Introduction: Navigating the Global Market for custom leather printing

In an increasingly competitive global marketplace, sourcing high-quality custom leather printing solutions presents a significant challenge for B2B buyers. Whether you are in Nigeria, Brazil, or any other region, the task of finding reliable suppliers that can deliver bespoke leather products tailored to your specific needs can be daunting. This comprehensive guide aims to demystify the world of custom leather printing by providing insights into various types of leather, applications across different industries, and essential criteria for vetting potential suppliers.

From fashion accessories to furniture upholstery, the applications of custom printed leather are vast, offering endless creative possibilities. Buyers will learn about the latest printing technologies, including the advantages of digital printing, which ensures vibrant designs and durability. Additionally, we will explore cost considerations, helping you balance quality with budget constraints while ensuring a sustainable and ethical sourcing process.

This guide empowers international B2B buyers to make informed purchasing decisions by equipping them with the knowledge necessary to navigate the complexities of the custom leather printing market. By understanding the nuances of product specifications, supplier capabilities, and market trends, you can confidently select the right partners to elevate your brand’s offerings and meet your business objectives.

Table Of Contents

- Top 9 Custom Leather Printing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather printing

- Understanding custom leather printing Types and Variations

- Key Industrial Applications of custom leather printing

- 3 Common User Pain Points for ‘custom leather printing’ & Their Solutions

- Strategic Material Selection Guide for custom leather printing

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather printing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather printing’

- Comprehensive Cost and Pricing Analysis for custom leather printing Sourcing

- Alternatives Analysis: Comparing custom leather printing With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather printing

- Navigating Market Dynamics and Sourcing Trends in the custom leather printing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather printing

- Strategic Sourcing Conclusion and Outlook for custom leather printing

- Important Disclaimer & Terms of Use

Understanding custom leather printing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Digital Printed Leather | High-resolution designs printed directly into the leather | Fashion items, upholstery, promotional goods | Pros: Vibrant colors, custom designs. Cons: Potentially higher costs for small batches. |

| Vegan Leather Printing | Utilizes synthetic or plant-based materials | Eco-friendly products, fashion accessories | Pros: Sustainable, cruelty-free. Cons: May lack the durability of genuine leather. |

| Suede Printing | Soft, textured finish with a luxurious feel | High-end fashion, luxury goods, upholstery | Pros: Elegant appearance, versatile. Cons: More prone to staining and wear. |

| Embossed Leather | Raised designs created through pressure | Branding, promotional items, luxury packaging | Pros: Adds texture and depth. Cons: Limited color options. |

| Nappa Leather Printing | Smooth, full-grain leather known for its softness | Apparel, accessories, high-quality goods | Pros: Durable, luxurious feel. Cons: Higher cost compared to other leathers. |

What Are the Characteristics of Digital Printed Leather?

Digital printed leather is a cutting-edge method that allows for intricate designs to be printed directly into the leather fibers. This technique offers vibrant colors and exceptional detail, making it ideal for fashion items, upholstery, and promotional goods. When considering a purchase, B2B buyers should note that while digital printing provides customization options, it may come at a higher cost for small batch orders. It’s a suitable choice for businesses looking to create unique products that stand out in the market.

How Does Vegan Leather Printing Differ from Traditional Options?

Vegan leather printing employs synthetic or plant-based materials, making it an attractive option for eco-conscious brands. This type of leather is increasingly popular in fashion accessories and eco-friendly products, as it caters to consumers seeking cruelty-free alternatives. B2B buyers should consider the sustainability angle, as well as the potential trade-offs in durability compared to genuine leather. While vegan leather can be less expensive, its longevity may vary based on the manufacturing process.

What Are the Benefits of Using Suede Printing for High-End Products?

Suede printing offers a soft, textured finish that adds a touch of luxury to any product. This variation is particularly popular in high-end fashion, luxury goods, and upholstery. Businesses that choose suede should be aware of its elegant appearance but also consider its susceptibility to staining and wear. For B2B buyers, this means weighing the aesthetic benefits against the practical implications of maintaining suede products in a commercial setting.

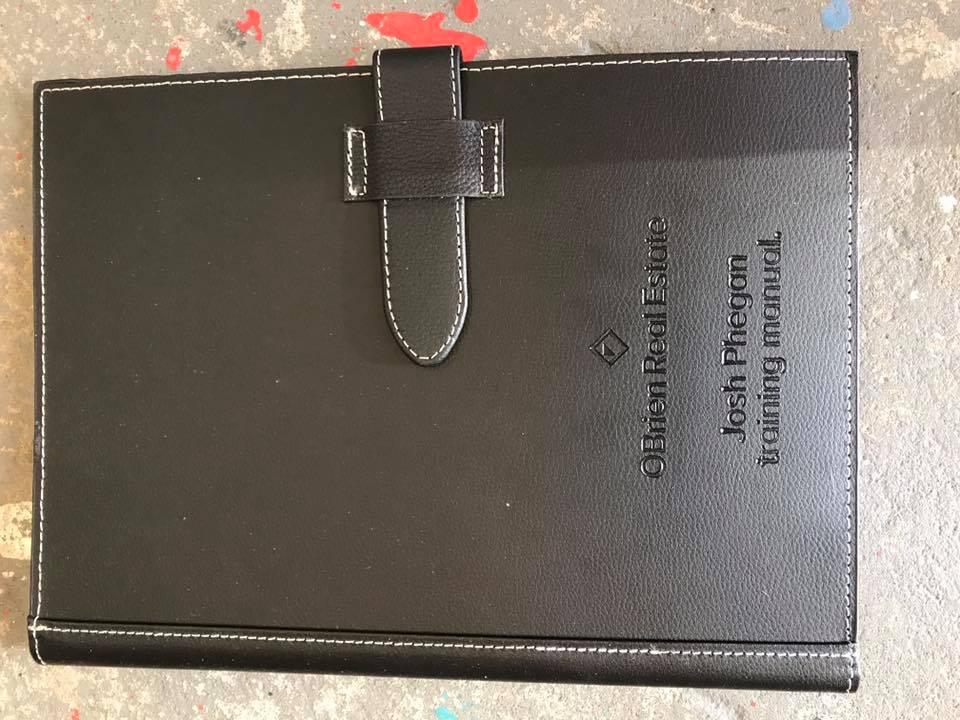

Illustrative image related to custom leather printing

Why Choose Embossed Leather for Branding and Packaging?

