Introduction: Navigating the Global Market for custom leather interior

In today’s competitive landscape, sourcing custom leather interiors poses a significant challenge for international B2B buyers seeking to elevate their product offerings and meet consumer demands. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the nuances of custom leather interiors can be daunting. This comprehensive guide delves into the various types of custom leather applications, including automotive, commercial, and luxury sectors, while also addressing critical aspects such as supplier vetting, pricing structures, and quality assessments.

Navigating the global market for custom leather interiors requires a strategic approach to ensure that your selections not only align with your brand identity but also meet regulatory standards and consumer preferences. This guide equips B2B buyers with actionable insights, helping you make informed purchasing decisions by outlining best practices for sourcing, evaluating suppliers, and understanding the total cost of ownership.

By focusing on the unique needs of diverse markets, including specific considerations for regions like Nigeria and Germany, this resource empowers businesses to enhance their product lines with high-quality, customizable leather solutions. With the right knowledge and tools, your organization can capitalize on the growing demand for premium leather interiors, ultimately driving profitability and customer satisfaction.

Table Of Contents

- Top 8 Custom Leather Interior Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather interior

- Understanding custom leather interior Types and Variations

- Key Industrial Applications of custom leather interior

- 3 Common User Pain Points for ‘custom leather interior’ & Their Solutions

- Strategic Material Selection Guide for custom leather interior

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather interior

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather interior’

- Comprehensive Cost and Pricing Analysis for custom leather interior Sourcing

- Alternatives Analysis: Comparing custom leather interior With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather interior

- Navigating Market Dynamics and Sourcing Trends in the custom leather interior Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather interior

- Strategic Sourcing Conclusion and Outlook for custom leather interior

- Important Disclaimer & Terms of Use

Understanding custom leather interior Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Custom Upholstery | Complete replacement of existing upholstery, tailored fit. | Automotive manufacturers, luxury rentals. | Pros: Premium look, enhanced durability. Cons: Higher cost, longer installation time. |

| Leather Seat Covers | Slip-on covers that overlay existing seats. | Car dealerships, budget-conscious buyers. | Pros: Lower cost, easy installation. Cons: Less durable, may not fit perfectly. |

| Heated & Ventilated Seats | Integrated heating and cooling systems within leather seats. | High-end vehicle manufacturers, luxury rentals. | Pros: Enhanced comfort, appealing for premium markets. Cons: More complex installation, higher maintenance. |

| Exotic Leather Interiors | Use of rare materials (e.g., crocodile, ostrich) for luxury appeal. | Custom automotive shops, high-end restorations. | Pros: Unique aesthetic, status symbol. Cons: Expensive, ethical sourcing concerns. |

| Preconfigured Interior Kits | Ready-made kits designed for specific vehicle models. | Automotive retailers, fleet services. | Pros: Quick installation, cost-effective. Cons: Limited customization options. |

What are the Characteristics of Full Custom Upholstery?

Full custom upholstery involves the complete replacement of existing vehicle upholstery with premium leather tailored to the specific dimensions of the vehicle. This option is ideal for automotive manufacturers or luxury rental services looking to provide a high-end experience. The key B2B purchasing considerations include the quality of materials used, installation expertise, and the warranty offered. While this option delivers a superior aesthetic and durability, it often comes at a higher cost and requires a longer installation time.

How Do Leather Seat Covers Differ from Other Options?

Leather seat covers serve as a cost-effective solution for those seeking to enhance their vehicle’s interior without a full overhaul. These slip-on covers are particularly popular among car dealerships and budget-conscious buyers. While they are easy to install and significantly cheaper than full upholstery, buyers should consider the potential downsides, such as less durability and a fit that may not be as precise. This option is suitable for fleet vehicles or older models where a complete interior replacement is not financially viable.

