Introduction: Navigating the Global Market for patent leather fabric

In the dynamic landscape of global commerce, sourcing high-quality patent leather fabric presents both opportunities and challenges for B2B buyers. The glossy allure of patent leather, known for its striking finish and versatility, can be a game-changer in various industries, from fashion to automotive upholstery. However, navigating the complexities of supplier selection, quality assurance, and pricing can be daunting, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam.

This comprehensive guide delves into the multifaceted world of patent leather fabric, exploring the different types available, their diverse applications, and the intricacies of supplier vetting. We address critical factors such as production processes, environmental considerations, and cost analysis, equipping you with the knowledge to make informed purchasing decisions. By understanding the nuances of patent leather sourcing, you can mitigate risks and enhance your supply chain efficiency.

Whether you are looking to enhance your product line or seeking reliable suppliers, this guide serves as your trusted resource. It empowers you to confidently navigate the global market, ensuring that you select the right materials that align with your business objectives and customer expectations. With actionable insights and expert recommendations, you can transform your sourcing strategy and position your business for success in the competitive landscape of patent leather fabric.

Table Of Contents

- Top 4 Patent Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for patent leather fabric

- Understanding patent leather fabric Types and Variations

- Key Industrial Applications of patent leather fabric

- 3 Common User Pain Points for ‘patent leather fabric’ & Their Solutions

- Strategic Material Selection Guide for patent leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for patent leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘patent leather fabric’

- Comprehensive Cost and Pricing Analysis for patent leather fabric Sourcing

- Alternatives Analysis: Comparing patent leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for patent leather fabric

- Navigating Market Dynamics and Sourcing Trends in the patent leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of patent leather fabric

- Strategic Sourcing Conclusion and Outlook for patent leather fabric

- Important Disclaimer & Terms of Use

Understanding patent leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Patent Leather | Smooth, glossy finish; uniform appearance | Footwear, handbags, luxury goods | Pros: High aesthetic appeal; durable. Cons: Susceptible to scratches. |

| Naplak Leather | Wrinkled, milled texture; less shiny | Fashion accessories, upholstery, vintage items | Pros: Unique vintage look; soft feel. Cons: Less uniformity in finish. |

| Patent Lambskin | Soft, supple texture; luxurious feel | High-end fashion, bespoke items | Pros: Comfort and flexibility; premium quality. Cons: Higher cost. |

| Patent Calfskin | Firm texture; strong durability | Bags, belts, high-performance footwear | Pros: Excellent durability; versatile. Cons: Heavier than other types. |

| Embossed Patent Leather | Textured patterns (e.g., crocodile or alligator) | Luxury goods, high-fashion items | Pros: Unique designs; adds value. Cons: Can be more expensive. |

What Are the Characteristics of Classic Patent Leather?

Classic patent leather is renowned for its smooth, glossy finish that resembles a mirror. This type is primarily used in the production of footwear and handbags, appealing to luxury brands that prioritize aesthetic appeal. When purchasing classic patent leather, B2B buyers should consider the quality of the underlying hide, as it must be free from macroscopic defects for the final product to maintain its high-end look. Additionally, while its durability is a significant advantage, it is essential to note that classic patent leather can be prone to scratches, which may affect its long-term appearance.

How Does Naplak Leather Differ from Traditional Patent Leather?

Naplak leather is characterized by its unique wrinkled texture, which offers a vintage and less uniform appearance compared to traditional smooth patent leather. This type is often used in fashion accessories and upholstery where a softer, more organic aesthetic is desired. B2B buyers should consider the intended use when selecting Naplak leather, as its softer texture may not be suitable for all applications. While it provides a distinctive look, the less uniform finish can be a drawback for buyers seeking consistency in their products.

What Makes Patent Lambskin a Preferred Choice for High-End Fashion?

Patent lambskin is favored for its soft and supple texture, making it ideal for high-end fashion and bespoke items. Its luxurious feel enhances the overall quality of products, appealing to discerning consumers. When sourcing patent lambskin, B2B buyers should focus on the leather’s thickness and finish, ensuring it meets the specific requirements for their designs. Although this type comes at a higher cost, its comfort and flexibility often justify the investment for brands targeting premium markets.

Why Choose Patent Calfskin for Durability and Versatility?

Patent calfskin is known for its firm texture and exceptional durability, making it a popular choice for bags, belts, and high-performance footwear. Its ability to withstand wear while maintaining a polished appearance makes it appealing for businesses looking to produce long-lasting products. Buyers should assess the weight and thickness of the calfskin when making purchases, as these factors can influence the final product’s performance. While it is heavier than other patent leather types, its versatility and strength can outweigh this drawback for many applications.

What Are the Advantages of Embossed Patent Leather in Luxury Goods?

Embossed patent leather features unique patterns, such as crocodile or alligator textures, adding a distinctive flair to luxury goods. This type is often used in high-fashion items, where the design can significantly enhance perceived value. B2B buyers should consider the specific embossing techniques and the quality of the base leather when selecting embossed patent leather, as these factors directly impact the final product’s quality and price. While the unique designs can elevate a brand’s offerings, they may also come at a higher cost, necessitating careful budget considerations.

Key Industrial Applications of patent leather fabric

| Industry/Sector | Specific Application of patent leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Footwear, handbags, and accessories | High aesthetic appeal and durability | Quality of finish, color options, and environmental standards |

| Automotive | Upholstery for luxury vehicles | Enhanced aesthetics and easy maintenance | Compliance with automotive standards and long-term durability |

| Furniture | Upholstery for modern furniture | Stylish appearance and easy-to-clean surface | Material thickness, fire resistance, and colorfastness |

| Electronics | Cases and coverings for gadgets | Protection with a premium look | Compatibility with electronic components and flexibility |

| Sporting Goods | Equipment and apparel | Unique style and weather resistance | Weight, flexibility, and resistance to wear and tear |

How is Patent Leather Fabric Used in the Fashion and Apparel Industry?

In the fashion industry, patent leather fabric is predominantly used for footwear, handbags, and accessories due to its glossy finish that exudes luxury. The durability of this material makes it a favored choice for high-end fashion brands looking to create long-lasting products. International buyers should consider the quality of the finish and a variety of color options when sourcing patent leather, ensuring it meets the aesthetic demands of their target markets.

What Role Does Patent Leather Play in the Automotive Sector?

