Introduction: Navigating the Global Market for printed leatherette fabric

In the ever-evolving landscape of the global textile market, sourcing high-quality printed leatherette fabric presents a unique challenge for international B2B buyers. With diverse applications ranging from fashion accessories to upholstery, understanding the nuances of this material is essential for making informed purchasing decisions. This guide serves as a comprehensive resource, covering various types of printed leatherette fabrics, their applications, and critical factors to consider when vetting suppliers.

Buyers from Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany, will find actionable insights tailored to their specific market needs. We delve into the performance characteristics of printed leatherette, including durability and ease of maintenance, while also exploring cost considerations that can significantly impact your bottom line. Additionally, we provide a strategic framework for evaluating potential suppliers to ensure that your sourcing process is efficient and effective.

By navigating this guide, you will be empowered to select the right printed leatherette fabric that aligns with your business objectives, ultimately enhancing your product offerings and market competitiveness. Whether you are looking to innovate your product line or maintain quality standards, this resource equips you with the knowledge necessary to thrive in the global market.

Table Of Contents

- Top 7 Printed Leatherette Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for printed leatherette fabric

- Understanding printed leatherette fabric Types and Variations

- Key Industrial Applications of printed leatherette fabric

- 3 Common User Pain Points for ‘printed leatherette fabric’ & Their Solutions

- Strategic Material Selection Guide for printed leatherette fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette fabric’

- Comprehensive Cost and Pricing Analysis for printed leatherette fabric Sourcing

- Alternatives Analysis: Comparing printed leatherette fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for printed leatherette fabric

- Navigating Market Dynamics and Sourcing Trends in the printed leatherette fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette fabric

- Strategic Sourcing Conclusion and Outlook for printed leatherette fabric

- Important Disclaimer & Terms of Use

Understanding printed leatherette fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Printed Faux Leather | Vibrant patterns, pliable, easy to sew | Bags, wallets, key fobs, embroidery | Pros: Versatile, visually appealing; Cons: Less durable than genuine leather. |

| Printed Marine Vinyl | UV resistant, marine-grade, resilient stretching | Upholstery, marine applications, crafts | Pros: Durable, weather-resistant; Cons: Heavier than other options. |

| Printed Pebble Leatherette | Textured surface, available in various colors and prints | Fashion accessories, home décor, upholstery | Pros: Unique texture, good for high-visibility items; Cons: Limited flexibility in design. |

| Custom Printed Leatherette | Tailored designs, high-quality print resolution | Branding, promotional products, fashion items | Pros: Personalized, enhances brand visibility; Cons: Minimum order quantities may apply. |

| Eco-Friendly Printed Leatherette | Made from recycled materials, sustainable production | Eco-conscious brands, fashion, upholstery | Pros: Sustainable choice, growing market appeal; Cons: Potentially higher costs. |

What Are the Key Characteristics of Printed Faux Leather?

Printed Faux Leather is characterized by its vibrant patterns and pliability, making it an excellent choice for a variety of applications. It is especially suitable for items such as bags, wallets, and key fobs due to its ease of cutting and sewing. B2B buyers should consider the aesthetic appeal and versatility of this fabric, as it allows for creative designs that can attract consumers. However, it is important to note that while it offers a striking appearance, its durability may not match that of genuine leather.

How Does Printed Marine Vinyl Stand Out in the Market?

Printed Marine Vinyl is specifically designed for marine applications, featuring UV resistance and resilient stretching capabilities. This makes it ideal for upholstery, marine-grade products, and crafts like jewelry. For B2B buyers, its durability and weather resistance are significant advantages, particularly in outdoor or high-use environments. However, its heavier weight compared to other types of leatherette may limit its use in lightweight applications.

What Makes Printed Pebble Leatherette a Unique Choice?

Printed Pebble Leatherette stands out due to its textured surface that adds depth to designs. It is available in a variety of colors and prints, making it suitable for fashion accessories and home décor items. B2B buyers should consider this type for high-visibility products that benefit from unique textures. The downside is its limited flexibility in design compared to smoother finishes, which may not be suitable for all applications.

Illustrative image related to printed leatherette fabric

Why Opt for Custom Printed Leatherette?

Custom Printed Leatherette allows businesses to create tailored designs with high-quality print resolution, making it an excellent choice for branding and promotional products. This type is particularly valuable for fashion items where brand visibility is crucial. B2B buyers should keep in mind the minimum order quantities that may apply, which can impact budget considerations. The personalization aspect can significantly enhance marketing efforts, making it a worthwhile investment for many businesses.

What Are the Benefits of Eco-Friendly Printed Leatherette?

Eco-Friendly Printed Leatherette is made from recycled materials, appealing to eco-conscious brands and consumers. This type supports sustainable production practices, making it an attractive option for businesses looking to align with environmental values. B2B buyers should consider the growing market appeal of sustainable products, although they may encounter higher costs compared to conventional options. The long-term benefits of brand loyalty and customer satisfaction in eco-friendly markets can outweigh these initial costs.

Key Industrial Applications of printed leatherette fabric

| Industry/Sector | Specific Application of printed leatherette fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Accessories | Handbags and wallets | Customizable designs enhance brand identity | Quality of print, durability, and eco-friendliness |

| Upholstery | Furniture and automotive interiors | Cost-effective alternative to genuine leather | Resistance to wear, ease of cleaning, and aesthetics |

| Marine & Outdoor | Boat upholstery and outdoor furniture | UV resistance and water repellency for longevity | Compliance with marine standards and colorfastness |

| Crafts & DIY | Custom craft projects and decorative items | Versatile material for a wide range of applications | Material thickness, print quality, and shipping options |

| Pet Products | Pet accessories and furniture | Durable and easy to clean, enhancing product appeal | Safety standards, color options, and texture |

How is Printed Leatherette Fabric Used in Fashion and Accessories?

