Introduction: Navigating the Global Market for washing chamois leather

In the global marketplace, sourcing high-quality washing chamois leather presents unique challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. As businesses increasingly prioritize sustainable and effective cleaning solutions, the demand for genuine chamois leather—known for its superior absorbency and durability—continues to rise. However, navigating the complexities of supplier selection, quality assurance, and cost-effectiveness can be daunting.

This comprehensive guide addresses these challenges by exploring the various types of washing chamois leather available, their specific applications across different industries, and essential criteria for vetting suppliers. Additionally, it delves into pricing strategies, helping buyers understand the cost implications of their choices and the long-term benefits of investing in high-quality chamois leather products.

By equipping B2B buyers with actionable insights and practical knowledge, this guide empowers informed purchasing decisions that align with operational needs and sustainability goals. Whether you’re based in Nigeria, Saudi Arabia, or elsewhere, understanding the nuances of washing chamois leather will enable you to enhance your product offerings and meet the evolving demands of your customers.

Table Of Contents

- Top 6 Washing Chamois Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for washing chamois leather

- Understanding washing chamois leather Types and Variations

- Key Industrial Applications of washing chamois leather

- 3 Common User Pain Points for ‘washing chamois leather’ & Their Solutions

- Strategic Material Selection Guide for washing chamois leather

- In-depth Look: Manufacturing Processes and Quality Assurance for washing chamois leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘washing chamois leather’

- Comprehensive Cost and Pricing Analysis for washing chamois leather Sourcing

- Alternatives Analysis: Comparing washing chamois leather With Other Solutions

- Essential Technical Properties and Trade Terminology for washing chamois leather

- Navigating Market Dynamics and Sourcing Trends in the washing chamois leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of washing chamois leather

- Strategic Sourcing Conclusion and Outlook for washing chamois leather

- Important Disclaimer & Terms of Use

Understanding washing chamois leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather Chamois | Made from real animal hide, highly absorbent | Automotive detailing, luxury car care | Pros: Exceptional absorbency, long-lasting durability. Cons: Higher cost, requires careful maintenance. |

| شامواه صناعي | Typically made from polyester or nylon, affordable | Mass-market automotive cleaning products | Pros: Cost-effective, easy to clean. Cons: Less absorbent, shorter lifespan compared to genuine leather. |

| Microfiber Chamois | Blended fibers for high absorbency and softness | General cleaning, home use | Pros: Versatile, good for various surfaces. Cons: Not as effective as leather for streak-free finishes. |

| Suede Chamois | Soft texture, often used for delicate surfaces | Fine automotive finishes, luxury detailing | Pros: Gentle on surfaces, good for polishing. Cons: Less durable, may require special care. |

| Eco-Friendly Chamois | Made from sustainable materials, biodegradable | Green cleaning products, eco-conscious brands | Pros: Environmentally friendly, growing market appeal. Cons: May be less effective than traditional options. |

What Are the Characteristics of Genuine Leather Chamois?

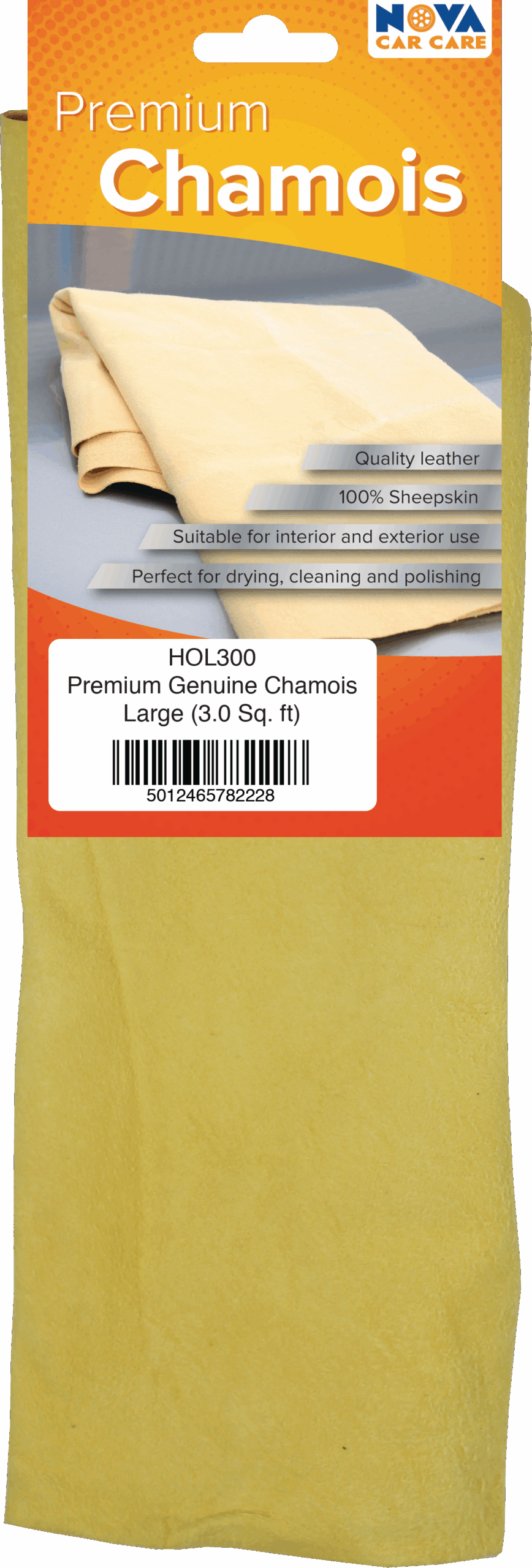

Genuine leather chamois is prized for its exceptional absorbency, capable of soaking up significant amounts of moisture without leaving streaks. It is made from animal hides, typically from goats or sheep, which provides a soft texture that is gentle on surfaces. This type of chamois is ideal for high-end automotive detailing, where maintaining the integrity of the vehicle’s finish is crucial. Buyers should consider the higher price point and the need for regular conditioning to maintain its quality.

