multi-layer | High-end automotive interiors | Superior durability and aesthetics | Higher cost due to complex production | عالية |

This guide provides a comprehensive overview of the various materials used in Alcantara rolls, emphasizing their properties, advantages, disadvantages, and considerations for international B2B buyers. By understanding these factors, businesses can make informed decisions that align with their specific needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara roll

What Are the Key Stages in the Manufacturing Process of Alcantara Rolls?

The production of Alcantara rolls involves several critical stages that ensure the creation of a high-quality product. The primary stages include material preparation, forming, assembly, and finishing.

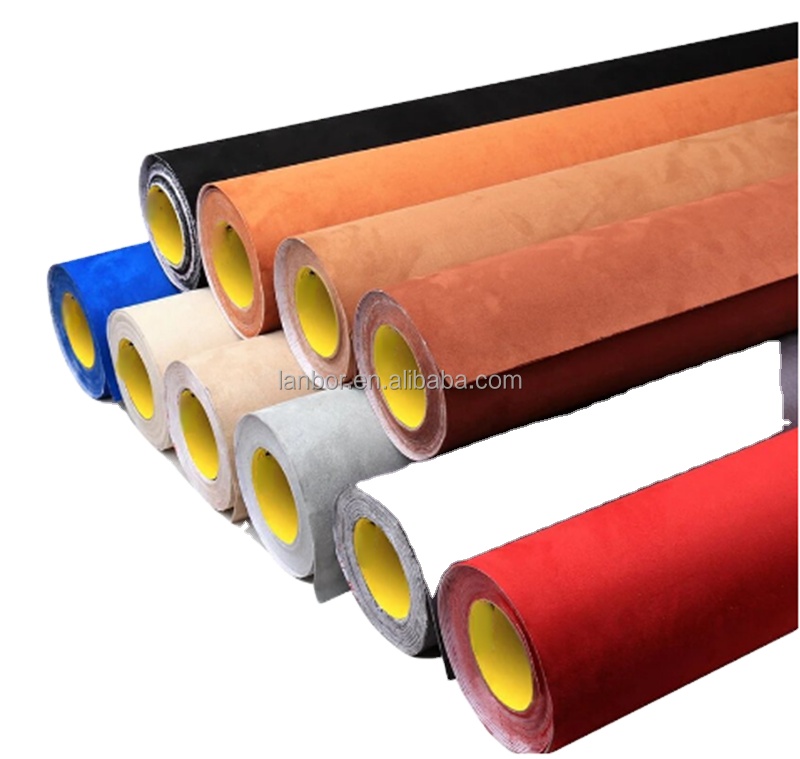

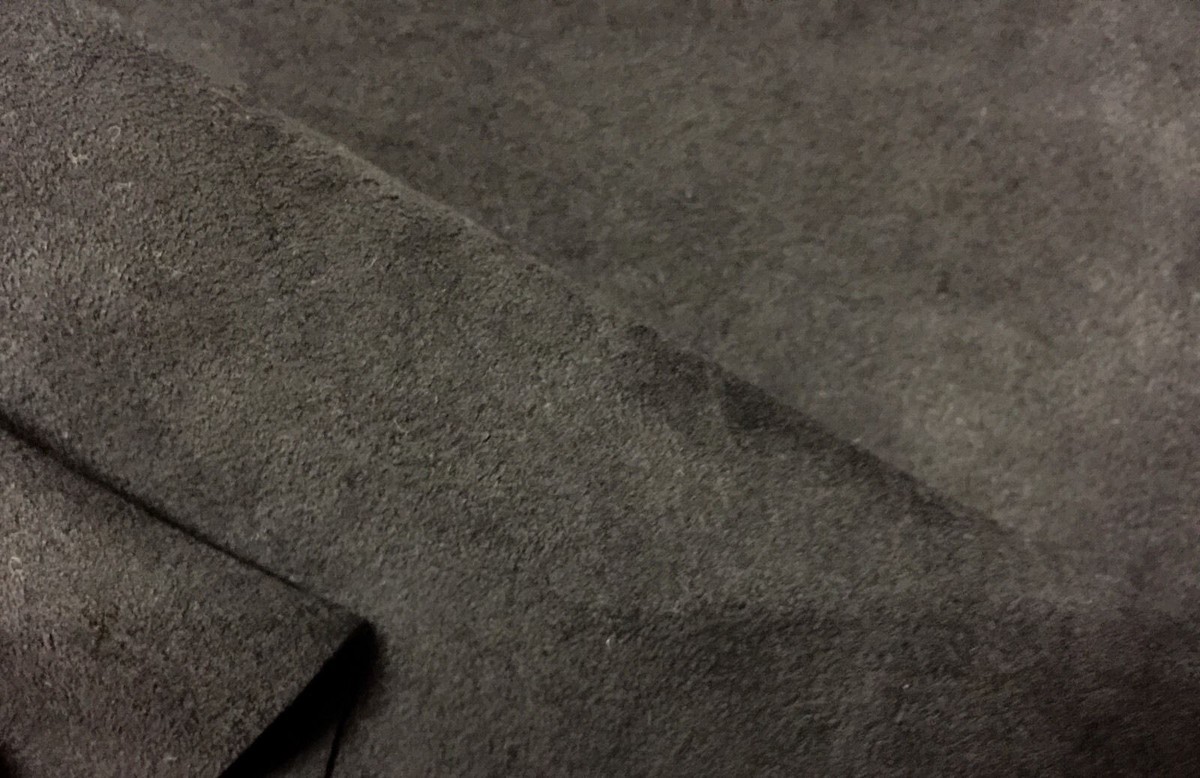

Illustrative image related to alcantara roll

Material Preparation: How Are the Raw Materials Processed?