In the fashion industry, printed leatherette fabric is widely utilized for creating handbags, wallets, and other accessories. Its vibrant designs allow brands to express their unique identity while remaining cost-effective compared to genuine leather. International buyers, particularly from regions like Africa and Europe, must ensure that the fabric meets quality standards for durability and print integrity to withstand daily use.

What Role Does Printed Leatherette Fabric Play in Upholstery?

Printed leatherette fabric serves as a popular choice in the upholstery sector for furniture and automotive interiors. It offers a cost-effective alternative to traditional leather, providing similar aesthetics without the high price tag. Buyers in South America and the Middle East should prioritize sourcing materials that are resistant to wear and tear, as well as easy to clean, to ensure longevity in high-use environments.

Illustrative image related to printed leatherette fabric

How is Printed Leatherette Fabric Beneficial in Marine and Outdoor Applications?

In marine and outdoor settings, printed leatherette fabric is used for boat upholstery and outdoor furniture, thanks to its UV resistance and water-repellent properties. This durability helps maintain the fabric’s appearance and functionality in harsh weather conditions. Buyers must consider compliance with marine safety standards and the fabric’s colorfastness to ensure it remains vibrant over time.

Why is Printed Leatherette Fabric Ideal for Crafts and DIY Projects?

Craft enthusiasts and DIY creators frequently turn to printed leatherette fabric for a variety of projects, including custom crafts and decorative items. Its versatility allows for easy manipulation and a wide range of design options. Buyers should focus on material thickness and print quality, as these factors significantly impact the final product’s appearance and durability.

How Does Printed Leatherette Fabric Enhance Pet Products?

In the pet product industry, printed leatherette fabric is employed in creating pet accessories and furniture due to its durability and ease of cleaning. This material is particularly appealing for pet owners looking for stylish yet practical solutions. Buyers need to ensure that the fabric meets safety standards and offers a variety of color options to cater to different consumer preferences.

3 Common User Pain Points for ‘printed leatherette fabric’ & Their Solutions

Scenario 1: Difficulty in Ensuring Color Consistency Across Batches

The Problem: B2B buyers often face the challenge of inconsistent color matching when ordering printed leatherette fabric in bulk. This can lead to significant issues for manufacturers, especially in industries like fashion and upholstery, where brand identity relies heavily on specific color palettes. When buyers receive a shipment with colors that vary from previous orders, it can derail production schedules, lead to increased costs, and ultimately impact customer satisfaction.

The Solution: To mitigate this issue, B2B buyers should establish a robust relationship with their suppliers that includes clear specifications regarding color standards. Before placing a bulk order, request physical swatches or samples of the printed leatherette fabric to ensure that the colors align with your requirements. Additionally, consider using a color management system that specifies Pantone or similar color codes to standardize expectations. Communicating these codes to the manufacturer can help maintain color consistency across different production runs. Finally, implementing a quality control process where samples are checked against these standards upon receipt can prevent inconsistencies from affecting the final product.

Illustrative image related to printed leatherette fabric

Scenario 2: Challenges with Fabric Durability and Performance

The Problem: Buyers may encounter concerns about the durability and performance of printed leatherette fabric, particularly when used in high-traffic areas or for products subjected to wear and tear, such as bags and upholstery. Fabrics that fail to withstand everyday use can lead to product returns and damage to a company’s reputation, which is critical in competitive markets.

The Solution: To address durability concerns, it is essential to select high-quality printed leatherette that is specifically designed for the intended application. Buyers should look for products labeled as UV-resistant, waterproof, or abrasion-resistant, depending on their needs. When sourcing, ask suppliers for details regarding the fabric’s specifications, such as tensile strength and resistance to fading or cracking. Conducting preliminary tests on samples can provide insight into how the fabric will perform under various conditions. Furthermore, consider investing in protective coatings or finishes that enhance the fabric’s longevity, ensuring that the final products meet performance expectations.

Scenario 3: Complications in Customization and Design Approval

The Problem: Another common pain point for B2B buyers is the complexity involved in customizing printed leatherette fabric. When businesses wish to create unique designs or patterns, they may struggle with the approval process, leading to delays in production. This is particularly true for companies that require rapid turnaround times to stay competitive in their respective markets.

Illustrative image related to printed leatherette fabric

The Solution: To streamline the customization process, establish a clear workflow for design approval that includes all stakeholders. Utilize digital tools and platforms that allow for easy sharing and feedback on design mock-ups. Collaborating closely with suppliers during the design phase can also facilitate adjustments and ensure that the final product meets expectations. It is advisable to create a detailed brief that outlines design elements, dimensions, and any specific requirements, thereby minimizing misunderstandings. Additionally, requesting a prototype before final production can help confirm that the design translates well onto the printed leatherette, reducing the risk of costly errors and ensuring timely delivery.

Strategic Material Selection Guide for printed leatherette fabric

What Are the Key Materials Used in Printed Leatherette Fabric?

When selecting printed leatherette fabric for various applications, understanding the properties and characteristics of the materials involved is crucial for B2B buyers. Here, we analyze four common materials used in printed leatherette fabric, focusing on their properties, pros and cons, and considerations for international buyers.

PVC (Polyvinyl Chloride)

Key Properties: PVC is known for its excellent durability and resistance to moisture, chemicals, and abrasion. It can withstand temperatures ranging from -10°C to 60°C, making it suitable for various environments.

Illustrative image related to printed leatherette fabric

Pros & Cons: PVC is relatively low-cost and easy to manufacture, which contributes to its popularity. However, it can be less flexible than other materials, potentially limiting its use in applications requiring intricate designs or shapes. Additionally, it may not be as environmentally friendly due to its production process and chemical additives.