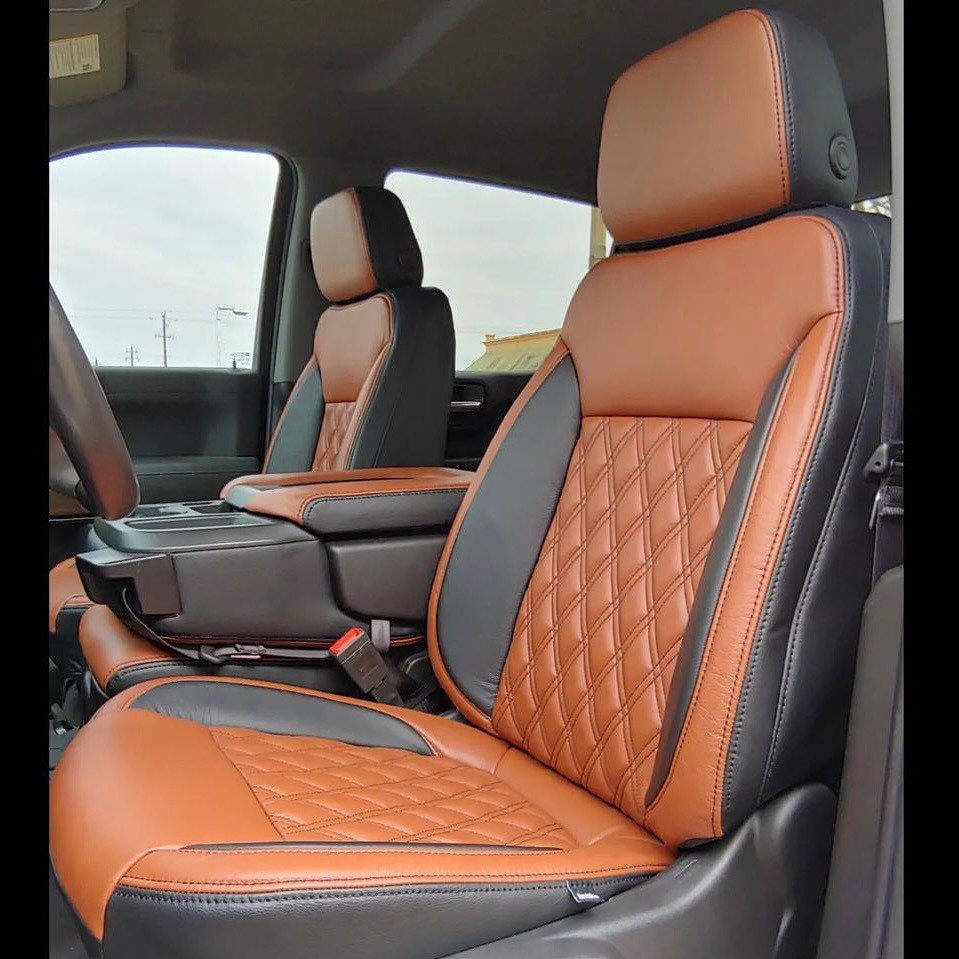

Illustrative image related to custom leather interior

What are the Benefits of Heated & Ventilated Seats?

Heated and ventilated seats offer an added layer of comfort by integrating temperature control within the leather upholstery. This feature is particularly appealing to high-end vehicle manufacturers and luxury rental services aiming to provide an elevated driving experience. When considering this option, B2B buyers should evaluate the complexity of installation and the potential for increased maintenance costs. The investment can yield significant returns in customer satisfaction and vehicle appeal, especially in regions with extreme climates.

What Makes Exotic Leather Interiors Unique?

Exotic leather interiors utilize rare materials such as crocodile or ostrich leather, offering a distinctive luxury aesthetic. This option is typically pursued by custom automotive shops and high-end restorations aiming to create a unique product. Key purchasing considerations include the ethical sourcing of materials and the overall cost, as these interiors can be significantly more expensive than standard leather. While they serve as a status symbol and enhance the vehicle’s appeal, buyers must weigh the potential ethical concerns associated with using exotic leathers.

Why Choose Preconfigured Interior Kits?

Preconfigured interior kits are designed for specific vehicle models, providing a quick and cost-effective solution for automotive retailers and fleet services. These kits streamline the installation process, allowing for rapid deployment without sacrificing quality. However, buyers should be aware that customization options may be limited compared to fully custom upholstery solutions. This option is ideal for businesses looking to enhance vehicle interiors efficiently, balancing quality and affordability while meeting customer demands.

Key Industrial Applications of custom leather interior

| Industry/Sector | Specific Application of custom leather interior | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom leather upholstery for vehicles | Enhances vehicle aesthetics and resale value | Compatibility with specific vehicle models and installation expertise |

| Hospitality | Leather furnishings for hotels and restaurants | Creates a luxurious ambiance, improving customer experience | Durability and maintenance of leather in high-traffic areas |

| Aviation | Leather interiors for private jets and helicopters | Provides comfort and luxury for high-net-worth clients | Compliance with aviation safety standards and materials certification |

| Marine | Custom leather seating in yachts and boats | Increases comfort and aesthetic appeal for luxury vessels | Resistance to moisture and UV exposure for longevity |

| Corporate Offices | Leather seating and decor for executive spaces | Projects professionalism and enhances employee satisfaction | Customization options to align with corporate branding |

How is Custom Leather Interior Used in the Automotive Industry?

In the automotive sector, custom leather upholstery is extensively utilized to enhance the interior of vehicles, providing a premium look and feel. This application not only improves the aesthetic appeal but also increases the vehicle’s resale value. B2B buyers, particularly in regions like Africa and Europe, must ensure that the leather products are compatible with specific vehicle models. Additionally, the installation process requires skilled professionals to achieve a factory-like finish, which is crucial for maintaining quality and durability.

What Role Does Custom Leather Play in the Hospitality Sector?

In hospitality, custom leather furnishings are used in hotels and restaurants to create an inviting and luxurious atmosphere. The use of leather in seating and decor can significantly elevate the customer experience, making it more comfortable and stylish. B2B buyers in South America and the Middle East should consider the durability and maintenance requirements of leather, especially in high-traffic areas. Selecting the right type of leather that can withstand wear and tear while maintaining its aesthetic appeal is essential for long-term investment.

How is Custom Leather Interior Applied in Aviation?

The aviation industry employs custom leather interiors in private jets and helicopters to provide an unparalleled level of comfort and luxury for clients. The high-quality leather not only enhances the visual appeal of the aircraft but also offers a tactile experience that is valued by high-net-worth individuals. B2B buyers need to ensure that the materials used comply with aviation safety standards and are certified for use in aircraft, which is a critical consideration in sourcing.

Why is Custom Leather Important for Marine Applications?

In the marine industry, custom leather seating is utilized in luxury yachts and boats, enhancing both comfort and aesthetic appeal. The right leather can transform the interior of a vessel into a sophisticated space, attracting affluent customers. B2B buyers must prioritize leather that is resistant to moisture and UV exposure to ensure longevity and durability in marine environments. Understanding the specific requirements of marine applications is vital for sourcing the right materials.

Illustrative image related to custom leather interior

How is Custom Leather Used in Corporate Offices?

In corporate settings, custom leather seating and decor are implemented to project professionalism and enhance employee satisfaction. High-quality leather furniture can create an upscale environment that reflects the company’s brand and values. B2B buyers in Europe should consider customization options that align with corporate branding while ensuring the leather is durable enough to withstand daily use. Investing in quality leather can significantly impact the workplace atmosphere and employee morale.

3 Common User Pain Points for ‘custom leather interior’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Custom Leather Interiors

The Problem:

B2B buyers often face significant challenges when it comes to ensuring the quality of custom leather interiors. In markets like Africa and South America, where local suppliers may not have stringent quality control measures, sourcing premium leather that meets international standards can be daunting. Buyers may worry about receiving subpar materials that not only compromise the aesthetic appeal of their vehicles but also impact durability and customer satisfaction. This is particularly pressing for automotive companies looking to enhance their brand reputation through high-quality interiors.