In the automotive sector, patent leather is commonly utilized for upholstery in luxury vehicles. Its glossy appearance elevates the vehicle’s interior while providing a durable surface that withstands wear and tear. When sourcing this material, businesses must ensure compliance with automotive safety standards, as well as durability requirements to prevent fading and cracking over time, especially in varying climates such as those found in Africa and the Middle East.

How is Patent Leather Fabric Applied in Furniture Design?

Patent leather fabric is gaining popularity in modern furniture design, especially for upholstery on chairs and sofas. Its stylish look combined with an easy-to-clean surface makes it ideal for both residential and commercial environments. Buyers in this sector should focus on material thickness and fire resistance to meet safety regulations, particularly in regions with stringent building codes, such as Europe.

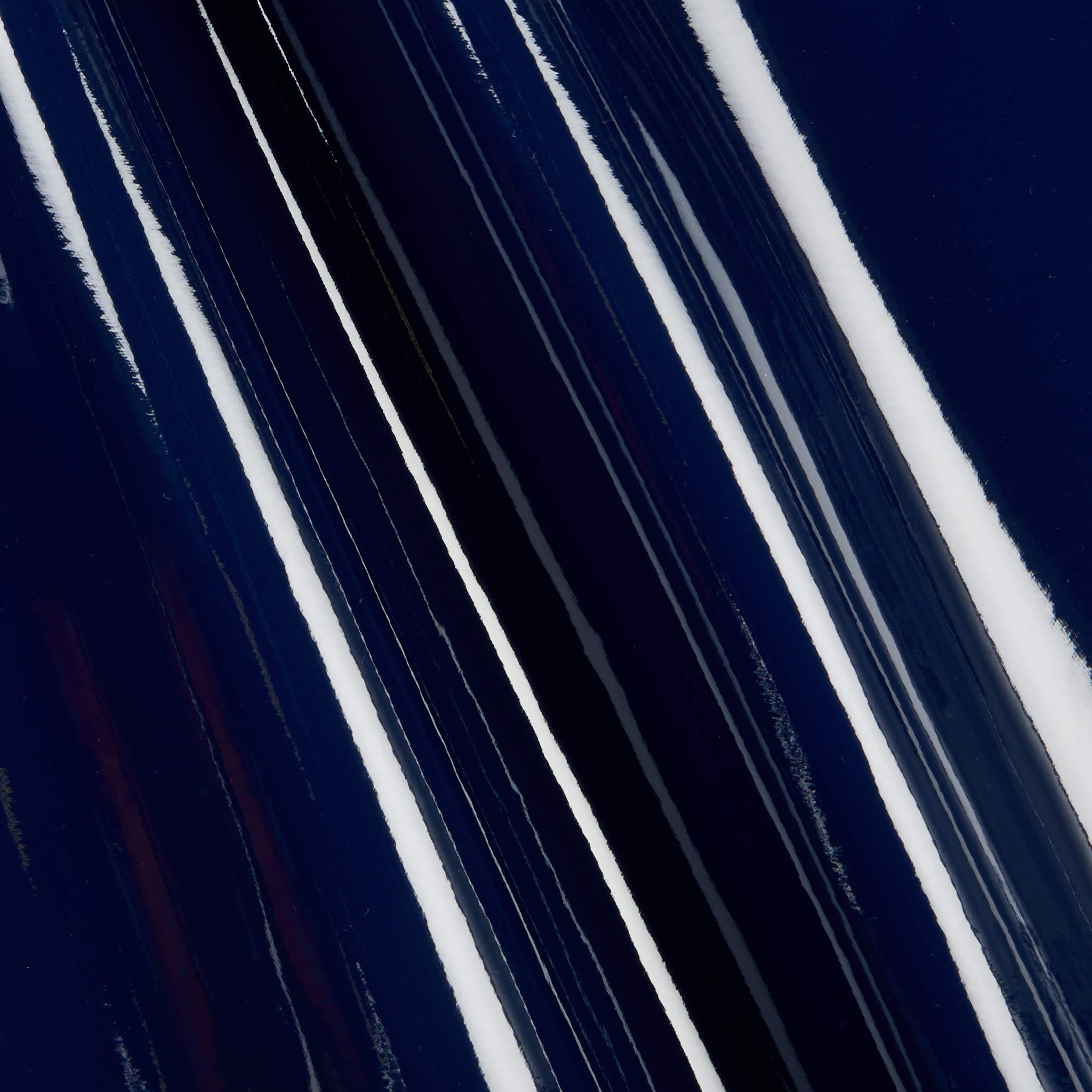

Illustrative image related to patent leather fabric

What Are the Uses of Patent Leather in Electronics?

In the electronics industry, patent leather is often used for protective cases and coverings for gadgets like smartphones and laptops. Its sleek appearance not only offers protection but also enhances the product’s overall look. Buyers should ensure compatibility with electronic components and assess the flexibility of the material to ensure it meets design specifications, particularly for international markets where design trends may vary.

Why is Patent Leather Fabric Important in Sporting Goods?

Patent leather fabric is increasingly being used in sporting goods, including equipment and apparel, due to its unique style and ability to resist weather elements. This material provides both aesthetic value and practical benefits, such as easy maintenance and durability. When sourcing for this application, businesses should consider the weight and flexibility of the fabric, ensuring it can withstand the rigors of athletic use across diverse climates.

3 Common User Pain Points for ‘patent leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Patent Leather Fabric for Manufacturing

The Problem: B2B buyers often struggle to find reliable suppliers of high-quality patent leather fabric. This challenge is magnified by the specific requirements for the production process, such as consistency in thickness, finish, and color. In regions like Africa and South America, where sourcing options may be limited, buyers may encounter issues with subpar materials that can lead to product defects and increased production costs. Furthermore, differences in manufacturing standards and quality assurance practices can lead to inconsistencies that jeopardize the end product’s quality.

The Solution: To mitigate sourcing challenges, buyers should prioritize establishing partnerships with reputable tanneries that specialize in patent leather. Conducting thorough due diligence, including visiting facilities if possible, can provide insights into their production processes and quality control measures. Additionally, buyers should request samples and test them for durability, gloss, and uniformity before placing larger orders. Utilizing platforms that aggregate multiple suppliers can also help streamline the sourcing process, allowing buyers to compare options and negotiate better terms. Finally, maintaining open communication with suppliers about specific needs and expectations will help ensure that the delivered materials meet quality standards.