Embossed leather features raised designs created through pressure, making it an excellent choice for branding and promotional items. This technique adds texture and depth, enhancing the visual appeal of products such as luxury packaging. Buyers should evaluate the limited color options that come with embossed leather, but recognize the unique branding opportunities it presents. For businesses focused on premium presentation, embossed leather can elevate their product offerings significantly.

What Makes Nappa Leather Printing a Preferred Choice for Quality Goods?

Nappa leather is known for its smooth, full-grain texture, making it a favorite for apparel, accessories, and high-quality goods. Its luxurious feel and durability make it an appealing option for B2B buyers looking to invest in premium products. However, the cost of Nappa leather is typically higher than other types, which may impact budget considerations. Companies should assess whether the investment aligns with their brand image and target market expectations.

Key Industrial Applications of custom leather printing

| Industry/Sector | Specific Application of custom leather printing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom leather jackets and bags | Unique branding opportunities and product differentiation | Quality of leather, printing technology, lead times, and minimum order quantities |

| Automotive | Personalized leather interiors for vehicles | Enhanced customer experience and brand loyalty | Durability, color accuracy, and compliance with safety standards |

| Furniture & Home Decor | Customized leather upholstery for furniture | Increased market appeal and customization options | Material sourcing, eco-friendliness, and design capabilities |

| Promotional Products | Branded leather accessories (e.g., wallets, keychains) | Effective marketing tool with lasting impressions | Cost-effectiveness, turnaround time, and design flexibility |

| Sporting Goods | Custom leather goods for sports teams (e.g., gloves, bags) | Team identity reinforcement and fan engagement | Material performance, customization options, and bulk pricing |

How is Custom Leather Printing Used in the Fashion & Apparel Industry?

In the fashion sector, custom leather printing is leveraged to create distinctive leather jackets, handbags, and accessories that resonate with consumers. This capability allows brands to showcase their unique designs and logos, enhancing brand recognition. International buyers should consider the quality of leather and printing technology used, as well as the supplier’s ability to meet specific lead times and minimum order quantities, which can vary by region.

What Are the Benefits of Custom Leather Printing in Automotive Interiors?

The automotive industry utilizes custom leather printing to enhance vehicle interiors with personalized designs and branding elements. This not only improves the aesthetic appeal of vehicles but also fosters brand loyalty among customers. Businesses must ensure that the printed leather meets durability standards and offers color accuracy to withstand wear and tear, especially in regions with varying climates.

How Does Custom Leather Printing Enhance Furniture & Home Decor?

In the furniture and home decor industry, custom leather printing is employed for upholstery, allowing for unique designs that cater to consumer preferences. This customization can lead to increased market appeal and a competitive edge. Buyers need to assess the sourcing of materials for sustainability, the printing capabilities for intricate designs, and the overall durability of the finished product.

Why Are Promotional Products Benefited by Custom Leather Printing?

Custom leather printing is a powerful tool for creating branded leather accessories such as wallets and keychains, which serve as effective promotional items. These products leave lasting impressions on clients and customers, reinforcing brand identity. When sourcing these items, businesses should consider cost-effectiveness, the speed of production, and the flexibility of design to ensure they meet marketing objectives.

How is Custom Leather Printing Used in Sporting Goods?

In the sporting goods sector, custom leather printing is applied to create personalized gear for teams, including gloves and bags. This fosters team identity and enhances fan engagement. Buyers must focus on the performance of the materials used, ensuring they can withstand rigorous use, while also considering customization options and bulk pricing for larger orders.

3 Common User Pain Points for ‘custom leather printing’ & Their Solutions

Scenario 1: Navigating Quality Control in Custom Leather Printing

The Problem: A B2B buyer in the fashion industry, sourcing custom leather for a new product line, faces significant anxiety over quality control. The fear of receiving leather with inconsistent printing quality, color fading, or surface imperfections can lead to production delays and financial loss. This is particularly concerning when buyers are unfamiliar with the suppliers’ standards and processes, which can vary greatly across regions.

The Solution: To mitigate quality control issues, buyers should prioritize suppliers with transparent quality assurance protocols. Requesting detailed samples before committing to large orders is crucial. This allows you to assess the color accuracy, texture, and durability of the printed leather firsthand. Additionally, inquire about the printing technology used; advanced digital printing techniques that penetrate the leather fibers typically yield better results than surface coatings. Establishing clear specifications and performance criteria upfront, such as rub tests or color fastness, can ensure the final product meets expectations, ultimately safeguarding your investment and timeline.

Illustrative image related to custom leather printing

Scenario 2: Overcoming Design Limitations in Custom Leather Printing

The Problem: A manufacturer looking to create a unique line of leather handbags struggles with design limitations imposed by traditional printing methods. Concerns arise regarding the ability to accurately reproduce intricate patterns or vibrant colors, which are essential for brand differentiation in a competitive market.

The Solution: To address design limitations, opt for suppliers who utilize state-of-the-art digital printing technology. This method allows for high-resolution images and complex designs, ensuring that every detail is captured accurately. When discussing your project, provide high-quality digital files and engage in a collaborative design process with the supplier. Many providers offer design consultations to help refine your artwork for optimal printing results. Additionally, consider testing different leather types, such as suede or vegan leather, which may enhance the visual impact of your designs. This proactive approach can lead to a standout product that resonates with consumers.

Scenario 3: Managing Lead Times and Delivery Challenges in Custom Leather Printing

The Problem: A buyer in the automotive sector faces the challenge of long lead times and unpredictable delivery schedules when sourcing custom leather for vehicle interiors. Delays in receiving materials can disrupt production schedules and negatively impact customer satisfaction.

Illustrative image related to custom leather printing

The Solution: To effectively manage lead times, establish a strong partnership with suppliers who have proven track records of reliability and timely delivery. When negotiating contracts, clarify turnaround times and set milestones for production phases. Consider using suppliers located closer to your manufacturing facilities to reduce shipping times. Additionally, implementing a just-in-time inventory system can help mitigate the risk of overstocking while ensuring that you have materials on hand when needed. Open lines of communication with your suppliers are essential; regular check-ins can help you stay updated on production status and quickly address any potential delays, ensuring a smooth workflow and keeping your projects on schedule.

Strategic Material Selection Guide for custom leather printing

What Are the Key Materials for Custom Leather Printing?