How Does Synthetic Chamois Differ from Genuine Leather?

Synthetic chamois, often composed of polyester or nylon, offers a budget-friendly alternative to genuine leather. While it may not match the absorbency and softness of real leather, it is still effective for general cleaning tasks, especially in mass-market automotive applications. B2B buyers should note that synthetic options are easier to clean and maintain, but they may need to replace them more frequently due to reduced durability.

What Are the Benefits of Using Microfiber Chamois?

Microfiber chamois are made from a blend of fibers designed to enhance absorbency while being gentle on surfaces. They are particularly versatile, suitable for various cleaning tasks in both automotive and household settings. While they excel in general cleaning applications, B2B buyers should be aware that microfiber chamois may not provide the same streak-free results on glass surfaces as traditional leather chamois.

Why Choose Suede Chamois for Delicate Surfaces?

Suede chamois are characterized by their soft texture, making them ideal for polishing and caring for delicate finishes. They are commonly used in luxury automotive detailing where the risk of scratching is a concern. However, buyers should consider that suede may require more careful handling and maintenance compared to other chamois types, potentially impacting long-term usability.

What Makes Eco-Friendly Chamois a Growing Choice?

Eco-friendly chamois are crafted from sustainable materials and are designed to be biodegradable, appealing to businesses focused on green practices. As consumer demand for environmentally responsible products rises, these chamois are gaining traction in the market. B2B buyers should evaluate their effectiveness compared to traditional options, as well as the potential for improved brand image through sustainable offerings.

Key Industrial Applications of washing chamois leather

| Industry/Sector | Specific Application of washing chamois leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Detailing | Drying and polishing vehicles | Provides a high-shine, streak-free finish; enhances customer satisfaction | Quality of leather, size and thickness, sourcing from reputable suppliers |

| Manufacturing & Logistics | Cleaning machinery and equipment | Prevents scratches on delicate surfaces; reduces downtime due to maintenance | Durability of the chamois, ability to withstand industrial cleaning agents |

| Hospitality | Cleaning and maintaining high-end fixtures | Ensures a pristine appearance; enhances guest experience | Softness and absorbency, compliance with eco-friendly standards |

| Marine Applications | Drying boats and marine equipment | Protects surfaces from water spots and corrosion; prolongs equipment lifespan | Resistance to saltwater and mold, availability of bulk purchasing options |

| Home Care | General cleaning and drying | Versatile use for various surfaces; eco-friendly alternative to synthetic cloths | Natural materials, ease of care, and longevity of the product |

How is washing chamois leather used in automotive detailing?

In the automotive detailing sector, washing chamois leather is employed primarily for drying and polishing vehicles. Its super-absorbent nature allows for rapid moisture removal, preventing water spots and streaks that can mar a vehicle’s finish. This is especially crucial for businesses that offer detailing services, as a high-quality finish enhances customer satisfaction and retention. Buyers should focus on sourcing durable chamois that can withstand frequent washing and maintain their absorbency over time, ensuring a consistent quality of service.

What role does washing chamois leather play in manufacturing and logistics?

In manufacturing and logistics, washing chamois leather is utilized for cleaning machinery and equipment. The soft texture helps prevent scratches on delicate surfaces, which is vital in environments where precision is key. Additionally, using chamois leather can minimize downtime by effectively cleaning equipment without damaging it. B2B buyers in this sector must consider the durability of the chamois and its compatibility with various industrial cleaning agents to ensure optimal performance in demanding environments.

Illustrative image related to washing chamois leather

Why is washing chamois leather important in the hospitality industry?

The hospitality industry employs washing chamois leather for cleaning and maintaining high-end fixtures and furnishings. Its ability to deliver a streak-free shine enhances the overall guest experience, reflecting the establishment’s commitment to quality and cleanliness. Buyers in this sector should prioritize chamois that are soft and absorbent, as well as those that meet eco-friendly standards to align with sustainability initiatives increasingly valued by consumers.

How does washing chamois leather benefit marine applications?

In marine applications, washing chamois leather is essential for drying boats and marine equipment. It effectively removes moisture, preventing water spots and corrosion that can damage surfaces over time. This application is particularly important for businesses involved in boat maintenance and repair. When sourcing chamois for marine use, buyers should ensure the material is resistant to saltwater and mold, as these factors can significantly affect the longevity and performance of the product.

What are the advantages of washing chamois leather in home care?

Washing chamois leather serves as a versatile tool in home care for general cleaning and drying of various surfaces. Its eco-friendly nature makes it an attractive alternative to synthetic cloths, appealing to environmentally conscious consumers. B2B buyers should focus on the natural materials used in chamois production, as well as the ease of care and longevity of the product, to provide customers with a sustainable and effective cleaning solution.

