Introduction: Navigating the Global Market for custom leather fire shields

Navigating the global market for custom leather fire shields presents a unique challenge for B2B buyers seeking quality, durability, and brand identity in their firefighting gear. As the demand for personalized firefighting equipment grows, sourcing custom leather fire shields that meet specific requirements can be daunting, especially when considering factors like supplier reliability, material quality, and compliance with local regulations. This guide aims to demystify the complexities of purchasing custom leather fire shields, providing a comprehensive overview of available types, applications, and the nuances of supplier vetting.

In the following sections, we will explore the various styles of custom leather fire shields, their applications within different firefighting contexts, and critical aspects of cost analysis. Additionally, we will offer insights into best practices for evaluating suppliers, ensuring that international buyers—particularly those from regions such as Africa, South America, the Middle East, and Europe, including Germany and Nigeria—can make informed purchasing decisions. By equipping you with actionable information, this guide empowers your organization to invest wisely in custom leather fire shields that not only enhance operational efficiency but also foster a sense of pride and identity among your firefighting teams.

Table Of Contents

- Top 8 Custom Leather Fire Shields Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather fire shields

- Understanding custom leather fire shields Types and Variations

- Key Industrial Applications of custom leather fire shields

- 3 Common User Pain Points for ‘custom leather fire shields’ & Their Solutions

- Strategic Material Selection Guide for custom leather fire shields

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire shields

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire shields’

- Comprehensive Cost and Pricing Analysis for custom leather fire shields Sourcing

- Alternatives Analysis: Comparing custom leather fire shields With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather fire shields

- Navigating Market Dynamics and Sourcing Trends in the custom leather fire shields Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire shields

- Strategic Sourcing Conclusion and Outlook for custom leather fire shields

- Important Disclaimer & Terms of Use

Understanding custom leather fire shields Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Issue Helmet Shields | Classic design, often featuring department insignia and rank. | Fire departments looking for uniformity. | Pros: Cost-effective; easily recognizable. Cons: Limited customization options. |

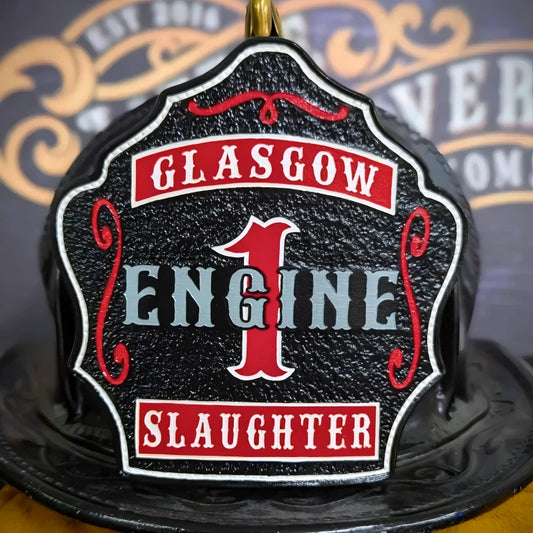

| Maltese Leather Shields | Iconic Maltese cross design, symbolizing firefighting tradition. | Departments wanting to highlight heritage. | Pros: Strong visual identity; traditional appeal. Cons: May not suit modern aesthetics. |

| Custom Full Shields | Fully personalized designs based on client specifications. | Specialized departments seeking unique branding. | Pros: Complete customization; reflects department identity. Cons: Higher cost; longer lead times. |

| Passport Inserts | Flexible inserts for quick changes, allowing for easy updates. | Departments with changing personnel or roles. | Pros: Versatile; cost-effective for updates. Cons: May lack durability compared to full shields. |

| Bugle Shields | Distinctive design for command presence, often used by officers. | Command staff in need of recognition. | Pros: Enhances authority; clear identification. Cons: Higher price point; may not appeal to all ranks. |

What Are the Characteristics of Standard Issue Helmet Shields?

Standard Issue Helmet Shields are designed for functionality and uniformity, typically featuring department insignia, rank, and other identifying information. These shields are commonly used by fire departments that prioritize a cohesive look across their teams. While they are cost-effective and easily recognizable, they offer limited customization options, which may not meet the needs of departments looking to express unique identities or branding.

How Do Maltese Leather Shields Stand Out in the Market?

The Maltese Leather Shields are characterized by their iconic Maltese cross design, which holds significant meaning in firefighting culture. These shields are particularly appealing to departments that wish to emphasize their heritage and commitment to tradition. While they provide a strong visual identity, the traditional aesthetic may not align with modern design preferences for all departments.

Why Choose Custom Full Shields for Unique Branding?

Custom Full Shields are tailored to the specific requirements of a fire department, allowing for complete personalization in design, layout, and materials. This option is ideal for specialized departments aiming to establish a unique brand identity. However, buyers should be prepared for higher costs and longer lead times, as each shield is made to order.