Alcantara is a synthetic suede made primarily from a blend of polyester and polyurethane. The manufacturing process begins with the careful selection and preparation of these raw materials. The polyester fibers are treated to enhance their properties, such as durability and softness. During this stage, the materials are also dyed to achieve the desired color before being blended with polyurethane. This meticulous preparation is crucial, as it affects the final product’s quality and performance.

Forming: What Techniques Are Used to Create Alcantara Rolls?

Once the materials are prepared, they undergo a forming process. This involves extruding the blended materials into a sheet form. The extrusion process is critical, as it determines the thickness and texture of the Alcantara. Advanced techniques, such as non-woven fabric technology, are employed to ensure that the fibers are evenly distributed, creating a consistent and durable product. The sheets are then cooled and cut into desired dimensions for the roll.

Assembly: How Is Alcantara Fabricated into Rolls?

The assembly stage involves rolling the formed sheets into finished rolls. This process requires precision to ensure that the rolls maintain a uniform thickness and texture throughout their length. Quality control measures are integrated during this stage to monitor any defects or inconsistencies. The rolls are then packaged appropriately for shipping, ensuring they remain in optimal condition until they reach the end-user.

Finishing: What Are the Final Touches Applied to Alcantara Rolls?

Finishing touches are applied to the Alcantara rolls to enhance their aesthetic and functional qualities. This may include additional treatments for water resistance or UV protection, which are particularly valuable in automotive and upholstery applications. The rolls are also inspected for color consistency, texture uniformity, and overall quality. Any discrepancies are addressed at this stage to ensure that only the highest quality products are shipped to clients.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance is a vital component of the manufacturing process for Alcantara rolls. It encompasses various international standards and industry-specific regulations to ensure that the final product meets the highest standards of quality.

What International Standards Are Relevant for Alcantara Manufacturing?

Alcantara manufacturers typically adhere to international quality management standards such as ISO 9001. This certification indicates that the manufacturer has established a quality management system (QMS) that consistently provides products that meet customer and regulatory requirements. Additionally, compliance with CE marking standards may be necessary for products sold in Europe, indicating they meet health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is integrated at several critical checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages. This includes checking the thickness, texture, and color consistency of the Alcantara sheets as they are formed and assembled.

- Final Quality Control (FQC): The finished rolls undergo a comprehensive inspection to verify that they meet all quality specifications before packaging and shipment.

What Common Testing Methods Are Used to Ensure Quality?

Common testing methods for Alcantara rolls include:

- Physical Testing: This may involve measuring tensile strength, abrasion resistance, and colorfastness to ensure durability and longevity.

- Chemical Testing: Evaluates the material’s resistance to various chemicals and conditions, essential for automotive applications.

- Environmental Testing: Assesses the product’s performance under different environmental conditions, ensuring it meets the necessary safety and durability standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

What Steps Can Buyers Take to Assess Supplier QC?

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and QC systems. Buyers should request access to recent audit reports and any corrective actions taken.

-

Request Documentation: Suppliers should provide documentation of their certifications (like ISO 9001) and adherence to industry standards. This documentation can help verify their commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide unbiased evaluations of the manufacturer’s processes and products. These inspections can be scheduled at various points in the supply chain.

-

Sample Testing: Before committing to large orders, buyers can request samples of Alcantara rolls to perform their tests for quality assurance.

What Nuances Should International Buyers Be Aware Of?

International buyers need to be aware of the differences in manufacturing standards across regions. For instance, suppliers in Europe may have stricter compliance with environmental regulations compared to those in other regions. Understanding these nuances can help buyers make informed decisions and ensure they receive products that meet their market standards.

الخاتمة

The manufacturing processes and quality assurance measures for Alcantara rolls are designed to produce a high-quality, durable product suitable for various applications, particularly in the automotive and upholstery industries. By understanding these processes and implementing thorough verification steps, B2B buyers can ensure they are sourcing reliable materials that meet their specific needs and standards.