3 Common User Pain Points for ‘washing chamois leather’ & Their Solutions

Scenario 1: Ineffective Cleaning Agents Damage Chamois Leather

The Problem: Many B2B buyers, particularly those in the automotive care industry, face the challenge of using inappropriate cleaning agents on chamois leather. This often leads to the degradation of the leather’s natural oils, rendering it brittle and less absorbent. For companies relying on chamois leather for high-quality finishes in vehicle detailing, this not only affects product longevity but also compromises the quality of service offered to clients. The financial implications of frequently replacing damaged chamois leather can be significant, especially for businesses operating in competitive markets.

The Solution: To ensure the longevity of chamois leather, B2B buyers should prioritize sourcing high-quality, pH-balanced cleaning agents specifically designed for leather care. It is essential to avoid harsh detergents or bleach, as these can strip the leather of its natural properties. Instead, investing in natural soaps or specialized car wash shampoos can effectively clean the chamois without causing damage. When cleaning, it’s advisable to rinse the leather thoroughly in warm water after each use, followed by gentle wringing to remove excess moisture. This method not only maintains the leather’s integrity but also enhances its performance in absorbing moisture. Providing staff training on proper cleaning techniques can further minimize the risk of damage, ensuring that every team member understands the importance of using the right products.

Scenario 2: Improper Drying Techniques Lead to Mold and Rot

The Problem: A common issue faced by businesses is the improper drying and storage of chamois leather. Many buyers neglect to dry their chamois thoroughly before storage, leading to mold growth and an unpleasant odor. This scenario is particularly problematic for businesses that operate in humid climates, where moisture retention can quickly turn into a costly liability. Not only does mold compromise the quality of the chamois leather, but it can also negatively impact customer satisfaction and brand reputation.

The Solution: To combat this issue, companies should establish a standardized drying protocol for chamois leather. After cleaning, chamois should be stretched out flat and hung in a well-ventilated area away from direct sunlight and heat sources. This allows for natural air drying, which prevents moisture accumulation. Furthermore, creating a designated storage space that is cool and dry will help maintain the leather’s condition. For businesses operating in humid environments, using silica gel packs or dehumidifiers in storage areas can further reduce moisture levels. Regular inspections of stored chamois leather can help identify any early signs of mold, allowing for prompt action to preserve the investment.

Scenario 3: Difficulty in Maintaining Leather Softness and Flexibility

The Problem: Over time, chamois leather can become stiff and less pliable, a concern that many B2B buyers encounter. This issue arises from inadequate conditioning and improper handling during the cleaning process. For businesses that rely on the flexibility and softness of chamois leather for effective application and drying, this can lead to inefficiencies and poor results, ultimately affecting customer satisfaction and repeat business.

The Solution: To maintain the softness and flexibility of chamois leather, it is crucial to implement a regular conditioning routine. After the leather is thoroughly dried, it should be gently rubbed against a hard surface to restore its pliability. Additionally, using a specialized leather conditioner designed for chamois can help rejuvenate the material. Buyers should ensure that staff are trained on the importance of conditioning and the correct techniques to avoid damaging the leather during use. Regularly scheduled maintenance checks on chamois leather will help identify when conditioning is needed, ensuring that the product remains in optimal condition for maximum performance. By prioritizing these practices, businesses can extend the lifespan of their chamois leather and enhance their service quality.

Strategic Material Selection Guide for washing chamois leather

What Materials Are Commonly Used for Washing Chamois Leather?

When selecting materials for washing chamois leather, it’s essential to consider several factors, including the properties of the materials, their advantages and disadvantages, and their impact on the application. Here, we analyze four common materials used in the washing process of chamois leather: natural soap, synthetic detergents, microfiber cloths, and water.

Illustrative image related to washing chamois leather

What Are the Key Properties of Natural Soap for Washing Chamois Leather?

Natural soap is a preferred choice for cleaning chamois leather due to its gentle formulation. It typically has a neutral pH, which helps maintain the leather’s natural oils, preventing it from becoming brittle. Additionally, natural soaps are biodegradable, making them environmentally friendly and compliant with various international standards.

Pros: Natural soap is gentle on leather, preserves its integrity, and is cost-effective. It is also widely available and can be sourced locally in many regions.

Cons: The effectiveness of natural soap can vary based on formulation, and it may not remove heavy stains as effectively as synthetic options.

Impact on Application: Using natural soap ensures that the chamois leather retains its absorbency and softness, which is crucial for its performance in drying applications.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East may prefer locally sourced natural soaps that comply with ASTM or JIS standards, ensuring quality and safety.

How Do Synthetic Detergents Compare in Washing Chamois Leather?

Synthetic detergents are commonly used in various cleaning applications due to their strong stain-removing capabilities. However, they can be harsh on natural materials like chamois leather.

Pros: Synthetic detergents are highly effective at removing tough stains and grime, making them suitable for heavy-duty cleaning tasks.

Cons: They can strip essential oils from chamois leather, leading to dryness and damage over time. This degradation can significantly reduce the lifespan of the leather.

Impact on Application: While synthetic detergents may provide immediate cleaning benefits, they can compromise the chamois leather’s long-term performance.

Considerations for International Buyers: B2B buyers should be aware of the potential regulatory restrictions on synthetic detergents in certain regions, particularly in Europe, where environmental regulations are stringent.

What Are the Benefits of Using Microfiber Cloths for Washing Chamois Leather?

Microfiber cloths are increasingly popular in the automotive and cleaning industries due to their superior absorbency and softness.

Pros: Microfiber cloths are highly effective at drying surfaces without leaving streaks. They can be washed and reused multiple times, making them a cost-effective option.