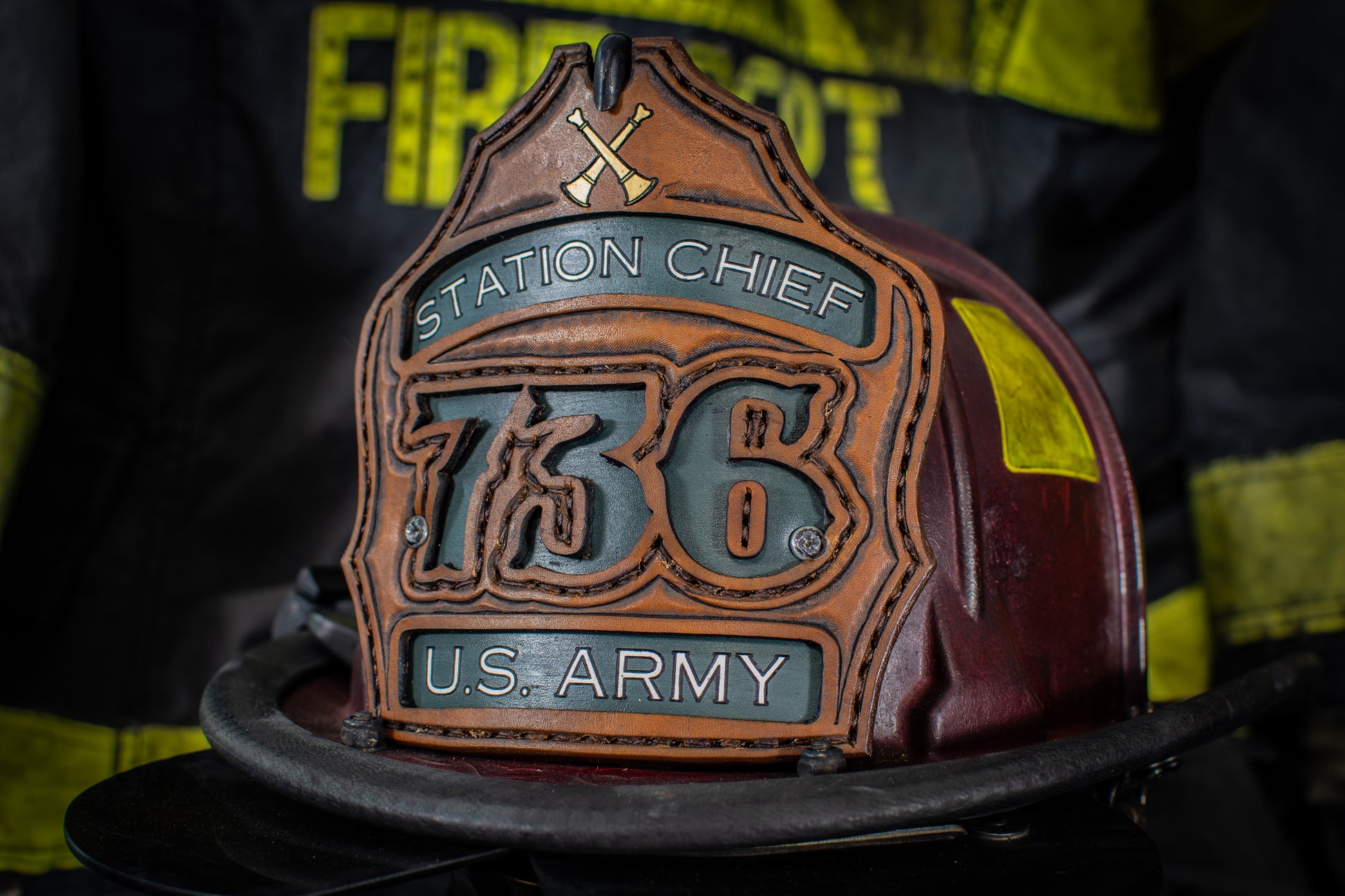

Illustrative image related to custom leather fire shields

What Are the Advantages of Using Passport Inserts?

Passport Inserts offer a flexible solution for departments that frequently update personnel or roles. These inserts can be easily swapped out, making them a practical choice for organizations that value adaptability without sacrificing visual clarity. While they are cost-effective for ongoing updates, they may not offer the same level of durability as more traditional full shields.

In What Situations Are Bugle Shields Most Effective?

Bugle Shields are specifically designed for command staff, featuring designs that denote authority and rank. These shields enhance the command presence during operations and are an essential tool for leaders in the field. However, they come at a higher price point and may not appeal to all ranks within the department, making them a more specialized purchase.

Key Industrial Applications of custom leather fire shields

| Industry/Sector | Specific Application of Custom Leather Fire Shields | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Firefighting Services | Identification and personalization of firefighter helmets | Enhances crew identity and morale while ensuring clarity in emergency situations | Customization options, durability, lead time for delivery |

| Industrial Safety | Protective gear for industrial firefighting teams | Provides clear identification during emergencies, aiding in quick response and safety | Compliance with safety regulations, bulk purchasing options |

| Oil & Gas Sector | Custom shields for specialized firefighting units in oil fields | Improves operational efficiency and safety in high-risk environments | Resistance to extreme heat and chemicals, customization capabilities |

| Emergency Response Units | Helmets for paramedics and rescue teams | Enhances visibility and recognition in critical situations, fostering teamwork | Lightweight materials, ease of customization, durability |

| Military and Defense | Custom shields for military firefighting units | Promotes unit cohesion and provides essential identification in the field | Custom designs, durability against harsh conditions, lead time for orders |

How Are Custom Leather Fire Shields Used in Firefighting Services?

In firefighting services, custom leather fire shields are primarily used for personalizing helmets, allowing for easy identification of ranks and units. This personalization fosters a sense of pride and unity among team members, which can be crucial during high-stress situations. B2B buyers in this sector should focus on sourcing options that offer extensive customization, ensuring that designs meet the specific needs of their department while maintaining durability against heat and smoke.

What Role Do Custom Leather Fire Shields Play in Industrial Safety?

In the industrial safety sector, custom leather fire shields serve as essential identification tools for firefighting teams. These shields help distinguish personnel in emergency scenarios, improving overall safety and response times. Businesses should prioritize sourcing durable materials that can withstand harsh conditions, as well as consider bulk purchasing options to maintain uniformity across their teams. Compliance with safety regulations is also critical, ensuring that the shields meet industry standards.

Why Are Custom Shields Important in the Oil & Gas Sector?

The oil and gas sector often faces unique firefighting challenges due to the volatile nature of the environment. Custom leather fire shields are designed for specialized firefighting units, providing clear identification and enhancing operational efficiency. B2B buyers in this industry must ensure that the shields are resistant to extreme heat and chemicals, as well as customizable to reflect the specific requirements of their teams. This tailored approach not only improves safety but also boosts team morale.

How Do Emergency Response Units Benefit from Custom Leather Fire Shields?