Scenario 2: Managing the Environmental Impact of Patent Leather Production

The Problem: Environmental concerns are increasingly becoming a priority for B2B buyers, particularly in Europe and the Middle East, where sustainability regulations are stringent. The production of patent leather involves chemical processes and materials that can pose risks to both the environment and human health. Buyers may face backlash from consumers or regulatory bodies if they cannot demonstrate responsible sourcing and manufacturing practices, leading to potential financial and reputational damage.

The Solution: To address these concerns, buyers should seek out suppliers that utilize eco-friendly processes and materials in their patent leather production. This includes sourcing from tanneries that adhere to environmental regulations and employ sustainable practices, such as water conservation techniques and the use of biodegradable chemicals. Buyers can also advocate for transparency in the supply chain, requiring suppliers to provide documentation on their environmental impact. By prioritizing partnerships with environmentally conscious manufacturers, buyers not only comply with regulations but also enhance their brand reputation and appeal to a growing market segment that values sustainability.

Scenario 3: Overcoming Storage and Packaging Issues for Patent Leather

The Problem: Patent leather is prone to damage during storage due to its glossy surface, which can adhere to other surfaces and become marked or scratched. B2B buyers who manage inventory may find that improper storage conditions lead to significant losses, impacting their bottom line. Additionally, fluctuations in temperature and humidity can exacerbate these issues, particularly in climates that vary widely, such as those found in Africa or the Middle East.

The Solution: To prevent damage during storage, buyers should implement best practices for handling and packaging patent leather. This includes storing the material in climate-controlled environments to minimize the risk of humidity and temperature fluctuations. Using protective coverings, such as breathable fabric or paper, can help keep patent leather from sticking to itself or other materials. Furthermore, buyers should educate their staff on proper handling techniques to avoid unnecessary contact that could lead to scratches or imperfections. Regularly inspecting inventory for damage and rotating stock can also help ensure that materials remain in optimal condition for production. By taking these proactive steps, buyers can significantly reduce losses and maintain the integrity of their patent leather inventory.

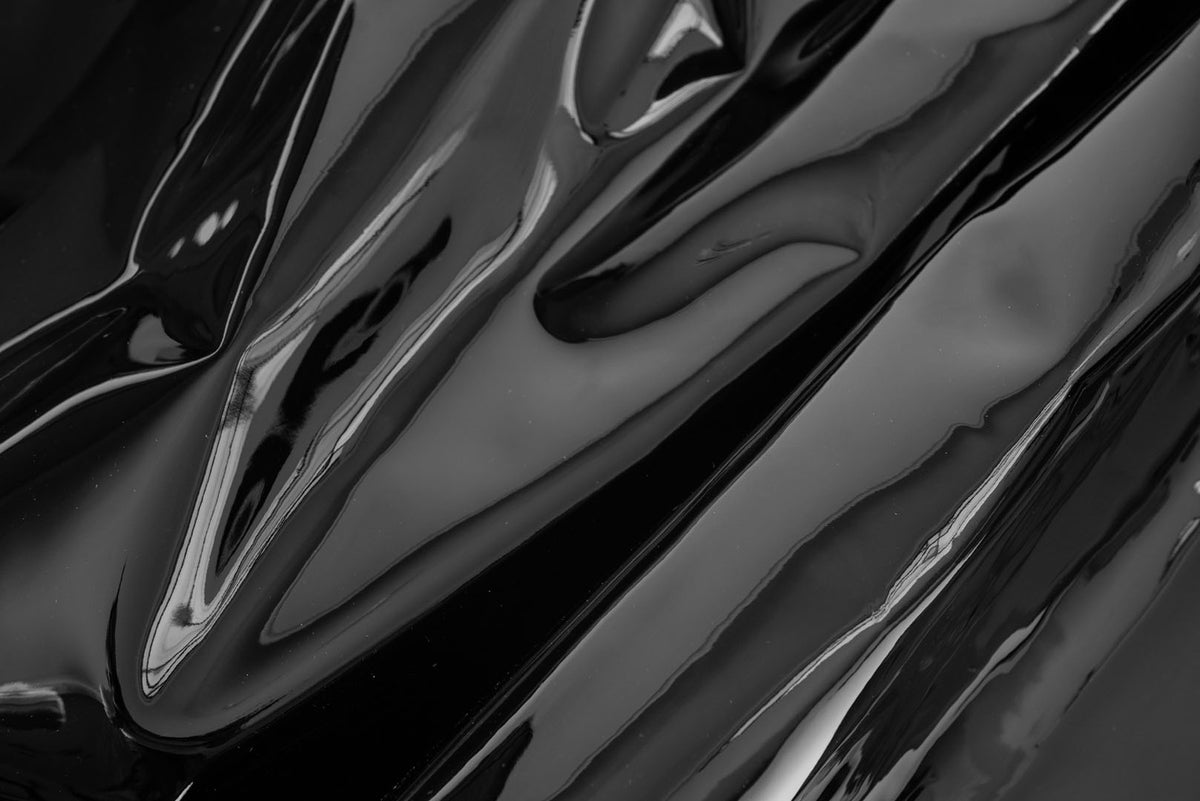

Illustrative image related to patent leather fabric

Strategic Material Selection Guide for patent leather fabric

What Are the Key Materials Used in Patent Leather Fabric?

Patent leather is a specialized material known for its glossy finish, achieved through a complex manufacturing process involving various base materials. Understanding these materials is crucial for international B2B buyers looking to source patent leather for various applications, from fashion to automotive interiors. Below, we analyze four common materials used in the production of patent leather, highlighting their properties, advantages, disadvantages, and considerations for international buyers.

What Are the Key Properties of Polyurethane in Patent Leather?

Polyurethane (PU) is a popular choice for patent leather due to its flexibility and durability. It can withstand a wide range of temperatures and provides excellent resistance to abrasion and chemicals. This makes PU patent leather suitable for various applications, including footwear, handbags, and upholstery.

Pros:

– High durability and flexibility.

– Excellent resistance to water and chemicals.

– Easier to clean and maintain.

Cons:

– May not have the same luxurious feel as natural leather.

– Environmental concerns regarding production processes.

Impact on Application: PU patent leather is compatible with a variety of media, including water-based dyes and solvents, making it versatile for different design needs.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local environmental regulations regarding synthetic materials. Understanding ASTM standards for synthetic leather can also guide quality assessment.

How Does PVC Compare as a Material for Patent Leather?

