Introduction: Navigating the Global Market for faux leather vs real leather

In the increasingly competitive landscape of global commerce, the decision to source faux leather versus real leather presents a critical challenge for B2B buyers. Understanding the nuances between these materials is essential, as it directly impacts product quality, customer satisfaction, and brand reputation. This guide delves into the multifaceted world of faux leather and real leather, exploring their distinct characteristics, applications across various industries, and strategies for effective supplier vetting.

As the demand for sustainable and ethically sourced materials rises—especially in regions like Africa, South America, the Middle East, and Europe—buyers must navigate a complex array of options. The guide provides comprehensive insights into the cost implications of both materials, their environmental impacts, and the long-term durability that can influence purchasing decisions. By equipping international B2B buyers with actionable knowledge, this resource empowers them to make informed choices that align with their business objectives and customer expectations.

From understanding the sensory differences between faux and real leather to evaluating supplier reliability and cost-effectiveness, this guide serves as a vital tool for those looking to enhance their procurement strategies in a rapidly evolving market. Embrace this opportunity to refine your sourcing process and elevate your product offerings.

Table Of Contents

- Top 5 Faux Leather Vs Real Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux leather vs real leather

- Understanding faux leather vs real leather Types and Variations

- Key Industrial Applications of faux leather vs real leather

- 3 Common User Pain Points for ‘faux leather vs real leather’ & Their Solutions

- Strategic Material Selection Guide for faux leather vs real leather

- In-depth Look: Manufacturing Processes and Quality Assurance for faux leather vs real leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather vs real leather’

- Comprehensive Cost and Pricing Analysis for faux leather vs real leather Sourcing

- Alternatives Analysis: Comparing faux leather vs real leather With Other Solutions

- Essential Technical Properties and Trade Terminology for faux leather vs real leather

- Navigating Market Dynamics and Sourcing Trends in the faux leather vs real leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux leather vs real leather

- Strategic Sourcing Conclusion and Outlook for faux leather vs real leather

- Important Disclaimer & Terms of Use

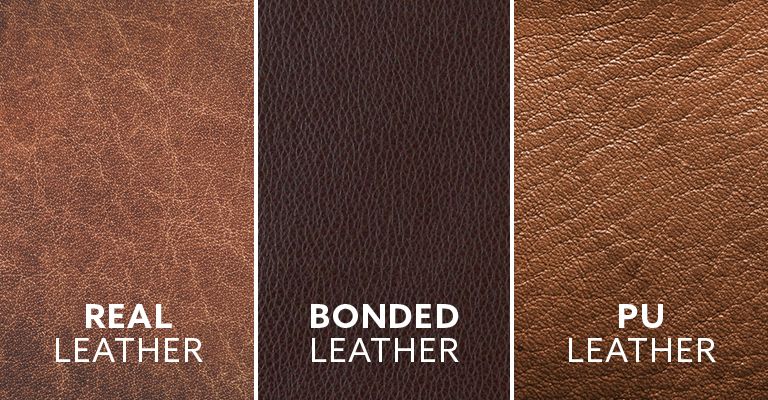

Understanding faux leather vs real leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Made from the top layer of animal hide; retains natural grain | High-end furniture, luxury handbags | Pros: Exceptional durability, develops character over time. Cons: Higher cost, requires maintenance. |

| Top Grain Leather | Sanded and refinished for a smoother surface | Apparel, wallets, automotive interiors | Pros: More affordable than full grain, good durability. Cons: Less breathable, may not develop a patina. |

| Faux Leather (PU) | Made from polyurethane; imitates leather appearance | Budget-friendly furniture, fashion accessories | Pros: Cost-effective, easy to clean. Cons: Shorter lifespan, less durable than real leather. |

| Vegan Leather | Made from non-animal materials (e.g., cork, apple peels) | Eco-friendly products, accessories | Pros: Sustainable, cruelty-free. Cons: Varied durability, may lack premium feel. |

| Bonded Leather | Composed of leather scraps bonded with polyurethane | Budget furniture, low-cost accessories | Pros: Affordable, can mimic real leather look. Cons: Less durable, prone to wear and tear. |

What Are the Key Characteristics of Full Grain Leather?

Full grain leather is the highest quality leather available, crafted from the top layer of animal hide while preserving its natural grain. This type of leather is known for its durability and unique character, developing a rich patina over time. Suitable for high-end furniture and luxury handbags, full grain leather represents a long-term investment for B2B buyers seeking premium materials. However, it does require regular maintenance to keep its appearance, which may be a consideration for businesses looking to minimize upkeep.

How Does Top Grain Leather Compare to Other Types?

Top grain leather is the second highest quality and is sanded and refinished to achieve a smoother surface. This type of leather is commonly used in apparel, wallets, and automotive interiors, striking a balance between quality and affordability. While it offers good durability and is easier to work with than full grain leather, it may not develop the same depth of character over time. Buyers should consider the trade-off between cost and the potential for a less authentic leather experience.

What Are the Benefits of Using Faux Leather (PU)?

Faux leather, particularly polyurethane (PU) leather, is a synthetic alternative that effectively mimics the look and feel of real leather. It is often employed in budget-friendly furniture and fashion accessories, making it an attractive option for businesses looking to reduce costs. While it is easy to clean and maintain, faux leather typically has a shorter lifespan and is less durable than its real counterparts. B2B buyers should weigh the cost savings against the potential need for more frequent replacements.

Illustrative image related to faux leather vs real leather

Why Choose Vegan Leather for Eco-Friendly Products?

Vegan leather is crafted from non-animal materials, such as cork or apple peels, making it a sustainable option for businesses focused on eco-friendly products. This type of leather is increasingly popular in the fashion industry and among consumers who prioritize ethical consumption. While vegan leather is generally considered cruelty-free, its durability can vary widely depending on the manufacturing process. B2B buyers should evaluate the specific material properties to ensure they meet their product requirements.

What Is Bonded Leather and Its Applications?

Bonded leather is made from leather scraps that are bonded together with polyurethane, creating a cost-effective alternative to traditional leather. It is often used in budget furniture and low-cost accessories. While it can mimic the appearance of real leather, bonded leather is less durable and more susceptible to wear and tear. Buyers should consider the intended use and longevity of the product, as the lower upfront cost may lead to higher long-term expenses due to replacement needs.

Key Industrial Applications of faux leather vs real leather

| Industry/Sector | Specific Application of faux leather vs real leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery and interior trim | Faux leather offers cost savings and design flexibility; real leather provides luxury and durability. | Evaluate material performance under varying climates; consider sourcing from local or sustainable suppliers. |

| Fashion and Apparel | Clothing, accessories, and footwear | Faux leather appeals to eco-conscious consumers; real leather enhances brand prestige and longevity. | Ensure compliance with ethical sourcing standards; assess trends in consumer preferences across regions. |

| Furniture | Sofas, chairs, and decorative items | Faux leather is easier to clean and maintain; real leather adds value and aesthetic appeal. | Focus on durability and maintenance requirements; consider regional preferences for material types. |

| Home Decor | Wall coverings and decorative accents | Faux leather offers a modern, versatile option; real leather provides a timeless, classic look. | Assess the impact of local climate on material performance; explore sustainable sourcing options. |

| Sports and Equipment | Gear bags, protective gear, and sports apparel | Faux leather is lightweight and water-resistant; real leather offers superior durability and performance. | Ensure compliance with safety standards; consider the weight and flexibility requirements for specific sports. |

How is Faux Leather Used in the Automotive Industry?