The Solution:

To mitigate these risks, buyers should establish clear quality benchmarks and vet suppliers thoroughly. This involves requesting samples of leather materials and reviewing certifications that validate the quality of the leather, such as ISO standards. Engaging suppliers who can provide detailed documentation on their sourcing and production processes is crucial. Additionally, buyers can implement a quality assurance protocol that includes on-site inspections or third-party audits to ensure compliance with their specifications. Investing in a relationship with a reputable supplier known for high-quality leather products can lead to long-term benefits, including better pricing and priority service.

Scenario 2: Customization Complexity and Vehicle Compatibility

The Problem:

Another pain point for B2B buyers is the complexity involved in customizing leather interiors to fit various vehicle makes and models. Buyers often struggle with the vast array of options available, including different leather types, colors, and styles. Moreover, ensuring that the custom interiors fit perfectly and integrate seamlessly with existing vehicle designs can be a logistical nightmare. This complexity can lead to increased costs and extended timelines if not managed effectively.

Illustrative image related to custom leather interior

The Solution:

To simplify the customization process, buyers should leverage technology by utilizing advanced configurator tools provided by reputable suppliers. These tools allow buyers to visualize the customization options in real-time, ensuring that the selected materials and designs are compatible with specific vehicle models. Additionally, engaging in collaborative design sessions with suppliers can yield tailored solutions that meet both aesthetic and functional requirements. Establishing a clear communication channel with the supplier regarding design preferences and vehicle specifications will help streamline the process. Regular updates and prototype reviews can also facilitate adjustments before final production, reducing the risk of costly mistakes.

Scenario 3: Installation Challenges and Technical Support

The Problem:

Installation of custom leather interiors can pose significant challenges, particularly for buyers who may not have access to skilled labor or the necessary tools. In many regions, especially where the aftermarket for automotive interiors is less developed, finding qualified technicians to install custom leather interiors correctly can be a hurdle. Improper installation not only diminishes the quality of the final product but also leads to increased warranty claims and dissatisfied customers.

The Solution:

To address installation challenges, buyers should consider partnering with suppliers who provide comprehensive installation support, including training and certification for local technicians. Suppliers can offer installation guides, video tutorials, and even on-site training sessions to ensure that the workforce is adequately prepared to handle the installation. Additionally, purchasing installation kits that include all necessary tools and materials can streamline the process. Buyers should also look into establishing a network of certified installers who are familiar with the specific requirements of their custom leather interiors. This proactive approach can enhance the overall customer experience and reduce the likelihood of installation-related issues.

Strategic Material Selection Guide for custom leather interior

What Are the Key Properties of Common Materials Used in Custom Leather Interiors?

When selecting materials for custom leather interiors, understanding the properties, advantages, and limitations of each option is crucial. This ensures that the chosen material aligns with both the aesthetic and functional requirements of the end product. Here, we analyze four common materials used in custom leather interiors: genuine leather, synthetic leather (PU), vinyl, and suede.

How Does Genuine Leather Perform in Custom Interiors?

Genuine leather is a natural material known for its durability and luxurious feel. It boasts excellent temperature resistance, making it suitable for various climates, and has a natural breathability that enhances comfort during extended use. However, it requires regular maintenance to prevent drying and cracking, which can be a drawback in high-usage scenarios.

Illustrative image related to custom leather interior

Pros: Genuine leather offers superior durability and a premium look, making it ideal for high-end vehicles. Its natural characteristics allow for better aging and patina development, which many consumers appreciate.

Cons: The cost of genuine leather is generally high, and its manufacturing process can be complex, requiring skilled labor. Additionally, it may not be suitable for all applications, particularly in regions with extreme humidity or temperature fluctuations.

For international buyers, compliance with standards such as ISO 14001 (environmental management) is essential, especially in Europe, where sustainability is increasingly prioritized. Buyers from Africa and South America may prefer genuine leather for its status and perceived quality.

What Advantages Does Synthetic Leather (PU) Offer?

Synthetic leather, particularly polyurethane (PU), has gained popularity due to its versatility and lower cost. It mimics the look and feel of genuine leather while being easier to clean and maintain. PU leather is also resistant to stains and fading, making it suitable for various applications, including automotive interiors.

Illustrative image related to custom leather interior

Pros: The affordability of PU leather allows for broader market access, and its lightweight nature can contribute to overall vehicle efficiency. Additionally, it can be produced in a variety of colors and textures, offering customization options.

Cons: While PU leather can be durable, it does not have the same lifespan as genuine leather and may wear out faster under heavy use. Moreover, it lacks the breathability of natural leather, which can lead to discomfort in warmer climates.

For buyers in the Middle East and Africa, where budget constraints may be more prevalent, PU leather presents a viable alternative. However, it is crucial to ensure that the material meets relevant standards, such as ASTM D751 (for physical properties).

How Does Vinyl Compare in Terms of Durability and Cost?

Vinyl is a synthetic material that is often used in automotive interiors due to its water resistance and low maintenance requirements. It is particularly popular in commercial vehicles, where durability is paramount. Vinyl can withstand high levels of wear and tear, making it suitable for heavy-duty applications.

Pros: The cost-effectiveness of vinyl makes it an attractive option for mass-produced vehicles. Its resistance to moisture and easy cleaning capabilities further enhance its appeal.

Illustrative image related to custom leather interior

Cons: Vinyl tends to be less breathable than both genuine and synthetic leather, which can affect comfort levels. Additionally, it may not provide the same luxurious feel or aesthetic appeal as leather options.

International buyers should consider local climate conditions when selecting vinyl, as extreme temperatures can affect its performance. Compliance with local and international standards, such as DIN 53387 (for testing the durability of plastics), is also essential.

What Role Does Suede Play in Custom Leather Interiors?