Polyvinyl Chloride (PVC) is another synthetic option frequently used in patent leather production. Known for its robustness, PVC can be produced in various thicknesses and finishes, making it adaptable for different applications.

Pros:

– Cost-effective and widely available.

– Good resistance to moisture and UV light.

Cons:

– Less breathable than other materials, which can affect comfort.

– Environmental concerns related to the disposal of PVC products.

Impact on Application: PVC patent leather is often used in lower-cost fashion items and accessories, where durability is essential but luxury feel is less critical.

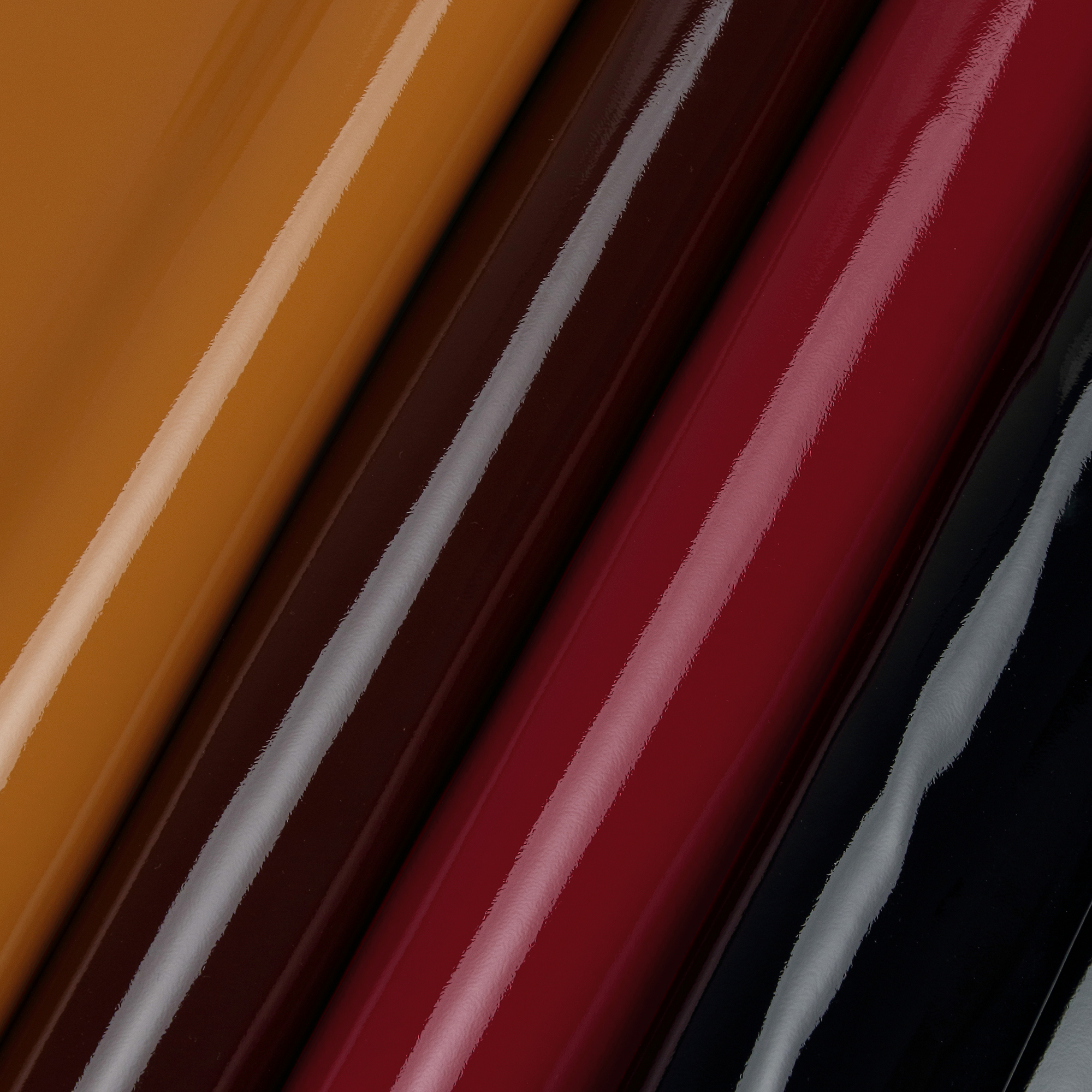

Illustrative image related to patent leather fabric

Considerations for International Buyers: Compliance with international standards such as REACH in Europe is essential, especially for buyers in the Middle East and Europe. Buyers should also assess the quality of PVC to ensure it meets their specific requirements.

What Are the Benefits of Using Natural Leather for Patent Leather?

Natural leather, particularly from goatskin or sheepskin, is often used for high-end patent leather products. This material provides a luxurious feel and can be treated to achieve a glossy finish.

Pros:

– Superior aesthetic appeal and tactile quality.

– Breathable and comfortable for wear.

Cons:

– Higher cost compared to synthetic options.

– Requires more maintenance to preserve the finish.

Impact on Application: Natural leather is ideal for premium products like luxury handbags and shoes, where quality and appearance are paramount.

Considerations for International Buyers: Buyers should ensure that the leather complies with international trade regulations and animal welfare standards. Knowledge of tanning processes and certifications can also influence purchasing decisions.

How Does Naplak Leather Differ from Traditional Patent Leather?

Naplak leather is a variant of patent leather characterized by its wrinkled appearance. This material is often used to create vintage or distressed looks in fashion and upholstery.

Pros:

– Unique aesthetic that appeals to niche markets.

– Can be produced from lower-quality hides, making it more economical.

Cons:

– Less uniform in appearance, which may not suit all applications.

– Potential durability issues compared to traditional patent leather.

Impact on Application: Naplak leather is often used in fashion items that require a retro or vintage look, making it popular among designers targeting specific consumer segments.

Considerations for International Buyers: Buyers should be aware of the specific market trends in their regions, as preferences for vintage aesthetics can vary widely. Understanding local fashion trends can help in making informed purchasing decisions.