Impact on Application: PVC is often used in upholstery, bags, and fashion accessories due to its vibrant color retention and print quality. However, it may not be suitable for high-end applications where a more luxurious feel is desired.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should consider compliance with local regulations regarding PVC, as some countries have restrictions on its use due to environmental concerns.

PU (Polyurethane)

Key Properties: PU offers superior flexibility and a soft touch compared to PVC. It is resistant to wear and tear, with a temperature range of -30°C to 80°C, making it versatile for various applications.

Pros & Cons: The primary advantage of PU is its aesthetic appeal and comfort, making it suitable for high-end products. However, it tends to be more expensive than PVC, which could affect budget considerations for larger orders.

Illustrative image related to printed leatherette fabric

Impact on Application: PU is widely used in automotive interiors, high-fashion items, and furniture upholstery, where a premium look and feel are essential. Its compatibility with various printing techniques also enhances design possibilities.

Considerations for International Buyers: B2B buyers in Europe, particularly Germany, may favor PU due to its compliance with stringent EU regulations regarding chemical safety and environmental impact.

Marine Vinyl

Key Properties: Marine vinyl is designed for outdoor use, featuring UV resistance and high durability against water and mold. It typically operates effectively in temperatures between -20°C and 70°C.

Pros & Cons: The significant advantage of marine vinyl is its resilience in harsh conditions, making it ideal for outdoor furniture and marine applications. However, it is generally more expensive than standard PVC, which may deter budget-conscious buyers.

Impact on Application: This material is particularly beneficial for applications in coastal regions or areas with high humidity, ensuring longevity and maintaining appearance over time.

Illustrative image related to printed leatherette fabric

Considerations for International Buyers: Buyers from South America and Africa, where outdoor living is prevalent, should ensure that marine vinyl meets local standards for UV protection and durability.

Faux Leather (Non-Woven)

Key Properties: Non-woven faux leather is lightweight and breathable, offering good flexibility. It typically has a temperature tolerance of -10°C to 60°C.

Pros & Cons: This material is cost-effective and easy to work with, making it suitable for mass production. However, its durability may not match that of PVC or PU, limiting its use in high-wear applications.

Impact on Application: Non-woven faux leather is often used for fashion accessories and lightweight upholstery, where cost and ease of handling are priorities.

Considerations for International Buyers: Buyers should be aware of the varying quality standards across regions, particularly in Europe, where certifications for non-woven materials may be more stringent.

Summary Table

| المواد | Typical Use Case for printed leatherette fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, bags, fashion accessories | Low-cost and durable | Less flexible, environmental concerns | منخفضة |

| البولي يوريثان | Automotive interiors, high-fashion items | Superior aesthetics and comfort | Higher cost | عالية |

| Marine Vinyl | Outdoor furniture, marine applications | UV resistance and durability | Generally more expensive | Med |

| Faux Leather (Non-Woven) | Fashion accessories, lightweight upholstery | Cost-effective and easy to handle | Limited durability | منخفضة |

This strategic material selection guide provides B2B buyers with essential insights into the characteristics and applications of printed leatherette fabrics, enabling informed purchasing decisions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette fabric

What Are the Key Stages in the Manufacturing Process of Printed Leatherette Fabric?

The manufacturing of printed leatherette fabric involves several meticulous stages to ensure the final product meets both aesthetic and functional standards. Here’s a breakdown of the main stages:

1. Material Preparation

The journey begins with the selection of high-quality synthetic materials, typically polyurethane (PU) or polyvinyl chloride (PVC). These materials are chosen for their durability, flexibility, and ease of printing. In this stage, the raw materials undergo various treatments, such as cleaning and conditioning, to enhance their properties. Chemical additives may also be introduced to improve UV resistance, flexibility, and overall longevity of the fabric.

2. Forming

Once the materials are prepared, they are formed into sheets or rolls. This process often involves extrusion, where the raw material is melted and shaped into the desired thickness. Precision is crucial here; the thickness and texture of the leatherette can significantly influence its appearance and usability. For printed leatherette, this forming stage may also include embossing or texturing to create a more authentic leather-like feel.