For emergency response units, custom leather fire shields are vital for enhancing visibility and recognition among team members. These shields help coordinate efforts during critical rescue operations, fostering teamwork and collaboration. Buyers in this sector should look for lightweight options that still offer robust durability, ensuring that shields can withstand the rigors of emergency situations while being comfortable for wear.

What Are the Advantages of Custom Shields for Military and Defense?

In military and defense applications, custom leather fire shields provide essential identification for firefighting units. These shields promote unit cohesion and are designed to endure harsh conditions encountered in the field. B2B buyers should focus on sourcing options that allow for custom designs while ensuring durability. Lead times for orders are also a crucial consideration, as timely delivery can significantly impact operational readiness.

3 Common User Pain Points for ‘custom leather fire shields’ & Their Solutions

Scenario 1: Difficulty in Customization for Unique Fire Department Identity

The Problem: B2B buyers, particularly fire department administrators, often struggle with the need to create unique identities for their teams. Many departments want custom leather fire shields that not only represent their logo and values but also cater to specific functional requirements. However, some suppliers may offer limited customization options, causing frustration among buyers who wish to showcase their department’s distinctiveness and pride. This can lead to dissatisfaction with generic products that fail to capture the essence of their team.

The Solution: To address this challenge, buyers should seek suppliers that specialize in fully customizable leather fire shields. Look for manufacturers who offer a robust design platform, allowing for detailed customization, including color, size, artwork, and text. Engaging directly with manufacturers can facilitate discussions about specific needs, ensuring that the final product aligns with the department’s identity. For example, consider using a supplier that provides a real-time design tool, enabling buyers to visualize their customizations before finalizing the order. Additionally, requesting samples or mock-ups can help ensure that the product meets expectations before bulk ordering.

Illustrative image related to custom leather fire shields

Scenario 2: Concerns Over Durability and Performance Under Extreme Conditions

The Problem: Fire departments across various regions face the harsh realities of extreme heat, smoke, and other challenging conditions. B2B buyers often worry that custom leather fire shields may not withstand such environments, potentially leading to wear and tear that compromises visibility and effectiveness. This concern is particularly pronounced in regions with high temperatures or those experiencing frequent fire incidents, where every piece of equipment must perform reliably.

The Solution: To alleviate these concerns, buyers should prioritize sourcing leather fire shields that are specifically designed for durability and resilience. It is essential to inquire about the materials used in the manufacturing process, ensuring they are made from high-quality, full-grain leather that can withstand extreme conditions. Additionally, buyers should ask about the finishing techniques applied, such as heat resistance and moisture sealing, which can enhance the shield’s longevity. Requesting performance guarantees or warranties from the supplier can also provide added assurance. Engaging with manufacturers that have a proven track record in producing high-quality firefighting gear can further mitigate concerns regarding durability.

Scenario 3: Complex Sizing and Compatibility Issues with Fire Helmets

The Problem: Another significant pain point for B2B buyers is navigating the sizing and compatibility of custom leather fire shields with different helmet models. Fire departments often use various helmet styles, and a one-size-fits-all approach can lead to ill-fitting shields that do not adhere properly or obstruct visibility. This mismatch not only affects the aesthetic appeal but can also pose safety risks during operations.

The Solution: To overcome sizing and compatibility challenges, buyers should take proactive steps in measuring their helmets accurately and understanding the specifications required for each model. It is advisable to consult the manufacturer’s sizing guide, which should outline the dimensions needed for different helmet types. When ordering, provide detailed measurements and specifications to the supplier. Some manufacturers may offer a personalized sizing service or a consultation to ensure the right fit. Additionally, consider suppliers that provide a range of adjustable mounting options to accommodate various helmet designs, ensuring that the custom leather fire shields fit securely and perform as intended.

Illustrative image related to custom leather fire shields

Strategic Material Selection Guide for custom leather fire shields

What Are the Key Materials Used in Custom Leather Fire Shields?

When selecting materials for custom leather fire shields, it’s essential to consider the properties that affect performance, durability, and compliance with international standards. Here, we analyze four common materials used in the production of these shields: full-grain leather, top-grain leather, synthetic leather, and treated leather.

How Does Full-Grain Leather Perform in Custom Fire Shields?

Full-grain leather is the highest quality leather available, made from the top layer of animal hide. It retains the natural grain, providing excellent durability and breathability. Full-grain leather can withstand high temperatures and is resistant to wear, making it ideal for environments where fire and heat exposure are prevalent.

Pros: Its durability ensures a longer lifespan, and it develops a unique patina over time, adding character. It is also easy to clean and maintain, which is crucial for firefighting equipment.

Cons: The cost of full-grain leather is relatively high, which may not be suitable for all budgets. Additionally, the manufacturing process can be more complex due to its thickness and natural characteristics.

Impact on Application: Full-grain leather shields are compatible with various firefighting environments, providing a reliable option for both urban and rural fire departments.

Illustrative image related to custom leather fire shields

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of import regulations and the potential for higher shipping costs due to the material’s weight. Compliance with local standards such as ASTM or DIN may also be necessary.

What Are the Advantages of Top-Grain Leather for Fire Shields?

Top-grain leather is a step down from full-grain but still offers significant benefits. It is sanded and finished to remove imperfections, resulting in a smoother surface. This material is slightly more flexible than full-grain leather, making it easier to work with during manufacturing.

Pros: Its affordability compared to full-grain leather makes it a popular choice for departments on a budget. It also offers good resistance to wear and is relatively easy to clean.

Illustrative image related to custom leather fire shields

Cons: While durable, top-grain leather may not be as long-lasting as full-grain, particularly under extreme conditions. The finishing process can also reduce its breathability.

Impact on Application: This material is suitable for custom designs that require detailed artwork or logos, making it an excellent choice for departments looking to showcase their identity.

Considerations for International Buyers: Buyers should ensure that the top-grain leather used meets local fire safety regulations. Additionally, understanding the sourcing of the leather is crucial, as some regions may have specific preferences for ethically sourced materials.