Cons: While they are versatile, microfiber cloths are not as absorbent as chamois leather and can become waterlogged quickly, reducing their effectiveness.

Illustrative image related to washing chamois leather

Impact on Application: Microfiber cloths can complement chamois leather by providing a streak-free finish, especially on glass surfaces.

Considerations for International Buyers: Buyers should ensure that microfiber products meet local quality standards, as there can be significant variations in quality across manufacturers.

How Does Water Quality Affect the Washing of Chamois Leather?

Water quality plays a crucial role in the cleaning process of chamois leather. Hard water, which contains high levels of minerals, can leave deposits on the leather, affecting its appearance and performance.

Pros: Soft water is ideal for washing chamois leather, as it prevents mineral buildup and helps maintain the leather’s softness.

Cons: In areas with hard water, additional treatments may be necessary to soften the water, increasing overall costs.

Impact on Application: The right water quality ensures that the chamois leather remains clean and functional, maximizing its lifespan.

Considerations for International Buyers: Buyers should consider local water quality when selecting washing methods and may need to invest in water softening solutions in regions with hard water.

Summary Table of Material Selection for Washing Chamois Leather

| المواد | Typical Use Case for washing chamois leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Soap | Cleaning chamois leather after use | Gentle on leather, preserves oils | May not remove heavy stains effectively | منخفضة |

| Synthetic Detergents | Heavy-duty cleaning of chamois leather | Strong stain removal | Can degrade leather over time | Med |

| Microfiber Cloths | Drying and polishing surfaces | Streak-free finish, reusable | Less absorbent than chamois | Med |

| المياه | Washing chamois leather | Essential for cleaning | Hard water can leave deposits | منخفضة |

This analysis provides a comprehensive overview of the materials involved in washing chamois leather, helping B2B buyers make informed decisions tailored to their specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for washing chamois leather

What Are the Key Stages in the Manufacturing Process of Washing Chamois Leather?

The manufacturing process of washing chamois leather involves several critical stages, ensuring that the final product meets quality and performance standards demanded by B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Chamois Leather Production?

Material preparation begins with the selection of high-quality animal hides, commonly sourced from goats or sheep. These hides undergo a thorough cleaning process to remove impurities and contaminants. Following this, they are soaked in a solution that softens the leather, allowing for easier manipulation during subsequent stages. This soaking phase is crucial, as it prepares the leather for shaping and further processing.

What Techniques Are Used in Forming and Assembly?

In the forming stage, the softened hides are cut into specific shapes and sizes suitable for various applications, such as automotive cleaning or household use. This step often employs precision cutting tools to ensure uniformity and minimize waste.

During the assembly stage, the cut pieces are stitched or bonded together, depending on the intended design of the chamois. Advanced techniques such as ultrasonic welding may also be utilized for synthetic chamois products, providing a robust seam without compromising the material’s integrity.

Illustrative image related to washing chamois leather

What Are the Finishing Processes for Chamois Leather?

Finishing is a vital step that enhances both the aesthetic appeal and functional properties of the chamois leather. This may include processes such as dyeing, conditioning, and applying protective coatings. The application of natural oils and waxes can increase the leather’s durability and water resistance, making it more suitable for washing and drying applications.

Moreover, the finishing phase often involves additional quality checks to ensure that the leather maintains its softness and absorbency, essential characteristics for effective cleaning.

What International Quality Standards Are Relevant to Chamois Leather Manufacturing?

For B2B buyers, understanding the quality assurance protocols in the manufacturing of washing chamois leather is crucial. Many manufacturers adhere to international standards such as ISO 9001, which focuses on maintaining a quality management system. Compliance with this standard ensures that production processes are consistently monitored and improved.

Additionally, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) may apply to certain markets. Buyers should inquire about these certifications as they reflect the manufacturer’s commitment to quality and safety.

How Are Quality Control Checkpoints Established in the Manufacturing Process?

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process. Key QC checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials, such as leather hides, undergo rigorous inspection for defects. Only materials meeting predefined quality criteria are accepted.

-

In-Process Quality Control (IPQC): Throughout the production stages, periodic checks are performed to ensure that processes remain within specified parameters. This may involve monitoring the cutting precision and stitching quality.

-

Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive inspection is conducted to verify that each item meets the required standards for absorbency, durability, and overall quality.

What Common Testing Methods Are Used for Chamois Leather Quality Assurance?

Manufacturers employ several testing methods to verify the quality of chamois leather. Common tests include:

-

Absorbency Tests: These tests measure the leather’s ability to absorb water, a critical performance indicator for cleaning applications.

-

Durability Tests: Evaluating the leather’s resistance to wear and tear ensures that it can withstand repeated use without degrading.

-

Chemical Resistance Tests: These assess the leather’s ability to withstand exposure to various cleaning agents without losing its integrity or performance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers. Here are several strategies:

-

Conduct Audits: Regular audits can provide insights into a supplier’s manufacturing processes and adherence to quality standards. Buyers should request access to audit reports and findings.

-

Request Documentation: Suppliers should provide documentation demonstrating compliance with international standards like ISO 9001 and any relevant certifications. This documentation serves as proof of their commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an extra layer of assurance. These independent entities can assess the quality of products before shipment, ensuring they meet the buyer’s specifications.

What Quality Control Considerations Are Important for International B2B Buyers?

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Variations in regional standards and regulations may impact the manufacturing and quality assurance processes.