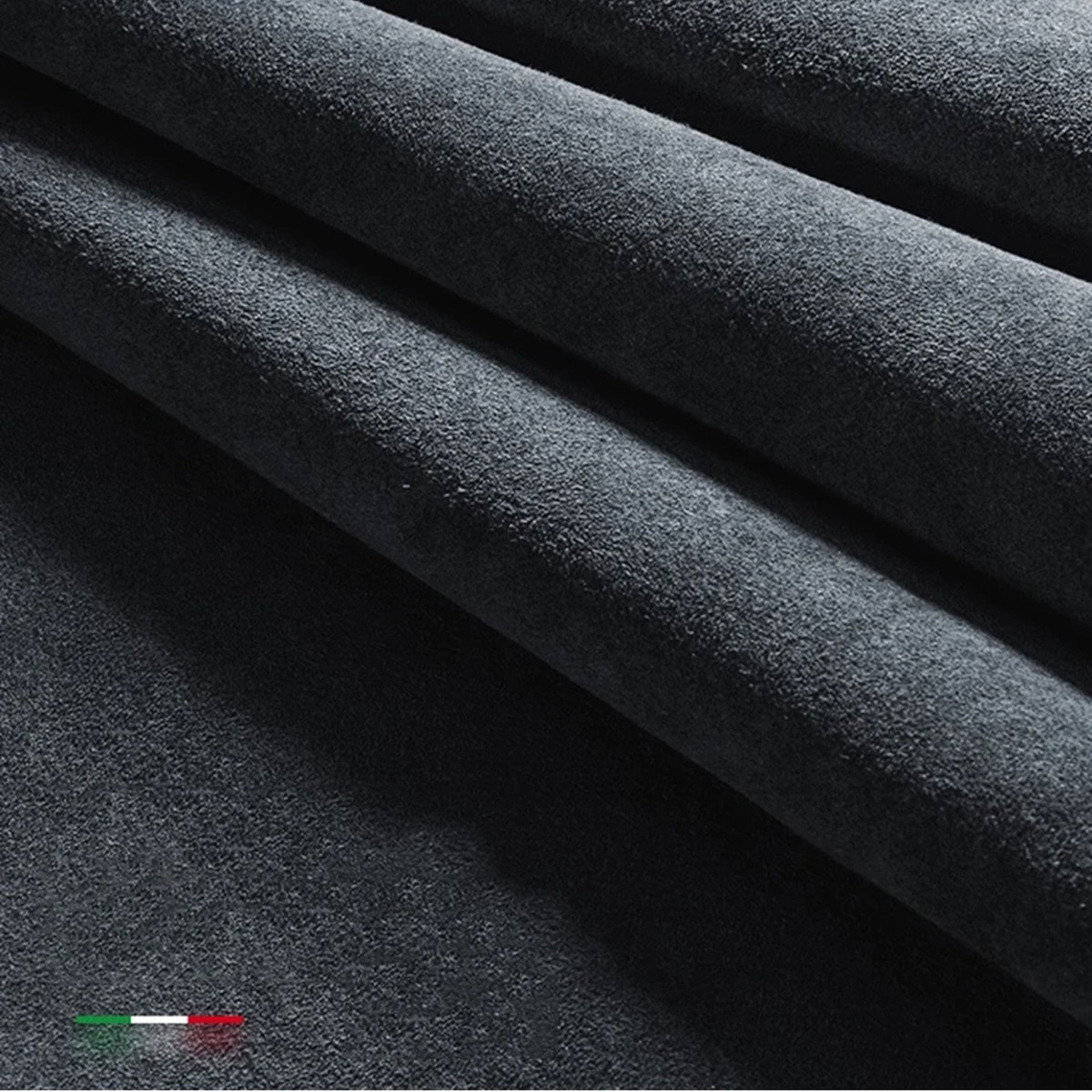

Illustrative image related to alcantara roll

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara roll’

This guide aims to provide B2B buyers with a structured approach to sourcing Alcantara rolls, ensuring informed decisions that align with their business needs. Alcantara, a premium synthetic fabric known for its durability and aesthetic appeal, is increasingly in demand across various industries, including automotive and interior design. By following this checklist, buyers can streamline their procurement process and secure high-quality materials.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before initiating the sourcing process. Consider factors such as the intended application (e.g., automotive interiors, furniture upholstery), desired fabric properties (e.g., softness, grip, durability), and any environmental considerations. Clearly defined specifications will help you communicate effectively with suppliers and ensure that the products meet your expectations.

Step 2: Identify Potential Suppliers

Research and compile a list of reputable suppliers specializing in Alcantara products. Focus on suppliers with a strong track record in your industry and geographical region. Look for companies that offer a variety of Alcantara options (e.g., foam-backed, perforated) to meet diverse needs. Consider using industry-specific platforms or trade shows to identify potential partners.

Step 3: Verify Supplier Certifications

Before proceeding, it’s essential to verify that potential suppliers hold the necessary certifications. Look for quality certifications such as ISO or OEKO-TEX, which indicate compliance with industry standards and environmental regulations. Certifications ensure that the materials are not only high quality but also ethically sourced and manufactured.

Step 4: Request Samples for Evaluation

Always request samples of the Alcantara rolls you are considering. Physical samples allow you to assess color accuracy, texture, and overall quality. Compare these samples against your defined specifications to ensure they meet your requirements. This step is crucial to avoid costly errors and ensure satisfaction with the final product.