Suede, a type of leather with a napped finish, is often used for accent pieces in custom interiors. It offers a unique texture and aesthetic appeal, making it a popular choice for luxury vehicles. Suede is known for its softness and comfort but requires careful maintenance to preserve its appearance.

Pros: Suede provides a distinct look and feel, adding a touch of luxury to any interior. Its softness enhances comfort, particularly in seating applications.

Cons: Suede is less durable than other materials and is more susceptible to staining and damage from moisture. This makes it less suitable for high-traffic areas or regions with high humidity.

Illustrative image related to custom leather interior

For buyers in Europe, where luxury and aesthetics are highly valued, suede can be an attractive option. However, it is essential to ensure that the suede meets quality standards, such as JIS K 6400 (for leather quality).

Summary Table of Material Selection for Custom Leather Interiors

| Material | Typical Use Case for custom leather interior | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Luxury vehicles, high-end interiors | Superior durability and aesthetics | High cost and maintenance requirements | High |

| Synthetic Leather (PU) | Mid-range vehicles, customizable interiors | Affordable and easy to maintain | Less durable than genuine leather | Medium |

| Vinyl | Commercial vehicles, budget-friendly options | Water-resistant and low maintenance | Less breathable and luxurious feel | Low |

| Suede | Accent pieces in luxury vehicles | Unique texture and comfort | Less durable and moisture-sensitive | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather interior

What Are the Key Stages in the Manufacturing Process of Custom Leather Interiors?

The manufacturing process for custom leather interiors involves several critical stages that ensure both the quality and aesthetic appeal of the final product. Understanding these stages helps B2B buyers gauge the complexity and craftsmanship involved in creating high-quality leather interiors.

Material Preparation: How Is Leather Selected and Processed?

The first step in the manufacturing process is the careful selection and preparation of leather materials. Quality leather is sourced from reputable suppliers and undergoes rigorous inspection to ensure it meets specified standards. This includes evaluating the hide for imperfections, thickness, and texture. Once selected, the leather is treated through a tanning process that enhances durability and resistance to wear and tear.

Additionally, various finishes may be applied to the leather, such as dyeing or embossing, which not only affect the appearance but also the tactile feel of the material. B2B buyers should inquire about the source of the leather and the tanning processes used, as these factors significantly influence the quality and longevity of the product.

Forming: What Techniques Are Used to Shape the Leather?

After material preparation, the leather is cut and shaped according to the specifications of the vehicle model. This process often involves advanced cutting technologies, such as laser cutting, which ensures precision and minimizes waste. The leather pieces are then formed into the desired shapes for seats, door panels, and other interior components.

Illustrative image related to custom leather interior

Techniques such as sewing, stitching, and heat sealing are commonly employed to join the pieces together. The use of specialized sewing machines allows for intricate designs and patterns, further enhancing the customizability of the interiors. B2B buyers should look for suppliers that employ state-of-the-art equipment and skilled labor to ensure high-quality craftsmanship.

Assembly: How Are the Components Brought Together?

Once the individual leather components are formed, the assembly stage begins. This involves combining the leather pieces with other materials, such as foam padding for comfort and structural elements for support. The assembly process is critical, as it affects both the fit and finish of the final product.

During assembly, quality control checks should be implemented to ensure that every piece aligns perfectly and meets design specifications. This stage often requires skilled artisans to handle the intricate work of fitting and securing the leather to various frames and structures. B2B buyers should inquire about the assembly techniques and the expertise of the workforce involved in the process.

Finishing: What Final Touches Enhance Quality and Appearance?

The finishing stage involves the application of protective coatings, polishing, and final inspections. These processes not only enhance the aesthetic appeal of the leather interiors but also provide additional durability against environmental factors such as UV exposure and moisture.

In this stage, any necessary adjustments are made to ensure that the final product adheres to quality standards. B2B buyers should verify that suppliers have a robust finishing process that includes thorough inspections and quality assurance measures.

Illustrative image related to custom leather interior

What Quality Assurance Standards Should B2B Buyers Expect?

Quality assurance is paramount in the production of custom leather interiors, ensuring that products meet both customer expectations and regulatory requirements. Understanding the standards and checkpoints involved can help B2B buyers make informed purchasing decisions.

Which International Standards Are Relevant for Custom Leather Interiors?

International standards, such as ISO 9001, outline the requirements for a quality management system and are crucial for manufacturers aiming to provide consistent quality. Compliance with such standards indicates a commitment to quality assurance and continual improvement.

In addition to ISO standards, industry-specific certifications, such as CE marking for safety or API standards for automotive applications, may also apply. These certifications demonstrate that the products meet specific performance and safety criteria, which are essential for B2B buyers in regulated markets.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that products meet established standards. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial check assesses raw materials and components upon arrival to ensure they meet specifications before production begins.

-

In-Process Quality Control (IPQC): Conducted during manufacturing, IPQC monitors production processes and identifies defects early, reducing waste and rework.

-

Final Quality Control (FQC): This final inspection ensures that the finished product meets all quality standards and specifications before it is shipped to customers.

B2B buyers should inquire about the specific QC processes in place at potential suppliers to ensure they maintain high standards throughout production.

Illustrative image related to custom leather interior

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of a supplier’s quality control practices is essential for B2B buyers looking to ensure the reliability of their products. Here are several methods to consider:

What Auditing and Reporting Practices Should Be in Place?

Regular audits of manufacturing facilities can provide insights into the effectiveness of a supplier’s quality management system. B2B buyers should request information about the frequency and scope of these audits, as well as any corrective actions taken in response to identified issues.

Additionally, suppliers should be able to provide detailed quality reports that outline inspection results, defect rates, and compliance with relevant standards. These documents serve as evidence of the supplier’s commitment to quality assurance.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can provide an additional layer of assurance regarding product quality. These independent evaluations can verify that the manufacturing processes and final products meet specified standards and regulations. B2B buyers should consider incorporating third-party inspections into their procurement process, particularly when sourcing from regions with varying quality assurance practices.