When considering custom leather printing, selecting the right material is crucial for achieving the desired product performance and aesthetic appeal. Below, we analyze four common materials used in custom leather printing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

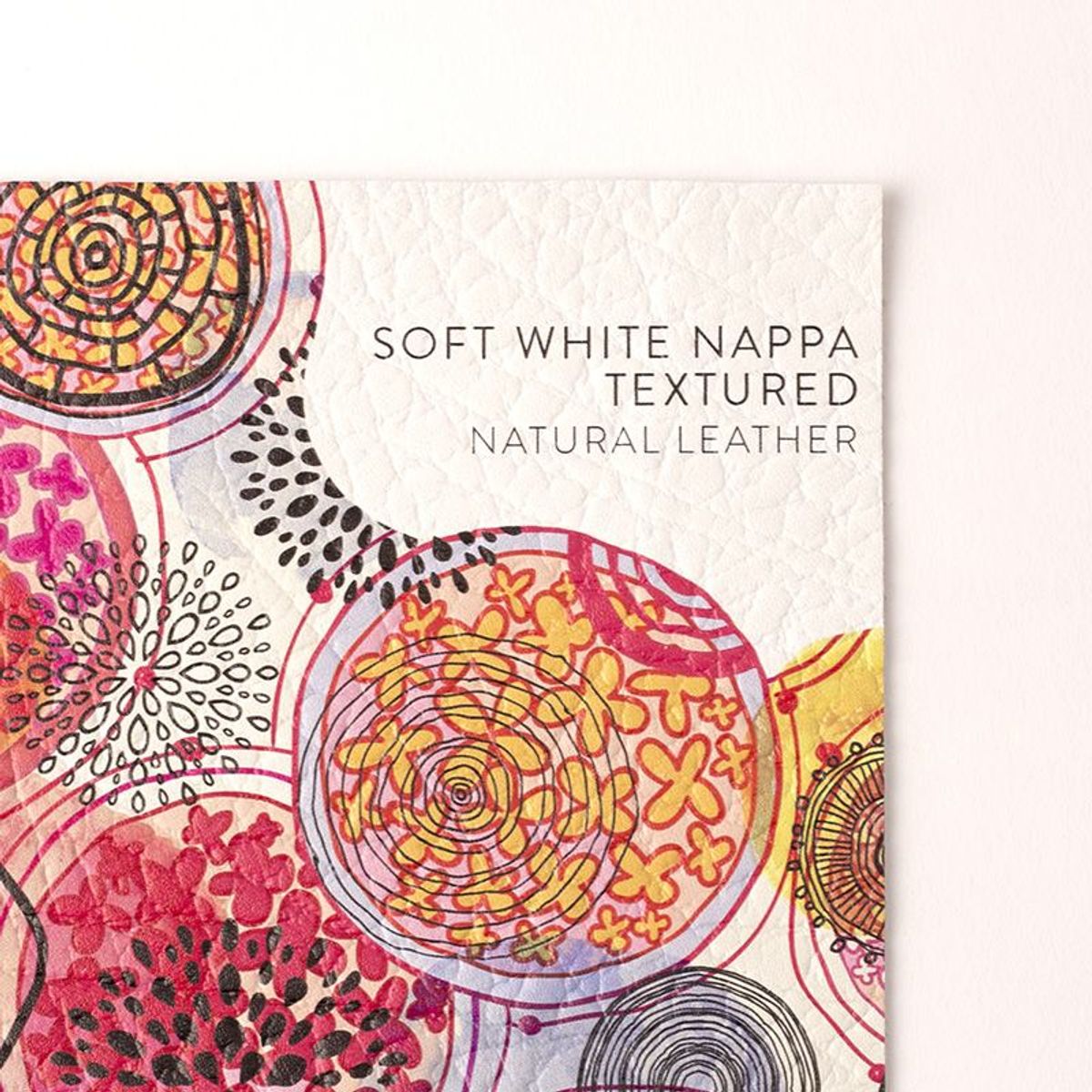

How Does Nappa Leather Perform in Custom Printing Applications?

Nappa leather is a full-grain bovine leather known for its softness and smooth texture. It typically has a temperature resistance that allows it to maintain its integrity under moderate heat, making it suitable for various applications, including fashion and luxury goods.

Illustrative image related to custom leather printing

Pros: Nappa leather is highly durable and offers excellent color retention, which is vital for vibrant printed designs. Its luxurious feel enhances the end product’s appeal, making it a preferred choice for high-end items.

Cons: The primary drawback is its higher cost compared to other leathers. Additionally, Nappa leather requires careful handling during manufacturing to avoid damage, which can complicate the production process.

Impact on Application: Nappa leather is compatible with a wide range of printing techniques, including digital printing, ensuring high-quality results. However, buyers should be aware of the potential for natural blemishes that may affect large designs.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding animal welfare and sourcing. Familiarity with standards such as ASTM for leather quality can guide purchasing decisions.

What Are the Benefits of Using Vegan Leather for Custom Printing?

Vegan leather, often made from synthetic materials or plant-based fibers, is an increasingly popular alternative. It is designed to mimic the appearance and texture of real leather while avoiding animal products.

Illustrative image related to custom leather printing

Pros: Vegan leather is generally more affordable and offers a wide variety of colors and textures. It is also easier to clean and maintain, appealing to environmentally conscious consumers.

Cons: The durability of vegan leather can be lower than that of natural leathers, particularly under extreme conditions. It may also have a different feel, which might not meet the expectations of luxury product buyers.

Impact on Application: Vegan leather is versatile and can be printed using various techniques, but its performance may vary based on the specific materials used. It is suitable for fashion accessories and home décor.

Illustrative image related to custom leather printing

Considerations for International Buyers: Buyers should verify the sustainability claims of vegan leather products and ensure compliance with environmental regulations, particularly in Europe, where eco-labeling is significant.

How Does Suede Compare for Custom Leather Printing?

Suede, a type of leather made from the underside of animal hides, offers a unique texture that is often associated with luxury. It has a moderate temperature resistance but can be sensitive to moisture.

Pros: The soft texture of suede adds a distinctive aesthetic to printed products, making it suitable for clothing and accessories. It also holds dye well, resulting in rich colors.

Cons: Suede is less durable than other leathers and can be prone to staining and wear. Its maintenance requirements can complicate its use in certain applications.