Illustrative image related to washing chamois leather

Buyers should familiarize themselves with local regulations that may influence product acceptance in their markets. Additionally, establishing clear communication channels with suppliers can help ensure that quality expectations are met consistently.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for washing chamois leather can significantly enhance the purchasing decisions of B2B buyers. By prioritizing suppliers that adhere to stringent quality standards and implementing robust QC measures, buyers can ensure they receive products that meet their operational needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘washing chamois leather’

مقدمة

In the competitive landscape of B2B procurement, sourcing quality washing chamois leather is essential for maintaining product excellence in car care and other applications. This guide provides a step-by-step checklist to help international buyers effectively evaluate and procure chamois leather, ensuring they make informed decisions that align with their business needs.

Step 1: Identify Your Specific Requirements

Before reaching out to suppliers, clearly define your specific requirements for chamois leather. Consider factors such as size, thickness, and absorbency, as these specifications will dictate the performance of the leather in practical applications.

- Usage Context: Determine whether the chamois will be used primarily for automotive detailing or broader applications like household cleaning.

- Material Type: Decide between genuine leather and synthetic options based on durability and cost considerations.

Step 2: Conduct Market Research for Suppliers

Research potential suppliers in the market, focusing on their reputation and product offerings. Utilize industry-specific platforms, trade shows, and online directories to gather information.

- Supplier Reviews: Look for testimonials and reviews from other B2B buyers to gauge the reliability and quality of their products.

- Product Range: Ensure the supplier has a diverse range of chamois leather options to meet varying client needs.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial to ensure quality and compliance with industry standards. Request documentation that proves the supplier adheres to relevant quality management systems, such as ISO certifications.

Illustrative image related to washing chamois leather

- Sustainability Practices: Inquire about the supplier’s sourcing and production practices, particularly if environmentally friendly processes are a priority for your company.

- Quality Control Measures: Understand how the supplier maintains quality throughout their production process.

Step 4: Request Samples for Testing

Before making a bulk purchase, always request samples of the chamois leather. Testing samples allows you to evaluate the product’s quality, absorbency, and durability firsthand.

- Performance Testing: Assess how well the chamois performs in real-world scenarios, such as drying surfaces without streaking.

- Material Feel: Check for softness and flexibility, which are critical for usability in various applications.

Step 5: Negotiate Pricing and Terms

Once you have selected a potential supplier, engage in negotiations regarding pricing and payment terms. Establish clear expectations on lead times, order quantities, and shipping arrangements.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Payment Terms: Discuss flexible payment options that align with your cash flow needs, such as net terms or advance payments.

Step 6: Finalize Logistics and Shipping Arrangements

Coordinate the logistics of shipping and delivery to ensure that the chamois leather arrives in a timely manner and in optimal condition.

- Shipping Methods: Discuss options for air or sea freight based on urgency and budget.

- Customs Clearance: Ensure that all necessary customs documentation is prepared in advance to avoid delays at the border.

Step 7: Establish a Long-term Relationship

After the initial purchase, focus on building a long-term relationship with your supplier. Regular communication and feedback can lead to better pricing, priority service, and access to new products.

Illustrative image related to washing chamois leather

- Performance Review: Periodically evaluate the supplier’s performance in terms of product quality and service delivery.

- Feedback Loop: Create a system for providing feedback to help the supplier improve their offerings and address your evolving needs.

By following these steps, B2B buyers can ensure a successful procurement process for washing chamois leather, ultimately leading to enhanced product quality and customer satisfaction.

Comprehensive Cost and Pricing Analysis for washing chamois leather Sourcing

In evaluating the costs associated with sourcing washing chamois leather, it is crucial to dissect the various components that contribute to the overall pricing structure. Understanding these elements not only aids in budgeting but also enhances negotiation power with suppliers.

What Are the Key Cost Components for Washing Chamois Leather?

-

Materials: The primary material cost for chamois leather is derived from the animal hides, typically from sheep or goats. The quality and sourcing of these hides can significantly affect the price. Premium hides with fewer blemishes command higher prices. Additionally, synthetic alternatives are available at lower costs, but they may not offer the same absorbency or durability.

-

Labor: Labor costs encompass the wages of workers involved in the tanning, cutting, and finishing processes. Regions with lower labor costs may provide a competitive edge, but this can sometimes compromise quality. Skilled labor is essential for ensuring that the chamois leather is processed correctly to maintain its natural properties.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead, thus reducing the overall cost of the final product.

-

Tooling: The initial investment in machinery and tools for processing chamois leather can be substantial. However, this cost is amortized over time, and advanced machinery can enhance production efficiency and quality.

-

Quality Control (QC): Implementing stringent quality control measures is vital to ensure the leather meets industry standards. This may involve additional costs but is necessary to prevent defects and ensure customer satisfaction.

-

Logistics: Transporting raw materials and finished products involves significant logistics costs, especially for international shipping. Factors like distance, shipping mode, and fuel prices can influence these costs.

-

Margin: Finally, the profit margin set by manufacturers and suppliers will affect the final price. This margin can vary based on market demand, competition, and perceived value.

What Influences Pricing for Washing Chamois Leather?

Several factors can influence the pricing of washing chamois leather:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect unit pricing significantly. Larger orders typically yield lower per-unit costs. Buyers should consider their consumption patterns when negotiating MOQs.

-

Specifications and Customization: Custom sizes, colors, or finishes can lead to additional costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Quality and Certifications: Higher quality leather that meets specific certifications (e.g., eco-friendly or organic) may come at a premium. Buyers should assess whether the benefits justify the costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven quality and service levels.