Illustrative image related to printed leatherette fabric

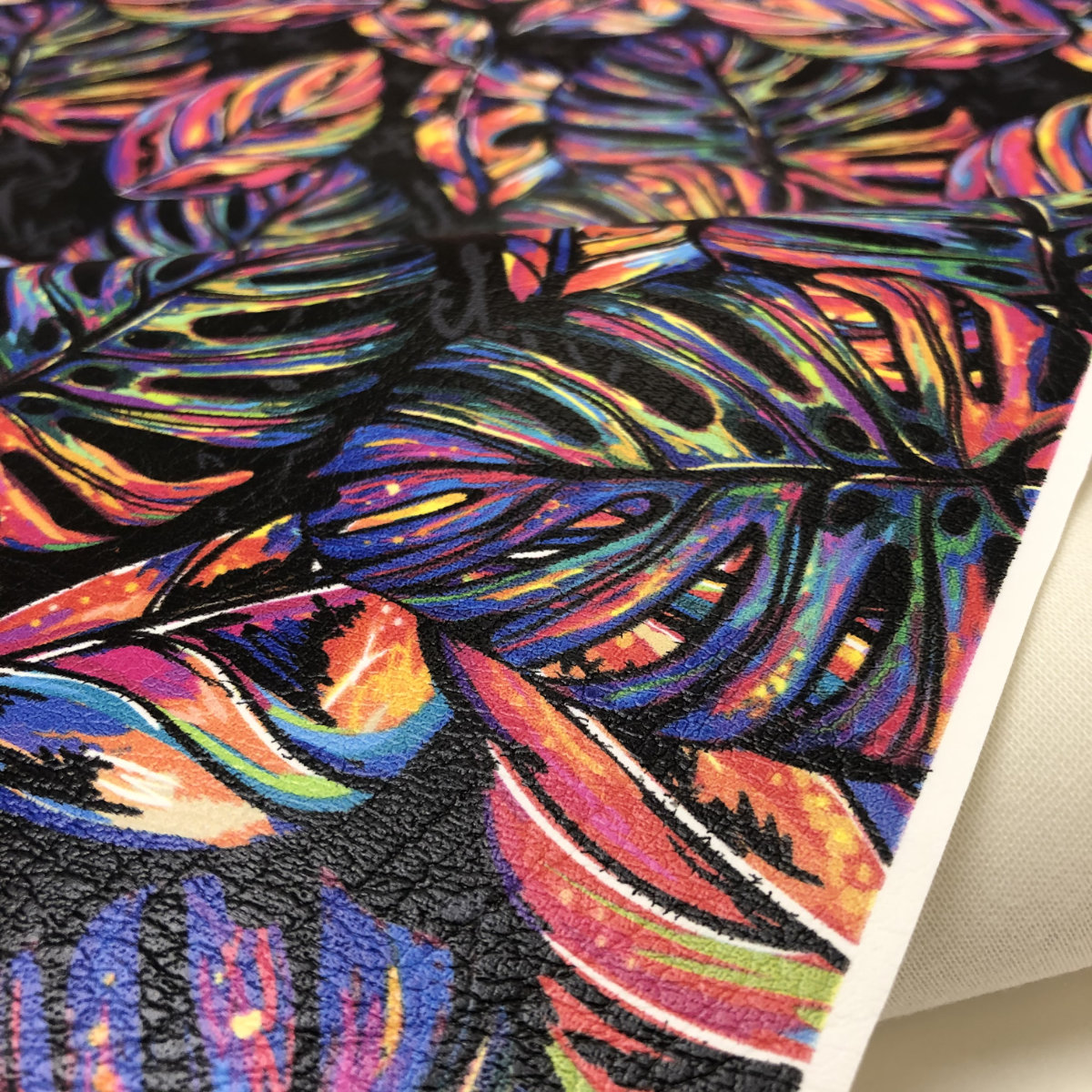

3. Printing

The printing process is where creativity meets technology. High-resolution digital printing techniques, such as dye-sublimation or UV printing, are commonly employed. These methods allow for vibrant colors and intricate designs to be applied directly onto the leatherette surface. Quality control during printing is vital, as any misalignment or color inconsistency can result in significant waste. Advanced printers equipped with color calibration tools help ensure that the output matches the design specifications.

4. Assembly

After printing, the fabric may undergo additional processes, such as cutting and stitching, depending on its intended application. For instance, if the leatherette is destined for bags or upholstery, it will be cut into specific shapes and sewn together. This stage requires skilled labor to ensure precise assembly, which is crucial for the durability and aesthetic appeal of the final product.

5. Finishing

The final stage involves applying coatings or treatments that enhance the fabric’s performance characteristics, such as water resistance or stain repellency. This may also include quality checks to ensure that the printed designs maintain their vibrancy and that the material’s tactile qualities meet industry standards. Finishing treatments can significantly influence the end-use applications, whether for fashion, automotive, or furniture industries.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing process of printed leatherette fabric, ensuring that products meet international standards and customer expectations. Here’s how QA is systematically integrated:

Relevant International Standards for Quality Assurance

B2B buyers should be aware of the various international quality standards that may apply to printed leatherette fabrics. ISO 9001 is a widely recognized standard that outlines criteria for a quality management system (QMS). Compliance with ISO 9001 demonstrates a commitment to consistent quality and customer satisfaction.

Illustrative image related to printed leatherette fabric

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in the European Economic Area, or specific certifications for environmental and safety standards, may also be relevant. Buyers should verify that their suppliers adhere to these standards to mitigate risks associated with product quality.

What Are the Key Quality Control Checkpoints?

Quality control in the manufacturing of printed leatherette is typically structured around three main checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival. Suppliers should provide certificates of compliance to ensure that the materials meet the specified standards. Any discrepancies should be addressed before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks should be conducted to monitor the quality of the fabric at various stages, including during forming, printing, and assembly. This may involve visual inspections, measurements of thickness, and color matching to ensure consistency.

-

Final Quality Control (FQC): Once the products are completed, a thorough inspection is performed to verify that they meet all specifications. This includes checking for defects, ensuring accurate dimensions, and confirming that the printed designs are vibrant and correctly aligned.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, it’s essential to ensure that suppliers maintain rigorous quality control measures. Here are some actionable steps:

Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality management systems. This not only helps in verifying compliance with international standards but also allows buyers to assess the supplier’s commitment to quality.

Illustrative image related to printed leatherette fabric

Request Quality Control Reports

Buyers should request detailed quality control reports from suppliers, which should include results from IQC, IPQC, and FQC. These reports can provide transparency and assurance regarding the quality of the products being supplied.

Utilize Third-Party Inspection Services

Engaging third-party inspection services can further enhance quality assurance. These independent entities can conduct on-site inspections and testing to verify that the products meet the required standards before shipment.

What Are the Quality Control Nuances for International Buyers?

When engaging with suppliers in different regions, international B2B buyers must navigate various quality control nuances:

-

Understanding Local Standards: Different regions may have varying standards and regulations. Buyers should familiarize themselves with local requirements in their target markets to ensure compliance.

-

Cultural Differences: Cultural attitudes toward quality and business practices can vary significantly. Building strong relationships with suppliers and understanding their operational ethos can lead to better collaboration and quality outcomes.

-

Logistical Challenges: International shipping may introduce additional risks, such as damage during transit. Buyers should consider suppliers that have robust packaging and shipping protocols to protect the integrity of the printed leatherette fabric.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing printed leatherette fabric, ensuring that they receive high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette fabric’

The procurement of printed leatherette fabric involves careful consideration and strategic planning. This guide serves as a practical checklist for B2B buyers looking to source high-quality printed leatherette fabric effectively. Following these steps will help ensure that your sourcing process is efficient and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes understanding the intended applications of the fabric—be it for upholstery, bags, or apparel—and the specific characteristics required, such as thickness, texture, and print quality.