Step 5: Evaluate Pricing Structures

Understanding the pricing model is vital for budget management. Inquire about pricing tiers based on order quantities, as bulk purchases often yield discounts. Additionally, clarify any shipping costs, lead times, and payment terms. A transparent pricing structure will help you make informed financial decisions and avoid unexpected expenses.

Step 6: Assess Production Capabilities and Lead Times

Inquire about the supplier’s production capabilities and typical lead times for orders. This information is critical to ensuring that the supplier can meet your project timelines. A reliable supplier should provide clear estimates and be able to accommodate fluctuations in demand, especially for large-scale projects.

Step 7: Establish Communication Protocols

Finally, set up clear communication channels with your chosen supplier. Establishing a point of contact can facilitate smoother interactions and quicker resolutions to any issues that may arise. Regular updates on order status, delivery timelines, and any potential challenges will help maintain a positive supplier relationship and ensure project success.

Illustrative image related to alcantara roll

By following these steps, B2B buyers can effectively navigate the sourcing process for Alcantara rolls, minimizing risks and enhancing overall procurement efficiency.

Comprehensive Cost and Pricing Analysis for alcantara roll Sourcing

What Are the Key Cost Components in Alcantara Roll Sourcing?

When considering the sourcing of Alcantara rolls, several cost components must be analyzed. Materials are the primary expense, with Alcantara typically composed of 68% polyester and 32% polyurethane. The quality of these materials directly affects the final product’s durability and appearance. Labor costs are also significant, especially in regions with higher wage standards, impacting the overall cost of production.

Manufacturing overhead includes expenses related to facility maintenance, utilities, and administrative costs, which can vary widely based on geographic location. Tooling costs, while typically a one-time expense, can be substantial for customized orders, as specialized machinery may be required to produce specific Alcantara variations. Quality Control (QC) is essential to ensure that the final product meets industry standards, particularly for automotive applications where safety and durability are critical. Finally, logistics encompasses shipping and handling, which can be influenced by distance, shipping methods, and packaging requirements.

How Do Volume and Customization Influence Alcantara Pricing?

Pricing for Alcantara rolls is heavily influenced by volume and minimum order quantities (MOQ). Suppliers often provide tiered pricing structures, where the unit cost decreases as the order size increases. For instance, ordering 25 yards of Alcantara may yield a lower price per yard compared to ordering just one yard.