Impact on Application: Suede is compatible with specialized printing techniques that can enhance its texture. However, moisture sensitivity may limit its use in outdoor applications.

Considerations for International Buyers: When sourcing suede, buyers should be aware of potential import restrictions related to animal products, particularly in regions with strict wildlife protection laws.

What Role Does Leatherette Play in Custom Leather Printing?

Leatherette, a synthetic alternative to leather, is made from PVC or polyurethane and is often used in budget-friendly applications. It offers a cost-effective solution for those looking to achieve a leather-like appearance without the associated costs.

Pros: Leatherette is highly affordable and easy to clean, making it a practical choice for various applications, including furniture and automotive interiors. It is also available in a wide range of colors and finishes.

Cons: Its durability is generally lower than that of natural leathers, and it may not provide the same luxurious feel. Additionally, it can be less environmentally friendly due to its synthetic composition.

Impact on Application: Leatherette is suitable for digital printing but may not hold up as well under high-stress conditions. It is ideal for promotional items and budget-conscious projects.

Considerations for International Buyers: Buyers should consider the environmental impact of synthetic materials and ensure compliance with local regulations regarding plastic use.

Summary Table of Material Selection for Custom Leather Printing

| المواد | Typical Use Case for Custom Leather Printing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| جلد نابا | High-end fashion items | Luxurious feel and durability | Higher cost and manufacturing complexity | عالية |

| جلد نباتي | Eco-friendly fashion accessories | Affordable and versatile | Lower durability than natural leather | Medium |

| Suede | Luxury clothing and accessories | Rich texture and color retention | Prone to staining and less durable | Medium |

| Leatherette | Budget-friendly promotional items | Cost-effective and easy to clean | Lower durability and feel | منخفضة |

This guide provides a comprehensive overview of material options for custom leather printing, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather printing

What Are the Key Stages in the Manufacturing Process of Custom Leather Printing?

The manufacturing process for custom leather printing involves several critical stages, each contributing to the final product’s quality and durability. Understanding these stages is essential for B2B buyers looking to ensure that their suppliers maintain high standards.

-

Material Preparation

The first stage begins with sourcing high-quality leather, which can be real or vegan alternatives. The leather is typically treated and tanned to ensure durability and suitability for printing. This preparation phase is crucial as it sets the foundation for the subsequent printing process. Buyers should inquire about the origins of the leather and the tanning processes used, as these factors significantly influence the material’s quality. -

Forming

Once the leather is prepared, it is cut and shaped according to the specific requirements of the project. This stage may involve creating patterns or templates that define the dimensions and style of the final product. Advanced technologies like computer-aided design (CAD) can be employed to enhance precision. B2B buyers should ensure that their suppliers utilize efficient and accurate forming techniques to minimize waste and ensure consistency. -

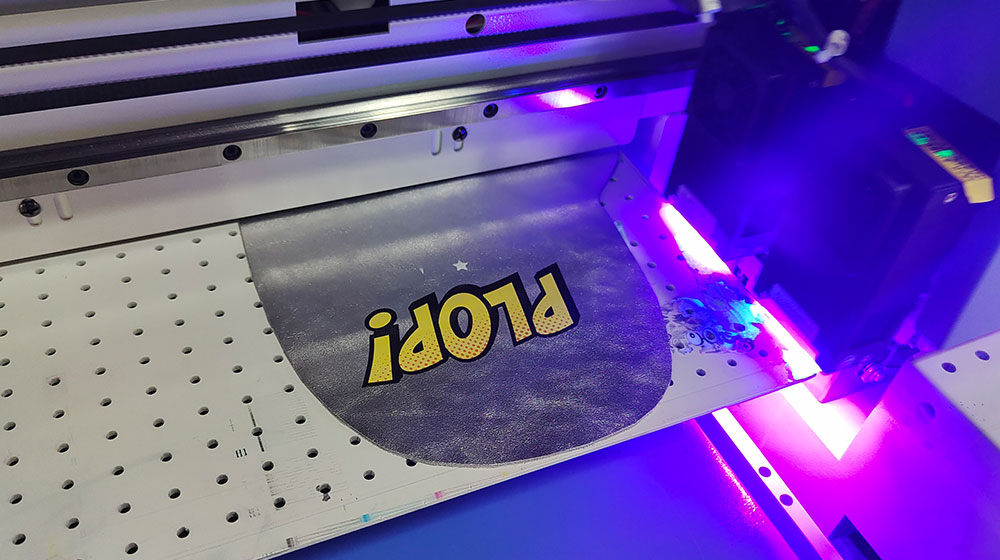

Printing

The heart of custom leather printing lies in the printing process itself. Digital printing techniques are commonly used, allowing for intricate designs to be printed directly onto the leather. The inks penetrate deeply into the leather fibers, resulting in vibrant colors and durability. Suppliers may utilize eco-friendly inks and advanced printers to ensure high-quality outputs. Buyers should request samples to evaluate print quality and color accuracy before placing bulk orders. -

Finishing

After printing, the leather undergoes a finishing process that includes treatments for water resistance, UV protection, and additional durability enhancements. This stage is vital to ensure that the printed leather maintains its aesthetic appeal and functional properties over time. B2B buyers should inquire about the specific finishing treatments applied and their long-term effects on the product’s usability. -

Assembly

The final stage involves assembling the printed leather into the desired product, whether it be bags, jackets, or upholstery. This assembly can include stitching, adding zippers, or other components. Quality craftsmanship is essential in this phase to ensure that the final product meets the required standards. Buyers should assess the supplier’s assembly techniques and craftsmanship standards.

How Do Quality Assurance Processes Ensure Consistent Quality in Custom Leather Printing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for custom leather printing. It ensures that every product meets the established standards for quality, durability, and safety. Here’s how QA processes typically function:

Illustrative image related to custom leather printing

-

International Standards and Certifications

Many suppliers adhere to international quality standards such as ISO 9001, which provides a framework for consistent quality management. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the end use of the leather products. B2B buyers should verify that their suppliers possess relevant certifications to ensure compliance with international quality standards. -

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): Assessing raw materials upon arrival to ensure they meet quality specifications.

– In-Process Quality Control (IPQC): Monitoring production processes to identify any deviations from standards during manufacturing.

– Final Quality Control (FQC): Conducting thorough inspections of finished products to ensure they meet design specifications and quality standards. -

Common Testing Methods

Various testing methods are employed to assess the quality of printed leather. These may include:

– Rub Testing: To evaluate the durability of the print against wear and tear.