In the automotive sector, faux leather is increasingly favored for upholstery and interior trim due to its cost-effectiveness and design versatility. It allows manufacturers to create various aesthetics while reducing production costs. However, real leather remains the go-to choice for luxury vehicles, providing durability and a premium feel that appeals to high-end consumers. B2B buyers must consider climate adaptability, as materials must withstand diverse weather conditions in regions like Africa and Europe, and prioritize suppliers that offer sustainable sourcing options.

What are the Applications of Faux Leather in Fashion and Apparel?

In fashion and apparel, faux leather is popular for clothing, accessories, and footwear, especially among brands targeting eco-conscious consumers. It allows for innovative designs without the ethical concerns of animal products. Conversely, real leather enhances brand prestige and is often associated with durability and quality. International buyers should monitor regional trends, as preferences for materials can vary significantly across markets in South America and the Middle East, and ensure that suppliers comply with ethical sourcing standards.

Illustrative image related to faux leather vs real leather

Why Choose Faux Leather or Real Leather for Furniture?

When it comes to furniture, faux leather is appreciated for its ease of cleaning and maintenance, making it suitable for high-traffic areas. In contrast, real leather adds value and a classic aesthetic, appealing to consumers looking for long-lasting quality. B2B buyers need to evaluate the durability and maintenance requirements of materials, especially in climates that may affect leather performance. Understanding regional preferences can also guide sourcing decisions, ensuring that products meet local market demands.

How is Faux Leather Used in Home Decor?

Faux leather is utilized in home decor for wall coverings and decorative accents, providing a modern and versatile aesthetic. It is often easier to work with and maintain than real leather, making it an attractive option for contemporary designs. However, real leather offers a timeless appeal and can elevate the perceived value of a space. Buyers should consider the local climate’s impact on material performance and explore sustainable sourcing options to meet growing consumer demand for eco-friendly products.

What are the Benefits of Faux Leather in Sports Equipment?

In the sports industry, faux leather is commonly used in gear bags, protective gear, and sports apparel due to its lightweight and water-resistant properties. It allows manufacturers to produce affordable, functional equipment. However, real leather is preferred for its superior durability and performance, particularly in high-impact sports. B2B buyers must ensure compliance with safety standards and consider the specific weight and flexibility requirements for different sports to optimize product performance and appeal.

3 Common User Pain Points for ‘faux leather vs real leather’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Leather Procurement

The Problem:

B2B buyers in industries such as fashion, furniture, and automotive often face challenges in ensuring the quality and authenticity of leather products. With the rise of faux leather marketed as “vegan leather,” distinguishing between high-quality real leather and lower-quality synthetic alternatives can be daunting. Buyers may worry about receiving products that do not meet their specifications or that will not withstand the test of time, leading to potential reputational damage and financial loss.

Illustrative image related to faux leather vs real leather

The Solution:

To navigate this challenge, B2B buyers should establish rigorous quality assurance protocols. This includes working directly with reputable suppliers known for their transparency in sourcing and production practices. Request samples of both real and faux leather to evaluate their characteristics—look for the texture, smell, and durability. Additionally, consider conducting lab tests to verify the material composition. Establishing long-term relationships with trusted suppliers who can provide documentation and certifications about their materials can also mitigate risks associated with quality assurance. Investing in a small batch of products for initial testing can further ensure that the final selection aligns with the desired quality standards.

Scenario 2: Managing Sustainability Concerns in Leather Sourcing

The Problem:

As global awareness of environmental issues grows, B2B buyers are increasingly pressured to source materials that align with sustainability goals. The leather industry is often criticized for its environmental impact, particularly concerning water usage, chemical tanning processes, and animal welfare. Buyers may struggle to find sustainable options that do not compromise on quality or aesthetics, leading to potential backlash from consumers and stakeholders.

The Solution:

B2B buyers should prioritize sourcing leather from suppliers who practice sustainable farming and tanning methods. Look for certifications such as the Leather Working Group’s (LWG) audit, which assesses environmental practices and promotes responsible sourcing. Engage with suppliers who offer eco-friendly faux leather alternatives made from recycled materials or plant-based sources. Conduct thorough research into the lifecycle of materials and their environmental impact, and be transparent with customers about the sourcing practices used. By aligning procurement strategies with sustainability goals, buyers can enhance brand reputation while meeting market demands.

Scenario 3: Addressing Cost vs. Longevity in Leather Investments

The Problem:

B2B buyers often face the dilemma of balancing initial costs with the long-term value of leather products. Faux leather may be more affordable upfront, but it typically has a shorter lifespan, leading to more frequent replacements. Conversely, while real leather is a higher initial investment, its durability and timeless appeal can offer better value over time. Buyers may feel uncertain about which option will yield the best return on investment for their business.

Illustrative image related to faux leather vs real leather

The Solution:

To address this issue, buyers should conduct a total cost of ownership (TCO) analysis when evaluating leather options. This involves considering not just the purchase price but also the expected lifespan, maintenance costs, and potential for resale or recycling. Encourage suppliers to provide insights into the longevity of their products and any warranties they offer. For products that will see heavy use, investing in high-quality real leather can pay off in the long run, as it often requires less frequent replacement and can develop a desirable patina over time. Additionally, consider offering a range of options to customers, including both faux and real leather, to cater to varying budget considerations while also educating them on the long-term benefits of investing in higher-quality materials.

Strategic Material Selection Guide for faux leather vs real leather

What Are the Key Materials Used in Faux Leather and Real Leather?

When considering material selection for faux leather versus real leather, it is essential to analyze the commonly used materials, their properties, and their implications for various applications. This analysis will help B2B buyers make informed decisions tailored to their specific needs and regional considerations.