-

Incoterms: The choice of Incoterms can affect the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for budgeting effectively.

What Tips Can Help Buyers Optimize Costs in Sourcing?

-

Negotiate Effectively: Building strong relationships with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate based on your volume and long-term purchasing potential.

-

Focus on Total Cost of Ownership (TCO): While the initial price is important, consider the TCO, which includes maintenance, longevity, and disposal costs. Investing in higher-quality chamois leather may yield savings over time.

-

Be Aware of Pricing Nuances: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of currency fluctuations, tariffs, and import duties that could affect overall costs.

-

Conduct Market Research: Understanding market trends and competitor pricing can provide leverage during negotiations. It also helps in assessing whether a supplier’s price is competitive.

Disclaimer on Pricing

Prices for washing chamois leather can vary widely based on the factors discussed. This analysis serves as a guideline, and actual costs may differ based on market conditions, supplier relationships, and specific buyer needs. Always conduct thorough due diligence and request quotes from multiple suppliers to ensure the best deal.

Alternatives Analysis: Comparing washing chamois leather With Other Solutions

Introduction: Exploring Alternatives to Washing Chamois Leather

When it comes to maintaining vehicle surfaces, washing chamois leather has long been a favored choice for its absorbency and effectiveness. However, with the evolving landscape of cleaning technologies, it’s essential for B2B buyers to consider various alternatives. This analysis compares washing chamois leather with two prominent alternatives—microfiber cloths and synthetic chamois. Each option has distinct advantages and disadvantages, making it crucial for businesses to select the most suitable solution for their specific requirements.

Comparison Table

| Comparison Aspect | Washing Chamois Leather | Microfiber Cloth | شامواه صناعي |

|---|---|---|---|

| Performance | Excellent absorption; streak-free finish | Good absorption; versatile | Moderate absorption; less durable |

| Cost | Higher initial investment; long lifespan | Affordable; requires frequent replacement | Moderate cost; less durable than leather |

| Ease of Implementation | Requires specific care and handling | Easy to use; no special care needed | Simple to use; minimal maintenance |

| Maintenance | Requires rinsing, drying, and conditioning | Machine washable; quick to dry | Easy to clean; less maintenance than leather |

| Best Use Case | Premium vehicle detailing | General car cleaning and drying | Budget-conscious applications |

Detailed Breakdown of Alternatives

Microfiber Cloths: A Versatile Choice for Car Care

Microfiber cloths have gained popularity due to their versatility and affordability. They can be used for various cleaning tasks, from washing to drying and applying wax. Their ability to trap dirt and dust particles makes them effective for general car maintenance. However, while they are easy to wash and maintain, they tend to lose their absorbency more quickly than chamois leather, requiring more frequent replacements. For businesses focused on cost-efficiency and flexibility, microfiber cloths are an excellent choice, although they may not provide the same high-shine finish as chamois leather.

Synthetic Chamois: A Budget-Friendly Alternative

Synthetic chamois offer a middle ground between traditional chamois leather and microfiber cloths. They are designed to mimic the absorbency of genuine leather but at a lower price point. While synthetic options are convenient and easy to clean, they often lack the durability and long-term performance of genuine chamois leather. Businesses looking for a cost-effective solution without sacrificing too much quality may find synthetic chamois suitable for less demanding applications. However, they may not achieve the same level of streak-free shine or longevity.

Conclusion: Making an Informed Decision on Cleaning Solutions

When selecting a cleaning solution, B2B buyers must weigh their specific needs against the strengths and weaknesses of each alternative. For businesses that prioritize high-quality finishes and long-term use, washing chamois leather remains a top choice despite its higher initial cost and maintenance requirements. On the other hand, for those seeking versatility and affordability, microfiber cloths or synthetic chamois can serve well in various applications. Ultimately, understanding the unique benefits of each option will empower buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for washing chamois leather

What Are the Key Technical Properties of Washing Chamois Leather?

Understanding the technical properties of chamois leather is crucial for businesses engaged in automotive care, textile manufacturing, and leather goods. Here are some essential specifications that B2B buyers should consider:

-

Material Grade

– Chamois leather is traditionally made from the skin of sheep or goats, but can also be manufactured synthetically. The grade of the leather significantly affects its absorbency, softness, and durability. Higher grades are more resilient and can absorb up to six times their weight in water, making them ideal for car drying applications. Businesses should prioritize sourcing high-grade materials to ensure longevity and performance. -

Absorbency Rate

– This property measures how much moisture the chamois can hold relative to its weight. A higher absorbency rate indicates superior performance in drying applications, which is critical in preventing water spots on vehicles. For businesses, understanding this specification aids in evaluating product quality and suitability for various applications, from automotive detailing to household cleaning. -

Thickness and Tolerance

– The thickness of chamois leather can vary, typically ranging from 0.8 to 1.2 mm. This thickness impacts the chamois’ flexibility and durability. Tolerance refers to the acceptable deviation in thickness, which can affect performance consistency. A consistent thickness ensures uniform absorbency and lifespan, making it a key factor for suppliers and manufacturers in quality control. -

Durability and Lifecycle

– Durability is a measure of how well chamois leather withstands repeated use and washing. A high-quality chamois can last for years if properly maintained. Businesses must consider lifecycle costs versus initial investment when selecting chamois leather products. Understanding the expected lifecycle helps in budgeting and inventory management. -

Chemical Resistance

– Chamois leather’s reaction to various cleaning agents is crucial for its maintenance. Natural soaps and car wash shampoos are suitable, while detergents and bleaches can degrade the leather. This knowledge is essential for buyers to ensure that their cleaning processes do not compromise the leather’s integrity, impacting overall product performance.