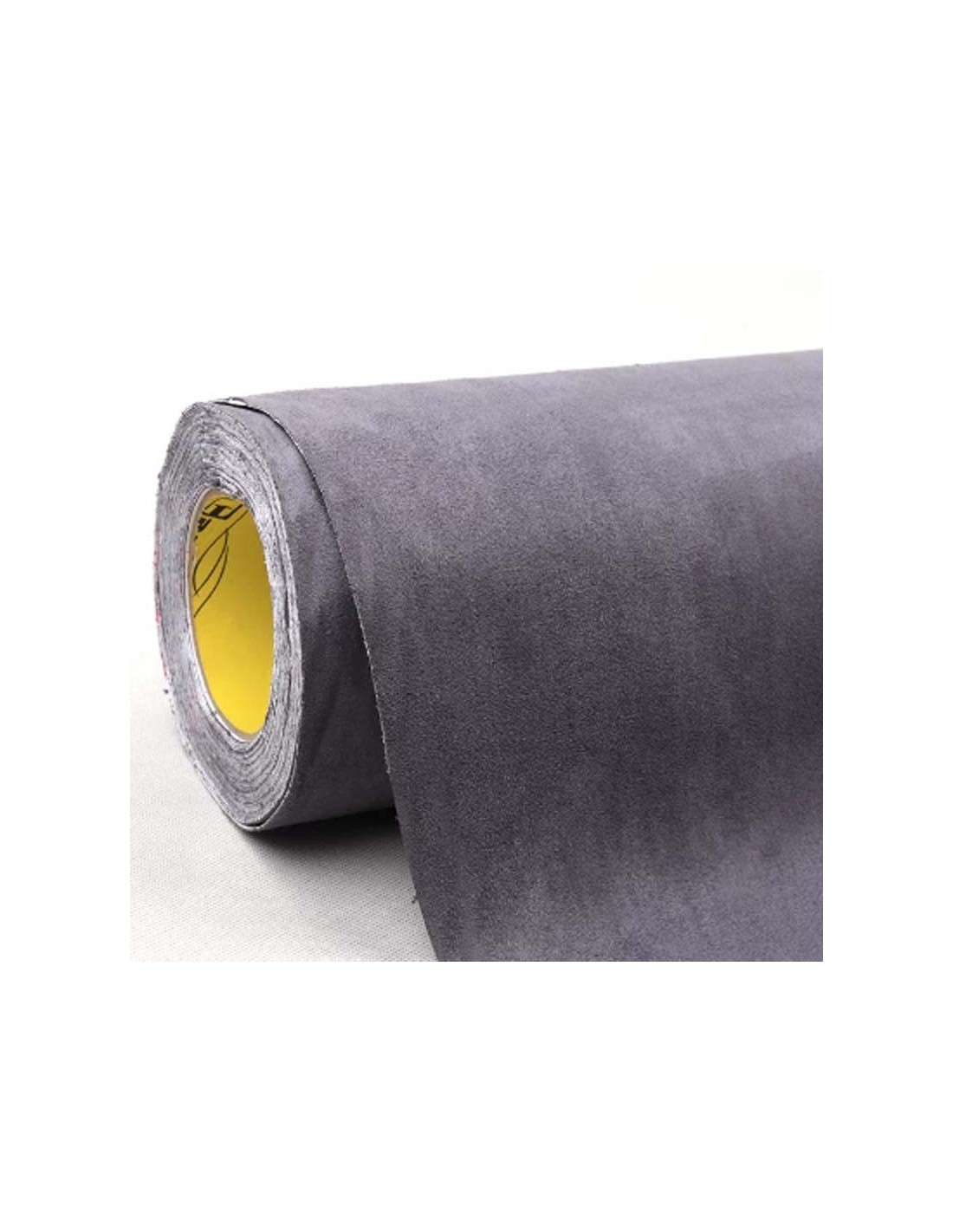

Illustrative image related to alcantara roll

Specifications and customization also play a crucial role in pricing. Unique colors, patterns, or finishes can increase the cost due to the additional resources needed for production. Furthermore, the quality and certifications associated with Alcantara products—such as eco-friendliness and compliance with automotive standards—can impact pricing, as higher-quality products typically command a premium.

What Supplier Factors Should Buyers Consider for Cost-Efficiency?

When sourcing Alcantara rolls, it’s essential to evaluate supplier factors such as reputation, reliability, and production capabilities. Established suppliers with a history of providing high-quality materials often justify higher prices due to their proven track record. Additionally, understanding the Incoterms used in the transaction is vital, as they dictate the responsibilities of both the buyer and supplier regarding shipping costs, insurance, and liability.

What Are Effective Negotiation Strategies for Alcantara Sourcing?

Effective negotiation strategies can significantly impact the cost-efficiency of Alcantara sourcing. Buyers should prepare by conducting thorough market research to understand average pricing and identify potential suppliers. Presenting a clear, detailed request that outlines specifications and expected volumes can help in securing favorable terms.

Additionally, buyers should be open to discussing Total Cost of Ownership (TCO), which encompasses not just the initial purchase price but also long-term costs related to maintenance, durability, and potential waste. Highlighting the benefits of long-term partnerships can encourage suppliers to offer better pricing or terms.

What Are Pricing Nuances for International Buyers in Diverse Markets?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of pricing nuances that can affect sourcing decisions. Currency fluctuations may impact costs, as well as import tariffs and duties that vary by country. Understanding local regulations regarding imports, especially in the automotive sector, is crucial to avoid unexpected expenses.

Additionally, differences in logistics capabilities and infrastructure can influence lead times and overall costs. Buyers should also consider the potential for sourcing locally if available, as this can reduce shipping costs and lead times, enhancing overall supply chain efficiency.

Disclaimer on Indicative Pricing

It’s important to note that the prices mentioned for Alcantara rolls are indicative and can vary based on multiple factors, including supplier, order size, customization, and current market conditions. Always consult directly with suppliers for the most accurate pricing and terms tailored to specific needs.

Alternatives Analysis: Comparing alcantara roll With Other Solutions

Exploring Alternatives to Alcantara Roll in Automotive Upholstery

When considering upholstery materials for automotive interiors, it’s essential to evaluate various options to determine the best fit for specific applications. Alcantara roll is a popular choice due to its premium quality, but there are other viable alternatives worth considering. Below, we compare Alcantara roll with two alternatives: synthetic leather and genuine leather. This analysis will help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Alcantara Roll | جلد صناعي | Genuine Leather |

|---|---|---|---|

| Performance | High durability, soft touch, excellent grip, and reduces glare. | Good durability, moderate grip, can feel less premium. | Superior durability, luxurious feel, high-end aesthetics. |

| Cost | Moderate to high cost, often premium-priced due to brand and quality. | Generally lower cost, making it budget-friendly. | High cost, varies significantly based on quality and source. |

| Ease of Implementation | Easy to cut and sew, flexible, good for complex shapes. | Generally easy to work with, can be less flexible than Alcantara. | More challenging to work with due to thickness and rigidity. |

| Maintenance | Easy to clean, resistant to stains and fading. | Easy to clean, but may not be as stain-resistant as Alcantara. | Requires regular conditioning and care to prevent drying and cracking. |

| Best Use Case | High-end automotive interiors, luxury vehicles, and specialty applications. | Budget-conscious projects, non-luxury vehicles, and commercial applications. | Luxury automotive interiors, bespoke projects, and high-quality furnishings. |

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, also known as faux leather or vegan leather, is a popular alternative to Alcantara. Its primary advantage lies in its cost-effectiveness, making it an attractive option for budget-conscious buyers. It is widely available and can be manufactured to mimic the appearance of genuine leather or Alcantara. However, synthetic leather may lack the premium feel and durability of Alcantara and can show wear over time, particularly in high-traffic areas.

Illustrative image related to alcantara roll

Why Consider Genuine Leather Over Alcantara Roll?