– Considerations: Identify if you need UV resistance, waterproofing, or specific colorfastness ratings, which can affect the performance and longevity of the fabric.

Illustrative image related to printed leatherette fabric

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in printed leatherette fabric. Look for companies with a strong track record and positive reviews in your target markets, such as Africa, South America, the Middle East, and Europe.

– Action Items: Utilize online platforms, trade shows, and industry publications to compile a list of potential suppliers. Pay special attention to their product range and pricing structures.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify the certifications and compliance of your potential suppliers. Certifications related to quality management (ISO), environmental standards (OEKO-TEX), and industry-specific regulations can be indicators of a reliable supplier.

– Why It Matters: Certifications not only ensure quality but also demonstrate the supplier’s commitment to sustainability and ethical practices, which are increasingly important to B2B buyers.

Step 4: Request Samples for Quality Assessment

Always request samples of the printed leatherette fabric before placing a bulk order. This allows you to evaluate the material’s quality, print clarity, and overall performance in real-world applications.

– What to Look For: Assess the samples for color vibrancy, durability, and ease of handling. Testing the fabric with your intended use in mind can reveal any potential issues early in the process.

Illustrative image related to printed leatherette fabric

Step 5: Discuss Customization Options

If your business requires specific designs or patterns, engage with suppliers about customization capabilities. Many manufacturers offer options for bespoke prints or colors, which can enhance your product’s uniqueness in the market.

– Key Questions: Inquire about minimum order quantities for custom designs and the lead times involved in production. This will help you plan your inventory and marketing strategies accordingly.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, negotiate the pricing and terms of the purchase. Consider factors such as bulk discounts, payment terms, and shipping costs.

– Strategic Insight: Establishing a good relationship with your supplier can lead to better pricing and more favorable terms in future transactions.

Step 7: Finalize Logistics and Shipping Arrangements

After agreeing on terms, finalize the logistics for delivery. Ensure that you understand the shipping options available, estimated delivery times, and any customs regulations that may apply, especially when importing from international suppliers.

– Action Steps: Prepare necessary documentation and confirm that the supplier can meet your timeline to avoid any disruptions in your supply chain.

Illustrative image related to printed leatherette fabric

By following this checklist, B2B buyers can navigate the complexities of sourcing printed leatherette fabric with greater confidence, ensuring that their procurement aligns with both quality standards and business objectives.

Comprehensive Cost and Pricing Analysis for printed leatherette fabric Sourcing

What Are the Key Cost Components in Sourcing Printed Leatherette Fabric?

When sourcing printed leatherette fabric, understanding the cost structure is crucial for effective budgeting and negotiation. The primary components influencing the total cost include:

-

Materials: The base fabric’s quality significantly affects the price. High-quality synthetic materials like PVC and PU can vary widely in cost, with prices ranging from $4 to over $12 per yard depending on the specifications and finishes.

-

Labor: Labor costs encompass the workforce involved in manufacturing, printing, and finishing the fabric. Regions with lower labor costs can offer competitive pricing, but this may also impact quality.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility—utilities, rent, and equipment maintenance. Efficient production processes can help reduce overhead costs.

-

Tooling: Custom designs may require specialized tools or molds, which can add to the upfront costs. For bulk orders, however, these costs can be amortized over a larger quantity, lowering the unit price.

-

Quality Control (QC): Ensuring that the fabric meets specified standards involves additional costs. Comprehensive QC processes may include testing for durability, colorfastness, and UV resistance.

-

Logistics: Shipping costs can vary significantly based on the distance from the supplier to the buyer, the volume of fabric ordered, and chosen shipping methods. Understanding Incoterms can help clarify responsibilities for shipping costs.

-

Margin: Suppliers typically apply a profit margin that reflects market conditions and competition. This margin can be negotiated based on order size and long-term relationships.

How Do Volume and Customization Affect Pricing for Printed Leatherette Fabric?

Volume plays a crucial role in pricing. Suppliers often have a minimum order quantity (MOQ), which can lead to discounts for larger orders. For instance, ordering 500 yards might yield a price reduction compared to ordering just 100 yards.

Customization, such as specific patterns or colors, can also influence costs. Custom prints may incur additional setup fees, but larger orders can dilute these costs, making it more economical to opt for tailored designs if you anticipate high demand.

What Supplier Factors Should International Buyers Consider?

When sourcing from international suppliers, several factors can impact pricing:

-

Supplier Reputation and Certifications: Suppliers with quality certifications (e.g., ISO) or positive customer feedback may charge a premium but often provide better quality assurance.

-

Geographical Location: Suppliers located closer to your market may offer lower shipping costs. However, be cautious of potential tariffs and duties that can affect overall expenses.

-

Lead Times: Longer production times can tie up capital and affect your supply chain. Suppliers with shorter lead times may charge more but can enhance your responsiveness to market demands.

What Are Effective Negotiation Strategies for Cost-Efficiency?

To maximize cost-efficiency, consider the following tips:

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service.

-

Leverage Total Cost of Ownership (TCO): Evaluate the complete cost of acquiring the fabric, including potential waste, shipping, and QC. Sometimes, a slightly higher upfront cost can result in lower overall expenses due to durability or lower defect rates.

-

Be Clear About Specifications: Providing precise specifications can minimize misunderstandings and reduce the likelihood of costly reworks.

-

Understand Pricing Nuances for Different Regions: Buyers from Africa, South America, the Middle East, and Europe may face unique pricing challenges due to currency fluctuations, local demand, and economic conditions. Tailoring your negotiation approach based on these factors can yield better results.

What Should Buyers Keep in Mind Regarding Pricing Indicators?

