Catalog

Material Insight: Custom Leather Printing

Custom Leather Printing – B2B Product Guide

Custom leather printing enables brands to deliver unique, high-impact designs on leather materials for applications across fashion, accessories, automotive interiors, and furniture. This process allows for precise color reproduction, intricate patterns, and personalized textures—making it ideal for differentiated product offerings in competitive markets. Whether for limited-edition collections or branded corporate gifts, custom printing adds value through aesthetic innovation and brand storytelling.

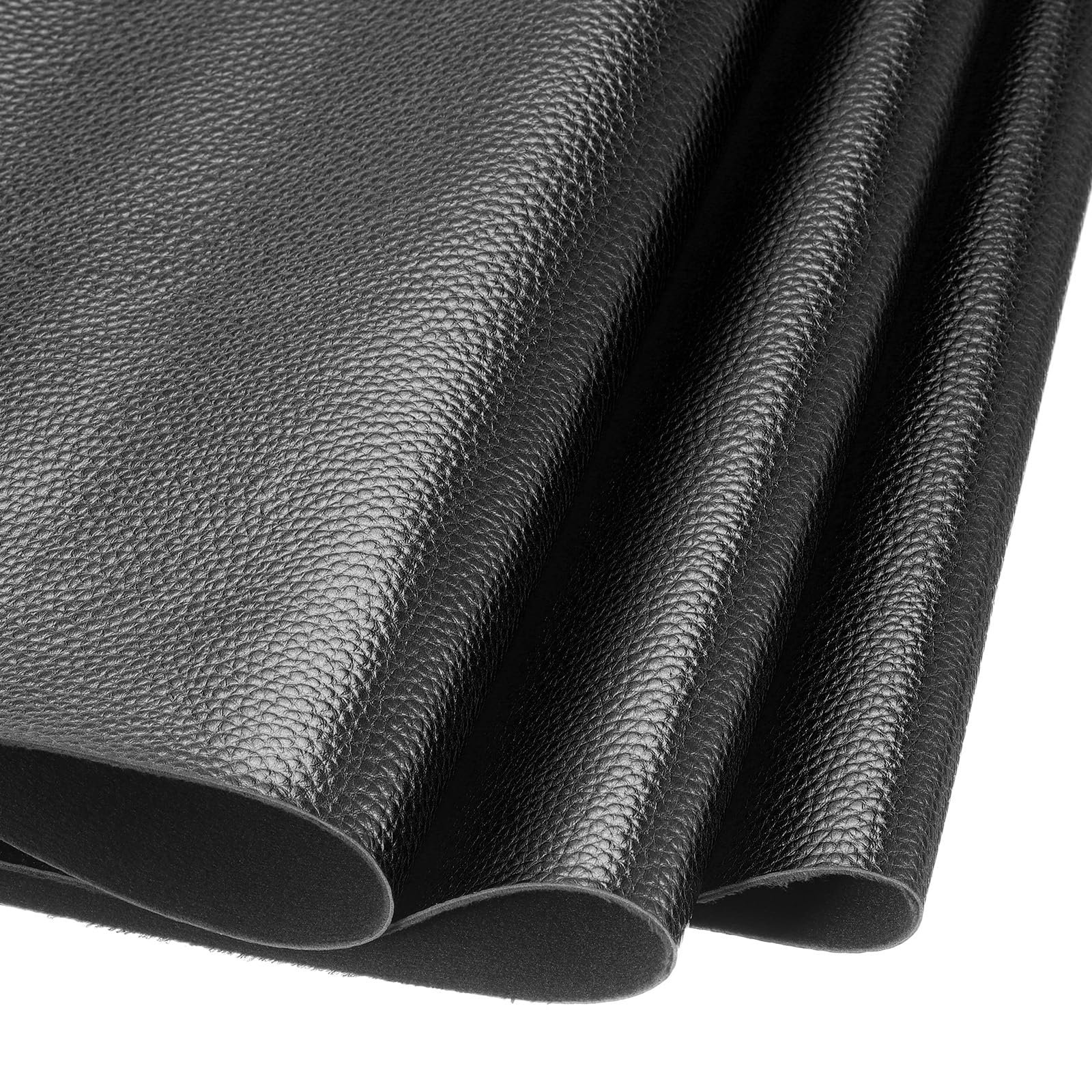

When it comes to materials, جلد صناعي stands out as the optimal choice for custom printing due to its consistent surface structure, superior ink receptivity, and environmental advantages over animal-derived leather. Unlike genuine leather, which features natural grain variations and imperfections that can interfere with print clarity, faux leather provides a uniform base that ensures sharp, vibrant results across large production runs. Additionally, modern eco-conscious faux leathers—like those developed by WINIW—are free from the ethical concerns and supply inconsistencies associated with animal hides, while offering enhanced durability, water resistance, and easier maintenance.