Illustrative image related to custom leather interior

What Unique Quality Control Considerations Exist for International Buyers?

B2B buyers from diverse markets, including Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances that may affect their purchasing decisions. Factors such as local regulations, customs requirements, and regional standards can influence the selection of suppliers.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have unique regulatory requirements that impact the quality assurance processes for leather products. For example, buyers in Europe may prioritize compliance with REACH regulations concerning chemical safety, while those in Africa may focus on local certifications related to environmental sustainability.

B2B buyers should conduct thorough research on the specific regulations applicable in their target markets and ensure that their suppliers are compliant. This diligence helps mitigate risks associated with non-compliance and enhances the overall reliability of the supply chain.

Conclusion

In summary, understanding the manufacturing processes and quality assurance standards for custom leather interiors is crucial for B2B buyers. By familiarizing themselves with the stages of production, quality control checkpoints, and the importance of compliance with international standards, buyers can make informed decisions that ensure they source high-quality products tailored to their specific needs.

Illustrative image related to custom leather interior

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather interior’

Introduction

Navigating the procurement of custom leather interiors can be a complex process, especially for B2B buyers looking to enhance vehicle aesthetics and comfort. This step-by-step checklist aims to streamline your sourcing efforts, ensuring that you make informed decisions while selecting the best suppliers for your custom leather needs.

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, clearly outline the specifications for your custom leather interiors. This includes the type of leather (genuine, synthetic, or exotic), color options, and specific designs that align with your brand’s aesthetic. Having a well-defined scope helps suppliers understand your requirements and ensures that you receive accurate quotes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers in the custom leather interior market. Look for companies with a solid reputation and proven track records in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize online resources, trade directories, and industry publications to compile a list of qualified candidates.

Step 3: Evaluate Supplier Capabilities

Once you have shortlisted potential suppliers, assess their capabilities in fulfilling your specific requirements. This evaluation should include:

– Production Capacity: Ensure they can meet your volume needs within your desired timeline.

– Customization Options: Verify that they offer a range of materials, colors, and design features to suit your preferences.

Step 4: Verify Certifications and Compliance

Ensure that your chosen suppliers comply with international standards and regulations relevant to leather production and automotive interiors. Look for certifications such as ISO, environmental compliance, and quality assurance. This step is vital to mitigate risks associated with product quality and sustainability.

Step 5: Request Samples and Prototypes

Before placing a large order, request samples or prototypes of the custom leather interiors. This allows you to assess the quality of materials, craftsmanship, and overall aesthetics firsthand. Pay attention to factors like texture, durability, and color accuracy to ensure they align with your expectations.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms with your shortlisted suppliers. Understand the breakdown of costs, including materials, labor, and shipping. Be clear about your budget constraints and negotiate terms that are favorable to both parties, ensuring transparency and trust.

Step 7: Establish a Clear Communication Plan

Effective communication is critical throughout the procurement process. Set up a clear communication plan that outlines points of contact, response times, and preferred communication channels. This ensures that any issues are addressed promptly and that you remain informed about the production and delivery timelines.

Illustrative image related to custom leather interior

By following this practical sourcing guide, B2B buyers can confidently navigate the complexities of procuring custom leather interiors, fostering successful partnerships that enhance their product offerings.

Comprehensive Cost and Pricing Analysis for custom leather interior Sourcing

What are the Key Cost Components in Custom Leather Interior Sourcing?

When sourcing custom leather interiors, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of leather and other materials (e.g., synthetic suede, vinyl) directly influence costs. Premium leathers, such as exotic varieties, come at a higher price point compared to standard leather options. It’s essential to assess the quality and durability of the materials, as they impact both the aesthetic and longevity of the product.

-

Labor: Skilled labor is required for the precise crafting and installation of custom leather interiors. Labor costs can vary significantly based on geographic location, the complexity of designs, and the experience of the workforce. In regions where labor is more expensive, buyers may face higher overall costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can mitigate overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Custom tooling may be necessary for specific vehicle models, leading to additional costs. This is particularly relevant for manufacturers who need to create bespoke molds or fixtures for unique designs.

-

Quality Control (QC): Implementing a robust QC process ensures that the final product meets the required standards. While this adds to costs, it can prevent costly returns and reworks, ultimately benefiting the buyer.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and the size of the order. International buyers should consider customs duties and tariffs that may apply, particularly when importing from regions like Europe or North America.

-

Margin: Suppliers typically add a profit margin to cover their risks and ensure business sustainability. Understanding the expected margins in the industry can help buyers negotiate better pricing.

What Influences the Pricing of Custom Leather Interiors?

Several factors can influence the pricing of custom leather interiors:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating for better rates if they can commit to higher volumes.

-

Specifications and Customization: Highly customized designs or specific specifications will generally incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected price increases.

-

Materials and Quality Certifications: The choice of materials impacts not only the cost but also the perceived value of the product. Certifications related to sustainability or quality can also affect pricing.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can lead to price variations. Established suppliers with a proven track record may command higher prices due to their reliability.

-

Incoterms: Understanding shipping terms is vital. Different Incoterms can affect the total cost of ownership, including who bears the risk and costs at various stages of the shipping process.

How Can Buyers Optimize Costs in Custom Leather Interior Sourcing?

International B2B buyers can adopt several strategies to optimize costs:

-

Negotiate Effectively: Leverage your buying power by negotiating prices, especially for larger orders. Establishing long-term relationships with suppliers can also lead to better terms over time.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors like maintenance, longevity, and potential resale value when assessing options.

-

Understand Pricing Nuances for International Sourcing: Be mindful of currency fluctuations, import taxes, and shipping costs when sourcing from different regions. For example, sourcing from Europe may involve higher logistics costs compared to local suppliers in Africa or South America.