While indicative prices can provide a baseline, they can fluctuate based on market conditions, material availability, and supplier capabilities. Always request updated quotes and consider seasonal trends that may affect pricing.

Illustrative image related to printed leatherette fabric

In summary, a comprehensive understanding of the cost structure, pricing influencers, and effective negotiation strategies is vital for international B2B buyers sourcing printed leatherette fabric. By considering these factors, buyers can make informed decisions that enhance their supply chain efficiency and profitability.

Alternatives Analysis: Comparing printed leatherette fabric With Other Solutions

Exploring Alternatives to Printed Leatherette Fabric

When considering materials for various applications, it’s essential to evaluate alternatives to printed leatherette fabric. Each option presents distinct benefits and drawbacks that can influence decision-making for B2B buyers. This section examines printed leatherette fabric alongside two viable alternatives: traditional leather and PVC (polyvinyl chloride) fabric.

Comparison Table

| Comparison Aspect | Printed Leatherette Fabric | Traditional Leather | PVC Fabric |

|---|---|---|---|

| Performance | Durable, water-resistant, suitable for various applications | Highly durable, breathable, develops a patina over time | Good waterproofing, flexible but less durable than leatherette |

| Cost | Mid-range, generally more affordable than leather | Higher initial investment, varies by quality | Lower cost, budget-friendly |

| Ease of Implementation | Easy to cut and sew, compatible with domestic machines | Requires specialized tools and skills | Simple to work with, easy to maintain |

| Maintenance | Low maintenance, easy to clean | Requires conditioning and care | Low maintenance, easily wiped clean |

| Best Use Case | Fashion items, upholstery, accessories | Luxury goods, high-end furniture | Budget applications, event decor, temporary use |

Detailed Breakdown of Alternatives

Traditional Leather

Traditional leather is revered for its durability and luxurious feel. It is a natural material that breathes well, making it suitable for high-end applications such as luxury handbags and furniture. However, the costs associated with quality leather can be significantly higher than printed leatherette, which may deter budget-conscious buyers. Additionally, traditional leather requires regular maintenance, such as conditioning and polishing, to retain its appearance over time. For businesses targeting the luxury market, the investment in leather can yield high returns, but it may not be suitable for all applications.

PVC Fabric

PVC fabric is a synthetic alternative that offers a cost-effective solution for various applications. It is widely used in budget-conscious projects such as event decor, temporary furnishings, and promotional items. PVC is also easy to clean and maintain, making it a practical choice for high-traffic areas. However, while PVC offers good waterproofing and flexibility, it generally lacks the durability and aesthetic appeal of both printed leatherette and traditional leather. For companies focused on affordability and short-term applications, PVC fabric can be a viable option, though it may not meet the expectations of customers seeking high-quality products.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate material for your business needs requires careful consideration of several factors, including performance, cost, and intended use. Printed leatherette fabric stands out for its versatility and affordability, making it an excellent choice for various applications. However, if your focus is on luxury and long-term durability, traditional leather may be worth the investment. Conversely, if budget constraints are paramount, PVC fabric offers a practical solution for temporary or less demanding applications. Ultimately, understanding the unique benefits and limitations of each option will enable B2B buyers to make informed decisions that align with their specific requirements and market positioning.

Essential Technical Properties and Trade Terminology for printed leatherette fabric

What Are the Key Technical Properties of Printed Leatherette Fabric?

When sourcing printed leatherette fabric, it is crucial for B2B buyers to understand various technical properties that can impact product quality and application suitability. Here are some essential specifications:

-

Material Composition: Printed leatherette is typically made from a base of polyvinyl chloride (PVC) or polyurethane (PU). The material choice affects durability, flexibility, and environmental impact. PVC is often more affordable but less eco-friendly, while PU offers a more premium, biodegradable option. Buyers should evaluate their target market’s preferences and sustainability goals when choosing the material.

-

Thickness: The thickness of leatherette fabric can range from 0.5mm to 2mm or more, depending on the intended application. A thicker fabric generally provides enhanced durability and resistance to wear and tear, making it suitable for upholstery or heavy-duty applications. Understanding the required thickness helps in selecting the right product that meets specific project needs.

-

UV Resistance: For applications exposed to sunlight, such as outdoor furniture or marine upholstery, UV resistance is critical. Printed leatherette with UV-protected ink prevents fading and deterioration over time, ensuring longevity. B2B buyers must check for UV ratings to guarantee performance in outdoor settings.

-

Tensile Strength: This property measures the fabric’s resistance to being pulled apart. Higher tensile strength indicates a more durable material that can withstand significant stress without tearing. This is especially important for products like bags or upholstery that experience daily use. Buyers should request tensile strength data to assess the suitability for their applications.

-

Colorfastness: This property indicates how well the colors in the printed leatherette resist fading when exposed to washing, light, and other environmental factors. Fabrics with high colorfastness ratings are essential for items that will be frequently cleaned or are subject to outdoor conditions. Buyers should prioritize suppliers that can provide colorfastness test results to ensure product quality.

-

Pliability: The pliability of leatherette fabric determines how easily it can be manipulated during production. Fabrics that are too stiff may be challenging to work with, while overly pliable materials may lack structural integrity. Understanding pliability helps buyers assess compatibility with their manufacturing processes.

What Are Common Trade Terms Associated with Printed Leatherette Fabric?

Navigating the world of printed leatherette fabric involves understanding specific industry jargon. Here are some common terms that are essential for B2B buyers:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end products. In the context of printed leatherette, an OEM may provide custom designs or specifications for clients who want unique offerings.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to plan their inventory and budget effectively, as it can impact cash flow and storage capabilities.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. Buyers should prepare an RFQ that clearly outlines their requirements to receive accurate and competitive quotes from manufacturers.