As a leader in synthetic leather innovation, WINIW brings over 20 years of industry expertise to the development of high-performance, sustainable faux leather solutions. Our advanced manufacturing processes integrate eco-friendly raw materials, low-impact dyes, and cutting-edge coating technologies to deliver printable substrates that meet strict quality and environmental standards. With a focus on B2B partnerships, WINIW supports brands and manufacturers in achieving scalable customization without compromising on sustainability or performance.

Key advantages of using WINIW’s faux leather for custom printing include:

– Consistent surface finish for high-resolution print accuracy

– Excellent adhesion and color fastness with UV, sublimation, and screen printing methods

– OEKO-TEX® and REACH-compliant materials for safe, eco-friendly production

– Customization in thickness, texture, and backing to suit diverse end uses

– Reduced environmental footprint with recyclable and PU/PVC-free options available

For businesses seeking reliable, scalable, and responsible custom leather printing solutions, WINIW’s expertise and product range offer a proven foundation for innovation and brand differentiation.

Technical Performance & Standards

WINIW Custom Leather Printing: Precision, Performance, Sustainability for B2B Applications

WINIW empowers brands and manufacturers with advanced custom leather printing solutions engineered for the demanding requirements of the modern B2B market. Our proprietary digital printing process transforms high-performance synthetic leather substrates into uniquely branded, durable, and compliant surfaces, eliminating the limitations of traditional printing methods. This technology delivers significant operational and strategic advantages, ensuring your finished goods meet the highest standards of quality, safety, and environmental responsibility without compromising on design flexibility or cost efficiency.

Key Technical Advantages:

- Cost-Effective Production: Our digital workflow eliminates the need for expensive screens, plates, and lengthy setup times associated with analog printing. This drastically reduces minimum order quantities (MOQs) and per-unit costs, especially for complex designs, small batches, or rapid prototyping. Material waste is minimized through precise ink deposition and optimized nesting software, directly improving your project’s ROI.

- Exceptional Durability & Performance: WINIW prints utilize advanced pigment-based inks cured with a proprietary topcoat system. This creates a permanent bond with the synthetic leather substrate, resulting in outstanding resistance to:

- Abrasion and scratching (exceeding standard leather goods requirements)

- Fading from UV exposure (tested to ISO 105-B02)

- Cracking, peeling, and delamination, even after repeated flexing

- Common solvents and cleaning agents, ensuring longevity in demanding use.

- Unmatched Color Customization & Accuracy: Achieve precise brand alignment with our extensive color matching capability. We support full Pantone® color system integration and custom color formulation, ensuring consistent reproduction across all production runs. Digital technology allows for virtually unlimited design complexity, gradients, and photorealistic imagery without additional cost or process constraints.

- Guaranteed REACH Compliance: All inks, coatings, and synthetic leather substrates used in WINIW custom printing are rigorously tested and certified to fully comply with the EU REACH regulation (EC 1907/2006), including Annex XVII restrictions. We provide comprehensive Substance of Very High Concern (SVHC) documentation, mitigating regulatory risk and ensuring product safety for global markets. Our formulations are inherently low-VOC and free from harmful azo dyes, phthalates, and heavy metals.

- ISO 9001 Certified Quality Management: Every step of our custom printing process – from substrate sourcing and pre-treatment to printing, curing, quality control, and shipment – operates under our certified ISO 9001:2015 Quality Management System. This guarantees consistent, traceable outputs, rigorous in-process inspections, and a structured framework for continuous improvement, directly reducing defects and ensuring batch-to-batch reliability for your supply chain.