-

Request Samples: Before finalizing an order, request samples to assess quality and suitability. This can help avoid costly mistakes and ensure the chosen materials meet expectations.

Disclaimer for Indicative Prices

Prices for custom leather interiors can vary widely based on the factors discussed above. Buyers should expect to receive tailored quotes based on specific project requirements, vehicle models, and selected materials. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing custom leather interior With Other Solutions

Understanding Alternatives to Custom Leather Interiors

When evaluating options for enhancing vehicle interiors, custom leather upholstery is a popular choice for businesses seeking luxury and durability. However, various alternatives can also provide appealing benefits. This section examines custom leather interiors against two notable alternatives: synthetic leather upholstery and fabric seat covers. Each option has unique characteristics that may be better suited to specific business needs.

Illustrative image related to custom leather interior

Comparison Table

| Comparison Aspect | Custom Leather Interior | Synthetic Leather Upholstery | Fabric Seat Covers |

|---|---|---|---|

| Performance | High durability, luxurious feel | Good durability, less luxurious feel | Moderate durability, comfort varies |

| Cost | Higher initial investment | Mid-range pricing | Lower cost, budget-friendly |

| Ease of Implementation | Requires professional installation | Can be DIY or professionally installed | Typically easy to install |

| Maintenance | Requires regular conditioning and care | Easier to clean, less maintenance | Machine washable, easy to maintain |

| Best Use Case | Premium vehicles, long-term investment | Cost-effective luxury for mid-range vehicles | Temporary solutions, budget-conscious buyers |

Detailed Breakdown of Alternatives

Synthetic Leather Upholstery

Synthetic leather, also known as faux leather or vegan leather, offers a compelling alternative to custom leather interiors. While it mimics the look and feel of real leather, it often comes at a lower price point. Synthetic leather is easier to clean and maintain compared to traditional leather, making it a practical choice for businesses that prioritize functionality over luxury. However, its durability may not match that of genuine leather, which could lead to higher replacement costs over time. Synthetic leather is an excellent option for mid-range vehicles, offering a balance of aesthetics and affordability.

Fabric Seat Covers

Fabric seat covers represent a budget-friendly alternative to both custom leather and synthetic upholstery. They are typically easy to install, often requiring no professional help, which can save costs for businesses looking to upgrade their vehicle interiors quickly. Fabric seat covers come in various colors and designs, allowing for personalization without a significant investment. However, they may not provide the same level of durability or luxury as leather options. Additionally, fabric can be more susceptible to stains and wear over time, making them a less desirable choice for high-end vehicles or long-term use.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the ideal interior solution for vehicles hinges on several factors, including budget, desired aesthetic, and maintenance capabilities. Custom leather interiors offer unparalleled luxury and durability, making them suitable for premium vehicles and long-term investments. Conversely, synthetic leather upholstery and fabric seat covers present cost-effective options with varying levels of performance and maintenance requirements. B2B buyers should carefully assess their specific needs, considering how each alternative aligns with their goals, whether that be enhancing brand image, meeting budget constraints, or providing comfort for users. By doing so, they can make informed decisions that best suit their operational requirements and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather interior

What Are the Key Technical Properties of Custom Leather Interiors?

When it comes to custom leather interiors, understanding the critical specifications is essential for making informed purchasing decisions. Here are some key properties that international B2B buyers should consider:

Illustrative image related to custom leather interior

Material Grade

Material grade refers to the quality and type of leather used in upholstery. Common grades include full-grain, top-grain, corrected-grain, and bonded leather. Full-grain leather is the highest quality, retaining the natural grain and texture, making it more durable and aesthetically pleasing. Understanding material grade is crucial for buyers as it impacts the longevity and luxury feel of the product, which can affect customer satisfaction and brand reputation.

Tolerance

Tolerance in the context of custom leather interiors refers to the allowable deviation in the dimensions of the leather pieces cut for upholstery. Precise tolerances ensure a perfect fit when installing the leather, which is essential for maintaining the aesthetic appeal and functionality of the interior. For B2B buyers, a tighter tolerance often indicates a higher quality product, which can lead to reduced installation issues and increased customer satisfaction.

Durability Rating

Durability rating assesses how well the leather can withstand wear and tear over time. Factors influencing durability include thickness, treatment processes, and the type of leather. Higher durability ratings indicate that the leather can resist scratches, stains, and fading, making it suitable for high-traffic areas. For buyers, investing in durable materials can lead to long-term cost savings and reduced maintenance needs.

Illustrative image related to custom leather interior

Finish Type

The finish type determines the leather’s appearance and tactile quality. Common finishes include aniline, semi-aniline, and pigmented leather. Aniline leather retains the natural characteristics of the hide, providing a luxurious feel but may require more maintenance. Pigmented leather is treated for durability and stain resistance, making it easier to clean. Understanding finish types helps B2B buyers choose products that align with their market preferences and target customer expectations.

What Are Common Trade Terms in the Custom Leather Interior Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the custom leather interior market. Here are several commonly used terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of custom leather interiors, an OEM might provide leather upholstery that meets the specifications of vehicle manufacturers. Buyers should understand OEM standards to ensure compatibility and quality.

Illustrative image related to custom leather interior

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. In the custom leather interior industry, MOQs can vary significantly based on the supplier’s capabilities and the materials used. Understanding MOQs is vital for buyers as it impacts inventory management and cash flow.

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. In the custom leather sector, an RFQ may include details about material specifications, quantities, and delivery timelines. A well-structured RFQ can lead to better pricing and terms.

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to avoid misunderstandings and ensure smooth transactions across borders.

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the finished product. In the custom leather interior market, lead times can be affected by factors such as material availability and production capacity. Understanding lead times helps buyers plan their inventory and meet customer demands effectively.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, ensuring they choose high-quality custom leather interiors that meet their specific needs and expectations.

Illustrative image related to custom leather interior

Navigating Market Dynamics and Sourcing Trends in the custom leather interior Sector

What Are the Key Market Trends Influencing the Custom Leather Interior Sector?