Illustrative image related to patent leather fabric

Summary Table of Patent Leather Materials

| المواد | Typical Use Case for patent leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Footwear, handbags, upholstery | High durability and flexibility | Less luxurious feel than natural leather | Medium |

| Polyvinyl Chloride (PVC) | Budget fashion items, accessories | Cost-effective and widely available | Less breathable | منخفضة |

| Natural Leather | Luxury handbags, shoes | Superior aesthetic appeal | Higher cost and maintenance required | عالية |

| Naplak Leather | Vintage-style fashion items | Unique aesthetic | Less uniform appearance | Medium |

This guide provides essential insights for international B2B buyers looking to navigate the complexities of patent leather materials, ensuring informed sourcing decisions that align with market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for patent leather fabric

What Are the Main Stages of the Manufacturing Process for Patent Leather Fabric?

The manufacturing process for patent leather fabric involves several intricate stages that ensure the final product meets the desired quality and aesthetic standards. Each stage requires specialized techniques and attention to detail to achieve the distinctive glossy finish characteristic of patent leather.

-

Material Preparation

The process begins with the selection of high-quality hides, typically sourced from bovine, sheep, or goat skins. Before tanning, the hides undergo a thorough inspection to eliminate defects such as deep wounds, holes, or irregularities. The hides are then soaked and cleaned to remove any impurities. Following this, they are subjected to a tanning process, which can involve using resins and oils to enhance their rigidity and texture. The ideal thickness for patent leather is between 0.8mm and 1.6mm, as thicker hides can lead to quality issues. -

Forming and Impregnation

Once the hides are tanned, they are sanded to create a smooth, uniform surface. This step is crucial as it prepares the leather for the subsequent impregnation phase, where the hides are treated with pigments to ensure a consistent color and finish. This process involves a careful application of pigments, which can be done through spraying or soaking, depending on the desired effect. For different finishes, such as Naplak leather, heavier hides are used to achieve a wrinkled appearance. -

Finishing and Coating

After impregnation, the hides undergo a coating process where a layer of varnish or lacquer is applied. This layer is what gives patent leather its signature high-gloss finish. The application requires precise control of environmental conditions to prevent dust or other contaminants from affecting the surface. The final step in this stage is drying, where the coated hides are hung or laid out in a controlled environment to cure properly. -

Cutting and Assembly

The finished hides are then cut into various shapes and sizes as per customer specifications. This stage may involve advanced cutting technology to ensure precision. Once cut, the leather pieces are assembled into products like shoes, bags, or accessories. The assembly process might include stitching, gluing, or other methods, depending on the product design.

How is Quality Assurance Implemented in Patent Leather Manufacturing?

Quality assurance is a critical aspect of patent leather manufacturing, ensuring that the final products meet international standards and customer expectations. A robust QA process includes various checkpoints and testing methods.

-

What Are the Relevant International Standards for Patent Leather?

Manufacturers often adhere to international standards such as ISO 9001, which sets out the criteria for a quality management system. Compliance with these standards indicates that the manufacturer is committed to providing consistent quality and improving customer satisfaction. Additional industry-specific certifications like CE (Conformité Européenne) are essential for products sold in European markets, ensuring they meet safety and environmental requirements. -

What Are the Key Quality Control Checkpoints?

The quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting the quality of raw materials before they enter the production process. Any hides that do not meet quality standards are rejected.

– In-Process Quality Control (IPQC): During production, samples are regularly taken to ensure that the tanning, impregnation, and coating processes are being executed correctly. This real-time monitoring helps catch any defects early in the process.

– Final Quality Control (FQC): After the products are assembled, they undergo a final inspection to check for defects, finish quality, and adherence to specifications. This step ensures that only high-quality products are shipped to customers. -

What Common Testing Methods Are Used?

Various testing methods are employed to assess the quality of patent leather, including:

– Adhesion Tests: To evaluate the bond strength of the coatings.

– Flexural Tests: To determine the durability of the leather under bending conditions.

– Water Resistance Tests: To check the leather’s ability to repel water and maintain its finish.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance practices of suppliers is crucial for ensuring reliable product quality.

-

What Role Do Audits and Reports Play?

Conducting supplier audits is one effective way for buyers to assess the quality assurance processes in place. This can include visiting manufacturing facilities to observe production practices and quality control measures firsthand. Requesting detailed quality assurance reports can also provide insights into the supplier’s adherence to standards and past performance. -

How Can Third-Party Inspections Enhance Trust?

Engaging third-party inspection services can add an extra layer of confidence for buyers. These independent entities can conduct comprehensive evaluations of the manufacturing processes and quality control systems, ensuring that the products meet the required standards before shipment. -

What Are the Nuances of Quality Control Certifications for International Buyers?

International B2B buyers should be aware of the specific quality control certifications that are recognized in their target markets. Certifications like ISO, CE, and others may have different requirements based on regional regulations. Understanding these nuances can help buyers make informed decisions and mitigate risks associated with non-compliance.

الخاتمة

The manufacturing processes and quality assurance practices for patent leather fabric are essential for ensuring product quality and reliability. By understanding the stages of production and the importance of quality control, B2B buyers can make informed decisions when sourcing patent leather products. Employing a combination of audits, reports, and third-party inspections can further enhance buyer confidence in their suppliers, ultimately leading to successful partnerships in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘patent leather fabric’

This guide serves as a practical checklist for B2B buyers seeking to procure patent leather fabric. Sourcing high-quality patent leather requires careful consideration of specifications, supplier reliability, and environmental factors. Use this checklist to navigate the complexities of purchasing patent leather efficiently.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your patent leather fabric. Consider factors such as thickness (typically between 0.8mm to 1.6mm), finish type (smooth or Naplak), and intended use (apparel, accessories, or upholstery). Clearly defined specifications will help you communicate effectively with suppliers and ensure that the materials meet your production needs.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in patent leather. Look for established companies with a solid reputation in the industry. Utilize platforms like trade directories, industry associations, and trade shows to find reputable manufacturers.

Illustrative image related to patent leather fabric

- Tip: Check for supplier certifications that ensure compliance with quality and environmental standards.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the capabilities of your shortlisted suppliers. Request detailed information about their production processes, including the types of materials used and their quality control measures. Understanding their manufacturing capabilities will provide insight into whether they can meet your specifications consistently.

- Tip: Inquire about their production volume and lead times to ensure they can fulfill your order requirements.

Step 4: Request Samples

Always ask for samples of the patent leather fabric you are interested in. This step allows you to evaluate the quality, finish, and texture firsthand. Inspect the samples for consistency in color, gloss level, and overall quality.

- Tip: Consider the durability and flexibility of the leather, as these factors will impact its performance in your final products.