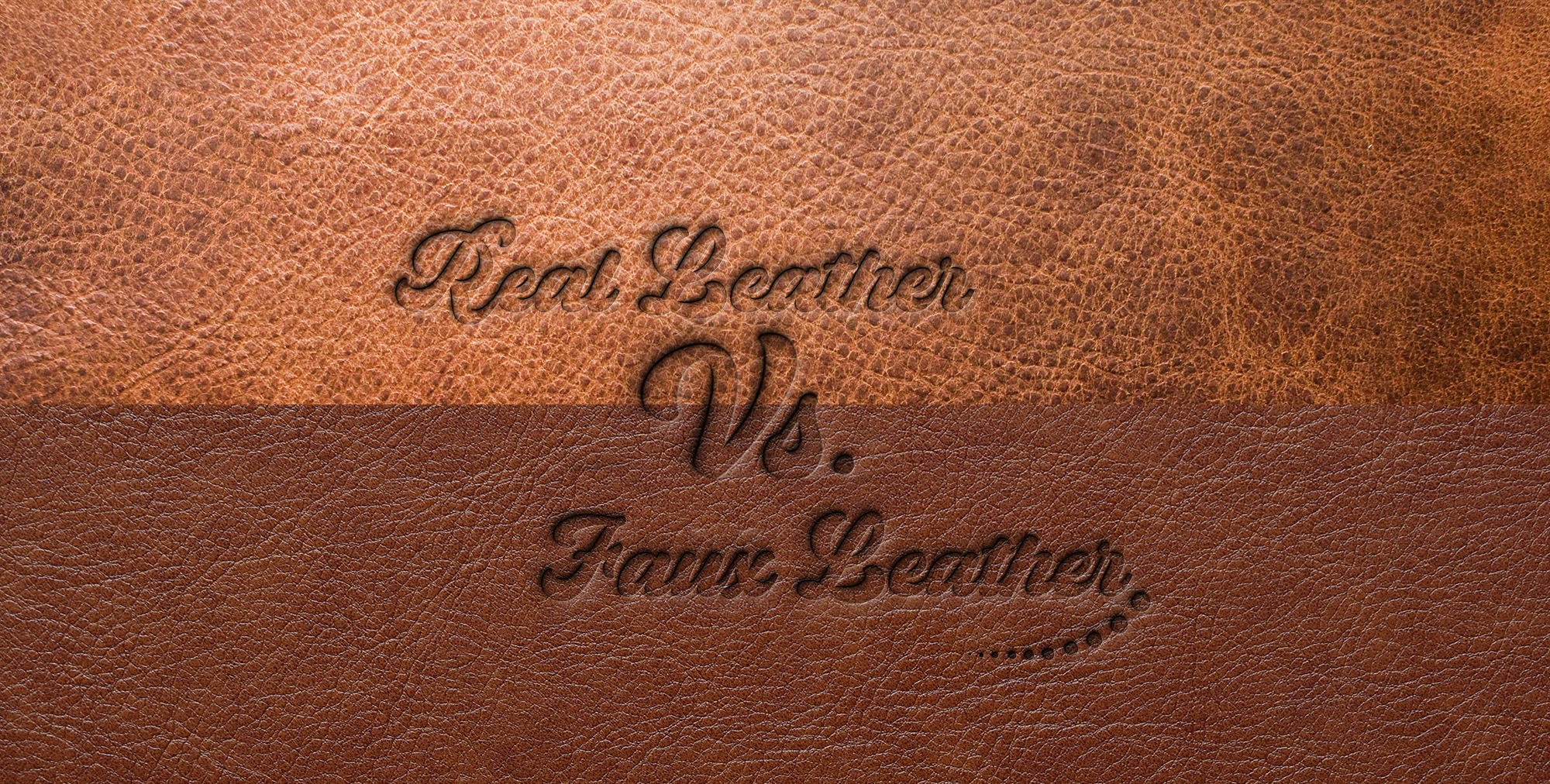

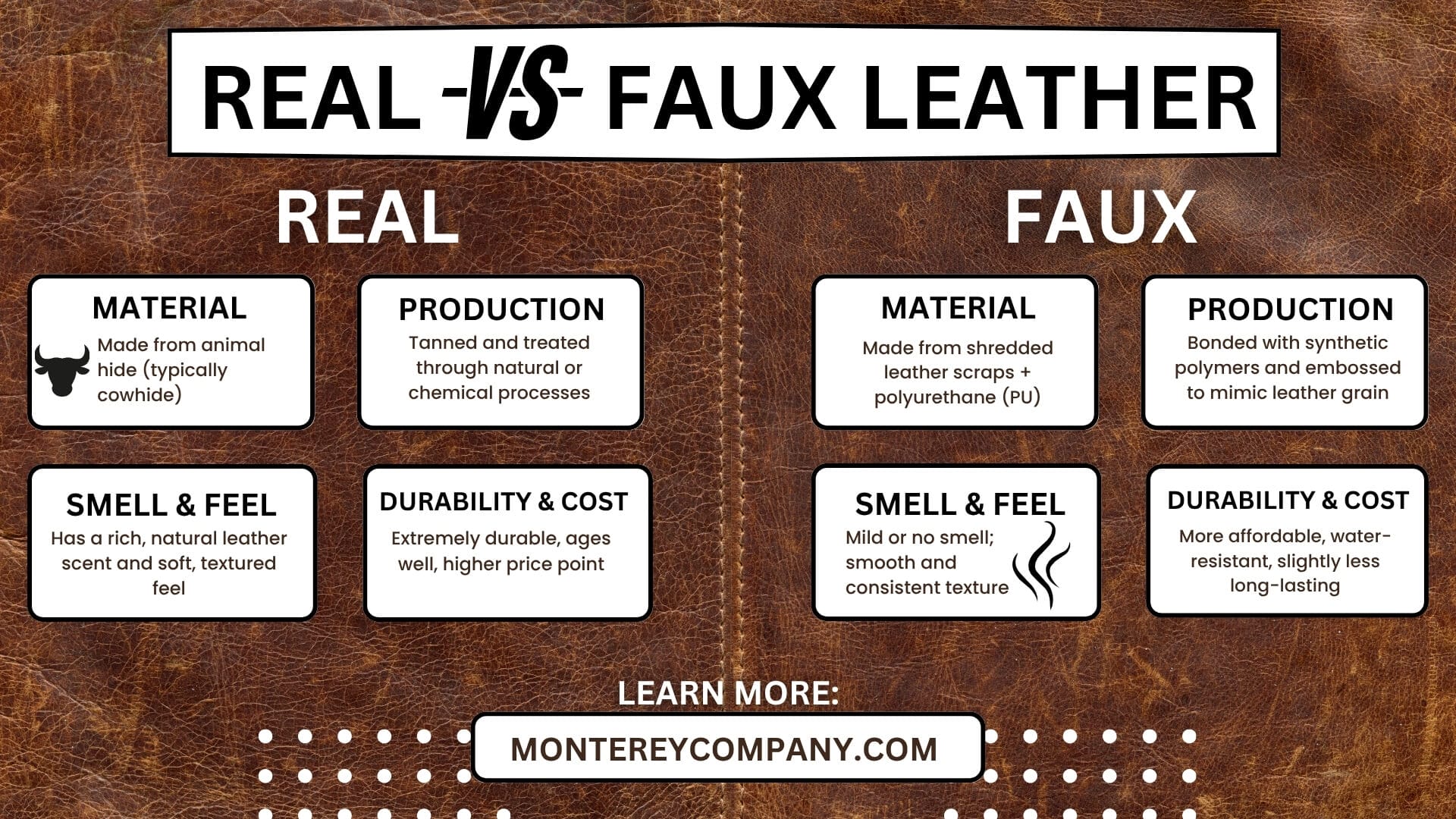

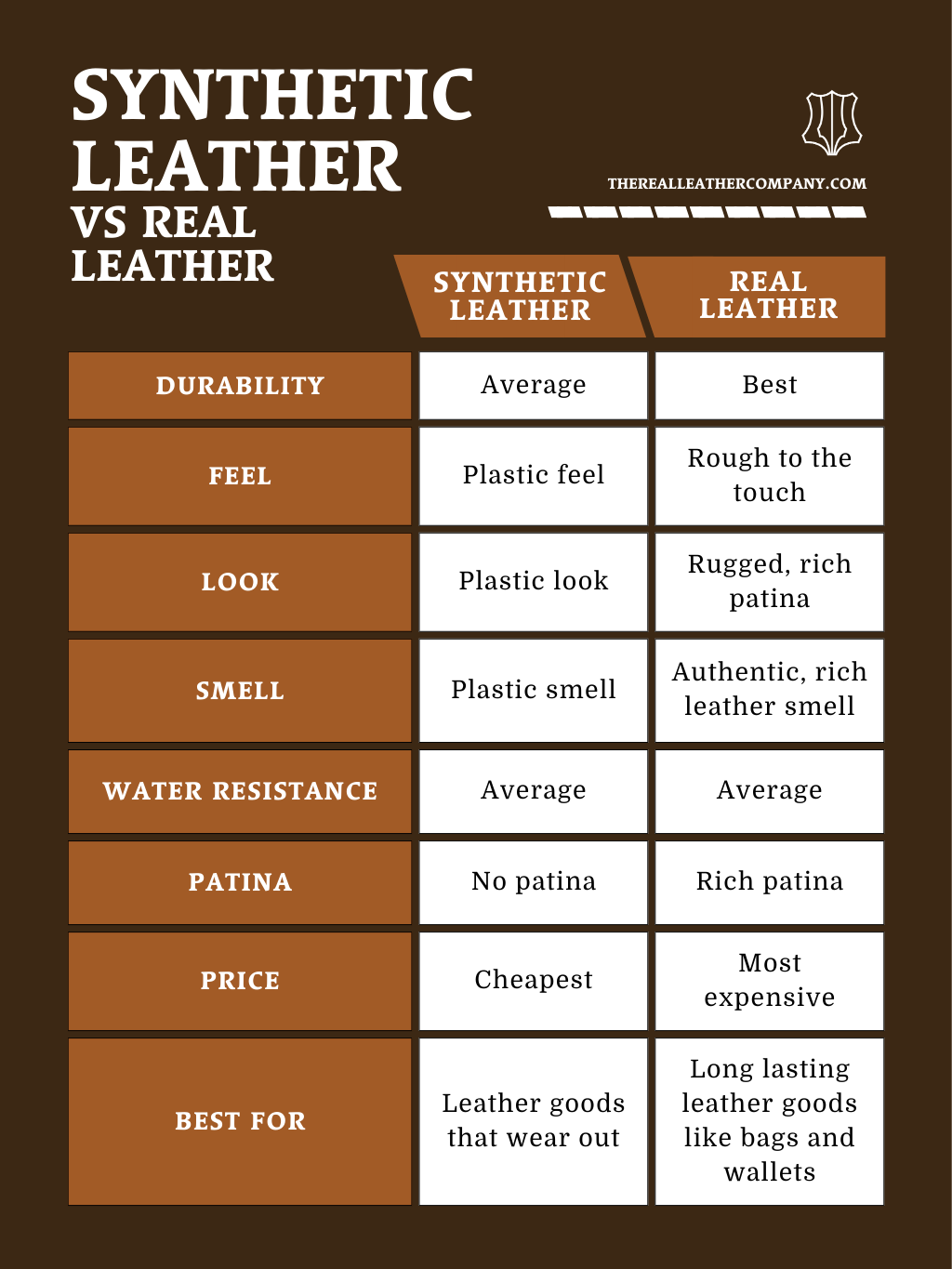

What Are the Key Properties of Real Leather?

Real leather is primarily derived from animal hides, predominantly from cows, goats, and sheep. Its key properties include:

Illustrative image related to faux leather vs real leather

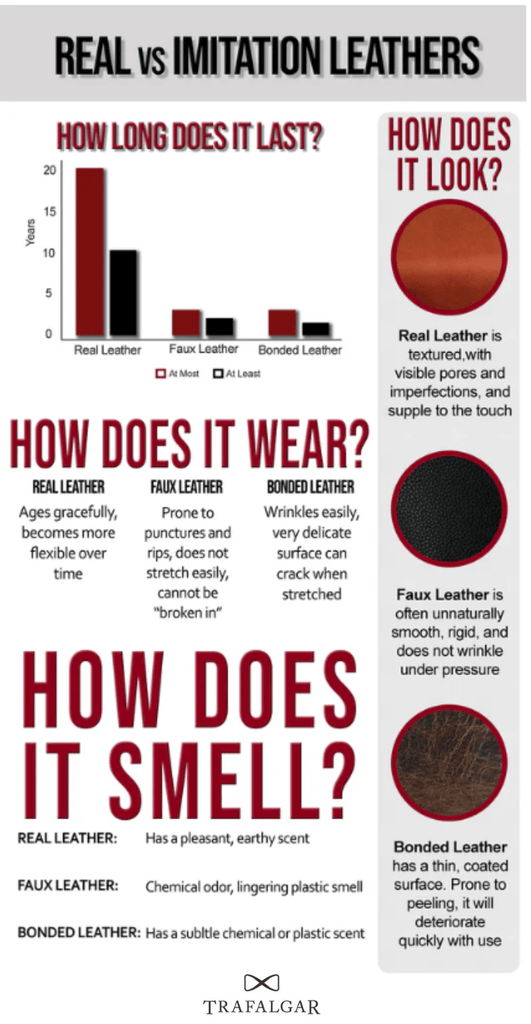

- Durability: Real leather is known for its exceptional longevity. When properly maintained, it can last for decades, developing a unique patina that enhances its aesthetic appeal.

- Breathability: It allows air circulation, making it comfortable for wearables and seating applications.

- Natural Insulation: Real leather has insulating properties, providing warmth in colder climates.

Pros: The primary advantages of real leather include its durability, luxurious feel, and ability to age beautifully. It is also biodegradable, making it a more sustainable option when sourced responsibly.

Cons: The main drawbacks are the higher cost and the need for regular maintenance to preserve its quality. Additionally, sourcing and processing can be complex due to animal welfare concerns and regulatory compliance.

How Does Faux Leather Compare in Terms of Key Properties?

Faux leather, often made from materials such as polyurethane (PU) or polyvinyl chloride (PVC), presents a different set of characteristics:

Illustrative image related to faux leather vs real leather

- Cost-Effectiveness: Generally, faux leather is more affordable than real leather, making it attractive for budget-conscious buyers.

- Uniform Appearance: Faux leather has a consistent texture and color, appealing for mass-produced items where uniformity is preferred.

- Water Resistance: Faux leather is typically more resistant to water and stains compared to real leather.

Pros: The primary advantages include lower cost, ease of cleaning, and no animal cruelty concerns. It is also available in a wider range of colors and finishes.

Cons: Faux leather is less durable and can wear out quickly, often developing cracks or peeling. Its production involves synthetic chemicals, which can have environmental implications.

What Are the Specific Considerations for International B2B Buyers?

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider several factors:

- Compliance with Standards: Different regions have varying regulations regarding material sourcing and environmental impact. For instance, European buyers may prioritize compliance with REACH regulations, while buyers in the Middle East may focus on local sustainability practices.

- Market Preferences: Cultural preferences can influence material choice. In regions with a strong tradition of leather craftsmanship, such as Germany, real leather may be preferred for high-end products, while markets in Africa may lean towards cost-effective alternatives.