Genuine leather is often regarded as the gold standard in upholstery materials, prized for its luxurious look and feel. It offers unmatched durability and can develop a unique patina over time, enhancing its aesthetic appeal. However, genuine leather comes at a higher price point and requires more maintenance to ensure longevity, including conditioning to prevent drying and cracking. Additionally, it may not be as easy to work with as Alcantara, making it less suitable for certain applications.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right upholstery material depends on several factors, including budget constraints, desired aesthetics, and the specific application within the automotive industry. For high-end vehicles where luxury and performance are paramount, Alcantara roll stands out as an excellent choice due to its combination of durability and elegance. Conversely, for budget-friendly projects or commercial vehicles, synthetic leather may offer a more practical solution. Meanwhile, genuine leather remains the preferred option for bespoke projects where quality and craftsmanship are key considerations.

Ultimately, B2B buyers should assess their specific needs and weigh the pros and cons of each alternative. This approach will ensure they choose the best material that aligns with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for alcantara roll

What Are the Key Technical Properties of Alcantara Rolls for B2B Buyers?

Understanding the technical specifications of Alcantara rolls is crucial for B2B buyers in industries such as automotive, fashion, and interior design. Here are several key properties to consider:

Illustrative image related to alcantara roll

1. Material Composition

Alcantara is primarily composed of 68% polyester and 32% polyurethane. This unique blend provides a soft, suede-like texture while ensuring durability and ease of maintenance. For B2B buyers, knowing the material composition helps assess the product’s quality and suitability for specific applications, particularly in luxury markets where aesthetics and performance are paramount.

2. Roll Width

Typically, Alcantara rolls are available in widths of 54 to 56 inches. This measurement is essential for manufacturers who need to optimize material usage and minimize waste during production. B2B buyers should consider their cutting and sewing processes to ensure that the roll width aligns with their operational requirements.

3. Thickness

The standard thickness of Alcantara is around 1.0 mm. This property impacts the fabric’s flexibility and application. Thicker materials may offer enhanced durability, while thinner options can provide more versatility in design. Buyers should evaluate the thickness concerning the end use, such as whether it will be used for seating, panels, or fashion accessories.

Illustrative image related to alcantara roll

4. Care Instructions

Alcantara is known for its ease of cleaning, which is a significant advantage in high-traffic applications like automotive interiors. Understanding care instructions can influence purchasing decisions, especially for buyers focused on long-term maintenance costs. Buyers should look for suppliers who provide clear care guidelines to ensure the longevity of their products.

5. Durability and Performance Ratings

Alcantara is engineered to withstand heavy use, making it an ideal choice for automotive and high-end furniture applications. Performance ratings, such as abrasion resistance and colorfastness, are crucial for buyers assessing the longevity of their investment. Ensuring that the selected Alcantara meets specific performance standards can significantly impact customer satisfaction and brand reputation.

What Trade Terminology Should B2B Buyers of Alcantara Rolls Be Familiar With?

Navigating the purchasing process requires familiarity with industry jargon. Here are some essential terms:

Illustrative image related to alcantara roll

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. In the context of Alcantara, many luxury automotive brands source their materials from OEM suppliers. Understanding this term is vital for buyers looking to establish partnerships with reputable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For Alcantara rolls, MOQs can vary significantly based on the supplier and the specific material type. Buyers should clarify MOQs to ensure they can meet their production needs without incurring excessive costs.

3. RFQ (Request for Quotation)

An RFQ is a formal request for pricing and availability from suppliers. B2B buyers should utilize RFQs when seeking competitive quotes for Alcantara rolls, allowing them to compare options effectively and negotiate favorable terms.

Illustrative image related to alcantara roll

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities when sourcing Alcantara rolls from different regions, including Europe and the Middle East.

5. Customization

Customization refers to the ability to modify products according to specific client needs, such as color, texture, and size. For B2B buyers, understanding the customization options available for Alcantara can significantly enhance product offerings and meet unique market demands.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing Alcantara rolls, ensuring they select the best materials for their applications while optimizing costs and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the alcantara roll Sector

What Are the Current Market Trends Influencing Alcantara Roll Sourcing?

The Alcantara roll market is experiencing a dynamic shift driven by several global factors. The increasing demand for sustainable and high-quality upholstery materials in automotive, fashion, and interior design sectors is paramount. Alcantara, made from a blend of polyester and polyurethane, presents itself as a superior alternative to traditional leather due to its durability, ease of maintenance, and aesthetic appeal. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that offer a diverse range of Alcantara products, including foam-backed and perforated varieties suitable for various applications.

Emerging technologies are also reshaping sourcing trends. E-commerce platforms are facilitating easier access to Alcantara materials, allowing buyers to compare prices and quality from various suppliers worldwide. The rise of digital swatch matching tools and online sample requests enhances the buyer experience, making it simpler to select the right fabric without the need for in-person visits. Additionally, the demand for customized solutions is growing, with manufacturers offering tailored Alcantara options to meet specific client requirements, particularly in luxury automotive interiors.