– Water Resistance Testing: To determine how well the leather withstands moisture.

– Colorfastness Testing: To ensure that colors remain vibrant over time and do not bleed. -

How Can B2B Buyers Verify Supplier Quality Assurance?

To ensure that suppliers maintain high-quality standards, B2B buyers should implement several verification strategies:

– Conduct Audits: Regular audits of suppliers can help assess their adherence to quality standards and production processes.

– Request Quality Reports: Suppliers should provide detailed reports on their quality control processes and outcomes.

– Third-party Inspections: Engaging independent third-party inspectors to evaluate the production process and finished products can provide unbiased insights into quality. -

Understanding QC Nuances for International Buyers

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local regulations and market expectations is crucial. Different regions may have varying standards for leather products, and it’s essential for buyers to communicate their specific requirements to suppliers. Establishing clear expectations regarding quality and compliance can prevent misunderstandings and ensure product satisfaction.

What Are the Challenges and Considerations for B2B Buyers in Custom Leather Printing?

B2B buyers need to navigate several challenges when sourcing custom leather printing. Here are some critical considerations:

-

Cultural Differences

Cultural factors can influence perceptions of quality and expectations in different markets. Buyers should conduct thorough research into local preferences and standards to ensure that their products resonate with target audiences. -

Supply Chain Reliability

The reliability of the supply chain is vital, especially for international transactions. Buyers should assess suppliers’ capabilities to deliver on time and maintain quality throughout the production cycle. Building strong relationships with suppliers can enhance trust and reliability. -

Sustainability Concerns

With growing emphasis on sustainability, buyers should inquire about the environmental impact of the materials and processes used in custom leather printing. Opting for suppliers who use eco-friendly practices can align with corporate social responsibility initiatives and appeal to environmentally-conscious consumers. -

Cost vs. Quality

Balancing cost and quality is often a challenge. While it may be tempting to choose the lowest-priced options, buyers must consider the long-term implications of quality issues, such as returns and brand reputation. Investing in higher-quality products can lead to greater customer satisfaction and loyalty.

By understanding the manufacturing processes and quality assurance measures involved in custom leather printing, B2B buyers can make informed decisions that align with their business goals and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather printing’

To successfully procure custom leather printing services, it is essential to follow a structured approach that ensures quality, reliability, and value. This guide serves as a checklist to help B2B buyers navigate the sourcing process effectively.

Illustrative image related to custom leather printing

1. Identify Your Project Requirements

Begin by clearly defining what you need from your custom leather printing. Consider the type of leather (e.g., smooth, textured, vegan), the intended use (clothing, accessories, upholstery), and the design specifications. This clarity will help you communicate effectively with suppliers and evaluate their offerings against your requirements.

2. Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in custom leather printing. Look for companies with a strong reputation in the industry, focusing on their experience and past projects. Pay attention to their geographical location as it can impact shipping times and costs, especially for international transactions.

3. Evaluate Quality Standards

Quality is paramount in custom leather printing. Ask potential suppliers about their printing technology, ink types, and the durability of their products. Ensure they adhere to industry standards for quality assurance, and request samples of their printed leather to assess color accuracy and material integrity.

4. Check for Certifications and Compliance

Verify that the suppliers possess relevant certifications, such as ISO standards or environmental compliance (e.g., REACH, RoHS). Certifications indicate a commitment to quality and sustainability, which can enhance your brand’s reputation. This is especially important when sourcing from regions with varying regulatory standards.

Illustrative image related to custom leather printing

5. Request Pricing and Lead Times

Obtain detailed quotes from multiple suppliers, including pricing, minimum order quantities, and lead times for production. This information is crucial for budgeting and scheduling your project. Look for transparency in pricing and any additional costs that may arise, such as shipping and handling.

6. Inquire About Customization Options

Discuss the extent of customization available with your chosen suppliers. This may include design flexibility, size variations, and additional features like debossing or embossing. Understanding the scope of customization will help you align the final product with your brand identity.

7. Establish Clear Communication Channels

Effective communication is key to a successful partnership. Ensure that the supplier is responsive and open to discussions regarding your needs. Set expectations for regular updates on the production process and any potential issues that may arise during the project.

By following this checklist, B2B buyers can streamline their sourcing process for custom leather printing, ensuring they partner with reliable suppliers who can meet their specific needs. Proper planning and due diligence will ultimately lead to high-quality products that enhance your brand’s offerings.

Illustrative image related to custom leather printing

Comprehensive Cost and Pricing Analysis for custom leather printing Sourcing

What Are the Key Cost Components in Custom Leather Printing?

When evaluating the cost structure of custom leather printing, several essential components must be considered. The primary elements include:

-

Materials: The choice of leather significantly impacts costs. Options range from traditional animal leathers, such as Nappa and suede, to vegan alternatives. Prices vary based on the type of leather, its quality, and sourcing practices. For example, higher-quality full-grain leather typically commands a premium price compared to corrected grain options.

-

Labor: Skilled labor is required for both the printing process and any necessary finishing touches. Labor costs may vary by region, with countries offering lower wage structures potentially providing cost advantages.

-

Manufacturing Overhead: This includes costs associated with equipment maintenance, energy consumption, and operational expenses of the printing facility. Advanced digital printing technologies can enhance efficiency but may also require significant initial investment.

-

Tooling: The setup for printing customized designs can entail tooling costs, particularly for unique shapes or sizes. This is often amortized over larger production runs.

-

Quality Control (QC): Ensuring that prints meet specified standards requires rigorous quality control processes, which can add to overall costs. This includes testing for color accuracy, durability, and adherence to specifications.

-

Logistics: Transportation and storage costs must also be factored in, especially for international shipments. The choice of shipping method (air vs. sea) can have a dramatic impact on costs and delivery times.

-

Margin: Suppliers will include their profit margins, which can vary based on market dynamics and competition.

What Influences Pricing for Custom Leather Printing?

Several factors can influence the pricing of custom leather printing, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Understanding the supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Highly customized designs, special finishes, or unusual dimensions can increase costs. Clear communication of requirements is essential to avoid unexpected price surges.

-

Materials and Quality Certifications: Suppliers offering certified organic or sustainably sourced materials may charge more. Buyers should weigh these factors against their brand values and market positioning.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers may offer better quality assurance but at a higher price point.