- Supply Chain Dynamics: Buyers must evaluate the reliability of suppliers and the logistics of sourcing materials, especially for real leather, which may involve longer lead times due to sourcing and processing.

Summary Table of Material Properties

| Material | Typical Use Case for faux leather vs real leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Real Leather | High-end fashion, luxury goods, durable furniture | Exceptional durability and aesthetic | Higher cost and maintenance required | High |

| Faux Leather (PU) | Budget-friendly apparel, accessories, furniture | Cost-effective and easy to clean | Less durable, may wear out quickly | Low |

| Faux Leather (PVC) | Mass-produced items, fashion, upholstery | Water-resistant and uniform appearance | Environmental concerns in production | Low |

| Eco-Friendly Leather | Sustainable fashion, luxury goods | Biodegradable and sustainably sourced | Limited availability and higher cost | Medium |

This analysis provides a comprehensive overview of the critical materials used in faux leather and real leather, equipping B2B buyers with the insights necessary to make informed purchasing decisions. Understanding the properties, advantages, and limitations of each material will enable businesses to align their product offerings with market demands and compliance standards.

Illustrative image related to faux leather vs real leather

In-depth Look: Manufacturing Processes and Quality Assurance for faux leather vs real leather

What Are the Key Manufacturing Processes for Faux Leather and Real Leather?

The manufacturing processes for faux leather and real leather differ significantly, impacting not only the final product quality but also the overall sustainability and ethical considerations of each material. Understanding these processes is crucial for B2B buyers looking to source leather goods that meet their quality, environmental, and ethical standards.

What Are the Main Stages in Faux Leather Manufacturing?

-

Material Preparation: Faux leather is primarily made from synthetic materials like polyvinyl chloride (PVC) or polyurethane (PU). The manufacturing begins with the formulation of these plastics, which are combined with additives to enhance flexibility, durability, and color. This step is vital as it determines the material’s overall quality and performance.

-

Forming: The prepared material undergoes a process where it is extruded into sheets or coated onto a fabric backing. This process can vary in thickness and texture, allowing manufacturers to create a range of faux leather products. Techniques such as embossing can be applied to mimic the grain of real leather.

-

Assembly: Once the sheets are formed, they are cut and sewn into the desired shapes for products like handbags, jackets, or upholstery. Automated sewing machines are often employed to ensure uniformity and speed in production.

-

Finishing: The final step involves applying protective coatings or treatments to enhance the faux leather’s appearance and durability. This could include a topcoat for water resistance or treatments to improve UV stability.

What Are the Key Techniques in Real Leather Manufacturing?

-

Material Sourcing: Real leather starts with the selection of animal hides, commonly from cattle. Sourcing from sustainable farms is increasingly important, as it ensures ethical practices and quality materials.

-

Tanning: The hides are then tanned, a critical process that preserves the leather and enhances its durability. Traditional vegetable tanning is preferred by some manufacturers due to its environmentally friendly nature, while chrome tanning is faster but can have more significant environmental implications.

-

Forming and Cutting: After tanning, the leather is conditioned and cut into desired shapes. The cutting process must be precise, as each hide has natural imperfections that can affect the final product.

-

Assembly: Similar to faux leather, real leather products are assembled through stitching and bonding. However, the sewing techniques may differ as real leather requires specialized equipment to handle its thickness and texture.

-

Finishing: Real leather undergoes finishing processes that may include dyeing, polishing, and conditioning. These steps enhance the leather’s aesthetic qualities and provide protection against wear and tear.

How Is Quality Assurance Conducted in Faux Leather vs. Real Leather Manufacturing?

Quality assurance (QA) is a vital aspect of both faux and real leather manufacturing, ensuring products meet international standards and customer expectations.

What International Standards Are Relevant for Quality Assurance?

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to both faux and real leather manufacturers. Compliance with ISO 9001 indicates that a supplier consistently provides products that meet customer and regulatory requirements.

-

CE Marking: Particularly relevant for products sold within the European Union, CE marking indicates compliance with health, safety, and environmental protection standards. This is crucial for B2B buyers in Europe, as it ensures the products meet necessary regulations.

-

API Standards: For leather products used in specific industries, such as automotive or aerospace, adherence to API (American Petroleum Institute) standards may be required, especially for performance and safety.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival. For faux leather, this includes checking the consistency and quality of synthetic materials. For real leather, hides are assessed for defects, thickness, and grain quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks ensure that production parameters are met. This includes monitoring the tanning process for real leather and the extrusion or coating processes for faux leather.

-

Final Quality Control (FQC): Once products are completed, a final inspection assesses the overall quality, appearance, and functionality. This is crucial for identifying any defects before products reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensuring product reliability.

Illustrative image related to faux leather vs real leather

-

Audits and Reports: Buyers should request regular quality audits and reports from suppliers. These documents provide insights into the supplier’s quality management practices and adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. This is particularly useful for buyers unfamiliar with local manufacturing practices.

-

Certifications: Suppliers should provide documentation of their compliance with relevant international standards (e.g., ISO 9001, CE). These certifications serve as a verification of their commitment to quality.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers must navigate various cultural, regulatory, and logistical challenges when sourcing leather products internationally. Understanding local manufacturing practices and quality expectations is essential.

-

Cultural Differences: Different regions may have varying standards for quality and craftsmanship. Buyers should be aware of these differences to set realistic expectations and avoid misunderstandings.

-

Regulatory Compliance: Buyers should familiarize themselves with the specific regulations governing leather products in their target markets. This includes understanding import regulations, safety standards, and environmental considerations.

-

Logistics and Supply Chain Management: Effective communication with suppliers about quality expectations and shipping timelines is crucial. Buyers should also consider the impact of local infrastructure on product quality and delivery.

In conclusion, understanding the manufacturing processes and quality assurance practices for faux leather and real leather is crucial for international B2B buyers. By focusing on these aspects, buyers can make informed sourcing decisions that align with their quality standards and ethical considerations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather vs real leather’

Introduction

In the competitive landscape of materials sourcing, understanding the distinctions between faux leather and real leather is essential for B2B buyers. This guide provides a structured checklist for evaluating your options, ensuring you make informed decisions that align with your business needs, sustainability goals, and customer preferences.

Step 1: Define Your Technical Specifications

Establish clear technical specifications that outline the desired characteristics of the leather products you seek. This includes factors such as durability, texture, appearance, and environmental impact. By specifying these requirements upfront, you can streamline the sourcing process and avoid costly mismatches.

Step 2: Assess Market Demand and Trends

Investigate current market trends and consumer preferences in your target regions. Understanding whether your clientele favors real leather for its authenticity or faux leather for ethical considerations will guide your sourcing strategy. Utilize market research reports and consumer surveys to gather relevant data.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request detailed company profiles, product samples, and references from buyers in similar industries. Look for suppliers with a proven track record and transparent business practices to ensure reliability and quality.

- Supplier certifications: Verify if the supplier holds relevant certifications (e.g., ISO, environmental standards) that indicate adherence to industry best practices.

- Production capabilities: Inquire about their production capacity, lead times, and flexibility to accommodate your specific order sizes and customization requests.