How Is Sustainability Reshaping the Alcantara Roll Sector?

Sustainability is becoming a critical consideration in the Alcantara roll sector. As environmental awareness rises globally, B2B buyers are increasingly looking for suppliers who can demonstrate a commitment to ethical sourcing and sustainable practices. Alcantara is produced in Italy under stringent environmental regulations, ensuring minimal ecological impact during its manufacturing process. This includes the use of water-based adhesives and dyes, which significantly reduce harmful emissions compared to traditional leather production methods.

The importance of ethical supply chains cannot be overstated. Buyers are not only concerned about the materials they source but also about the social implications of their procurement decisions. Certifications such as OEKO-TEX® and Global Organic Textile Standard (GOTS) are becoming vital for demonstrating compliance with environmental and social responsibility standards. By choosing Alcantara, buyers can align their sourcing strategies with sustainable practices, enhancing their brand reputation and meeting the growing consumer demand for eco-friendly products.

What Is the Historical Context of Alcantara’s Development in B2B Markets?

Alcantara was first introduced in the late 1970s as a premium synthetic material designed to mimic the luxurious feel of suede while offering enhanced durability and ease of care. Over the decades, it has evolved into a sought-after fabric for high-end automotive interiors, fashion, and home furnishings. Its unique blend of aesthetics and functionality has made it a preferred choice among luxury brands, including Audi, Lamborghini, and Maserati.

The development of Alcantara has also been influenced by advancements in textile technology, allowing for the creation of various textures and finishes to cater to diverse market needs. As the global market continues to evolve, the demand for Alcantara remains robust, driven by its ability to meet the dual demands of luxury and sustainability. This historical perspective is crucial for B2B buyers as it underscores the fabric’s established reputation and ongoing innovation in response to market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara roll

-

How do I ensure the quality of Alcantara rolls before purchasing?

To ensure quality, request samples from suppliers to evaluate the texture, color, and durability of the Alcantara rolls. Look for manufacturers that provide detailed specifications and certifications, such as ISO standards. Additionally, inquire about their quality assurance processes, including testing methods for color fastness, abrasion resistance, and environmental impact. Engaging in a factory visit, if possible, can also provide insights into their production practices and quality control measures. -

What is the best Alcantara roll for automotive applications?

For automotive applications, Alcantara Soft (foam-backed) is often the best choice due to its durability, ease of cleaning, and superior grip compared to leather. This type offers enhanced comfort, reduces glare, and remains cool to the touch, making it ideal for seats and interiors. Ensure you consider the specific requirements of your project, such as color and texture, and consult with suppliers for tailored recommendations based on your needs. -

What are the typical minimum order quantities (MOQs) for Alcantara rolls?

Minimum order quantities for Alcantara rolls can vary significantly among suppliers. Generally, MOQs can range from one yard to several hundred yards, depending on the supplier’s policies and the type of Alcantara. It’s advisable to communicate your project requirements upfront to determine if the supplier can accommodate smaller or larger orders. Some suppliers may offer tiered pricing based on order size, allowing for better budgeting and planning. -

How can I customize Alcantara rolls for my specific needs?

Customization options for Alcantara rolls typically include color selection, texture variations, and backing types. Many suppliers offer a range of colors and finishes, and some can accommodate bespoke requests. To initiate customization, discuss your requirements directly with the supplier, and request samples to confirm that the final product meets your expectations. Be prepared to provide details about your application to ensure the best possible outcome. -

What payment terms should I expect when sourcing Alcantara rolls internationally?

Payment terms can vary widely among suppliers, but standard practices often include options like advance payment, partial payment upfront with the balance upon delivery, or net terms (e.g., net 30 or net 60). It’s essential to clarify these terms during negotiations and consider using secure payment methods such as letters of credit or escrow services for large transactions. Always ensure the terms are documented in your purchase agreement to avoid misunderstandings. -

How do I vet suppliers when sourcing Alcantara rolls internationally?

Vetting suppliers involves checking their business credentials, customer reviews, and industry certifications. Request references from previous clients and inquire about their experience with international shipping, particularly to your region. It’s also beneficial to assess their responsiveness and willingness to provide detailed information about their products and services. Engaging third-party inspection services can further ensure that the supplier meets your quality standards before placing a large order. -

What logistics considerations should I keep in mind when importing Alcantara rolls?

When importing Alcantara rolls, consider shipping methods, lead times, and customs regulations in your country. Discuss logistics with your supplier to determine the best shipping options, whether by air or sea, based on cost and urgency. Ensure you understand the import duties and taxes applicable in your region to avoid unexpected costs. Additionally, collaborate with a reliable freight forwarder to streamline the import process and handle any potential challenges. -

What are the care instructions for maintaining Alcantara rolls once received?

To maintain Alcantara rolls, follow care instructions provided by the manufacturer, which typically recommend gentle cleaning methods. Use a soft brush or cloth to remove dust and debris, and avoid harsh chemicals that may damage the fabric. For stains, a damp cloth with mild soap can be effective; however, always test a small area first. Regular maintenance will extend the life of the Alcantara and keep it looking fresh, especially in high-traffic applications like automotive interiors.