-

Incoterms: Understanding shipping terms (such as FOB, CIF) can help buyers manage logistics costs effectively. These terms define who bears the risk and cost at various stages of the shipping process.

How Can Buyers Negotiate Better Prices in Custom Leather Printing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiation tactics can significantly affect costs:

-

Leverage Volume: Commit to larger orders to negotiate better prices. Suppliers often provide discounts for bulk purchases.

-

Build Relationships: Establishing a strong partnership with suppliers can lead to more favorable pricing and terms over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also factors like durability, maintenance, and potential waste. Investing slightly more upfront in higher-quality leather can yield better long-term value.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Europe may offer different pricing structures than those in South America or Africa due to varying operational costs.

-

Request Samples: Before committing to a large order, request samples to evaluate quality and suitability. This can prevent costly mistakes and ensure you are satisfied with the product.

Final Thoughts on Custom Leather Printing Costs

While indicative prices for custom leather printing can start around $26.25 for basic options, actual costs will vary based on the factors discussed. Buyers should conduct thorough market research and supplier assessments to ensure they achieve the best value for their investment.

Illustrative image related to custom leather printing

Alternatives Analysis: Comparing custom leather printing With Other Solutions

In the competitive landscape of custom leather products, businesses often seek the most effective methods for personalization and branding. While custom leather printing offers a unique solution, it’s essential to explore alternatives that may fit specific business needs or budget constraints. Below is a comparison of custom leather printing against other viable methods: embossing and laser engraving.

| Comparison Aspect | Custom Leather Printing | Embossing | Laser Engraving |

|---|---|---|---|

| Performance | High-quality, vibrant colors; suitable for intricate designs | Limited to single-color designs; great for logos and text | Precise and durable; can create detailed designs but limited color options |

| Cost | Moderate to high, depending on material and design complexity | Generally lower; cost-effective for bulk orders | Variable; can be high based on complexity and machine setup |

| Ease of Implementation | Requires specialized printing equipment and design software | Relatively easy; often involves manual processes | Requires skilled operators and specific machinery |

| Maintenance | Minimal maintenance; durable if cared for properly | Low; occasional equipment checks needed | Moderate; requires regular maintenance of laser machines |

| Best Use Case | Ideal for fashion items, accessories, and personalized gifts | Best for branding, promotional items, and simpler designs | Suitable for high-end products, industrial applications, and detailed artwork |

What Are the Advantages and Disadvantages of Embossing?

Embossing is a popular method that involves creating raised designs on leather by applying heat and pressure. One of its primary advantages is its cost-effectiveness, especially for bulk orders. It also provides a tactile element that can enhance the luxury feel of a product. However, embossing is limited to single-color designs, which may not be suitable for brands looking to showcase colorful logos or intricate patterns. Additionally, the manual nature of the process can lead to inconsistencies if not managed properly.

How Does Laser Engraving Compare to Custom Leather Printing?

Laser engraving offers a high level of precision and can create intricate designs directly on the leather surface. This method is particularly advantageous for brands needing durability, as engraved designs are less likely to fade over time. However, the costs associated with laser engraving can be higher, especially for complex designs that require extensive machine setup. Additionally, like embossing, laser engraving is typically monochromatic, limiting the creative options compared to the vibrant prints achieved through custom leather printing.

What Should B2B Buyers Consider When Choosing Between These Options?

When selecting the right solution for custom leather products, B2B buyers should consider their specific needs, budget, and the intended use of the products. Custom leather printing is ideal for businesses seeking vibrant, multi-color designs and personalization. In contrast, embossing is better suited for bulk branding projects requiring simplicity and cost-effectiveness. Laser engraving, while precise and durable, may be more appropriate for high-end products where detail is paramount, albeit at a higher cost.

In conclusion, understanding the strengths and weaknesses of each method is crucial for making an informed decision. By evaluating factors such as performance, cost, and ease of implementation, businesses can align their choice with their branding goals and customer expectations.

Illustrative image related to custom leather printing

Essential Technical Properties and Trade Terminology for custom leather printing

What Are the Key Technical Properties in Custom Leather Printing?

Understanding the technical properties of custom leather printing is crucial for B2B buyers looking to make informed decisions. Here are some of the most important specifications to consider:

1. Material Grade

Material grade refers to the quality classification of the leather used for printing. Different grades, such as full-grain, top-grain, and corrected grain, have varying levels of durability, appearance, and cost. Full-grain leather, for instance, is the highest quality and retains the natural grain pattern, making it ideal for high-end products. Knowing the material grade helps buyers assess the longevity and aesthetic appeal of their printed leather products.

2. Tolerance

Tolerance in leather printing refers to the permissible variation in dimensions and specifications during production. It is essential for ensuring that custom designs fit the intended application, whether that be in fashion, furniture, or accessories. High tolerance levels minimize discrepancies, ensuring that products meet exact specifications, which is vital for maintaining brand standards and customer satisfaction.

Illustrative image related to custom leather printing

3. Ink Adhesion

Ink adhesion describes how well the printing ink bonds to the leather surface. Superior ink adhesion ensures that the design remains vibrant and intact even after prolonged use. For B2B buyers, selecting a printing service that guarantees high ink adhesion can lead to reduced returns and increased customer satisfaction, especially in high-traffic applications such as bags and shoes.

4. Rub Resistance

Rub resistance measures the durability of the printed design against friction. This property is particularly important for items that will experience regular wear, such as clothing and accessories. A higher rub resistance rating indicates that the printed design will withstand daily use without fading or peeling, which is a critical consideration for B2B buyers focused on product longevity.

5. Finish Type

The finish type of printed leather affects both its appearance and functionality. Options include matte, glossy, and textured finishes. Each type has unique characteristics that can enhance or detract from the design. Understanding the implications of each finish allows buyers to select the right option based on the intended use and target market.

Illustrative image related to custom leather printing

What Are Common Trade Terms in Custom Leather Printing?

Navigating the custom leather printing landscape requires familiarity with specific trade terminology. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then sold by another company under its brand name. In the context of custom leather printing, understanding OEM relationships can help buyers identify potential partners for high-quality leather products that align with their brand identity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it impacts inventory costs and production planning. Understanding the MOQ helps buyers gauge whether a supplier can meet their project needs without incurring excessive costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. In custom leather printing, an RFQ helps buyers clarify their requirements and obtain competitive pricing, enabling better budgeting and decision-making.