How Does Synthetic Leather Compare for Custom Fire Shields?

Synthetic leather, or faux leather, is made from materials like polyurethane (PU) or polyvinyl chloride (PVC). It is designed to mimic the look and feel of real leather while offering some unique advantages.

Pros: Synthetic leather is often more affordable and easier to clean than natural leather. It is also resistant to water and stains, making it a practical choice for firefighting environments.

Cons: While it can be durable, synthetic leather may not withstand high temperatures as well as natural leather, which can be a critical factor in fire-related applications. It also lacks the breathability and natural feel of real leather.

Impact on Application: Synthetic leather shields can be used in less demanding environments or for decorative purposes, but they may not be suitable for frontline firefighting gear.

Considerations for International Buyers: Buyers should verify that the synthetic materials comply with local safety and environmental standards, particularly in regions with strict regulations.

What Are the Benefits of Treated Leather for Fire Shields?

Treated leather is leather that has undergone specific treatments to enhance its properties, such as water resistance and flame retardancy. This makes it a viable option for custom fire shields.

Illustrative image related to custom leather fire shields

Pros: Treated leather offers a balance between the aesthetics of natural leather and the enhanced performance characteristics needed for firefighting applications. It is often more resistant to environmental factors.

Cons: The treatment process can add to the cost, and the durability may vary based on the type of treatment used. Additionally, treated leather may require specific care to maintain its properties.

Impact on Application: Treated leather shields are well-suited for high-stress environments, providing both functionality and a professional appearance.

Considerations for International Buyers: Buyers should ensure that the treatments used comply with local fire safety standards and investigate the environmental impact of the chemicals used in the treatment process.

Summary Table of Material Selection for Custom Leather Fire Shields

| المواد | Typical Use Case for custom leather fire shields | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-performance firefighting environments | Exceptional durability and breathability | Higher cost and complex manufacturing | عالية |

| Top-Grain Leather | Custom designs for fire departments | More affordable with good durability | Less durable than full-grain | Medium |

| جلد صناعي | Decorative or low-demand applications | Cost-effective and easy to clean | May not withstand high temperatures | منخفضة |

| Treated Leather | High-stress firefighting applications | Enhanced performance characteristics | Potentially higher cost and care needs | Medium |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions when sourcing custom leather fire shields, ensuring they meet both performance and compliance needs in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire shields

What Are the Key Stages in the Manufacturing Process of Custom Leather Fire Shields?

The manufacturing process for custom leather fire shields involves several key stages, each critical to ensuring the final product meets the demands of durability, clarity, and functionality.

Illustrative image related to custom leather fire shields

Material Preparation: How Is Quality Leather Selected?

The process begins with the selection of high-quality leather, typically full-grain or top-grain, known for its strength and resistance to wear. Suppliers often source leather from reputable tanneries, ensuring it meets specific standards for thickness and durability. The leather undergoes inspection to identify any defects, such as scars or inconsistencies, which could affect the final product. In B2B transactions, buyers should request samples of the leather to assess its quality before placing bulk orders.

Forming: What Techniques Are Used to Shape the Shields?

Once the leather is prepared, the next stage involves cutting and shaping. Manufacturers use precision cutting tools or dies to create the shield’s base shape, ensuring uniformity across all products. Advanced techniques such as laser cutting may also be employed for intricate designs or custom logos. This stage often includes tooling, where designs are embossed or stamped onto the leather, adding aesthetic value and brand identity.

Assembly: How Are the Shields Constructed?

After forming, the shields are assembled. This may involve stitching, which is often done with heavy-duty, weather-resistant thread to ensure durability. Some manufacturers use rivets or other fasteners to enhance structural integrity. Quality assurance during assembly is crucial; each shield should be checked for alignment, stitching consistency, and overall craftsmanship.

Finishing: What Are the Final Touches Applied?

The final stage is finishing, where the shields receive protective coatings to enhance durability and resistance to environmental factors. This may include applying a leather conditioner or water-resistant finish. Manufacturers often conduct a final inspection at this stage to ensure that each shield meets the specified design and quality criteria.

What Quality Control Measures Are Essential for Custom Leather Fire Shields?

Quality control (QC) is paramount in manufacturing custom leather fire shields, ensuring that each product not only meets customer expectations but also complies with international standards.

Illustrative image related to custom leather fire shields

What International Standards Should Buyers Be Aware Of?

For custom leather fire shields, adherence to international standards such as ISO 9001 is vital. This standard ensures that manufacturers maintain a quality management system that consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific certifications like CE (European Conformity) may be relevant, particularly for products intended for the European market.

What Are the Key QC Checkpoints in the Production Process?

Quality control checkpoints are typically established throughout the production process. These include:

-

Incoming Quality Control (IQC): This involves inspecting the raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor the production process and ensure that each step adheres to quality standards.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed to verify that the shields meet all design and quality specifications before shipping.

What Common Testing Methods Are Used?

Manufacturers often employ various testing methods to ensure product durability and performance. Common tests may include:

-

Flexibility Tests: Assessing the leather’s ability to withstand bending without cracking.

-

Heat Resistance Tests: Evaluating how well the leather holds up under high temperatures, which is crucial for fire shields.

-

Water Resistance Tests: Checking the leather’s ability to repel water, ensuring it remains functional in adverse conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is critical.

What Steps Can Buyers Take for Supplier Audits?

Buyers should consider conducting supplier audits, which can be either announced or unannounced. During these audits, buyers can review the supplier’s production processes, quality control measures, and compliance with international standards. This firsthand observation can provide valuable insights into the supplier’s operational capabilities.

What Documentation Should Buyers Request?

Buyers should request relevant documentation, including:

-

Quality Management System Certifications: Such as ISO 9001 or other relevant certifications.

-

Test Reports: Documentation of the testing performed on the leather and finished shields, including results from third-party laboratories when applicable.

-

Production Samples: Requesting samples from previous production runs can help assess the quality and craftsmanship before committing to a larger order.