Step 5: Verify Environmental Practices

Given the environmental concerns associated with leather production, it’s essential to assess your suppliers’ sustainability practices. Inquire about their tanning processes and whether they use eco-friendly chemicals. Suppliers committed to sustainable practices are more likely to deliver high-quality products while minimizing environmental impact.

Step 6: Check for Packaging and Storage Solutions

Discuss packaging solutions with potential suppliers to prevent damage during transit. Patent leather is sensitive to humidity and temperature changes, so ensure that suppliers have proper storage and wrapping methods to avoid adhesion and surface imperfections.

- Tip: Request information on how they handle long-term storage to ensure that the leather maintains its quality over time.

Step 7: Negotiate Terms and Place Orders

Once you’ve selected a supplier, negotiate terms such as pricing, minimum order quantities, and payment options. Clearly outline delivery schedules and quality expectations in your purchase agreement. Establishing a good relationship with your supplier can lead to better terms in future orders and ensure a smoother procurement process.

By following these steps, you can effectively navigate the complexities of sourcing patent leather fabric, ensuring you find a reliable supplier that meets your specific needs and standards.

Comprehensive Cost and Pricing Analysis for patent leather fabric Sourcing

What Are the Key Cost Components in Sourcing Patent Leather Fabric?

When sourcing patent leather fabric, several cost components contribute to the overall pricing structure. The primary elements include:

-

Materials: The cost of raw materials is significant, as patent leather is typically derived from high-quality hides (bovine, sheep, or goat) that are processed with synthetic resins and lacquers. Prices can vary based on the type of leather and its quality. For instance, premium grades of lambskin or calfskin will command higher prices than lower grades.

-

Labor: Skilled labor is essential for the tanning and finishing processes required to produce patent leather. The intricacies involved in achieving the glossy finish and ensuring uniform quality can lead to higher labor costs, especially if specialized artisans are required.

-

Manufacturing Overhead: This encompasses the costs of utilities, rent, and equipment maintenance in production facilities. Given the specialized machinery required for patent leather production, overhead can be considerable.

-

Tooling: The setup and maintenance of equipment for processing patent leather can add to costs. This includes costs related to molds or specialized tools used in the finishing process.

-

Quality Control (QC): Ensuring the final product meets industry standards and buyer specifications necessitates a robust QC process, which adds to labor and operational costs.

-

Logistics: Shipping and handling costs are crucial, particularly for international transactions. The costs can vary based on the destination, shipping method, and applicable tariffs.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability, which can vary widely based on market demand and competition.

How Do Price Influencers Affect Patent Leather Fabric Costs?

Several factors can influence the price of patent leather fabric, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often benefit from economies of scale, leading to lower per-unit costs. Buyers should consider negotiating for bulk pricing.

-

Specifications and Customization: Custom colors, finishes, or textures can increase costs. Buyers seeking unique specifications should be prepared for higher prices due to the additional labor and materials involved.

-

Materials and Quality Certifications: Premium materials and certified products (e.g., eco-friendly or sustainably sourced leather) typically command higher prices. Buyers should assess the trade-offs between cost and quality.

-

Supplier Factors: Established suppliers with a reputation for quality may charge more. However, they often offer reliability and consistency that can justify the higher prices.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is crucial as they dictate who is responsible for shipping costs, insurance, and risk during transport. This can significantly impact the total cost.

What Buyer Tips Can Help in Negotiating Patent Leather Fabric Prices?

To optimize sourcing strategies, international B2B buyers should consider the following tips:

-

Negotiate Wisely: Leverage volume to negotiate better pricing. Discuss potential discounts for bulk orders or long-term contracts that ensure stable pricing over time.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also additional costs such as shipping, tariffs, and maintenance. Sometimes a higher initial cost can lead to lower TCO if the quality is superior.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations and their impact on pricing, especially when dealing with suppliers in different regions. Also, consider local economic conditions that might affect pricing.

-

Request Samples: Before placing large orders, request samples to assess quality and ensure it meets your specifications. This can prevent costly errors down the line.

-

Build Relationships with Suppliers: Establishing a good rapport with suppliers can lead to better terms, access to exclusive products, and improved responsiveness to your needs.

الخاتمة

Sourcing patent leather fabric involves a complex interplay of costs and influencing factors. By understanding the detailed cost structure and leveraging negotiation strategies, international B2B buyers can navigate the market effectively, ensuring they make informed purchasing decisions while optimizing their supply chain. Remember, while indicative prices may provide a baseline, actual costs can fluctuate based on the factors discussed, necessitating thorough research and negotiation.

Alternatives Analysis: Comparing patent leather fabric With Other Solutions

Understanding Alternatives to Patent Leather Fabric

In the competitive landscape of leather materials, patent leather fabric stands out due to its unique glossy finish and durability. However, it is essential for B2B buyers to consider alternative materials that may provide similar aesthetic appeal or functional benefits at different costs or with varying properties. This section explores several viable alternatives to patent leather, offering insights that can inform purchasing decisions.

Comparison Table

| Comparison Aspect | Patent Leather Fabric | جلد صناعي | Aniline Leather |

|---|---|---|---|

| Performance | High durability, scratch-resistant, waterproof | Good durability, less breathable | Soft, natural feel, less resistant to wear |

| Cost | Moderate to high | Generally lower | Higher than synthetic but variable |

| Ease of Implementation | Requires specialized finishing techniques | Easy to manufacture and process | Requires careful handling and finishing |

| Maintenance | Low maintenance, easy to clean | Moderate; can be wiped clean | Requires regular conditioning |

| Best Use Case | Fashion items, accessories | Budget-friendly fashion, upholstery | High-end goods, luxury items |

Detailed Breakdown of Alternatives

Synthetic Leather: Is it a Suitable Option?

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to patent leather. It mimics the appearance of real leather while being more affordable and easier to produce. Synthetic leather is relatively durable and resistant to water, making it suitable for a range of applications, from fashion to upholstery. However, it lacks the breathability and luxurious feel of natural materials, which may deter buyers looking for high-end products.

Aniline Leather: What Are Its Advantages and Disadvantages?

Aniline leather is a premium choice known for its soft texture and natural appearance. Unlike patent leather, it is dyed with transparent dyes that allow the leather’s natural grain to show through. This results in a luxurious look and feel, making it ideal for high-end products like furniture and handbags. However, aniline leather is less resistant to stains and wear compared to patent leather, requiring more maintenance and care. Buyers should consider whether the aesthetic benefits outweigh the need for more diligent upkeep.