4. Incoterms

Incoterms (International Commercial Terms) are standardized international trade terms that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and delivery responsibilities, which can significantly affect the overall cost and timeline of their projects.

Illustrative image related to custom leather printing

5. Digital Printing Technology

Digital printing technology refers to the process of printing designs directly onto leather using digital methods. This technology offers flexibility, allowing for high-resolution images and intricate designs. For B2B buyers, understanding digital printing capabilities can aid in selecting suppliers that can deliver innovative and customized solutions.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions in the custom leather printing market, ensuring that they select the right materials and partners for their business needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather printing Sector

What Are the Key Trends Driving the Custom Leather Printing Market?

The custom leather printing sector is witnessing significant transformation due to various global drivers and emerging technologies. Increasing demand for personalized products across industries such as fashion, automotive, and furniture is pushing businesses to adopt custom leather printing solutions. The rise of e-commerce has further fueled this trend, allowing buyers from regions like Africa, South America, the Middle East, and Europe to access a broader range of custom options.

Technological advancements, particularly in digital printing, are also reshaping market dynamics. Digital printing allows for high-quality, vibrant designs that can penetrate the leather’s fibers, ensuring durability and color accuracy without compromising the material’s texture. This method is gaining traction among B2B buyers looking for quick turnaround times and the ability to create unique designs. Moreover, the availability of various leather types, including vegan options, is expanding the market’s reach, appealing to a more diverse clientele.

Additionally, businesses are increasingly focusing on customization capabilities, providing buyers with the ability to order bespoke sizes and styles. This trend is particularly relevant for B2B buyers in regions like Nigeria and Brazil, where local artisans and manufacturers seek to differentiate themselves in competitive markets. Overall, the custom leather printing sector is evolving rapidly, driven by technological innovation and changing consumer preferences.

How Is Sustainability and Ethical Sourcing Impacting Custom Leather Printing?

Sustainability and ethical sourcing are becoming paramount in the custom leather printing sector. With growing awareness about environmental impacts, B2B buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices. The tanning processes traditionally used in leather production can be harmful, leading to pollution and resource depletion. Therefore, buyers are seeking out suppliers that utilize eco-friendly tanning methods or offer alternative materials, such as vegan leather and pineapple leather, which significantly reduce the environmental footprint.

Moreover, ethical supply chains are gaining importance. Buyers are looking for transparency in sourcing, ensuring that the leather is obtained from responsible sources. Certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) are becoming critical in the decision-making process for B2B purchases. These certifications provide assurance that the materials are not only sustainable but also ethically produced, aligning with the values of conscious consumers.

As the demand for ethically sourced materials continues to rise, businesses that prioritize sustainability will likely enjoy a competitive advantage in the global market. For international buyers, this shift towards sustainability is not just a trend but a necessity to meet the expectations of an increasingly eco-conscious clientele.

How Has the Custom Leather Printing Market Evolved Over Time?

The evolution of the custom leather printing market can be traced back to traditional leatherworking techniques that have been refined over centuries. Initially, leather printing relied on manual processes and limited designs, which restricted customization options. However, the advent of digital printing technology in the late 20th century marked a significant turning point. This innovation allowed for the use of advanced dyes and inks that penetrate the leather, enabling intricate designs and high-resolution images to be printed directly onto the material.

As technology progressed, the market expanded to include various types of leather, including vegan and synthetic alternatives, catering to a wider audience. Today, the custom leather printing sector stands at the intersection of technology and artistry, providing businesses with the tools needed to create bespoke products that resonate with contemporary consumer demands. This evolution reflects a broader trend towards personalization and sustainability, which are now key drivers in the B2B landscape.

In conclusion, the custom leather printing market has come a long way, driven by technological advancements, evolving consumer preferences, and a growing emphasis on sustainability. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with market trends and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather printing

-

How do I choose the right supplier for custom leather printing?

Selecting the right supplier involves assessing their experience, quality of materials, and production capabilities. Start by researching suppliers with a solid reputation in the custom leather printing industry. Request samples to evaluate the quality of their printed leather and inquire about their production processes. Additionally, consider their ability to meet your specific customization needs, delivery timelines, and responsiveness to inquiries. It’s also beneficial to check customer reviews and testimonials, particularly from businesses in your region, to gauge their reliability. -

What types of leather can I customize for printing?

You can choose from various types of leather for custom printing, including Nappa leather, suede, and vegan leather alternatives. Each type has its unique properties and applications, such as smoothness, durability, and environmental impact. For instance, Nappa leather is known for its softness and flexibility, making it ideal for fashion items, while vegan leather is a great option for eco-conscious brands. Ensure you align your choice with the intended use of the final product, whether it be for apparel, accessories, or upholstery. -

What is the minimum order quantity (MOQ) for custom leather printing?

The MOQ for custom leather printing can vary widely among suppliers, typically ranging from a few square meters to larger bulk orders. Many suppliers are willing to accommodate small businesses or startups, but ordering in larger quantities often results in better pricing and reduced per-unit costs. It’s crucial to clarify MOQ terms before engaging in negotiations, as this can impact your budgeting and project timelines, especially for international orders. -

How can I ensure quality assurance in my custom leather prints?

To ensure quality assurance, establish clear guidelines and expectations with your supplier regarding the printing process. Request detailed specifications about the inks used, printing technology, and finishing processes. Additionally, consider implementing a sampling stage where you can review a printed sample before full production. Regular communication during the production phase can also help address any potential issues early on, ensuring that the final product meets your quality standards. -

What payment terms should I expect when sourcing custom leather printing?

Payment terms for custom leather printing can vary by supplier and region. Common arrangements include upfront payments, deposits (typically 30-50%), and payment upon delivery. It is advisable to negotiate terms that suit your cash flow needs while also ensuring the supplier’s confidence in your commitment. Be cautious with payment methods; using secure, traceable transactions can protect you from fraud, especially in international trade. -

How do I manage logistics and shipping for international orders of custom leather prints?

Managing logistics for international orders requires careful planning. Start by discussing shipping options with your supplier, as they often have preferred carriers that can provide competitive rates and reliable service. Ensure you understand the customs requirements for both the exporting and importing countries, including tariffs and taxes. It may also be beneficial to engage a freight forwarder to streamline the shipping process and ensure compliance with all regulations. -

What customization options are available for my printed leather products?