Top 8 Alcantara Roll Manufacturers & Suppliers List

1. Alcantara – Automotive Fabric Solutions

Domain: keystonbros.com

Registered: 1997 (28 years)

مقدمة: Alcantara Suede – Automotive Fabric. Product options include Alcantara Cover, Alcantara Soft, Alcantara Pannel, Alcantara EXO, Alcantara Pannel MB-4 Perf, and Alcantara Pannel S-2000 Perf. Pricing requires login to view. Additional details such as roll size, cleaning code, abrasion, and UFAC class are not specified in the provided text.

2. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

مقدمة: Alcantara Soft is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Available colors include: Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, Raw Amber, Dark Brown, Brombeer…

3. Relicate – Alcantara Fabric & Leather Solutions

Domain: relicate.com

Registered: 2013 (12 years)

مقدمة: Alcantara fabric available in various types including: Pannel (Unbacked), Cover (Backed), EXO Outdoor, Foam Backed, Multilayer, Perforated, and Starlite. Product offerings include solid color leather, Nappa Italia leather, Napali leather, and various OEM auto leather colors for brands like BMW, Ferrari, Lamborghini, Porsche, Rolls Royce, and American cars. Specialty leathers include distressed and…

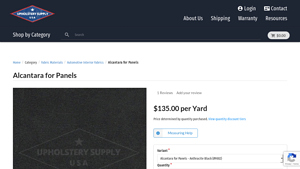

4. Upholstery Supply USA – Alcantara for Panels

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

مقدمة: {“name”: “Alcantara for Panels”, “color_options”: [“Anthracite Black (#9002)”, “Black (#9040)”, “Amber Glow (#1110)”, “Dark Brown (#9500)”, “Red (#4996)”, “Silver Grey (#4978)”, “Orion Grey (#2934)”, “Slate Grey (#2957)”], “price_per_yard”: {“1_to_9”: 135.00, “10_to_24”: 130.00, “25_plus”: 125.00}, “material_type”: “Genuine Alcantara Textile”, “made_in”: “Italy”, “applications”: [“Automotive Inter…

5. Hydes Leather – Alcantara Products

Domain: hydesleather.com

Registered: 2006 (19 years)

مقدمة: Hydes Leather is the official distributor of Alcantara in North America, offering a complete range of Alcantara products used by luxury auto brands in Europe. Alcantara is 100% made in Italy and is known for its style, elegance, functionality, and environmental ethics. The types of Alcantara available include:

1. Alcantara Panel: Unbacked, thin, and workable, used for headliners, doors, dashboard…

6. Alcantara – Craft Fabric for Car Interiors

Domain: ebay.com

Registered: 1995 (30 years)

مقدمة: Alcantara Craft Fabric for sale on eBay. Key details include: Brand New condition, dimensions of 1.4×1.6m, suitable for car interior decoration and headliner applications. Current price is $179.99, previously listed at $199.99. Free shipping available. Popular related searches include Alcantara Fabric Roll, Alcantara Black, and Alcantara Suede Fabric.

7. OEM Auto Fabric – ALCANTARA – BLACK

Domain: oemautofabric.com

Registered: 2018 (7 years)

مقدمة: {“Product Name”: “ALCANTARA – BLACK”, “Material”: “Genuine Alcantara”, “Color”: “Black”, “Width”: “61 inches”, “Price Range”: “$3.00 – $120.00”, “SKU”: “ALCANTARA-BLACK”, “Categories”: [“Bodycloth”, “Specialty Fabrics”], “Tags”: [“Alcantara”, “Suede”]}

8. Alcantara – Synthetic Suede for Car Interiors

Domain: carwow.co.uk

Registered: 2011 (14 years)

مقدمة: Alcantara is a synthetic suede-like fabric made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is commonly used in car interiors for steering wheels, gear levers, seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic,…

Strategic Sourcing Conclusion and Outlook for alcantara roll

In today’s competitive landscape, effective strategic sourcing of Alcantara rolls is paramount for businesses aiming to enhance their product offerings while ensuring sustainability and quality. Alcantara’s unique blend of durability, aesthetic appeal, and ease of maintenance positions it as a preferred choice for luxury automotive interiors and other applications. By leveraging the distinct characteristics of Alcantara, such as its superior grip and temperature regulation, businesses can deliver exceptional value to their customers.

International B2B buyers from regions like Africa, South America, the Middle East, and Europe should prioritize sourcing from reputable suppliers who guarantee genuine Italian Alcantara. This not only ensures high-quality materials but also aligns with ethical sourcing practices. Understanding the pricing tiers based on quantity can lead to significant cost savings, making it essential to explore bulk purchasing options.

As the demand for sustainable and high-performance materials continues to rise, investing in Alcantara will position your brand at the forefront of innovation. Now is the time to engage with suppliers who can offer customized solutions tailored to your specific needs. Embrace the opportunity to elevate your product line with Alcantara, and take proactive steps towards a more sustainable and stylish future in your business offerings.

Illustrative image related to alcantara roll

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.