-

Incoterms (International Commercial Terms): These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Knowledge of Incoterms helps buyers understand shipping, insurance, and risk management, which are vital when importing printed leatherette from overseas suppliers.

-

Lead Time: This term refers to the amount of time it takes from placing an order until it is delivered. Understanding lead times is essential for inventory management and ensuring timely product availability, especially in fast-paced markets.

-

Fabric Weight: Measured in grams per square meter (gsm), fabric weight indicates the heaviness of the material. A higher gsm typically correlates with increased durability and sturdiness, which may be necessary for certain applications. Buyers should consider fabric weight to ensure that the material meets their specific performance criteria.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing printed leatherette fabric, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the printed leatherette fabric Sector

What Are the Key Trends Influencing the Printed Leatherette Fabric Market?

The printed leatherette fabric sector is experiencing dynamic growth driven by several global factors. One of the primary drivers is the rising demand for sustainable and cruelty-free materials in various industries, including fashion, automotive, and upholstery. This trend is particularly pronounced in regions like Europe, where consumers are increasingly favoring products that align with ethical standards. Additionally, the proliferation of e-commerce has facilitated easier access to diverse fabric options, enabling international B2B buyers from Africa, South America, and the Middle East to explore a wide range of printed leatherette fabrics without geographical constraints.

Emerging technologies are also reshaping the sourcing landscape. Digital printing technology, for instance, allows for more intricate designs and customizations, catering to specific market needs. This capability not only enhances product variety but also reduces waste, as manufacturers can produce on demand rather than maintaining large inventories. Furthermore, automation in manufacturing processes is improving efficiency and lowering production costs, making printed leatherette fabrics more accessible to smaller businesses and startups.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in Printed Leatherette Fabrics?

Sustainability has become a critical consideration for B2B buyers in the printed leatherette fabric market. The environmental impact of traditional leather production is substantial, leading to increased scrutiny from consumers and regulatory bodies alike. Consequently, businesses are turning to printed leatherette options that minimize ecological footprints. Buyers should prioritize suppliers who use eco-friendly materials and processes, such as water-based inks and recycled substrates, to ensure that their sourcing practices align with sustainability goals.

Illustrative image related to printed leatherette fabric

Moreover, the importance of ethical supply chains cannot be overstated. Buyers should look for manufacturers that adhere to fair labor practices and transparency throughout their production processes. Certifications such as OEKO-TEX® and GRS (Global Recycle Standard) can serve as indicators of a supplier’s commitment to ethical and sustainable practices. By choosing certified materials, businesses not only contribute to environmental conservation but also bolster their brand reputation, appealing to a growing segment of environmentally conscious consumers.

How Has the Printed Leatherette Fabric Sector Evolved Over Time?

The evolution of the printed leatherette fabric sector can be traced back to the early 20th century when synthetic materials were first introduced as alternatives to traditional leather. Initially developed to provide a cost-effective and cruelty-free option, advancements in textile technology have transformed printed leatherette into a versatile material, suitable for a wide array of applications. Over the decades, improvements in manufacturing techniques, including digital printing and enhanced material formulations, have led to a surge in quality and design possibilities.

Today, printed leatherette fabrics are widely utilized across multiple sectors, from fashion accessories to automotive interiors. The material’s adaptability and aesthetic appeal have made it a favorite among designers and manufacturers alike. As trends continue to shift towards sustainability and ethical sourcing, the printed leatherette fabric market is likely to further innovate, responding to the demands of a conscientious global consumer base.

By understanding these market dynamics, B2B buyers can make informed decisions that not only meet their business needs but also align with evolving consumer values and industry standards.

Illustrative image related to printed leatherette fabric

Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette fabric

-

How can I identify a reliable supplier for printed leatherette fabric?

To identify a reliable supplier, start by researching their reputation through online reviews and testimonials. Look for suppliers who have been in the industry for several years and have a portfolio showcasing their products. Verify certifications and compliance with international standards, especially if sourcing from different regions. It’s also wise to request samples to assess quality and responsiveness. Engage in direct communication to gauge their customer service and willingness to accommodate your needs. -

What are the key factors to consider when selecting printed leatherette fabric?

When selecting printed leatherette fabric, consider durability, UV resistance, and ease of maintenance. Evaluate the fabric’s texture and weight to ensure it fits your intended use, whether for upholstery, accessories, or garments. Additionally, check for customization options, as the ability to create unique designs can set your products apart in competitive markets. Lastly, assess the environmental impact of the materials used, as sustainability is increasingly important to consumers. -

What is the typical minimum order quantity (MOQ) for printed leatherette fabric?

The typical MOQ for printed leatherette fabric varies by supplier and can range from as low as 10 yards to over 100 yards. Factors influencing MOQ include the complexity of the print, the fabric type, and the supplier’s production capacity. Before finalizing your order, discuss your requirements with potential suppliers to negotiate MOQs that align with your business needs while ensuring cost-effectiveness. -

What are the common payment terms for B2B transactions involving printed leatherette fabric?

Payment terms in B2B transactions can vary widely but commonly include options like upfront payment, 30% deposit with the balance due upon delivery, or net 30/60 terms. It is essential to clarify payment conditions before placing an order to avoid misunderstandings. Additionally, consider using secure payment methods, such as letters of credit or escrow services, particularly for international transactions, to protect your investment. -

How do I ensure quality assurance for printed leatherette fabric?

To ensure quality assurance, establish clear specifications and quality standards before production begins. Request samples for evaluation and conduct quality checks upon receipt of the goods. Engaging a third-party inspection service can also provide an unbiased assessment of the fabric’s quality before shipment. Regular communication with your supplier throughout the production process is key to addressing any issues promptly. -

What are the logistics considerations when importing printed leatherette fabric?