Illustrative image related to patent leather fabric

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right leather solution depends on various factors, including budget, intended use, and desired aesthetics. Patent leather offers durability and a striking appearance, making it suitable for fashion accessories and high-impact applications. Alternatively, synthetic leather provides a cost-effective solution for businesses aiming to balance quality and price. On the other hand, aniline leather appeals to those prioritizing luxury and natural beauty, albeit with higher maintenance needs. B2B buyers should assess their specific requirements against these alternatives to make informed decisions that align with their product offerings and market demands.

Essential Technical Properties and Trade Terminology for patent leather fabric

What Are the Key Technical Properties of Patent Leather Fabric?

When sourcing patent leather fabric, understanding its technical properties is crucial for ensuring quality and suitability for your applications. Here are some essential specifications to consider:

Material Grade

Patent leather can be made from various hides, including bovine, sheep, and goat. Each type has its own grade that indicates the quality of the leather. Higher grades typically exhibit fewer imperfections and a more uniform finish. For B2B buyers, selecting the appropriate material grade is vital as it impacts the durability and aesthetic appeal of the final product, whether it’s for fashion items, upholstery, or accessories.

Illustrative image related to patent leather fabric

Thickness and Tolerance

The standard thickness for patent leather usually ranges from 0.8 to 1.6 mm. This range is important because it affects the material’s rigidity and workability. A consistent thickness ensures uniformity in production and helps maintain the desired finish. Tolerance levels should also be defined, as variations can lead to quality issues during manufacturing. Buyers should specify thickness requirements to avoid discrepancies.

Surface Finish

The glossy surface of patent leather is achieved through a multi-layer application of varnishes or lacquers. The finish can be smooth or textured, such as in the case of Naplak leather, which has a wrinkled appearance. Understanding the surface finish is essential for buyers as it influences the leather’s final look and feel, impacting customer perception and satisfaction.

Environmental Control

The production process for patent leather requires stringent environmental controls to prevent dust and other contaminants from affecting the finish. Buyers should inquire about the manufacturer’s practices to ensure that the leather is produced in a clean environment, minimizing the risk of defects that could compromise product quality.

Illustrative image related to patent leather fabric

Packaging and Storage Conditions

Patent leather is sensitive to humidity and temperature changes, which can cause it to stick together if improperly packaged. It’s crucial for buyers to understand the recommended storage practices to maintain the integrity of the leather during transport and storage. This knowledge can prevent potential damage and ensure that the leather arrives in optimal condition.

What Are Common Trade Terms Used in the Patent Leather Industry?

Familiarizing yourself with industry-specific jargon can facilitate smoother transactions and better communication with suppliers. Here are some key terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are later sold under another company’s brand. In the context of patent leather, buyers may engage with OEMs to create custom leather goods tailored to their specifications.

Illustrative image related to patent leather fabric

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For patent leather, MOQs can vary significantly based on the manufacturer and the type of leather. Understanding MOQs helps buyers plan their inventory and budget effectively.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other terms for a specific quantity of goods. When sourcing patent leather, submitting an RFQ can help buyers compare prices and terms across multiple suppliers, aiding in informed decision-making.

Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and risks involved in the shipment of patent leather.

Tanning Process

This refers to the method by which raw hides are treated to produce leather. Different tanning processes can impact the quality, durability, and finish of patent leather. Buyers should inquire about the tanning methods used to ensure they meet their quality standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies, ensuring they receive high-quality patent leather that meets their business needs.

Navigating Market Dynamics and Sourcing Trends in the patent leather fabric Sector

What Are the Current Market Dynamics and Key Trends in the Patent Leather Fabric Sector?

The patent leather fabric market is experiencing robust growth, driven by a surge in demand across various sectors, including fashion, automotive, and furniture. As global consumers increasingly favor high-gloss finishes for both aesthetics and durability, manufacturers are innovating with new techniques and materials. The rise of e-commerce has also facilitated easier access for B2B buyers in regions such as Africa, South America, the Middle East, and Europe. International buyers, particularly in emerging markets like Nigeria and Vietnam, are capitalizing on the growing trend of personalized and bespoke leather goods, leading to increased demand for unique patent leather textures and colors.

Key sourcing trends include a shift towards direct procurement channels, enabling businesses to establish relationships with tanneries and manufacturers that offer custom solutions. Technology integration, such as digital platforms for sourcing and inventory management, is simplifying the procurement process. Companies are increasingly leveraging data analytics to forecast demand and optimize supply chains, allowing for more agile responses to market fluctuations. Moreover, the development of hybrid materials that combine traditional leather with synthetic alternatives is creating new opportunities for innovation in product offerings.

How Is Sustainability Impacting the Sourcing of Patent Leather Fabric in B2B?

Sustainability is becoming a pivotal consideration in the patent leather fabric sector. The environmental impact of leather production has prompted international buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of sustainable sourcing methods, such as responsible animal husbandry and environmentally friendly tanning processes. B2B buyers are increasingly focused on ethical supply chains, ensuring that their partners comply with international labor standards and environmental regulations.

The market is witnessing a rise in ‘green’ certifications, which are critical for establishing credibility and trust with consumers. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming prerequisites for many buyers, particularly in Europe, where consumer awareness around sustainability is particularly high. Additionally, innovations in bio-based and synthetic leathers are gaining traction, offering alternatives that reduce the carbon footprint associated with traditional patent leather production.

What Is the Evolution of Patent Leather Fabric and Its Relevance for B2B Buyers?

Patent leather has a rich history dating back to the early 19th century when it was first introduced as a durable, high-gloss material suitable for various applications. Initially crafted using linseed oil and other natural substances, the material evolved with the advent of synthetic resins, enabling a wider array of colors and finishes. This evolution has made patent leather a staple in fashion and design, appealing to both luxury brands and mass-market producers.

Illustrative image related to patent leather fabric

For B2B buyers, understanding the historical context of patent leather is crucial for recognizing its value in contemporary markets. The material’s ability to merge tradition with modern aesthetics positions it as a versatile option for a diverse range of applications—from high-fashion accessories to functional automotive interiors. As the market continues to evolve, buyers who are well-versed in the history and innovation of patent leather will be better equipped to make informed sourcing decisions that align with current trends and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of patent leather fabric

-

How can I ensure the quality of patent leather fabric before purchasing?