What Are Common Trade Terms Related to Washing Chamois Leather?

Familiarity with trade terminology is vital for effective communication and negotiation in the B2B landscape. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or products that may be marketed by another manufacturer. For chamois leather, knowing the OEMs helps buyers identify reliable sources for high-quality materials that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQs is crucial for inventory management and cost control, particularly for businesses that may not require large volumes of chamois leather. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific products. When sourcing chamois leather, submitting an RFQ allows businesses to compare offers and negotiate better terms, ensuring they get the best value. -

Incoterms (International Commercial Terms)

– These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping costs, insurance, and risk management when purchasing chamois leather from global suppliers. -

Lead Time

– Lead time refers to the time taken from placing an order until it is delivered. Understanding lead times is essential for inventory planning and ensuring that production schedules are met, particularly when dealing with suppliers from different regions. -

Sustainability Standards

– With increasing focus on environmental impact, sustainability standards refer to the practices that ensure the leather is sourced and processed in an eco-friendly manner. Businesses should prioritize suppliers who adhere to these standards to enhance their brand reputation and meet regulatory requirements.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions when sourcing washing chamois leather, ultimately leading to better product performance and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the washing chamois leather Sector

What Are the Key Market Trends Influencing the Washing Chamois Leather Sector?

The global washing chamois leather market is experiencing significant growth driven by several key factors. Increasing consumer awareness regarding vehicle maintenance and the rising demand for high-quality car care products are notable trends. As more consumers seek effective solutions for drying and polishing vehicles, genuine chamois leather is gaining preference due to its superior absorbency and ability to deliver a streak-free finish. Additionally, the automotive sector’s expansion in regions like Africa and the Middle East is fueling demand, as these markets witness a surge in vehicle ownership.

Technological advancements in manufacturing processes are also shaping the market dynamics. Innovations in synthetic alternatives are emerging, offering cost-effective options for buyers. However, genuine chamois leather retains its appeal due to its durability and long lifespan when properly maintained. International B2B buyers should be aware of these emerging trends, as they may influence sourcing decisions. Collaborating with manufacturers that prioritize quality can lead to better product offerings and customer satisfaction.

Furthermore, the rising popularity of eco-friendly products is pushing suppliers to consider sustainable practices. Buyers from regions like Europe and South America are increasingly favoring suppliers who can demonstrate environmentally responsible sourcing methods, thus driving the need for transparency in the supply chain.

Illustrative image related to washing chamois leather

How Can Sustainability and Ethical Sourcing Impact the Washing Chamois Leather Market?

Sustainability is becoming a cornerstone of the washing chamois leather sector. The environmental impact of production processes, particularly those involving animal-derived materials, is under scrutiny. As awareness of ecological issues grows, B2B buyers are increasingly prioritizing suppliers that adhere to ethical sourcing practices. This includes ensuring that animal welfare standards are met and that the leather is sourced from suppliers who practice sustainable farming.

The demand for ‘green’ certifications is also on the rise. Buyers should look for products that come with certifications such as OEKO-TEX or similar, which indicate that the materials used are free from harmful substances and produced in an environmentally friendly manner. Additionally, suppliers who invest in sustainable materials, such as plant-based alternatives or recycled leather, are likely to stand out in a competitive market.

By aligning purchasing strategies with sustainability goals, businesses not only enhance their brand image but also meet the increasing consumer demand for eco-friendly products. This shift towards ethical sourcing is essential for maintaining a competitive edge, particularly in markets like Europe and North America, where consumers are more likely to support companies with robust sustainability commitments.

What Is the Historical Context of Washing Chamois Leather?

The use of chamois leather dates back centuries, originating from the need for effective drying and polishing tools in various applications, including automotive care. Traditionally made from the skins of chamois goats, these leathers were prized for their unique absorbent properties. Over time, the market evolved, and while authentic chamois leather remains in demand, synthetic alternatives have emerged to cater to cost-sensitive consumers.

The evolution of manufacturing processes has also played a critical role in shaping the industry. As automotive care became more mainstream in the 20th century, the demand for high-quality chamois leather surged, leading to innovations in processing techniques. Today, international buyers benefit from a diverse range of products, including both genuine and synthetic chamois leathers, allowing for tailored solutions based on specific market needs.

Understanding this historical context is vital for B2B buyers as it informs sourcing decisions and highlights the importance of quality and sustainability in product selection. The ongoing innovation within the sector promises continued growth and adaptation to changing market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of washing chamois leather

-

How do I ensure the quality of chamois leather when sourcing internationally?

To ensure the quality of chamois leather, request samples from potential suppliers before placing bulk orders. Look for certifications that indicate quality standards, such as ISO or other industry-specific certifications. It’s also beneficial to conduct factory visits or audits if feasible, or rely on third-party inspection services. This helps confirm that the supplier follows proper manufacturing processes and uses quality raw materials, ultimately ensuring that the chamois leather meets your specifications and expectations. -

What is the best way to compare suppliers of chamois leather?

Comparing suppliers can be streamlined by creating a checklist of key criteria, including pricing, minimum order quantities (MOQ), lead times, quality certifications, and customer reviews. Reach out to multiple suppliers for quotes and assess their responsiveness and willingness to provide information. Additionally, consider their logistics capabilities and after-sales support, which can impact your overall experience. Engaging in trade shows or industry events may also provide valuable insights into supplier reputations and product offerings. -

What customization options are available for chamois leather products?