WINIW Custom Printing Technical Specifications

| Feature | المواصفات | Benefit for B2B Clients |

|---|---|---|

| Substrate | Premium PU/TPU Synthetic Leather (Various weights, textures, backings available) | Consistent base quality; compatible with diverse end-uses |

| Print Resolution | Up to 1440 dpi | Exceptional detail, smooth gradients, photorealistic output |

| Color System | Full Pantone® Matching System (PMS) support; Custom RGB/CMYK formulation | Absolute brand color accuracy and consistency |

| Durability (Test) | ISO 12947 (Martindale Abrasion): >50,000 cycles; ISO 105-B02 (AATCC Grey Scale): ≥4 | Long-lasting appearance; withstands rigorous use |

| Compliance | Full REACH SVHC compliance; OEKO-TEX® STANDARD 100 (upon request); RoHS | Market access assurance; reduced regulatory risk |

| موك | Low (Typically starts at 50 linear meters / 50 sqm) | Cost-effective prototyping & small-batch production |

| Lead Time | Standard: 10-15 working days (after artwork approval) | Predictable planning for your production schedule |

| Quality Standard | ISO 9001:2015 Certified Process | Guaranteed consistency; traceable quality control |

WINIW’s custom leather printing solution is engineered for B2B partners who demand more than just a printed surface. It delivers a strategic combination of economic efficiency, uncompromised performance, design freedom, and certified safety – all underpinned by a robust quality management system. Partner with WINIW to transform your vision into durable, compliant, and distinctive products that stand out in the marketplace.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Leather Printing vs. Real Leather

When sourcing materials for high-end upholstery, accessories, or fashion applications, businesses must evaluate both aesthetic performance and long-term value. Two prominent options are custom leather printing on synthetic substrates and traditional real leather. While both offer distinct advantages, the choice depends on project requirements, sustainability goals, and budget constraints.

Custom leather printing involves applying detailed patterns and textures onto premium synthetic leather—often made from polyurethane (PU) or recycled materials—using advanced digital or rotary printing techniques. This method allows for unmatched design flexibility, including rare patterns, brand-specific colors, and consistent batch-to-batch repeatability. In contrast, real leather is derived from animal hides and prized for its natural grain, breathability, and aging characteristics.

Below is a comparative analysis of custom leather printing and real leather across key business decision-making criteria:

| Criteria | Custom Leather Printing (PU/Synthetic Base) | Real Leather (Animal Hide) |

|---|---|---|

| Cost | Lower initial cost; scalable for bulk orders | Higher cost due to sourcing, tanning, and grading |

| المتانة | High abrasion resistance; UV-stable prints; consistent surface | Natural aging improves look but may show scratches and wear; variable grain quality |

| Eco-Friendliness | Can be made from recycled materials; lower water/energy use in production; some bio-based options available | Resource-intensive; involves land use, methane emissions, and chemical tanning (unless chrome-free) |

Key Advantages of Custom Leather Printing:

– – Design freedom: replicate exotic textures (e.g., crocodile, ostrich) without ethical or legal concerns

– – Uniform appearance across large production runs, critical for commercial furniture and automotive interiors

– – Improved sustainability profile when using water-based inks and recycled backings

– – Lightweight and easier to process in automated cutting and sewing lines

Key Advantages of Real Leather:

– – Natural breathability and soft hand feel, preferred in luxury apparel and premium automotive seating

– – Develops a desirable patina over time, enhancing perceived value

– – Biodegradable at end-of-life (depending on tanning method)

For B2B clients prioritizing cost-efficiency, design control, and environmental responsibility, custom leather printing offers a compelling alternative to real leather. WINIW’s advanced synthetic leather solutions combine high-fidelity printing with eco-conscious materials, supporting sustainable innovation without compromising on aesthetics or performance.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global B2B Partners

WINIW stands as a leading manufacturer of premium synthetic leather, engineered to meet the exacting demands of global brands and manufacturers. Our operational scale, technical expertise, and uncompromising quality systems form the foundation of reliable, sustainable partnerships.

Core Manufacturing Capabilities

- Integrated Production Facility: A state-of-the-art 100,000 sqm manufacturing campus housing end-to-end production, from base material extrusion to finished roll goods. This scale ensures consistent capacity for high-volume OEM orders and rapid scalability for strategic partners.