The custom leather interior market is experiencing robust growth driven by increasing consumer demand for personalization and premium quality in automotive interiors. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where consumers are looking for ways to enhance vehicle aesthetics and comfort. Key drivers include the rise of the automotive aftermarket, where vehicle owners seek to upgrade factory interiors, and the growing popularity of electric vehicles, which often emphasize luxury features.

Emerging B2B technology trends are reshaping sourcing strategies. For instance, the adoption of digital configurators allows buyers to customize leather interiors to their specifications easily. These platforms not only enhance customer engagement but also streamline the supply chain by connecting manufacturers with consumers directly. Additionally, advancements in materials science have led to the development of synthetic leathers and eco-friendly options, appealing to a growing segment of environmentally conscious buyers.

Market dynamics also reflect a shift toward local sourcing. International buyers, particularly from emerging markets, are increasingly looking for suppliers who can provide quick turnaround times and adapt to local tastes. This shift is crucial for buyers in regions like Nigeria and Germany, where cultural preferences significantly influence design choices. As the competition intensifies, suppliers who can offer a blend of quality, customization, and fast service will have a distinct advantage in attracting international B2B clients.

How Is Sustainability Shaping Sourcing Decisions in the Custom Leather Interior Market?

Sustainability has become a pivotal consideration in the custom leather interior sector. The environmental impact of traditional leather production, including deforestation and water pollution, has prompted buyers to seek alternatives that align with green initiatives. Ethical sourcing is gaining traction, with a focus on ensuring that leather is derived from suppliers who adhere to sustainable practices. This trend is particularly relevant for B2B buyers in markets that prioritize corporate social responsibility.

Illustrative image related to custom leather interior

Buyers are increasingly interested in suppliers who can offer certifications that validate their commitment to sustainability. Look for materials labeled with certifications such as the Leather Working Group (LWG) or Global Organic Textile Standard (GOTS), which indicate adherence to environmental and ethical standards. Additionally, the rise of bio-based synthetic leathers presents an opportunity for suppliers to meet the demands of eco-conscious consumers while maintaining high-quality standards.

Incorporating sustainable practices not only enhances brand reputation but also aligns with regulatory trends aimed at reducing carbon footprints across industries. For international buyers, particularly in Europe, the ability to demonstrate a commitment to sustainability can be a decisive factor in procurement decisions.

What Is the Historical Context of Custom Leather Interiors in the Automotive Industry?

The evolution of custom leather interiors in the automotive industry dates back to the early 20th century when luxury vehicles first began to feature leather upholstery as a sign of status and comfort. Initially, leather was a premium option reserved for high-end models, but over time, advancements in manufacturing processes made it more accessible to a broader market.

In the late 20th century, the introduction of aftermarket customization services allowed vehicle owners to personalize their interiors further, leading to a surge in demand for custom leather products. Today, the market is characterized by a blend of traditional craftsmanship and modern technology, catering to an increasingly diverse clientele seeking both luxury and personalization. The historical trajectory of this sector underscores the importance of adapting to consumer preferences and technological advancements, providing valuable insights for B2B buyers looking to navigate the current landscape effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather interior

1. How can I ensure the quality of custom leather interiors before purchasing?

To ensure the quality of custom leather interiors, request samples of the leather material and review the supplier’s certifications and compliance with international standards. Additionally, inquire about their manufacturing processes, quality assurance measures, and warranties. Establishing a direct line of communication with the supplier can also help you gauge their responsiveness and commitment to quality. Finally, consider visiting the supplier’s facility if possible, or request references from other clients to validate their reliability and product quality.

Illustrative image related to custom leather interior

2. What are the typical minimum order quantities (MOQ) for custom leather interiors?

Minimum order quantities (MOQ) can vary significantly based on the supplier and the specifics of your order. Generally, MOQs for custom leather interiors range from 50 to 500 units, depending on factors such as the complexity of customization and the materials used. It’s advisable to discuss your requirements upfront with potential suppliers to negotiate an MOQ that aligns with your business needs. Some suppliers may be flexible, especially for long-term partnerships or larger contracts.

3. What customization options should I consider when sourcing leather interiors?

When sourcing custom leather interiors, consider options such as color, texture, stitching patterns, and additional features like heating or cooling elements. Evaluate whether the supplier offers a variety of leather types, including genuine leather, synthetic alternatives, or exotic materials. Additionally, inquire about the possibility of bespoke designs that align with your brand identity. Ensure that the supplier can accommodate your specific customization requests without compromising on quality or lead times.

4. What payment terms are commonly accepted by suppliers of custom leather interiors?

Payment terms can vary widely, but most suppliers offer options such as upfront payment, partial payment upon order confirmation, and balance upon delivery. It’s essential to clarify the accepted payment methods, which may include bank transfers, letters of credit, or escrow services, particularly for international transactions. Negotiating favorable terms that provide you with adequate protection while ensuring the supplier’s commitment to fulfilling the order is critical.

5. How can I vet suppliers for custom leather interiors effectively?

To vet suppliers effectively, start by checking their industry reputation through online reviews and testimonials. Verify their credentials, including certifications for quality standards and compliance with international regulations. Request samples of their previous work and assess their production capabilities. Engaging in direct conversations to understand their customer service approach and responsiveness can also provide insights into their reliability. Lastly, consider visiting their facilities if feasible or utilizing third-party inspection services for added assurance.

6. What logistics considerations should I be aware of when importing custom leather interiors?

When importing custom leather interiors, consider shipping methods, lead times, and potential customs regulations in your country. It’s essential to work with a logistics partner experienced in international trade to ensure compliance with import duties and taxes. Additionally, factor in the costs of shipping insurance and freight forwarders to mitigate risks. Understanding the logistics timeline from production to delivery will help you manage customer expectations effectively.