To ensure the quality of patent leather fabric, request samples from potential suppliers. Evaluate the sheen, flexibility, and consistency of the finish. Additionally, inquire about the tanning processes and materials used, as these factors greatly influence durability. Check for certifications that indicate adherence to industry standards. Conducting a factory visit, if feasible, can provide deeper insights into the supplier’s quality control measures and production capabilities. -

What are the key characteristics to look for in high-quality patent leather?

High-quality patent leather should exhibit a smooth, reflective surface without imperfections such as scratches or bubbles. It should be durable, flexible, and resistant to cracking. The thickness typically ranges from 0.8 to 1.6mm, and the leather should maintain its gloss over time. When evaluating samples, ensure that the leather feels firm yet pliable, which indicates proper tanning and finishing processes were employed. -

What are the typical minimum order quantities (MOQs) for patent leather fabric?

Minimum order quantities (MOQs) for patent leather fabric can vary significantly based on the supplier and the specific type of leather. Generally, MOQs range from 50 to 500 square meters. It’s essential to discuss your requirements upfront with suppliers to find flexibility in MOQs, especially if you are a new buyer or testing a new product line. Some suppliers may offer lower MOQs for custom orders or samples. -

How can I find reliable suppliers of patent leather fabric internationally?

To find reliable international suppliers, leverage online B2B marketplaces such as Alibaba or Global Sources. Attend industry trade shows to connect directly with manufacturers. Additionally, consider sourcing agents who specialize in leather products. Always vet suppliers by checking references, reading reviews, and asking for product certifications. Conducting a factory audit can further ensure that the supplier meets your quality and ethical standards. -

What payment terms are commonly accepted in international B2B transactions for patent leather?

Common payment terms in international B2B transactions include letters of credit (LC), telegraphic transfer (TT), and PayPal for smaller orders. Many suppliers may require a deposit (often 30%) upfront, with the balance due before shipment. It’s crucial to clarify payment terms before confirming an order to avoid any misunderstandings. Ensure that the chosen payment method provides adequate protection against potential disputes. -

What should I consider regarding shipping and logistics for patent leather purchases?

When planning shipping and logistics for patent leather purchases, consider the supplier’s location, shipping method (air vs. sea), and associated costs. Ensure that the supplier is familiar with exporting requirements, including customs documentation and duties. It’s advisable to work with a freight forwarder who can handle logistics and ensure timely delivery. Additionally, factor in lead times for production and shipping to avoid delays in your supply chain. -

How can I customize patent leather for my specific needs?

Customization of patent leather typically involves selecting specific colors, textures, or finishes. Many suppliers offer options for custom orders, but it’s essential to communicate your requirements clearly. Discuss the desired specifications, including thickness and any special treatments or embossing you require. Be prepared for potential minimum order quantities and longer lead times for custom products. Request samples of customized options to ensure they meet your expectations before committing to a larger order. -

What quality assurance measures should I implement when sourcing patent leather?

Implementing quality assurance measures when sourcing patent leather involves establishing clear specifications and standards for the product. Require suppliers to provide test reports for durability, colorfastness, and environmental compliance. Conduct inspections at various stages of production, either through third-party services or by visiting the manufacturing site. Establish a protocol for handling defects and returns to ensure that you receive products that meet your quality expectations.

Top 4 Patent Leather Fabric Manufacturers & Suppliers List

1. Buy Leather Online – Patent Leather

Domain: buyleatheronline.com

Registered: 2015 (10 years)

مقدمة: Patent leather is characterized by a glossy surface like a mirror, obtained by applying one or more layers of paints or lacquers, pigmented or not, based on linseed oil, nitrocellulose, polyurethane and/or other synthetic resins. Patent leather can also have a ‘wrinkled’ appearance and that case it is called ‘Naplak leather’. Available colors include White, Ivory, Beige, Pink, Green, Yellow, Red, …

2. RYC Fabrics – Patent Leather Vinyl

Domain: rycfabrics.com

Registered: 2010 (15 years)

مقدمة: Patent leather vinyl is a high-gloss material known for its shiny finish and durability. It is commonly used in fashion, upholstery, and accessories due to its water-resistant properties and ease of cleaning. Available in various colors and textures, patent leather vinyl offers a stylish and modern look, making it a popular choice for both casual and formal applications.

3. Online Fabric Store – Super Glossy Patent Leather

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

مقدمة: This company, Online Fabric Store – Super Glossy Patent Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

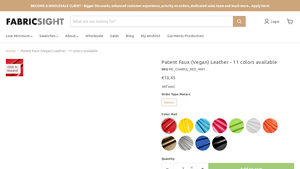

4. Fabricsight – Patent Faux Leather

Domain: fabricsight.com

Registered: 2019 (6 years)

مقدمة: {“name”: “Patent Faux Leather”,”colors_available”: 11,”sku”: “MC_CHAROL_RED_4001″,”original_price”: “€10,45″,”current_price”: “€10,45″,”weight”: “150 g/m²”,”width”: “1.55 m”,”minimum_order_quantity”: “12 Meters”,”composition”: “85% Polyurethane, 15% Polyester”,”description”: “Shiny patent leather, perfect for outerwear garments. Design jackets, bottoms and accessories.”,”swatch_price”: “€1,00”,”av…

Strategic Sourcing Conclusion and Outlook for patent leather fabric

As the demand for patent leather fabric continues to grow across various international markets, strategic sourcing becomes paramount for B2B buyers seeking to capitalize on this opportunity. Understanding the unique characteristics of patent leather, including its glossy finish and durability, allows businesses to align their product offerings with market trends. Buyers should prioritize suppliers who offer high-quality materials and maintain rigorous production standards, ensuring consistency and reliability.

Moreover, exploring diverse sourcing channels, from established tanneries to innovative manufacturers, can provide competitive advantages. Engaging with suppliers from regions like Africa, South America, the Middle East, and Europe not only broadens product availability but also fosters relationships that can lead to customized solutions tailored to specific market needs.

Looking ahead, the patent leather market is poised for growth, driven by fashion trends and an increasing preference for sustainable materials. B2B buyers are encouraged to act proactively—invest in quality sourcing strategies, explore partnerships with reputable suppliers, and remain agile to adapt to evolving consumer preferences. Embrace this opportunity to enhance your product line and meet the rising demand for premium patent leather fabrics in a dynamic global marketplace.

Illustrative image related to patent leather fabric

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.