- Dedicated R&D Innovation Hub: A 120+ member technical team, including material scientists and textile engineers, drives continuous improvement. We hold 37 patents for eco-processes and performance textiles, focusing on bio-based polymers, reduced water consumption, and enhanced durability.

- Strict Quality Control Ecosystem: Multi-stage QC protocols aligned with ISO 9001 and ISO 14001 standards. Every batch undergoes 18+ physical performance tests (abrasion, colorfastness, tensile strength) and chemical compliance screening (REACH, OEKO-TEX® STANDARD 100) prior to shipment.

Global Supply Chain Reliability

WINIW delivers traceable, audit-compliant synthetic leather to 40+ countries, with established logistics networks ensuring:

| Region | Key Compliance Standards Met | Typical Lead Time |

|---|---|---|

| Europe | REACH, EU Ecolabel, SCIP | 25-35 days |

| North America | CPSIA, California Prop 65 | 20-30 days |

| Asia-Pacific | GB, AS/NZS, JIS | 15-25 days |

Our facility maintains B Corp™ certification and LEED Gold standards, reflecting our commitment to reducing environmental impact through solar energy integration, closed-loop water systems, and 92% waste-recycled production cycles. For partners requiring sustainable material solutions without compromising on performance or delivery precision, WINIW provides the infrastructure and expertise to support long-term growth.

Contact Us for Samples

WINIW B2B Product Guide: Premium Synthetic Leather Solutions

WINIW specializes in high-performance, eco-friendly synthetic leather designed for demanding commercial and industrial applications. Our advanced microfiber materials deliver the look, feel, and durability of genuine leather—without the environmental impact. Trusted by manufacturers and designers across furniture, automotive, apparel, and luxury goods sectors, WINIW offers scalable, sustainable, and customizable leather alternatives.

Why Choose WINIW Synthetic Leather?

- Eco-Conscious Production: Our PU and microfiber leathers are free from harmful solvents, PVC, and heavy metals. All products are REACH and RoHS compliant.

- Superior Durability: Engineered for high abrasion resistance, UV stability, and long-term performance in diverse environments.

- Customization Ready: Available in a wide range of textures, colors, thicknesses, and backings to meet exact client specifications.

- Consistent Quality: Uniform grain structure and thickness ensure seamless integration into automated production lines.

- Global Supply Reliability: With ISO-certified manufacturing and strategic logistics partners, we support just-in-time delivery worldwide.

Core Product Lines

- WINIW Soft-Touch Microfiber Leather: Ideal for premium upholstery, handbags, and automotive interiors. Offers exceptional softness and drape.

- WINIW Performance Series: Reinforced backing and high tensile strength for heavy-use applications such as transportation seating and commercial furniture.

- WINIW EcoPure™: Made with bio-based polyols and recyclable components, this line supports carbon reduction goals and circular design principles.

- WINIW Fashion Grade: High-definition embossing and custom dyeing for footwear, accessories, and designer apparel.

Technical Specifications (Typical Values)

| Property | Value | Test Method |

|---|---|---|

| Thickness | 0.6 mm – 2.0 mm | ISO 2417 |

| Tensile Strength | ≥ 25 N/5mm (warp & weft) | ISO 1767 |

| Elongation at Break | ≤ 30% | ISO 1767 |

| Martindale Abrasion | 50,000+ cycles | ISO 12947 |

| Color Fastness (Rubbing) | Grade 4–5 (dry), Grade 4 (wet) | ISO 105-X12 |

| Light Fastness | ≥ 4 (Blue Scale) | ISO 105-B02 |

Custom Leather Printing Services

WINIW offers advanced digital and rotary printing capabilities for brands seeking unique patterns, logos, or textures. Our custom printing service enables:

- Brand-specific designs and watermark integration

- Batch flexibility—from prototypes to bulk runs

- Rapid turnaround with color-matching accuracy (Pantone® certified)

- Low MOQs for emerging designers and niche markets

Request a Free Sample

Experience the quality and versatility of WINIW synthetic leather firsthand. We provide complimentary samples tailored to your application needs.

Ready to Customize Your Leather?

Contact our materials team to discuss custom printing, technical specs, or sustainability certifications.

CTA: Start your custom leather printing project today.

البريد الإلكتروني: MKT88@MicrofiberLeather.com

Free samples available upon request.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.