Step 4: Conduct Material Tests

Request samples of both faux leather and real leather to conduct material tests. Evaluate their physical characteristics, including texture, odor, and durability. This hands-on assessment allows you to compare how each material aligns with your specifications and customer expectations.

- Durability tests: Check for wear resistance, flexibility, and how the material ages over time.

- Environmental impact assessment: Understand the sourcing and production processes to gauge the sustainability of the materials.

Step 5: Review Pricing and Total Cost of Ownership

Analyze the pricing structures of both faux leather and real leather options. While faux leather may appear cheaper initially, consider the total cost of ownership, including longevity and maintenance costs. Real leather often lasts longer and may provide better value over time.

Illustrative image related to faux leather vs real leather

- Long-term value: Factor in potential replacement costs for faux leather products, which may wear out faster than their real leather counterparts.

- Bulk purchase discounts: Negotiate for bulk pricing to maximize cost efficiency.

Step 6: Understand Legal and Ethical Considerations

Stay informed about the legal and ethical aspects of sourcing leather materials, particularly in the regions you operate. This includes compliance with animal welfare regulations, environmental laws, and trade agreements. Ethical sourcing is increasingly important to consumers and can affect brand reputation.

- Traceability: Ensure the supplier can trace the origin of their materials, particularly for real leather, to verify ethical sourcing practices.

- Sustainability initiatives: Seek suppliers actively engaged in sustainable practices to align with modern consumer values.

Step 7: Finalize Supplier Agreements

Once you’ve assessed all factors, finalize your agreements with the selected suppliers. Ensure that contracts clearly outline terms of delivery, quality assurance, and compliance with your specifications. A well-defined agreement protects your interests and fosters a strong supplier relationship.

By following this checklist, you can navigate the complexities of sourcing faux leather and real leather, ensuring that your choices meet both market demands and your business objectives.

Illustrative image related to faux leather vs real leather

Comprehensive Cost and Pricing Analysis for faux leather vs real leather Sourcing

What Are the Key Cost Components in Sourcing Faux Leather vs Real Leather?

When evaluating the costs associated with sourcing faux leather versus real leather, several components must be considered.

-

Materials: The primary cost component varies significantly between the two materials. Real leather, sourced from animal hides, incurs higher raw material costs due to the need for sustainable sourcing and quality control. Faux leather, primarily made from synthetic materials like PVC or polyurethane, tends to have lower material costs, but these can fluctuate based on the quality and type of synthetic used.

-

Labor: Labor costs can differ based on the complexity of production. Real leather production often requires skilled labor for tanning and crafting, contributing to higher labor costs. In contrast, the manufacturing of faux leather can be more automated, potentially lowering labor costs but also impacting quality.

-

Manufacturing Overhead: The overhead costs associated with real leather production are generally higher due to the need for specialized equipment and facilities that can handle the tanning process. Faux leather manufacturing may have lower overhead, but the quality assurance processes for synthetic materials can add to costs.

-

Tooling: The tooling costs can vary depending on the complexity of the designs. Real leather may require more intricate tooling for unique patterns and textures, while faux leather can be produced with simpler molds, affecting initial setup costs.

-

Quality Control (QC): Both materials require rigorous quality control, but the standards may differ. Real leather requires checks for natural imperfections, while faux leather focuses on uniformity and durability. QC costs should be factored into the overall pricing strategy.

-

Logistics: Shipping costs can be influenced by the weight and volume of the materials. Real leather is typically heavier, leading to higher logistics costs. Furthermore, international shipping regulations may vary for animal products, impacting the overall cost structure.

-

Margin: Profit margins can differ significantly between the two. Real leather products often command a higher price point due to perceived value, while faux leather typically has lower margins but can attract higher volume sales.

What Price Influencers Should B2B Buyers Consider?

When sourcing either material, several price influencers come into play:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders, so understanding the MOQ can lead to cost savings.

-

Specifications and Customization: Custom designs and specific material requirements can influence pricing. Real leather customization can be more costly due to the labor-intensive processes involved.

-

Quality and Certifications: Certifications for sustainability and quality can affect the pricing of both materials. Real leather may come with certifications that justify higher costs, while faux leather products may need certifications to verify their quality.

-

Supplier Factors: Reliability, reputation, and geographic location of suppliers can impact pricing. Suppliers in regions with established leather industries may offer better prices for real leather due to lower logistics costs.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they dictate the responsibilities of buyers and sellers in shipping costs, risk, and insurance, impacting the total cost.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

-

Negotiation: Always negotiate terms with suppliers. Many suppliers expect negotiation and may offer better pricing, especially for larger orders or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront costs. Real leather may have a higher initial price but can last significantly longer, offering better value over time.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should consider currency fluctuations, import tariffs, and local market conditions when sourcing. Understanding these nuances can lead to better pricing strategies and supplier selection.

-

Disclaimer on Indicative Prices: Keep in mind that prices can fluctuate based on market conditions, availability, and supplier pricing strategies. Always request updated quotes before making sourcing decisions.

By considering these elements, B2B buyers can make more informed decisions regarding the sourcing of faux leather versus real leather, ensuring they align quality, cost, and sustainability with their business objectives.

Alternatives Analysis: Comparing faux leather vs real leather With Other Solutions

In the competitive landscape of materials for products such as furniture, fashion, and accessories, businesses must consider various alternatives to faux leather and real leather. While both options have their merits, exploring alternative solutions can help buyers identify the most suitable choice based on performance, cost, and sustainability. This analysis will compare faux leather and real leather against two viable alternatives: recycled materials and plant-based leathers.

| Comparison Aspect | Faux Leather Vs Real Leather | Recycled Materials | Plant-Based Leathers |

|---|---|---|---|

| Performance | Moderate durability, less breathable than real leather; prone to wear. | Varies by material; can be durable if sourced from high-quality recyclables. | Good durability; breathable and often water-resistant, but can vary widely in quality. |

| Cost | Generally lower than real leather, but may require more frequent replacement. | Cost-effective if sourced properly; can be lower than both types of leather. | Often more expensive than faux leather due to production processes, but competitive with real leather. |

| Ease of Implementation | Easy to source and manufacture; widely available. | Varies; may require specialized sourcing and processing. | Emerging market, so availability may vary; requires education on benefits. |

| Maintenance | Easy to clean but may not age well; limited lifespan. | Maintenance depends on material; often easy to clean. | Requires care similar to real leather, but can be more forgiving than faux leather. |

| Best Use Case | Fashion items, low-cost furniture. | Eco-friendly products, bags, and accessories. | High-end fashion, eco-conscious brands looking for sustainable options. |

What Are the Pros and Cons of Recycled Materials as an Alternative to Faux and Real Leather?

Recycled materials, such as plastics or textiles repurposed into new products, offer a sustainable alternative to both faux and real leather. The primary advantage is their environmental impact; utilizing recycled materials reduces waste and can lower the carbon footprint associated with production. However, the performance can vary significantly based on the quality of the source material. While high-quality recycled products can be durable and aesthetically pleasing, lower-quality options may not hold up well over time, leading to potential dissatisfaction among consumers.

How Do Plant-Based Leathers Compare to Faux and Real Leather?