Customization options for printed leather products are extensive. You can specify designs, colors, textures, and even the type of leather used. Many suppliers allow you to upload your own artwork or select from a library of designs. Additionally, you can customize the dimensions and shapes of your leather products, catering to specific market needs or trends. Discuss your vision with your supplier to explore all available options. -

How can I effectively communicate my design specifications to the supplier?

To effectively communicate your design specifications, provide clear and detailed guidelines. Use digital files in high-resolution formats and specify color codes (e.g., Pantone) to ensure accurate reproduction. Include dimensions, placement, and any special requirements for textures or finishes. Regularly engage with the supplier during the design phase to clarify any uncertainties and confirm that your expectations are understood. Utilizing mockups can also help visualize the final product before production begins.

Top 9 Custom Leather Printing Manufacturers & Suppliers List

1. Contrado – Custom Printed Leather

Domain: contrado.com

Registered: 2004 (21 years)

مقدمة: Printed Leather allows you to create custom leather prints using your artwork or designs. Options include Smooth Nappa Leather, Textured Nappa Leather, Bubble Nappa Leather, Vegan Leather, Furnishing Leatherette, and Suede. Leather Swing Tags are available in a 10-pack. Prices include: Smooth Nappa Leather ($26.25), Textured Nappa Leather ($26.25), Bubble Nappa Leather ($26.25), Vegan Leather, Fur…

2. Bags of Love – Printed Leather Products

Domain: bagsoflove.com

Registered: 2003 (22 years)

مقدمة: Printed Leather allows for personalized designs using photos and custom artwork. Available options include: 1. Real Leather Printing – $26.25, ships in 2-3 days. 2. Vegan Leather Printing – $37.50, ships in 1-2 days. 3. Suede Printing (fire-rated) – $23.98, ships in 1-2 days. 4. Leather Swing Tags (10 pack) – $29.95, ships in 1-2 days. 5. Leather Swatch Pack – $1.95, ready same day. 6. Real Leathe…

3. Voutsa – Custom Leather Product

Domain: voutsa.com

Registered: 2012 (13 years)

مقدمة: Custom Leather product from Voutsa, priced at $2,500.00. Each hide measures 48″ wide x 66″ long and can be printed with any pattern. Note that slight color variations may occur due to the nature of the hides. For orders, contact [email protected]

4. Leathergenix – Custom Printed Leather

Domain: leathergenix.com

Registered: 2009 (16 years)

مقدمة: Leathergenix specializes in custom leather printing, offering high-end luxury leathers for various applications. Key products include:

– Printed leather jackets, handbags, shoes, and aviation seat interiors.

– Custom printed leather for interior design, including pillows and furniture.

– Lifestyle accessories such as pet collars, headphones, tablet covers, and high-end handbags.

– Vegan leather pr…

5. GVT Fast – Custom Printed Leather

Domain: gvtfast.com

Registered: 2020 (5 years)

مقدمة: {“Product Name”: “Custom Printed Leather”, “Price”: “€ 100,00 – € 190,00”, “VAT”: “22% not included”, “Leather Types”: [{“Type”: “Whole White Chrome-Tanned Calfskin”, “Thickness”: “1.4-1.6 mm”}, {“Type”: “Half Calf Vegetable Tanned”, “Thickness”: “2.0-2.2 mm”}], “Print Options”: [{“Whole Leather”: true}, {“Cut Panel Size”: “60×60 cm”}], “Suggested Uses”: [“Leathergoods”, “Small Leathergoods”], “Ba…

6. QinPrinting – Leather-Bound Book Printing Services

Domain: qinprinting.com

Registered: 2017 (8 years)

مقدمة: QinPrinting offers leather-bound book printing services with eco-friendly imitation leather that is cruelty-free. Custom options include foil-stamped or debossed text, patterns, and logos. Suitable for memoirs, notebooks, yearbooks, and premium books. Minimum order quantity (MOQ) is 100 pieces. Custom and standard sizes available (width: 3.74″-12.6″, height: 3.74″-16.5″). Binding options include s…

7. Foglizzo – Customizable Leather Solutions

Domain: foglizzo.com

Registered: 2002 (23 years)

مقدمة: Custom Leather range offers a wide assortment of customizable leathers for designers. Personalization techniques include laser-cutting, embossing, weaving, custom coloring, embroidery, perforating, cutting, and digital printing. The process involves seven steps: 1) Briefing with the client to understand their vision and requirements, 2) Inspiration and research to create a moodboard, 3) Design pro…

8. Pip Supply – Custom Printed Faux Leather Sheets

Domain: pipsupply.com

Registered: 2018 (7 years)

مقدمة: Custom Printed Faux Leather Sheets – CPSIA compliant faux leather – Free Domestic Shipping for orders $75 and up – Current Processing Time: 4-8 Business Days

9. Rainbow Leather – Custom Foiling & Printing Solutions

Domain: rainbowleather.com

Registered: 1999 (26 years)

مقدمة: Foiling: Special effect for standout appeal. Digital Printing: Customizable colors and effects. Embossing: Custom plates or extensive library options. Cutting: Custom plates or extensive library options. Perforation: Custom plates or extensive library options. Monogramming: Custom gold, silver, and blind embossed options. Cork Catalog: Customizable natural cork sheets. Cow Suede Catalog: Available…

Strategic Sourcing Conclusion and Outlook for custom leather printing

In the evolving landscape of custom leather printing, strategic sourcing is vital for international B2B buyers looking to capitalize on market opportunities. By leveraging digital printing technologies, businesses can access a diverse range of high-quality leathers, including vegan options, to meet consumer demands for sustainability and personalization. This capability allows brands to differentiate their products, from fashion items to home decor, ensuring they resonate with target audiences across Africa, South America, the Middle East, and Europe.

Buyers should prioritize partnerships with reliable suppliers who utilize advanced printing techniques, as these ensure vibrant colors and durability. Furthermore, sourcing from manufacturers that offer swift turnaround times enhances responsiveness to market trends and customer preferences.

As the demand for custom leather products continues to grow, now is the time for businesses to invest in innovative sourcing strategies. By embracing the potential of custom leather printing, companies can not only enhance their product offerings but also secure a competitive edge in the global marketplace. Engage with suppliers today to explore the boundless possibilities that custom leather printing can bring to your brand’s future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.