Many manufacturers offer customization options, such as size, thickness, color, and packaging. When discussing customization, clearly outline your requirements, including branding needs like logos or specific labeling. Some suppliers may also provide tailored solutions for specific applications, such as automotive or household use. Be sure to inquire about any additional costs associated with customization and the impact on lead times. -

What are the typical minimum order quantities (MOQ) for chamois leather?

MOQs can vary widely based on the supplier and the type of chamois leather product. Generally, they range from a few hundred to several thousand units. It’s essential to discuss MOQs during your initial conversations with suppliers to ensure they align with your business needs. If you’re a smaller buyer, some manufacturers may be open to negotiating lower MOQs or offering a tiered pricing structure based on order volume. -

What payment terms should I expect when sourcing chamois leather internationally?

Payment terms can vary significantly among suppliers. Common arrangements include upfront payment, partial payment before shipment, or payment upon delivery. It’s crucial to clarify these terms before finalizing your order. Additionally, consider using secure payment methods such as letters of credit or escrow services to mitigate financial risks. Establishing a good relationship with your supplier can also lead to more favorable payment terms over time. -

How can I ensure timely logistics and delivery for my chamois leather orders?

To ensure timely logistics, collaborate closely with your supplier to establish realistic timelines and shipping methods. Discuss their shipping partners and track record for on-time delivery. Utilize freight forwarders who specialize in international shipping to navigate customs and logistics challenges. Additionally, consider incorporating buffer time into your planning to account for potential delays, especially when dealing with international suppliers. -

What quality assurance (QA) processes should I implement when sourcing chamois leather?

Implementing a robust QA process involves setting clear quality standards and conducting regular inspections during production and pre-shipment. Establish a checklist that includes criteria such as texture, absorbency, and absence of defects. If possible, involve third-party inspection services to validate the quality before shipment. Establishing a strong communication channel with your supplier regarding QA expectations will also help maintain consistent product quality. -

What are the environmental considerations when sourcing chamois leather?

When sourcing chamois leather, consider the environmental impact of the production process. Inquire about the supplier’s practices regarding sustainable sourcing of raw materials and waste management. Certifications such as OEKO-TEX or Leather Working Group can indicate adherence to environmental standards. Additionally, assess whether the supplier employs eco-friendly tanning processes, which can reduce the ecological footprint of the chamois leather products you intend to purchase.

Top 6 Washing Chamois Leather Manufacturers & Suppliers List

1. Reddit – Chamois Leather Shammy

2. Granville Oil – Genuine Chamois Leather

Domain: granvilleoil.com

Registered: 2004 (21 years)

مقدمة: Genuine Chamois Leather; absorbs around six times its weight in water; requires proper care to maintain durability; recommended cleaning agents include natural soap or car wash shampoo; avoid detergents or bleaches; should be rinsed thoroughly after use; should be dried flat and away from direct sunlight; can be conditioned by rubbing against a hard surface; should be stored in a cool, dry place.

3. PeachParts – Leather Chamois Cleaning Guide

Domain: peachparts.com

Registered: 2009 (16 years)

مقدمة: To clean a leather chamois, use mild liquid dish soap and warm water. Soak and swish the chamois in the solution for 3 to 4 minutes. For stubborn stains, apply a small amount of liquid dish soap directly into the chamois fibers. Rinse thoroughly after 15 minutes. It is recommended to wash the chamois after it has been used to dry a car, ensuring the car is clean beforehand to avoid scratching the …

4. Facebook – Cleaning Tips

Domain: facebook.com

Registered: 1997 (28 years)

مقدمة: This company, Facebook – Cleaning Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Pistonheads – Chamois Leather Cleaning Methods

Domain: pistonheads.com

Registered: 1999 (26 years)

مقدمة: Chamois leather cleaning methods discussed include: using washing up liquid with plenty of rinses, avoiding detergents to preserve oils, using leather cleaner/conditioner from Autoglym, and jet washing on a pre-cleaned tile floor. Some users suggest simply buying a new chamois instead of cleaning.

6. Duel Auto Care – Microfibre Drying Towel

Domain: duelautocare.co.uk

Registered: 2019 (6 years)

مقدمة: Microfibre drying towel; efficient and safe drying; no pre-use maintenance required; minimal ongoing maintenance; must be washed with dedicated microfibre wash solution or non-bio detergent; low-temperature tumble dry or air dry recommended.

Strategic Sourcing Conclusion and Outlook for washing chamois leather

In conclusion, effective strategic sourcing for washing chamois leather provides significant advantages for international B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. By prioritizing high-quality, genuine chamois leather, businesses can enhance their product offerings and ensure customer satisfaction through superior performance and durability.

Illustrative image related to washing chamois leather

Understanding the proper care and maintenance of chamois leather not only extends the lifespan of the product but also reduces replacement costs and waste, aligning with sustainable practices that are increasingly important in today’s market. Buyers should seek suppliers who offer comprehensive guidance on maintenance to maximize the value of their purchases.

As the demand for eco-friendly and effective car care products continues to grow, now is the time for businesses to invest in genuine chamois leather. By leveraging the unique benefits of this material, companies can differentiate themselves in a competitive landscape. We encourage you to explore partnerships with reputable suppliers and integrate high-quality chamois leather into your offerings to meet evolving consumer needs and preferences. Embrace the future of car care and position your business for success!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.