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of the nuances in quality control and certification that can vary significantly between regions. For instance, while European buyers may prioritize CE marking, buyers from Africa and South America might focus more on local certifications and standards. Understanding these differences is crucial for navigating the complexities of international trade.

How Can Buyers Ensure Compliance with Local Regulations?

Buyers should familiarize themselves with local regulations regarding imported goods, including safety and quality standards that must be met. Engaging with local trade organizations or regulatory bodies can provide guidance on compliance requirements, ensuring that imported custom leather fire shields are accepted in the target market.

Conclusion: Why Is Quality Assurance Crucial for Custom Leather Fire Shields?

In the competitive landscape of custom leather fire shields, the manufacturing process and quality assurance are fundamental to delivering products that meet the rigorous demands of the fire service. By understanding the intricacies of manufacturing and QC measures, B2B buyers can make informed decisions, ensuring they source high-quality products that uphold safety and performance standards. Investing time in supplier verification and understanding international standards can lead to long-lasting partnerships and successful procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire shields’

مقدمة

This sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring custom leather fire shields. Whether you’re a fire department looking to enhance your gear or a retailer seeking to expand your product offerings, following these steps will help ensure you make informed purchasing decisions that meet both quality and safety standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for sourcing custom leather fire shields. Consider factors such as size, material quality, and design features that align with your operational needs.

– Size Requirements: Measure the helmets that will be used with the shields to ensure a proper fit.

– Material Quality: Look for full-grain leather, which offers durability and resistance to heat and wear.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather fire shields. This step is crucial to ensure you find manufacturers that understand the unique demands of firefighting equipment.

– Supplier Reviews: Read customer testimonials and case studies to gauge the quality and reliability of their products.

– Industry Experience: Prioritize suppliers with a proven track record in the firefighting sector.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it’s essential to verify the certifications and compliance of potential suppliers. This ensures that the shields meet industry standards for quality and safety.

– Quality Assurance: Check if the supplier adheres to any recognized quality management systems, such as ISO certifications.

– Material Compliance: Ensure that the leather used complies with relevant safety standards, particularly if the shields are expected to withstand extreme conditions.

Step 4: Request Customization Options

Customization is a key aspect of sourcing custom leather fire shields. Engage with suppliers to understand the extent of customization available, including design, color, and insignia options.

– Design Flexibility: Ask if the supplier offers a shield builder tool for real-time customization.

– Artwork Capabilities: Inquire about their ability to incorporate logos, ranks, and other personalized elements.

Step 5: Assess Lead Times and Production Capacity

Understanding the supplier’s lead times and production capacity is crucial to ensure timely delivery of your order, especially in emergency service environments.

– Production Schedule: Request detailed timelines for both sample production and full orders.

– Bulk Orders: Confirm if the supplier can handle large orders efficiently and if they offer discounts for bulk purchases.

Step 6: Confirm Shipping and Logistics Arrangements

The logistics of shipping can significantly impact your procurement process. Discuss shipping options, costs, and delivery times with potential suppliers.

– International Shipping: Ensure the supplier has experience in shipping to your region, considering customs and import regulations.

– Tracking and Insurance: Confirm that the shipping method includes tracking options and insurance for high-value orders.

Step 7: Review After-Sales Support and Warranty

Finally, check the after-sales support and warranty policies offered by the supplier. Good support can make a significant difference in your overall satisfaction.

– Warranty Terms: Understand the warranty coverage for defects or damage during shipping.

– Customer Support: Assess the responsiveness of their customer service team for any future inquiries or issues.

Illustrative image related to custom leather fire shields

By following this practical checklist, B2B buyers can effectively navigate the procurement process for custom leather fire shields, ensuring they select the right products that meet their operational needs and standards.

Comprehensive Cost and Pricing Analysis for custom leather fire shields Sourcing

What Are the Key Cost Components in Custom Leather Fire Shields?

When sourcing custom leather fire shields, understanding the cost structure is essential. The main components include:

- Materials: High-quality leather is the primary material, often full-grain for durability. The cost can vary based on the type and source of leather, with premium grades commanding higher prices.

- Labor: Skilled artisans typically handcraft these shields, and labor costs can be significant, particularly in regions with high wage standards. The complexity of the design also affects labor costs.

- Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Manufacturers often factor these costs into the pricing of custom orders.

- Tooling: Custom designs may require specialized tools and molds, which can increase initial costs. This is especially relevant for unique artwork or specific layouts.

- Quality Control (QC): Ensuring that each shield meets quality standards involves additional labor and inspection processes, which can influence the final price.

- Logistics: Shipping costs can vary significantly based on distance, weight, and the shipping method chosen. For international buyers, understanding Incoterms is crucial to managing these costs effectively.

- Margin: Finally, manufacturers will add a profit margin, which can vary widely depending on the supplier’s business model and market positioning.

How Do Price Influencers Affect Custom Leather Fire Shields?

Several factors influence the pricing of custom leather fire shields:

- Volume/MOQ (Minimum Order Quantity): Bulk orders often lead to discounted pricing. Suppliers typically have set thresholds that can unlock better rates, making it advantageous for departments or organizations to order in larger quantities.

- Specifications and Customization: The more complex the design or customization required, the higher the cost. Simple, standardized designs are usually more cost-effective.

- Materials Quality and Certifications: Higher-quality materials and certifications (though not typically required for shields) can justify a higher price point. Buyers should assess the material quality to ensure it meets their durability requirements.

- Supplier Factors: The reputation and location of the supplier can impact pricing. Established brands may charge a premium due to their craftsmanship and reliability.

- Incoterms: Understanding shipping terms is vital for international buyers. Different Incoterms (like FOB, CIF) can significantly influence the total landed cost.

What Are Some Effective Buyer Tips for Custom Leather Fire Shields?

When negotiating prices for custom leather fire shields, consider the following strategies:

- Negotiate Based on Volume: Leverage larger orders to negotiate better rates. Suppliers are often willing to provide discounts for bulk purchases, so plan accordingly.

- Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and potential replacement costs. A higher upfront investment in quality materials can lead to savings over time.

- Understand Pricing Nuances for International Buyers: Be aware of potential tariffs, taxes, and shipping costs that could affect the overall price when importing to regions like Africa, South America, the Middle East, and Europe. Researching local regulations can help avoid unexpected expenses.

- Request Detailed Quotes: Always ask for itemized quotes from suppliers to understand the breakdown of costs. This transparency can aid in negotiations and help identify areas for potential savings.

- Establish Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing and service. Regular communication and feedback can enhance collaboration and result in improved terms over time.

Disclaimer

Prices for custom leather fire shields can vary widely based on numerous factors. The figures provided here are indicative and should be verified with suppliers for accurate pricing tailored to specific requirements. Always perform due diligence and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing custom leather fire shields With Other Solutions

Introduction: Exploring Alternative Solutions to Custom Leather Fire Shields

In the realm of firefighting equipment, custom leather fire shields serve a vital role in representing department identity and rank. However, various alternatives exist that can fulfill similar purposes, each with its own advantages and drawbacks. Understanding these alternatives is essential for B2B buyers who are evaluating the best solutions for their fire departments.

Comparison Table of Custom Leather Fire Shields and Alternatives

| Comparison Aspect | Custom Leather Fire Shields | Alternative 1: Plastic Helmet Shields | Alternative 2: Vinyl Decals |

|---|---|---|---|

| Performance | Durable, withstands heat and smoke; custom designs available | Lightweight and flexible; can be printed with high clarity | Limited durability; requires careful application |

| Cost | $70 – $140 per shield, depending on customization | $20 – $50 per shield | $5 – $15 per decal |

| Ease of Implementation | Requires specific mounting; custom orders may take time | Easy to install; most come with adhesive backing | Simple application, but may require special tools |

| Maintenance | Requires occasional cleaning; leather conditioner may be needed | Minimal maintenance; wipe clean as needed | Requires careful handling; may peel over time |

| Best Use Case | Ideal for departments valuing tradition and craftsmanship | Suitable for budget-conscious departments needing quick solutions | Good for temporary identification or events |

Detailed Breakdown of Alternatives

Alternative 1: Plastic Helmet Shields

Plastic helmet shields are an increasingly popular option among fire departments, primarily due to their lightweight nature and lower cost. These shields often come with adhesive backing for easy installation, making them an attractive choice for departments looking for quick and efficient solutions. However, while they can be printed with high clarity and various designs, their durability does not match that of leather. Exposure to heat and smoke can lead to warping or discoloration over time, which may compromise the shield’s functionality and appearance.

Alternative 2: Vinyl Decals

Vinyl decals present a cost-effective solution for fire departments that require temporary identification or event-specific branding. They are extremely affordable and easy to apply, making them ideal for short-term use or special occasions. However, their limited durability means they may not withstand the rigorous conditions of active firefighting, and they can peel or fade when exposed to harsh environments. This makes them less suitable for departments looking for long-lasting identification solutions, as they may require frequent replacements.

Conclusion: How to Choose the Right Solution for Your Fire Department

When selecting a solution for fire helmet identification, B2B buyers should carefully assess their department’s specific needs, budget, and values. Custom leather fire shields offer unmatched durability and a sense of tradition, making them ideal for departments focused on craftsmanship and identity. In contrast, plastic helmet shields and vinyl decals can serve as budget-friendly alternatives for those prioritizing cost and ease of implementation. Ultimately, the choice should align with the department’s operational requirements and long-term goals, ensuring that the selected solution effectively represents their commitment to service and professionalism.

Essential Technical Properties and Trade Terminology for custom leather fire shields

What Are the Key Technical Properties of Custom Leather Fire Shields?

When sourcing custom leather fire shields, understanding their technical properties is crucial for making informed purchasing decisions. Here are essential specifications to consider:

1. Material Grade

The primary material used in custom leather fire shields is full-grain leather, known for its durability and resistance to wear. Full-grain leather retains the natural grain of the hide, providing superior strength and longevity compared to lower grades. For B2B buyers, selecting high-grade leather ensures that the shields will withstand extreme conditions, including heat and smoke, essential for firefighting environments.

2. Heat Resistance

Fire shields must exhibit exceptional heat resistance to protect the integrity of the design and the safety of the wearer. Typically, leather can handle temperatures up to 300°F (149°C) before significant degradation occurs. This property is vital for fire departments seeking reliable gear that can endure high-stress situations without compromising on performance.

3. Custom Sizing Tolerance

Custom leather fire shields are tailored to fit specific helmet models. Accurate sizing is critical, as improper fit can lead to visibility issues or shield detachment during use. Tolerances should be clearly defined to ensure a snug fit that meets the specifications of different helmet brands and models. This attention to detail ensures that shields function effectively and maintain their appearance over time.

4. Durability and Lifespan

The durability of a fire shield is measured by its resistance to wear and tear from daily use. A well-constructed leather shield can last several years, making it a cost-effective investment for departments. This property is particularly important for B2B buyers who need to balance quality with budget constraints, ensuring that they receive long-lasting products that reduce the need for frequent replacements.

5. Clarity and Finish

The clarity of the shield’s design is paramount, especially during emergencies. High-quality leather shields should have a smooth finish that allows for clear visibility of lettering and logos. This feature is crucial for identification and rank recognition in chaotic situations, enhancing safety and operational effectiveness.

What Trade Terms Should B2B Buyers Know When Sourcing Custom Leather Fire Shields?