Plant-based leathers, derived from materials like pineapple leaves, apple peels, or cork, present a compelling alternative for eco-conscious brands. These materials often boast good durability and a unique aesthetic appeal that can attract environmentally minded consumers. However, they can be more expensive than both faux and real leather, which may deter budget-conscious buyers. Additionally, the market for plant-based leathers is still evolving, meaning availability can be inconsistent, and education on their benefits is necessary for buyers to make informed decisions.

Conclusion: How Can B2B Buyers Choose the Right Leather Alternative?

When choosing between faux leather, real leather, and alternative solutions, B2B buyers should carefully evaluate their specific needs, including product application, target market, and budget constraints. Understanding the performance characteristics, cost implications, and maintenance requirements of each option will help businesses make informed decisions. Ultimately, selecting the right material is crucial for aligning with brand values, meeting customer expectations, and achieving sustainability goals. By analyzing all available options, businesses can position themselves competitively in their respective markets.

Essential Technical Properties and Trade Terminology for faux leather vs real leather

When navigating the complexities of sourcing materials for products, understanding the essential technical properties and industry terminology related to faux leather and real leather is crucial. This knowledge not only aids in making informed purchasing decisions but also enhances negotiations with suppliers.

Illustrative image related to faux leather vs real leather

What Are the Key Technical Properties of Faux Leather vs Real Leather?

-

Material Composition

– Real Leather: Sourced from animal hides, primarily from cattle, sheep, or goats. The type of hide and its treatment can significantly impact the leather’s quality and durability.

– Faux Leather: Typically made from synthetic materials such as polyurethane (PU) or polyvinyl chloride (PVC). The composition affects its environmental impact and lifespan. -

Durability and Longevity

– Real Leather: Known for its exceptional durability, real leather can last decades with proper care. It develops a unique patina over time, adding to its aesthetic appeal and value.

– Faux Leather: Generally less durable, faux leather may only last a few years before showing signs of wear. While it requires less maintenance, its lifespan is limited compared to genuine leather. -

Environmental Impact

– Real Leather: When sourced sustainably, real leather can be less harmful to the environment than synthetic alternatives. It is biodegradable and often utilizes by-products from the meat industry.

– Faux Leather: The production process for faux leather can have significant environmental repercussions, particularly due to the chemicals used in its manufacturing. However, it does not involve animal products, appealing to certain markets. -

Aesthetic and Sensory Properties

– Real Leather: Offers a unique texture, smell, and appearance that cannot be replicated. Its natural imperfections are often seen as desirable characteristics.

– Faux Leather: Features a uniform texture and may lack the depth and character of real leather. It often emits a synthetic smell, which can deter some consumers. -

Cost and Market Positioning

– Real Leather: Typically commands a higher price point due to its quality and longevity. It is often positioned as a premium product in the market.

– Faux Leather: Generally more affordable, making it accessible to a broader consumer base. This can be advantageous for businesses targeting budget-conscious markets.

What Trade Terminology Should B2B Buyers Know in the Leather Industry?

-

OEM (Original Equipment Manufacturer)

– Refers to companies that manufacture products based on specifications provided by another company. In leather sourcing, understanding OEM can help buyers identify manufacturers who can produce custom leather goods. -

MOQ (Minimum Order Quantity)

– The smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially when sourcing materials like leather. -

RFQ (Request for Quotation)

– A document sent to suppliers requesting pricing for specific products or materials. An RFQ is vital for comparing costs and establishing supplier relationships in the leather market. -

Incoterms (International Commercial Terms)

– A set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can clarify shipping costs and delivery responsibilities when importing leather products. -

Tannage

– The process of treating animal hides to produce leather. This term is crucial for buyers to understand as different tanning methods (chrome vs. vegetable tanning) can significantly affect the leather’s characteristics and environmental impact. -

Grain

– Refers to the surface texture of leather, which can be classified as full-grain, top-grain, or corrected-grain. Understanding the differences helps buyers select the right type of leather for their products based on quality and performance requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing materials, ensuring they meet both market demands and sustainability goals.

Navigating Market Dynamics and Sourcing Trends in the faux leather vs real leather Sector

What Are the Current Market Dynamics and Trends in the Faux Leather vs Real Leather Sector?

The global market for faux leather and real leather has been experiencing significant transformation, influenced by various factors including consumer preferences, technological advancements, and environmental concerns. One of the primary drivers is the increasing demand for sustainable and ethically sourced materials. In regions such as Africa, South America, the Middle East, and Europe, B2B buyers are increasingly prioritizing suppliers who can demonstrate sustainable practices, especially as consumers become more eco-conscious. The rise of “vegan leather” has also led to a surge in faux leather production, with innovations in materials such as bio-based polyurethanes and recycled plastics, appealing particularly to younger demographics.

Current B2B sourcing trends indicate a shift towards transparency and traceability in the supply chain. International buyers are seeking detailed information about the origin of materials, production processes, and the overall environmental impact. For instance, in Europe, stringent regulations on waste and emissions are pushing companies to adopt cleaner production methods. Similarly, in markets like Vietnam, the emphasis on quality and durability is shaping sourcing strategies, with buyers favoring suppliers who can provide high-quality, long-lasting products—often associated with real leather.

Emerging technologies such as 3D printing and AI-driven design are also revolutionizing product development in both sectors. These innovations allow for rapid prototyping and customization, catering to the unique preferences of diverse markets. As a result, B2B buyers are encouraged to stay informed about technological trends that could enhance their product offerings and operational efficiency.

How Is Sustainability Influencing Sourcing Decisions in the Leather Industry?

Sustainability has become a cornerstone of sourcing strategies in the leather industry, influencing decisions significantly among B2B buyers. The environmental impact of production processes, particularly in the tanning of real leather and the manufacturing of faux alternatives, is under increasing scrutiny. Real leather, when sourced from sustainable ranches and processed using environmentally friendly methods, can have a lower overall ecological footprint compared to conventional faux leather, which often relies on petroleum-based materials like PVC and polyurethane.

Illustrative image related to faux leather vs real leather

Moreover, the market is witnessing a rise in certifications that validate the sustainability claims of leather products. For example, the Leather Working Group (LWG) certification assesses the environmental compliance and performance of leather manufacturers, while the Global Organic Textile Standard (GOTS) applies to organic textiles, including some faux leather options. B2B buyers are increasingly seeking suppliers with these certifications as part of their commitment to ethical sourcing and reducing their carbon footprint.

The demand for transparency in supply chains is also growing, with buyers favoring suppliers who can provide verifiable data regarding their sourcing practices. This trend not only helps mitigate risks associated with unethical practices but also enhances brand reputation in a market that values corporate responsibility.

How Has the Faux Leather vs Real Leather Landscape Evolved Over Time?

The faux leather vs real leather landscape has evolved considerably over the decades, driven by technological advancements and shifting consumer attitudes. Initially, faux leather was regarded as a low-cost alternative, often criticized for its lack of durability and aesthetic appeal compared to real leather. However, significant improvements in manufacturing processes have led to the development of high-quality faux leather that closely mimics the look and feel of genuine leather. This transformation has been particularly appealing to environmentally conscious consumers and the growing vegan demographic.