7. How can I ensure timely delivery of custom leather interiors?

To ensure timely delivery, establish clear timelines with your supplier during the negotiation phase. Regular communication throughout the production process can help identify any potential delays early. Consider setting up milestone checks to monitor the progress of your order. Additionally, having contingency plans in place, such as alternative suppliers or expedited shipping options, can help mitigate any unforeseen delays and keep your project on track.

8. What quality assurance measures should I expect from suppliers of custom leather interiors?

Expect suppliers to implement rigorous quality assurance measures, including material inspections, production checks, and final product evaluations. Inquire about their quality control processes and whether they adhere to recognized industry standards. Request documentation of quality tests performed on materials, such as durability and colorfastness. A reliable supplier should also provide a warranty or guarantee for their products, which can offer you additional peace of mind regarding quality and durability.

Top 8 Custom Leather Interior Manufacturers & Suppliers List

1. Leather Seats – Custom Upholstery Kits

Domain: leatherseats.com

Registered: 2000 (25 years)

Introduction: Custom Leather Seat Upholstery, Leather Upholstery Kits, Build Your Own Interior, Custom Upholstery Configurator, Pre-Configured Interior Packages, Matching Materials, Ecstasy Leather Hides, Standard Leather Hides, Vinyl by the Yard, DIY Installation Tools, Basic Install Kit, Complete Install Kit, Headrest Shrinker, Hog-Ring Pliers, Upholstery Adhesive, Leather Maintenance, Interior Accessories, C…

2. Katzkin – Custom Leather Seat Covers

Domain: katzkin.com

Registered: 1998 (27 years)

Introduction: Katzkin offers custom leather seat covers and interiors for a wide range of vehicles, including popular models like Ford F-150, Jeep Wrangler, Toyota Tacoma, Chevy Silverado, and Ram 1500. They provide over 3,000 interior options in 120 colors and materials. Katzkin’s products are not just traditional seat covers; they replace the cloth upholstery entirely, including door panels and center console…

3. Lseat – Genuine Leather Seat Covers

Domain: lseat.com

Registered: 2011 (14 years)

Introduction: Leather Seat Covers, Custom Leather Interior, Replacement Seat Covers, Genuine Leather options for various car brands including Acura, Alfa Romeo, Audi, BMW, Chevrolet, Ford, Mercedes Benz, Porsche, and more. Sale: Up to 50% off Genuine Leather Seat Covers, Regular price $699 per row. Featured products include custom leather seat covers for specific models like Lexus SC430, Porsche Boxster, Chevro…

4. Barbarossa Leather – Custom Leather Colors

Domain: barbarossaleather.com

Registered: 2005 (20 years)

Introduction: Custom Leather Colors available in a full spectrum including traditional earth tones and vibrant colors like turquoise, yellow, and lavender. Variegated patterns and textures are also offered. Key color categories include: White, Beige, Sepia, Orange, Red, Purple, Blue, Green, Grey, Brown, Black, and Metallic. Specific color names include Abyss, Amazon, Anaconda, Arabesque, Aspen, Aviator, Aztec, …

5. Tint World – Custom Leather Interiors

Domain: tintworld.com

Registered: 2001 (24 years)

Introduction: Custom Leather Interiors for Cars and Trucks, OEM Quality, 1000+ Patterns, Heating/Cooling Systems, Alea leather interiors, Grade ‘A’ Italian Leather, Custom Tailor-Made for Each Vehicle, Original Manufacturer Specifications Fitment, Seat Heating and Cooling System Options, OEM Factory Approved Worldwide, Complete Cloth Interior Replacement, Door Panels and Custom Consoles, Authorized Leather Spec…

6. Katskinz – Leather Upholstery Kits for Ford Mustang

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Katskinz leather upholstery kits for replacing cloth seats in a Ford Mustang; prices range from $1,600 to $2,100 installed.

7. Coverking – Genuine Leather Seat Cover

Domain: coverking.com

Registered: 1996 (29 years)

Introduction: {“product_name”:”Genuine Leather Seat Cover”,”material”:”Genuine Leather”,”fit_type”:”Custom Fit”,”color_options”:[“Black”,”Tan”,”Gray”],”features”:[“Durable and long-lasting material”,”Easy to clean”,”Custom-fit design for various vehicle models”,”Enhanced comfort and style”],”installation”:”Easy installation with no tools required”,”warranty”:”1-year warranty”}

8. Trimtek Leather – Custom Automotive Interiors

Domain: trimtekleather.com

Registered: 2016 (9 years)

Introduction: Trimtek Leather offers custom leather car and truck interiors made from the finest imported automotive leathers, engineered to meet or exceed factory performance specifications. Their products are tested and trusted by major automotive brands including Chrysler, Dodge, Jeep, and Ford. Customers can custom build their leather seats by contacting Trimtek with design ideas for a quote, which can be s…

Strategic Sourcing Conclusion and Outlook for custom leather interior

In the evolving landscape of custom leather interiors, strategic sourcing stands as a critical factor for B2B buyers aiming to enhance their offerings. By partnering with reputable manufacturers who provide tailored solutions, businesses can ensure a high-quality product that resonates with the preferences of diverse markets. The ability to customize designs, colors, and materials not only meets consumer demands but also differentiates your brand in competitive marketplaces.

Furthermore, understanding the logistics of sourcing—such as lead times, shipping options, and installation capabilities—can significantly impact your supply chain efficiency and customer satisfaction. This is especially vital for buyers from regions like Africa, South America, the Middle East, and Europe, where unique market dynamics may influence purchasing decisions.

As you look to the future, consider the benefits of establishing long-term relationships with suppliers who can provide innovative solutions and adaptability to market trends. Embrace the opportunity to elevate your product offerings with custom leather interiors that reflect quality and craftsmanship. Engage now with manufacturers to explore how you can transform your vehicle interiors and meet the evolving needs of your clientele.

Illustrative image related to custom leather interior

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.