Logistics considerations include shipping methods, customs clearance, and delivery timelines. Choose a shipping method that balances cost and speed, such as sea freight for bulk orders or air freight for smaller quantities. Ensure you understand the customs regulations of your country to avoid delays and additional charges. Collaborate with experienced freight forwarders who can guide you through the logistics process and provide insights into local import requirements. -

Can I customize printed leatherette fabric designs?

Yes, many suppliers offer customization options for printed leatherette fabric, allowing you to create unique designs that cater to your brand’s identity. Customization can include specific patterns, colors, and textures. When discussing your project with suppliers, provide detailed design specifications and inquire about any associated costs or minimum order quantities for custom prints. Be prepared for possible lead times that could affect your production schedule. -

What trends are currently shaping the market for printed leatherette fabric?

Current trends in the printed leatherette fabric market include sustainable materials, vibrant patterns, and multifunctional uses. Eco-friendly production processes and recycled materials are gaining traction as consumers prioritize sustainability. Additionally, bold colors and intricate designs are popular in fashion and home decor. Keeping abreast of these trends will help you align your product offerings with market demands and enhance your competitive edge.

Top 7 Printed Leatherette Fabric Manufacturers & Suppliers List

1. Zipper Valley – Printed Faux Leather

Domain: zippervalley.com

Registered: 2020 (5 years)

مقدمة: Printed Faux Leather is pliable, vibrant, and bursting with personality. It is easy to cut and sews beautifully, even on domestic machines. Ideal for bags, wallets, key fobs, embroidery, and other creative projects. Available styles include Printed Pebble with various patterns. Regular prices range from $6.99 to $12.49, with discounts on select items. In stock items include 11 options, while 3 are…

2. Contrado – Custom Printed Faux Leather Fabric

Domain: contrado.com

Registered: 2004 (21 years)

مقدمة: Custom Printed Faux Leather Fabric

– Material Composition: 85% PVC, 15% Polyester

– Max Width: 1.39 yards

– Weight: 20.65 oz

– Certification: Greenguard Certified

– Care Instructions: Surface wipe only; clean gently by hand with a mild soapy damp cloth.

– Uses: Ideal for upholstery, bags, and more.

– Features: Soft polyester back with a PVC face, unique textured leather effect, vibrant printing on…

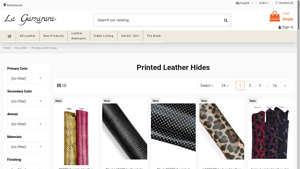

3. Lagarza Rara – Premium Printed Leather Hides

Domain: lagarzarara.com

Registered: 2005 (20 years)

مقدمة: Printed leather hides available in various designs and colors, suitable for upholstery, fashion, and accessories. High-quality materials ensure durability and aesthetic appeal. Ideal for both commercial and personal projects.

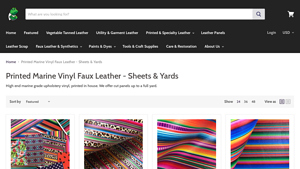

4. Frog Jelly Leather – Printed Marine Vinyl

Domain: frogjellyleather.com

Registered: 2016 (9 years)

مقدمة: Printed Marine Vinyl Faux Leather – Sheets & Yards

– High-end marine grade upholstery vinyl, printed in-house.

– Cut panels available up to a full yard.

– UV resistant marine upholstery vinyl with resilient stretching.

– Suitable for bags, jewelry (earrings), crafts (hair bows), and upholstery.

– Price range: from $4.25 to $4.99 per item.

– Various patterns available including Wild Serape, Braided…

5. Buyleatheronline – Printed Leather Hides

Domain: buyleatheronline.com

Registered: 2015 (10 years)

مقدمة: Printed leather hides are characterized by a design or texture on the surface, enhancing or leaving intact the natural grain of the skins. Suitable for various applications including craft, leather goods, bags, wallets, shoes, and more. Subcategories include embossed leather. Price range: €0.00 – €280.00. Available colors include white, beige, pink, red, green, blue, brown, black, and many others….

6. Leatherette Lane – Custom Printed Fabric Rolls

Domain: leatherettelane.co.uk

Registered: 2024 (1 years)

مقدمة: Custom Printed Leatherette fabric rolls available in various designs including animals, floral, seasonal, and special occasions. Free UK delivery on orders over £40 and free international delivery on orders over £150.

7. Bags of Love – Custom Printed Faux Leather Fabric

Domain: bagsoflove.com

Registered: 2003 (22 years)

مقدمة: Custom Printed Faux Leather Fabric

– Price: from $37.50

– Material: 100% vegan faux leather with a PVC face and soft poly back

– Ideal for: upholstery, bag making, phone cases, and more

– Features: leather effect texture, vibrant colors, sharp and crisp details

– Design options: upload a single image, create a collage, or add text

– Pattern options: design a pattern repeat from a single image

– Cu…

Strategic Sourcing Conclusion and Outlook for printed leatherette fabric

As the demand for printed leatherette fabric continues to grow across diverse markets, strategic sourcing has emerged as a critical factor for B2B buyers aiming to capitalize on this trend. By prioritizing suppliers that offer high-quality, versatile products, businesses can enhance their product lines while ensuring durability and aesthetic appeal. The ability to customize prints and patterns adds a unique selling proposition that can differentiate offerings in competitive markets, particularly in regions such as Africa, South America, the Middle East, and Europe.

Investing in robust supplier relationships and understanding regional preferences will enable companies to effectively navigate the complexities of sourcing. Buyers should focus on suppliers that not only meet quality standards but also provide competitive pricing and sustainable practices. This approach not only supports business growth but also aligns with the increasing consumer demand for eco-friendly products.

Looking ahead, B2B buyers are encouraged to explore innovative designs and sustainable materials in their sourcing strategies. Engaging with suppliers who are committed to quality and customization will position your business favorably in the evolving marketplace. Embrace the opportunity to elevate your brand by leveraging the potential of printed leatherette fabric.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to printed leatherette fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.