Understanding industry jargon can significantly streamline the purchasing process. Here are key terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another brand’s name. In the context of custom leather fire shields, this term is relevant when sourcing shields that may be produced by a third party but branded for a specific fire department or organization. Knowing the OEM can help buyers assess quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For custom leather fire shields, understanding MOQ is essential for budgeting and planning purchases, especially for larger departments that may require multiple units. Negotiating MOQs can also lead to cost savings for bulk orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When seeking custom leather fire shields, submitting an RFQ can help buyers obtain competitive pricing and detailed information about customization options, lead times, and payment terms.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers sourcing custom leather fire shields from overseas, as they dictate shipping costs, risk, and logistics responsibilities, ensuring clarity and reducing potential disputes.

5. Lead Time

Lead time refers to the time required to produce and deliver the custom leather fire shields after an order is placed. Understanding lead time helps buyers plan their inventory and ensures that they receive products when needed, particularly important for emergency services that require timely equipment.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they procure high-quality custom leather fire shields that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather fire shields Sector

What Are the Key Trends Influencing the Custom Leather Fire Shields Market?

The global market for custom leather fire shields is influenced by several dynamic factors. One significant driver is the increasing demand for personalized firefighting gear, which underscores the importance of individual identity and department pride among firefighting personnel. Customization options have expanded, allowing departments from diverse regions—particularly in Africa, South America, the Middle East, and Europe—to tailor products to meet specific needs. This trend is further supported by advancements in digital design technologies, enabling buyers to visualize and modify designs in real-time.

Illustrative image related to custom leather fire shields

Another emerging trend is the integration of e-commerce platforms, which facilitates easier access for international buyers. This shift is particularly impactful in regions like Germany and Nigeria, where traditional procurement methods may be less efficient. The emphasis on durability and performance is also growing, as fire departments seek products that withstand harsh conditions while maintaining aesthetic appeal. Additionally, the rise of social media has created a platform for showcasing unique designs, further fueling demand for custom leather products.

As the market evolves, international B2B buyers are increasingly prioritizing suppliers who can provide not only quality products but also a reliable supply chain. This includes considerations such as lead times, bulk order capabilities, and after-sales support. Suppliers that leverage these trends effectively will likely gain a competitive edge in the custom leather fire shields sector.

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Fire Shields Industry?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the custom leather fire shields market. The environmental impact of leather production, particularly in terms of water usage and chemical treatments, necessitates a shift towards more sustainable practices. Fire departments and organizations are increasingly aware of their carbon footprints and are seeking suppliers that prioritize eco-friendly materials and processes.

Buyers are encouraged to look for certifications such as the Leather Working Group (LWG) certification, which indicates that leather is sourced from tanneries that adhere to stringent environmental standards. Additionally, the use of vegetable-tanned leather is gaining traction, as it presents a more sustainable alternative to traditional tanning methods that often involve harmful chemicals.

Illustrative image related to custom leather fire shields

Ethical supply chains are also a focal point, with a growing demand for transparency in sourcing practices. Buyers should consider suppliers who can demonstrate ethical labor practices and fair treatment of workers throughout the production process. This not only helps mitigate reputational risks but also aligns with the values of many modern consumers and organizations.

What Is the Brief Evolution of Custom Leather Fire Shields?

The evolution of custom leather fire shields reflects broader trends in firefighting equipment and personalization. Historically, fire shields were standardized, serving primarily functional purposes. However, as firefighting evolved, so did the need for equipment that conveyed identity and pride. The introduction of custom designs allowed firefighters to express individuality and departmental values.

In recent years, advancements in leatherworking techniques and digital design tools have revolutionized the production of these shields. Handcrafted quality has become a hallmark of custom leather fire shields, with artisans emphasizing durability, clarity, and tradition. Today, these shields are not just functional items but are also seen as symbols of heritage and camaraderie among firefighting crews, making them a vital aspect of modern firefighting culture.

Illustrative image related to custom leather fire shields

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire shields

1. How do I customize my order for leather fire shields?

To customize your leather fire shields, begin by selecting a supplier that offers a dedicated design tool or custom order form. You’ll typically be able to choose various elements such as color, text, size, and artwork specific to your fire department’s identity. It’s essential to provide clear specifications and any logos or designs you want incorporated. Many suppliers also offer a proofing process where you can review the design before production to ensure it meets your expectations.

2. What are the minimum order quantities (MOQ) for custom leather fire shields?

Minimum order quantities for custom leather fire shields can vary significantly between suppliers. Many manufacturers set a MOQ of around 6-10 units to make production economically viable. However, some may offer flexibility for smaller orders, especially for first-time buyers. It’s advisable to discuss your specific needs with potential suppliers to understand their policies and negotiate if necessary, especially for bulk orders.

3. What payment terms should I expect when ordering custom fire shields?

Payment terms for custom fire shields often depend on the supplier’s policies and the size of your order. Common arrangements include a deposit upfront, usually around 30-50%, with the balance due upon completion or prior to shipment. Some suppliers may also offer net payment terms for established customers. Always clarify payment methods accepted (credit card, bank transfer, etc.) and any currency considerations, especially for international transactions.

4. How do I vet suppliers for custom leather fire shields?

To vet suppliers effectively, start by researching their background, including years in business and customer reviews. Check their portfolio for past projects similar to your needs, focusing on quality and craftsmanship. Request references from previous clients, particularly those from your region. Additionally, inquire about their production processes, material sourcing, and compliance with relevant standards to ensure reliability and quality in your order.

Illustrative image related to custom leather fire shields

5. What logistics considerations should I keep in mind when sourcing internationally?

When sourcing custom leather fire shields internationally, consider shipping times, costs, and customs regulations specific to your country. Verify whether the supplier offers freight options and whether they handle customs clearance. Understanding the incoterms (e.g., FOB, CIF) used in your agreement can also clarify responsibilities related to shipping and insurance. Additionally, factor in potential delays due to customs inspections, especially for leather goods.

6. How are quality assurance and inspection handled during production?

Quality assurance typically involves multiple stages of inspection throughout the production process. Many suppliers will conduct initial checks on raw materials and finalize inspections before shipping. You can request a quality assurance plan from the supplier, detailing their procedures. If you’re ordering a large batch, consider arranging for an independent inspection service to assess the products before shipment, ensuring they meet your specifications and standards.