Historically, the leather industry was largely dominated by real leather products, valued for their durability and luxury status. However, as awareness of animal welfare and environmental issues increased, the market began to diversify. The introduction of innovative materials and production techniques has allowed faux leather to emerge as a viable competitor, offering a range of options from budget-friendly to premium products.

Illustrative image related to faux leather vs real leather

As we move forward, the competition between faux and real leather will likely intensify, influenced by ongoing advancements in material science and consumer preferences for sustainability. International B2B buyers must navigate this evolving landscape with an understanding of the benefits and challenges associated with each option, ensuring that their sourcing strategies align with market demands and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of faux leather vs real leather

-

1. How do I choose between faux leather and real leather for my products?

Choosing between faux leather and real leather involves considering your target market, product longevity, and environmental impact. Faux leather is typically less expensive and offers a uniform look, making it suitable for budget-conscious consumers. However, real leather provides durability and a unique aesthetic that can enhance perceived value. Assess your customer preferences and brand positioning to make an informed decision. Additionally, consider the sourcing and production practices of your suppliers to align with your sustainability goals. -

2. What are the key quality indicators to look for in leather products?

When sourcing leather products, key quality indicators include the type of leather (full-grain, top-grain, etc.), stitching quality, and finishing techniques. Full-grain leather, for instance, is the most durable and ages beautifully, making it a premium choice. Inspect samples for blemishes, which can indicate authenticity in real leather, and ensure consistent stitching without loose threads. Request certifications that demonstrate the leather’s origin and tanning process to ensure compliance with international standards. -

3. How do I verify the authenticity of leather from suppliers?

To verify leather authenticity, request certification documents from your suppliers that detail the leather’s origin and tanning methods. Conduct physical inspections of samples, looking for natural imperfections typical of real leather, such as pores and variations in texture. Consider employing third-party testing services that specialize in material verification. Establishing long-term relationships with reputable suppliers can also provide confidence in the authenticity of the products you receive. -

4. What are the minimum order quantities (MOQs) for faux leather and real leather?

Minimum order quantities (MOQs) can vary significantly between faux and real leather suppliers. Faux leather manufacturers often have lower MOQs due to lower production costs and faster turnaround times. In contrast, real leather suppliers may require higher MOQs, especially for premium grades, due to the costs associated with sourcing and processing animal hides. It’s essential to discuss your specific needs with potential suppliers to negotiate MOQs that fit your business model and budget. -

5. What payment terms should I expect when sourcing leather?

Payment terms can vary widely among suppliers and depend on factors such as order size and established relationships. Common terms include a deposit (typically 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may offer credit terms after establishing a reliable payment history. It’s crucial to clarify payment methods accepted (e.g., bank transfer, letter of credit) and ensure that all terms are documented in the purchase agreement to avoid disputes. -

6. How can I customize faux leather or real leather products?

Customization options for leather products often include choice of color, texture, and design elements like embossing or stitching patterns. When working with suppliers, provide clear specifications and design files to facilitate the customization process. Discuss lead times for custom orders, as these may vary based on the complexity of the design and the supplier’s capabilities. Request samples of customizations before finalizing larger orders to ensure they meet your expectations. -

7. What logistics considerations should I keep in mind when sourcing leather internationally?

Logistics for international leather sourcing involve understanding shipping regulations, customs duties, and import/export restrictions specific to leather goods. Ensure your suppliers are knowledgeable about the necessary documentation required for international shipments, such as certificates of origin and compliance with local regulations. Consider working with logistics providers who specialize in handling leather products to navigate any potential complications efficiently. Additionally, factor in lead times to manage inventory effectively. -

8. How do I ensure quality assurance (QA) for leather products upon delivery?

Implement a robust quality assurance (QA) process by establishing clear inspection criteria before placing orders. Upon delivery, inspect samples for consistency with agreed specifications, including color, texture, and craftsmanship. Conduct random sampling for larger shipments to assess overall quality. If possible, consider third-party QA inspections to provide an unbiased evaluation of the products. Establish a clear return policy with your suppliers to address any discrepancies or defects promptly.

Top 5 Faux Leather Vs Real Leather Manufacturers & Suppliers List

1. Buffalo Jackson – Real Leather Goods

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Real leather is made from animal hides (buffalo or cattle) and has a natural, imperfect surface with a distinctive smell. It is durable, improves with use, and develops character over time. Faux leather is made from PVC or polyurethane, has a uniform surface, feels cold and even, and has a plasticky smell. It is not as durable as real leather.

2. Reddit – Pure vs Vegan Leather

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion highlights the differences between pure leather and vegan/faux leather in terms of quality, durability, and care. Key points include:

1. Vegan leather is often made from plastic, while pure leather is a natural material.

2. Pure leather is considered more environmentally friendly in the long run and lasts significantly longer if properly cared for.

3. Vegan leather may be easier …

3. Real Leather – Durable Animal Hides

Domain: realeather.com

Registered: 2005 (20 years)

Introduction: Real leather is a durable material made from animal hides, primarily as a byproduct of the meat industry, and is considered more environmentally friendly due to its longevity and recycling aspect. There are two main types of leather: 1) Vegetable-Tanned Leather, which is made using natural tannins and takes up to two months to produce, valued for its firmness and natural tan color, commonly used i…

4. Is It Leather – Key Identification Guide

Domain: isitleather.com

Registered: 2021 (4 years)

Introduction: Real leather is made from animal hides and may be labeled as “genuine leather” or “real leather,” while fake leather may use terms like “faux leather,” “vegan leather,” “PU leather,” and others. Key tests to identify real leather include: 1. Inspecting the tag for authenticity. 2. Feeling the surface, where real leather feels bumpy and thick, while fake leather feels stiff and cold. 3. Conducting …

5. Overlook Boots – Breathable Faux Leather

Domain: overlookboots.com

Registered: 2014 (11 years)

Introduction: This company, Overlook Boots – Breathable Faux Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for faux leather vs real leather

What Are the Key Takeaways for B2B Buyers Considering Faux Leather vs. Real Leather?

In the evolving landscape of faux leather and real leather, strategic sourcing decisions are critical for B2B buyers. Real leather offers unmatched durability and a unique aesthetic that can enhance brand perception and customer loyalty, particularly in high-end markets. Its longevity can lead to lower total cost of ownership, making it a viable investment for businesses. Conversely, faux leather, often marketed as a sustainable alternative, appeals to environmentally-conscious consumers but typically lacks the longevity and premium feel of genuine leather.

How Can International Buyers Navigate the Faux Leather vs. Real Leather Market?

As international buyers from regions such as Africa, South America, the Middle East, and Europe assess their sourcing strategies, it is essential to evaluate the specific needs of your target market. Consider factors such as environmental impact, consumer preferences, and product lifecycle costs. Engaging with suppliers who prioritize sustainable practices and high-quality materials can enhance your competitive edge.

Illustrative image related to faux leather vs real leather

What’s Next for Your Sourcing Strategy?

Looking ahead, the faux leather industry is poised for continued innovation, while real leather remains a staple for luxury and durability. By aligning your sourcing strategies with market trends and consumer demands, you can effectively position your business for success. Explore partnerships with reputable suppliers to stay ahead in this dynamic market, and seize the opportunity to meet the diverse needs of your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to faux leather vs real leather