7. What is the typical lead time for custom leather fire shields?

Lead times for custom leather fire shields can vary based on order complexity and supplier workload. Generally, you can expect a timeline of 4 to 8 weeks for production, with additional time for shipping depending on your location. Always confirm lead times with your supplier at the time of order, as factors like customization complexity or peak production seasons can influence delivery schedules.

8. Are there any specific regulations I should be aware of when importing leather goods?

When importing leather goods, it’s crucial to be aware of regulations regarding animal welfare and trade restrictions in your country. Many regions have strict guidelines on the importation of animal products, including leather. Ensure that your supplier complies with international standards and provides necessary certifications. Additionally, familiarize yourself with any tariffs or taxes that may apply to leather imports to avoid unexpected costs.

Illustrative image related to custom leather fire shields

Top 8 Custom Leather Fire Shields Manufacturers & Suppliers List

1. Little River Customs – Custom Firefighter Helmet Shields

Domain: littlerivercustoms.com

Registered: 2019 (6 years)

مقدمة: Custom Firefighter Helmet Shields handcrafted in leather, designed for clarity, tradition, and durability. Each shield withstands heat, smoke, and years of use. Options include full custom designs and various styles such as Maltese, Standard Issue, and Passport. Prices range from $40.00 to $140.00 USD. Features include the ability to customize layouts, colors, numbers, and text using a Shield Buil…

2. Fully Involved Leatherworks – Customizable Fire Helmet Shields

Domain: fullyinvolvedleatherworks.com

Registered: 2014 (11 years)

مقدمة: Leather Fire Helmet Shields are customizable, hand carved designs that are 6 1/2″ tall, fitting traditional style helmets including composite and leather types, as well as the Phoenix TL-2. The shields feature carved, tooled, hand painted designs, sewn with real stitching, and sealed with a water resistant clear finish for durability. Products include various custom options such as the American Fl…

3. Five Alarm Fronts – Custom Leather Firefighter Gear

Domain: fivealarmfronts.com

Registered: 2012 (13 years)

مقدمة: Five Alarm Fronts and Leatherworks specializes in custom leather work for fire departments, including Fire Helmet Fronts, Leather Suspenders, Radio Straps/Holsters, and Duty Belts. All products are handmade to order by firefighters in the U.S.A. using 9/10oz leather. The company emphasizes a one-off approach to create quality shields tailored to customer specifications. Current turnaround times fo…

4. Box 31 Leatherworks – Traditional Leather Helmet Front Shields

Domain: box31leather.com

Registered: 2019 (6 years)

مقدمة: Traditional Leather Helmet Front Shields from Box 31 Leatherworks are designed for firefighters, featuring high-quality leather construction for durability. Available in 6″ or 6.5″ tall panels with a metal stiffener for shape retention. Fast shipping: standard designs ship in 2 business days, custom designs ship 2 days after proof approval. Pricing: Traditional Panel Shields (1-1, 1-2, 2-1, 2-2) a…

5. Fireline Shields – Handmade Leather Products for Firefighters

Domain: firelineshields.com

Registered: 2009 (16 years)

مقدمة: Fireline Shields offers a variety of handmade leather products specifically designed for firefighters, including: 1. Helmet Shields: Available in Standard, Custom, BOSTON, CAL Fire, FDNY, FLS Passport, Gillis, and LA County styles. 2. Radio Straps: Designed for holding radios securely. 3. Glove Holders: Additional accessory for firefighters. 4. Customization Options: Customers can request personal…

6. GB Shields – Hand-Made Leather Products

Domain: gbshields.com

Registered: 2015 (10 years)

مقدمة: GB Shields offers a variety of top-quality hand-made leather products including: 1. Helmet Shields – Featuring designs like the “ROCKER” Helmet Shield with diamond plate texture and pearlized paint options. 2. Radio Straps – The “STUTTERTONE” Radio Strap allows for engraved text and logo customization, with various hardware and leather color choices. 3. Radio Holsters – Designed for secure carryin…

7. The Fire Store – Custom Helmet Fronts & Shields

Domain: thefirestore.com

Registered: 1999 (26 years)

مقدمة: Fronts/Shields: Box 31 Shields, Brim Trims, Gold Leaf Fronts/Shields, Leather Helmet Fronts/Shields, Phenix Brim Stamps, Silver Leaf Fronts/Shields, Taylor’s Tins Fronts/Shields.

8. MSA Safety – Custom Cairns Fire Helmet Shields

Domain: us.msasafety.com

Registered: 2004 (21 years)

مقدمة: Custom Cairns Fire Helmet Shields and Fronts add personalization to fire helmets with millions of configurations. Available in standard (E-FRT) and passport (C-PST) options, these fronts come in multiple colors, sizes, and configurations. Made from three layers of chrome-tanned leather (1) 3 oz. center layer between (2) 4.5 oz. layers, with panel text printed directly on the leather. Options inclu…

Strategic Sourcing Conclusion and Outlook for custom leather fire shields

How Can Strategic Sourcing Benefit Your Procurement of Custom Leather Fire Shields?

In conclusion, the strategic sourcing of custom leather fire shields offers significant advantages for international B2B buyers. By selecting high-quality, handcrafted products, organizations can enhance their operational effectiveness while showcasing brand identity and team pride. Engaging suppliers that prioritize durability and customization ensures that each shield not only meets functional requirements but also reflects the values of the fire service community.

Buyers should leverage bulk ordering options to maximize cost efficiencies and ensure uniformity across teams. This approach not only strengthens brand presence but also fosters a sense of camaraderie among firefighters. As the market for custom leather fire shields continues to evolve, staying informed about innovations and trends will be crucial for maintaining a competitive edge.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should take proactive steps to establish partnerships with reputable manufacturers. By doing so, they can secure reliable, high-quality products that stand the test of time. Consider reaching out to suppliers today to explore customization options that align with your unique needs and elevate your team’s identity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.